DeDietrich Innovens MCA 15, Innovens MCA 25/28 MI, Innovens MCA 25 Installation And Service Manual

Page 1

Innovens

Wall-hung gas condensing boilers

MCA 15 - MCA 25

MCA 25/28 MI

EN

Installation and

Service Manual

300022146-001-B

Page 2

EG - VERKLARING VAN OVEREENSTEMMING

EC - DECLARATION OF CONFORMITY

EG - KONFORMITÄTSERKLÄRUNG

DÉCLARATION DE CONFORMITÉ CE

Fabrikant/Manufacturer/Hersteller/Fabricant : Remeha B.V.

Adres/Address /Adresse : Kanaal Zuid 110

Stad,Land/City,Country/Land,Ort/Ville, pays : Postbus 32, NL-7300 AA Apeldoorn

verklaart hiermede dat de toestel(len) : MCA ../.. (MI) (BIC)

this is to declare that the following product(s) :

erklärt hiermit das die Produk(te) :

déclare ici que les produit(s) suivant(s) :

op de markt gebracht door : De Dietrich Thermique

distributor : 57, rue de la Gare, F-67580

Vertreiber :

Commercialisé (s) par :

voldoet/voldoen aan de bepalingen van de onderstaande EEG-richtlijnen:

is/are in conformity with the following EEC-directives:

den Bestimmungen der nachfolgenden EG-Richtlinien entspricht/entsprechen:

répond/répondent aux directives CEE suivantes:

EEG-Richtlijn: 90/396/EEG toegepaste normen:

EEC-Directive: 90/396/EEC tested and examined to the following norms:

EG-Richtlinie: 90/396/EWG verwendete Normen, normes appliquées:

CEE-Directive: 90/396/CEE EN 297

(1994*), 483(1999*), 677(1998*)

92/42/EEG

92/42/EEC

92/42/EWG

92/42/CEE

2006/95/EEG

EN 50165(1997*), EN 60335-1(1994*)

2006/95/EEC EN 60335-2-102(2004*) 08

2006/95/EWG

2006/95/CEE

2004/108/EEG

EN 50165(1997*)

2004/108/EEC EN 55014-2

(1997*), EN 55014-1(2000*),

2004/108/EWG EN 61000-3-2(2000*) , 61000-3-3(1995*)

2004/108/CEE

97/23/EEG (art. 3, lid 3)

97/23/EEC (article 3, sub 3)

97/23/EWG (Art. 3, Abzats 3)

97/23/CEE (art.3 section 3)

*) inclusief (eventuele) aanvulling, including (if any) competion

einschließlich (falls vorhanden) Vervollständigung, y compris (le cas échéant) complément

Apeldoorn, decembre 2009

W.F. Tijhuis

Approval manager

703/2009/12/128

C002860-A

MCA 15 - MCA 25 MCA 25/28 MI

Declaration of conformity

The appliance complies with the standard model described in

declaration of compliance [. It is manufactured and distributed

pursuant to the requirements of european directives.

The original of the declaration of compliance is available from the

manufacturer.

Page 3

Contents

1 Introduction ................................................................................................6

1.1 Used symbols .......................................................6

1.2 Abbreviations ........................................................6

1.3 General ..................................................................7

1.3.1 Manufacturer's liability .............................................7

1.3.2 Installer's liability .....................................................7

1.4 Homologations ......................................................7

1.4.1 Certifications ...........................................................7

1.4.2 Gas categories ........................................................8

1.4.3 Additional Directives ................................................8

1.4.4 Factory test .............................................................8

2 Safety instructions and recommendations ..............................................9

2.1 Safety instructions ...............................................9

2.2 Recommendations ................................................9

3 Technical description ..............................................................................11

3.1 General description ............................................11

3.2 Main parts ............................................................11

3.3 Operating principle .............................................12

3.3.1 Skeleton Diagrams ................................................12

3.3.2 Shunt pump ...........................................................12

3.3.3 Water flow rate ......................................................13

3.4 Technical characteristics ...................................13

3.4.1 Sensor characteristics ...........................................14

4 Installation ................................................................................................16

4.1 Regulations governing installation ...................16

4.2 Package list .........................................................16

4.2.1 Standard delivery ..................................................16

4.2.2 Accessories ...........................................................16

29/04/2010 - 300022146-001-B

4.3 Choice of the location ........................................17

4.3.1 Data plate ..............................................................17

4.3.2 Location of the appliance ......................................18

4.3.3 Ventilation .............................................................18

4.3.4 Main dimensions ...................................................19

1

Page 4

MCA 15 - MCA 25 MCA 25/28 MI

Contents

4.4 Installing the mounting frame ...........................20

4.5 Positioning the boiler .........................................21

4.6 Hydraulic connections .......................................22

4.6.1 Flushing the system ..............................................22

4.6.2 Connection of the heating circuit ...........................22

4.6.3 Hydraulic connection of the water circuit for domestic

use ........................................................................23

4.6.4 Connecting the expansion vessel .........................23

4.6.5 Connecting the condensate discharge pipe ..........24

4.6.6 Filling the siphon ...................................................24

4.7 Gas connection ...................................................25

4.8 Flue gas system connections ............................26

4.8.1 Classification .........................................................26

4.8.2 Lengths of the air/flue gas pipes ...........................27

4.9 Installing the outside sensor .............................28

4.9.1 Choice of the location ............................................28

4.9.2 Installing the outside sensor ..................................28

4.10 Electrical connections ........................................29

4.10.1 Control unit ............................................................29

4.10.2 Recommendations ................................................30

4.10.3 Position of the PCBs .............................................31

4.10.4 Accessing the connection terminal blocks ............32

4.10.5 Connecting a direct heating circuit ........................34

4.10.6 Connecting a direct heating circuit and a domestic hot

water tank ..............................................................35

4.10.7 Connecting two circuits and a domestic hot water tank

before the mixing tank ...........................................37

4.10.8 Connecting two circuits and a domestic hot water tank

after the mixing tank ..............................................39

4.10.9 Hot water storage tank connection ........................41

4.10.10 Pool connection .....................................................46

4.10.11 Connecting a mixed tank .......................................48

4.10.12 Connecting the options .........................................49

4.10.13 Connection in cascade ..........................................50

4.11 Electrical diagram ...............................................53

4.12 Filling the system ...............................................54

4.12.1 Water treatment ....................................................54

4.12.2 Filling the system ..................................................56

5 Start-up ......................................................................................................57

5.1 Control panel .......................................................57

5.1.1 Description of the keys ..........................................57

5.1.2 Description of the display ......................................58

5.1.3 Access to the various browsing levels ..................60

5.1.4 Browsing in the menus ..........................................62

5.2 Check points before commissioning ................63

5.2.1 Preparing the boiler for commissioning .................63

29/04/2010 - 300022146-001-B

2

Page 5

5.2.2 Gas circuit .............................................................64

5.2.3 Hydraulic circuit .....................................................64

5.2.4 Electrical connections ...........................................64

5.3 Putting the appliance into operation ................65

5.4 Gas settings ........................................................66

5.4.1 Adapting to another gas type ................................66

5.4.2 Setting the air/gas ratio (Full load) ........................67

5.4.3 Setting the air/gas ratio (Part load) ......................69

5.4.4 Basic setting for the gas/air ratio ...........................71

5.5 Checks and adjustments after

commissioning ...................................................71

5.5.1 Displaying the parameters in extended

mode .....................................................................71

5.5.2 Setting the parameters specific to the

installation .............................................................72

5.5.3 Naming the circuits and generators ......................75

5.5.4 Setting the heating curve ......................................76

5.5.5 Finalizing work ......................................................78

5.6 Reading out measured values ...........................78

5.7 Changing the settings ........................................79

5.7.1 Language selection ...............................................80

5.7.2 Calibrating the sensors .........................................80

5.7.3 "Professional" settings ..........................................82

5.7.4 Configuring the network ........................................88

5.7.5 Returning to the factory settings ...........................96

6 Switching off the appliance .....................................................................97

6.1 Installation shutdown .........................................97

6.2 Frost protection ..................................................97

7 Checking and maintenance .....................................................................98

7.1 General instructions ...........................................98

7.2 Chimney sweep instructions .............................98

7.3 Customising maintenance .................................99

7.3.1 Maintenance message ..........................................99

7.3.2 Installer's contact details .....................................100

29/04/2010 - 300022146-001-B

7.4 Standard inspection and maintenance

operations .........................................................100

7.4.1 Checking the hydraulic pressure .........................101

7.4.2 Checking the opened expansion vessel ..............101

7.4.3 Checking the ionisation current ...........................101

7.4.4 Checking the transfer capacity ............................101

7.4.5 Checking the tightness of the combusted gases

evacuation and air inlet connections ...................101

7.4.6 Checking combustion ..........................................102

7.4.7 Checking the automatic air vent ..........................103

3

Page 6

MCA 15 - MCA 25 MCA 25/28 MI

7.4.8 Checking the safety valve ...................................104

7.4.9 Checking the siphon ............................................104

7.4.10 Checking the burner and cleaning the heat

exchanger ...........................................................105

Contents

7.5 Specific maintenance operations ....................106

7.5.1 Replacing the ionisation/ignition electrode ..........106

7.5.2 Cleaning the plate exchanger (domestic hot water

end) and the water filter cartridge .......................106

7.5.3 Replacing the 3-way valve ..................................109

7.5.4 Replacing the non-return valve ...........................110

7.5.5 Assembling the boiler ..........................................111

8 Troubleshooting .....................................................................................112

8.1 Messages (Code type Bxx or Mxx) ..................112

8.2 Message history ................................................114

8.3 Faults (Code type Lxx or Dxx) .........................115

8.3.1 Deletion of sensors from the memory in the

PCB .....................................................................123

8.3.2 Deleting the IOBL 3WV modules from the memory in

the PCB ..............................................................123

8.4 Failure history ...................................................124

8.5 Parameter and input/output check (mode

tests) ..................................................................125

9 Spare parts ..............................................................................................129

9.1 General ..............................................................129

9.2 Spare parts ........................................................129

9.2.1 Casing .................................................................130

9.2.2 Heat exchanger and burner ................................131

9.2.3 Fan ......................................................................132

9.2.4 Control panel .......................................................133

9.2.5 Connecting pipes (MCA 15 - MCA 25) ................134

9.2.6 Connecting pipes (MCA 25/28 MI) ......................135

9.2.7 Spare parts list ....................................................136

29/04/2010 - 300022146-001-B

4

Page 7

29/04/2010 - 300022146-001-B

5

Page 8

1. Introduction

1 Introduction

1.1 Used symbols

MCA 15 - MCA 25 MCA 25/28 MI

In these instructions, various danger levels are employed to draw the

user's attention to particular information. In so doing, we wish to

safeguard the user's safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

1.2 Abbreviations

CAUTION

Risk of material damage.

Signals important information.

¼ Signals a referral to other instructions or other pages in the

instructions.

4 3CE: Collective conduit for sealed boiler

4 DHW: Domestic hot water

4 Interscenario switch: Home automation switch that can be used

to centralise and control several scenarios

4 Hi: Lower heating value LHV

4 Hs: Higher heating value HHV

4 IOBL: Carrier current home automation bus

4 PPS: Polypropylene hardly inflammable

4 PCU: Primary Control Unit - PCB for managing burner operation

4 PSU: Parameter Storage Unit - Parameter storage for PCBs

PCU and SU

4 SCU: Secondary Control Unit - Diematic iSystem control panel

PCB

4 SU: Safety Unit - Safety PCB

4 3WV: 3-way valve

6

29/04/2010 - 300022146-001-B

Page 9

MCA 15 - MCA 25 MCA 25/28 MI 1. Introduction

1.3 General

1.3.1. Manufacturer's liability

Our products are manufactured in compliance with the requirements

of the various european applicable Directives. They are therefore

delivered with [ marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.4 Homologations

1.3.2. Installer's liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 Warn the user of the obligation to check the appliance and

maintain it in good working order.

4 Give all the instruction manuals to the user.

1.4.1. Certifications

29/04/2010 - 300022146-001-B

CE identification no

NOx classification

Type of connection Chimney: B23 , B

PIN 0063BT3444

5 (EN 297 pr A3, EN 656)

Flue gas outlet: C13 , C33, C43, C53, C63, C83 , C

33

93

7

Page 10

1. Introduction

MCA 15 - MCA 25 MCA 25/28 MI

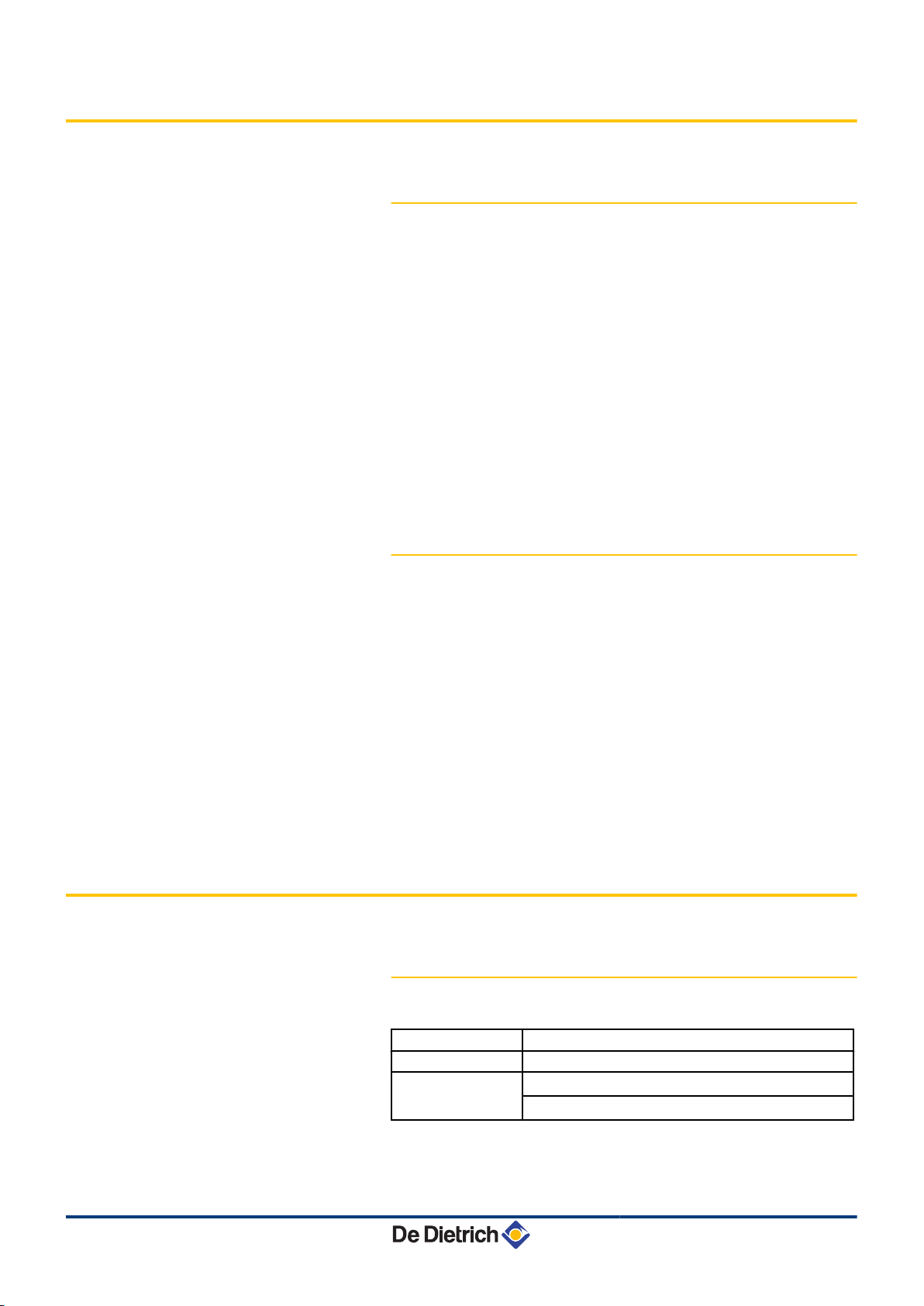

1.4.2. Gas categories

Gas category Gas type Connection pressure (mbar)

II

2ESi3P

Natural gas H (G20) 20

Natural gas L (G25) 25

Propane (G31) 37

The boiler is preset in the factory to operate on natural gas H (G20).

¼ For operation on another type of gas, see chapter: "Adapting

to another gas type", page 66.

1.4.3. Additional Directives

Apart from the legal provisions and Directives, the additional

Directives described in these instructions must also be observed.

For all provisions and Directives referred to in these instructions, it is

agreed that all addenda or subsequent provisions will apply at the

time of installation.

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

1.4.4. Factory test

Before leaving the factory, each boiler is set for optimum performance

and tested to check the following items:

4 Electrical safety

4 Adjustment (CO2)

4 Domestic hot water mode (Only on models with domestic hot water

production)

4 Water tightness

4 Gas tightness

4 Parameter settings

8

29/04/2010 - 300022146-001-B

Page 11

MCA 15 - MCA 25 MCA 25/28 MI

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If you smell gas:

1. Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

2. Isolate the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them immediately.

5. If the gas leak is before the gas meter, contact the

gas supplier.

2. Safety instructions and recommendations

2.2 Recommendations

DANGER

If you smell flue gases:

1. Switch the appliance off.

2. Open the windows.

3. Trace possible leaks and seal them immediately.

WARNING

4 Installation and maintenance of the boiler must be

carried out by a qualified professional in compliance

with prevailing local and national regulations.

4 When working on the boiler, always disconnect the

boiler from the mains and close the main gas inlet

valve.

4 After maintenance or repair work, check all

installations to ensure that there are no leaks.

CAUTION

29/04/2010 - 300022146-001-B

The boiler must be installed in a frost-free environment.

Keep this document close to the place where the boiler is

installed.

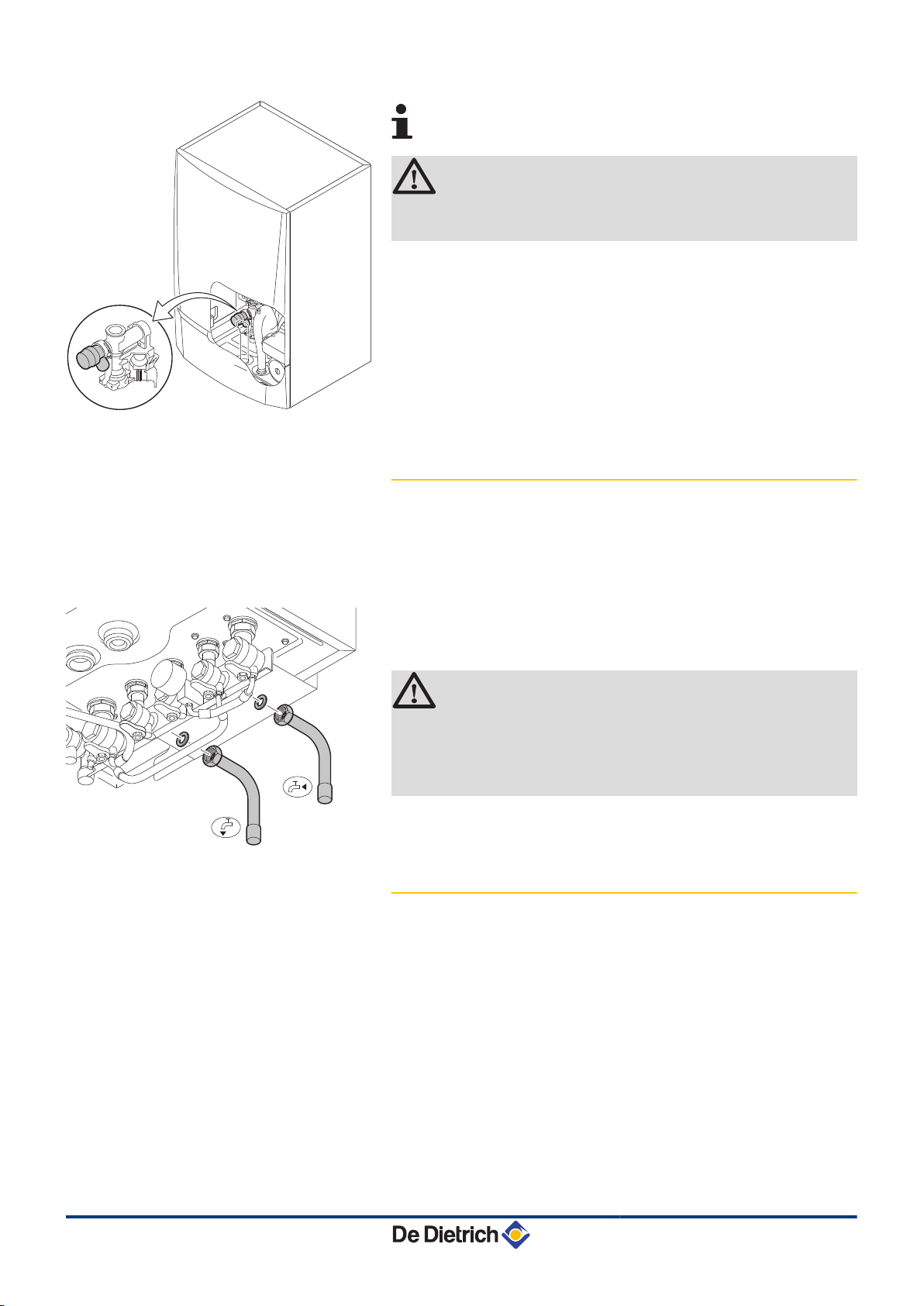

Casing components

9

Page 12

2. Safety instructions and recommendations MCA 15 - MCA 25 MCA 25/28 MI

Only remove the casing for maintenance and repair operations. Put

the casing back in place after maintenance and repair operations.

Instructions stickers

The instructions and warnings affixed to the appliance must never be

removed or covered and must remain legible during the entire lifespan

of the boiler. Immediately replace damaged or illegible instructions

and warning stickers.

Modifications

Modifications may only be made to the boiler after the written

permission of De Dietrich Thermique to do so.

10

29/04/2010 - 300022146-001-B

Page 13

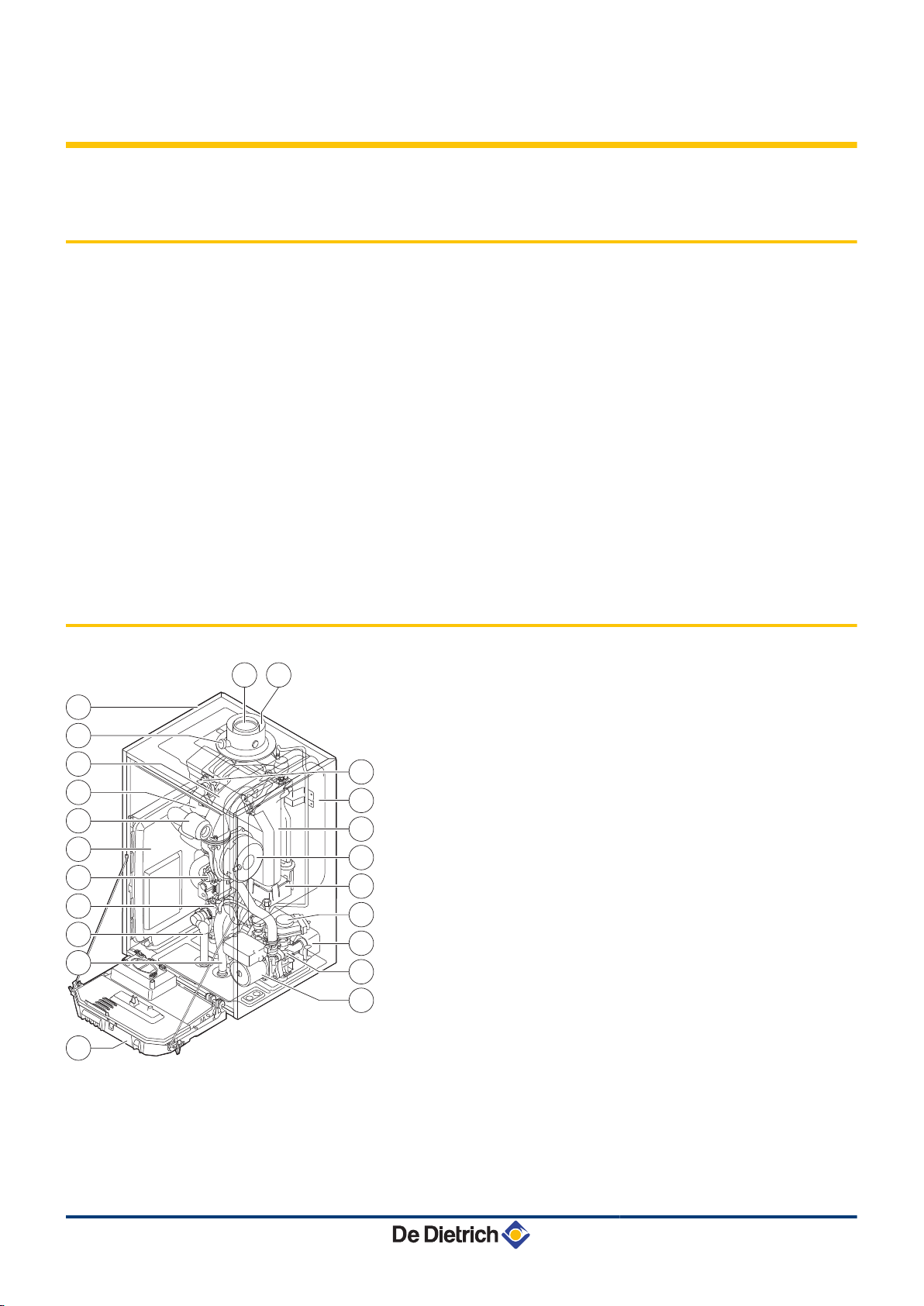

T001867-C

2

15

14

13

16

17

18

19

20

21

3

4

5

6

7

8

9

10

11

12

1 22

MCA 15 - MCA 25 MCA 25/28 MI 3. Technical description

3 Technical description

3.1 General description

Wall-hung gas condensing boilers

4 High efficiency heating.

4 Low pollutant emissions.

4 Top of the range electronic DIEMATIC iSystem control panel

4 Installation and connection facilitated by the mounting frame

delivered with the appliance.

4 Flue gas discharge via a forced flue, chimney, bi-flow or 3CE type

connection.

4 MCA 15 - MCA 25: Heating only (Possibility of producing domestic

hot water via an independent tank which has been installed

separately).

4 MCA 25/28 MI: Heating and micro-storage domestic hot water

production.

3.2 Main parts

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Flue gas discharge pipe

Casing/air box

Outlet for measuring combustion gases

Mixer pipe

Heating flow hose

Áir intake silencer

Box for the control PCBs

Combined venturi and gas valve unit

Flow end hydrobloc

Safety valve outlet pipe

Siphon

Control panel

Shunt pump

Return end hydrobloc

Plate heat exchanger (DHW circuit) (Only on models with

domestic hot water production)

Inverter valve

Condensate receiver tank

Fan

Heat exchanger (Heating circuit)

29/04/2010 - 300022146-001-B

11

Page 14

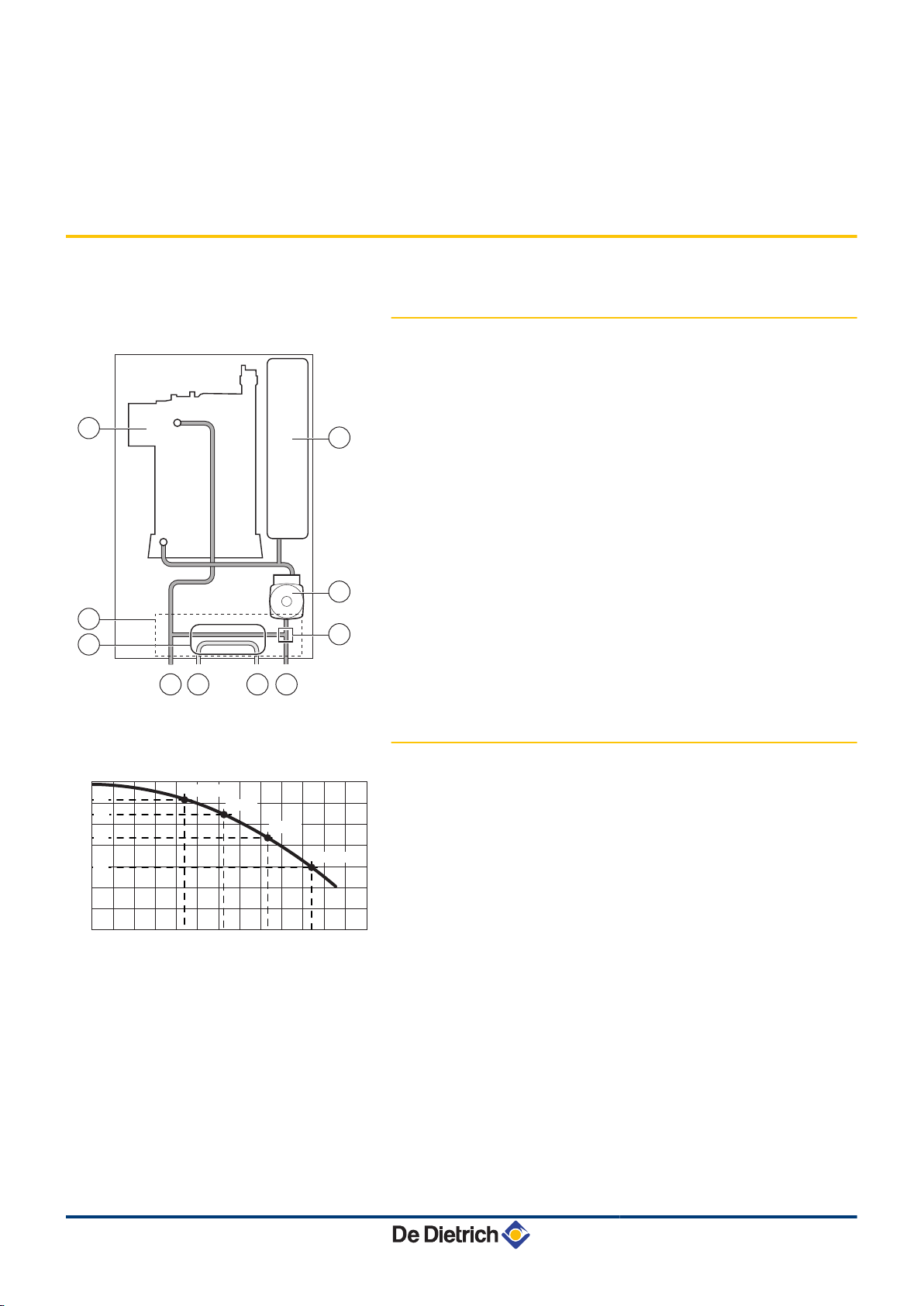

T001868-B

1

2

3

10

9

8

4 5 6 7

T002537-B

0 200 400 600 800 1000 1200

Q (l/h)

10 kW

15 kW

20 kW

25 kW

615

545

435

295

437 623 830 1037

0

100

200

300

400

500

700

H (mbar)

600

3. Technical description

MCA 15 - MCA 25 MCA 25/28 MI

3.3 Operating principle

20

21

22

Expansion vessel

Ignition/ionization electrode

Air intake

3.3.1. Skeleton Diagrams

1

2

3

4

5

6

7

Heat exchanger (Heating circuit)

Hydrobloc

Plate heat exchanger (DHW circuit) (Only on models with

domestic hot water production)

Heating flow

Domestic hot water outlet

Domestic cold water inlet

Heating return

8

9

10

Inverter valve

Shunt pump (Heating circuit)

Expansion vessel

3.3.2. Shunt pump

H

Q

The boiler is fitted with a modulating pump which is regulated by the

control panel as a fuction of ΔT.

The graph shows the manometric height at various outputs. The

parameters MIN.PUMP SPEED and MAX.PUMP SPEED are used to

modify the pump settings. If flow noise can be heard in the system, it

is possible to reduce the maximum pump speed with the parameter

MAX.PUMP SPEED (First of all, vent the heating system). If

circulation in the radiators is too low or the radiators do not fully heat

up, increase the minimum pump speed with the parameter

MIN.PUMP SPEED.

Manometric height central heating circuit

Water flow

12

¼ See chapter: ""Professional" settings", page 82.

29/04/2010 - 300022146-001-B

Page 15

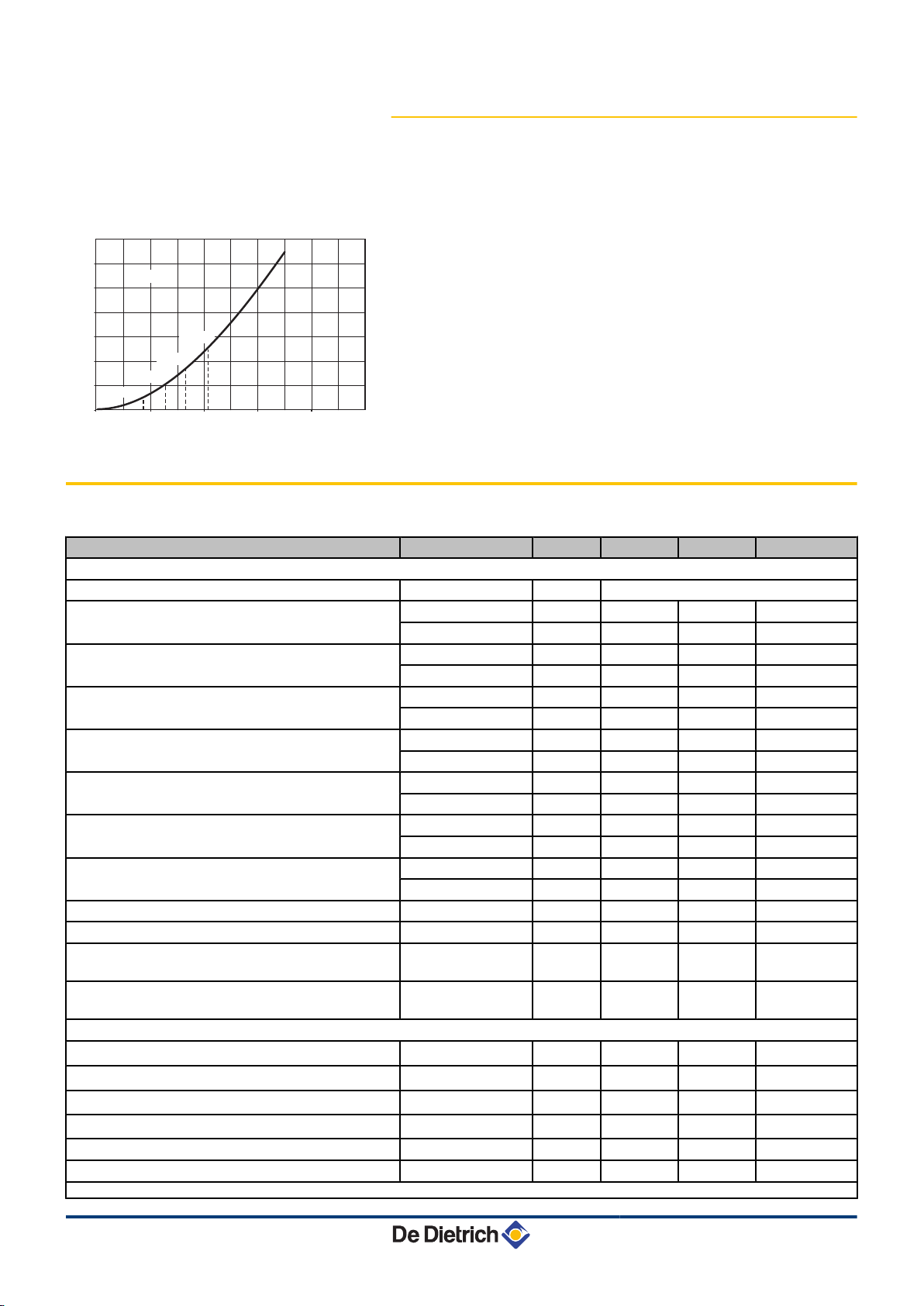

T001978-A

0

100

200

300

400

500

600

700

0 500

1037437

15001000 2000 2500

∆p [mbar]

Q [l/h]

623 830

∆T = 20K

10 kW

15 kW

20 kW

25 kW

MCA 15 - MCA 25 MCA 25/28 MI 3. Technical description

3.3.3. Water flow rate

The boiler's modulating control system limits the maximum difference

in temperature between the heating flow and return and the maximum

speed at which the flow temperature increases. In this way, the boiler

does not require a minimum water flow rate.

Δp

Q

Pressure drop

Water flow (max = 1680 l/h)

3.4 Technical characteristics

Boiler type

General

Flow rate setting Adjustable

Nominal output (Pn)

Heating System (80/60 °C)

Nominal output (Pn)

Heating System (50/30 °C)

Nominal output (Pn)

DHW System

Nominal input (Qn)

Heating System (Hi)

Nominal input(Qn)

Heating System (Hs)

Nominal input (Qnw)

DHW System (Hi)

Nominal input (Qnw)

DHW System (Hs)

minimum-maximum kW 3,0 - 14,5 5,0 - 24,1 5,0 - 24,1

Factory setting kW 14,5 24,1 19,4

minimum-maximum kW 3,4 - 15,8 5,6 - 25,5 5,6 - 25,5

Factory setting kW 15,8 25,5 20,5

minimum-maximum kW - - 5,0 - 28,6

Factory setting kW - - 28,6

minimum-maximum kW 3,1 - 15,0 5,2 - 25,0 5,2 - 25,0

Factory setting kW 15,0 25,0 20,1

minimum-maximum kW 3,4 - 16,7 5,8 - 27,8 5,8 - 27,8

Factory setting kW 16,7 27,8 22,3

minimum-maximum kW - - 5,2 - 28,0

Factory setting kW - - 28,0

minimum-maximum kW - - 5,8 - 31,1

Factory setting kW - - 31,1

Heating efficiency under full load (Hi) (80/60 °C) - % 96,5 96,3 96,3

Heating efficiency under full load (Hi) (50/30 °C) - % 105,3 102,0 102,0

Heating efficiency under partial load (Hi) (Return

- % 94,9 96,1 96,1

temperature 60°C)

Heating efficiency under partial load (EN 92/42)

- % 108,5 108,0 108,0

(Return temperature 30°C)

Data on the gases and combustion gases

Gas consumption - Natural gas H (G20) minimum-maximum

Gas consumption - Natural gas L (G25) minimum-maximum

Gas consumption - Propane G31 minimum-maximum

NOx-Emission per year or (n =1)

m3/h

m3/h

m3/h

mg/kWh 33 38 38

Mass flue gas flow rate minimum-maximum kg/h 5,3 - 25,2 8,9 - 42,1 8,9 - 47,1

Flue gas temperature minimum-maximum °C 30 - 65 30 - 80 30 - 85

(1) Front panel removed

29/04/2010 - 300022146-001-B

MCA 15 MCA 25 MCA 25/28 MI

Modulating, Start/Stop, 0 - 10 V

0,33 - 1,59 0,55 - 2,65 0,55 - 2,96

0,38 - 1,85 0,64 - 3,08 0,64 - 3,45

0,13 - 0,61 0,21 - 1,02 0,21 - 1,15

13

Page 16

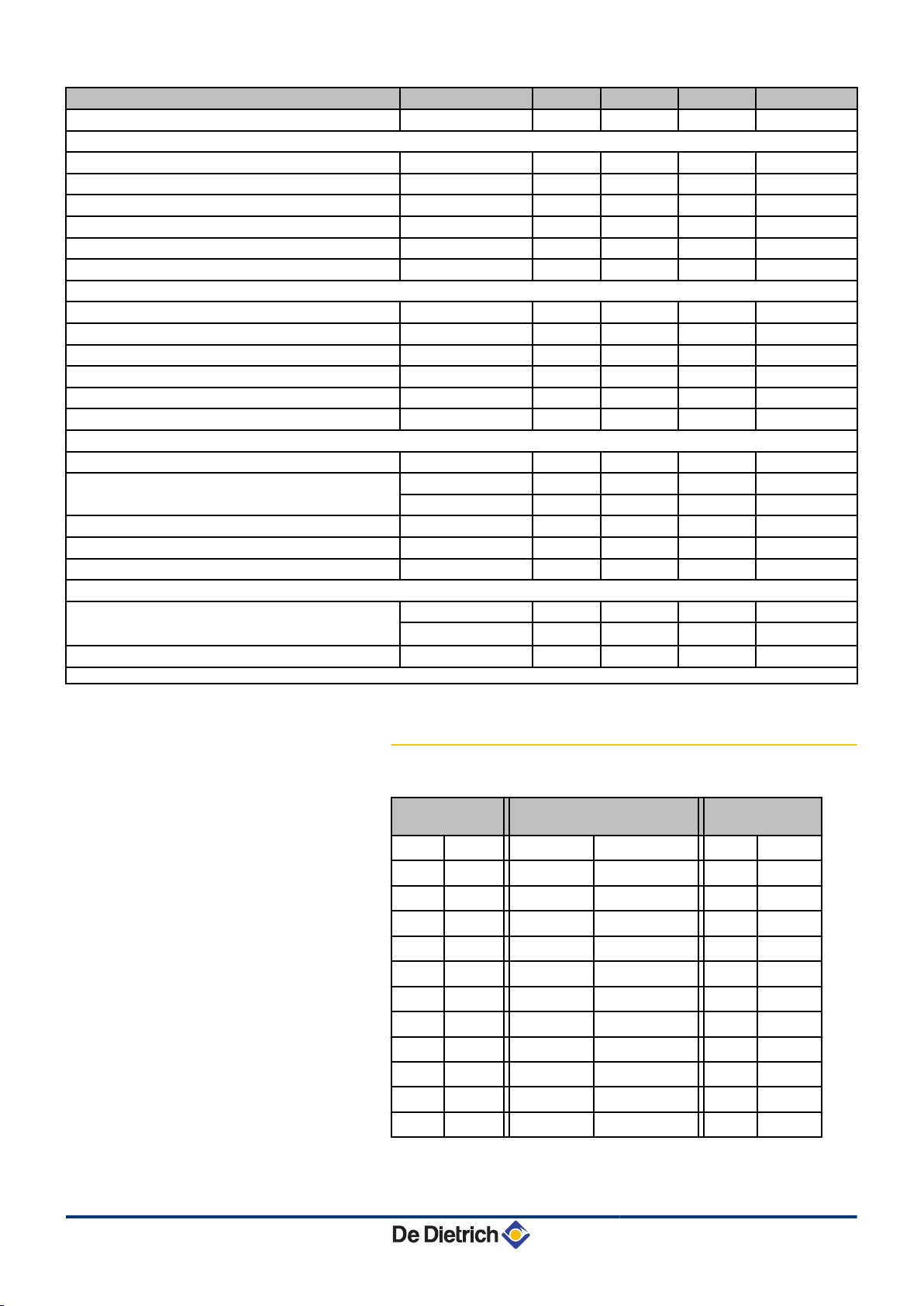

3. Technical description MCA 15 - MCA 25 MCA 25/28 MI

Boiler type

Maximum counter pressure

Characteristics of the heating circuit

Water content

Water operating pressure minimum kPa (bar) 80 (0,8) 80 (0,8) 80 (0,8)

Water operating pressure (PMS) maximum kPa (bar) 300 (3,0) 300 (3,0) 300 (3,0)

Water temperature maximum °C 110 110 110

Operating temperature maximum °C 90 90 90

Manometric height central heating circuit (∆T = 20K)

Characteristics of the domestic hot water circuit

Specific hot water flow D (60 °C)

Specific hot water flow D (40 °C)

Domestic water resistance

Flow rate threshold minimum l/min - - 1,2

Water content

Operating pressure (Pmw) maximum kPa (bar) - - 800 (8,0)

Electrical characteristics

Power supply voltage

Power consumption - Full load

Power consumption - Part load maximum W 25 25 25

Power consumption - Standby maximum W 4 4 4

Electrical protection index

Other characteristics

Weight (empty)

Acoustic level at 1 meter at high speed

(1) Front panel removed

maximum W 101 116 124

Factory setting W 63 76 76

Pa 80 120 130

l 1,7 1,7 1,7

mbar 545 295 295

l/min - - 8,2

l/min - - 13,7

mbar - - 490

l - - 0,33

VAC 230 230 230

Total kg 43 43 44

Mounting

(1)

kg 36 36 37

dBA 35 42 44

MCA 15 MCA 25 MCA 25/28 MI

IPX4D IPX4D IPX4D

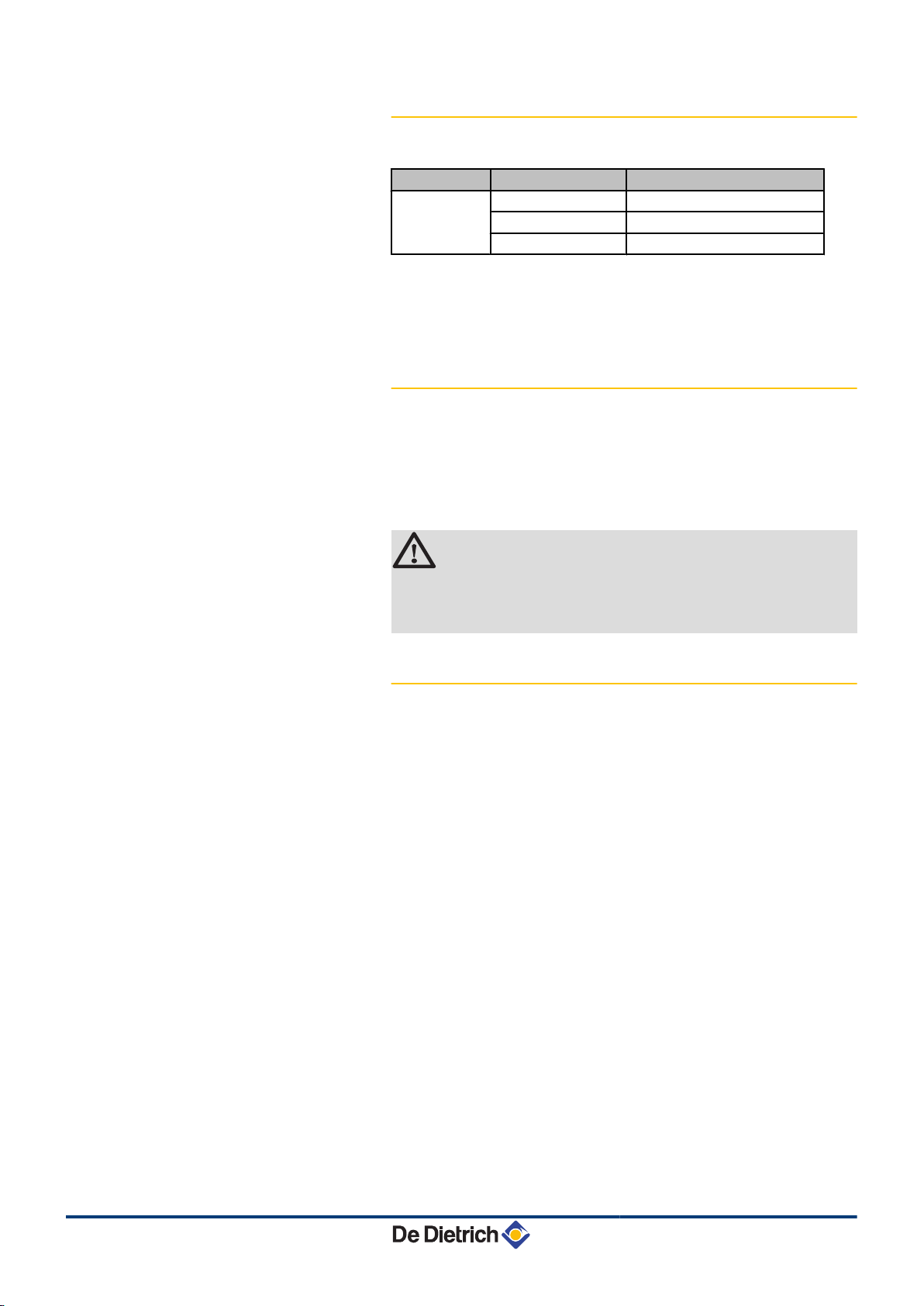

3.4.1. Sensor characteristics

Outside sensor

-20 °C

-16 °C

-12 °C

-8 °C

-4 °C

0 °C

4 °C

8 °C

12 °C

16 °C

20 °C

24 °C

2392 ¨

2088 ¨

1811 ¨

1562 ¨

1342 ¨

1149 ¨

984 ¨

842 ¨

720 ¨

616 ¨

528 ¨

454 ¨

Outlet sensor circuit B+C

Domestic hot water sensor

0 °C

10 °C

20 °C

25 °C

30 °C

40 °C

50 °C

60 °C

70 °C

80 °C

90 °C

32014 ¨

19691 ¨

12474 ¨

10000 ¨

8080 ¨

5372 ¨

3661 ¨

2535 ¨

1794 ¨

1290 ¨

941 ¨

Boiler sensor

Return sensor

-20 °C

-10 °C

0 °C

10 °C

20 °C

25 °C

30 °C

40 °C

50 °C

60 °C

70 °C

80 °C

98932 ¨

58879 ¨

36129 ¨

22804 ¨

14773 ¨

12000 ¨

9804 ¨

6652 ¨

4607 ¨

3252 ¨

2337 ¨

1707 ¨

14

29/04/2010 - 300022146-001-B

Page 17

MCA 15 - MCA 25 MCA 25/28 MI 3. Technical description

Outside sensor Outlet sensor circuit B+C

Domestic hot water sensor

Boiler sensor

Return sensor

90 °C

100 °C

110 °C

1266 ¨

952 ¨

726 ¨

29/04/2010 - 300022146-001-B

15

Page 18

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

4 Installation

4.1 Regulations governing installation

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

4.2 Package list

4.2.1. Standard delivery

The delivery includes:

4 The boiler, fitted with a connection cable

4 Mounting frame

4 Mounting template

4 Connection kit

4 Run-off collector for siphon and safety valve

4 Outside sensor

4 Installation and Service Manual

4 User Guide

4.2.2. Accessories

Various options are available depending on the configuration of the

installation:

Boiler options

Description package Description package

Stand-off frame HR39 RX12 cable AD134

Pipework kit for stand-off frame HR40 TELCOM 2 voice remote monitoring module AD152

Pipe cover HR42 Flow sensor AD199

Flue gas thermostat HR43 DHW sensor AD212

adapter 80/125 HR38 Optional PCB for 3-way valve AD249

adapter 80-80 HR46 Hot water storage tank sensor AD250

Exchanger cleaning kit HR44 Outside radio-controlled temperature sensor AD251

Boiler body cleaning kit HR45 Boiler radio module AD252

DHW tank BS60 EE54 Radio remote control AD253

Kit for connection between MCA and BS60 EA138 Interactive remote control AD254

Control system options

16

29/04/2010 - 300022146-001-B

Page 19

T001539-B

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

Boiler options Control system options

Description package Description package

DHW tank SR130 EE22 Room sensor FM52

Kit for connection between MCA and SR130 EA137

4.3 Choice of the location

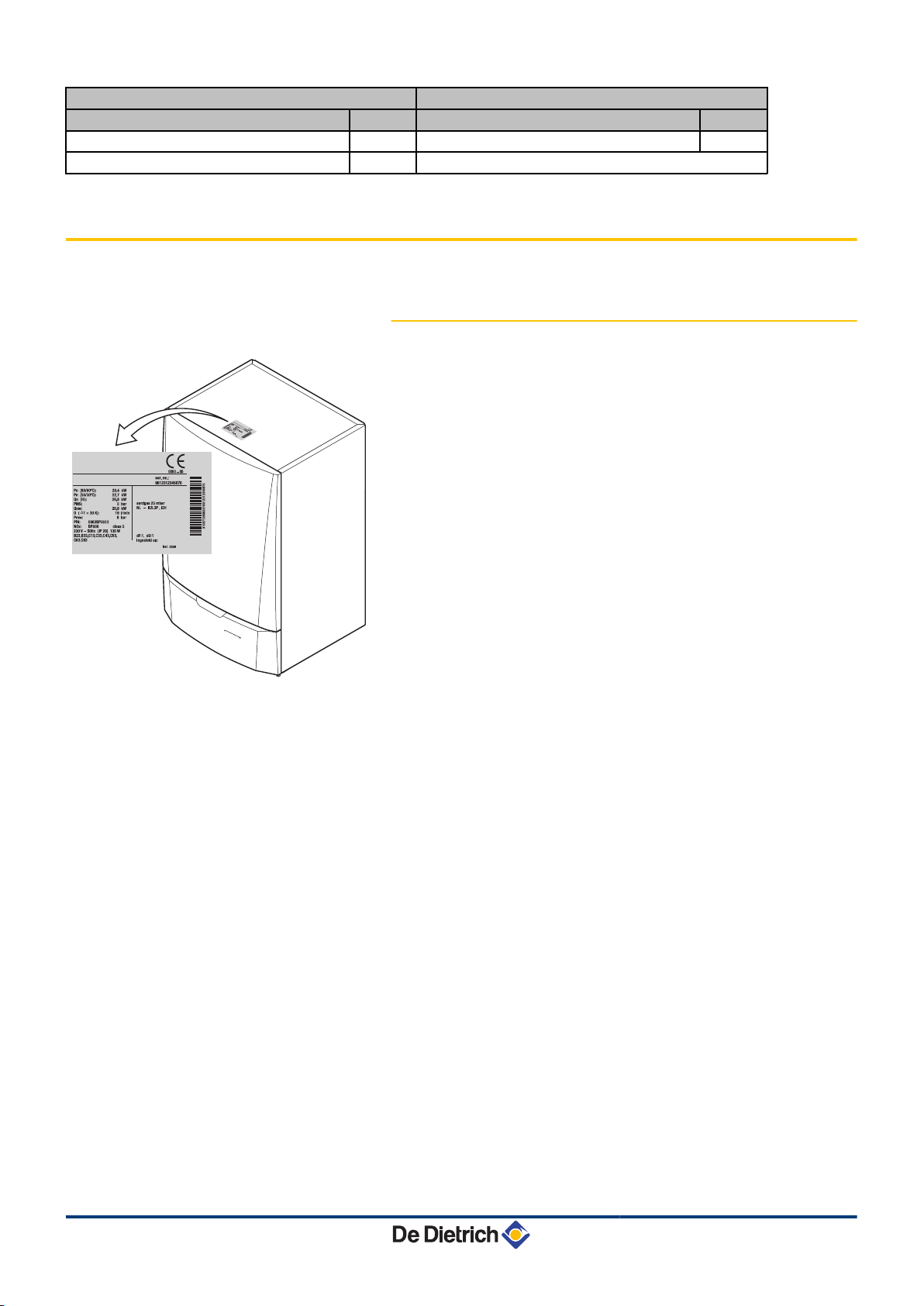

4.3.1. Data plate

The data plate located on top of the boiler provides important

information on the appliance: serial number, model, gas category, etc.

29/04/2010 - 300022146-001-B

17

Page 20

T001583-A

450

min.1000

450

min.

250

min.

250

690

T001584-A

min. 550

min.550

min. 250

50 (2)

min. 250

100

min. (1)

4. Installation

MCA 15 - MCA 25 MCA 25/28 MI

4.3.2. Location of the appliance

4 Before mounting the boiler, decide on the ideal position for

mounting, bearing the Directives and the dimensions of the

appliance in mind.

4 When choosing the position for mounting the boiler, bear in mind

the authorised position of the combustion gas discharge outlets

and the air intake opening.

4 To ensure adequate accessibility to the appliance and facilitate

maintenance, leave enough space around the boiler.

WARNING

4 Fix the appliance to a solid wall capable of bearing

the weight of the appliance when full of water and fully

equipped.

4 It is forbidden to store inflammable products and

materials in the boiler room or close to the boiler,

even temporarily.

CAUTION

4 The boiler must be installed in a frost-free

environment.

4 A connection to the mains drainage system for the

discharge of condensate must be available close to

the boiler.

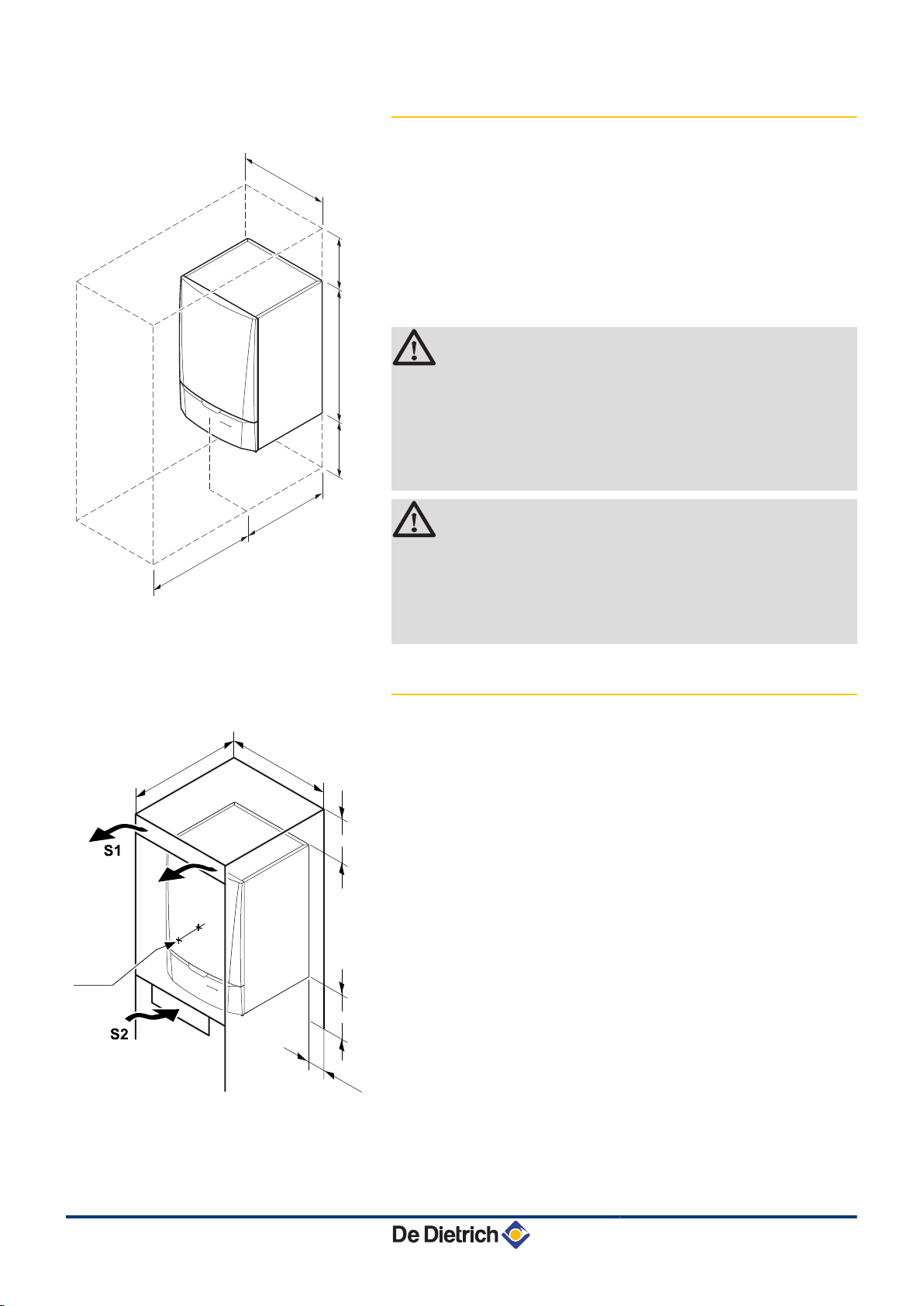

4.3.3. Ventilation

(1)

(2)

If the boiler is installed in a closed box, respect the minimum

dimensions given in the diagram opposite. Also allow openings to

obviate the following hazards:

4 Accumulation of gas

4 Heating of the box

Minimum cross section of the openings: S1 + S2 = 150 cm

Distance between the front of the appliance and the

internal wall of the cupboard.

Distance to allow on either side of the appliance.

2

18

29/04/2010 - 300022146-001-B

Page 21

T001116-B

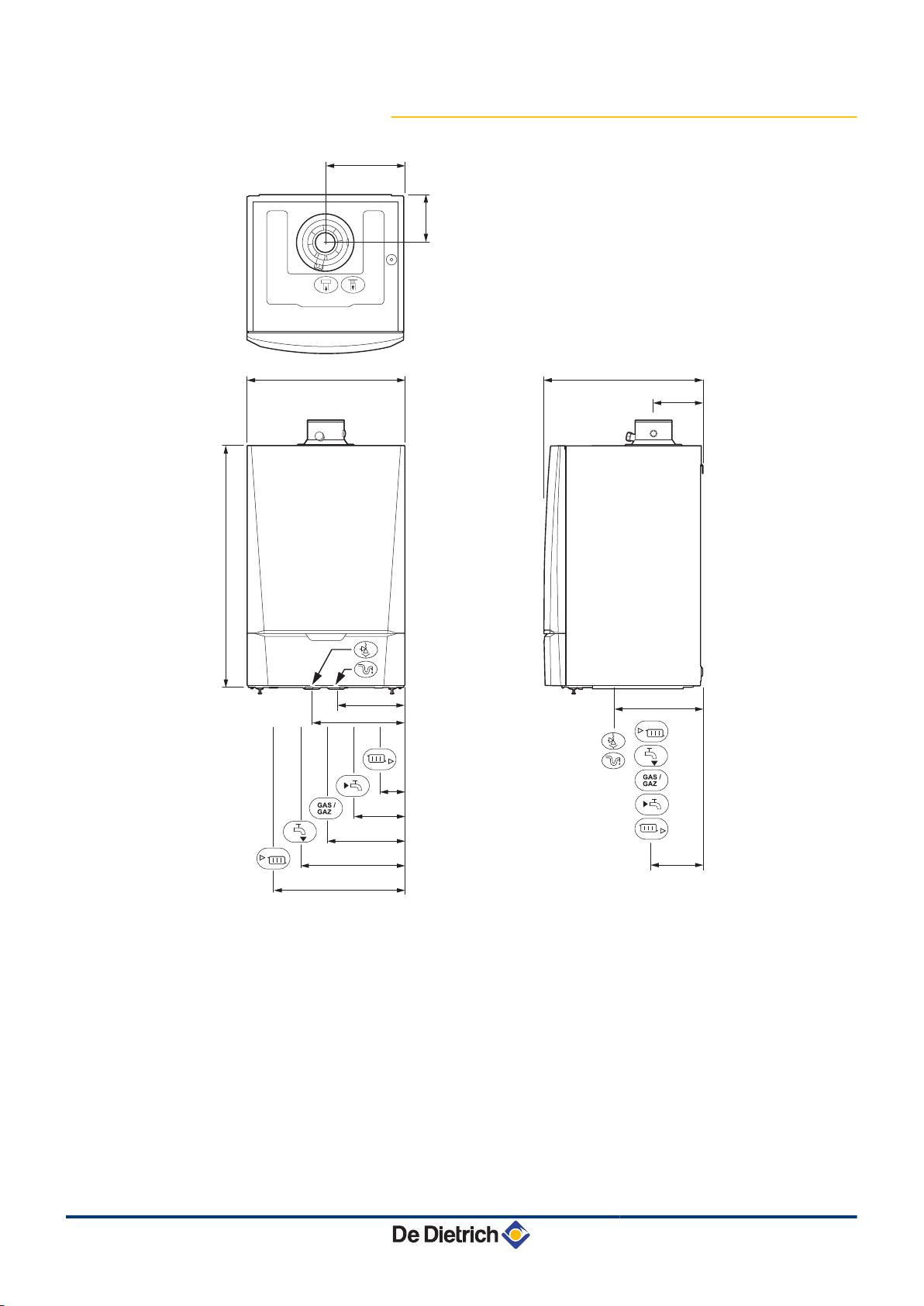

67

195

265

132

199

266

331

690

450

450

225

140

140

150

257,5

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

4.3.4. Main dimensions

i

h

ê

j

z

x

Gas /

Gaz

Connection of the combustion gas exhaust pipe Ø 60 mm

Connection of the air intake pipe Ø 100 mm

Safety valve outlet pipe Ø 25 mm

Condensates discharge Ø 25 mm

Heating circuit return G¾"

Domestic cold water inlet G½"

Gas connection G½"

29/04/2010 - 300022146-001-B

y

{

Domestic hot water outlet G½"

Heating circuit flow G¾"

19

Page 22

T001869-A

1

2

3

4

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

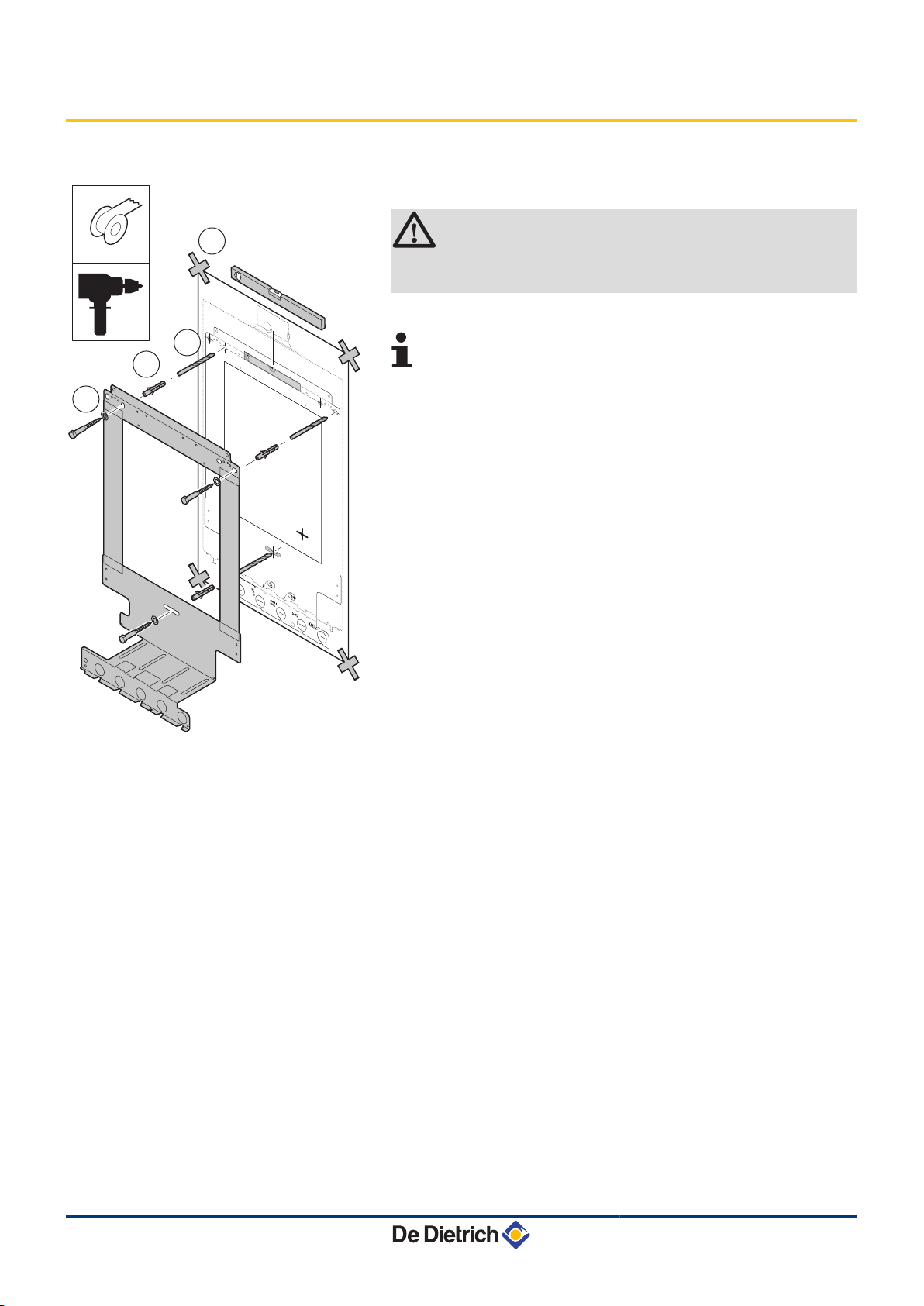

4.4 Installing the mounting frame

The boiler is delivered with a mounting template.

1. Position the mounting template to the wall with adhesive tape.

CAUTION

Using a spirit level, check that the mounting axis is

perfectly horizontal.

2. Drill 3 holes with a Ø of 10 mm.

Additional holes are provided in case one or other of the

standard locating holes prevents the correct location of the

plugs.

3. Put the plugs in place.

4. Secure the mounting frame to the wall using the 3 hexagonal

headed screws provided for this purpose.

20

29/04/2010 - 300022146-001-B

Page 23

T001870-A

T001627-A

T001872-A

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

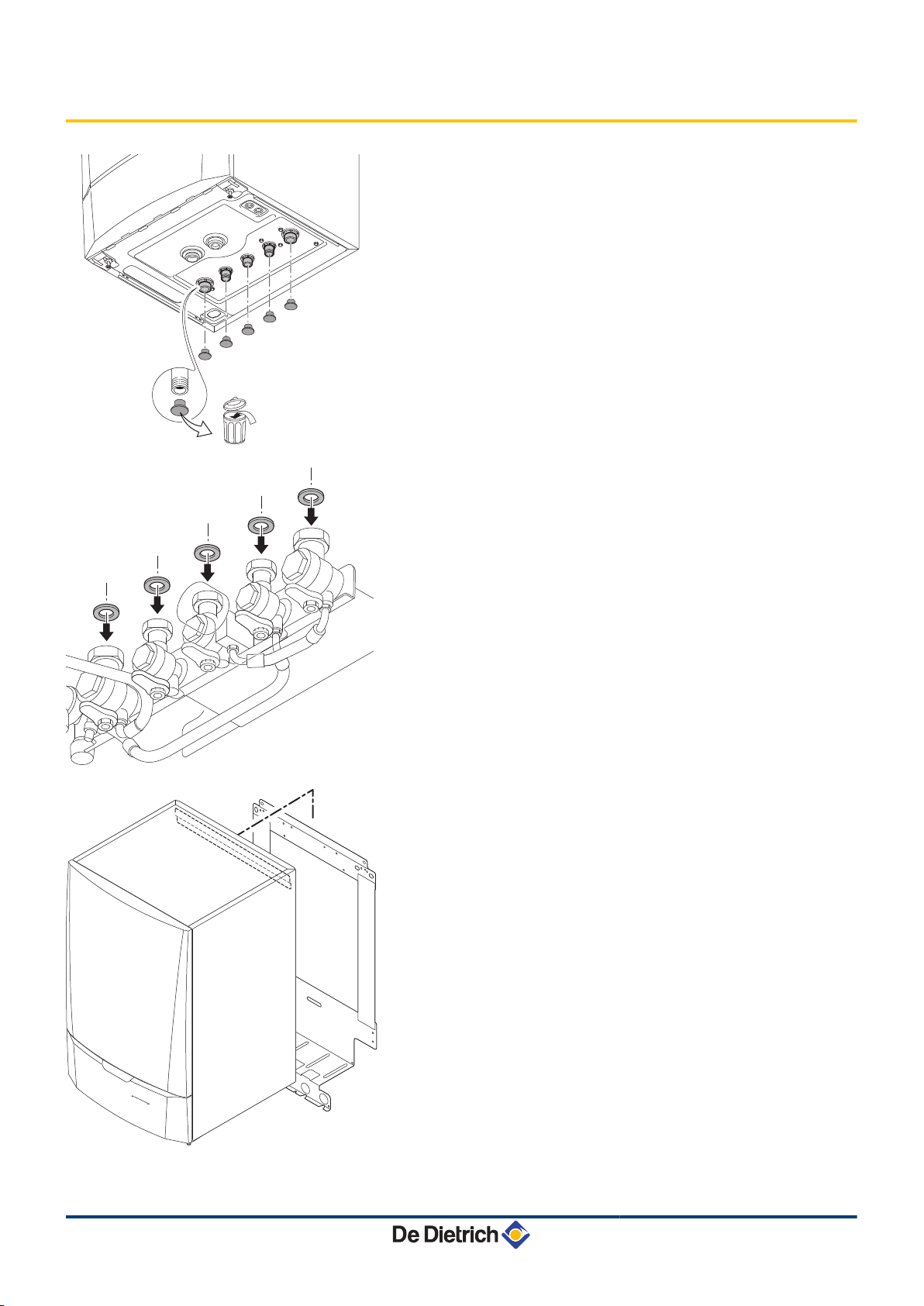

4.5 Positioning the boiler

1. Remove the protective caps from all of the hydraulic inlets and

outlets on the boiler.

2. Fit a fibre gasket to each joint on the valve plate.

29/04/2010 - 300022146-001-B

3. Position the boiler above the plumbing fixtures plate and locate it

against the mounting frame. Gently lower the boiler.

4. Tighten the valve nuts on the boiler.

21

Page 24

T001625-A

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

4.6 Hydraulic connections

4.6.1. Flushing the system

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

Installing the boiler in new installations (installations

n

less than 6 months old)

4 Clean the installation with a universal cleaner to eliminate debris

from the appliance (copper, flaxen thread, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

Installing the boiler in existing installations

n

4 Remove sludge from the installation.

4 Flush the installation.

4 Clean the installation with a universal cleaner to eliminate debris

from the appliance (copper, flaxen thread, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

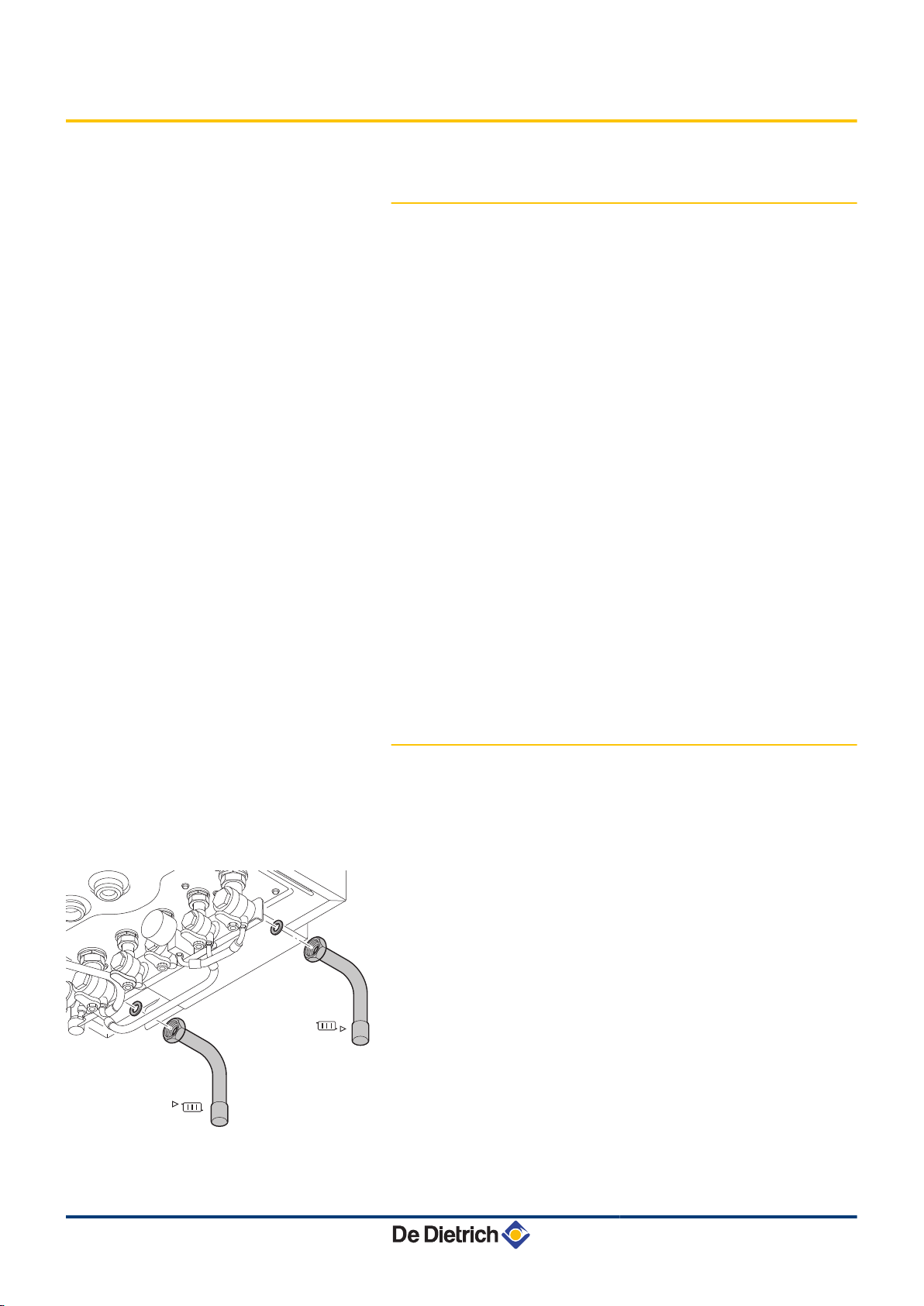

4.6.2. Connection of the heating circuit

1. Connect the heating water outlet pipe to the heating flow

connection.

2. Connect the heating water inlet pipe to the heating return

connection.

{

z

Connection by internal brazing ∅ 22 mm

Connection by internal brazing ∅ 22 mm

22

29/04/2010 - 300022146-001-B

Page 25

T001633-B

T001626-A

MCA 15 - MCA 25 MCA 25/28 MI

4. Installation

4 The boiler is factory fitted with a safety valve mounted

on the left hydrobloc.

CAUTION

4 The heating pipe must be mounted in accordance

with prevailing provisions.

4.6.3. Hydraulic connection of the water circuit

for domestic use

1. Connect the cold water inlet pipe to the domestic cold water

connection.

2. Connect the domestic hot water outlet pipe to the domestic hot

water connection.

x

y

Connection by internal brazing ∅ 16 mm

Connection by internal brazing ∅ 16 mm

CAUTION

4 The domestic water pipes must be connected in

accordance with prevailing provisions.

4 If using synthetic pipes, follow the manufacturer's

(connection) instructions.

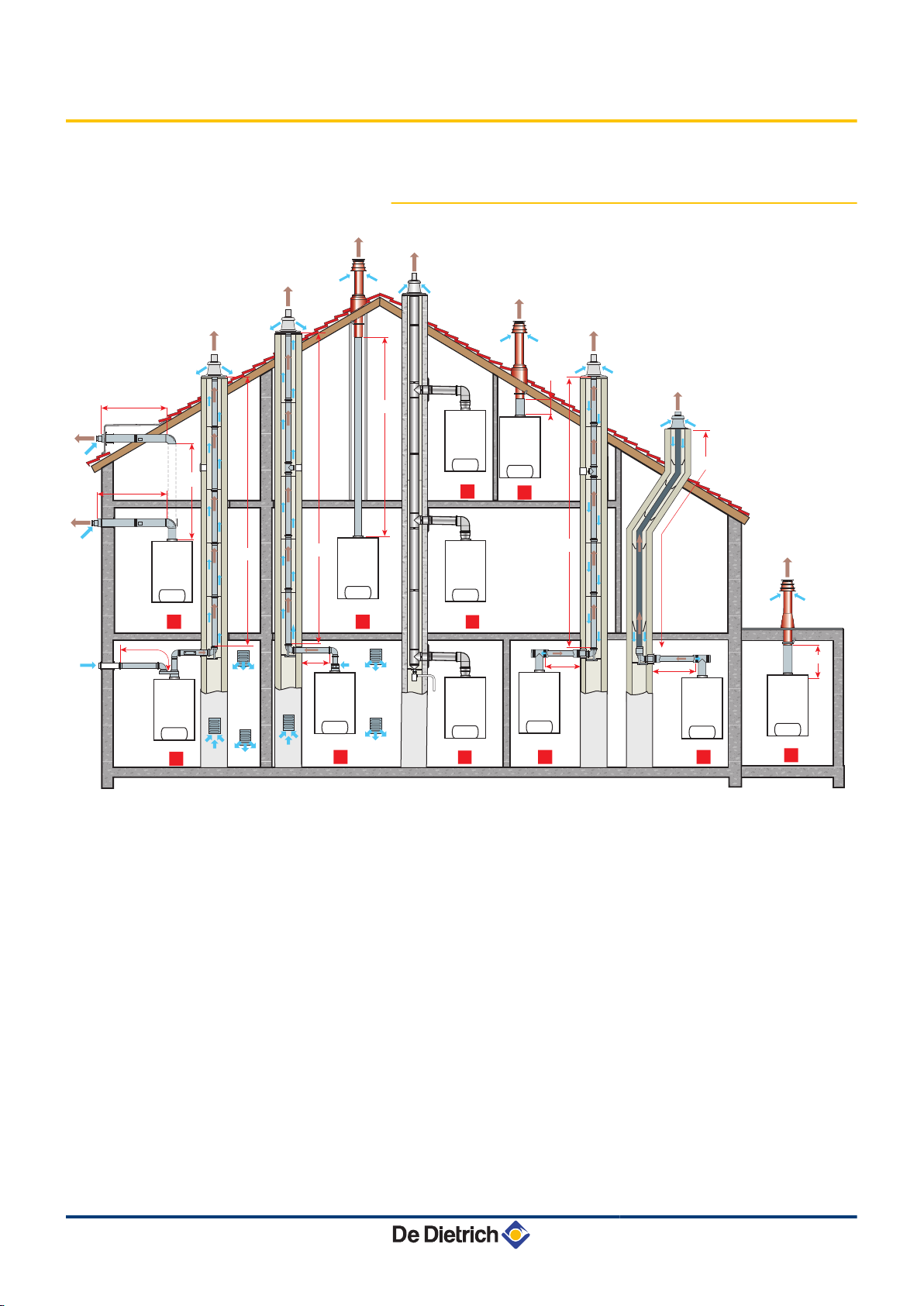

4.6.4. Connecting the expansion vessel

The boiler is fitted as standard with an 12-litre expansion vessel.

If the water volume is greater than 150 litres or the static height of the

system exceeds 5 metres, an additional expansion vessel must be

fitted. Refer to the table below to determine the opened expansion

vessel required for the installation.

29/04/2010 - 300022146-001-B

Conditions of validity of the table:

4 3-bar safety valve

4 Average water temperature: 70 °C

Flow temperature: 80 °C

Return temperature: 60 °C

4 The filling pressure in the system is lower than or equal to the initial

pressure in the opened expansion vessel

23

Page 26

T001873-C

T001523-B

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

Initial pressure of the

expansion vessel

0.5 bar 4,8 6,0 7,2 8,4 9,6 12,0 14,4 Volume of the installation x 0,048

1 bar 8,0 10,0

1.5 bar 13,3 16,6 20,0 23,3 26,6 33,3 39,9 Volume of the installation x 0,133

(1) Factory configuration

Volume of the opened expansion vessel depending on the volume of the installation (in litres)

100 125 150 175 200 250 300 > 300

(1)

12,0

14,0 16,0 20,0 24,0 Volume of the installation x 0,080

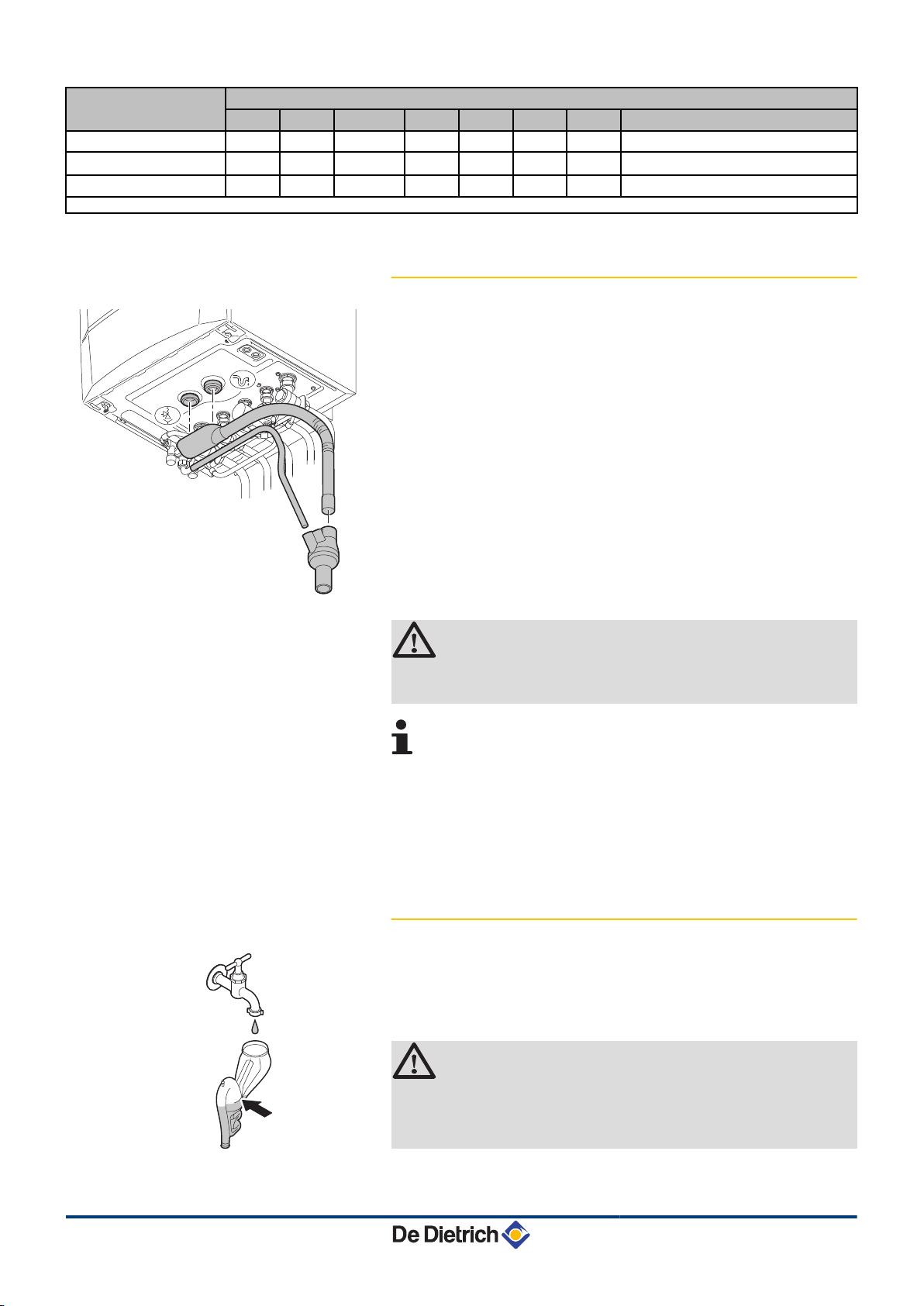

4.6.5. Connecting the condensate discharge pipe

1. Mount a standard drainage pipe, Ø 32 mm or more, leading to the

mains drainage system.

2. Mount the flow collector.

3. Into this, insert the condensate collector hose coming from the

siphon j and the safety valve ê.

4. Into this, insert the discharge hose from the disconnector.

5. Mount a trap or a siphon in the discharge pipe.

CAUTION

Do not make a fixed connection owing to maintenance

work on the siphon.

4 Do not plug the condensate discharge pipe.

4 Set the discharge pipe at a gradient of at least 30

mm per metre, maximum horizontal length 5 metres.

4 Do not drain condensation water into a roof gutter at

any time.

4 Connect the condensate discharge pipe in

accordance with prevailing standards.

4.6.6. Filling the siphon

1. Remove the siphon.

2. Fill the siphon with water. This must be filled up to the level

markers.

3. Re-assemble the siphon.

CAUTION

24

4 Fill the water siphon before starting the boiler to avoid

combustion products escaping from the boiler.

4 Mount the vent hose above the siphon.

29/04/2010 - 300022146-001-B

Page 27

T001621-A

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

4.7 Gas connection

The diameters of the pipes must be defined in accordance

with the standards in force in your country.

g

Connection by internal brazing ∅ 18 mm

1. Connect the gas inlet pipe.

WARNING

4 Close the main gas valve before starting work on the

gas pipes.

4 Before mounting, check that the gas meter has

sufficient capacity. To do this, you should bear in

mind the consumption of all domestic appliances.

4 If the gas meter has too low a capacity, inform the

energy supply company.

CAUTION

4 Ensure that there is no dust in the gas pipe. Blow into

the pipe or shake it before mounting.

4 We recommend installing a gas filter on the gas pipe

to prevent clogging of the gas valve unit.

4 Connect the gas pipe in accordance with prevailing

standards and regulations.

29/04/2010 - 300022146-001-B

25

Page 28

4

2

6

2

2

1

5

3

12

12

12

L1

L1

Lmax = L1+L2

Lmax =

L

1+L2

Lmax

Lmax

Lmax

Lmax

max

max

max

1m

1m

1m

Lmax

L2

L2

Lmax

Lmax

C

33

C

93

B

23

C

93

C

33

C

33

C

13

C

53

C

43

C

43

C

43

T000275-D

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

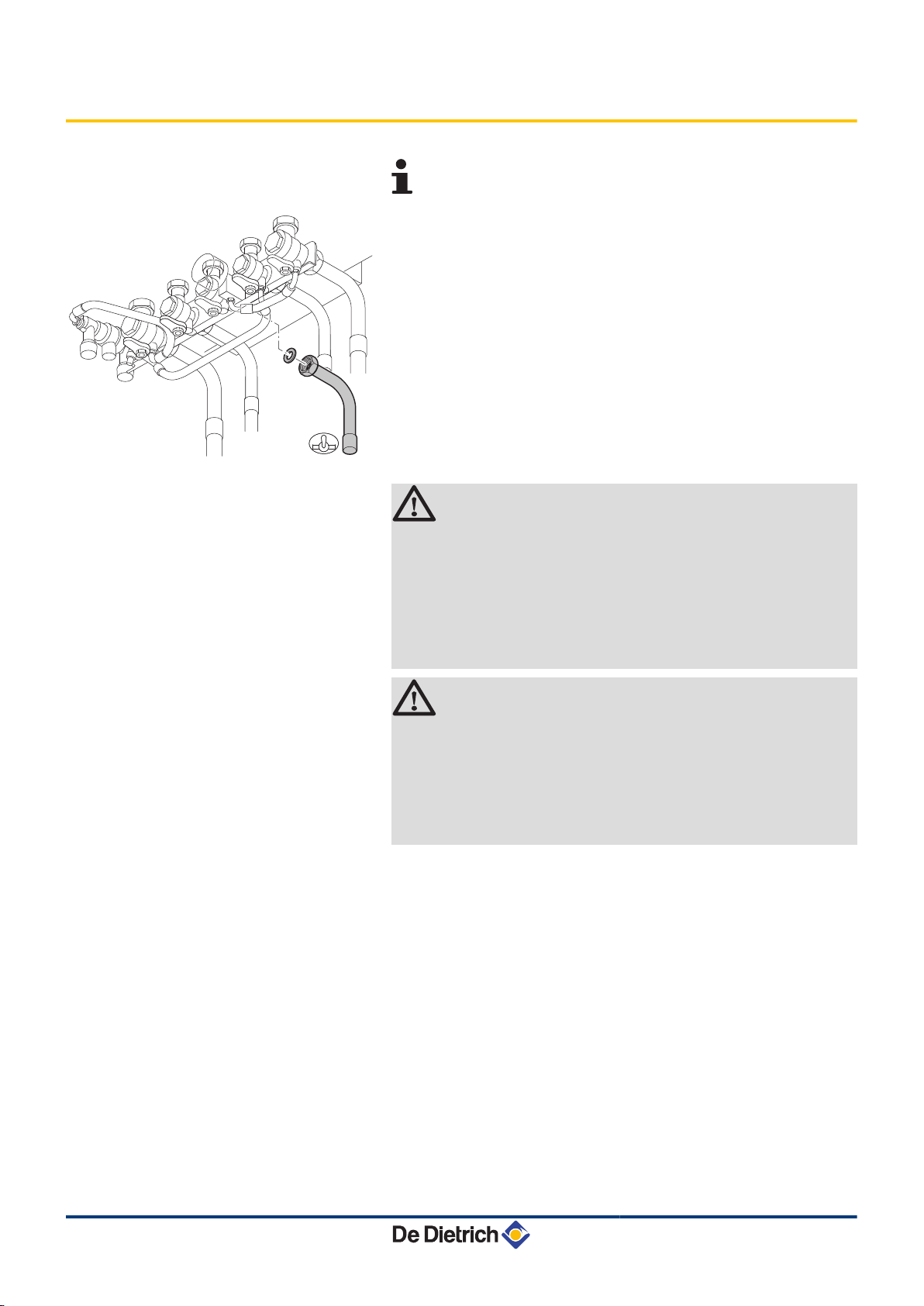

4.8 Flue gas system connections

4.8.1. Classification

26

1

Configuration C

13

Air/flue gas connection by means of concentric pipes to a

horizontal terminal (so-called forced flue)

2

Configuration C

33

Air/flue gas connection by means of concentric pipes to a

vertical terminal (roof outlet)

3

Configuration C

Air/flue gas connection by concentric pipes in the boiler

room and single pipes in the chimney (combustive air in

counter current in the chimney)

93

29/04/2010 - 300022146-001-B

Page 29

MCA 15 - MCA 25 MCA 25/28 MI

4. Installation

4

5

6

12

Configuration C

93

Air/flue gas connection by concentric pipes in the boiler

room and single "flex" in the chimney (combustive air in

counter current in the chimney)

WARNING

4 Only factory components are authorised for

connecting the boiler and the terminal.

4 The clear section must comply with the

standard.

4 The chimney must be swept before the

installation of the evacuation conduit.

Configuration C

53

Air and flue gas connection separated by means of a biflow adapter and single pipes (combustive air taken from

outside)

Configuration B

23

Connection to a chimney using a connection kit

(combustive air taken from the boiler room)

Configuration C

43

Air/flue gas connection to a collective conduit for

watertight boilers (3CE system)

4.8.2. Lengths of the air/flue gas pipes

Type of air/flue gas connection

C13Concentric pipes connected to a horizontal terminal Alu or PPS 60/100 mm 12.0 3.5 4.2

C33Concentric pipes connected to a vertical terminal Alu or PPS 60/100 mm 13.0 4.9 5.5

C93Concentric pipes in the boiler room

Single conduits in the chimney (combustive air in

counter-current)

Concentric pipes in the boiler room

Flexible single conduit in the chimney

C53Bi-flow adapter and separate single air/flue gas ducts

(combustive air taken from outside)

B23Chimney (rigid or flexible duct in furnace flue,

combustive air taken from the premises)

Alu or PPS 60/100 mm

PPS 60/100 mm

Alu 60/100 mm

PPS 80 mm (Rigid duct) 50.0 50.0 50.0

Diameter Maximum length in metres

MCA 15 MCA 25 MCA 25/28

MI

80/125 mm 12.3 23.0 25.7

80/125 mm 10.7 21.0 23.6

15.0 8.1 9.1

60 mm (Rigid duct)

9.9 20.0 22.7

80 mm (Flexible

duct)

50.0 50.0 50.0

2 x 80 mm

80 mm (Flexible

duct)

45.0 45.0 45.0

29/04/2010 - 300022146-001-B

WARNING

Maximum length = lengths of the straight air/flue gas ducts

+ equivalent lengths of other components

For the list of flue gas system accessories and the equivalent lengths,

refer to the current price list.

27

Page 30

8800N001-C

8800N002-C

4. Installation

4.9 Installing the outside sensor

4.9.1. Choice of the location

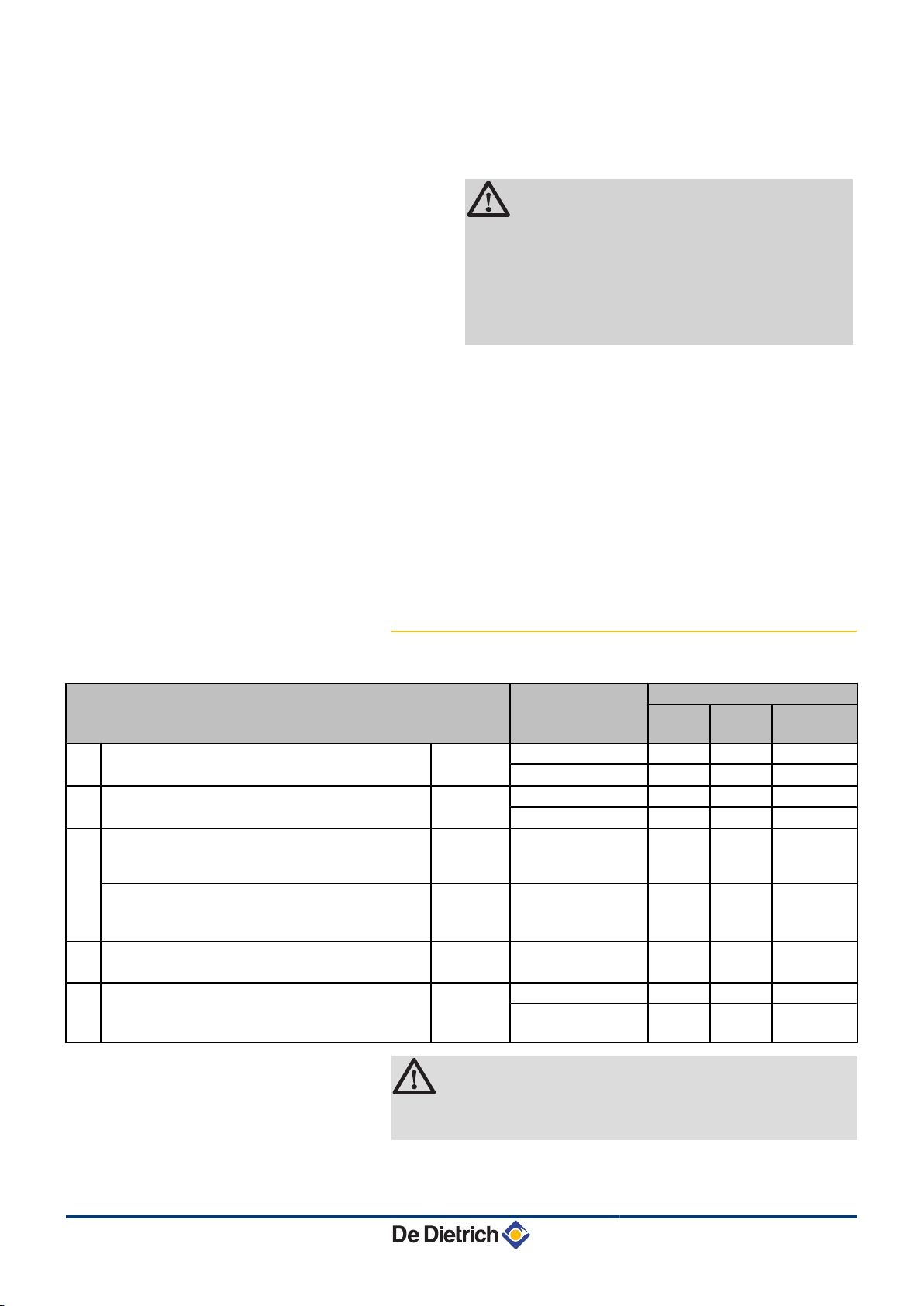

It is important to select a place that allows the sensor to measure the

outside conditions correctly and effectively.

Advised positions:

4 on one face of the area to be heated, on the north if possible

4 half way up the wall in the room to be heated

4 under the influence of meteorological variations

4 protected from direct sunlight

4 easy to access

MCA 15 - MCA 25 MCA 25/28 MI

A

B

H

Z

Recommended position

Possible position

Inhabited height controlled by the sensor

Inhabited area controlled by the sensor

Positions to be avoided:

4 masked by a building element (balcony, roof, etc.)

4 close to a disruptive heat source (sun, chimney, ventilation grid,

etc.)

28

4.9.2. Installing the outside sensor

Mount the sensor using the screws and dowels provided.

29/04/2010 - 300022146-001-B

Page 31

8800N003-B

C002336-E

C

A

B

E

D

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

4.10 Electrical connections

A

CB wood screws diameter 4 + dowels

4.10.1. Control unit

The boiler is fully pre-wired. The mains supply is made via the cable

C connected to the mains. All other external connections can be made

to the connection connectors (low voltage). The main characteristics

of the control unit are described in the table below.

Power supply voltage 230 VAC/50Hz

Rating of the main fuse F1 (230 VAC) 6.3 AT

Fuse rating F2 (230 VAC) 2 AT

Fan-DC 27 VDC

CAUTION

Keep to the polarity shown on the terminals: phase (L),

neutral (N) and earth *.

A

B

C

D

E

Routing of the 230 V cables

Routing of the sensor cables

Power supply cable

6,3 AT fuse

2 AT fuse

CAUTION

The following components of the appliance are at a

voltage of 230 V:

4 Boiler pump.

4 Combined venturi and gas valve unit.

4 Inverter valve.

4 The majority of components in the control panel and

the terminal box.

4 Power supply cable.

29/04/2010 - 300022146-001-B

29

Page 32

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

4.10.2. Recommendations

WARNING

4 Only qualified professionnals may carry out electrical

connections, always with the power off.

4 The boiler is entirely pre-wired. Do not modify the

connections inside the control panel.

4 Earth the appliance before making any electrical

connections.

Make the electrical connections of the appliance according to:

4 the instructions of the prevailing standards.

4 the instructions on the circuit diagrams provided with the

appliance.

4 the recommendations in the instructions.

CAUTION

4 Separate the sensor cables from the 230 V cables.

4 Outside the boiler: Use 2 pipes or cable guides at

least 10 cm apart.

30

29/04/2010 - 300022146-001-B

Page 33

PCU

SU

PSU

On/off

OT BL RL Tout Tdhw

2

3

1

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

TS + C AUXC

SCU

SCU

PCU

C002299-F

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

4.10.3. Position of the PCBs

A

Z

E

Do not connect anything to the terminal block.

Optional PCB (Package AD249)

Do not connect anything to the terminal block.

29/04/2010 - 300022146-001-B

31

Page 34

C002325-C

2

1

C002326-B

4

3

3

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

4.10.4. Accessing the connection terminal blocks

To access the connection terminal blocks, proceed as follows:

1. Unscrew the 2 screws under the front panel by a quarter turn.

2. Remove the front panel.

3. Open the holding clips located on the sides.

4. Tilt the control panel forward.

32

29/04/2010 - 300022146-001-B

Page 35

C002327-B

5

6

6

C002330-C

7

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

5. Lift the clip located in front of the control panel.

6. Lift the control panel cover.

7. Unclip the PCB cover.

29/04/2010 - 300022146-001-B

33

Page 36

C002304-M

2

3

On/off

OT BL RL Tout Tdhw

1

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

SCU PCU

4

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

4.10.5. Connecting a direct heating circuit

A

Z

E

Do not connect anything to the terminal block.

Connect the outside temperature sensor.

Connect a safety thermostat if the heating circuit is for

underfloor heating.

4 Remove the bridge.

4 Connect the wires from the safety thermostat to the

connector.

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

If safety thermostat is connected to

BL on the connection terminal

block:

"Installer" level

#SYSTEM menu

"Installer" level

#PRIMARY INSTAL.P

menu

R

IN.BL

Do not connect anything to the terminal block.

EXTENDED

STOP HEAT

¼ "Displaying the parameters

in extended mode", page 71

¼ ""Professional" settings",

page 82

34

29/04/2010 - 300022146-001-B

Page 37

C002305-j

3

4

5

6

7

8

On/off

OT BL RL Tout Tdhw

1 2

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

SCU PCU

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

4.10.6. Connecting a direct heating circuit and a

domestic hot water tank

A

Z

E

R

Do not connect anything to the terminal block.

CAUTION

Do not connect anything to the Mr outlet on the

terminal block. The reversal valve is connected

to the PCU PCB in the boiler.

Connect the outside temperature sensor.

Connect a safety thermostat if the heating circuit is for

underfloor heating.

4 Remove the bridge.

4 Connect the wires from the safety thermostat to the

connector.

29/04/2010 - 300022146-001-B

35

Page 38

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

T

Connect the DHW tank anode.

CAUTION

4 If the tank is fitted with a Titan Active

System® impressed current anode,

connect the anode to the inlet (+ on the

anode, - on the tank).

4 If the tank is not fitted with an impressed

current anode, put the simulation

connector in place (delivered with the DHW

sensor - package AD212).

Y

U

Connect the DHW sensor (Package AD212).

Connect the domestic hot water looping pump

(Optional).

I

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

If a domestic hot water looping pump

is connected to MA on the terminal

block:

O.PUMP A

If safety thermostat is connected to

BL on the connection terminal block:

IN.BL

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

#PRIMARY INSTAL.P

menu

Do not connect anything to the terminal block.

EXTENDED

¼ "Displaying the parameters

in extended mode", page 71

DHW LOOP

¼ "Setting the parameters

specific to the installation", page

72

TOTAL STOP

¼ ""Professional" settings",

page 82

36

29/04/2010 - 300022146-001-B

Page 39

C002367-F

3

6

9

10

11

7

8

1 2

4

5

13

12

On/off

OT BL RL Tout Tdhw

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

TS + C AUXC

SCU PCU

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

4.10.7. Connecting two circuits and a domestic hot

water tank before the mixing tank

A

Z

E

R

Do not connect anything to the terminal block.

CAUTION

Do not connect anything to the Mr outlet on the

terminal block. The reversal valve is connected

to the PCU PCB in the boiler.

Connect the outside temperature sensor.

Connect a safety thermostat if the heating circuit is for

underfloor heating.

29/04/2010 - 300022146-001-B

4 Remove the bridge.

4 Connect the wires from the safety thermostat to the

connector.

T

Connecting an additional circuit to the AD249 option.

37

Page 40

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

Y

U

I

O

P

a

z

Connect the heating pump (circuit A).

If underfloor heating is being used, put a safety

thermostat in place after the heating pump. The

safety thermostat will shut down the heating

pump in the event of overheating.

Low loss header.

Connect the DHW tank anode.

CAUTION

4 If the tank is fitted with a Titan Active

System® impressed current anode,

connect the anode to the inlet (+ on the

anode, - on the tank).

4 If the tank is not fitted with an impressed

current anode, put the simulation

connector in place (delivered with the DHW

sensor - package AD212).

Connect the heating pump (circuit B).

Connect the 3-way valve (circuit B).

Connect the DHW sensor (Package AD212).

Connect the domestic hot water looping pump to the

AUX outlet on the AD249 option

e

Do not connect anything to the terminal block.

38

29/04/2010 - 300022146-001-B

Page 41

C002293-j

4

6

8

9

11

10

2

7

1

3

5

12

On/off

OT BL RL Tout Tdhw

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

TS + C AUXC

SCU PCU

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

4.10.8. Connecting two circuits and a domestic hot

water tank after the mixing tank

A

Z

E

R

T

Do not connect anything to the terminal block.

Connect the outside temperature sensor.

Connect a safety thermostat if the heating circuit is for

underfloor heating.

4 Remove the bridge.

4 Connect the wires from the safety thermostat to the

connector.

Low loss header

Connecting an additional circuit to the AD249 option.

29/04/2010 - 300022146-001-B

39

Page 42

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

Y

U

I

O

P

a

Connect the heating pump (circuit A).

If underfloor heating is being used, put a safety

thermostat in place after the heating pump. The

safety thermostat will shut down the heating

pump in the event of overheating.

Connect the DHW tank anode.

CAUTION

4 If the tank is fitted with a Titan Active

System® impressed current anode,

connect the anode to the inlet (+ on the

anode, - on the tank).

4 If the tank is not fitted with an impressed

current anode, put the simulation

connector in place (delivered with the DHW

sensor - package AD212).

Connect the heating pump (circuit B).

Connect the 3-way valve (circuit B).

Connect the DHW sensor (Package AD212).

Connect the domestic hot water looping pump to the

MAUX outlet on the AD249 option.

z

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

O.DHW:

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

EXTENDED

PUMP

Do not connect anything to the terminal block.

¼ "Displaying the parameters in extended mode", page

71

¼ "Setting the parameters specific to the installation",

page 72

40

29/04/2010 - 300022146-001-B

Page 43

C002368-H

On/off

OT BL RL Tout Tdhw

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

SCU PCU

4

5

6

8

7

3

2

1

9

M

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

4.10.9. Hot water storage tank connection

QUADRO DU 750 storage tank

n

In this installation example, the storage tank (type QUADRO DU

750) incorporates a domestic hot water zone. The boiler starts up

systematically to maintain the domestic hot water zone in the storage

tank or to maintain the independent tank at temperature.

If the storage tank does not have a DHW zone, use an

independent domestic hot water tank.

A

Z

E

Do not connect anything to the terminal block.

Connect the heating pump (Circuit A).

Connect the DHW tank anode.

If the tank is not fitted with an impressed current

anode, put the simulation connector in place

(delivered with the DHW sensor - package

AD212).

R

T

Connect the DHW sensor (Package AD212).

Connect the sensor from the storage tank (Package

AD250).

29/04/2010 - 300022146-001-B

41

Page 44

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

Y

U

I

O

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

(1)

I.SYST

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

EXTENDED

STORAGE TANK

Buffer tank.

Solar sensor probe.

Connect the solar station to the solar collectors.

Do not connect anything to the terminal block.

¼ "Displaying the parameters in extended mode", page

71

¼ "Setting the parameters specific to the installation",

page 72

The DHW part is maintained at the DHW set point by the

boiler.

The heating zone is maintained at the set temperature

calculated according to the outside temperature. The zone

is reheated when the heating buffer temperature sensor

T falls -6°C below the calculated set temperature.

Reheating in the heating zone stops when the heating

buffer temperature rises above the calculated set

temperature.

42

29/04/2010 - 300022146-001-B

Page 45

2

10

G000030A

9

On/off

OT BL RL Tout Tdhw

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

SCU PCU

1

3

5

7

6

8

M

4

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

PS storage tank and DHW tank connected to the boiler

n

The boiler only starts up if the storage tank is not hot enough to

guarantee loading of the DHW tank.

A Connect a domestic hot water tank if the storage tank R

is only used for heating

Z

E

R

Connect the DHW sensor (Package AD212).

Connect the heating pump (Circuit A).

Buffer tank.

T

Y

U

Connect the sensor from the storage tank.

Solar sensor probe.

Connect the solar station to the solar collectors.

29/04/2010 - 300022146-001-B

43

Page 46

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

I

Connect the DHW tank anode.

If the tank is not fitted with an impressed current

anode, put the simulation connector in place

(delivered with the DHW sensor - package

AD212).

O

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

(1)

I.SYST

O.DHW:

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

EXTENDED

STORAGE TANK

PUMP

Do not connect anything to the terminal block.

¼ "Displaying the parameters in extended mode", page

71

¼ "Setting the parameters specific to the installation",

page 72

The DHW part is maintained at the DHW set point by the

boiler.

The heating zone is maintained at the set temperature

calculated according to the outside temperature. The zone

is reheated when the heating buffer temperature sensor

falls -6°C below the calculated set temperature. Reheating

in the heating zone stops when the heating buffer

temperature rises above the calculated set temperature.

PS storage tank and DHW tank connected to the storage

n

tank

The boiler only starts up production of domestic hot water if the

storage tank is not hot enough to guarantee tank loading.

44

29/04/2010 - 300022146-001-B

Page 47

C002369-F

3

6

5

2

1

4

8

7

On/off

OT BL RL Tout Tdhw

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

SCU PCU

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

A

Z

E

R

T

Y

U

Do not connect anything to the terminal block.

Connect the heating pump (Circuit A).

Connect the DHW tank anode.

If the tank is not fitted with an impressed current

anode, put the simulation connector in place

(delivered with the DHW sensor - package

AD212).

Buffer tank.

Solar sensor probe.

Connect the solar station to the solar collectors.

Domestic hot water boiler.

Connect the DHW sensor.

I

Do not connect anything to the terminal block.

29/04/2010 - 300022146-001-B

45

Page 48

C002298-i

1

3

5

2

6

On/off

OT BL RL Tout Tdhw

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

SCU PCU

4

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

(1)

I.SYST

O.DHW:

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

EXTENDED

ST.TANK+DHW

PUMP

¼ "Displaying the parameters in extended mode", page

71

¼ "Setting the parameters specific to the installation",

page 72

#SYSTEM menu

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

The DHW tank is loaded from the storage tank. If, during

DHW loading, the temperature of the storage tank falls

below the primary DHW set point (parameter

PRIM.TEMP.DHW), the boiler maintains the latter at

temperature to guarantee the loading of the DHW tank

The heating zone is maintained at the set temperature

calculated according to the outside temperature. The zone

is reheated when the heating buffer temperature sensor

falls -6°C below the calculated set temperature. Reheating

in the heating zone stops when the heating buffer

temperature rises above the calculated set temperature.

4.10.10. Pool connection

46

A

Z

E

Connect the secondary swimming pool pump.

Connect the swimming pool sensor.

Plate heat exchanger.

29/04/2010 - 300022146-001-B

Page 49

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

R

Pool heating cut-off control

When the parameter I.TEL: is on 0/1 B, the

swimming pool is no longer heated when the

contact is open (factory setting), only the

antifreeze continues to be active.

The contact direction can still be adjusted by the

parameter CT.TEL.

T

Y

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

CIRC. B:

If I.TEL: is used

I.TEL:

MAX. CIRC. B

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

#SECONDARY LIMITS menu

EXTENDED

SWIM.P.

0/1 B

Set the value of MAX.CIRC.B to

the temperature corresponding

to the needs of the exchanger

Connect the primary swimming pool pump.

Do not connect anything to the terminal block.

¼ "Displaying the parameters in

extended mode", page 71

¼ "Setting the parameters specific

to the installation", page 72

¼ ""Professional" settings", page

82

Controlling the pool circuit

n

The control system can be used to manage a swimming pool circuit

in both cases:

Case 1: The control system regulates the primary circuit (boiler/

exchanger) and the secondary circuit (exchanger/pool).

4 Connect the primary circuit pump (boiler/exchanger) to the MB

outlet on the connection terminal block. The temperature

MAX.CIRC.B is then guaranteed during comfort periods on

programme B in summer and winter alike.

4 Connect the swimming pool sensor (package AD212) to the S

DEP B inlet on the connection terminal block.

4 Set the set point of the pool sensor using key C in the range 5 -

39°C.

Case 2: The pool has already a regulation system that is to be

kept. The control system only regulates the primary circuit

(boiler/exchanger).

4 Connect the primary circuit pump (boiler/exchanger) to the MB

outlet on the connection terminal block.

The temperature MAX.CIRC.B is then guaranteed during comfort

periods on programme B in summer and winter alike.

29/04/2010 - 300022146-001-B

The swimming pool can also be connected to circuit C by

adding the AD249 option:

4 Make the connection to the terminal blocks marked

C.

4 Set the parameters for circuit C.

47

Page 50

C002432-E

6

7

1

2

3

4

8

5

On/off

OT BL RL Tout Tdhw

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

TS + C AUXC

SCU PCU

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

Hourly programming of the secondary circuit pump

n

The secondary pump operates during programme B comfort periods

in summer and winter alike.

Stopping

n

To prepare your pool for winter, consult your pool specialist.

4.10.11. Connecting a mixed tank

A

Z

E

Do not connect anything to the terminal block.

Option of connecting the electric tank (with AD249

option)

or to E

Outlet circuit A - Option of connecting the electric tank (or

to Z)

48

R

Power control relay to the electrical resistor

29/04/2010 - 300022146-001-B

Page 51

C002294-F

V

PRG

TELCOM 2

ALP

AL2

AL1

3

2

1

SET

#09

V

8

7

65

4321

7

1

5

9

On/off

OT BL RL Tout Tdhw

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

TS + C AUXC

SCU PCU

3

4

2

8

6

MODE

r

x

0 2 4 6 8 10 12 14 16 18 22 2420

c

MODE

r

x

0 2 4 6 8 10 12 14 16 18 22 2420

c

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

T

Connect the DHW tank anode.

If the tank is not fitted with an impressed current

anode, put the simulation connector in place

(delivered with the DHW sensor - package

AD212).

Y

U

I

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

If the electric tank is connected to MA:

CIRC. A:

(1)

If the electric tank is connected to

MAUX:

S.AUX:

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

Connect the DHW sensor (Package AD212).

Connect the outside temperature sensor

Do not connect anything to the terminal block.

EXTENDED

¼ "Displaying the parameters in

extended mode", page 71

DHW ELEC

¼ "Setting the parameters specific

to the installation", page 72

DHW ELEC

4.10.12. Connecting the options

For example: TELCOM remote vocal monitoring module, remote

controls for circuits A and B, second DHW tank

29/04/2010 - 300022146-001-B

49

Page 52

4

7

8

5

32

6

1

C002435-C

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

A

Z

E

R

T

Y

Do not connect anything to the terminal block.

Connect the load pump to the second tank.

Second domestic hot water tank

Connect the DHW sensor from the second tank.

Alarm indicator

Connect the TELCOM remote vocal monitoring module

(depending on its availability in your country).

U

I

O

Settings to be made for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

O.PUMP A

If second tank connected:

S.AUX:

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

(1)

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

EXTENDED

FAILURE

DHW

Connecting the BUS cascade, VM

Connect the remote control (Package AD254/FM52).

Do not connect anything to the terminal block.

¼ "Displaying the parameters in extended

mode", page 71

¼ "Setting the parameters specific to the

installation", page 72

4.10.13. Connection in cascade

DHW tank after the mixing tank

n

A

Z

50

Master boiler

Secondary boiler

29/04/2010 - 300022146-001-B

Page 53

MCA 15 - MCA 25 MCA 25/28 MI 4. Installation

E

R

T

Y

U

I

Secondary boiler

D.H.W. load pump

Connect the DHW sensor (Package AD212)

Cable BUS

Low loss header

Cascade outlet sensor

Connect the sensor to the terminal block S SYST on the

master boiler.

Settings to be made for this type of installation: Master boiler

Parameters Access Settings to be made See chapter

INSTALLATION

O.DHW:

CASCADE:

MASTER

CONTROLLER

SYSTEM NETWORK

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

(1)

(1)

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

#NETWORK menu

"Installer" level

#SYSTEM menu

(1)

"Installer" level

#SYSTEM menu

EXTENDED

PUMP

ON

ON

ADD SLAVE

¼ "Displaying the parameters in extended

mode", page 71

¼ "Setting the parameters specific to the

installation", page 72

¼ "Configuring the network", page 88

Settings to be made for this type of installation: Follower boilers

Parameters Access Settings to be made See chapter

INSTALLATION

CASCADE:

MASTER

CONTROLLER

SLAVE NUMBER

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

(1)

(1)

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#NETWORK menu

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

EXTENDED

ON

OFF

2, 3, ...

¼ "Displaying the parameters in extended

mode", page 71

¼ "Configuring the network", page 88

29/04/2010 - 300022146-001-B

51

Page 54

4

3

5

2

6

7

1

C002591-B

4. Installation MCA 15 - MCA 25 MCA 25/28 MI

DHW tank on master boiler

n

A

Z

E

R

T

Y

Connect the DHW sensor (Package AD212)

Master boiler

Secondary boiler

Secondary boiler

Low loss header

Cascade outlet sensor

Connect the sensor to the terminal block S SYST on the

master boiler.

Settings to be made for this type of installation: Master boiler

Parameters Access Settings to be made See chapter

INSTALLATION

O.DHW:

CASCADE:

MASTER

CONTROLLER

SYSTEM NETWORK

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

(1)

(1)

(1)

"Installer" level

#SYSTEM menu

"Installer" level

#SYSTEM menu

"Installer" level

#NETWORK menu

"Installer" level

#SYSTEM menu

(1)

"Installer" level

#SYSTEM menu

EXTENDED

RV

ON

ON

ADD SLAVE

¼ "Displaying the parameters in extended

mode", page 71