ConductiGlass

®

Lining

Note that grounding through

a Tantalum plug does not

solve the problem. As the

medium is non conductive,

the “lightning conductor”

effect of any electrode

is only efficient a couple

of centimetres around it.

grounding with

a Tantalum plug

is not efficient

Working principle

The principle of the ConductiGlass®solution consists in increasing

the conductivity of the glass-lining to a value high enough to allow

the discharge to the ground of the electrostatic charges as soon as

they are created in the reaction medium, prohibiting then their

accumulation up to dangerous voltages.

Practical realisation

This is achieved by adding to the glass a small quantity of very thin

Platinum fibres, continuously dispersed in the whole thickness of

the glass-lining.

The fibres are not joined, but the glass thicknesses which are inbetween them are extremely small and can be compared to a network

of micro-condensers discharging in line to let the electrostatic charges

flow gently to the ground without any damage for the glass-lining.

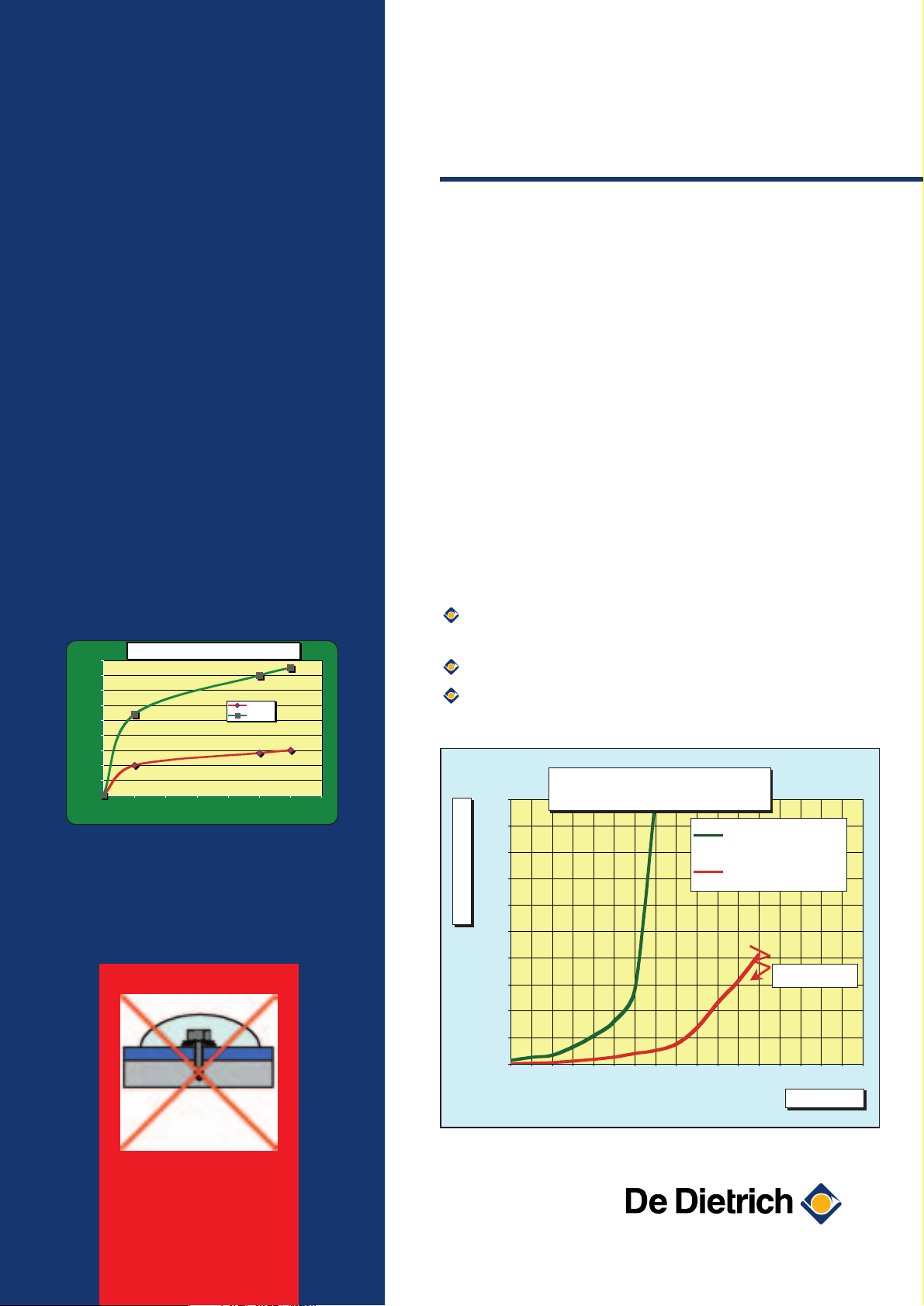

The opposite sketch compares the behaviours of ConductiGlass

®

and conventional DD 3009 glass-linings when applying them an

increasing voltage (at 150 °C). Let’s have a look on the DD 3009

curve : a very weak leak current appears around 5 kV and grows

regularly up to the breakdown of the glass-lining occurring around

15 kV. As far as ConductiGlass®is concerned, the leak current

starts at a higher value from low voltage, then grows quickly prohibiting the voltage to increase :

the flow to the ground of the electrostatic charges

is then as fast as their creation,

integrity of the glass-lining is preserved,

risks of explosion are dismissed.

The probleme of

electrostatic charges

The mixing of non conductive products

in a glass-lined reactor may lead to the

development of electrostatic charges in

the heart of the reaction medium.

In a glass-lined reactor, insulating

properties of the lining prohibit these

charges to flow to the ground and enhance

their accumulation up to very high voltages

that become really dangerous for the

operators and the equipment. All the

operators are nowadays perfectly aware

of the safety rules and incidents very

rare. But these rules are unfortunately

not applicable to all processes, and very

often the accumulation of electrostatic

charges cannot be avoid.

This phenomenon is accelerated by the

temperature as shown on the picture :

for a glass thickness of 1 mm, the breakdown voltage which is 40 kV at 22 °C

falls down to 14 kV at 150 °C.

This major problem which was one of

the last remaining in glass-lining technology is solved from now on by the use

of a new kind of glass-lining named

ConductiGlass®.

Working principle of

CONDUCTIGLASS®

0

50

100

150

200

250

300

350

400

450

500

34567891011121314151617181920

Voltage (kV)

Leak current (µA)

CONDUCTIGLASS®

3009 GLASS

damage !

ConductiGlass

®

Delete any risk of

electrostatic damage

on glass-lined

equipment

INFLUENCE OF THE TEMPERATURE

0

5

10

15

20

25

30

35

40

45

0 0,2 0,4 0,6 0,8 1 1,2 1,4

Email Thickness (mm)

Breakdown Voltage (kV)

150 ∞C

22 ∞C

Loading...

Loading...