DeDietrich Elitec DTG 1304 Eco.NOx/V, Elitec DTG 1305 Eco.NOx/V, Elitec DTG 1306 Eco.NOx/V Technical Instructions

Page 1

Elitec

DTG 1300 Eco.NOx/V

Gas-fired boilers

English

23/06/05

Technical

instructions

Page 2

Contents

Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1 Important recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Symbols used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Composition of the range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3 Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6 Main dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7 Package list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1 Implementation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2 Levelling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Control panel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connecting the furnace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2 Connecting the gas channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3 Connecting to a chimneye . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4 Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Adapting to another gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

1 Attaching the label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2 Changing the burner injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3 Changing the ignition burner injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4 Setting the injector pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5 Pressure settings and calibrated injector markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Commissionning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

1 Refilling the installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2 Final checks before commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3 Commissionning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4 Furnace operation equipped with safety box 577 DBC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5 Checks and adjustments after commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1 Cleaning main burner and ignition burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2 Cleaning heater body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 5

Incidents and solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 3

Declaration of compliance

1

Declaration of compliance A.R. 8/1/2004 - BE

Manufacturer DE DIETRICH THERMIQUE S.A.S.

57 rue de la gare

F-67580 MERTZWILLER

+33 3 88 80 27 00

*

+33 3 88 80 27 99

+

Issued by See end of notice

We hereby certify that the range of equipment specified below is in accordance with the format stated in the EC declaration of comformity,

that it is manufactured and distributed in accordance with the regulations and requirements in European Directives and with the regulations

and requirements defined in the Royal Decree dated 8th January 2004.:

Product type Floor-standing gas boiler DTG 1300 Eco.NOx/V

Formats 18, 24, 30 kW

Standard applied - Royal Decree dated 8th January 2004

- 90/396/EEC Gas Appliance Directive

Reference Standard : EN 297 ; EN 437

- 73/23/EEC Low Voltage Directive

Reference Standard : EN 60.335.1

- 89/336/EEC Electromagnetic Compatibility Directive

Reference Standard : EN 61000-6-3 ; EN 61000-6-1

- 92/42/EEC Efficiency Directive * *

Low temperature gas boiler

Inspecting organisation Gas Wärme Institut / DVGW PV N° 14846 (06/01/2004)

Measured values NOx: < 70 mg / kWh

CO: < 10 mg / kWh

Date: 22 juin 2004 Signature

Technical Director

Mr. Bertrand Schaff

1

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

3

Page 4

1 Important recommendations

Introduction

For a proper operating of the boiler, follow carefully the

instructions.

Any intervention on the appliance and heating equipment

must be carried out by a qualified technician.

The manufacturer is not liable for any improper use of the

appliance or failure to maintain or install the unit correctly

(the user shall take care to ensure that the system is

installed by a qualified fitter).

2 Regulations

Certificate of compliance

For the application of article 25 of the modified decree dated 02/08/

1977 and of article 1 of the modifed decree dated 05/02/1999, the

installation engineer must be in possession of the certificates of

compliance approved by the Ministries in charge of construction and

gas safety:

- Different forms (forms 1, 2 or 3) for a new gas installation

- "Model 4" in particular after replacing a furnace with a new one

Residential buildings

Statutory terms and conditions of installation and maintenance:

The installation and maintenance of the appliance must be carried

out by a qualified professional in compliance with the statutory texts

of the codes of conduct in force, particularly:

- Order of 2 August 1977

Technical and safety rules applicable to combustible gas and

liquefied hydrocarbon installations situated inside residential

buildings and their annexes.

- NF P 45-204 standards

Gas installation, (formerly DTU 61-1, gas installations: April 1982,

addendum no 1: July 1984).

Check that the equipment is properly set for the type of gas

used.

Keep to the polarity shown on the terminals : phase (L),

neutral (N) and earth

Check the seal on the gas and water pipe connections.

Establishments open to the public

Statutory terms and conditions of installation:

The installation and maintenance of the appliance must be carried

out in compliance with the statutory texts and rules of the codes of

conduct in force, particularly:

- Safety regulations against fire and panic in establishments open to

the public:

a. General regulations

For all appliances:

- Articles GZ - Installations operating on combustible gases and

liquefied hydrocarbons.

Then, depending on use:

- Articles CH-Heating, ventilation, refrigeration, air conditioning and

production of steam and domestic hot water.

b. Instructions specific to each type of establishment open to the

public (hospitals, stores, etc.)

4

.

- Local Sanitary Regulations

For appliances connected to the electricity network:

- NF C 15-100 standards Low voltage electrical installation - Rules..

4

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 5

3 Symbols used

Symbols used

Caution danger

Risk of injury and damage to equipment.

Attention must be paid to the warnings on safety

of persons and equipment.

Z

Specific information

Reference

Information must be kept in mind to maintain

comfort.

Refer to another manual or other pages in this

instruction manual.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

5

Page 6

1Introduction

Description

The ELITEC DTG 1300 Eco.NOx/V boiler is a floor-standing cast

iron gas-fired boiler with an atmospheric burner with very low

pollutant emission with integrated domestic hot water production.

The boiler must only be connected to a chimney.

The design of the cast iron heater body with interleaved spurs gives

very high performance. Also, the baffling in the smoke circuits limits

the natural chimney effect and gives high performance yields.

2 Composition of the range

Heating and domestic hot water

- DTG 1300 Eco.NOx/V or H Panel B:

Boiler with (110 ou 130 l) domestic hot water tank and electronic

command panel

- DTG 1300 Eco.NOx/V or H Panel E:

Boiler with (110 ou 130 l) domestic hot water tank and electronic

command panel with extractable or built-in Easymatic regulator

3 Certifications

3.1 Introduction

97/23/CE Directive

The boilers are equipped with an anti smoke release safety device ;

they may therefore be installed in inhabited areas. It consists of a

thermostat located in the anti-blowback which causes the burner to

stop for 15 minutes. This is indicated by an alarm light flashing on the

control panel. The boiler automatically restarts after 15 minutes if the

cause of the cut off has been removed.

The tightly packed insulation of the boiler equipment reduces losses

into the atmosphere to very low levels.

- DTG 1300 Eco.NOx/V or H Panel D:

Heater with (110 ou 130 l) domestic hot water tank and DIEMATIC

3 electronic command panel

The command panel gives priority to producing domestic hot

water.

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 EC.

De Dietrich boilers and DHW tanks conform to the regulations in

article 3.3 of the 97/23/CEE Directive and is backed by the CE mark

for the 90/396/CEE, 92/42/CEE, 72/73 CEE and 89/336/CEE

directives.

CE identification no: CE-0085BP0002

Type B11

boiler

BS

The boilers leave the factory operating with H natural gas. To operate

with L Natural gas or with propane: see chapter "Adapting to another

gas"

France:

Thermal performance level (according to NFD 30-002): B300

Performance class III boiler according to ATG B 84

recommendations.

Switzerland:

Boilers are tested under the LRV-92 standard.

6

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 7

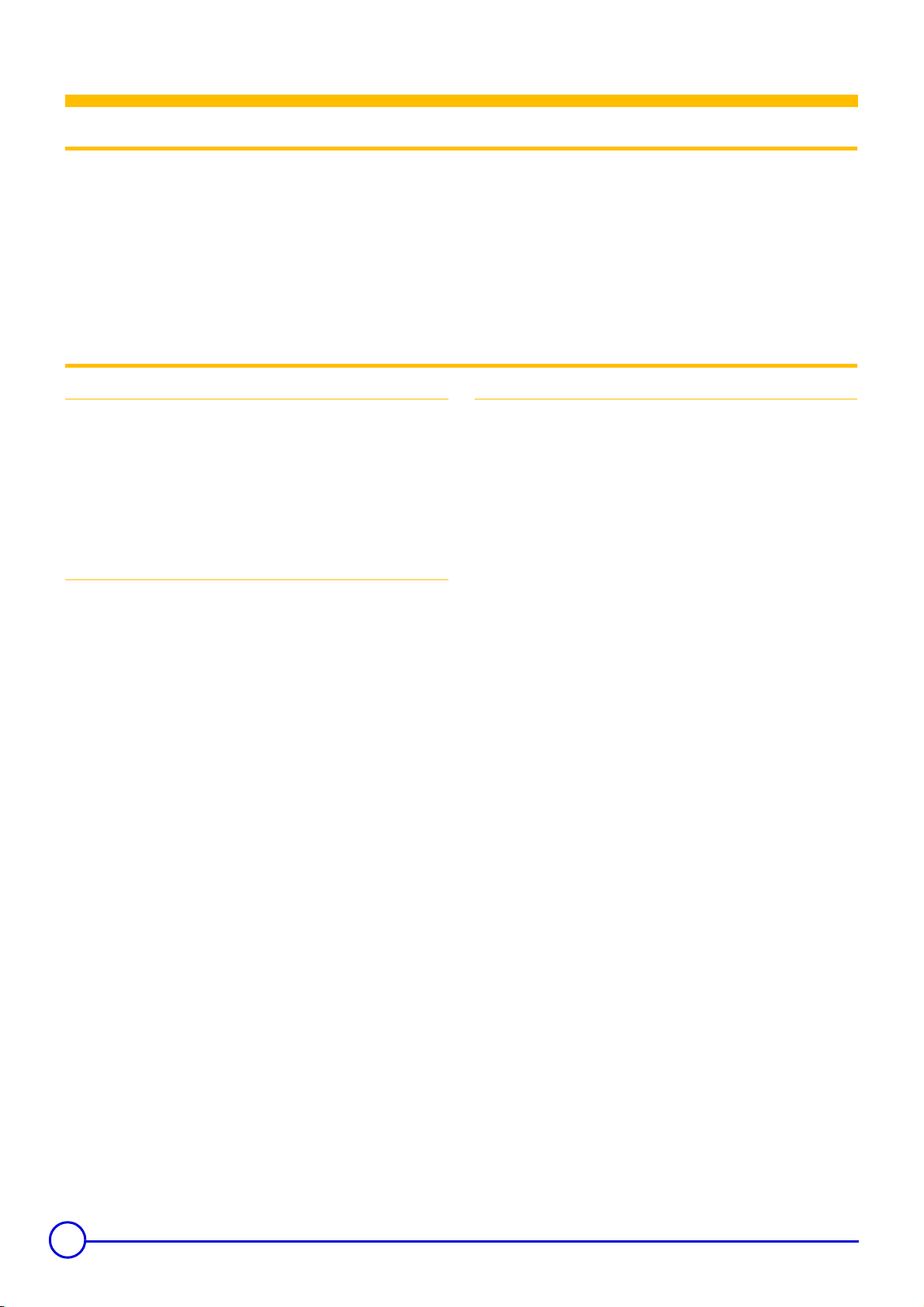

3.2 User country

User country Gas category Gas type Connection pressure (mbar)

FR

ES, PT, IE, CH, GB, DK, CZ, GR

IT, SE, NO, FI, IS

AT

DE

NL

LU

HU

II

II

II

II

II

II

II

2ESi3P

2H3P

I

2H

2H3P

2ELL3P

2L3P

2E3P

2ES3P

G20 20

G25 25

G31 37

G20 20

G31 30/37

G20 20

G20 20

G31 50

G20 20

G25 20

G31 50

G25 25

G31 50

G20 20

G25 20

G31 50

G20 25

G25.1 25

G31 30/50

4Main parts

1

2

9

6

4

8518N070

10

11

3

5

8

7

18

19

Gas regulation block: It has a progressive opening,

2

regulation valve and safety valve in series which is controlled

by the boiler adjustment dial.

3

Gas inlet

4

Burner

5

Flame inspection window

Ignition electrode: This ensures ignition burner ignition using

6

a high voltage spark.

Ionisation probe: This detects the presence of a burner

7

ignition flame through ionisation.

8

Ignition burner

9

Ignition burner gas supply pipe

Anti-smoke release thermostat (located on the rear wall of

the anti-blowback device): In the event of smoke release, the

burner is cut and the boiler goes into standby for 15 minutes. It

10

must not be switched off or moved at any time.The boiler

restarts normally after this thermostat has cooled and the 15

minutes has finished (indicated by an alarm indicator flashing

on the command panel).

11

Sensor tube

18

Domestic hot water tank

19

Flange for the domestic hot water tank

Safety box: Mounted on the gas block to ensure and check

1

ignition sequences, plus burner operation and extinguishing

sequences.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

7

Page 8

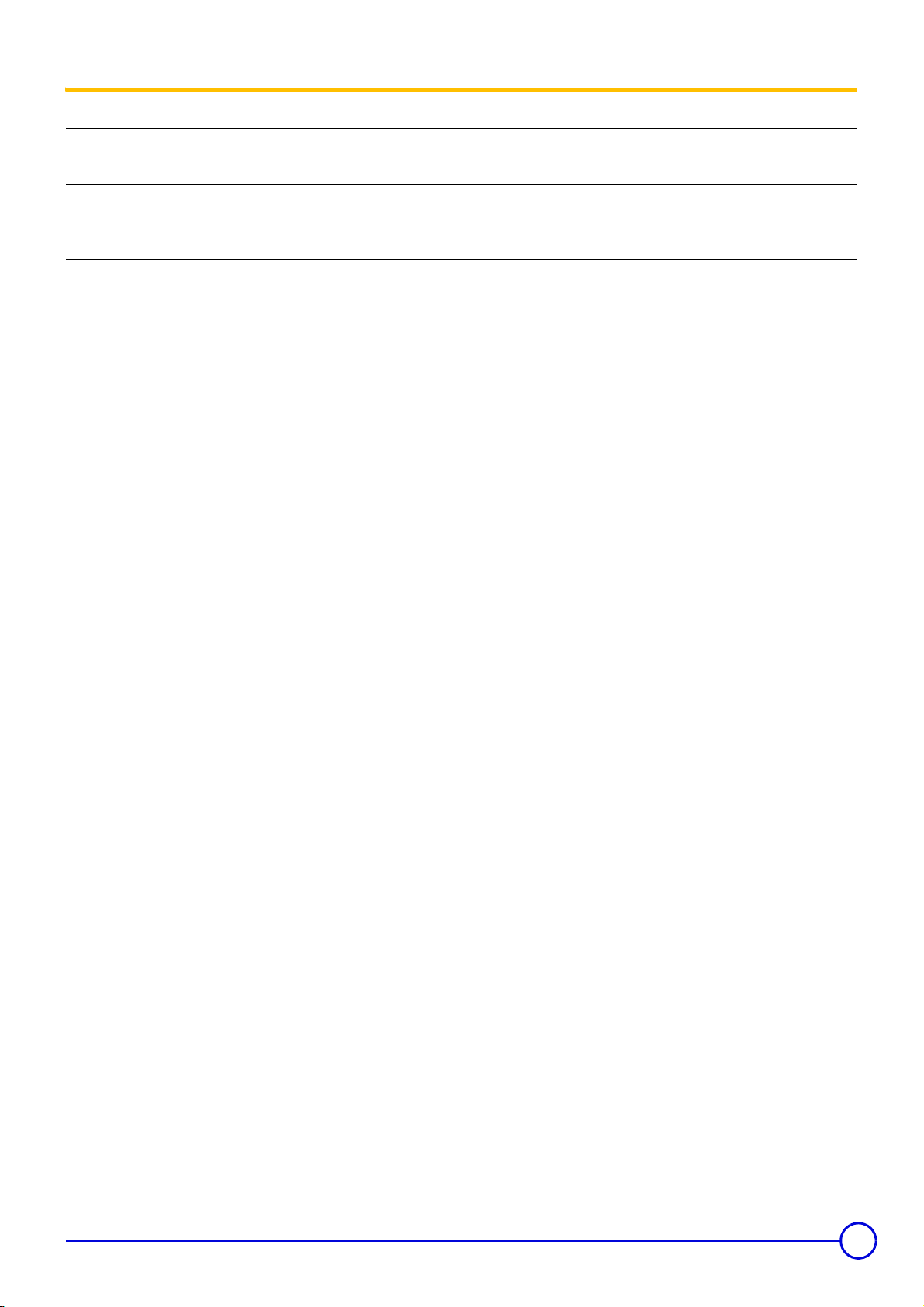

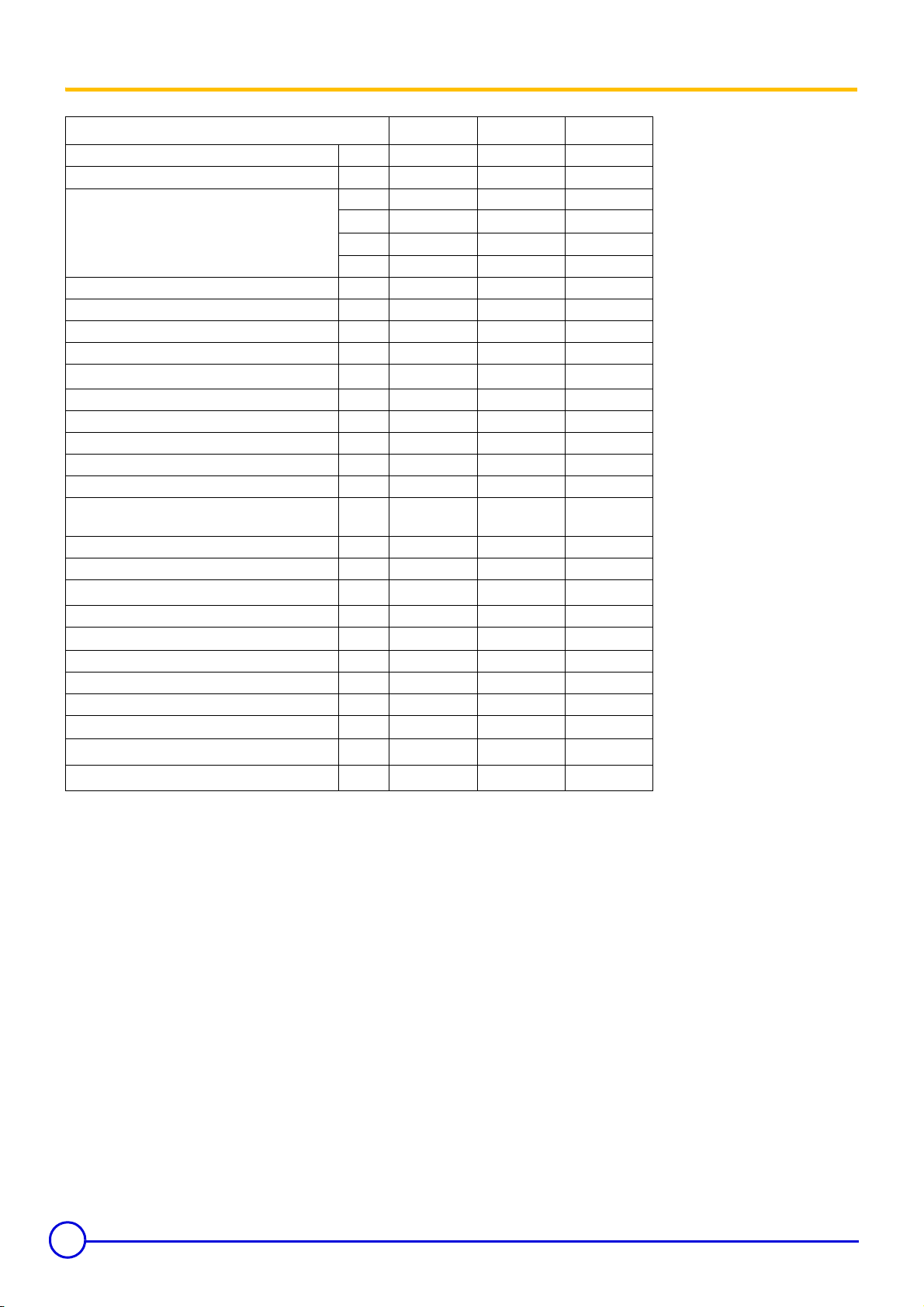

5 Technical characteristics

DTG ... Eco.NOx 1304 1305 1306

Nominal power Pn kW 12 18 24

Power input kW 13,4 20,1 26,7

Gas flow rate

- Natural gas H (G20)

- Natural gas L (G25)

- Propane (G31)

(1)

(1)

3

/h

m

3

/h

m

1,42 2,13 2,83

1,65 2,47 3,29

kg/h 1,04 1,56 2,07

Number of cast iron parts 3 4 5

Number of nozzles 2 3 4

Mass flue gas flow rate (G20) kg/h 48 53 70

Smoke temperature °C 100 120 125

Minimal ionisation current

(2)

µA 0,3 0,3 0,3

Required depressurisation at the nozzle mbar 0,05 0,05 0,05

Min water temperature °C 30 30 30

Max water temperature °C 90 90 90

Maximum admissible operating pressure bar 4 4 4

Electrical connection V-HZ 230-50 230-50 230-50

Absorbed electrical power

(Heating mode)

W121212

Gas connection inch R 1/2 R 1/2 R 1/2

Water connection inch R 1 R 1 R 1

Smoke connection (internal diameter) mm

110 / 111

(3)

110 / 111

(3)

125 / 130

Water capacity l 7,1 8,8 10,5

Loss of hydraulic circuit load at

∆T = 15 K

mbar 4 8 15

Net weight kg 87 100 118

Shipping weight kg 97 113 133

Tank storage capacity l 110 110 130

Hourly flow at

Specific flow à ∆T = 30 K selon EN 625

Flow in 10 minutes à

(1)

15°C / 1013 mbar

(2 )

In order to measure the ionisation current, take out the ionisation

∆T = 35 K

∆T = 30 K

(4) (6)

(4) (6)

l/h 440 590 690

l/min 19,0 19,0 22,0

l/min 190 190 220

cable connector and insert a micro-ammeter.

(3)

According to the national standard (possible adaptation of the two

diameters).

(4)

Domestic cold water à 10°C

(5)

Domestic hot water at 45°C

Primary input temperature at 80°C

(6)

Set DHW temperature chaudière à 80°C

Domestic hot water à 40°C

Tank load temperature at 60°C

1 mbar = 10 mmCE = 10 daPa = 100 Pa

(3)

8

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 9

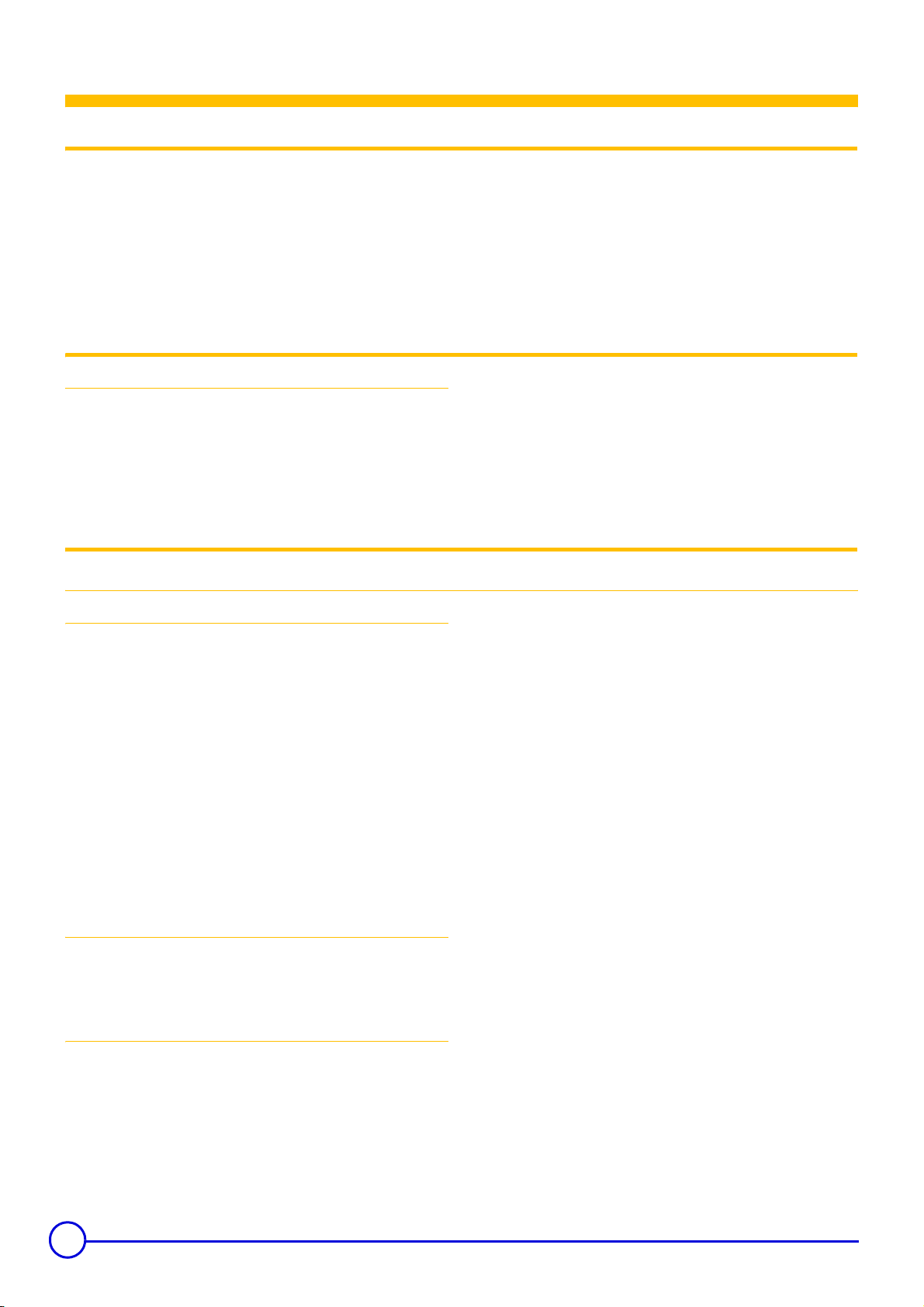

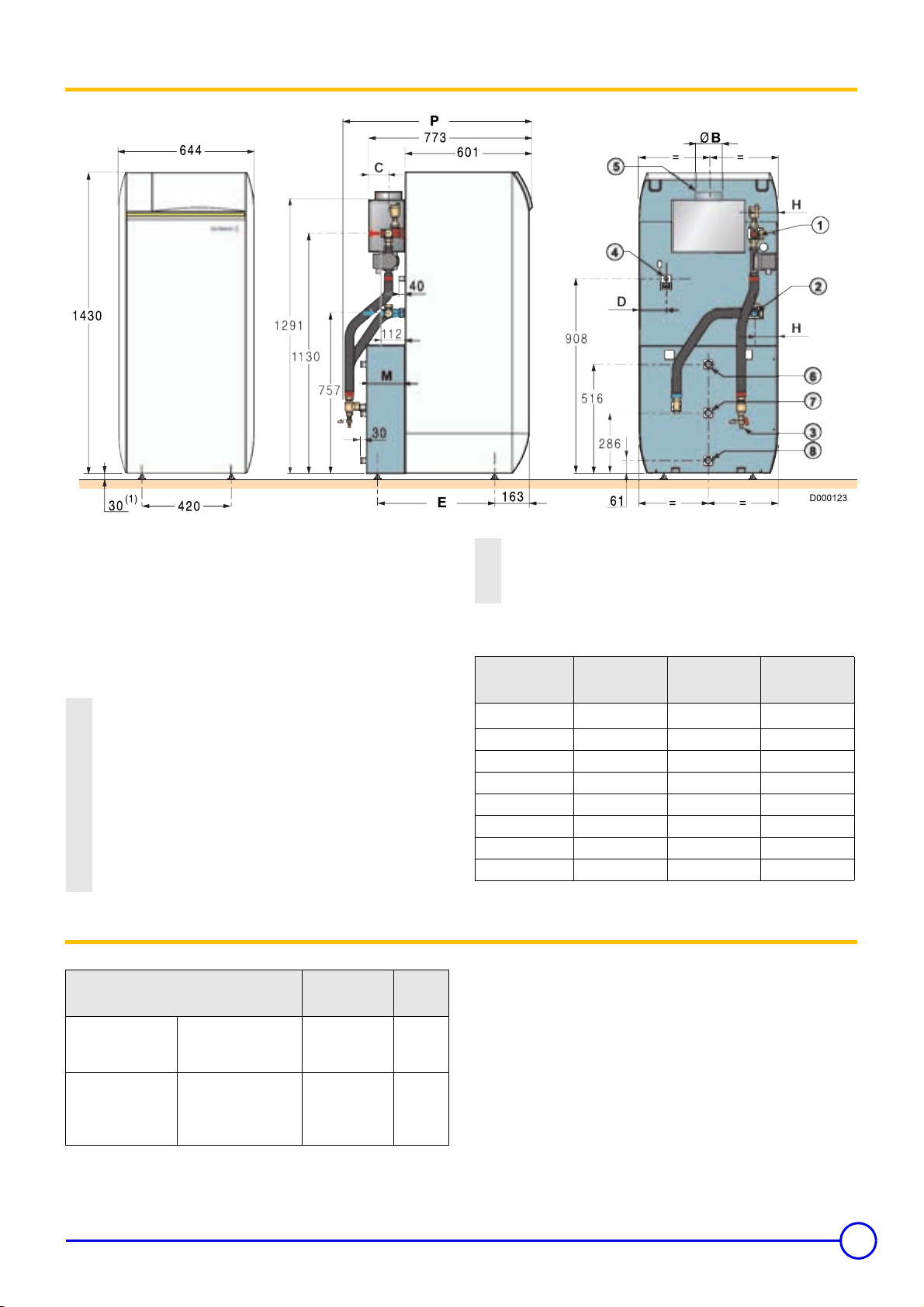

6 Main dimensions

(1)

Adjustable feet : basic sizes : 40 mm. Can be adjusted from 40 mm

to 55 mm. All height dimensions are given with a feet setting of 40

mm (see chapter Levelling).

(2)

According to the national standard (possible adaptation of the two

diameters)

R = Thread

G = Exterior cylinder thread, sealed by flat joint

Heating outlet

1

R 1 (1") for one single boiler

G1 (1") for boiler with DHW tank

Heating return

2

R 1 (1") for one single boiler

G1 (1") for boiler with DHW tank

Filling and emptying tap (connection for 14 mm interior diameter

3

pipe)

4 Gas inlet ø K

5 Smoke nozzle ø B

7 Package list

Pack

no.

GL 30

GL 11

GL 12

GL 25

GL 26

GL 35

GL 27

Boiler assembly

Control panel

Description Reference

DTG 1304 Eco.NOx/V

DTG 1305 Eco.NOx/V

DTG 1306 Eco.NOx/V

B (Base)

E (Easymatic)

ER (Easyradio)

D (Diematic 3)

8518-9024

8518-9025

8518-9026

8518-7000

8518-7001

100000473

8518-7002

6 Hot water outlet R 3/4 (3/4")

7 Circulation R 3/4 (3/4")

8 Cold water inlet R 3/4 (3/4")

IN ORDER TO FACILITATE BLEEDING, the installation must be

filled via the drainage/filling valve.

Formats DTG

...Eco.NOx/V

øB

C 100 93 85

D 156 120 84

E 550 550 635

H 143 107 71

øK (inch) R 1/2 R 1/2 R 1/2

M 182 182 267

P 878 878 1050

Refer to the applicable price list for any optional features used.

Z

1304 1305 1306

110 / 111

(2)

125 / 130

(2)

150 / 153

(2)

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

9

Page 10

Installation

5

ht

w

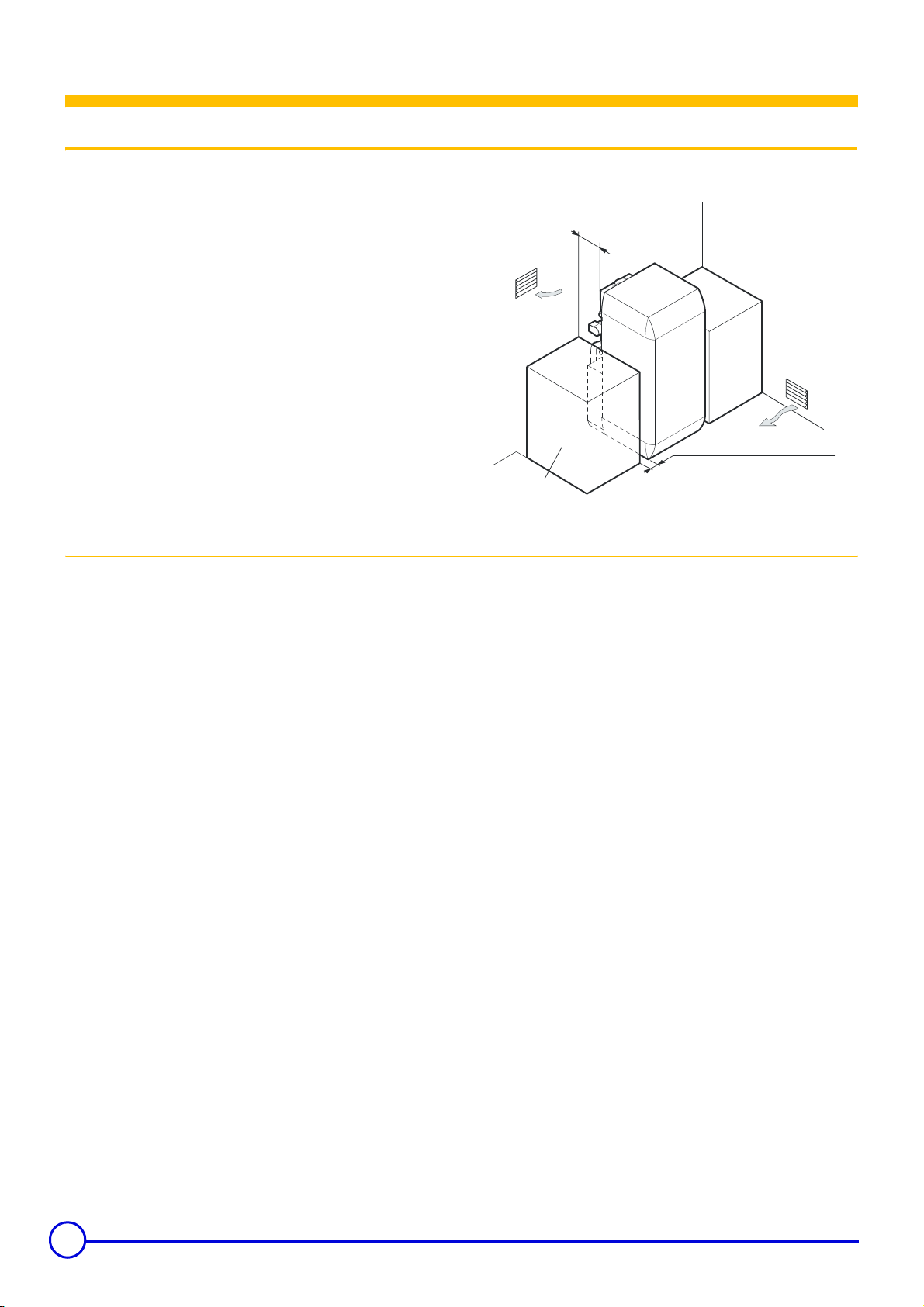

1 Implementation

The boiler can be installed :

- in the kitchen,

- in the cellar,

- in the boiler house.

It is necessary to have in every case :

- 5 cm on one of the boiler sides,

- 70 cm minimum in front,

- and 5 at the rear.

Also have the required space for installing the expansion reservoir

and the heating circulator.

5 cm from the

cm to the left or rig

Furniture

82518N07

1.1 Ventilation

The ventilation section, obligatory in the location where the heater is

installed where there is a direct air inlet must conform with the DTU

61.1 (P45-204) standard and in particular with the instruction on

general management (Book 1764, April 1982).

In order to avoid damage to the boilers, it is necessary to

prevent the contamination of combustion air by chlorine

and/or fluoride compounds, which are particularly

corrosive.

These compounds are present, for example, in aerosol sprays,

paints, solvents, cleaning products, washing products, detergents,

glues, snow clearing salts, etc.

Therefore :

- Do not suck in air evacuated from premises using such products:

hairdressing salons, dry cleaners, industrial premises (solvents),

premises containing refrigeration systems (risk of refrigerant

leakage), etc.

- Do not stock such products close to the boilers.

If the boiler and/or peripheral equipment are corroded by such

chloride or fluoride compounds, the contractual guarantee

cannot be applied.

10

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 11

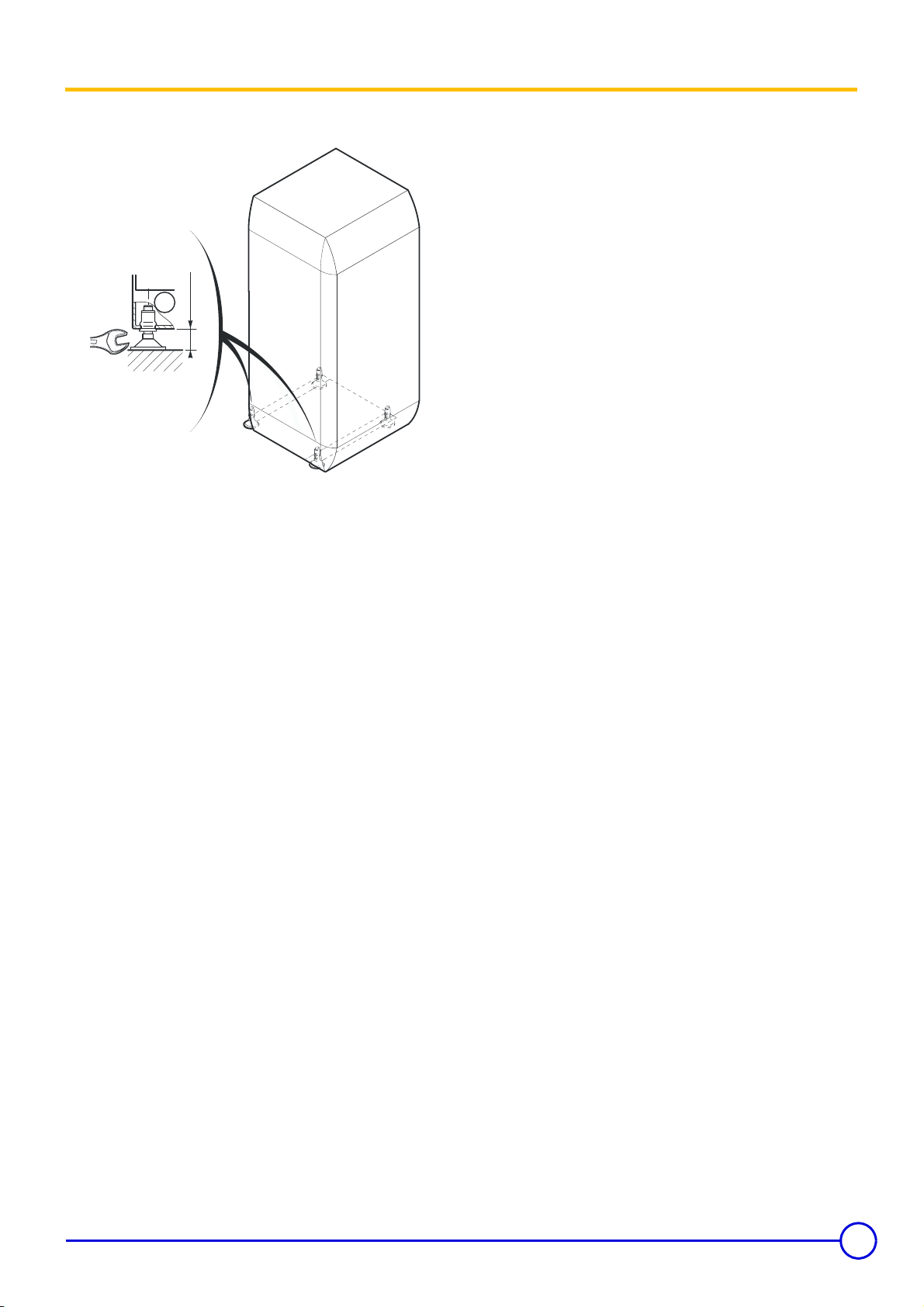

2 Levelling

Levelling is done using the 4 feet located on the heater socket and

using a flat screwdriver.

17

Lift the tank slightly with a lever to adjust the feet.

(1)

Adjustable feet : Basic dimension 40 mm. Can be adjusted from

40 mm

880351N7

40 mm to 55 mm.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

11

Page 12

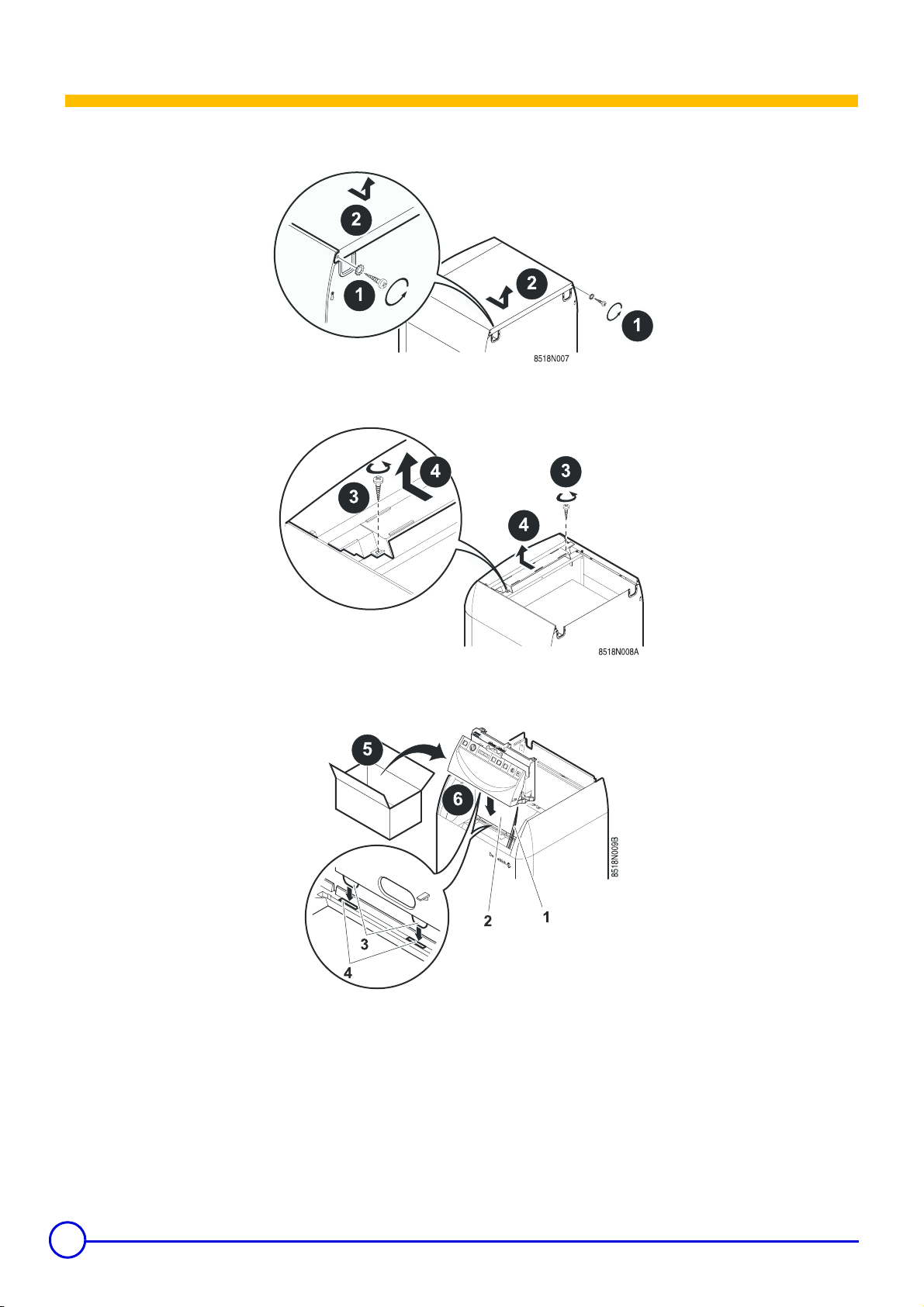

Control panel assembly

The command panel is attached as follows :

1. Unscrew the 2 mounting screws at the back of the column head. 2. Remove the upper casing of the boiler.

3. Unscrew the 2 mounting screws from the screen

5. Take the command panel out of its packaging.

6. Slide the panel along the front plate. Push the 1 tubes through the

lower opening on the panel case.

. 4. Take out the shutter + screen assembly.

12

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 13

7. Take out the heater door.

`Keep the position of the contact spring with relation to the bulbs.

8. Place the bulbs in the sensor tube in front of the boiler. Push them

into the funnel until it butts against it.

9. Use the contact spring 5 for the sensor tube if bulbs 6 are on

number 2.

11. Push the screen support against the front plate.

12. Tighten the 2 pre-assembled plate screws after having pushed

the support fixing wings against the screws.

`Tighten the assembly before engaging the glove finger.

If there are 4 bulbs, the sensor tube contact spring is useless.

10. Then carefully fold the tubes and replace the traction stop tongue in the funnel.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

13

Page 14

13. Attach the burner cable to the 12 connector studs located on the

inner face of the command panel.

16. Attach the anti-release safety device onto the 3 connector studs on the command panel.

14. Connect the earth cable to the clip located on the front plate.

15. Open the side of the panel.

17. Close the panel front. 18. Re-assemble the shutter * screen assembly.

Connect the panel's electrical connections according to the

Z

panel's instructions

19. Thread the connection label into the screen slots. Correctly place the label using the truncated corner 7.

14

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 15

20. Screw the panel front onto the screen using a mounting screw. Re-assemble the door and the column head.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

15

Page 16

Connecting the furnace

1 Hydraulic connections

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

1.1 Important recommendations for connecting the boiler to the heating circuit

There must be no total or partial closing mechanism

between the boiler and the safety valves (France: DTU -

65.11, § 4.22 - NF P 52-203).

Heating installations must be designed and implemented

to prevent heating circuit water and products contained in

it returning to the drinking water system (article 16-7

Departmental Health Regulations). A CB disconnector

(area disconnector for different uncontrollable

pressures)must be installed for filling the heating circuit

according to the NF P 43-011 standard.

Prior connecting the heating circuit hydraulic connections, it is vital

that the heating circuits are rinsed to prevent articles that may

damage certain parts from being introduced (safety valves, pumps,

non return valve...).

1.2 Hydraulic connection of the water circuit for domestic use

Please see the document delivered with the domestic hot water

Z

preparer.

2 Connecting the gas channel

Each time, a blocking tap will be located as near as possible to the

heater.

In the event where the burner is located at the highest point in the

installation, a dry running or water pressure control device my be

fitted.

Take care to ensure the hydraulic isolation of the primary and

secondary circuits using stop valves in order to facilitate maintenance

operations on the calorifier. These are used to carry out maintenance

on the tank and its systems without draining the entire installation.

These valves are also used to isolate the calorifier when conducting

a pressurised check on the leak tightness of the installation if the test

pressure for the calorifier is greater than the admissible operating

pressure.

IN ORDER TO FACILITATE BLEEDING, the installation must

be filled via the drainage/filling valve

Pipe diameters must be defined in accordance with ATG's

(Association Technique de Gaz) B171 specifications.

The load loss between the meter and heater must be lower than 1

mbar (heater operating).

Equipment pressure supply values :

- Natural gas H/E (G20) : 20 mbar

- Natural gas L/LL (G25) : 25 mbar

- Propane (G31) : 37 mbar

The boilers leave the factory operating with H/E natural gas. For

operating with natural gas L or propane, carry out the actions

described in the chapter "Adapting to another gas".

16

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 17

3 Connecting to a chimneye

The equipment must be installed following the codes of practice

using sealed stainless steel, aluminium or internally meshed tubing

capable of withstanding hot combustion gases and any likely acid

condensation.

1

4 Electrical connections

Connections must be made by a qualified technician.

Connections inside the command panel must not be

modifed in any way.

2

The pipe must be laid out to allow any likely condensation to drain.

It must be in accordance with existing regulations for pipes used for

this purpose. Standard meshed connection pipes are to be avoided.

The pipe connecting the outlet conduit must also be as short as

possible and without a reduced diameter.

The vertical section of the draught diverter outlet must be a minimum

length 3x the diameter of the nozzle before an elbow joint is fitted.

The pipe must have a diameter not less than the heater's nozzle

diameter along its whole length.

This pipe must be able to be easily disassembled and must not have

a sudden change in diameter.

The outlet conduit must be maintained in a good condition, checked

and cleaned at least once a year.

Boiler Good

Boiler Poor

Keep to the polarity shown on the terminals : phase (L),

neutral (N) and earth

4

.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

17

Page 18

Adapting to another gas

Operations to be carried out to allow the change from H/E natural gas

to L/LL natural gas or to propane and vice versa.

The actions described below must be carried out by a

qualified technician.

Check the seals for the gas.

1 Attaching the label

This indicates the type of gas for which the burner is set.

2 Changing the burner injectors

Lift out the injector with a number 12 spanner assemble the new

injectors with their new joint.

Conversion kits

Natural gas H/E

Natural gas L/LL

Propane

Nozzle marking

Natural gas H/E 210B 2,10

Natural gas L/LL 245B 2,45

Propane 140A 1,40

Package GL34

8518-7007

Package GL31

8518-7004

Package GL32

8518-7005

Nozzle diameter

(mm)

3 Changing the ignition burner injector

.

4

Prior to re-assembling the injector for each burner also replace

the aluminium joint. First tighten the injectors by hand and

carefully lock them using a spanner.

Nozzle marking

3

1

Natural gas H/E 4 0,40

Natural gas L/LL

(France)

Natural gas L

≠ France)

(

Propane 3 0,30

40,40

50,50

Nozzle diameter

(mm)

Unscrew the connecting nut (14 spanner),

Pull the gas supply pipe towards yourself.

Take out the ignition burner nozzle.

Fit the new nozzle .

Re-attach the supply tube (14 spanner)

18

France:The 40 mm ignition burner injection fitted in the factory

is suitable for operation on natural gas H/E and L/LL (no

conversion necessary for switching from H/E to L/LL and vice

versa).

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 19

4 Setting the injector pressure

5 Pressure settings and calibrated injector markings

`Connect a manometer to the pressure socket located on the

manifold.

`Remove the protective cover C on the regulator by unscrewing

it using a screwdriver.

`Set the pressure on the injectors by moving the gas regulator on

the valve.

Manifold pressure (mbar)

Natural gas H 15

Natural gas L 12,1

Propane 29

Number of parts in the heater 4 5 6

Nozzle H/E 210B 210B 210B

Nozzle L/LL 245B 245B 245B

Nozzle Propane 140A 140A 140A

Manifold pressure H/E mbar 15 15 15

Manifold pressure L/LL mbar 12,1 12,1 12,1

Manifold pressure

Propane

Gas flow rate H/E

Gas flow rate L/LL

Flow rate Propane Kg/h 1,56 2,07 2,59

mbar 29 29 29

3

m

m3/h

2,13 2,83 3,52

/h

2,47 3,29 4,10

Flows are stated at 15°C - 1013 mbar.

Setting the start up pressure

E Protective hood

F Ionisation probe connection

G Ignition electrode connection

Start up pressure may be set if necessary using a flat screwdriver,

after the protection has been removed E.

Start up pressure is set in the factory on minimum. If it is necessary

to optimise heater start up, it may be set on another value between

0º and 270º.

Gas valve opening diagram

Downstream pressure

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

Time (seconds)

19

Page 20

1 Refilling the installation

Aut

Dh

V

Aut

Commissionning

Firstly, fill the tank with domestic hot water.

Domestic hot water circuit

- Fill the calorifier via the cold water input pipe. If necessary, rinse

the domestic circuit (particularly when commissioning), allowing

the water to flow for a certain amount of time.

- Bleed the domestic circuit (tank and distribution network); to do

this:

- Completely fill the calorifier with water, leaving the hot water valve

open; close this valve only when the flow is regular and there is no

noise in the pipes.

- Then successively degas all the hot water pipes by opening the

corresponding valves in order to prevent the noise caused by air

movement when drawing off water.

- Check the safety devices (particularly the valve or safety unit),

referring to the instructions provided with these components.

When reheating domestic hot water, a certain amount of water

may escape via the valve or the safety unit because of the

expansion of the water in the calorifier. There is no cause for

concern at this absolutely normal phenomenon, which must in

no event be hindered.

Heating circuit

The heating circuit (boiler and tank exchanger) must be filled using

the drainage tap to the rear of the tank. When filling the heating

circuit, correctly bleed the exchanger on the domestic water calorifier

as follows::

Unscrew the cap on the automatic bleed valve by a few turns

Ensure that the non-return angle valve is in the automatic

position

Ensure that the drainage tap is in the open position

Fill the low flow heating circuit using the drainage tap in order to

favor the bleed

After filling the installation, close the drainage tap

Unstick the load pump in necessary: to do this, unscrew the

protection cap in front of the pump and insert a screwdriver into the

slit (V) on the pump center line. Turn several times to the right and

left.

- Cold run the pump for a few minutes to enable priming.

- The heating circuit must be bled from the highest point of the

installation using a suitable bleeding device (not provided).

omatic

bleed valve

1

6

w pump

85 7518N0

0

2

omatic

position

3

2 Final checks before commissioning

Check the following points before starting the heater :

- Check that the equipment is properly set for the type of gas used.

The boilers leave the factory operating with H/E natural gas.

- Check the gas pressure upstream from the boiler.

- Check the seals on the gas and water connections.

20

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 21

3 Commissionning

The first start-up is to be performed by your installation

engineer.

- Open the gas blocking tap.

- Check that the safety thermostat has not triggered. Remove the

safety thermostat hood and press the reset button with a

screwdriver.

- Place the stop/start switch

4 Furnace operation equipped with safety box 577 DBC

The ignition and burner surveillance sequences are ensured by the

safety box.

Normal operating cycle

on On.

8

Operating principle

- Create a requirement for heat.

Please consult the document delivered with the command

Z

panel before carrying out any action with it.

- The safety box carries out its ignition cycle.

Switching off : Place the start/stop switch on Off.

Operating cycle on safety (start up without flame signal)

Required input signals

Box output signals

Contact closed

The box closes the TCH contact when there is a requirement for heat.

The ignition transformer TA integrated into the safety control box and

the ignition burner valve VBA (supply to the ignition burner) are

switched on.

Gas from the ignition burner is ignited by the ignition electrode and

within the time interval ts; a minimum current of 0.3 µA appears on

the ionisation sensor SF and the gas valve regulation flap (supplying

the principal burner) opens.

Required input signals

Box output signals

Contact closed

- If a flame is not detected before the safety time ts, the box makes

2 more ignition attempts. If, at the end of the last attempt, there is

still no flame signal, the box goes into safety and the safety

indicator comes on. To restart the heater, press the reset button on

the safety box.

- If there is a loss of flame in normal operation, the box automatically

repeats the start up sequence.

Resetting : The box is reset after going into safety by pressing the

reset button. If the reset button does not work, wait at least 15

seconds before trying a second time.

The box may be on safety on its first start up : press the reset

button to release it.

If the reset button is pressed in normal operation, the gas valves

close and the box starts a new ignition sequence.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

21

Page 22

Operating cycle with the anti-smoke release thermostat cut

off

Required input signals

Box output signals

Contact closed

In the event of smoke release, the burner is cut and the boiler goes

into standby for 15 minutes. This timed phase is indicated by an

alarm indicator flashing. The 15 minute timed period can only be

interrupted by a sector cut.

Key :

A Start of operation

A

1

A

2

Second ignition attempt

Third ignition attempt

B Formation of flame in ignition burner

C End of first ignition attempt

C

1

C

2

End of second ignition attempt

On safety through absence of flame signal

D Smoke anti-release thermostat cut

E Resetting

F Restart of heater

SF Burner flame signal

VA Alarm indicator

TA Ignition transformer

TAF Anti-backflow thermostat

TCH Heat requirement

VBA Ignition burner valve

VBP Main burner valve

ts Safety time : about 55 seconds

tn Anti-smoke release thermostat cooling time (times

vary)

t

TAF

Box standby time : 15 minutes

5 Checks and adjustments after commissioning

5.1 Checking pressure to the nozzle

`Unscrew the screw inside the nozzle pressure socket a few

turns.

`Connect a manometer to the pressure socket and check that

the pressure to the socket corresponds to the pressure stated

below. Adjust the pressure to the injectors if necessary.

`Tighten the pressure socket screw.

`Check the seal again

Manifold pressure (mbar)

Natural gas H/E 15

Natural gas L/LL 12,1

Propane 29

Checking burner safety

Cut the gas by closing the stop tap.

Check the reaction of the safety system. (Safety box on safety

because of ionisation fault).

Checking the safety thermostat

`Place the Summer/Winter switch on

to cut the heating

%

accelerator to prevent the temperature rising in the installation.

`Place the 3 position switch "

- AUTO - TEST STB" on the

!

TEST STB position. The burner starts regardless of the setting.

Keep the switch in this position until the safety thermostat cuts

(110ºC).

`To restart the heater, press the safety thermostat reset button

and repeat the starting operations.

22

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 23

Checking the anti-smoke release thermostat

In the event of smoke release by the anti-blowback device, the antirelease safety device switches off the burner with the safety box on

standby for 15 minutes (this is indicated by an alarm indicator

flashing).

Checking procedure :

Turn of the heater and take out the smoke duct linking the heater to

the chimney. Close off the smoke duct to the heater using a metal

sheet (or other heat proof material).

On start up, combustion products are evacuated to the back of the

heater by the anti-blowback device opening inside.

The anti-blowback thermostat triggers for a few seconds, cuts the

burner and starts the safety box timer (alarm indicator flashing).

After checking, re-assemble the smoke duct connecting the heater to

the chimney.

Wait for about 5 minutes (thermostat cooling time) the cut and

reconnect the current using the Start/Stop switch. The boiler restarts.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

23

Page 24

Maintenance

1 Cleaning main burner and ignition burner

The main burner and the ignition burner injector with its filter must be

regularly cleaned to ensure good performance. Il est conseillé de le

faire au moins 1 fois par an.

1

Ionisation probe

2

Ignition electrode

3

Flame diffuser

4

Earth electrode

Main burner

Switch off the boiler electrical power supply

Cut the gas supply.

Open the heater door

Disconnect the burner connector under the command panel

Unscrew the union joint on the gas inlet pipe

Unscrew the screws

Take out the burner earth wire

Disassemble the burner drawer

Clean the burner with a brush, a vacuum cleaner or a blower

Do not use a metal brush !

- Re-assemble the burner earth wire

Ignition burner

Unscrew the connecting screw, then pull the gas supply pipe

towards you

Take out the injector and the filter

Remove ionisation probe 1 and the earth electrode 4 deposits

(for example using sand paper)

- Re-attach the supply tube (14 spanner),

- Check the position of the ionisation probe 1, the ignition electrode

gap 2 and the position of the flame diffuser 3 in terms of the sizes

indicated on the drawing (required in the event of heater

malfunction).

Check the seals for the gas.

24

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 25

2 Cleaning heater body

8518N016

`Sweep the heater.

`Take out the burner drawer from the heater body.

1

2

`Do not block the gas ramp openings.

With the burner out :

Take out the column head fixed by 2 screws and toothed washers

Take out the insulation

Open the sweeping trap by unscrewing the 2 screws

Clean the heater body with the special brush delivered with the

product.

To re-assemble, perform the above actions in reverse order.

3

4

3 Maintenance

Maintenance and cleaning of the heater must be carried out at least

once a year by a qualified technician.

Stages Actions

Water level Regularly check the level of water in the system and top up if required, taking care that cold water is not

added suddenly into the boiler when it is hot.

This operation must be carried out several times per season ; if not, look for the probable leak and

immediately fix it.

Ice In the event that the heating stops during winter, increasing the risk of ice (holiday home for example), it is

recommended that sufficient anti-freeze is used to stop the heating water from freezing.

As a default, completely empty the installation (check with your installation engineer).

We advise you against draining the system unless it is

absolutely necessary (For example : Several months' absence

with the risk of ice in the building).

4 Periodic checks on the domestic hot water tank

Titane anode

No maintenance operations

The panel must be switched on to ensure that the anode is

working

Magnesium anode

The titanium anode can be replaced by a magnesium anode.

It is recommended that you take out a maintenance contract with a

qualified installation engineer. In the event that this is not possible,

sign a maintenance contract with an after-sales service company

recommended by your installation engineer or De Dietrich.

Sweeping the smoke conduct and the purge tank must be carried out

at least once a year during boiler maintenance.

The magnesium anodes must be checked at least every 2, years.

After the first check, determine the frequency of future checks on the

basis of anode wear. The anodes can be checked by two methods:

- Inspection:

the anode must be replaced if its diameter is less than 15 mm

(original diameter = 33 mm)

- Function test:

- disconnect the earth wire from the anode

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

25

Page 26

- measure the strength of the cu rrent between the tank and the

anode ; if the current measured is less than 0.1 mA, the anode

should be replaced.

Valve or safety unit

The safety unit must be periodically manoeuvred (at least

once a month). To do this, put the safety unit in the

drainage position. This manoeuvre evacuates any

desposits which may in time block the safety unit valve.

Failure to comply with this maintenance rule may cause

damage to the tank structure.

In hard water regions, we recommend descaling the tank annually in

order to maintain its performance.

- Remove limescale deposits in the form of sludge or strips in the

bottom of the tank. On the other hand, do not touch limescale

adhering to the walls of the tank as it provides effective protection

against corrosion and improves the insulation of the DHW tank.

- The exchanger will have to be descaled, if need be, in order to

maintain optimum performance.

4.1 Operations to be carried out to check or replace the anode and descale the installation

Descaling

The TAS titanium anode (standard)

6x

13

8185N101

The magnesium anode (optional)

1. Fit a new watertight seal to the calorifier flange

2. Cut the power supply to the boiler

3. Cut off the cold water supply and drain the DHW tank. To drain

though the safety unit, turn the unit to drain and turn on a hot

water tap (or a bleed valve) to allow air to enter.

4. Remove the front panel and the sensors.

5. Remove the cover (13 mm spanner).

6. Check the anode and replace it if necessary.

7. When reassembling, replace the watertight seal; to do this:

- Replace the lip seal and position it in the visit opening, making

sure that you place its lug outside the DHW tank.

- Position the retainer ring around the seal, making sure you place

the lug above the retainer ring.

- Fix the cover to the flange using *1 screws, tightening them

uniformly in a cross pattern.

8. Proceed with filling according to the instruction in the chapter "Commissioning". Check the seal and the safety devices on the calorifier after reassembly.

The flange mounting bolts must not be excessively tight:

6N.m±

Nota: Approximately 6 Nm is obtained by holding the box

: use a torque wrench.

@

spanner by the small lever.

26

8 18 0775N

6x

13

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 27

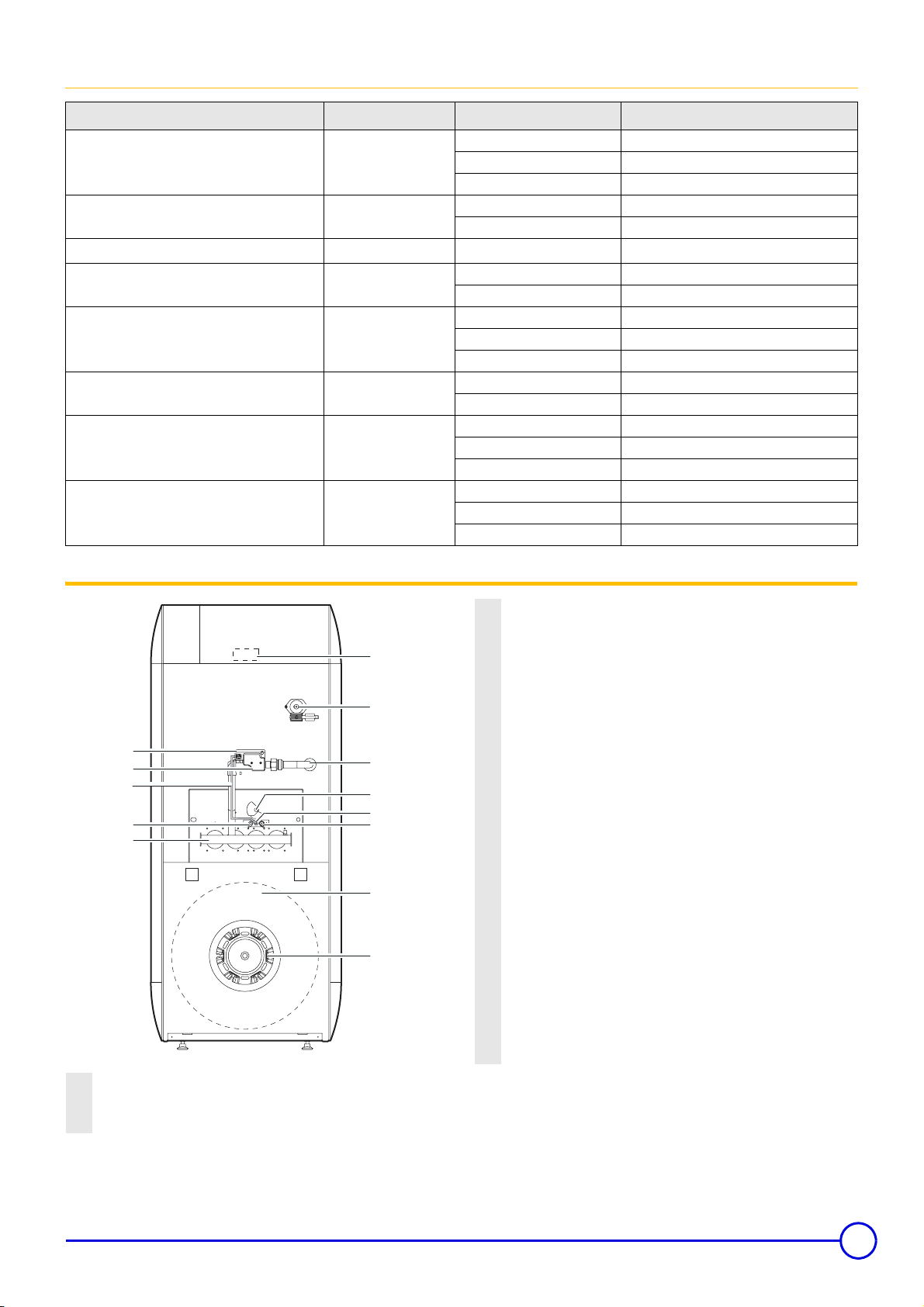

Incidents and solutions

Symptoms Probable causes Solution

The heater does not start

and the safety box is not

affected (red alarm

indicator off)

The burner does not

ignite and the safety box

is not affected (red alarm

indicator off)

The burner ignites and

the safety box goes into

standby (burner cut and

the alarm indicator

flashes)

The burner ignites and

the safety box is affected

(alarm indicator on)

The burner ignites but

with reduced power

Dirty cast iron body

(hearth)

Noisy heater

- The heater thermostat is

requiring heat

- Setting (option) is not requiring

heat.

- The safety thermostat has been

triggered after overheating.

- No current - Place the Stop/Start switch on "On"

- On safety because of a lack of

gas

- Faulty gas valve - Check the gas valve and replace if necessary.

- No spark from the electrode - Check the electric cable connection to the safety box and the electrode

- No ionisation current - Check the ionisation probe and earth wire connection.

- Blocked filter or ignition burner

injector

- Anti-blowback thermostat cut - Check the draught in the chimney connection, check the condition of the

- Inversion of the phase and

neutral wires on the heater's

command panel

- Upstream pressure too weak - Check gas supply

- Dirty filter - Clean the filter

- Unsuitable injectors (See Table

"Pressure setting and marking of

calibrated injectors")

- Faulty gas valve - Check gas valve and replace if necessary

- Injectors too small - Check them (See Table "Pressure setting and marking of calibrated

- Upstream pressure too high - Revoir l’alimentation en gaz

- Dirty burner - Clean the burner

- Insufficient or poorly placed air

supply

- Faulty gas valve - Check gas valve and replace if necessary

- Poor purge - Purger correctement

- Body has scale - Détartrer le circuit chauffage

- Unsuitable injectors (Whistling) - Check injectors

- Create a demand by moving the heater thermostat or the setting level

(option).

- Solve the cause of overheating and reset the safety thermostat.

- Purge the gas supply pipe then reset the heater using the panel reset

button

- Check the position of the ionisation probe and the flame diffuser in the

ignition burner

- Clean the filter and the ignition burner injector

anti-blowback thermostat, then press the Start/Stop button to cancel the 15

timer and restart the heater

- Please note the seriousness of unplanned intervention on the combustion

product evacuation checking device : evacuation faults must be solved by

improving the draught in the chimney.

- In the event of a thermostat fault, it must be replaced by a part stated on

our "Spare parts list". Its position must not be modified, which is defined by

the 2 bosses on the holding bracket which are located in the 2 holes on the

draught diverter. The thermostat must not be placed out of service.

- Connect the phase to terminal 1 and neutral to 2.

- Check them

injectors")

- Enlarge air supply, smoothen airation holes

- Burner clogged by building dust

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

27

Page 28

Symptoms Probable causes Solution

Heater too hot or too cold

for requirements

Flame returns - Injectors too large

- 3 position switch on position !- Check the position of the 3 position switch

- Wrong setting for the heater

thermostat

- Set the heater thermostat if the heater has SV-matic setting or an ambient

thermostat

- Check pressure injectors

- Pressure too weak

Whistling

- Injectors too small

- Check pressure injectors

- Pressure too high

28

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 29

To order a spare part, quote the reference number next to the part required.

Domestic hot water tanks

1

12

13

2

4

5

8

3

9

11

6

7

14

10

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

29

Page 30

.

Boiler body + Draught diverter + Insulation

Spare parts - DTG 1300 Eco.NOx/V

23/06/05 - 300002940-002A

26

27

33

34

35

28

32

28

29

23

25

30

31

24

22

39

36

37

41

38

40

85 15118N

DE DIETRICH THERMIQUE S.A.S. - Spare parts centre

4, rue d’Oberbronn - F-67110 REICHSHOFFEN - Tél. : (+33) 03 88 80 26 50 - Fax : (+33) 03 88 80 26 98

cpr

dedietrichthermique.com

Page 31

Gas line

Cladding

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

31

Page 32

Linking kit

32

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 33

Rep Code no. Description

Tank

1 8955-5509 LI130 foam for DTG 1304 and 1305 Eco.NOx/V

1 8955-5510 LI130 foam for DTG 1306 Eco.NOx/V

2 8970-5511 7 mm seal kit

3 200000092 Complete buffer tank

4 200000093 Complete Anode

5 9501-3023 20x8.5x2 vitron seal

6 9497-4525 Ny lo n sp a cer

7 200000049 Connector

8 9536-5009 Sensor attachment lug

9 9786-0646 Adjustable foot

10 8955-4026 Insulation, buffer tank

11 8518-8686 Upper angle fastening, length 644

11 8518-8687 Upper angle fastening, length 744

12 9501-3010 Gasket 29x19x3

13 9501-3011 Gasket 29x15x3

14 8801-4965 TAS anode cable, length 2 m

15 8801-4963 Titan_Active_System_® simulation connector

Boiler body

22 8375-5507 Assembled boiler body - 4 sections

22 8375-5508 Assembled boiler body - 5 sections

22 8375-5509 Assembled boiler body - 6 sections

23 8518-8025 Front mounting square

24 9536-5611 Sensor tube

25 8375-0004 Body lifter

26 9754-9933 Straight 1" pipe

27 9494-6190 Nipple N280 1"

28 9492-0297 ElbowNr. 92 1"

Draught diverter

29 8518-8515 Draught diverter complete - 4 sections

29 8518-8516 Draught diverter complete - 5 sections

29 8518-8517 Draught diverter complete - 6 sections

30 9758-1501 Flue gas nozzle Ø 110/111

30 300000300 Staged smoke nozzle Ø 125/130

30 300000301 Staged smoke nozzle Ø 150/153

31 8518-8054 Inspection hatch - 4 sections

31 8518-8055 Inspection hatch - 5 sections

31 8518-8056 Inspection hatch - 6 sections

32 200000204 Anti-backflow thermostat complete

33 8375-8077 Mounting square

34 9536-3355 Static thermostat

Rep Code no. Description

35 200000095 Electric circuit - Anti-backflow thermostat

36 8366-5501 Body screws packet + Draught diverter

Insulating material for body

37 200000522 Complete insulating material for body - 4 sections

37 200000523 Complete insulating material for body - 5 sections

37 200000524 Complete insulating material for body - 6 sections

38 9755-0514 Insulation under burner - 4 sections

38 9755-0515 Insulation under burner - 5 sections

38 9755-0516 Insulation under burner - 6 sections

39 8388-5656 Insulation back of hearth - 4 sections

39 8388-5657 Insulation back of hearth - 5 sections

39 8388-5658 Insulation back of hearth - 6 sections

40 9428-5095 Silicone filler tube

41 9696-0227 Brush

Gas circuit

52 200003132 Gas circuit complete - 4 sections

52 200003133 Gas circuit complete - 5 sections

52 200003134 Gas circuit complete - 6 sections

54 8518-5508 FURIGAS b urner drawer - 4 sections

54- 8518-5509 FURIGAS burner drawer - 5 sections

54 8518-5510 FURIGAS b urner drawer - 6 sections

56 8388-5533 FURIGAS burner + Screws

57 9536-0220 Pressure socket

58 8375-4945 Earth cable

60 8518-8922 Complete ignition burner - 4-6 sections

62 8518-5515 Ignition burner gas supply pipe - 4-6 sections

63 8518-5516 Valve

64 8518-5517 Elbow flange 1/2" + Gasket

66 9502-3314 Gasket

67 8518-5519 Box + Wiring

68 8518-4904 Burner cable

69 9495-2101 N174 1/2" x 1" nut

70 9495-2081 Moving part N3 71 1/2"

71 9501-3062 Green joint 30 x 21 x 2

72 9754-9898 Gas inlet pipe - 3 to 6 sections

74 8388-5636 Burner drawer insulation kit 4 sections

74 8388-5637 Burner drawer insulation kit 5 sections

74 8388-5638 Burner drawer insulation kit 6 sections

76 8366-5502 Screws

77 8518-7007 Conversion set H/E - Package GL34

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

33

Page 34

Rep Code no. Description

Cladding

86 8518-8631 Cladding - 4 sections

86 8518-8632 Cladding - 5 sections

86 8518-8633 Cladding - 6 sections

87 8518-8640 Front plate - 4 sections

87 8518-8641 Front plate - 5 sections

87 8518-8642 Front plate - 6 sections

88 8518-8530 Complete right hand side panel

89 8518-8531 Complete left hand side panel

89 9482-0110 Catch

91 8518-8663 Upper rear panel - 4 sections

91 8518-8664 Upper rear panel - 5 sections

91 8518-8665 Upper rear panel - 6 sections

92 8518-8654 Lower back panel - 4 sections

92 8518-8655 Lower back panel - 5 sections

92 8518-8656 Lower back panel - 6 sections

93 8518-8651 Complete rear tank panel Ll110

93 8518-8652 Complete rear tank panel Ll130

94 8518-8549 Complete door

95 9482-0120 Bolt

96 8518-8678 Complete header column

98 8518-8679 Additional part set

99 9752-5376 Funnel

100 9752-5372 Narrow screen

101 9752-5374 Narrow shutter

102 9752-5370 Narrow body

Rep Code no. Description

198 9536-2447 KVT sensor

199 8575-4909 DHW connector

Linking kit

176 9491-4424 1" connection cross

177 9513-2249 UP15-30 circuit

178 9499-4110 Stainless steel hose, length 750

179 8955-4900 Power supply cable load pump

180 8575-4925 DHW connector pump

182 8999-8522 Complete G1 connector + nut

183 9491-4419 Elbow90°

184 9491-4292 Non-return valve

185 9491-4421 Brass reducer

186 8500-0023 Automatic air vent

187 9490-2073 Emptying tap without joint 1/2"

188 9795-0113 Solid plug 1/2"

189 9501-3010 Gasket 29x19x3

190 9495-0198 Plug laiton G1

191 9501-3062 Green seal 30x21x2

34

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 35

Warranty

You have just purchased a DE DIETRICH appliance and we

thank you for the trust you have placed in our products.

Please note that your appliance will provide good service for a

longer period of time if it is regularly checked and maintained.

Your fitter and the DE DIETRICH customer support network are

at your disposal at all times.

Warranty terms

Starting from the purchase date shown on the original fitter's

invoice, your appliance has a contractual guarantee against any

manufacturing defect.

The length of the guarantee is mentioned in the price catalogue.

The manufacturer is not liable for any improper use of the

appliance or failure to maintain or install the unit correctly (the

user shall take care to ensure that the system is installed by a

qualified fitter).

In particular, the manufacturer shall not be held responsible for

any damage, loss or injury caused by installations which do not

comply with the following:

- applicable local laws and regulations

- specific requirements relating to the installation, such as

national and/or local regulations

- the manufacturer's instructions, in particular those relating to

the regular maintenance of the unit

- the rules of the profession

France

The preceding dispositions are not exclusive of benefits for the

purchaser of the legal guarantee as stated in Civil Code articles

1641 to 1648.

Belgium

The preceding dispositions about the contractual guarantee are

not exclusive of profit if the need arises for the purchaser in

Belgium of the applicable legal dispositions on hidden defects.

Switzerland

The application of the warranty is subject to the terms and

conditions of sale, delivery and warranty of the company

marketing DE DIETRICH products.

Other countries

The above provisions do not restrict the benefit of the legal laws

regarding hidden defects applicable in the buyer's country.

The warranty is limited to the exchange or repair of such parts as

have been recognised to be faulty by our technical department

and does not cover labour, travel and carriage costs.

The warranty shall not apply to the replacement or repair of parts

damaged by normal wear and tear, negligence, repairs by

unqualified parties, faulty or insufficient monitoring and

maintenance, faulty power supply or the use of unsuitable fuel.

Sub-assemblies such as motors, pumps, electric valves etc. are

guaranteed only if they have never been dismantled.

23/06/05 - 300002940-001B DTG 1300 Eco.NOx/V

35

Page 36

36

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 37

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 38

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 39

DTG 1300 Eco.NOx/V 23/06/05 - 300002940-001B

Page 40

FR

DE DIETRICH THERMIQUE S.A.S.

www.dedietrich.com

Direction des Ventes France

57, rue de la Gare

F- 67580 MERTZWILLER

+33 (0)3 88 80 27 00

+33 (0)3 88 80 27 99

AT

DE DIETRICH HEIZTECHNIK

www.dedietrich.com

Am Concorde Park 1 - B 4 / 28

A-2320 SCHWECHAT / WIEN

+43 (0)1 / 706 40 60-0

+43 (0)1 / 706 40 60-99

office@dedietrich.at

DE

BE

CH

DE DIETRICH HEIZTECHNIK

www.dedietrich.com

Rheiner Strasse 151

D- 48282 EMSDETTEN

+49 (0)25 72 / 23-5

+49 (0)25 72 / 23-102

info@dedietrich.de

VAN MARCKE

www.vanmarcke.be

Weggevoedenlaan 5

B- 8500 KORTRIJK

+32 (0)56/23 75 11

VESCAL S.A.

www.chauffer.ch / www.heizen.ch

Z.I de la Veyre, St-Légier

1800 VEVEY 1

+41 (0)21 943 02 22

+41 (0)21 943 02 33

LU

RU

CN

NEUBERG S.A.

www.dedietrich.com

39 rue Jacques Stas

L- 2010 LUXEMBOURG

+352 (0)2 401 401

DE DIETRICH

www.dedietrich.com

8 Gilyarovskogo Str. 7

R- 129090 MOSCOW

+7 495.974.16.03

+7 495.974.66.08

dedietrich@nnt.ru

DE DIETRICH

www.dedietrich.com

Room 512, Tower A, Kelun Building

12A Guanghua Rd, Chaoyang District

C-100020 BEIJING

+86 (0)106.581.4017

+86 (0)106.581.4018

+86 (0)106.581.7056

+86 (0)106.581.4019

contact

BJ

@dedietrich.com.cn

In the interest of customers, DE DIETRICH THERMIQUE are continuous ly endeavouring to make improvements in produc t quality. All the specifications stated in this document are therefore s ubject to change w ithout notice

DE DIETRICH THERMIQUE

57, rue de la Gare F- 67580 MERTZWILLER - BP 30

www.dedietrich.com

AD001Z • 02.2006

Loading...

Loading...