DeDietrich INNOVENS PRO MCA 160 User Manual

INNOVENS PRO MCA 160

SUSTAINABLE COMFORT

®

WALL-MOUNTED GAS CONDENSING BOILER

MCA 160: from 34.7 to 161.6 kW for heating only

MCA 160 MCA 160 installed in cascade

The INNOVENS PRO MCA 160 boiler can be supplied with a choice of either

Heating and domestic hot

water using an independent

tank

Condensation

All natural gases

Propane

of the following two control panels:

- DIEMATIC EVOLUTION: according to the options connected, this enables

command and control of up to 3 heating circuits according to the outside

temperature + 1 DHW circuit. It also allows optimised management of

combined systems and the control of 2 to 8 boilers in cascade configuration

(see page 5) when combined with boilers with the IniControl 2 panel (or

DIEMATIC EVOLUTION).

- IniControl 2: for operation via a 0-10V input, supplied with this panel

as standard. It is used as a secondary boiler as part of an installation in

cascade configuration, actuated by a boiler equipped with the DIEMATIC

EVOLUTION panel or in a cascade system where each boiler is controlled

via a 0-10V input.

CE identification no.:

0063CQ3781

PROJECT

Different air-flue gas connection configurations are possible; we offer

connection solutions using a horizontal or vertical forced flue, on a chimney

or bi-flow. MCA 160 units can be fitted in cascade only, or in combination

with MCA 45-115 boilers.

Complete hydraulic systems for connection of a cascade of 2 to 8 boilers

are available.

Operating cOnditiOns

Maximum operating pressure: 4 bar

Maximum operating temperature: 90°C

Safety thermostat; 110°C

Power supply: 230 V/50 Hz

International Protection marking: IP X1B

apprOval

B

23

- B

23P/B33

- C

13x

- C

33x

- C

93x

- C

- C63 - C

53

83

gas categOry

Equipped and preconfigured to operate using natural gas and propane

(with conversion kit)

NOx class: 6 (EN 15502-1)

PRESENTATION OF THE RANGE

The INNOVENS PRO MCA 160 gas condensing boiler is a new

high-power wall-mounted boiler. It boasts an innovative design and

a new aesthetic, with a sleek finish. Exceptionally compact (602 x

enhanced perfOrmance

- Efficiency up to 108.5%

- NOx class 6, in line with EN 15502-1

advantages

- Compact packaged heating body made from

aluminium/silicium alloy with a large heat exchange surface

area and moderate pressure losses, providing high resistance

to corrosion and only requiring a very low irrigation flow rate

(except for a flow temperature > 75°C) thanks to the burner

regulator device which manages the transition phases within

the installation which are the source of the very low flow rates

in the boiler. The front access facilitates maintenance,

- Stainless premix burner with braided metal fibre surface,

modulating the output from 18 to 100% to ensure the comfort

level meets requirements, equipped with an air intake silencer.

Low CO and NOx emissions, enabling optimum protection of

the environment,

- Gas line with non-return valve,

Operates using natural gas and propane with conversion

kit

- The INNOVENS PRO MCA 160 boiler can be supplied with

either of the following two control panels:

• DIEMATIC EVOLUTION: suitable for all installation situations,

even the most complex; in its original configuration, it can

be used to control and regulate 2 direct circuits and up to 2

circuits with mixing valve (by adding 2 optional flow sensors).

Add a PCB + sensor to enable a third circuit with mixing

valve to be actuated. A DHW sensor can be fitted to enable

regulation with the DHW circuit prioritised. It is specially

designed to allow optimisation of combined systems.

This control panel can also be used to control an installation

in cascade configuration, where just the first boiler will be

600 x 1 112 mm for 160 kW), is its very easy to install and maintain.

It is supplied assembled and factory-tested.

- Low pollutant emissions: NOx < 39 mg/kWh.

equipped with this panel, and "slave" boilers will be equipped

with an IniControl 2 control panel. To connect more than

the 3 circuits available on the master boiler, it is possible to

insert 1 (or several) additional boiler(s) with the DIEMATIC

EVOLUTION panel into the cascade

• IniControl 2: this is mainly used in installations (cascade or

non-cascade) with an external control cabinet to control all

of the secondary circuits via a 0-10V input, which this panel is

fitted with as part of its original equipment,

- A range of equipment such as an automatic air vent, PPS

flue gas pipes, air-flue gas connection parts with measuring

ports, mains connection cable, internal lighting, heating pump

connector and signalling connector, wall mounting bracket, and

a siphon for draining the condensates,

- Complete cascade hydraulic systems for 2 and up to

8 boilers for installations between 300 and 1216 kW; see

page 12,

- Complete cascade hydraulic systems combining MCA

45/115 and MCA 160 units are also available; see page 17.

- Multiple options to ensure these boilers are as easy to

operate as possible:

• hydraulic connection kit comprising the flow/return valves, the

gas valve, the safety valve, and the filling valve

• primary pump, low-loss header, condensate neutralisation

tray, etc.

- Air-flue gas connection possible via horizontal or vertical

forced flue, on a chimney or bi-flow (see page 22).

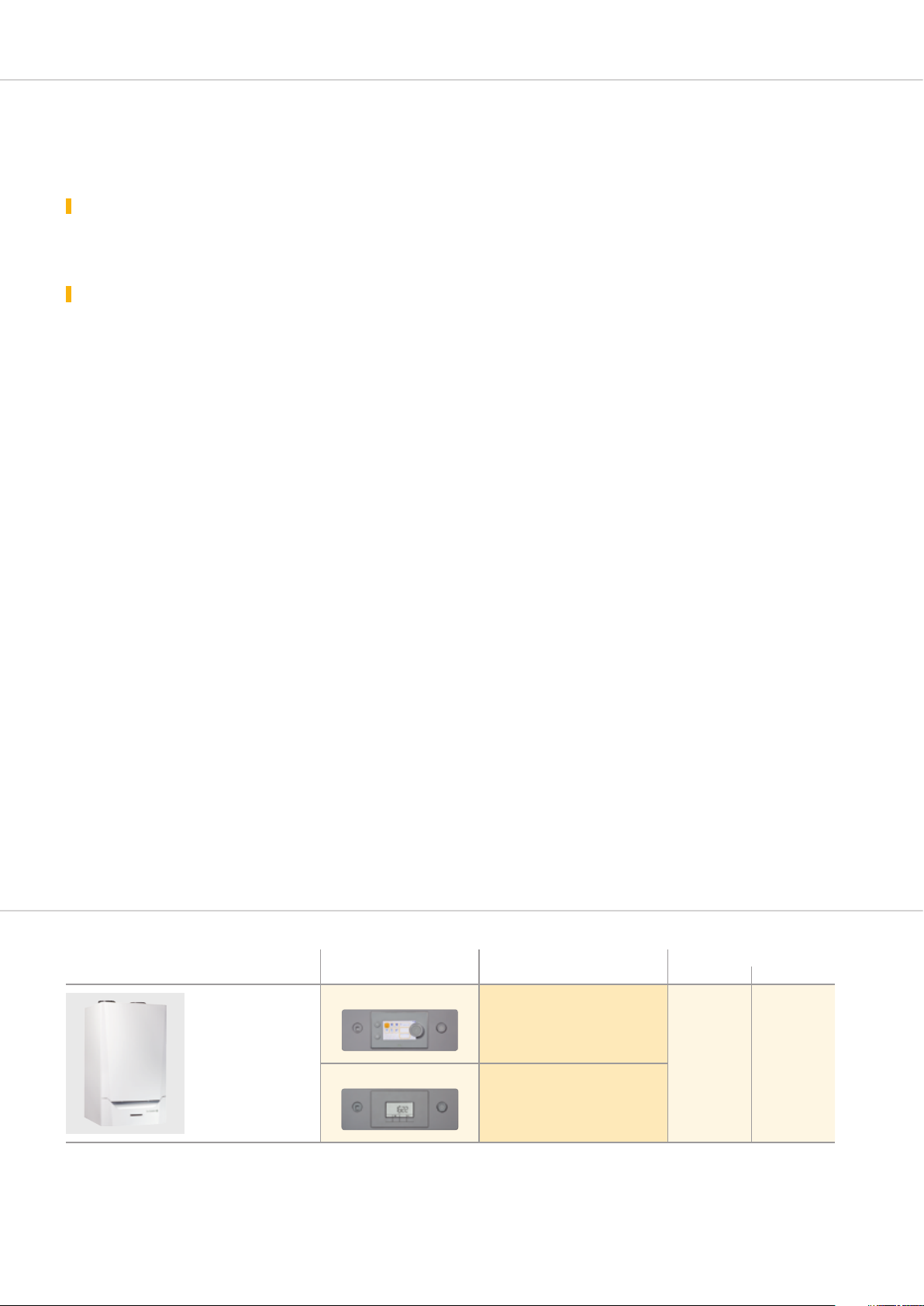

MODELS AVAILABLE

Boiler

For heating only

(option to connect a

domestic hot water

tank*)

MCA_Q0200

*Only in combination with the DIEMATIC EVOLUTION control panel

2

Control

DIEMATIC EVOLUTION

IniControl 2

panel

INNOVENS PRO

model

MCA 160 DIEMATIC EVOLUTION

MCA_Q0211MCA_Q0212

MCA 160 IniControl 2

Power range (kW)

at 50/30°C at 80/60°C

34.7 to 161.6 31.5 to 152.1

TECHNICAL SPECIFICATIONS

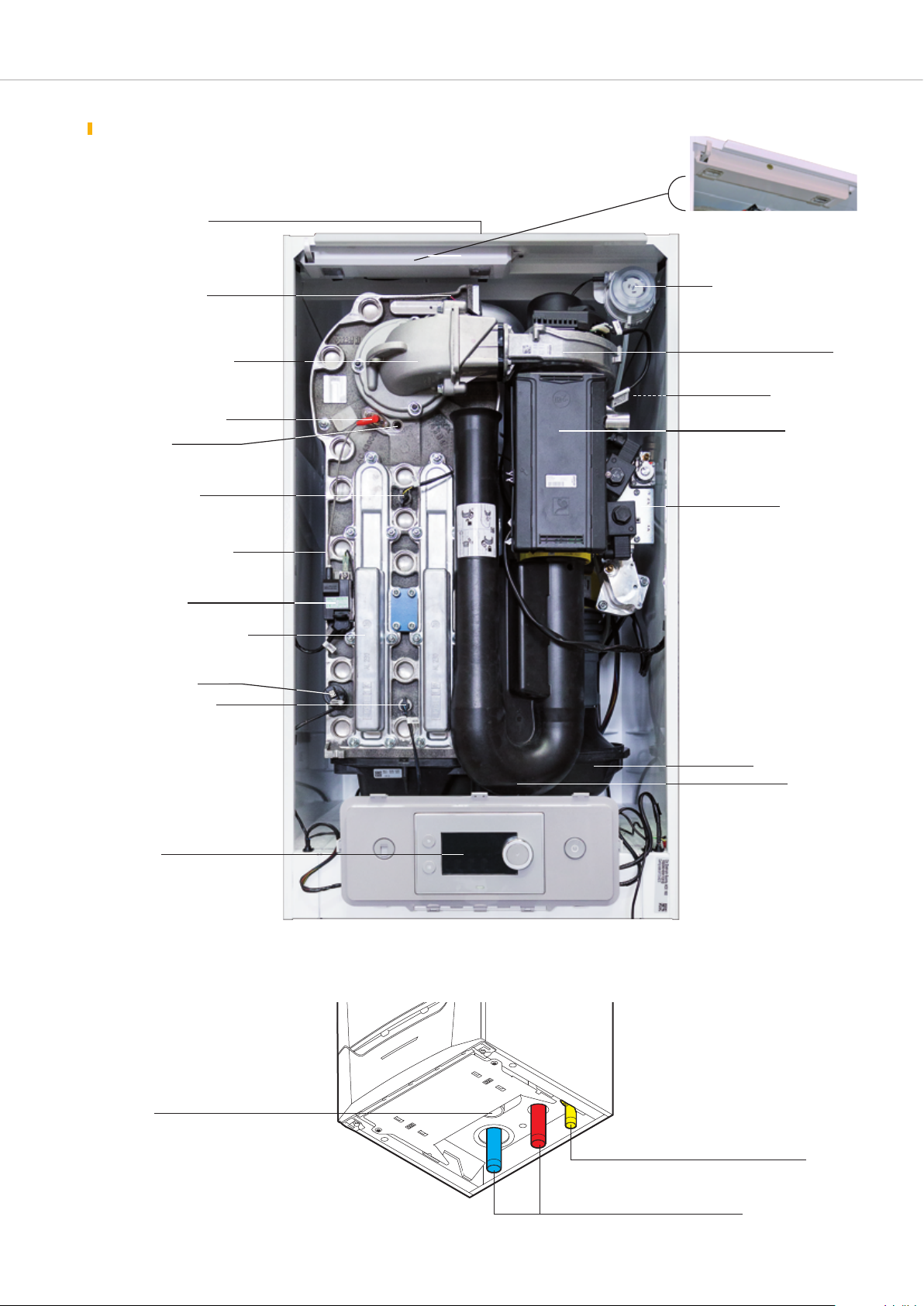

descriptiOn

Air-flue gas connection

with measuring port

(not visible)

Flow temperature sensor

Gas line with non-return valve

Ionisation/ignition electrode

Flame inspection

window

Exchanger temperature

sensor

Packaged heating body made

from aluminium/silicium alloy

Ignition transformer

Heat exchanger inspection hatch

Detail of the boiler internal

Differential pressure switch (air)

Automatic air vent

lighting

Fan

(not visible)

Operating unit

Gas valve block

MCA_Q0011

Water pressure sensor

Return temperature sensor

Control panel

- DIEMATIC EVOLUTION: see p. 7

- IniControl 2: see p. 9

View of the boiler from underneath

Location for

siphon connection

Condensate manifold

Intake silencer

MCA_Q0210

MCA_F0088

Gas inlet

Heating flow and return

3

TECHNICAL SPECIFICATIONS

5050

1045

200

5050

5050

100 100

229

46

80

1045

175 110185

300

600

130

1112

214

4

1

243

the technical specificatiOns

Boiler

Generator type: heating only

Boiler type: condensing

NOx class: 6

Burner: premix burner

Boiler type MCA 160

Useful output

Nominal output Pn at 50/30°C kW 161 . 6

Efficiency in % LHV, load...%

and water temp.... °C

Useful efficiency at …%

of the rated heat output (2)

Nominal water flow rate at Pn and ∆t = 20 K m

Stand-by losses at ∆t = 30 K W 191

Electrical output of auxiliaries at Pn_gen W 275

Electrical output of auxiliaries in standby W 5

Useful output at 50/30°C min./max. kW 34.7-161.6

Useful output at 80/60°C min./max. kW 31 .5-152.1

Flue gas mass flow rate min./max. kg/h 57/277

Flue gas temperature min./max. °C 32/66

Pressure available at boiler outlet Pa 200

Water content l 17

Minimum required water flow rate * m

Water side pressure drop at ∆t = 20 K mbar 17 0

Max. gas flow rate

(15°C-1013 mbar)

Weight (empty) kg 147

* for operation at > 75°C, the minimum flow rate must be calculated at ∆t = 45 K

(1) Q

nom = nominal heat output

- nominal determined at Q

- intermediate at 30% Q

- 100% Pn at av. temp. 70°C % 9 7. 5

- 30% Pn at return temp. 30°C % 108.5

- at 30 Eta 1 % 9 7. 8

- at 100% Eta 4 % 8 7. 8

- natural gas H/L m

- propane m

Energy used:

natural gas or propane

Combustion evacuation:

chimney or sealed

nom (1) kW 15 2 .1

nom (1) kW 50.8

Average operating temperature:

- O

- O

pT_max

pT_min

: 85°C

: 25°C

“CE certificate” ref.: CE 0063CQ3781

3

/h 6.5

3

/h 0.4

3

/h 16.5/19.6

3

/h 6.3

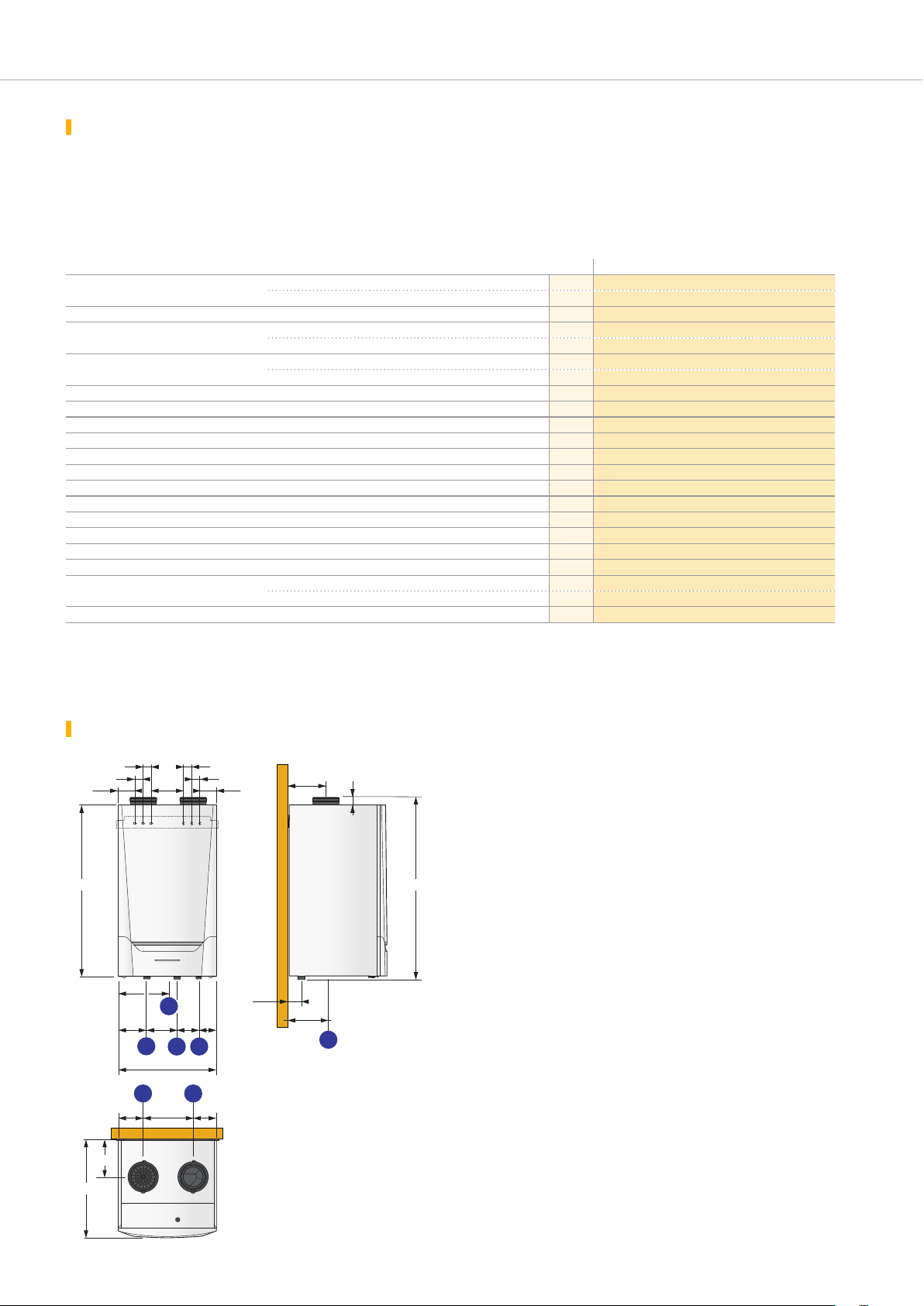

main dimensiOns (in mm and inches)

100 100

226

200

300

175 110185

1

600

5 6

130

243

305152 143

5050

80

229

214

46

1112

Heating return R 1" 1/4

Heating flow R 1" 1/4

Gas inlet R 1"

Condensate discharge (siphon

supplied)

4

MCA_F0225

Air supply pipe Ø 150 mm

Combustion product discharge

Ø 150 mm

602

4

SELECTING THE CONTROL PANEL

M

M

M M M

M M M M M MM M

M

M

M M M

M M M M M MM M

M

M M M

M M M M M MM M

M M

M M M

M M MM M

M M M

M

M

M M M

M M M M M MM M

M

M

M M M

M M M M M MM M

M

M M M

M M M M M MM M

M M

M M M

M M MM M

M M M

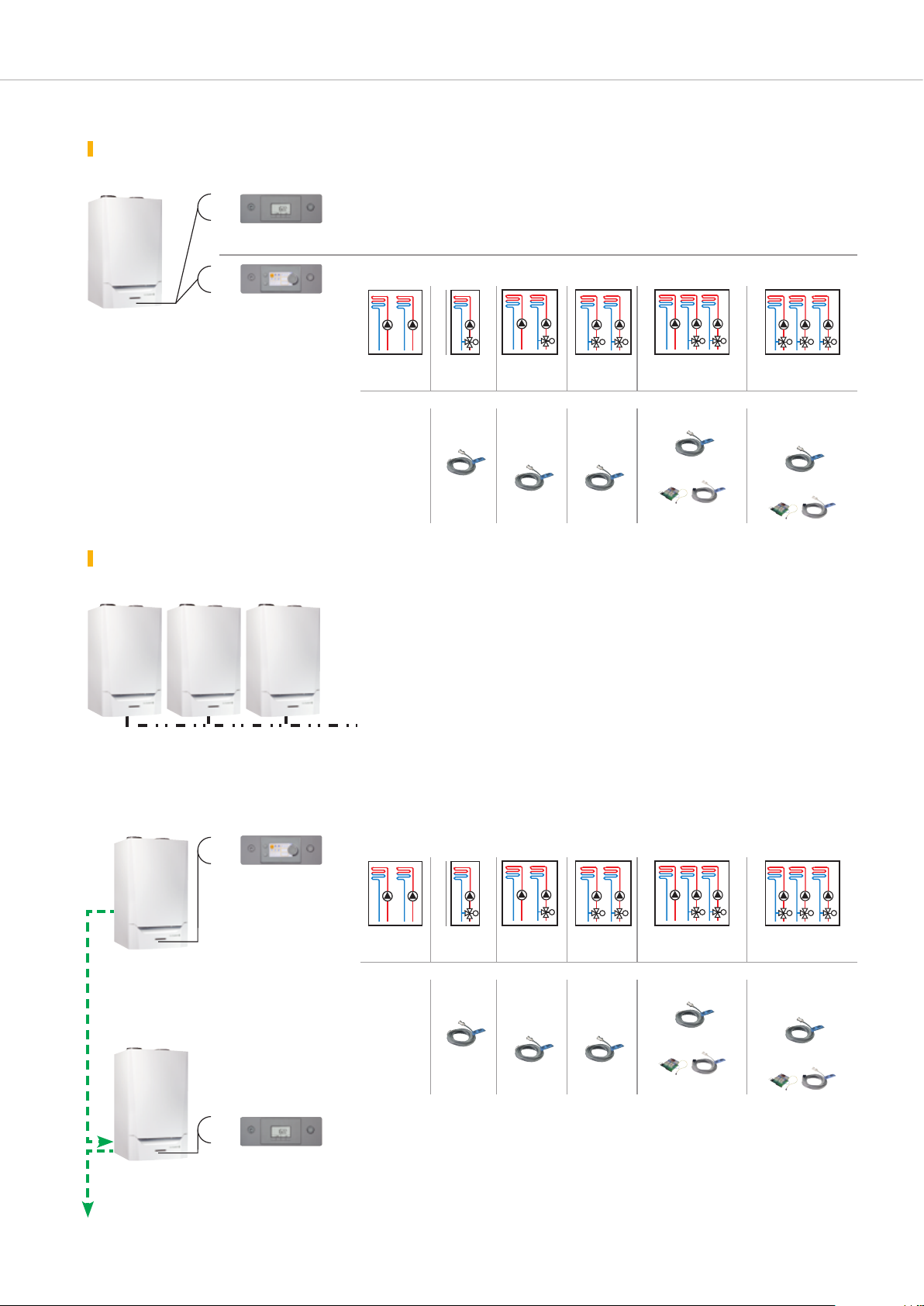

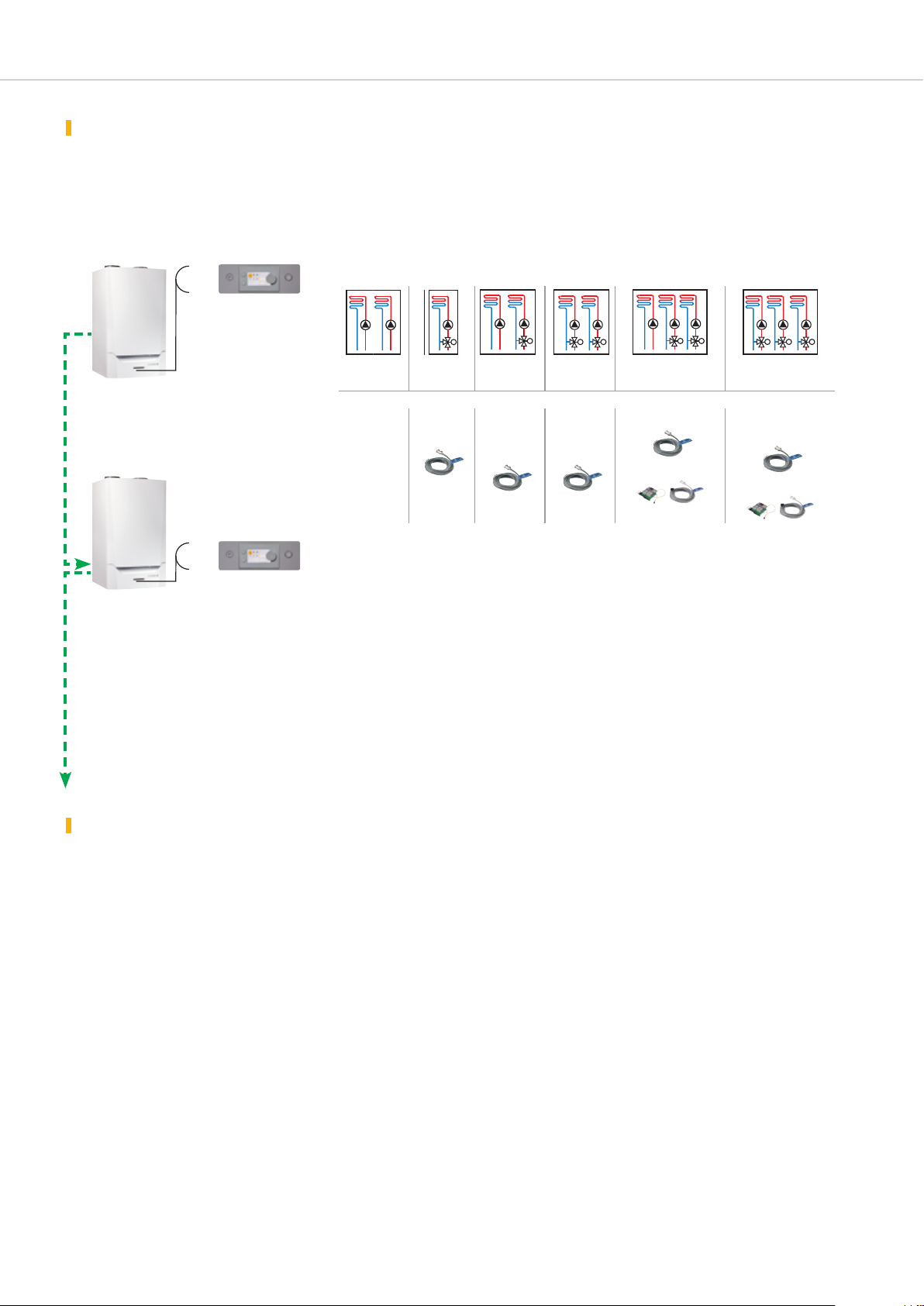

The control panel is selected based on the installation to be created:

installatiOn with 1 single bOiler

Two types of panel are possible

- For installations with 0-10 V control cabinet in a boiler room.

IniControl 2

or

- For control of one circuit:

DIEMATIC Evolution

MCA 160…

M

M

M M

M M

MM M

2 x direct

Options:

standard 1 flow sen-

installatiOn Of 2 tO 8 bOilers in cascade

With IniControl 2 control panels

All the boilers will be connected via a 0-10 V input to a control cabinet in the boiler room

which will manage all the secondary circuits (see p. 22).

0-10 V

MCA 160

IniControl 2

With DIEMATIC EVOLUTION control panel for the 1st

and 1 IniControl 2 panel for each of the secondary boilers

MCA 160

IniControl 2

MCA 160

IniControl 2

boiler in the cascade (master boiler)

- For control of one circuit:

valve

sor AD199

direct

+ 1 valve

1 flow

sensor

AD199

2 x valve

2 flow

sensors

AD199

direct

+ 2 x with valve

1 flow sensor AD199

+ 1 PCB AD249

3 x with valve

2 flow sensors

AD199

+ 1 PCB AD249

Boiler 1

MCA 160 DIEMATIC EVOLUTION

(master)

BUS

Boilers 2 to 8

MCA 160 IniControl 2

(secondary)

DIEMATIC Evolution

IniControl 2

2 x direct

valve

M

direct

+ 1 valve

M

M M

2 x valve

+ 2 x with valve

direct

M M

3 x with valve

Options:

standard 1 flow sen-

sor AD199

1 flow

sensor

AD199

2 flow

sensors

AD199

1 flow sensor AD199

+ 1 PCB AD249

2 flow sensors

+ 1 PCB AD249

- No additional secondary circuit may be connected to the IniControl 2 panel.

MM M

AD199

5

SELECTING THE CONTROL PANEL

M

M

M M M

M M M M M MM M

M

M

M M M

M M M M M MM M

M

M M M

M M M M M MM M

M M

M M M

M M MM M

M M M

installatiOn Of 2 tO 8 bOilers in cascade (cOntinued)

To connect more than 3 heating circuits to a cascade installation,

one of the MCA 160 IniControl 2 boilers in the cascade must

be replaced with one (or several, depending on the number

With a DIEMATIC EVOLUTION control panel for the first boiler in the cascade (master boiler)

and 1 or several DIEMATIC EVOLUTION panels for each of the secondary boilers

- For control of one circuit:

DIEMATIC Evolution

of additional circuits to be managed) MCA 160 DIEMATIC

EVOLUTION boiler(s) (see example in the hydraulic diagram on

page 36).

Boiler 1

MCA 160 DIEMATIC EVOLUTION

(master)

BUS

DIEMATIC Evolution

Boiler 2

MCA 160 DIEMATIC EVOLUTION

(secondary)

Boilers 3 to 8

MCA 160 IniControl 2 or

MCA 160 DIEMATIC EVOLUTION

if necessary (secondary)

2 x direct

valve

M

direct

+ 1 valve

M

M M

2 x valve

+ 2 x with valve

direct

M M

3 x with valve

Options:

standard 1 flow sen-

sor AD199

1 flow

sensor

AD199

2 flow

sensors

AD199

1 flow sensor AD199

+ 1 PCB AD249

2 flow sensors

AD199

+ 1 PCB AD249

- Management of circuits 4, 5 and 6, if applicable (see above).

- 1 or several DIEMATIC EVOLUTION panels according to the number of circuits to be

managed.

MM M

dhw prOductiOn

The DIEMATIC EVOLUTION control panel includes the “priority

DHW” function, and can therefore be completed with 1 or

6

2 DHW sensors - package AD212 for the control of one or

2 independent tanks.

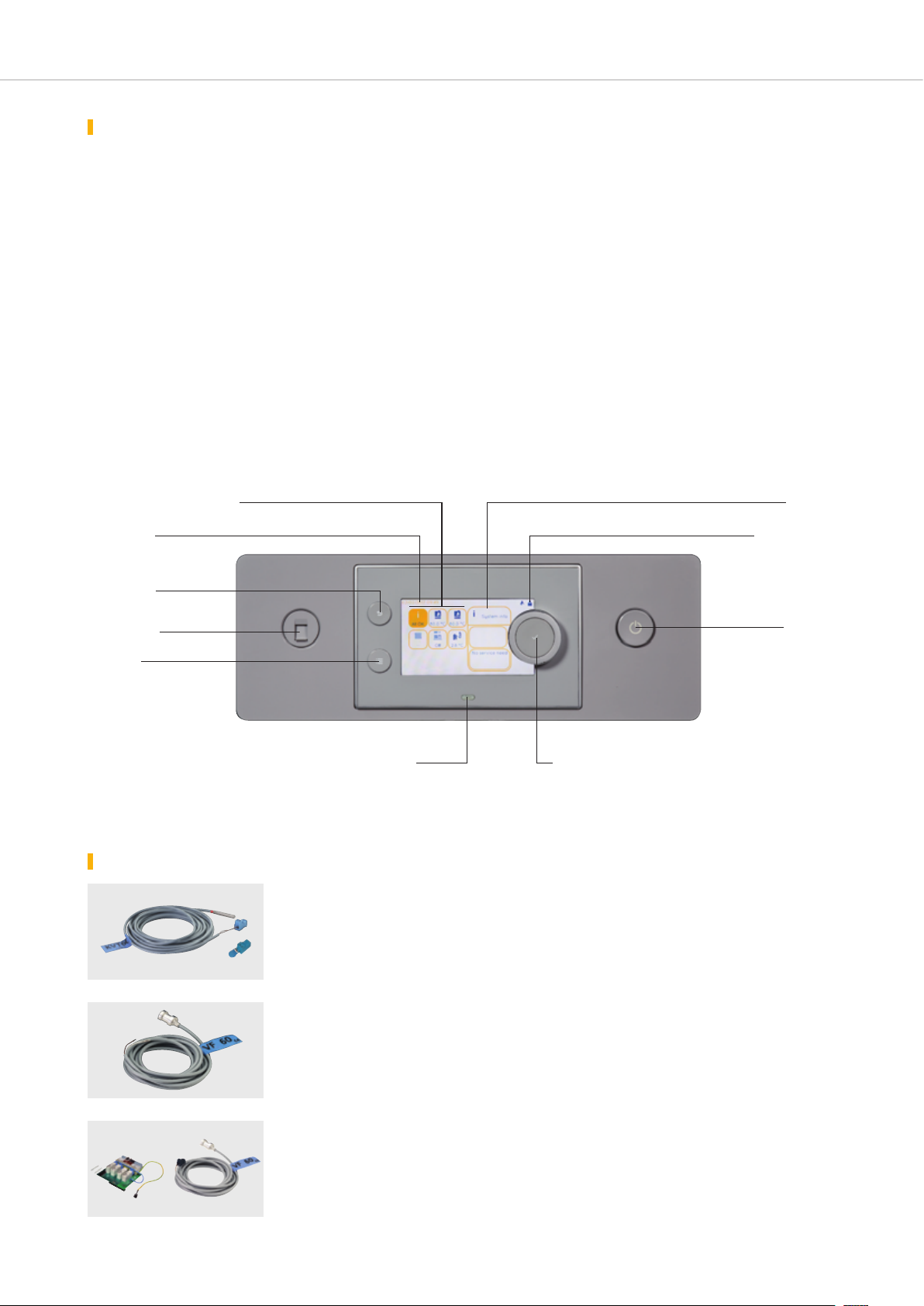

THE DIEMATIC EVOLUTION CONTROL PANEL

presentatiOn Of the DIEMATIC EVOLUTION control panel

The DIEMATIC EVOLUTION control panel is a highly

advanced panel with new ergonomic controls, integrating a

programmable electronic control system which modulates the

boiler temperature by acting on the modulating burner, based

on the outside temperature (outside sensor delivered) and the

room temperature, where required, if an interactive remote

control (supplied as an option) is connected.

As standard, the DIEMATIC EVOLUTION is able to automatically

run a central heating system with a direct circuit without mixing

valve and 1 circuit with mixing valve (please note: the flow

sensor - package AD199 - must be ordered separately).

By simply adding 1 “PCB + sensor for 1 valve circuit” option

(package AD249), it will be possible to control up to 3 circuits

in total, with the option to equip each of these circuits with a

remote control (option).

Pictograms with info on the installation

(circuit temperature, outside air

temperature, circuits, etc.)

Date and time

Button to return to

the previous

level or menu

Socket for the

PC connection

Button for

the main display

The connection of a domestic hot water sensor enables the

programming and control of a DHW circuit (package AD212 option).

This control system has been specifically developed to enable

optimal management of systems combining different

heating generators (boiler + heat pump or + solar system…).

It allows the installer to configure the entire heating system, no

matter how complex.

For larger installations, it is also possible to connect 2 to

7 boilers in cascade configuration.

The DIEMATIC EVOLUTION panel will then be used as the

master for the installation, with the secondary boilers equipped

with the IniControl 2 control panel. To connect more than the

3 circuits available on the master boiler, a second boiler (or

several boilers) with DIEMATIC EVOLUTION can be included in

the cascade.

Dialogue and

information fields

Current menu display

On/Off button

Status indicator LED:

- fixed green = normal operation

- flashing green = warning

- red = blockage

- continuous red = locked

the DIEMATIC EVOLUTION control panel options

Sensor for domestic hot water (length 5 m) - Package AD212

It allows regulation with temperature prioritised and

programming of domestic hot water production via

an independent tank.

8518Q022GT220_Q0002

Flow sensor downstream of valve (length 2.5 m) - Package AD199

This sensor is necessary for connecting the first

circuit with mixing valve on a boiler equipped with

the DIEMATIC EVOLUTION control panel.

PCB + sensor for 1 mixing valve - Package AD249

It allows a mixing valve with an electromechanical

or electrothermal motor to be controlled. The PCB

is inserted in the DIEMATIC EVOLUTION panel and

MCA_Q0013

MCA_Q0211

Rotary/push button:

- turn to select a menu or parameter

- press to confirm the selection

Can be used as a cascade flow sensor.

is connected using plug-in connectors. DIEMATIC

EVOLUTION can house 1 “PCB + sensor” option,

enabling it to control 1 additional mixing valve.

7

THE DIEMATIC EVOLUTION CONTROL PANEL

the DIEMATIC EVOLUTION control panel options

AD137

AD200

AD140

Wired programmable room thermostat - Package AD137

Wireless programmable room thermostat - Package AD200

Non-programmable room thermostat - Package AD140

Programmable thermostats provide weekly

programming and regulation of the heating by

8801Q0028666Q120A

activating the burner according to the various

operating modes: “Automatic” depending on the

programming, “Permanent” at a set temperature or

a receiver box to be mounted on the wall close to

the boiler.

The non-programmable thermostat is used to

regulate the room temperature based on the set

point, by activating the burner.

“Holiday”. The "wireless" version is delivered with

8801Q003

Sensor for buffer tank - Package AD250

Comprises 1 sensor for managing a buffer

Can be used as a cascade flow sensor.

tank with a boiler equipped with a DIEMATIC

EVOLUTION control panel.

8518Q022

AD308

AD310

AD309

S-BUS cable with plugs, 1 .5 m - Package AD308

S-BUS cable with plugs, 12 m - Package AD309

S-BUS cable with plugs, 20 m - Package AD310

The BUS cable enables two boilers equipped with

the DIEMATIC EVOLUTION or IniControl 2 panel

to be connected as part of a cascade installation.

MCA_Q01149-MCA_Q01150-MCA_Q0151

DIEMATIC VM EVOLUTION control system (wall-mounted) - Package AD315

(Available first quarter 2018)

The DIEMATIC VM EVOLUTION electronic control

system, integrated into a wall unit, allows 3 heating

circuits and 2 DHW circuits to be controlled and

regulated; each of the heating circuits can be a

direct circuit or a circuit with a 3-way motorised

mixing valve.

- DIEMATIC VM EVOLUTION can be integrated

into a DIEMATIC iSystem via the Modbus as

supplementary only.

- DIEMATIC VM EVOLUTION can control a

cascade of boilers equipped with an IniControl 2

control panel.

It is possible to link together up to 8* DIEMATIC

VM EVOLUTION control systems and to thereby

create numerous combinations, regardless of the

* 1 “master” control system + 7 “slave” control

systems.

type of installation:

- DIEMATIC VM EVOLUTION can be used in

relation with one or several generators equipped

VM_Q0009

with DIEMATIC EVOLUTION or IniControl 2.

8

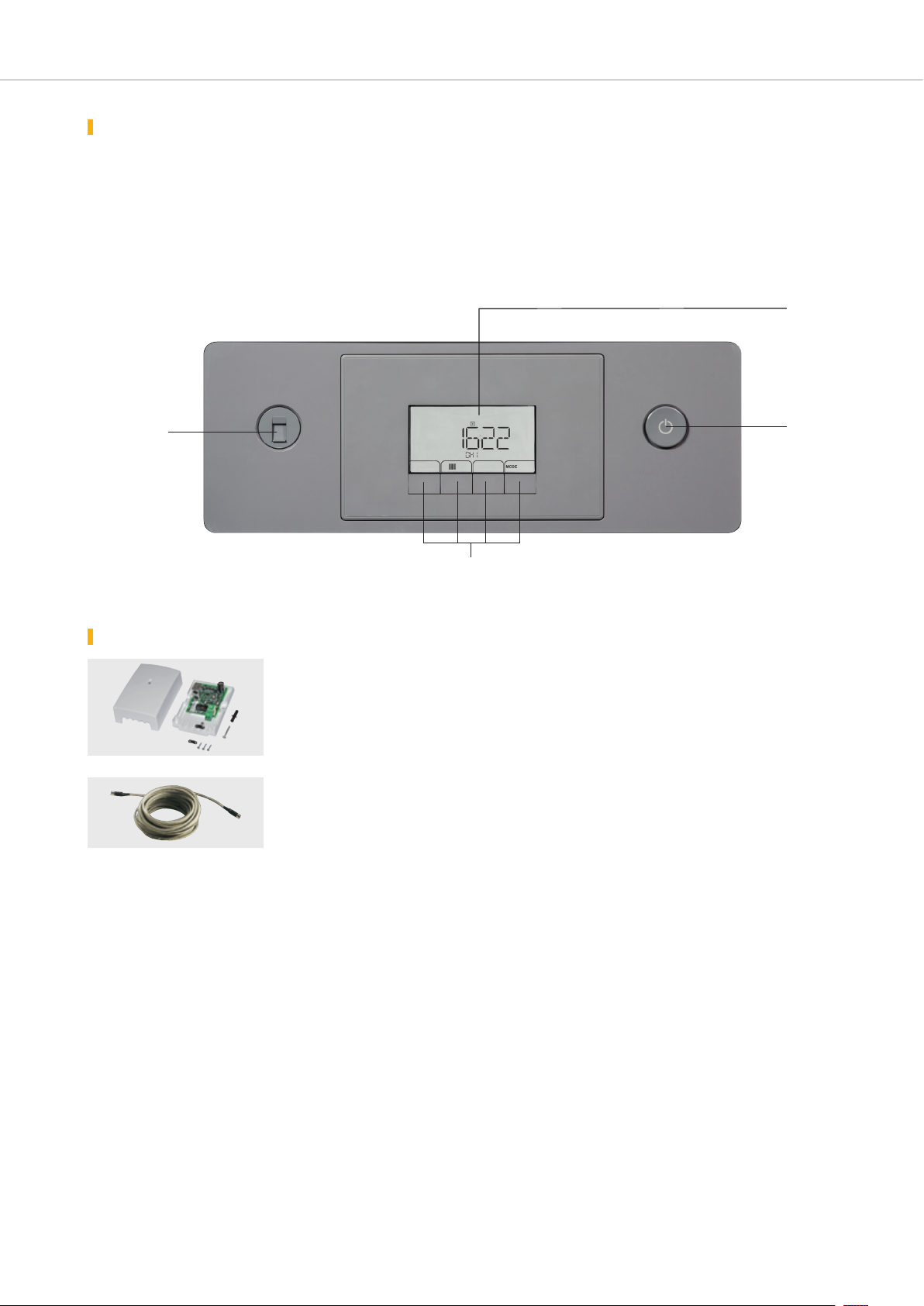

The IniControl 2 CONTROL PANEL

presentatiOn Of the IniControl 2 control panel

The IniControl 2 control panel is used to manage the boiler

(without programming) via a configurable 0 - 10 V signal. For a

cascade installation, the IniControl 2 panel will be fitted to the

secondary boilers linked in series to the master boiler equipped

with the DIEMATIC EVOLUTION panel via the BUS cable

(option).

Socket for the

PC connection

The boiler temperature, heating network pressure, and generator

operating status are displayed using alphanumeric codes and

symbols on a large screen integrating a flashing alarm function.

For monitoring the installation, there is an option to read the

fault log and the operating timer counters.

Digital display

(large format)

On/Off switch

MCA_Q0212

Keys:

- access to the various menus or parameters,

- setting, manual reset variant according to the selections

inicOntrOl 2 cOntrOl panel options

ModBUS - OpenTherm interface - Package AD286

As part of a “mixed” cascade, this interface must

be affixed to the wall close to the MCA 160 boiler,

VM_Q00038227_Q020

BUS connection cable (12 m) - Package AD314

Enables a link to be created between 2 boilers

equipped with DIEMATIC iSystem and IniControl/

IniControl 2 panels.

enabling the MCA 45/115 boiler to be connected

to the MCA 160.

9

THE BOILER OPTIONS

Pump output in W

3

Flow rate m3/h

Flow rate m

3

/h

: Proportional pressure

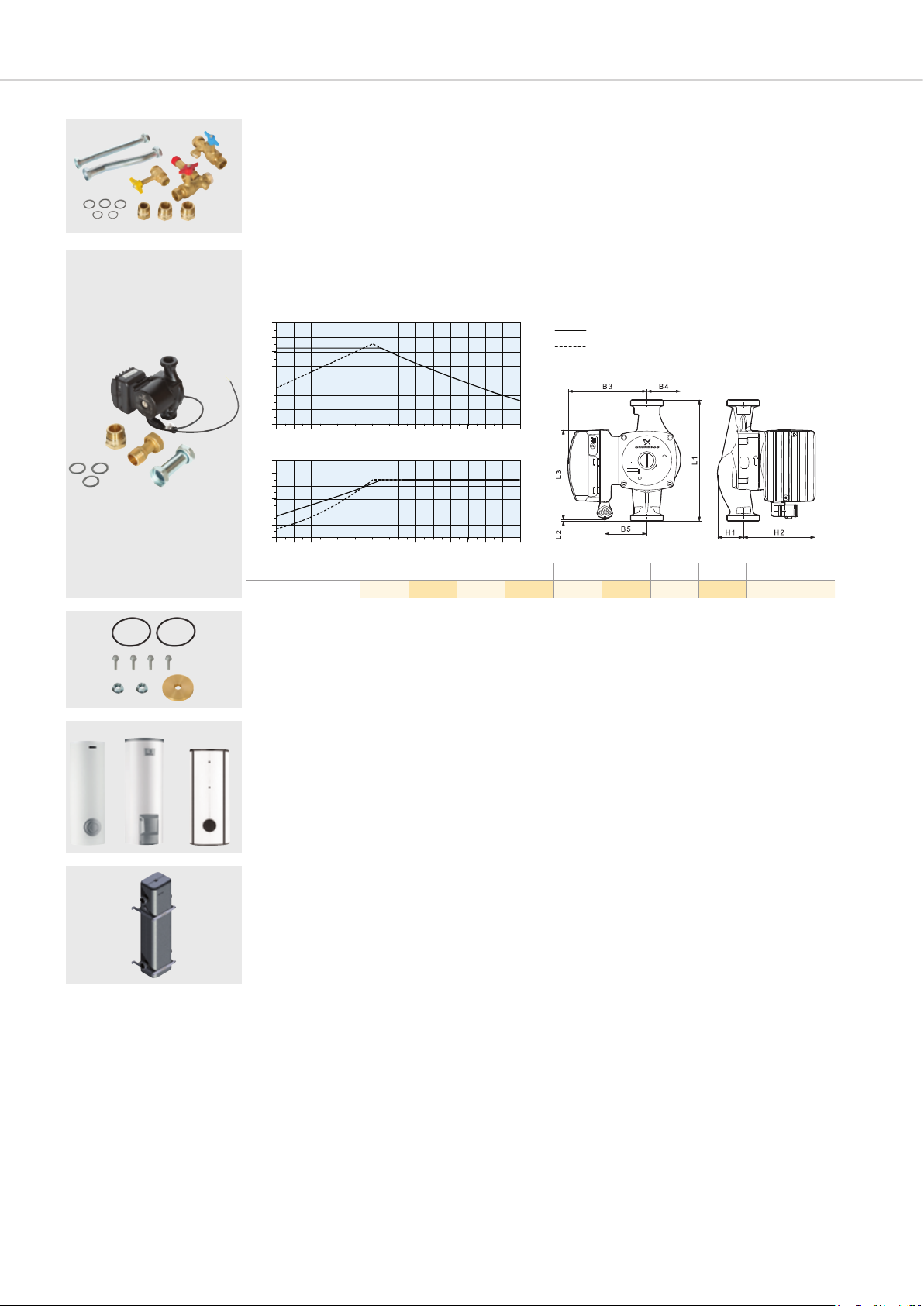

Hydraulic connection kit + gas valve - Package EH680

These kits comprise:

- 1 gas valve Rp 3/4,

- 1 heating return valve integrating the filling and

MCA_Q0206

drain valve Rp 1 1/4,

Modulating primary heating pump (EEI < 0.23) - Package EH651

Specifications for the GRUNDFOS UPMXL 25-105 130 AUTO pump

14

12

10

8

6

4

2

Manometric height in mWG

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0

240

200

160

120

80

40

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0

Dimensions (mm)

MCA_Q0205

UPMXL 25-105 13 0 22 131 117 50 64 27 112 G 1 1/2

- 1 heating flow valve with 3-bar safety valve and

port for connecting the expansion vessel Rp 1 1/4.

: Constant pressure

Flow rate m3/h

3

MCA_F0501

3

/h

Flow rate m

L1 L2 L3 B3 B4 B5 H1 H2 Connection

Type XXXX XX-XX XXX

XXXV ~

XX/XXHz

GFXXX

EEI<0.23

EuP Ready

1/1(A)

I

P

(W)

1

XX

X.XX

XX

X.XX

Max.

Min.

A

High Efficiency

P/N:XXXXXXX

PC:XXXXXX

XX

IP XX

TF XX

Max.X.XMPa

MCA_F0502

BLC

BPB B…

BLC_Q0001A

BPB_Q0001A

Propane conversion kit - EH693

This kit comprises a diaphragm which must be

installed on the gas valve unit to enable operation

with propane.

Domestic hot water preparation

The De Dietrich independent tanks in the B…

series, with a capacity of 150 to 3000 litres,

enable the production of domestic hot water for

individual and collective housing and industrial

RSB_Q0004A

Low-loss header, 120/80 - 2” - Package GV47

For any installations with several circuits or for

cascade installations, the use of a low-loss header

is strongly recommended.

MCA_Q0138 MCA_Q0204

and commercial premises. The specifications and

performance of these tanks is given in the price

catalogue and respective technical brochures.

The header is supplied with insulation and fitted

with a wall-mounting bracket and an accessories kit

comprising a plug, an air vent and a 1/2" drain valve.

10

THE BOILER OPTIONS

SA3

DU15

SA4

Gravity flow condensate neutralisation station (up to 450 kW) - Package SA3

Condensate neutralisation station with lift pump:

- Package SA4 for boilers or cascades of boilers up to 300 kW

- Package DU15 for boilers or cascades of boilers up to 1300 kW

C330_Q0005

The materials used for the condensate drain pipes

must be appropriate. Otherwise, the condensate

must be neutralised.

C330_Q0008

C330_Q0006

3

2

Mini

150 mm

1

Principle: Acid condensates are conveyed via a

reservoir filled with granulates before being sent to

the wastewater network.

Condensate draining

Condensate neutralisation station

Siphon

MCA_F0086

Granulate recharge for neutralisation station - Ref. 9422-5601 (10 kg)

Granulate recharge for neutralisation station - Package SA7 (25 kg)

An annual inspection of the system is required,

including a check of the effectiveness of the

C330_Q0009

granulates via a pH measurement. If necessary,

the granulates must be replaced.

300 mbar gas pressure regulator: - GDJ 20 - Package SA12

- GDJ 25 - Package AD245

- GDJ 50 - Package AD246

It is fitted on the gas inlet circuit. It is needed if the

gas is supplied at a pressure of 300 mbar.

Regulator

GDJ 20 24 240 Rp 3/4”

GDJ 25 70 700 Rp 1”

C230_Q0002

GDJ 50 14 0 1400 Rp 2”

Max. natural gas flow rate

in m

3

/h

Max power consumed

in kW

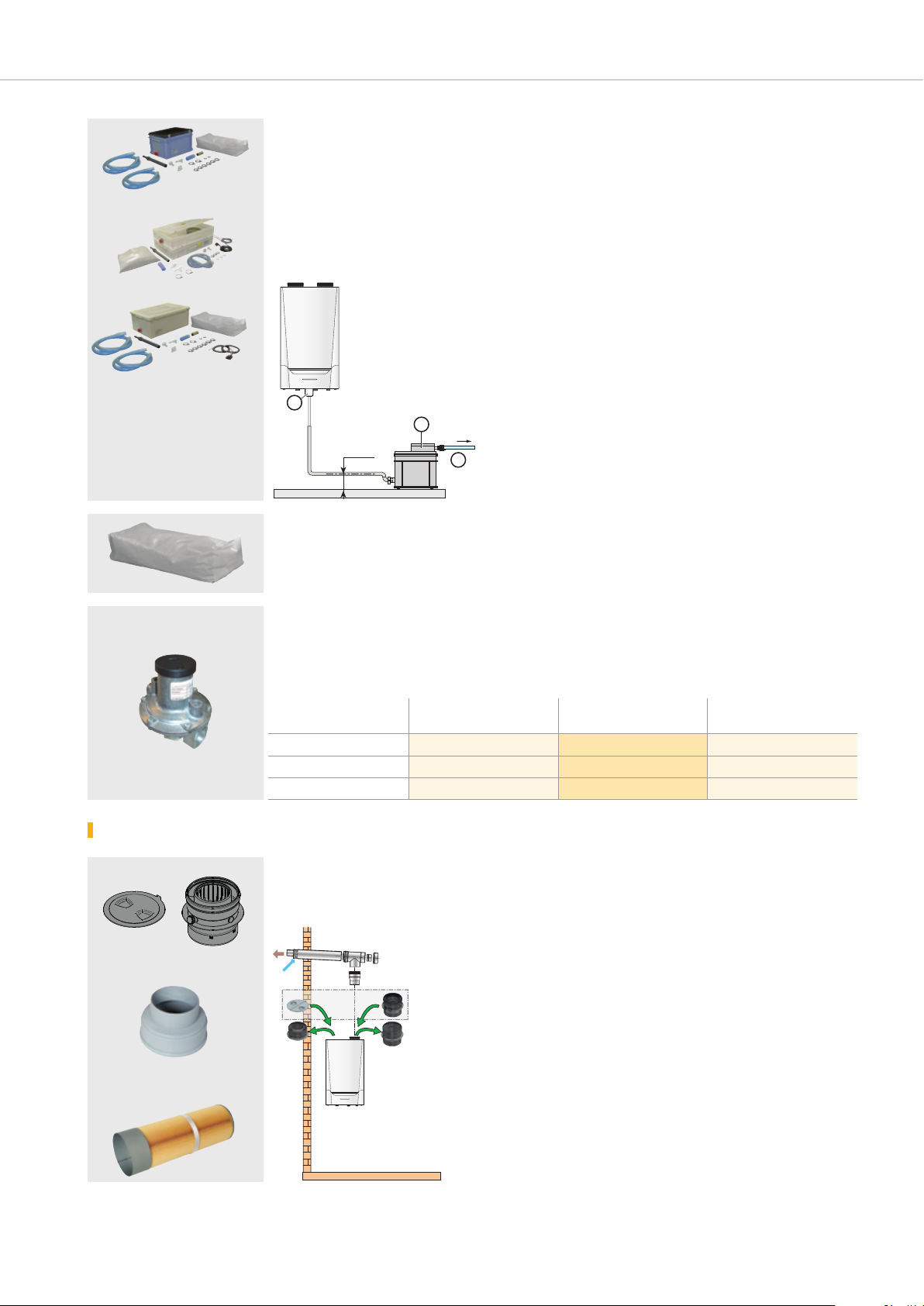

flue system accessOries specific tO the innOvens prO mca 160 bOiler

EH692

EH645

Concentric air-flue gas connection conversion kit - Package EH692

Ø 150 mm to Ø 200 mm adapter - Package EH645

Air filter - Package EH646

FUMI_F0216

EH692

MCA_Q0209

Connection

Ø

EH646

MCA_Q0203

MCA_F0090

11

Loading...

Loading...