DeDietrich EMC-M 24, EMC-M 24/28 MI, EMC-M 30/35 MI, EMC-M 34/39 MI Installation And Service Manual

EN

Wall-hung gas condensing boilers

EMC-M 24

EMC-M 24/28 MI

EMC-M 30/35 MI

EMC-M 34/39 MI

Installation and

Service Manual

7601972-03

EG declaration of conformity

The device complies with the standard type described in the EG

declaration

of conformity. It was manufactured and commissioned in

accordance with European directives.

The original of the declaration of compliance is available from the

manufacturer.

Contents

1 Introduction ................................................................................................6

1.1 Symbols used .......................................................6

1.2 Abbreviations ........................................................6

1.3 General ..................................................................6

1.3.1

Manufacturer’s liability .............................................6

1.3.2 Installer’s liability .....................................................7

1.3.3 User’s liability ..........................................................7

1.4 Homologations ......................................................8

1.4.1 Certifications ...........................................................8

1.4.2 Additional Directives ................................................8

2 Safety instructions and recommendations ..............................................9

2.1 Safety instructions ...............................................9

2.2 Recommendations ................................................9

3 Technical description ..............................................................................11

3.1 General description ............................................11

3.2 Main parts ............................................................11

3.3 Skeleton Diagrams .............................................12

3.4 Operating principle .............................................12

3.4.1 Regulation of the water temperature .....................12

3.4.2 Protection against a shortage of water ..................13

3.4.3 Maximum temperature protection .........................13

3.5 Circulating pump ................................................13

3.6 Technical specifications ....................................14

4 Installation ................................................................................................16

4.1 Regulations governing installation ...................16

4.2 Choice of the location ........................................16

4.2.1 Data plate ..............................................................16

4.2.2 Location of the boiler .............................................16

4.2.3 Ventilation .............................................................17

210212 - 7601972-03

1

4.3 Main dimensions .................................................18

4.4 Installing the mounting frame ...........................19

4.5 Positioning the boiler .........................................19

4.6 Hydraulic connections .......................................20

4.6.1

Flushing the system ..............................................20

4.6.2 Water flow rate ......................................................20

4.6.3 Connection of the heating circuit ...........................21

4.6.4 Connection of the water circuit for domestic

use ........................................................................21

4.6.5 Connecting the expansion vessel .........................21

4.6.6 Connecting the condensate discharge pipe ..........22

4.6.7 Automatic air bleed ...............................................23

4.7 Gas connection ...................................................23

4.8 Flue gas system connections ............................24

4.8.1 Classification .........................................................24

4.8.2 Lengths of the air/flue gas pipes ...........................25

4.8.3 Additional Directives ..............................................26

4.9 Electrical connections ........................................27

4.9.1 Control unit ............................................................27

4.9.2 Recommendations ................................................27

4.9.3 PC/Laptop connection ...........................................28

4.9.4 Connecting service tool .........................................28

4.9.5 Access to the connector block ..............................29

4.9.6 Connection options ...............................................29

4.10 Electrical diagram ...............................................33

4.11 Filling the system ...............................................33

4.11.1 Water treatment ....................................................33

4.11.2 Filling the siphon ...................................................34

4.11.3 Filling the system ..................................................35

4.11.4 Venting the system ................................................35

5 Commissioning ........................................................................................37

5.1 Connection box ...................................................37

5.1.1 Control panel .........................................................37

5.2 Check points before commissioning ................38

5.2.1 Preparing the boiler for commissioning .................38

5.2.2 Hydraulic circuit .....................................................38

5.2.3 Electrical connections ...........................................38

5.3 Commissioning the boiler ..................................39

5.4 Gas settings ........................................................40

5.4.1 Gas circuit .............................................................40

5.4.2 Adapting to another gas type ................................40

5.4.3 Setting the air/gas ratio (Full load) ........................41

5.4.4 Setting the air/gas ratio (Part load) ......................43

Contents

210212 - 7601972-03

2

5.5 Finalizing work ....................................................44

5.6 Reading out measured values ...........................44

5.6.1

Status and sub-status ...........................................44

5.7 Changing the settings ........................................45

5.7.1 Parameter descriptions .........................................46

5.7.2 Setting the maximum heat input for central heating

operation ...............................................................48

6 Switching off the boiler ............................................................................49

6.1 Installation shutdown .........................................49

6.2 Antifreeze protection ..........................................49

7 Checking and maintenance .....................................................................50

7.1 General instructions ...........................................50

7.2 Standard inspection and maintenance

operations ...........................................................50

7.2.1 Open the boiler ......................................................50

7.2.2 Checking the hydraulic pressure ...........................51

7.2.3 Checking the expansion vessel .............................51

7.2.4 Checking the ionization current .............................51

7.2.5 Checking the transfer capacity ..............................51

7.2.6 Checking the flue gas discharge and the air

supply ....................................................................52

7.2.7 Checking combustion ............................................52

7.2.8 Checking the automatic air vent ............................52

7.2.9 Checking the siphon ..............................................53

7.2.10 Checking the burner and cleaning the heat

exchanger .............................................................54

7.3 Specific maintenance operations ......................55

7.3.1 Replacing the ionization/ignition electrode ............55

7.3.2 Replacing the 3-way valve ....................................56

7.3.3 Cleaning the plate exchanger ...............................56

7.3.4 Cleaning the domestic water cartridge ..................57

7.3.5 Replacement of the expansion vessel ..................57

7.3.6 Re-assembling the boiler ......................................58

8 Troubleshooting .......................................................................................60

8.1 Error codes ..........................................................60

8.2 Shutdowns and lock-outs ..................................60

8.2.1 Blocking .................................................................60

8.2.2 Lock out .................................................................62

210212 - 7601972-03

3

9 Spare parts ................................................................................................67

9.1 General ................................................................67

9.2 Spare parts ..........................................................67

9.2.1

Casing ...................................................................69

9.2.2 Heat exchanger .....................................................70

9.2.3 Gas/air system ......................................................71

9.2.4 Connection box .....................................................72

9.2.5 Hydraulic unit/Connecting pipes ............................73

9.2.6 Spare parts list ......................................................74

10 Appendix ...................................................................................................76

10.1 User instruction card ..........................................76

Contents

210212 - 7601972-03

4

210212 - 7601972-03

5

1 Introduction

1.1 Symbols used

In these instructions, various danger levels are employed to draw the

user’s attention to particular information.

In so doing, we wish to

safeguard the user’s safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

1.2 Abbreviations

4 3CE: Combination of air supply and combustion gas discharge

4 DHW: Domestic hot water

4 PCU: Primary Control Unit - Electronic system to control burner

function

4 SCU: Secondary Control Unit - Additional electronic system

1.3

General

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

1. Introduction EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

6

210212 - 7601972-03

In the interest of customers, we are continuously endeavouring to

make

improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.3.2. Installer’s liability

The installer is responsible for the installation and inital start up of the

appliance.

The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.3.3. User’s liability

To guarantee optimum operation of the appliance, the user must

respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Call on qualified professionals to carry out installation and initial

start up.

4 Get your installer to explain your installation to you.

4 Have the required checks and services done.

4 Keep the instruction manuals in good condition close to the

appliance.

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

To prevent hazardous situations from arising, if the mains lead is

damaged it must be replaced by the original manufacturer, the

manufacturer’s dealer or another suitably skilled person.

EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI 1. Introduction

210212 - 7601972-03

7

1.4 Homologations

1.4.1. Certifications

CE identification no

PIN 0063CM3019

NOx classification

5 (Standards EN)

Type of connection Chimney: B23, B

23P

, B

33

Flue gas outlet: C

13(x)

, C

33(x)

, C

43(x)

, C53, C

63(x)

,

C

83(x)

, C

93(x)

1.4.2. Additional Directives

Apart from the legal provisions and Directives, the additional

Directives described in these instructions must also be observed

.

For all provisions and Directives referred to in these instructions, it is

agreed that all addenda or subsequent provisions will apply at the

time of installation.

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations

.

1. Introduction EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

8

210212 - 7601972-03

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If you smell gas:

1.

Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

2. Shut off the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them immediately.

5. If the gas leak is before the gas meter, contact the

gas supplier.

DANGER

If you smell flue gases:

1.

Switch the appliance off.

2. Open the windows.

3. Trace possible leaks and seal them immediately.

2.2 Recommendations

WARNING

4 Installation and maintenance of the boiler must be

carried out by a qualified professional in compliance

with prevailing local and national regulations.

4 When working on the boiler, always disconnect the

boiler from the mains and close the main gas inlet

valve.

4 After maintenance or repair work, check all

installations to ensure that there are no leaks.

CAUTION

The boiler must be installed in a frost-free environment.

Keep this document close to the place where the boiler is

installed.

Casing components

EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI 2. Safety instructions and recommendations

210212 - 7601972-03

9

Only remove the casing for maintenance and repair operations. Put

the casing back in place after maintenance and repair operations.

Instructions stickers

The

instructions and warnings affixed to the appliance must never be

removed or covered and must remain legible during the entire lifespan

of the appliance. Immediately replace damaged or illegible

instructions and warning stickers.

Modifications

Modifications may only be made to the boiler after the written

permission of De Dietrich Thermique to do so.

2. Safety instructions and recommendations EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

10

210212 - 7601972-03

3 Technical description

3.1 General description

Wall-hung gas condensing boilers

4 High efficiency heating.

4 Low pollutant emissions.

4 Installation and connection facilitated by the mounting frame

delivered with the appliance.

4 Flue gas discharge via a forced flue, chimney, bi-flow or 3CE type

connection.

4 EMC-M 24: Heating only (Possibility of producing domestic hot

water via an independent tank which has been installed

separately).

4 EMC-M 24/28 MI - 30/35 MI - 34/39 MI: Heating and domestic hot

water production.

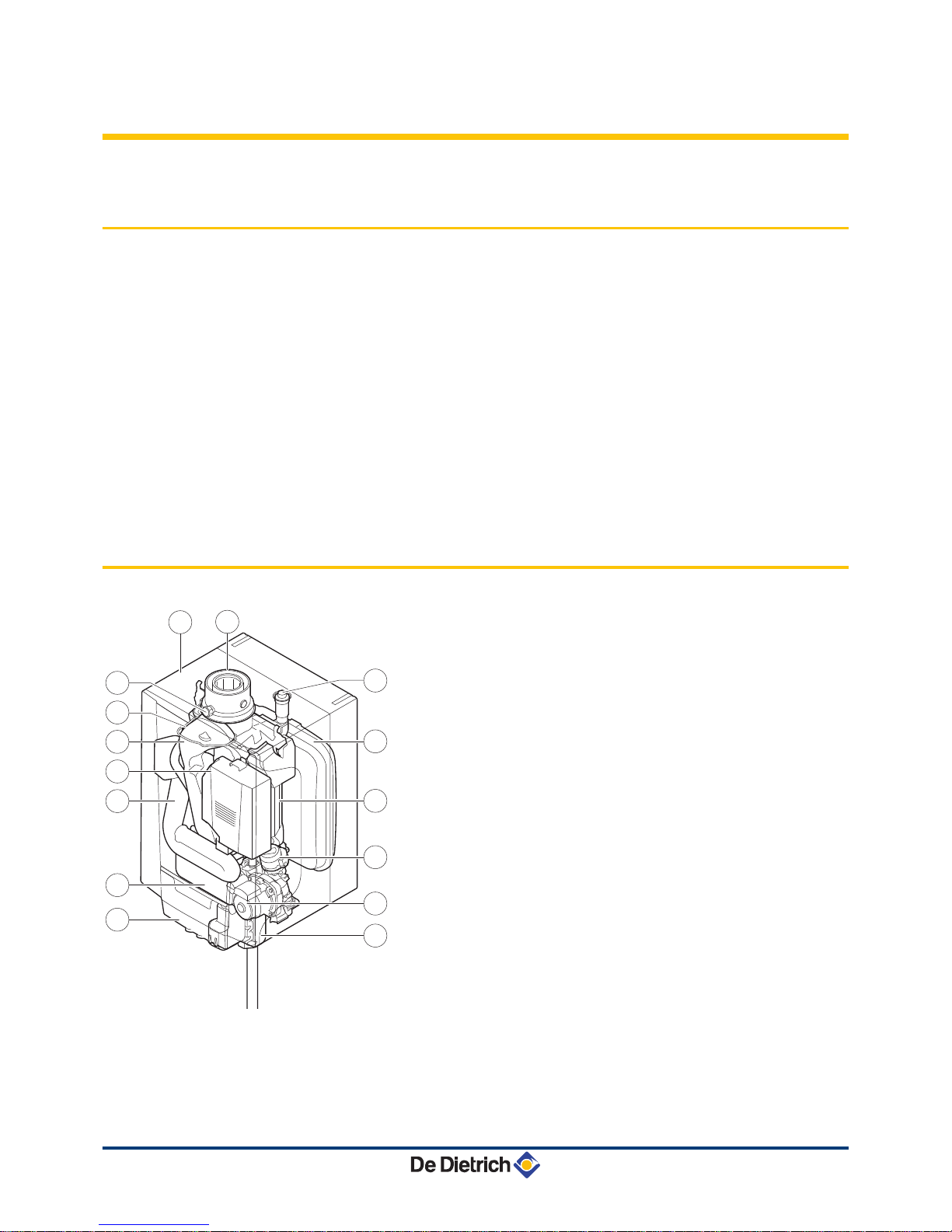

3.2 Main parts

1

Flue gas outlet/Air intake

2

Casing/air box

3

Outlet for measuring combustion gases

4

Ignition/ionization electrode

5

Flue gas discharge pipe

6

Gas/air system with a fan, gas block and automatic burner

unit

7

Air intake silencer

8

Plate heat exchanger (DHW) (Only on models with

domestic hot water production

)

9

Connection box

10

Siphon

11

Shunt pump

12

3-way valve

13

Heat exchanger (Central heating)

14

Expansion vessel

15

Automatic air vent

T004783-A

3

5

6

7

9

8

13

12

14

15

11

10

1

2

4

EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI 3. Technical description

210212 - 7601972-03

11

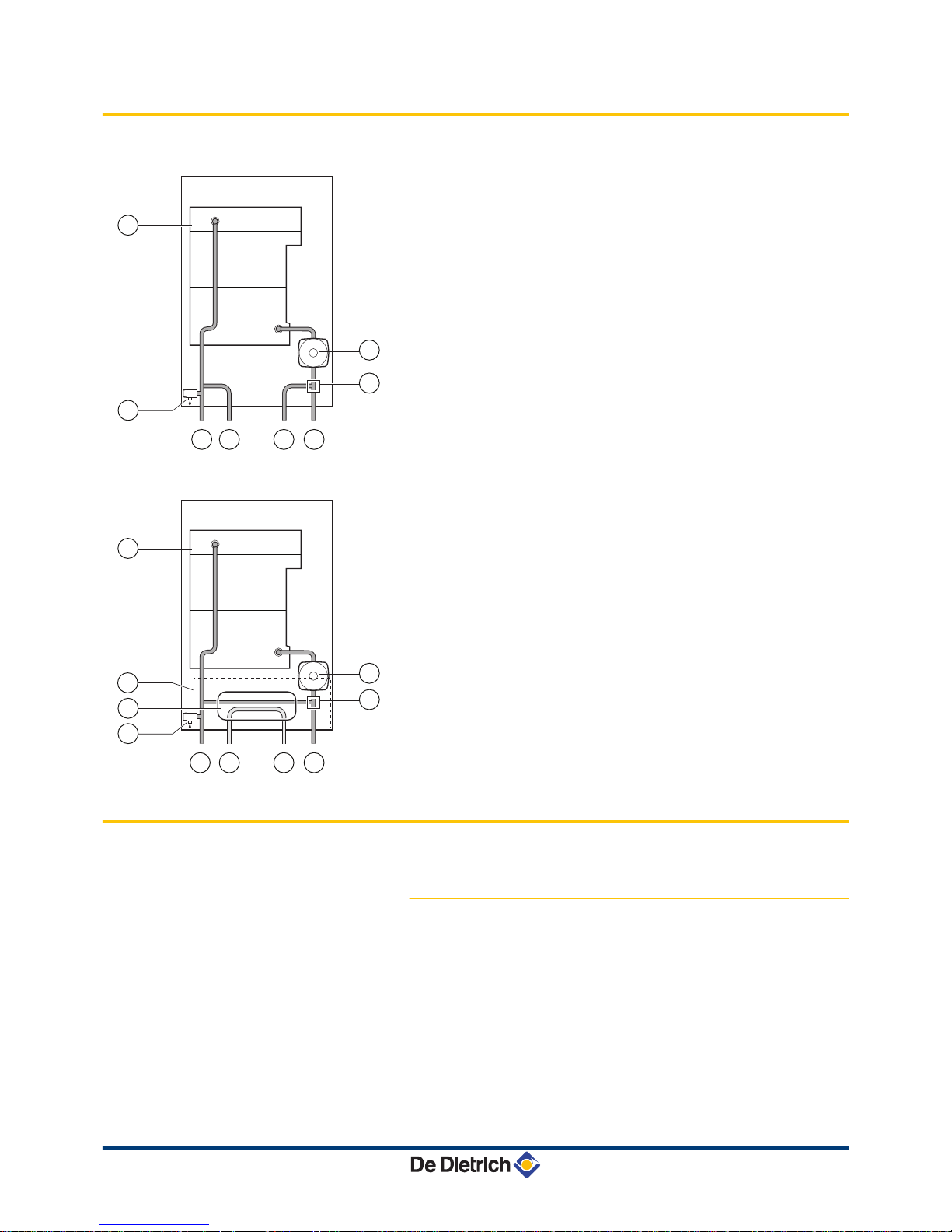

3.3 Skeleton Diagrams

EMC-M 24

1

Heat exchanger (Central heating)

2

Safety valve

3

Heating flow (Primary circuit)

4

Heating flow (Secondary circuit)

5

Heating return (Secondary circuit)

6

Heating return (Primary circuit)

7

3-way valve

8

Shunt pump (Central heating)

EMC-M 24/28 MI - 30/35 MI - 34/39 MI

1

Heat exchanger (Central heating)

2

Hydroblock

3

Plate heat exchanger (DHW)

4

Safety valve

5

Heating flow

6

Domestic hot water outlet (DHW)

7

Domestic cold water inlet

8

Heating return

9

Shunt pump (Central heating)

10

3-way valve

3.4 Operating principle

3.4.1. Regulation of the water temperature

The boiler is fitted with an electronic temperature regulator having an

outlet

and return temperature probe. The flow temperature can be set

between 20°C and 90°C. The boiler reduces its power when the set

outlet-temperature is attained. The cutout temperature is the set

heating outlet-temperature + 5 °C.

T003806-A

3 4 5 6

1

2

8

7

T003393-D

5 6 7 8

1

2

3

4

10

9

3. Technical description EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

12

210212 - 7601972-03

3.4.2. Protection against a shortage of water

The boiler is fitted with a safety device to prevent the shortage of water

based on temperature measurements.

By reducing its output when

the water flow rate is in danger of becoming insufficient, the boiler

continues to operate as long as possible. In case of insufficient ΔT

≥ 50°C flow or an excessive increase in flow temperature, the boiler

will enter shutdown mode for 10 minutes. When there is no water in

the boiler, or if the pump is not running, the system is locked

(breakdown)

In the event of a fault, the status signal for the B

button on

the connection box flashes red.

¼For more detailed information, see chapter:

"Shutdowns and

lock-outs", page 60.

3.4.3. Maximum temperature protection

The maximum temperature protection locks the boiler if the water

temperature becomes too high (

110°C).

In the event of a fault, the status signal for the B

button on

the connection box flashes red.

¼For more detailed information, see chapter:

"Shutdowns and

lock-outs", page 60.

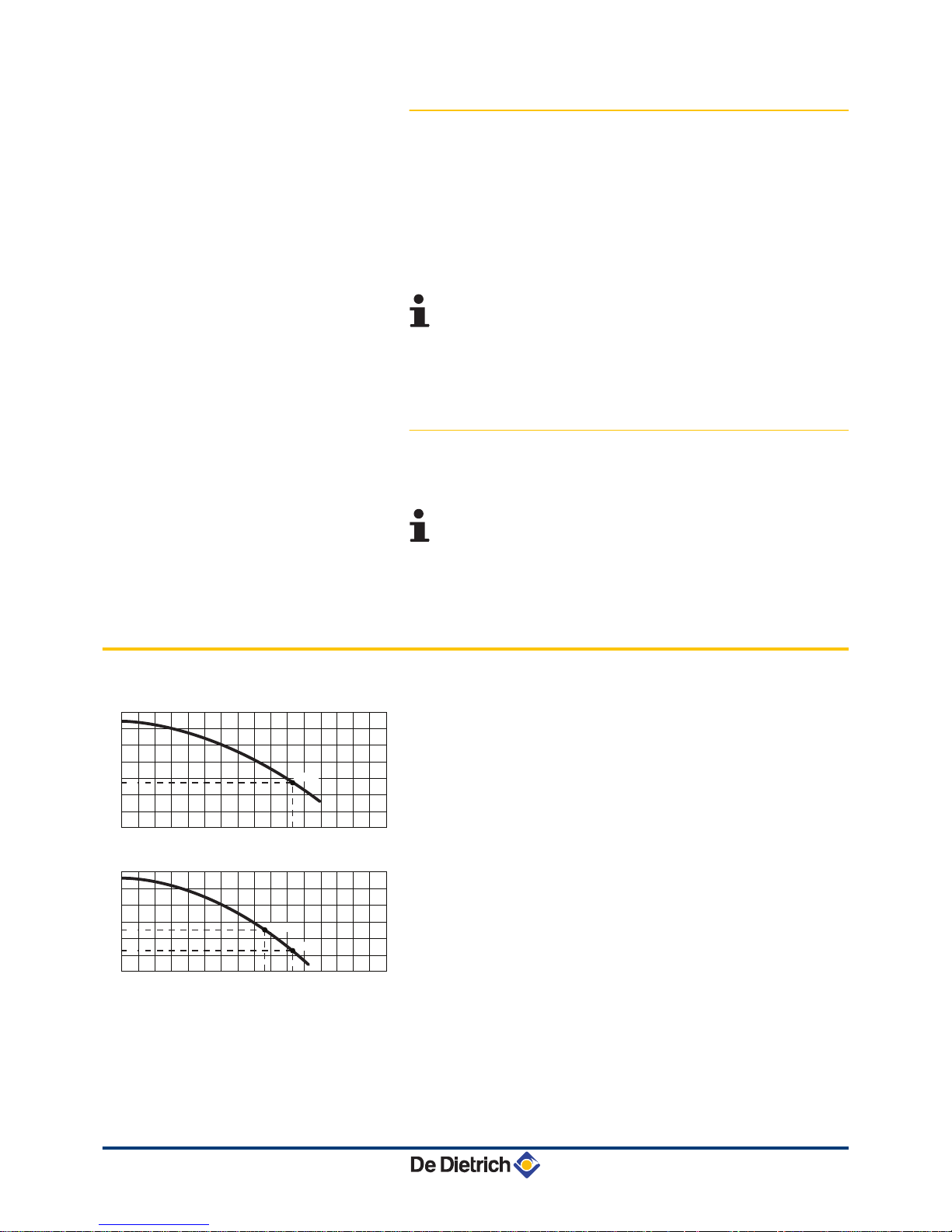

3.5 Circulating pump

The boiler is fitted with an on/off circulation pump.

EMC-M 24

H

Manometric height central heating circuit

Q

Water flow ( ΔT=20K)

EMC-M 24/28 MI

H

Manometric height central heating circuit

Q

Water flow ( ΔT=20K)

R000367-A

12001000600 800400200

0

0

100

200

300

400

500

600

Q (l/h)

16001400

700

H (mbar)

1030

24 kW

275

R000365-A

12001000600 800400200

0

0

100

200

300

400

500

600

H (mbar)

Q (l/h)

16001400

860

1030

20 kW

24 kW

253

127

EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI 3. Technical description

210212 - 7601972-03

13

EMC-M 30/35 MI - 34/39 MI

H

Manometric height central heating circuit

Q

Water flow ( ΔT=20K)

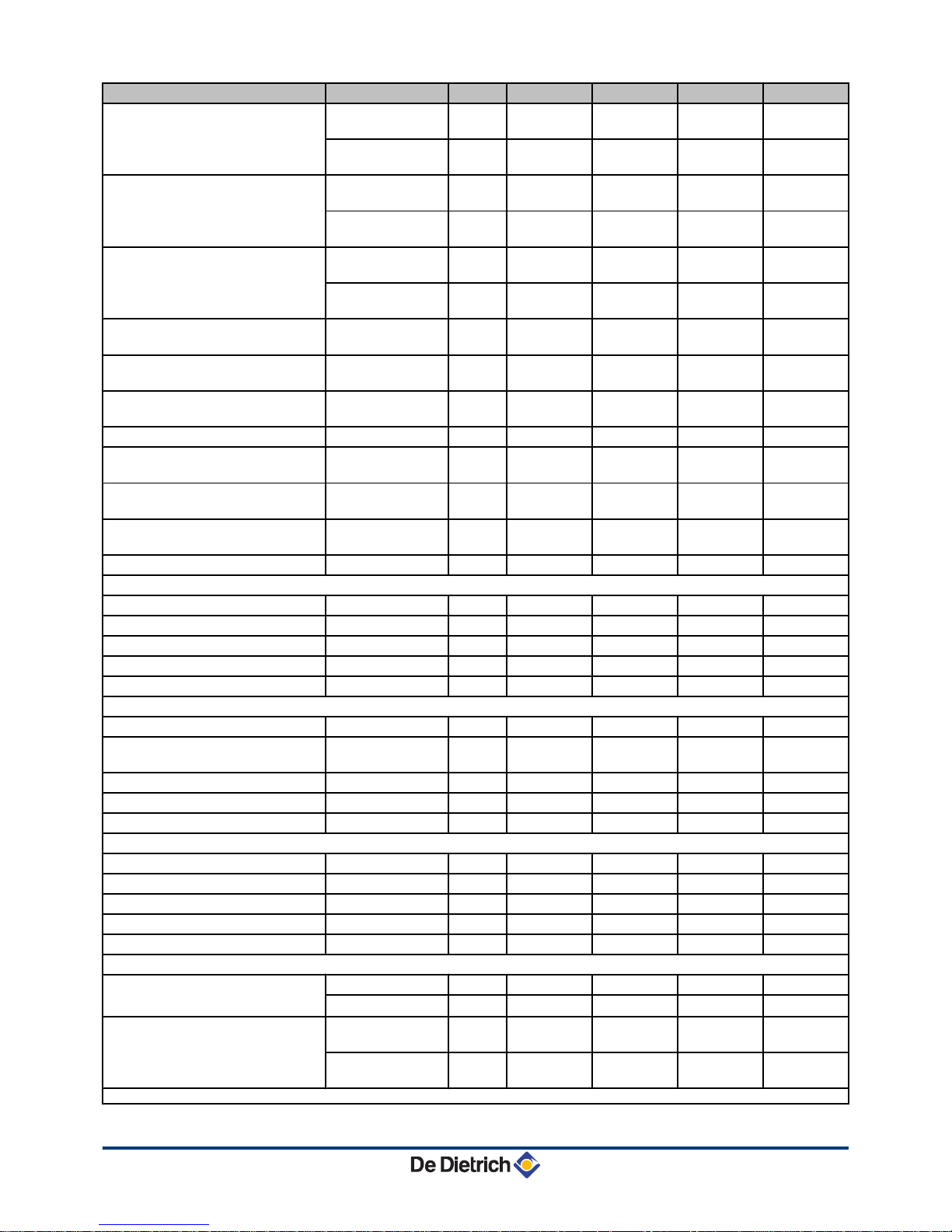

3.6 Technical specifications

Boiler type EMC- M

24 24/28 MI 30/35 MI 34/39 MI

General

EC indentification no. PIN

0063CM3019

Flow rate setting Adjustable

Modulating, Start/Stop

Nominal output (Pn)

Heating System (80/60 °C)

minimummaximum

kW 5,5 - 23,4 5,5 - 23,4 7,7 - 29,2 7,7 - 33,8

Factory setting kW 23,4 19,5 29,2 29,1

Nominal output (Pn)

Heating System (50/30 °C)

minimummaximum

kW 6,1 - 24,8 6,1 - 24,8 8,5 - 31,0 8,5 - 35,7

Factory setting kW 24,8 20,7 31,0 30,7

Nominal output (Pn)

DHW System

minimum maximum

kW - 5,5 - 27,5 7,7 - 33,9 7,7 - 37,8

Factory setting kW - 27,5 33,9 37,8

Nominal input (Qn)

Heating System (Hi)

minimum maximum

kW 5,6 - 24,0 5,6 - 24,0 7,8 - 30,0 7,8 - 34,9

Factory setting kW 24,0 20,0 30,0 30,0

Nominal input (Qn)

Heating System (Hs)

minimum maximum

kW 6,2 - 26,7 6,2 - 26,7

8,7 - 33,3 8,7 - 38,8

Factory setting kW 26,7 22,2 33,3 33,3

Nominal input (Qnw)

DHW System (Hi)

minimummaximum

kW -

5,6 - 28,2 7,8 - 34,9 7,8 - 39

Nominal input (Qnw)

DHW System (Hs)

minimummaximum

kW -

6,2 - 31,3 8,7 - 38,8 8,7 - 43,3

Nominal input (Qn)

Propane (Hi)

minimum kW

7,1 7,1 10 10

Nominal input (Qn)

Propane (Hs)

minimum kW

7,7 7,7 10,9 10,9

Heating efficiency under full load

(Hi) (80/60 °C)

- % 97,6 97,6 97,2 96,9

Heating efficiency under full load

(Hi) (50/30 °C)

- % 103,3 103,3 103,3 102,4

Heating efficiency under partial load

(Hi) (Return temperature 60

°C)

- % 97,8 97,8 98,4 98,4

Heating efficiency under partial load

(Hi) (92/42 EEG)

(Return temperature 30

°C)

- % 109,2 109,2 108,8 108,8

Data on the gases and combustion gases

Equipment categories

- II

2ESi3P

Type of air/flue gas connection

B23, B

23P

, B33, C

13x

, C

33x

, C

43x

, C53, C

63x

, C

83x

, C

93x

(1) Front panel removed

R000368-A

12001000600 800400200

0

0

100

200

300

400

500

600

Q (l/h)

16001400

700

H (mbar)

1250

30 kW

317

187

1500

35 kW

3. Technical description EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

14

210212 - 7601972-03

Boiler type EMC- M

24 24/28 MI 30/35 MI 34/39 MI

Gas inlet pressure G20 (Gas H) minimum-

maximum

mbar 17 - 30 17 - 30 17 - 30 17 - 30

Connecting

pressure

mbar 20 20 20 20

Gas inlet pressure G25 (Gas L) minimum-

maximum

mbar 20 - 30 20 - 30 20 - 30 20 - 30

Connecting

pressure

mbar 25 25 25 25

Gas inlet pressure G31 (Propane) minimum-

maximum

mbar 30- 50 30- 50 30- 50 30- 50

Connecting

pressure

mbar 37 37 37 37

Gas consumption G20 (Gas H) minimum-

maximum

m3/h

0,59 - 2,54 0,59 - 2,98 0,83 - 3,68 0,83 - 4,13

Gas consumption G25 (Gas L) minimum-

maximum

m3/h

0,69 - 2,95 0,69 - 3,47 0,96 - 4,28 0,96 - 4,80

Gas consumption G31 (Propane) minimum-

maximum

m3/h

0,29 - 0,98 0,29 - 1,15 0,41 - 1,42 0,41 - 1,47

NOx annual emission (n=1)

mg/kWh 58 58 52 56

NOx classification (EN 297 pr A3, EN

483)

5 5 5 5

Mass flue gas flow rate minimum-

maximum

kg/h

9,4 - 38,7 9,4 - 45,5 13,1 - 56,2 13,1 - 62,9

Flue gas temperature minimum-

maximum

°C

32 - 78 32 - 84 31 - 82 31 - 86

Maximum counter pressure

Pa 80 116 105 120

Characteristics of the heating circuit

Water content

l 1,4 1,6 1,7 1,7

Water operating pressure minimum bar 0,8 0,8 0,8 0,8

Water operating pressure (PMS) maximum bar 3,0 3,0 3,0 3,0

Water temperature maximum °C 110 110 110 110

Operating temperature maximum °C 90 90 90 90

Characteristics of the domestic hot water circuit

Specific hot water flow (∆T = 30K)

l/min - 14 17 19

Domestic water resistance (without

flow restrictor)

mbar - 123 215 260

Flow rate threshold minimum l/min - 1,2 1,2 1,2

Water content

l - 0,16 0,18 0,18

Operating pressure (Pmw) maximum bar - 8 8 8

Electrical characteristics

Power supply voltage

VAC 230 230 230 230

Power consumption Full load maximum W 117 117 145 159

Power consumption Part load maximum W 96 82 101 101

Power consumption - Standby maximum W 3 3 3 3

Electrical protection index

IP X4D X4D X4D X4D

Other characteristics

Weight (empty)

Total kg 24,5 26 28,5 28,5

Mounting

(1)

kg 23 24 27 27

Acoustic level at 1 metre

maximum Heating

System

dB(A) 40 38 42 42

maximum DHW

System

dB(A) _ 42 45 46

(1) Front panel removed

EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI 3. Technical description

210212 - 7601972-03

15

4 Installation

4.1 Regulations governing installation

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

4.2 Choice of the location

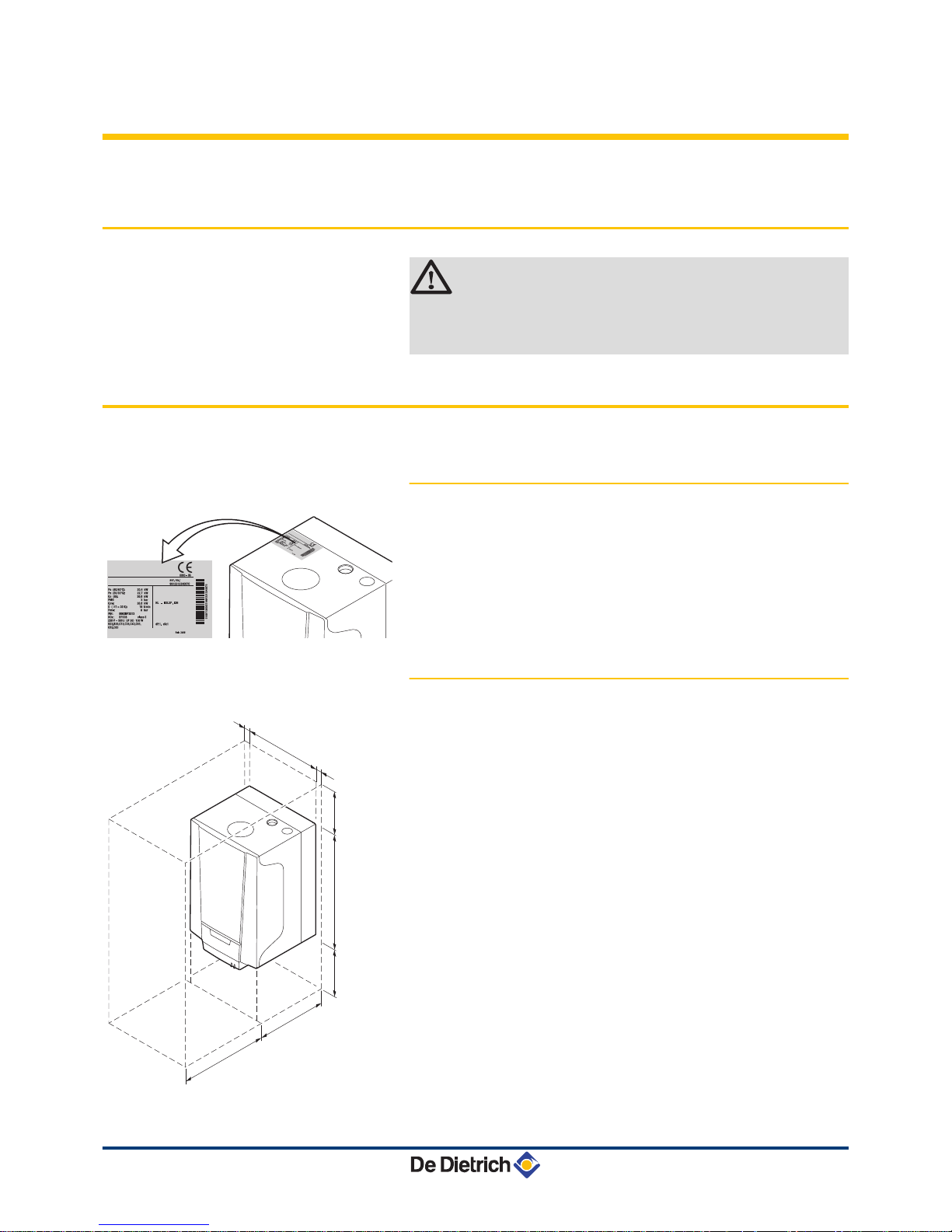

4.2.1. Data plate

The identification plate on top of the boiler features the boiler serial

number and important boiler specifications, for example the model

and unit category. The dF and dU codes are also stated on the type

plate.

4.2.2.

Location of the boiler

4 Before mounting the boiler, decide on the ideal position for

mounting, bearing the Directives and the dimensions of the

appliance in mind.

4 When choosing the position for mounting the boiler, bear in mind

the authorised position of the combustion gas discharge outlets

and the air intake opening.

4 Make sure there is enough room underneath the boiler for the

connection box.

4 To ensure adequate accessibility to the appliance and facilitate

maintenance, leave enough space around the boiler.

4 Mount the boiler onto a flat surface.

R000292-A

R000424-A

368

5

1000

364

≥ 200

5

≥ 250

554

4. Installation EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

16

210212 - 7601972-03

WARNING

4 Fix the appliance to a solid wall capable of bearing

the weight of the appliance when full of water and fully

equipped.

4 Do not place the appliance above a heat source or a

cooking appliance.

4 Do not locate the boiler in direct or indirect sunlight.

4 It is forbidden to store inflammable products and

materials in the boiler room or close to the boiler,

even temporarily.

CAUTION

4 The boiler must be installed in a frost-free

environment.

4 An earthed electrical connection must be available

close to the boiler.

4 A connection to the mains drainage system for the

discharge of condensate must be available close to

the boiler.

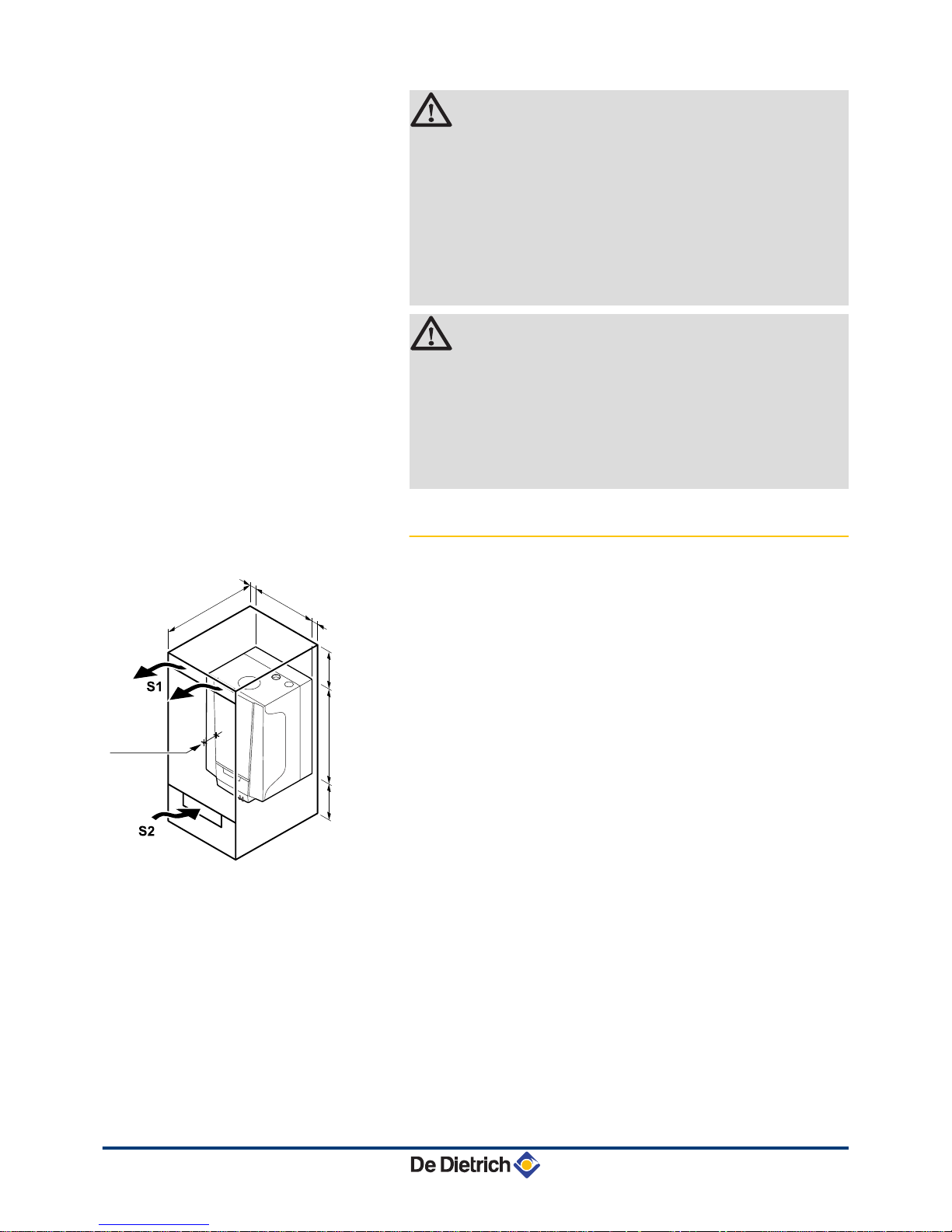

4.2.3. Ventilation

(1)

Distance between the front of the boiler and the internal

wall of the casing box.

If the boiler is installed in a closed casing, respect the minimum

dimensions given in the diagram opposite.

Also allow openings to

obviate the following hazards:

4 Accumulation of gas

4 Heating of the box

Minimum cross section of the openings: S1 + S2 = 150 cm

2

R000421-A

368

5

5

≥ 250

≥ 250

554

≥ 464

≥

100

(1)

EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI 4. Installation

210212 - 7601972-03

17

4.3 Main dimensions

i

Connection of the combustion gas exhaust pipe; Ø 60 mm

h

Connection of the air intake pipe; Ø 100 mm

ê

Safety valve outlet pipe; Ø 15 mm

j

Condensates discharge; Ø 25 mm

{

Heating circuit flow; G¾"

y

Domestic hot water outlet; G½"

Gas /

Gaz

Gas connection; G½"

x

Domestic cold water inlet; G½"

z

Heating circuit return; G¾"

R000354-A

368

184

364

243

541

209

230

664

151

35

52

1

2

3

4

1

= 117

2

= 184

3

= 251

4

= 316

46

90

187

76

4. Installation EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

18

210212 - 7601972-03

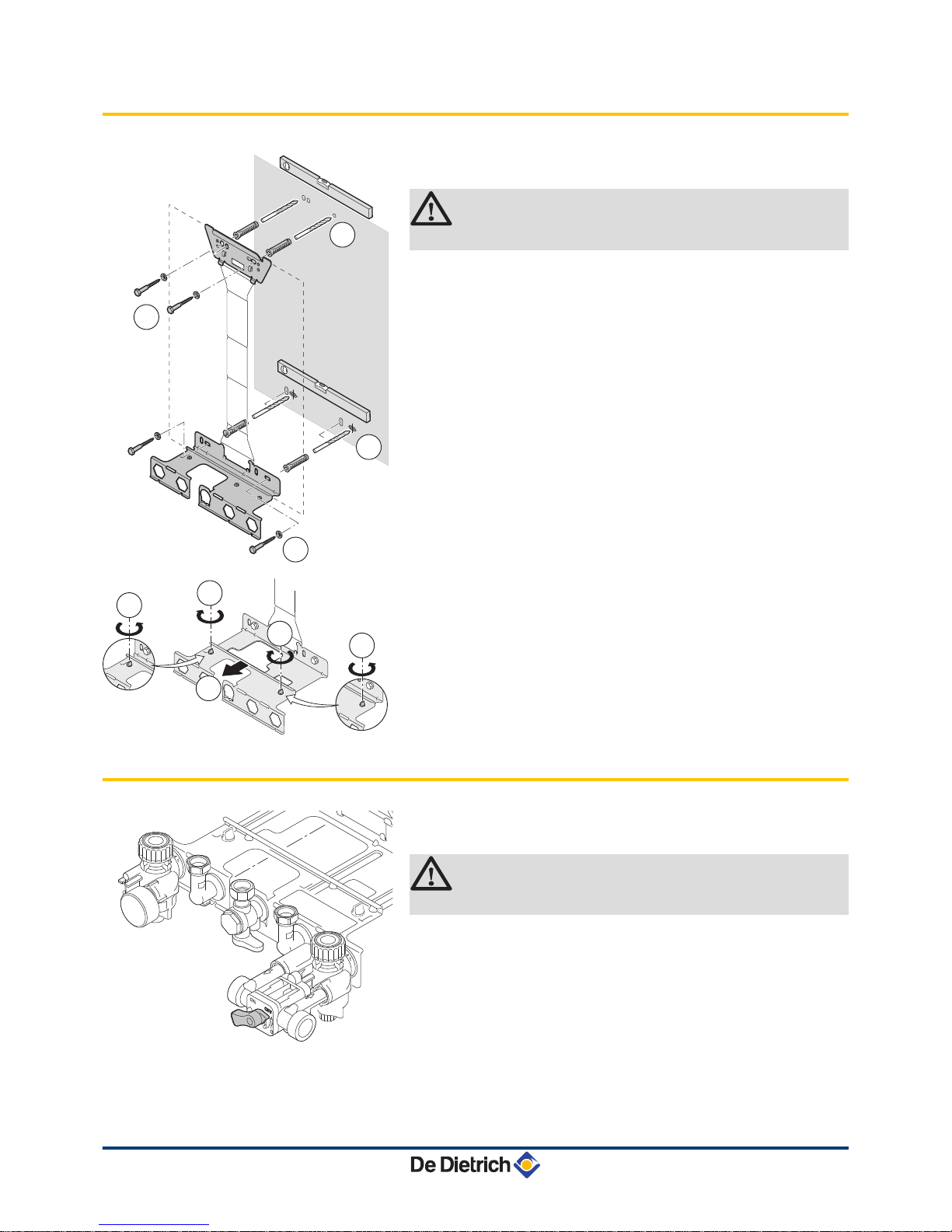

4.4 Installing the mounting frame

1. Drill 2 holes with Ø 10 mm for the lower part of the mounting

frame. Put the plugs in place.

CAUTION

Make sure that all the drill holes are level.

2. Affix

the lower part of the mounting frame to the wall using 2 of the

screws supplied.

3. Open out the mounting frame and mark out the 2 drill holes for the

upper part of the mounting frame on the wall. Drill 2 holes with a

Ø of 10 mm. Put the plugs in place.

4. Affix the upper part of the mounting frame to the wall using 2 of

the screws supplied.

5. Extend the mounting frame to its maximum depth to install a boiler

with a built-in expansion vessel. To do so, remove the plastic

screws from the lower bracket, and once it has been extended,

replace the screws to fix the mounting frame.

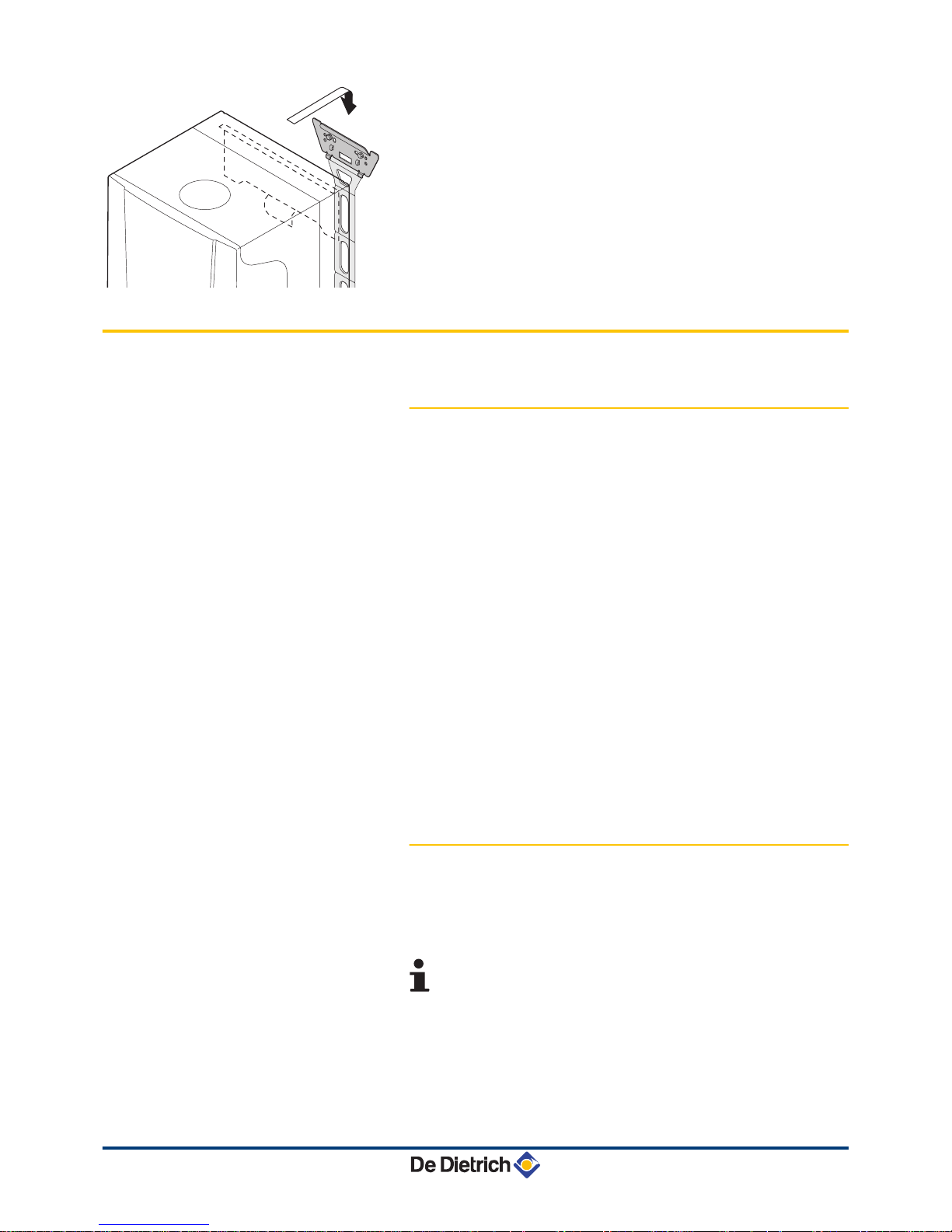

4.5 Positioning the boiler

1. Remove the protective caps from all of the hydraulic inlets and

outlets on the boiler.

CAUTION

The cock from the filling loop must be closed.

2. Fit a fibre gasket to each joint on the valve plate.

T003395-F

1

2

3

4

R000419-A

3

2

3

1

1

T002375-D

EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI 4. Installation

210212 - 7601972-03

19

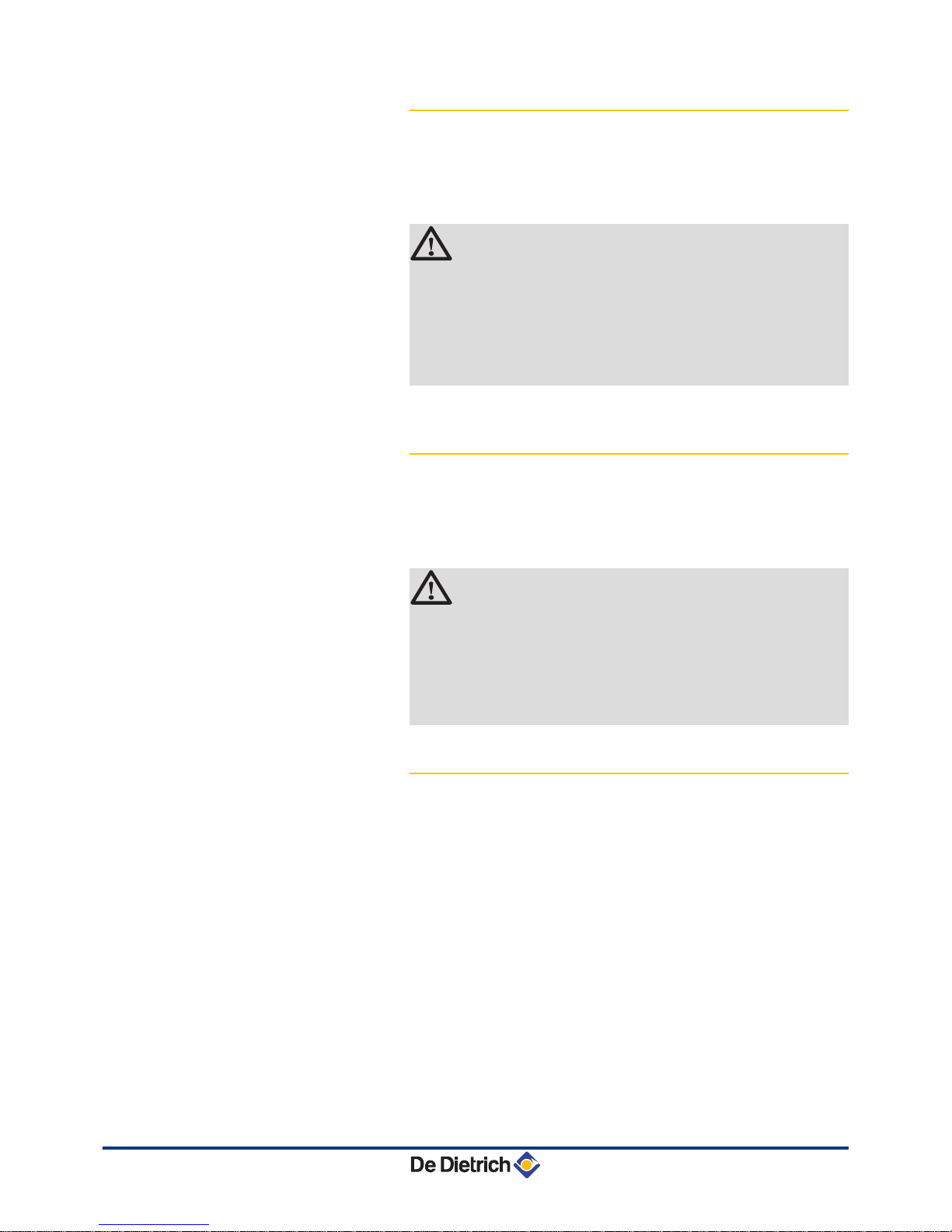

3. Position the boiler above the plumbing fixtures plate and locate it

against the mounting frame. Gently lower the boiler.

Mount the

boiler using the suspension bracket on the back of the boiler.

4. Tighten the valve nuts on the boiler.

4.6 Hydraulic connections

4.6.1. Flushing the system

Installation must be carried out in accordance with the prevailing

regulations,

the codes of practice and the recommendations in these

instructions.

Installing the boiler in new installations (installations less than

6 months old)

4 Clean the installation with a universal cleaner to eliminate debris

from the appliance (copper, hemp, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

Installing the boiler in existing installations

4 Remove sludge from the installation.

4 Flush the installation.

4 Clean the installation with a universal cleaner to eliminate debris

from the appliance (copper, hemp, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

4.6.2. Water flow rate

The boiler’s modulating control system limits the maximum difference

in

temperature between the heating flow and return and the maximum

speed at which the flow temperature increases. In this way, the boiler

does not require a minimum water flow rate.

If using a heating and domestic hot water production type

boiler on an installation in which the flow can be fully

disconnected from the return (e.g. by using thermostatic

valves), you should either fit a bypass or fit an expansion

vessel to the heating flow conduit.

R000420-A

4. Installation EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

20

210212 - 7601972-03

4.6.3. Connection of the heating circuit

1. Connect the heating water return pipe to the heating return

connection z.

2.

Connect the heating water outlet pipe to the heating flow

connection {.

CAUTION

4 The heating pipe must be mounted in accordance

with prevailing provisions.

4 Carry out any welding work required at a safe

distance from the boiler or before the boiler is fitted

.

4 Install a drain under the safety valve leading to the

sewage system ê.

4.6.4. Connection of the water circuit for

domestic use

1. Connect the cold water inlet pipe to the domestic cold water

connection k.

2.

Connect the domestic hot water outlet pipe to the domestic hot

water connection m.

CAUTION

4 The domestic water pipes must be connected in

accordance with prevailing provisions.

4 Carry out any welding work required at a safe

distance from the boiler or before the boiler is fitted

.

4 If using synthetic pipes, follow the manufacturer’s

(connection) instructions.

4.6.5. Connecting the expansion vessel

The boiler is fitted as standard with an 8-litre expansion vessel.

If

the water volume is greater than 100 litres or the static height of the

system exceeds 5 metres, an additional expansion vessel must be

fitted. Refer to the table below to determine the expansion vessel

required for the installation.

Conditions of validity of the table:

4 3-bar safety valve

4 Average water temperature: 70 °C

Flow temperature: 80 °C

Return temperature: 60 °C

4 The filling pressure in the system is lower than or equal to the initial

pressure in the expansion vessel

EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI 4. Installation

210212 - 7601972-03

21

Initial pressure of the

expansion vessel

Volume of the expansion vessel depending on the volume of the installation (in litres)

100 125 150 175 200 250 300 > 300

0.5 bar 4,8 6,0 7,2 8,4 9,6 12,0 14,4 Volume of the installation x 0,048

1 bar

8,0

(1)

10,0 12,0 14,0 16,0 20,0 24,0 Volume of the installation x 0,080

1.5 bar 13,3 16,6 20,0 23,3 26,6 33,3 39,9 Volume of the installationx 0,133

(1) Factory configuration

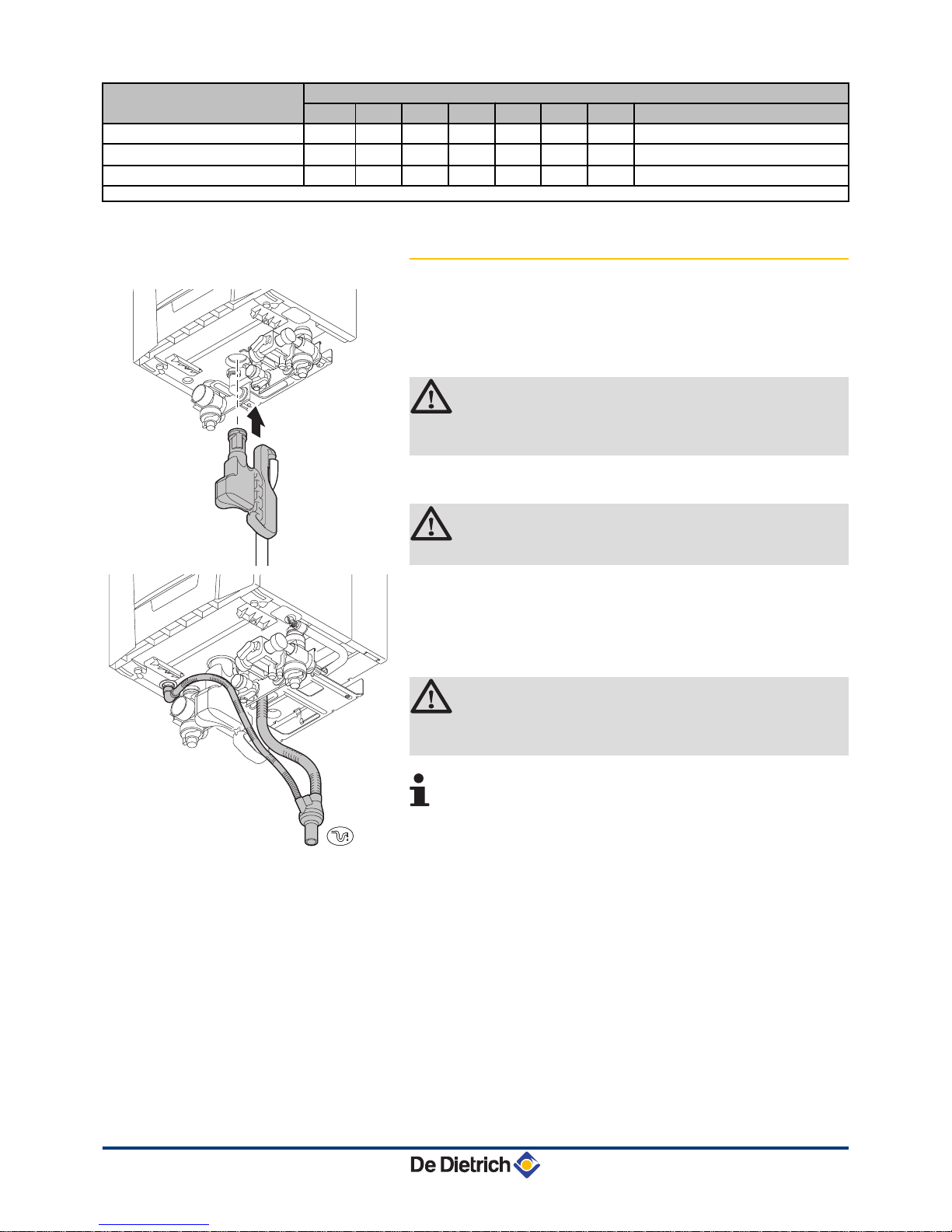

4.6.6. Connecting

the condensate discharge pipe

The syphon is supplied separately as standard with the boiler

(Includes flexible plastic drain hose

). Fit these parts underneath the

boiler. To do this, proceed as follows:

1. Fill the syphon with water up to the mark.

CAUTION

Fill the water siphon before starting the boiler to avoid

combustion products escaping from the boiler.

2.

Press the syphon firmly into the j opening provided for it

underneath the boiler.

The syphon must click into place.

CAUTION

Check whether the syphon is solidly fitted in the boiler.

3. Mount

a standard drainage pipe, Ø 32 mm or more, leading to the

mains drainage system.

4. Mount the flow collector.

5.

Insert the hoses from the siphon drain j and safety valve ê.

6. Mount a trap or a siphon in the discharge pipe.

CAUTION

Do not make a fixed connection owing to maintenance

work on the siphon.

4 Do

not plug the condensate discharge pipe. Make an

open connection with the drain.

4 Set the discharge pipe at a gradient of at least 30 mm

per metre, maximum horizontal length 5 metres.

4 Do not drain condensation water into a roof gutter at

any time.

4 Connect the condensate discharge pipe in

accordance with prevailing standards.

T004860-B

T004868-D

4. Installation EMC-M 24 EMC-M 24/28 MI EMC-M 30/35 MI EMC-M 34/39 MI

22

210212 - 7601972-03

Loading...

Loading...