Page 1

DTG 130 Eco.NOx

Low temperature gas boiler

ELITEC

Installation and

Service Manual

300002915-001-E

EN

Page 2

2

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

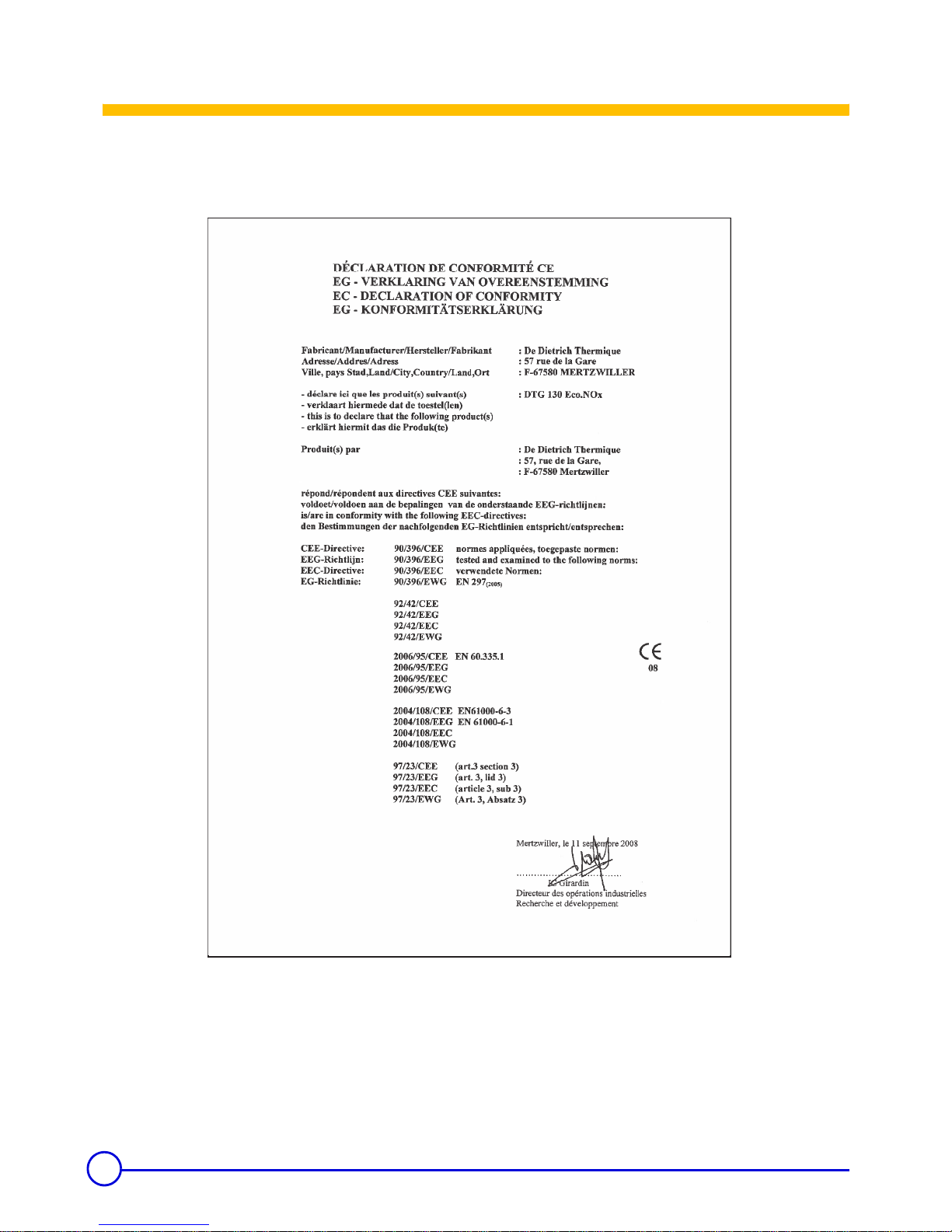

Declaration of conformity 1

The appliance complies with the standard model described in declaration of compliance 1. It is manufactured and distributed pursuant to the

requirements of european directives. The original of the declaration of compliance is available from the manufacturer.

L000148-A

Page 3

3

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Used symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3.1 User country. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.3.2 Directive 97/23/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2 Safety instructions and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.4 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1 Regulations governing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.1 France . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.2 Germany . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.3 Switzerland. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1.4 Other countries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Package list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.1 Position of the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.2 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.3 Main dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.3.4 Assembling the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.3.5 Levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.4 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.4.1 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.4.2 Hydraulic connection of the heating circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.4.3 Hydraulic connection of the water circuit for domestic use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.4.4 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.4.5 Water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.5 Gas connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.6 Connection to a chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.7 Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.8 Skeleton Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.1 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.2 Check points before commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.3 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.4 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.4.1 Changing the burner injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.4.2 Changing the ignition burner injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.4.3 Setting the injector pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.4.4 Setting the start up pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.4.5 Attaching the label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.4.6 Pressure setting and marking of calibrated injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.5 Checks and adjustments after commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.6 Changing the settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Page 4

4

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

6 Switching off the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.1 Precautions to take if there is a danger of frost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.2 Precautions to take in the event of prolonged shutdown (one year or more) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7 Checking and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.1 Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.1.1 Water level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.1.2 Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.1.3 Checking the ignition burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.1.4 Checking pressure to the nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

7.1.5 Checking burner safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

7.1.6 Checking the safety thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

7.1.7 Checking the downdraught thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

7.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.2.1 Cleaning main burner and ignition burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.2.2 Cleaning of the heating body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.2.3 Cleaning painted surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.3.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.3.2 Incidents and solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

8 Spare parts - DTG 130 Eco.NOx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8.1 Boiler body + Draught diverter + Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8.2 Gas line + Conversion set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.2.1 3 sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.2.2 4-6 sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.2.3 7-9 sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.3 Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.4 Control panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Page 5

5

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

1Introduction

1.1 Used symbols

Caution danger

Risk of injury and damage to equipment. Attention must be

paid to the warnings on safety of persons and equipment.

Specific information

Information must be kept in mind to maintain comfort.

Z

Reference

Refer to another manual or other pages in this instruction

manual.

DHW: Domestic hot water

1.2 General

Congratulations on your choice of a high quality product. We

strongly advise you to read the following instructions in order to

guarantee the optimal operation of your appliance. We are sure

that it will be entirely to your satisfaction and will meet with all

of your expectations.

` Keep these instructions in a safe place close to the appliance.

` For a proper operating of the boiler, follow carefully the

instructions.

` The manufacturer is not liable for any improper use of the

appliance or failure to maintain or install the unit correctly (the

user shall take care to ensure that the system is installed by a

qualified engineer).

` In the interest of customers, De Dietrich Thermique SAS are

continuously endeavouring to make improvements in product

quality. All the specifications stated in this document are

therefore subject to change without notice.

Page 6

6

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

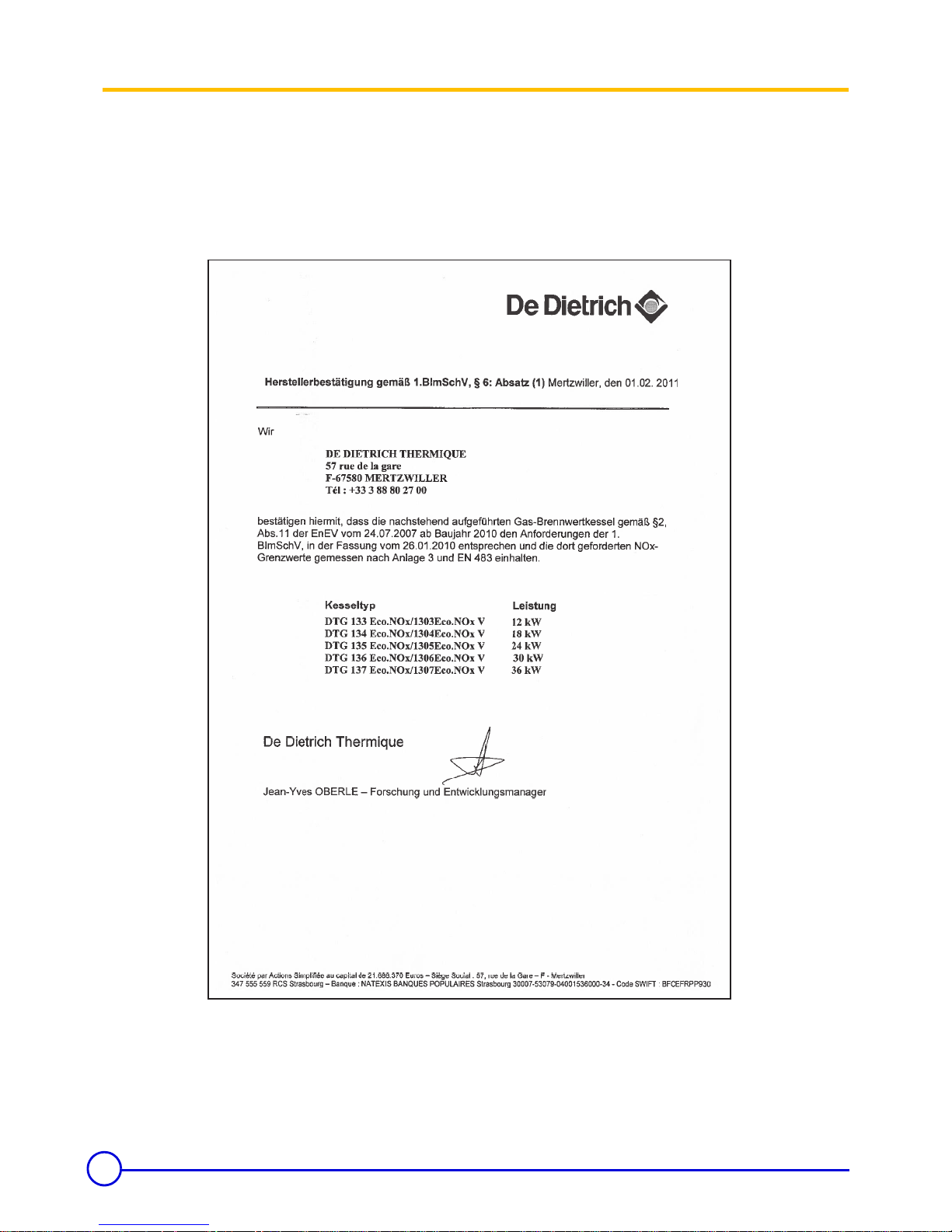

1.3 Homologations

CE identification no: CE-0085BP0002

Type B11

BS

boiler

France: Performance class III boiler according to ATG B 84

recommendations.

Thermal performance level (according to NFD 30-002): B300

Switzerland: Boilers are tested under the LRV-92 standard.

Germany:

DTG 130 EcoNox Boilers comply with the 1. BImSchV prescription,

version 2010.

L000147-A

Page 7

7

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

1.3.1 User country

DTG 130 Eco.NOx boilers are delivered preset for operation on

natural gases of H/E groups.

Z

For operation on another gas group, see the chapter "Gas

settings" (Page: 25).

1.3.2 Directive 97/23/EC

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 EC.

De Dietrich boilers and DHW tanks conform to the regulations in

article 3.3 of the 97/23/CEE Directive and is backed by the CE mark

for the 90/396/CEE, 92/42/CEE, 2006/95/EC and 2004/108/EC

directives.

User country

Gas

category

Gas type

Connection

pressure (mbar)

FR

II

2ESi3P

G20 20

G25 25

G31 37

ES, PT, IE, CH, GB, DK,

CZ, GR, SI, LT, SK

II

2H3P

G20 20

G31 30/37

IT, SE, NO, FI, IS, EE,

TR, LV, BG

I

2H

G20 20

AT

II

2H3P

G20 20

G31 50

DE

II

2ELL3P

G20 20

G25 20

G31 50

NL

II

2L3P

G25 25

G31 50

LU

II

2E3P

G20 20

G25 20

G31 50

HU

II

2ES3P

G20 25

G25.1 25

G31 30/50

RU, UA

I

2H

G20 20

G20 13

PL

II

2ELwLs3P

GZ50 20

GZ410 20

GZ350 13

G31 30/37

CY

I

3P

G31 30

User country

Gas

category

Gas type

Connection

pressure (mbar)

Page 8

8

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

2 Safety instructions and recommendations

2.1 Safety instructions

Fire hazard

Do not stock products of an inflammable nature close to

the appliance.

If you smell gas, do not use a naked flame, do not smoke,

do not operate electrical contacts or switches (doorbell,

lights, motor, lift, etc.).

1. Isolate the gas supply

2. Open the windows

3. Extinguish all flames

4. Evacuate the premises

5. Contact a qualified professional

6. Inform the gas supplier

Risk of intoxication

Do not obstruct the air inlets in the room (even partially).

If you smell flue gases

1. Switch the appliance off

2. Open the windows

3. Evacuate the premises

4. Contact a qualified professional

Risk of being burnt

Avoid direct contact with the flame viewport.

Depending on the settings of the appliance:

- The temperature of the flue gas conduits may exceed 60°C

- The temperature of the radiators may reach 95°C

- The temperature of the domestic hot water may reach 65°C

Risk of damage

Do not stock chloride or fluoride compounds close to the

appliance.

Install the appliance in frost-free premises.

Do not neglect to service the appliance: Contact a qualified

professional or take out a maintenance contract for the annual

servicing of the appliance.

2.2 Recommendations

Only qualified professionals are authorised to work on the

appliance and the instalation.

Before any work, switch off the mains supply to the

appliance.

Check regularly that the installation contains water and is

pressurised.

Keep the appliance accessible at all times.

Avoid draining the installation.

The appliance should be on Summer or Antrifreeze mode rather than

switched off to guarantee the following functions:

- Frost protection

- Protection against corrosion on domestic hot water tanks fitted

with a titanium anode

Page 9

9

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

3 Technical description

3.1 General description

Boilers in the DTG 130 Eco.NOx range have the following

characteristics:

- Cast iron floor-standing gas boiler.

- Connecting to a chimney.

- Atmospheric burner with total premixing and very low pollutant

emission.

- Heating body in cast iron with overlapping studs making it possible

to obtain extremely high efficiency. Also, the baffling in the smoke

circuits limits the natural chimney effect and gives high

performance yields.

- Efficient insulation of the entire boiler unit for very low losses to the

ambient air.

- Flue gas anti-overflow safety system. The downdraught thermostat

located in the draught diverter cuts off the gas supply and puts the

boiler into safety shutdown in the event of flue gas blow back.

- Electronic control panel:

-B: Basic control panel

-

Diematic 3 (D)

: Control panel with top of the range regulation

The control panel gives priority to producing domestic hot water.

The figure given after DTG 130 indicates the number of

sections which make up the boiler.

For example: DTG 130-5 Eco.NOx: 5 section boilers

Page 10

10

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

3.2 Technical characteristics

(a)

15 °C - 1013 mbar

(b)

In order to measure the ionization current, take out the ionization

cable connector and insert a micro-ammeter.

(c)

According to the national standard (possible adaptation of the two

diameters).

(d)

Availability in line with the country's sales plan.

(e)

Underload on GZ350 gases and H-13 mbar

See: Leaflet on conversion to another gas

1 mbar = 100 Pa

Models DTG ... Eco.NOx

133

(d)

134 135 136 137

138

(d)

139

(d)

Nominal output Pn kW 12 18 24 30 36

42

(e)

48

(e)

Power input kW 13.4 20.1 26.7 33.3 39.9 46.4 52.9

Gas flow rate

Natural gas H/E

(a)

GZ50

m

3

/h

1.42 2.13 2.83 3.52 4.22 4.91 5.60

Natural gas L/LL

(a)m3

/h

1.65 2.47 3.29 4.10 4.91 5.71 6.51

H - 13 mbar

m

3

/h

1.42 2.13 2.83 3.52 4.22 4.79 5.13

GZ350

(a)m3

/h

1.97 2.95 3.92 4.89 5.87 6.50 7.29

GZ410

(a)m3

/h

1.71 2.56 3.41 4.25 5.09 5.92 6.75

Propane Kg/h 1.04 1.56 2.07 2.59 3.10 3.60 4.11

Number of cast iron parts 3 4 5 6 7 8 9

Number of nozzles 2 3 4 5 6 7 8

Mass flue gas flow rate (H/E) Kg/h 48 53 70 81 97 109 120

Smoke temperature °C 100 120 125 130 133 135 135

Minimal ionization current

(b)

µA 0.30.30.30.30.30.30.3

Required depressurisation at the nozzle mbar 0.05 0.05 0.05 0.05 0.05 0.05 0.05

Min water temperature °C 30303030303030

Max water temperature °C 90909090909090

Maximum admissible operating pressure bar 4 4 4 4 4 4 4

Electrical connection V/Hz 230-50 230-50 230-50 230-50 230-50 230-50 230-50

Absorbed electrical power W 12 12 12 12 12 12 12

Gas connection inch R 1/2 R 1/2 R 1/2 R 1/2 R 3/4 R 3/4 R 3/4

Water connection inch R 1R 1R 1R 1R 1R 1R 1

Smoke connection (internal diameter) mm

110/111

(c)

110/111

(c)

125/130

(c)

150/153

(c)

150/153

(c)

150/153

(c)

180

Water content l 7.1 8.8 10.5 12.2 13.9 15.6 17.3

Loss of hydraulic circuit load at ∆T=15K

mbar 4 8 15 23 33 46 60

Net weight kg 87 100 118 135 153 162 183

Shipping weight kg 97 113 133 148 166 181 203

Page 11

11

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

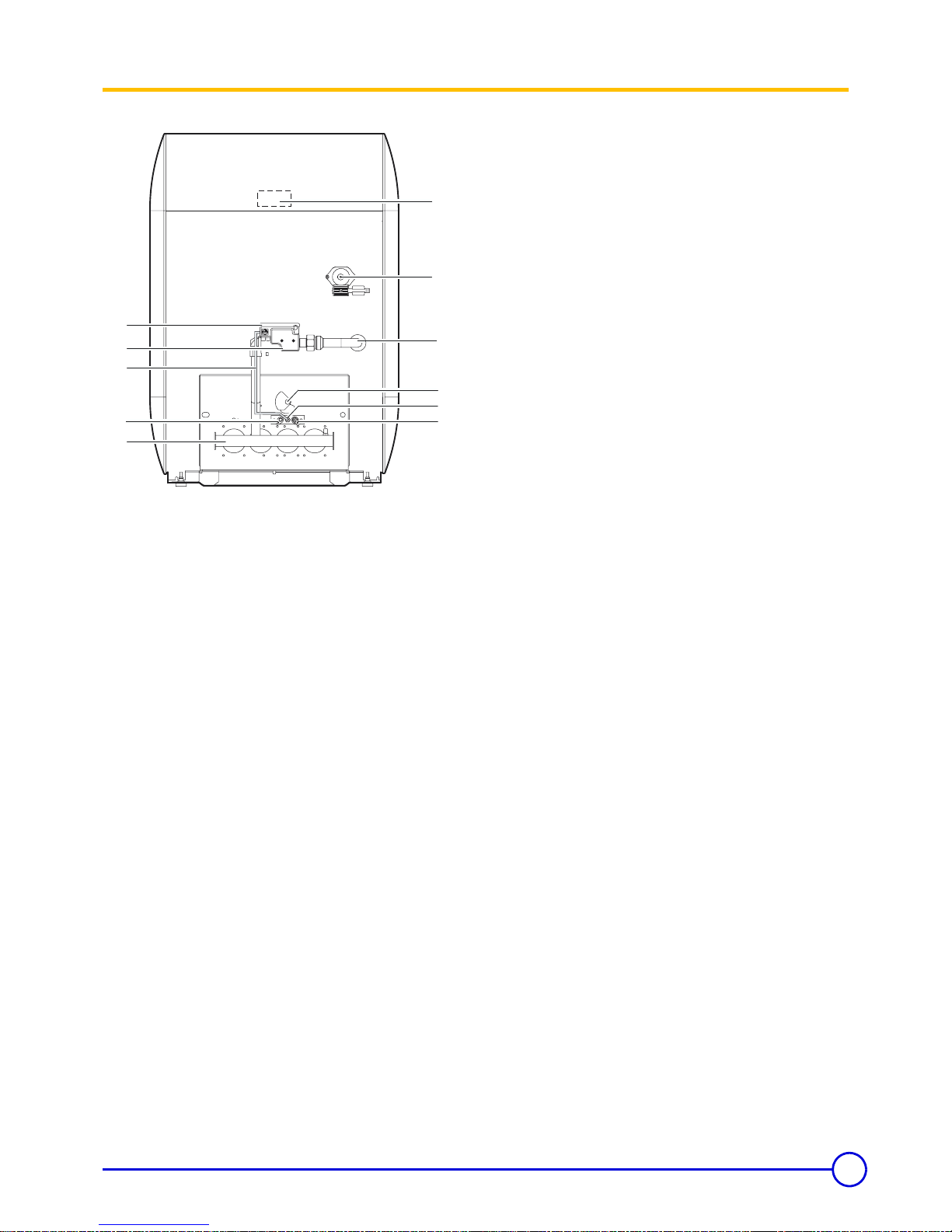

3.3 Main parts

1. Safety box:

Mounted on the gas block to ensure and check ignition

sequences, plus burner operation and extinguishing sequences.

2. Gas regulation block:

It has a progressive opening, regulation valve and safety valve in

series which is controlled by the boiler adjustment dial.

3. Gas inlet

4. Burner

5. Flame inspection window

6. Ignition electrode:

This ensures ignition burner ignition using a high voltage spark.

7. Ionization probe:

This detects the presence of a burner ignition flame through

ionization.

8. Ignition burner

9. Ignition burner gas supply pipe

10. Downdraught thermostat (located on the rear wall of the anti-

blowback device)

In the event of smoke release, the burner is cut and the boiler

goes into standby for 15 minutes. It must not be switched off or

moved at any time.The boiler restarts normally after this

thermostat has cooled and the 15 minutes has finished (indicated

by an alarm indicator flashing on the control panel).

11. Sensor tube

9

5

10

8518N002

4

1

2

3

6

7

8

11

Page 12

12

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

3.4 Operating principle

577 DBC safety box

Operating principle

The ignition and burner surveillance sequences are ensured by the

safety box.

Normal operating cycle

If heating is required, the boiler thermostat TCH closes the contact.

The ignition transformer TA integrated into the safety control box and

the ignition burner valve VBA (supply to the ignition burner) are

switched on.

Gas from the ignition burner is ignited by the ignition electrode and

within the time interval ts; a minimum current of 0.3 µA appears on

the ionization sensor SF and the gas valve regulation flap (supplying

the principal burner) opens.

Operating cycle on safety (start up without flame

signal)

If a flame is not detected before the safety time ts, the box makes 2

more ignition attempts. If, at the end of the last attempt, there is still

no flame signal, the box goes into safety and the safety indicator

comes on. To restart the heater, press the reset button on the safety

box.

If there is a loss of flame in normal operation, the box automatically

repeats the start up sequence.

Resetting

The box is reset after going into safety by pressing the reset button.

If the reset button does not work, wait at least 15 seconds before

trying a second time.

The box may be on safety on its first start up. Press the resetting

button of the burner.

If the reset button is pressed in normal operation, the gas valves

close and the box starts a new ignition sequence.

AB

ts

TCH

VA

TA

SF

VBP

TAF

VBA

8518N001

AA1C

1

CE

ts

TCH

VA

TA

SF

VBA

VBP

8518N044

A

2

C

2

TAF

ts ts

Page 13

13

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

Operating cycle with the downdraught thermostat

cut off

In the event of smoke release by the anti-blowback device, the antirelease safety device switches off the burner with the safety box on

standby for 15 minutes (this is indicated by an alarm indicator

flashing). The 15 minute timed period can only be interrupted by a

sector cut.

To restart the boiler:

Wait for around 5 minutes (thermostat cooling time) and press the

reset button on the safety control box. If interruptions of this kind

happen repeatedly, contact your fitter.

Legend

A Start of operation

A

1

Second ignition attempt

A

2

Third ignition attempt

B Formation of flame in ignition burner

C End of first ignition attempt

C

1

End of second ignition attempt

C

2

On safety through absence of flame signal

D Anti-blowback thermostat cut

E Resetting

F Restart of the boiler

SF Burner flame signal

TA Ignition transformer

TAF Anti-backflow thermostat

TCH Boiler thermostat

VA Safety lockout warning light

VBA Ignition burner valve

VBP Main burner valve

tn Downdraught thermostat cooling time: times vary

ts Safety time: 55 seconds

t

TAF

Waiting time: 15 minutes

Required input signals

Box output signals

Contact closed

8518N045

D F

TCH

VA

TA

SF

VBP

TAF

VBA

t

TAF

t

n

Page 14

14

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

4 Installation

4.1 Regulations governing installation

4.1.1 France

Residential buildings

Statutory terms and conditions of installation and maintenance:

The installation and maintenance of the appliance must be carried

out by a qualified professional in compliance with the statutory texts

of the codes of conduct in force, particularly:

- Order of 27 April 2009 amending the Order of 2 August 1977

Technical and safety rules applicable to combustible gas and

liquefied hydrocarbon installations situated inside residential

buildings and their annexes.

- NF P 45-204 standards

Gas installation, (formerly DTU 61-1, gas installations: April 1982,

addendum no 1: July 1984).

- Local Sanitary Regulations

For appliances connected to the electricity network:

- NF C 15-100 standards Low voltage electrical installation - Rules..

Establishments open to the public

Statutory terms and conditions of installation:

The installation and maintenance of the appliance must be carried

out in compliance with the statutory texts and rules of the codes of

conduct in force, particularly:

- Safety regulations against fire and panic in establishments open

to the public:

a. General regulations

For all appliances:

- Articles GZ - Installations operating on combustible gases and

liquefied hydrocarbons.

Then, depending on use:

- Articles CH-Heating, ventilation, refrigeration, air conditioning and

production of steam and domestic hot water.

b. Instructions specific to each type of establishment open to the

public (hospitals, stores, etc.).

Certificate of compliance

In application of Article 25 of the Order of 27 April 2009 amending the

Order of 2 August 1977 amended and Article 1 of the amended Order

of 05/02/1999, the installer is required to draw up certificates of

conformity approved by the Ministers responsible for construction

and gas safety:

- Different forms (forms 1, 2 or 3) for a new gas installation.

- Model 4 in particular after replacing a furnace with a new one.

4.1.2 Germany

The installation and maintenance of the appliance must be carried

out by a qualified professional in compliance with the statutory texts

of the codes of conduct in force, particularly:

- DIN 4705: calculation of chimney dimensions

- DIN EN 12828 (June 2003 edition): heating systems in buildings.

Planning of hot water heating installations (up to a maximum

operating temperature of 105°C and a maximum output of 1 MW)

- DIN 4753: drinking and industrial water heating installations

- DIN 1988: technical rules on drinking water installations (TRW)

- DVGW-TRGI: technical rules on gas installations, including

complementary equipment

- Working paper DVGW G 260/I: technical rules on the nature of the

gas

Page 15

15

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

4.1.3 Switzerland

The installation and maintenance of the appliance must be carried

out by a qualified professional in compliance with the statutory texts

of the codes of conduct in force, particularly:

- Directives of the Association des Etablissements Cantonaux

d'Assurance Incendie AEAI

- Local and cantonal regulations

- Directives of the Société Suisse de l'Industrie des Gaz et des Eaux

SSIGE

- Directives on liquefied gases, part 2

The safety distance between combustible substances and the boiler

and gaseous effluents must comply with the requirements of the

AEAI standard.

4.1.4 Other countries

Installation and maintenance of the boiler must be carried out by a

qualified professional in compliance with prevailing local and national

regulations.

4.2 Package list

(a)

Availability in line with the country's sales plan.

Description Reference Pack no.

Boiler assembly

DTG 133 Eco.NOx

(a)

8518-9003 GL1

DTG 134 Eco.NOx 8518-9004 GL2

DTG 135 Eco.NOx 8518-9005 GL3

DTG 136 Eco.NOx 8518-9006 GL4

DTG 137 Eco.NOx 8518-9007 GL5

DTG 138 Eco.NOx

(a)

8518-9008 GL6

DTG 139 Eco.NOx

(a)

8518-9009 GL7

Control panel

B (Base) 8518-7000 GL25

D (Diematic 3) 8518-7002 GL27

Tank BH 150 8952-9085 GL29

Options available (Refer to the current price list)

Linking kit 8999-7049 EA92

Strengthener 8952-7720 EA82

Conversion kits

Propane 8518-7005 GL32

Natural gas H/E - GZ50 8518-7007 GL34

Natural gas L/LL - GZ410 8518-7004 GL31

GZ350 8518-7006 GL33

H - 13 mbar 100003720 GL103

Page 16

16

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

4.3 Mounting

4.3.1 Position of the boiler

Installations possible:

- in the kitchen

- in the cellar

- in the boiler house

Clearance to allow for:

- 5 cm on one of the boiler sides (B)

- 70 cm minimum in front

- 5 at the rear (A)

Also have the required space for installing the expansion reservoir

and the heating circulator.

4.3.2 Ventilation

Do not obstruct the air inlets in the room (even partially).

France: the cross section of the aeration vent, which is compulsory

in the boiler room in which the boiler is installed, must comply with the

DTU 61.1 (P 45 204) standard and, in particular, with the instruction

on boiler room layout (Book 1764 April 1982).

Germany: the cross section of the ventiliation vents, which are

compulsory in the room in which the boiler is installed, must comply

with the VDI 2050 form 1 standard and with other prevailing

regulations.

Other countries: the cross section of the aeration inlet, which is

compulsory in the premises in which the boiler is installed, must

comply with the standards in force in the country.

Caution:

In order to avoid damage to the boiler, it is necessary to prevent the

contamination of combustion air by chlorine and/or fluoride

compounds, which are particularly corrosive. These compounds are

present, for example, in aerosol sprays, paints, solvents, cleaning

products, washing products, detergents, glues, snow clearing salts,

etc. Therefore:

- Do not pull in air evacuated from premises using such products:

hairdressing salons, dry cleaners, industrial premises (solvents),

premises containing refrigeration systems (risk of refrigerant

leakage), etc.

- Do not stock such products close to the boilers.

If the boiler and/or peripheral equipment are corroded by such

chloride or fluoride compounds, the contractual guarantee

cannot be applied.

A

B

Page 17

17

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

4.3.3 Main dimensions

DTG 130 Eco.NOx

DTG 1300 Eco.NOx/B 150 - Right

DTG 1300 Eco.NOx/B 150 - Left

1

4

2

3

850

A

F

C

G

601

= =

E

H

D

ØB

583

413

100

39

15

30

345

194

373

(1)

5

1

2

3

850

L

F

846

E

5

9

ØB

450

580

29

850

L

F

846

= =

E

ØB

413

5

Page 18

18

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

DTG 1300 Eco.NOx/H 150

1. Heating flow

R1 (1") for one single boiler

G1 (1") for boiler with DHW tank

2. Heating return

R1 (1") for one single boiler

G1 (1") for boiler with DHW tank

3. Filling and emptying tap

(connection for 14 mm interior diameter pipe)

4. Gas inlet

ø K

5. Smoke nozzle

ø B

6. Hot water outlet - R 3/4 (3/4")

7. Circulation - R 3/4 (3/4")

8. Cold water inlet - R 3/4 (3/4")

9. Drain cock

(connection for 14 mm interior diameter pipe)

(a)

Availability in line with the country's sales plan.

(b)

According to the national standard (possible adaptation of the two

diameters)

(1) Adjustable feet : basic sizes : 30 mm.

Can be adjusted from 30 mm to 42 mm.

All height sizes are stated with feet completely screwed in.

(2) For hydraulic module mounted to the left or without module

(3) For hydraulic module mounted on the right

R = Thread

G = Exterior cylindrical threading, sealed by sheet gasket

The linking kit is not shown on the central view for easier reading.

Z

All instructions and features for the type BH 150 domestic hot

water tank are stated in the instructions supplied with the tank.

270

450

580

413 185

30 (1)

mon

té à

gauche ou sans

monté à droite

1

4

2

3

9

00

600

C

601

773

= =

E

H

D

ØB

583

39

34

1195

1044

1578

373

5

6

7

8

846

200

(2)

(3)

Models

DTG ... Eco.NOx

DTG ... Eco.NOx/B 150

DTG ... Eco.NOx/H 150

133

(a)

1303

(a)

134

1304

135

1305

1305

136

1306

1306

137

1307

138

1308

139

1309

A 522 522 600 600 744 744 822

øB

110 / 111

(b)

110 / 111

(b)

125 / 130

(b)

150 / 153

(b)

150 / 153

(b)

150 / 153

(b)

180

C 1001009385858594

D 74 92 98 66 103 67 70

E 372 372 450 450 594 594 672

F 773 773 773 773 773 773 798

G 728 728 728 728 728 728 768

H 118 82 85 49 85 49 52

øK (inch) R 1/2 R 1/2 R 1/2 R 1/2 R 3/4 R 3/4 R 3/4

L 1122 1122 1200 1200 1344 1344 1422

Page 19

19

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

4.3.4 Assembling the appliance

Boiler delivered assembled (without control panel)

Take out the shutter + screen assembly

Slide the panel along the front plate.

Push the 1 tubes through the lower opening on the panel case.

Ensure that the centring pins 3 fall into the slots 4.

5. Contact spring

6. Bulbs

Place the bulbs in the sensor tube in front of the boiler. Push

them into the funnel until it butts against it.

2 bulbs (A): Use the contact spring

3 bulbs (B): The contact spring is not used

8518N010B

A

B

Page 20

20

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

Attach the anti-release safety device onto the 3 connector studs

on the control panel

Make the electrical connections:

Z

See: Control panel instructions.

Thread the connection label into the screen slots. Correctly place

the label using the truncated corner.

4.3.5 Levelling

- Slightly lift the appliance using a lever.

- Adjust the 4 feet using a flat-bladed screwdriver.

(1)

Adjustable feet :

Basic dimension 0 mm.

Can be adjusted from 0 mm to 12 mm.

Page 21

21

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

4.4 Hydraulic connections

4.4.1 Regulations

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

Installing the boiler in new installations

(installations less than 6 months old)

- Clean the installation with a universal cleaner to eliminate debris

from the appliance (copper, flaxen thread, flux).

- Thoroughly flush the installation until the water runs clear and

shows no impurities.

Installing the boiler in existing installations

- Remove sludge from the installation.

- Flush the installation.

- Clean the installation with a universal cleaner to eliminate debris

from the appliance (copper, flaxen thread, flux).

Thoroughly flush the installation until the water runs clear and shows

no impurities.

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

Important recommendations for connecting the

boiler to the heating circuit

Between the boiler and the safety valves there must be no

complete or partial closing device.

France: DTU - 65.11, § 4.22 - NF P 52-203

Heating installations must be designed and implemented

to prevent heating circuit water and products contained in

it returning to the drinking water system (article 16-7

Departmental Health Regulations). A CB disconnector

(area disconnector for different uncontrollable

pressures)must be installed for filling the heating circuit

according to the NF P 43-011 standard.

Before connecting the heating circuit hydraulic connections, it is

essential to rinse the heating circuits to remove any particles which

might damage certain components (safety valve, pumps, valves...).

In the event where the burner is located at the highest point in the

installation, a dry running or water pressure control device my be

fitted.

4.4.2 Hydraulic connection of the heating circuit

1. Heating flow

2. Heating return

3. Drain cock (connection for 14 mm interior diameter pipe)

Insulate the heating flow and return pipes only outside the

casing.

The drainage device can be connected with a flexible hose.

4.4.3 Hydraulic connection of the water circuit for domestic use

Z

See: Domestic hot water calorifier instructions.

Page 22

22

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

4.4.4 Filling the system

Boiler self-standing:

The installation must be filled via the draining/filling valve. Check that

the entire installation has been correctly bled.

With domestic hot water tank:

Z

See: Domestic hot water calorifier instructions.

4.4.5 Water treatment

Central heating systems must be cleaned to eliminate

debris (copper, strands, brazing flux) linked to the

installation of the system and deposits that can cause

malfunctions (noise in the system, chemical reaction

between metals). On the other hand, it is important to

protect central heating systems against corrosion, scaling

and microbiological growth by using a corrosion inhibitor

adapted to all types of systems (steel, cast iron radiators,

heated floor, PER)

Switzerland: The water quality must comply with the SICC directives

No. 97-1F "Treatment of water intended for heating, steam,

refrigeration and air conditioning installations".

4.5 Gas connection

It is necessary to abide by the prevailing instructions and regulations.

Each time, a blocking tap will be located as near as possible to the

heater. A gas filter must be fitted to the boiler inlet.

The load loss between the meter and heater must be lower than 1

mbar (heater operating).

France

Pipe diameters must be defined in accordance with ATG's

(Association Technique de Gaz) B171 specifications.

Other countries

The diameters of the pipes must be defined in accordance with the

standards in force in your country.

Page 23

23

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

4.6 Connection to a chimney

Good

Poor

A 40 mm (minimum)

The appliance must be installed in accordance with the Codes of

Practice using a leak proof pipe made of a material capable of

withstanding hot combustion gases and any acidic condensation.

The pipe must be laid out to allow any likely condensation to drain.

It must be in accordance with existing regulations for pipes used for

this purpose. Standard meshed connection pipes are to be avoided.

The pipe connecting the outlet conduit must also be as short as

possible and without a reduced diameter.

The vertical section of the draught diverter outlet must be a minimum

length 3x the diameter of the nozzle before an elbow joint is fitted.

The pipe must have a diameter not less than the heater's nozzle

diameter along its whole length. This pipe must be able to be easily

disassembled and must not have a sudden change in diameter.

The outlet conduit must be maintained in a good condition, checked

and cleaned at least once a year.

4.7 Electrical connections

Only qualified professionnals may carry out electrical

connections, always with the power off.

Do not modify the connections inside the control panel.

Make the electrical connections of the appliance according to:

- The instructions of the prevailing standards,

- The instructions on the circuit diagrams provided with the

appliance,

- The recommendations in the instructions.

Standards to be respected

France: Electrical connections must be in compliance with the NF C

15.100 standard.

Other countries: The electrical connections shall comply with

standards in force.

Rules to be respected

- Power the appliance via a circuit which includes a remote

omnipolar switch with a gap of more than 3 mm.

- Connect all of the cables to the terminal blocks in the control panel.

Keep to the polarity shown on the terminals: phase (L),

neutral (N) and earth 4.

The available output per outlet is 450 W (2 A, with cos ϕ =

0.7) and the inrush current must be lower than 16 A.

If the charge exceeds one of these values, relay the

command using a contactor (fitted outside the control

panel).

Separate the sensor cables from the 230 V cables.

Outside the boiler : Use 2 pipes or cable guides at least

10 cm apart.

For the 230 V electrical connections, use 3-wire cables with a crosssection of 0.75 mm². For other electrical connections, use the 3 wire

cable with a diameter of 0.75 mm².

Make the electrical connections:

Z

Control panel instructions.

Z

Options brochure.

4.8 Skeleton Diagrams

Z

Control panel instructions

1

2

A

Page 24

24

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

5 Commissioning

Initial commissioning must be done by a qualified

professional.

5.1 Control panel

Z

Control panel instructions

5.2 Check points before commissioning

Hydraulic circuit

- Check that the installation and boiler are adequately filled with

water and correctly irrigated and bled.

- Check that there are no leaks on the hydraulic connections.

Gas circuit

- Check that the appliance is properly set for the type of gas used. If

this is not the case:

Z

5.4 Gas settings (Page: 25)

- Check the supply pressure.

- Check the pressure at the nozzles.

Z

5.4.6 Pressure setting and marking of calibrated injectors

(page: 27)

5.3 Commissioning procedure

Initial commissioning must be done by a qualified

professional.

1. Check the water pressure in the installation. Top up with more

water if necessary.

2. Open the gas valve.

3. Check that the safety thermostat has not triggered. Remove the

safety thermostat hood and press the reset button with a

screwdriver.

4. Set the On/Off switch to 8.

5. Make the settings on the control panel

Z

Control panel instructions

Page 25

25

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

5.4 Gas settings

DTG 130 Eco.NOx boilers are delivered preset for operation on

natural gases of H/E groups.

For operation on another group of gases, carry out the following

operations.

These actions must be carried out by a qualified

technician.

5.4.1 Changing the burner injectors

Cut the electricity and gas supply to the boiler.

Lift out the injector with a number 12 spanner assemble the new

injectors with their new joint.

Reassembly:

Correctly replace the seals.

First tighten the injectors by hand and carefully lock them using

a spanner.

Carry out a gas tightness check

5.4.2 Changing the ignition burner injector

Unscrew the connecting nut (14 spanner)

Pull the gas supply pipe towards yourself

Take out the ignition burner nozzle

Fit the new nozzle

Re-attach the supply tube (14 spanner)

Carry out a gas tightness check.

Models DTG

Nozzle

marking

Nozzle

diameter (mm)

Natural gas H/E

GZ50

133 to 137 204B 2.04

138 to 139 210B 2.10

Natural gas L/LL

GZ410

245B 2.45

Propane 140A 1.40

H - 13 mbar 225B 2.25

GZ350 310B 3.10

Nozzle marking

Nozzle diameter

(mm)

Natural gas H/E

GZ50

40.40

1

3

4

Natural gas L/LL

(France)

40.40

Natural gas L/LL

(

≠ France)

GZ410

50.50

Propane 3 0.30

H - 13 mbar 4 0.40

GZ350 6 0.60

Nozzle marking

Nozzle diameter

(mm)

Page 26

26

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

5.4.3 Setting the injector pressure

Turn the boiler on.

Z

.5.2 Check points before commissioning (page: 24)

5.3 Commissioning procedure (page: 24)

The pressure must be set by a qualified professional.

- Connect a manometer to the pressure socket located on the

manifold.

- Remove the protective cover

on the regulator by unscrewing it

using a screwdriver.

- Set the pressure on the injectors by moving the gas regulator on

the valve:

: Increase the pressure

: Reduce the pressure

5.4.4 Setting the start up pressure

E Protective hood

F Ionization probe connection

G Ignition electrode connection

Start up pressure may be set if necessary using a flat screwdriver,

after the protection has been removed E.

Start up pressure is set in the factory on minimum. If it is necessary

to optimise heater start up, it may be set on another value between

0º and 270º.

Gas valve opening diagram

Downstream pressure (mbar)

Time (s)

Manifold pressure (mbar)

Natural gas H/E

GZ50

DTG 133 to 137

DTG 138 to 139

16

15

Natural gas L/LL 12.1

GZ410 12.5

Propane 29

H - 13 mbar

8.4 to 10.2

depending on the model

GZ350

6 to 7

depending on the model

Page 27

27

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

5.4.5 Attaching the label

Affix the label which indicates for which type of gas the boiler is fitted

and set.

5.4.6 Pressure setting and marking of calibrated injectors

(1)

15 °C - 1013 mbar

(a)

Availability in line with the country's sales plan.

5.5 Checks and adjustments after commissioning

Z

Carry out all the checks mentioned in the chapter "Checking

and maintenance" (Page: 29).

5.6 Changing the settings

Z

Control panel instructions

Models DTG ... Eco.NOx

133

(a)

134 135 136 137

138

(a)

139

(a)

Burner

nozzles

Natural gas H/E

GZ50

204B 204B 204B 204B 204B 210B 210B

Natural gas L/LL

GZ410

245B 245B 245B 245B 245B 245B 245B

Propane 140A 140A 140A 140A 140A 140A 140A

H - 13 mbar 225B 225B 225B 225B 225B 225B 225B

GZ350 310B 310B 310B 310B 310B 310B 310B

Manifold

pressure

Natural gas H/E

GZ50

mbar 16 16 16 16 16 15 15

Natural gas L/LL mbar 12.1 12.1 12.1 12.1 12.1 12.1 12.1

GZ410 mbar 12.5 12.5 12.5 12.5 12.5 12.5 12.5

Propane mbar 29 29 29 29 29 29 29

H - 13 mbar mbar 10.2 10.2 10.2 10.2 10.2 9.6 8.4

GZ350 mbar777776.26

Gas flow

rate

Natural gas H/E

GZ50

m

3/h(1)

1.42 2.13 2.83 3.52 4.22 4.91 5.60

Natural gas L/LL

m

3/h(1)

1.65 2.47 3.29 4.10 4.91 5.71 6.51

GZ410

m3/h

(1)

1.71 2.56 3.41 4.25 5.09 5.92 6.75

Propane Kg/h 1.04 1.56 2.07 2.59 3.10 3.60 4.11

H - 13 mbar

m

3/h(1)

1.42 2.13 2.83 3.52 4.22 4.79 5.13

GZ350

m3/h

(1)

1.97 2.95 3.92 4.89 5.87 6.50 7.29

Page 28

28

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

6 Switching off the boiler

Set the On/Off switch to 0.

On the Off position 7, the domestic hot water calorifier

fitted with a titanium anode is not protected against

corrosion.

6.1 Precautions to take if there is a danger of frost

Heating circuit:

Use a correctly dosed antifreeze to prevent the heating water

freezing. If this cannot be done, drain the system completely. In all

cases, consult the fitter.

Domestic hot water circuit:

Drain the domestic water tank and pipes.

6.2 Precautions to take in the event of prolonged shutdown (one year or more)

- Close the gas valve

- The boiler and the chimney must be swept carefully.

Close the door of the boiler to prevent the internal circulation of air.

Page 29

29

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

7 Checking and maintenance

7.1 Checks

Make the following checks at least 1 time a year:

- Water level

- Safety devices

- Checking the ignition burner

- Checking pressure to the nozzle

- Checking burner safety

- Checking the safety thermostat

- Checking the downdraught thermostat

7.1.1 Water level

Regularly check the level of water in the installation. Top it up, if need

be, avoiding the abrupt input of cold water into the hot boiler. If this

operation is repeated several times per season, locate the leak and

repair it.

Do not drain the installation, except in cases of absolute

necessity. For example: Several months' absence with the risk

of ice in the building.

7.1.2 Safety devices

Check the safety devices (particularly the valve or safety unit),

referring to the instructions provided with these components.

7.1.3 Checking the ignition burner

1. Ionization probe

2. Ignition electrode

3. Flame diffuser

4. Earth electrode

Check the position of the ionization probe 1, the ignition electrode

gap 2 and the position of the flame diffuser 3 in terms of the sizes

indicated on the drawing (required in the event of heater

malfunction).

Page 30

30

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

7.1.4 Checking pressure to the nozzle

- Unscrew the screw inside the nozzle pressure socket a few turns.

- Connect a manometer to the pressure outlet. Check that the

pressure is correct.

- Tighten the pressure socket screw.

Carry out a gas tightness check.

7.1.5 Checking burner safety

Close the gas valve. Check the reaction of the safety system. (Safety box on safety

because of ionization fault).

7.1.6 Checking the safety thermostat

Place the Summer/Winter switch on % to cut the heating

accelerator to prevent the temperature rising in the installation.

Place the 3 position switch "

!

- AUTO - TEST STB" on the TEST

STB position. The burner starts regardless of the setting. Keep the

switch in this position until the safety thermostat cuts (110ºC).

To restart the heater, press the safety thermostat reset button and

repeat the starting operations.

7.1.7 Checking the downdraught thermostat

In the event of smoke release by the anti-blowback device, the antirelease safety device switches off the burner with the safety box on

standby for 15 minutes (this is indicated by an alarm indicator

flashing).

Check that the anti-overflow system is working correctly on

commissioning for the first time and during annual servicing of the

boiler.

Checking procedure

Only a qualified professional may carry out the check.

Ensure correct ventilation in the premises during the check.

- Turn of the heater and take out the smoke duct linking the heater

to the chimney. Block the boiler flue gas nozzle using a metal plate

(or other heat-resistant material).

- On start up, combustion products are evacuated to the back of the

heater by the anti-blowback device opening inside.

- The anti-blowback thermostat triggers for a few seconds, cuts the

burner and starts the safety box timer (alarm indicator flashing).

- After checking, re-assemble the smoke duct connecting the heater

to the chimney. Wait for about 5 minutes (thermostat cooling time)

the cut and reconnect the current using the Start/Stop switch. The

boiler restarts.

Manifold pressure

(mbar)

Natural gas H/E

GZ50

DTG 133 to 137

DTG 138 to 139

16

15

Natural gas L/LL 12.1

GZ410 12.5

Propane 29

H - 13 mbar

8.4 to 10.2

depending on the model

GZ350

6 to 7

depending on the model

Page 31

31

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

7.2 Maintenance

Carry out the following maintenance at least 1 time a year:

- Cleaning main burner and ignition burner

- Cleaning of the heating body

- Cleaning painted surfaces

7.2.1 Cleaning main burner and ignition burner

Cut the electricity and gas supply to the boiler.

Main burner

Clean the burner trains (slits) using a soft brush, a shorthandled brush or a vacuum cleaner.

Do not use a metal brush.

On reassembly, replace the burner earth wire fixed to the

right holding nut on the burner drawer.

Ignition burner

Clean the filter and the ignition burner injector.

Remove ionization probe 1 and the earth electrode 4 deposits

(for example using sand paper).

Carry out a gas tightness check.

Page 32

32

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

7.2.2 Cleaning of the heating body

If it is necessary to sweep the boiler, remove the burner drawer to

prevent deposits and soot blocking the orifices in the gas trains.

With the burner out:

- Remove the upper panel from the boiler.

- Remove the top insulating material.

- Remove the sweeping hatch from the draught diverter.

- If necessary, clean the boiler body using the special brush

provided.

- Clean the combustion chamber using a vacuum cleaner.

7.2.3 Cleaning painted surfaces

- Use a soapy solution and a sponge only.

- Rinse with clean water.

- Dry with a soft cloth or a chamois leather.

3

8518N016

4

1

2

Page 33

33

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

7.3 Troubleshooting

7.3.1 Error messages

Z

Control panel instructions

7.3.2 Incidents and solutions

Symptoms Probable causes Solution

The heater does not start and the safety

box is not affected (red alarm indicator

off)

The heater thermostat is requiring

heat

Setting (option) is not requiring

heat

Create a demand by moving the heater thermostat or the setting level

(option)

The safety thermostat has been

triggered after overheating

Solve the cause of overheating and reset the safety thermostat

No current

Set the On/Off switch to

8

The burner does not ignite and the

safety box is not affected (red alarm

indicator off)

On safety because of a lack of

gas

Purge the gas supply pipe then reset the heater using the panel reset button

Gas valve defective Check the gas valve and replace if necessary

No spark from the electrode Check the electric cable connection to the safety box and the electrode

No ionization current

Check the ionization probe and earth wire connection

Check the position of the ionization probe and the flame diffuser in the

ignition burner

The burner ignites and the safety box

goes into standby (burner cut and the

alarm indicator flashes)

downdraught thermostat cut.

Check for adequate draw on the chimney connection. Reset the safety

control box.

Check that the downdraught thermostat is in good working order. Reset the

safety control box.

Please note the seriousness of unplanned intervention on

the combustion product evacuation checking device:

evacuation faults must be solved by improving the draught

in the chimney.

In the event of a thermostat fault, it must be replaced by a

part stated on our "Spare parts list". Its position must not

be modified, which is defined by the 2 bosses on the

holding bracket which are located in the 2 holes on the

draught diverter. The thermostat must not be placed out of

service.

The burner ignites and the safety box is

affected (alarm indicator on)

Inversion of the phase and

neutral wires on the heater's

control panel.

Connect the phase to terminal 1 and neutral to 2.

The burner ignites but with reduced

power

Upstream pressure too weak Check gas supply

Dirty filter Clean the filter

Gas valve unit defective Replace the gas valve unit

Gas valve defective Check gas valve and replace if necessary

Unsuitable injectors Check injectors

Dirty cast iron body (hearth)

Upstream pressure too high Check gas supply

Dirty burner Clean the burner

Insufficient or incorrectly placed

air supply

Enlarge air supply, smoothen airation holes

Gas valve defective Check gas valve and replace if necessary

Noisy heater

Poor purge Purge correctly

Body has scale Descale the heating circuit

Unsuitable injectors (Whistling) Check injectors

Page 34

34

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

Heater too hot or too cold for

requirements

3 position switch on position

!

Check the position of the 3 position switch

Wrong setting for the heater

thermostat

Set the heater thermostat if the heater has SV-matic setting or an ambient

thermostat

Flame returns

Injectors too large

Check pressure injectors

Pressure too weak

Whistling

Injectors too small

Pressure too high

Symptoms Probable causes Solution

Page 35

DE DIETRICH THERMIQUE S.A.S. - Spare parts centre

4, rue d’Oberbronn - F-67110 REICHSHOFFEN -

*

+33 (0)3 88 80 26 50 - + +33 (0)3 88 80 26 98

cpr

dedietrichthermique.com

8 Spare parts - DTG 130 Eco.NOx

01/02/11 - 300002915-002-C

To order a spare part, give the reference number shown on the list.

8.1 Boiler body + Draught diverter + Insulation

Page 36

36

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

8.2 Gas line + Conversion set

8.2.1 3 sections

8.2.2 4-6 sections

Page 37

37

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

8.2.3 7-9 sections

8.3 Casing

8.4 Control panels

Z

Control panel instructions

Page 38

38

DTG 130 Eco.NOx 01/02/11 - 300002915-001-E

Ref. Code no. Description

Boiler body

1 85188500 Complete base frame - 3 sections

1 85188501 Complete base frame - 4 sections

1 85188502 Complete base frame - 5 sections

1 85188503 Complete base frame - 6 sections

1 85188504 Complete base frame - 7 sections

1 85188505 Complete base frame - 8 sections

1 85188506 Complete base frame - 9 sections

2 97581059 Adjustable feet

3 83755506 Assembled boiler body - 3 sections

3 83755507 Assembled boiler body - 4 sections

3 83755508 Assembled boiler body - 5 sections

3 83755509 Assembled boiler body - 6 sections

3 83755510 Assembled boiler body - 7 sections

3 83755511 Assembled boiler body - 8 sections

3 83755512 Assembled boiler body - 9 sections

4 85188025 Mounting square

5 95365611 1/2" sensor tube - Length 160 mm

6 83750004 Body lifter

7 97549270 Heating flow pipe - 1" - Length 375 mm

8 97549512 Heating return pipe - 1" - Length 135 mm

9 94902073 Drain cock 1/2"

10 94920297 Elbow 1"

Draught diverter

11 85188514 Draught diverter complete - 3 sections

11 85188515 Draught diverter complete - 4 sections

11 85188516 Draught diverter complete - 5 sections

11 85188517 Draught diverter complete - 6 sections

11 85188518 Draught diverter complete - 7 sections

11 85188519 Draught diverter complete - 8 sections

11 85188520 Draught diverter complete - 9 sections

12 97581501 Flue gas nozzle Ø 110/111

12 300000300 Flue gas nozzle Ø 125/130

12 300000301 Flue gas nozzle Ø 150/153

12 97581497 Flue gas nozzle Ø 180

13 85188053 Inspection hatch - 3 sections

13 85188054 Inspection hatch - 4 sections

13 85188055 Inspection hatch - 5 sections

13 85188056 Inspection hatch - 6 sections

13 85188057 Inspection hatch - 7 sections

13 85188058 Inspection hatch - 8 sections

13 85188059 Inspection hatch - 9 sections

14 200000204 Anti-backflow thermostat

15 83758077 Mounting square

16 95363355 Static thermostat

17 200000095 Electric circuit - Anti-backflow thermostat

18 83665501 Screw bag

Insulating material for body

19 200000510

Complete insulating material for body - 3

sections

19 200000511

Complete insulating material for body - 4

sections

19 200000512

Complete insulating material for body - 5

sections

19 200000513

Complete insulating material for body - 6

sections

19 200000514

Complete insulating material for body - 7

sections

19 200000515

Complete insulating material for body - 8

sections

19 200000186

Complete insulating material for body - 9

sections

20 97550513 Insulation under burner - 3 sections

20 97550514 Insulation under burner - 4 sections

20 97550515 Insulation under burner - 5 sections

20 97550516 Insulation under burner - 6 sections

20 97550517 Insulation under burner - 7 sections

20 97550518 Insulation under burner - 8 sections

20 97550519 Insulation under burner - 9 sections

21 83885655 Insulation back of hearth - 3 sections

21 83885656 Insulation back of hearth - 4 sections

21 83885657 Insulation back of hearth - 5 sections

21 83885658 Insulation back of hearth - 6 sections

21 83885659 Insulation back of hearth - 7 sections

21 83885660 Insulation back of hearth - 8 sections

21 83885661 Insulation back of hearth - 9 sections

22 94285095 Tube of silicon mastic

23 96960227 Brush

Gas line

50 200003131 Complete gas circuit - 3 sections

51 85185507 FURIGAS burner drawer - 3 sections

52 200003132 Complete gas circuit - 4 sections

52 200003133 Complete gas circuit - 5 sections

52 200003134 Complete gas circuit - 6 sections

53 200003135 Complete gas circuit - 7 sections

53 200003136 Complete gas circuit - 8 sections

53 200003137 Complete gas circuit - 9 sections

54 85185508 FURIGAS burner drawer - 4 sections

54- 85185509 FURIGAS burner drawer - 5 sections

54 85185510 FURIGAS burner drawer - 6 sections

55 85185511 FURIGAS burner drawer - 7 sections

55 85185512 FURIGAS burner drawer - 8 sections

Ref. Code no. Description

Page 39

39

01/02/11 - 300002915-001-E DTG 130 Eco.NOx

55 85185513 FURIGAS burner drawer - 9 sections

56 83885533 FURIGAS burner + Screws

57 95360220 Pressure socket

58 83754945 Earth cable

59 85188921 Complete ignition burner - 3-7-8-9-10 sections

60 85188922 Complete ignition burner - 4-5-6 sections

61 85185514

Ignition burner gas supply pipe - 3-7-8-9-10

sections

62 85185515 Ignition burner gas supply pipe - 4-5-6 sections

63 85185516 Valve

64 85185517 Elbow flange

65 85185518 Right flange

66 95023314 Gasket

67 85185519 Box + Wiring

68 85184904 Burner cable

69 94952101 N374 1/2" x 1" nut

70 94952081 Schraubenmutter N371 1/2"

71 95013062 Green seal 30x21x2

72 97549898 Gas inlet pipe - 3-4-5-6 sections

73 97549899 Gas inlet pipe - 7-8-9 sections

74 83885635 Burner drawer insulation kit 3 sections

74 83885636 Burner drawer insulation kit 4 sections

74 83885637 Burner drawer insulation kit 5 sections

74 83885638 Burner drawer insulation kit 6 sections

75 83885639 Burner drawer insulation kit 7 sections

75 83885640 Burner drawer insulation kit 8 sections

75 83885641 Burner drawer insulation kit 9 sections

76 83665502 Screws

77 85187007 Conversion set H/E/GZ50

77 85187004 Conversion set L/LL/GZ410

77 85187005 Propane conversion kit

Casing

86 85188507 Casing - 3 sections

86 85188508 Casing - 4 sections

86 85188509 Casing - 5 sections

86 85188510 Casing - 6 sections

86 85188511 Casing - 7 sections

86 85188512 Casing - 8 sections

86 85188513 Casing - 9 sections

87 85188521 Front plate - 3 sections

87 85188522 Front plate - 4 sections

87 85188523 Front plate - 5 sections

87 85188524 Front plate - 6 sections

87 85188525 Front plate - 7 sections

87 85188526 Front plate - 8 sections

Ref. Code no. Description

87 85188527 Front plate - 9 sections

88 97525376 Funnel

89 94820110 Catch

90 94820120 Pin

91 85188528 Complete right hand side panel

92 85188529 Complete left hand side panel

93 200000254 Upper rear panel - 3 sections

93 200000255 Upper rear panel - 4 sections

93 200000256 Upper rear panel - 5 sections

93 200000257 Upper rear panel - 6 sections

93 200000258 Upper rear panel - 7 sections

93 200000259 Upper rear panel - 8 sections

93 200000270 Upper rear panel - 9 sections

94 85188542 Lower back panel - 3 sections

94 85188543 Lower back panel - 4 sections

94 85188544 Lower back panel - 5 sections

94 85188545 Lower back panel - 6 sections

94 85188546 Lower back panel - 7 sections

94 85188547 Lower back panel - 8 sections

94 85188548 Lower back panel - 9 sections

95 85188549 Complete door - 3-4 sections

95 85188550 Complete door - 5-6 sections

95 85188551 Complete door - 7-8 sections

95 85188552 Complete door - 9 sections

96 85188553 Complete top panel - 3-4 sections

96 85188554 Complete top panel - 5-6 sections

96 85188555 Complete top panel - 7-8 sections

96 85188556 Complete top panel - 9 sections

99 85188535 Additional part set

100 97525372 Narrow screen

101 97525373 Wide scren

102 97525374 Narrow shutter

103 97525375 Wide shutter

104 97525370 Narrow body

105 97525371 Wide body

106 200001290 Housing screws packet

Control panels

Z

Control panel instructions

GL25 B control panel

GL27 D control panel

Ref. Code no. Description

Page 40

© Copyright

All technical and technological information contained in these technical instructions, as well as any

drawings and technical descriptions supplied, remain our property and shall not be multiplied

without our prior consent in writing.

Subject to alterations.

01/02/11

DE DIETRICH THERMIQUE

57, rue de la Gare F- 67580 MERTZWILLER - BP 30

DE DIETRICH THERMIQUE S.A.S.

www.dedietrich-thermique.fr

DE DIETRICH REMEHA GmbH

www.dedietrich-remeha.de

VAN MARCKE

www.vanmarcke.be

WALTER MEIER (Klima Schweiz) AG

www.waltermeier.com

DE

BE

CH

NEUBERG S.A.

www.dedietrich-heating.com

LU

FR

DE DIETRICH

www.dedietrich-otoplenie.ru

RU

ÖAG AG

www.oeag.at

AT

Direction des Ven te s France

57, rue de la Gare

F- 67580 MERTZWILLER

+33 (0)3 88 80 27 00

+33 (0)3 88 80 27 99

Rheiner Strasse 151

D- 48282 EMSDETTEN

+49 (0)25 72 / 23-5

+49 (0)25 72 / 23-102

info@dedietrich.de

Weggevoerdenlaan 5

B- 8500 KORTRIJK

+32 (0)56/23 75 11

Bahnstrasse

24

CH-8603 SCHWERZENBACH

+41 (0) 44 806 44 24

+41 (0) 44 806 44 25

39 rue Jacques Stas

L- 2010 LUXEMBOURG

+352 (0)2 401 401

ул. Гиляровс кого , д. 8

129090 г. Москва

+7 495 988-43-04

+7 495 988-43-04

dedietrich@nnt.ru

Schemmerlstrasse 66-70

A-1110 WIEN

+43 (0)50406 - 61624

+43 (0)50406 - 61569

dedietrich@oeag.at

ch.klima@waltermeier.com

DE DIETRICH

www.dedietrich-heating.com

CN

Room 512, Tower A, Kelun Building

12A Guanghua Rd, Chaoyang District

C-100020 BEIJING

+86 (0)106.581.4017

+86 (0)106.581.4018

+86 (0)106.581.7056

+86 (0)106.581.4019

contactBJ@dedietrich.com.cn

Serviceline +41 (0)8 00 846 846

WALTER MEIER (Climat Suisse) SA

Z.I. de la Ve yr e B, St-Légier

CH-1800 VEVEY 1

+41 (0) 21 943 02 22

+41 (0) 21 943 02 33

ch.climat@waltermeier.com

Serviceline +41 (0)8 00 846 846

AD001-AC

офис 52

Loading...

Loading...