Page 1

PROJECT

S U S T A I N A B L E C O M F O R T

®

EVODENS PRO

en

Istruzioni in ligua italiana disponibili su richiesta

Control panel & High-efficiency wall-hung gas boiler

Service Manual

AMC Pro 45 - 65 - 90 - 115

Diematic Evolution

Page 2

Contents

2 AMC Pro 7725087 - v.01 - 06062019

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Control panel components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Description of the home screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3 Description of the main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 User instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1 Changing the display settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2 Accessing the user level menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.3 Home screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.4 Activating holiday programs for all zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.5 Heating circuit configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.6 Changing the room temperature of a zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.6.1 Definition of zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.6.2 Changing the name and symbol of a zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.6.3 Changing the operating mode of a zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.6.4 Timer program to control the room temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.6.5 Changing the heating activity temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.6.6 Changing the room temperature temporarily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.7 Changing the domestic hot water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.7.1 Changing the domestic hot water operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.7.2 Increasing the domestic hot water temperature temporarily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.7.3 Timer program to control the DHW temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.7.4 Changing the comfort hot water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.8 Switching the central heating on or off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.9 Reading the installer's name and phone number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Installer instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

6.1 Accessing the installer level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Configuring the installation at installer level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2.1 Setting the installer details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.2.2 Setting the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.3 Changing boiler parameters when SCB-10 is fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.2.4 Setting the maximum load for CH operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.5 Setting the heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.2.6 Screed drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.3 Commissioning the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3.1 Chimney sweep menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3.2 Saving the commissioning settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4 Maintaining the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.1 Viewing the service notification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.2 Reading out measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.4.3 Viewing production and software information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.4 Changing the domestic hot water temperature temporarily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5 Resetting or restoring settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5.1 Resetting the configuration numbers CN1 and CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5.2 Carrying out an auto-detect for the CAN matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.5.3 Restoring the commissioning settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5.4 Resetting to factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 Installation examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Page 3

Contents

7725087 - v.01 - 06062019 AMC Pro 3

7.1 Access to the expansion box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2 Connection options for the expansion PCB - SCB-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 Zone functions of SCB-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.4 Setting the 0-10 Volt input function of SCB-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.4.1 Analogue temperature regulation (°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

7.4.2 Analogue output-based control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.5 Cascade control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.6 Connecting diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.6.1 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.6.2 Connection example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.6.3 Connection example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

7.6.4 Connection example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

7.6.5 Connection example 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

7.6.6 Connection example 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.6.7 Connection example 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.6.8 Connection example 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.6.9 Connection example 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.6.10 Connection example 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.6.11 Connection example 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.6.12 Connection example 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.6.13 Connection example 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.1 Introduction to parameter codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2.1 Control unit settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.2.2 SCB-10 expansion PCB settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

8.3 List of measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.3.1 Control unit counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.3.2 SCB-10 expansion PCB counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.3.3 Control unit signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.3.4 SCB-10 expansion PCB signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1 Maintenance regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

9.2 Opening the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

9.3 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.3.1 Checking the water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

9.3.2 Checking the ionisation current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

9.3.3 Checking the flue gas outlet/air supply connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

9.3.4 Checking the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

9.3.5 Cleaning the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

9.3.6 Checking the burner and cleaning the heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3.7 Checking the non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

9.4 Specific maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.4.1 Replacing the ionisation/ignition electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.4.2 Cleaning the condensate collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

9.5 Finalising work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

10.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.1.1 Display of error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.1.2 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.1.3 Blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.1.4 Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10.2 Error history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

10.2.1 Reading out and clearing the error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

11 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

11.1 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

12 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

12.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

12.2 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

12.3 Spare part list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Page 4

1 Safety

4 AMC Pro 7725087 - v.01 - 06062019

1 Safety

1.1 Liabilities

1.1.1 Manufacturer's liability

Our products are manufactured in compliance with the

requirements of the various Directives applicable. They

are therefore delivered with the marking and any

documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We

therefore reserve the right to modify the specifications

given in this document.

Our liability as manufacturer may not be invoked in the

following cases:

Failure to abide by the instructions on installing and

maintaining the appliance.

Failure to abide by the instructions on using the

appliance.

Faulty or insufficient maintenance of the appliance.

1.1.2

The installer is responsible for the installation and initial

commissioning of the appliance. The installer must

observe the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Install the appliance in compliance with prevailing

legislation and standards.

Carry out initial commissioning and any checks

necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the

obligation to check the appliance and keep it in good

working order.

Give all the instruction manuals to the user.

Installer's liability

1.1.3 User's liability

To guarantee optimum operation of the system, you

must abide by the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Call on a qualified professional to carry out installation

and initial commissioning.

Get your installer to explain your installation to you.

Page 5

1 Safety

7725087 - v.01 - 06062019 AMC Pro 5

Have the required inspections and maintenance

carried out by a qualified installer.

Keep the instruction manuals in good condition close

to the appliance.

Page 6

2 About this manual

6 AMC Pro 7725087 - v.01 - 06062019

2 About this manual

2.1 Additional documentation

The following documentation is available in addition to this manual:

Installation and user manual

Water quality instructions

2.2

Symbols used in the manual

This manual contains special instructions, marked with specific symbols.

Please pay extra attention when these symbols are used.

Caution

Risk of material damage.

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

Page 7

AD-4000070-01

17

14

13

10

9

6

7

8

2

1

12

3

4

11

5

18

19

20

16

15

3 Description of the product

7725087 - v.01 - 06062019 AMC Pro 7

3 Description of the product

The AMC Pro boiler is delivered with a combination of the control panel,

control unit and extension PCB. The contents of this manual are based on

the following software and navigation information:

Tab.1 Software and navigation information

Name visible in display Software version

Boiler AMC Pro CU-GH08 1.7

Control panel Diematic Evolution MK3 1.29

PCB SCB-10 SCB-10 1.03

3.1

General description

3.2 Main components

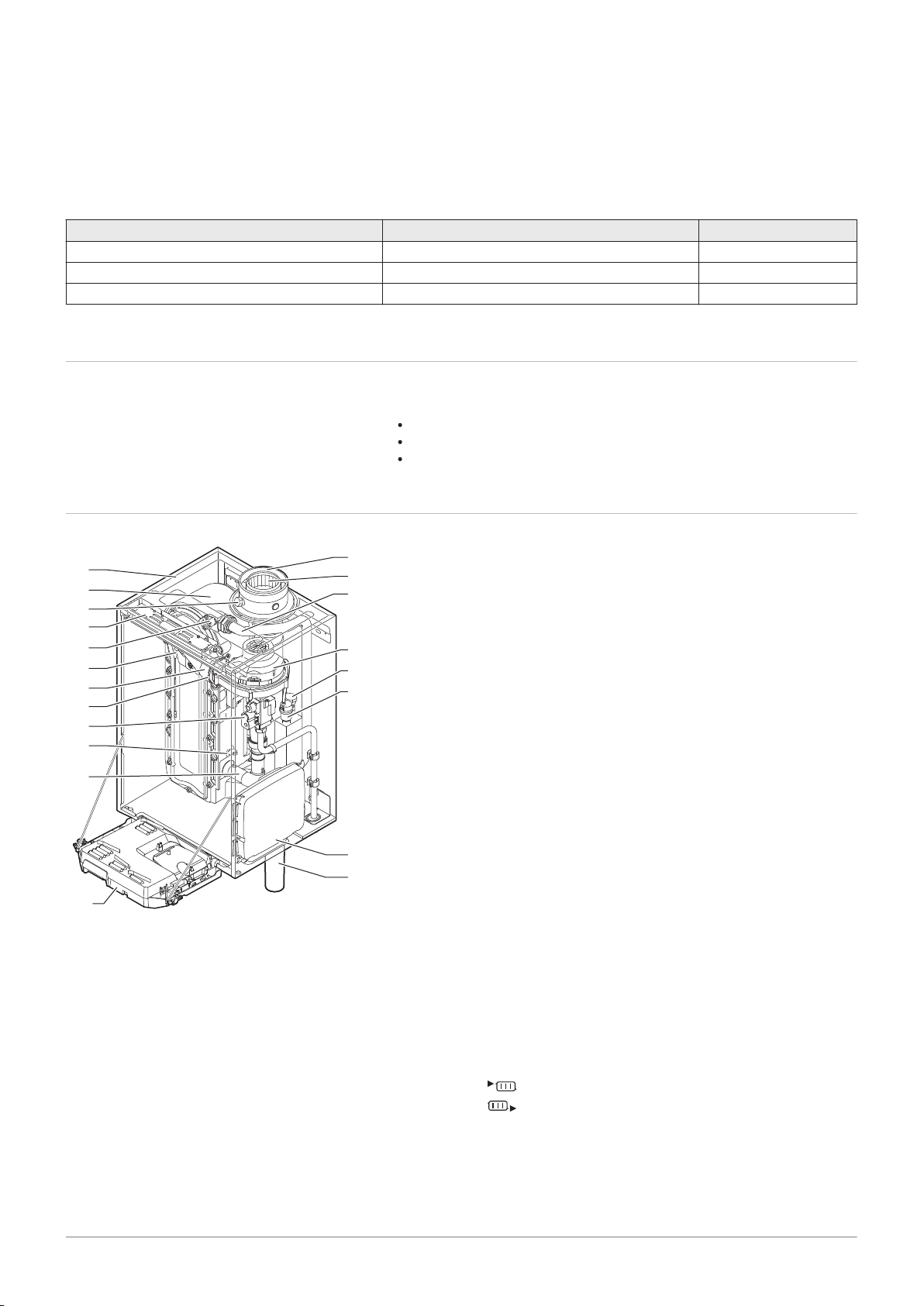

Fig.1

Main components

The AMC Pro boiler is a high-efficiency wall-hung gas boiler with the

following properties:

High-efficiency heating.

Limited emissions of polluting substances.

Ideal choice for cascade configurations.

1

Casing/air box

2

Heat exchanger (CH)

3

Interior light

4

Type plate

5

Flow sensor

6

Ionisation/ignition electrode

7

Mixing tube

8

Non-return valve

9

Combined gas valve unit

10

Return sensor

11

Air intake silencer

12

Instrument box

13

Siphon

14

Expansion box for the control PCBs

15

Automatic air vent

16

Hydraulic pressure sensor

17

Fan

18

Supply line

19

Flue gas measuring point

20

Flue gas discharge pipe

21

Air supply

Heating circuit flow

Heating circuit return

Page 8

AD-3000932-01

3

4

1

6

2

5

AD-3001157-01

All OK

Error Status

22/02/2018 11:20 Home Screen

i

i

All OK

2

5

43

1

AD-3000935-01

A B

C

4 Use of the control panel

8 AMC Pro 7725087 - v.01 - 06062019

4 Use of the control panel

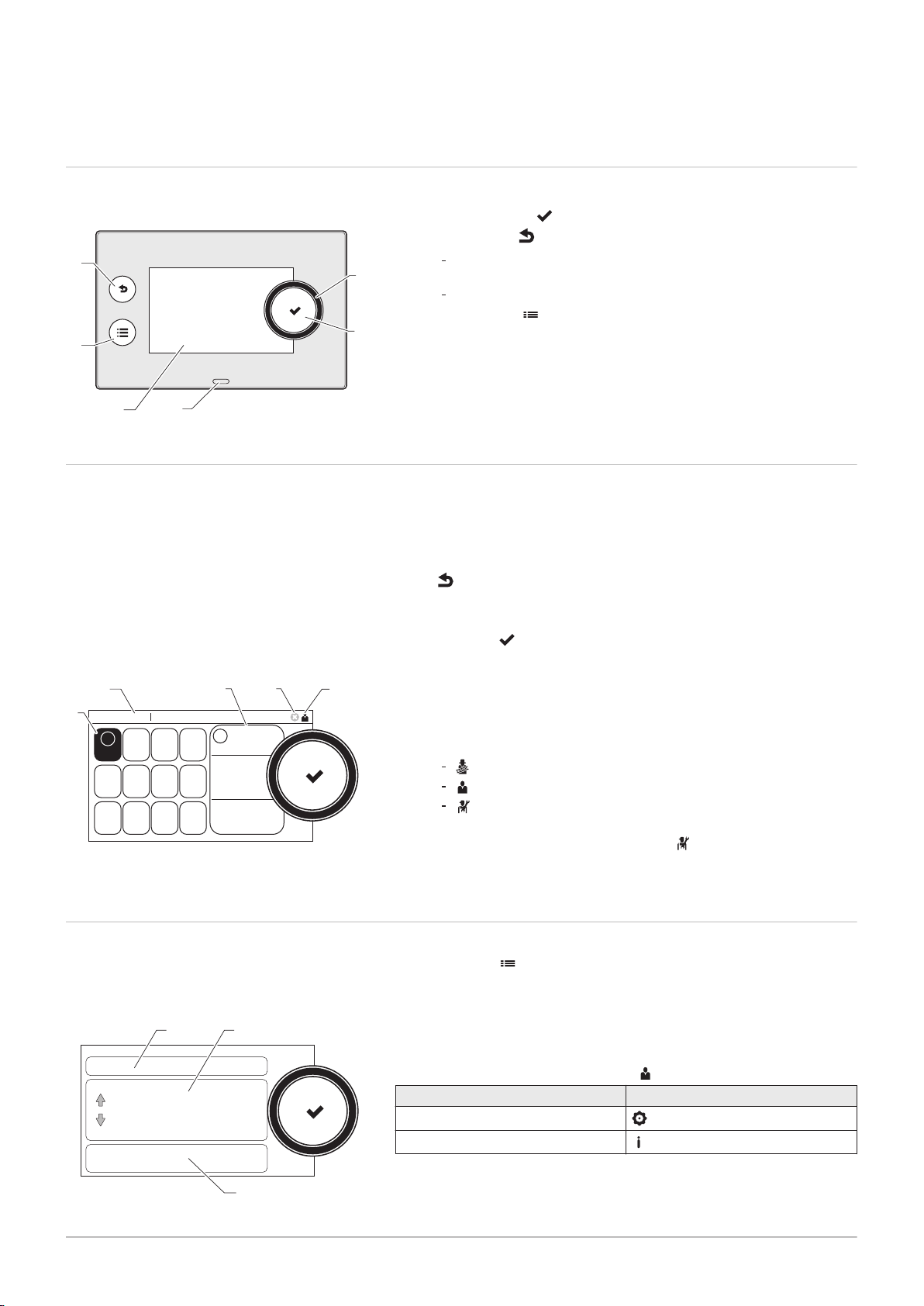

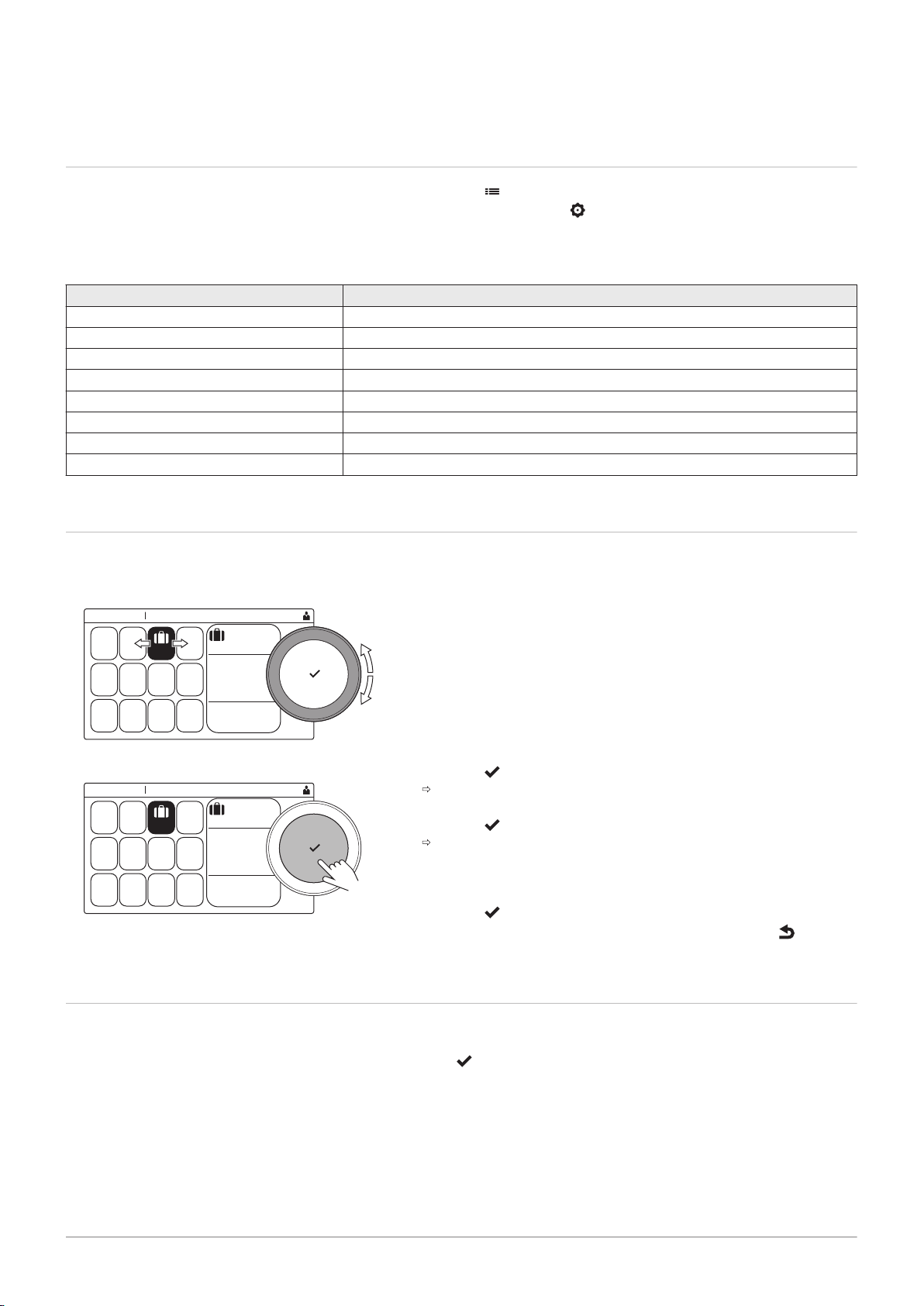

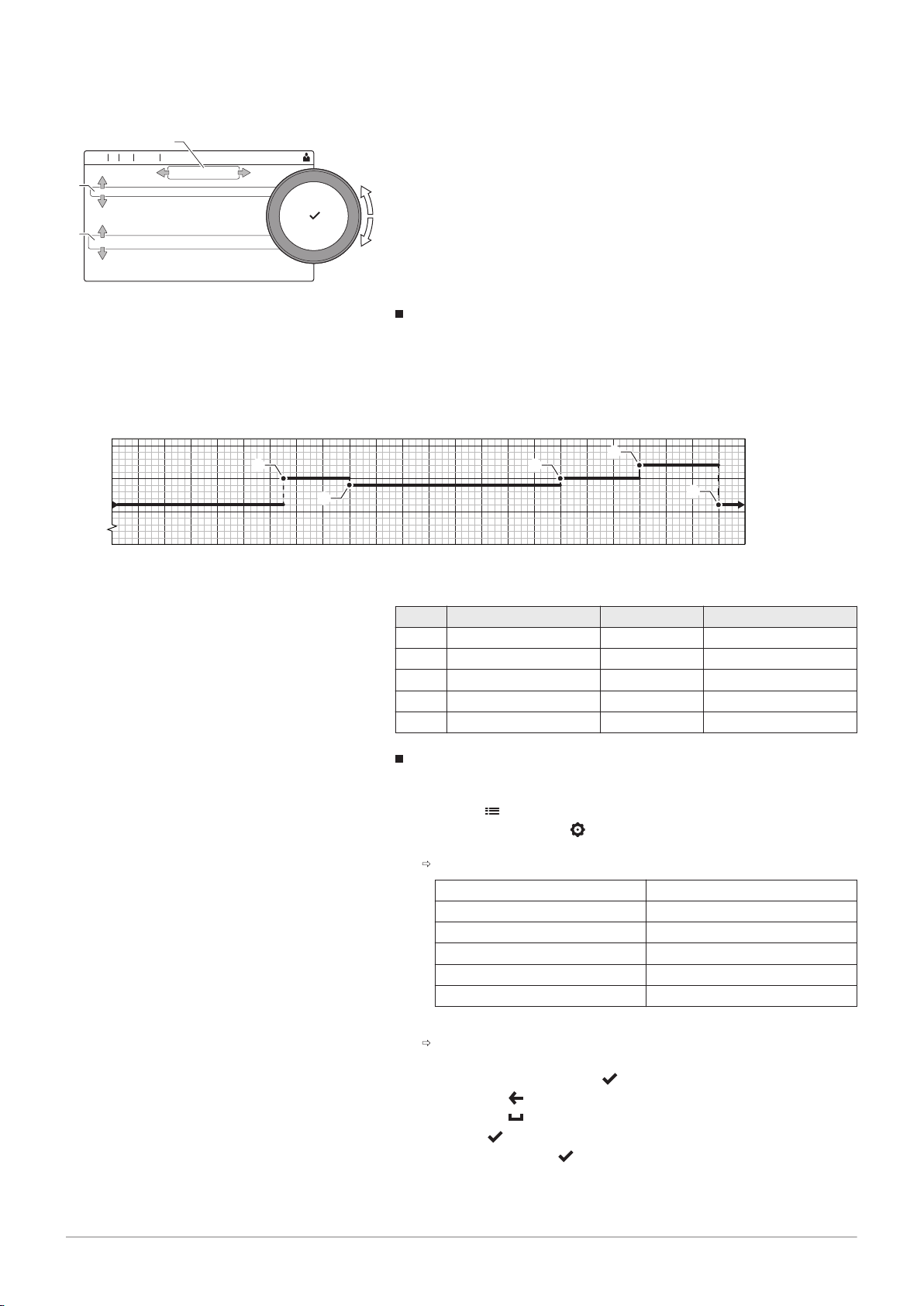

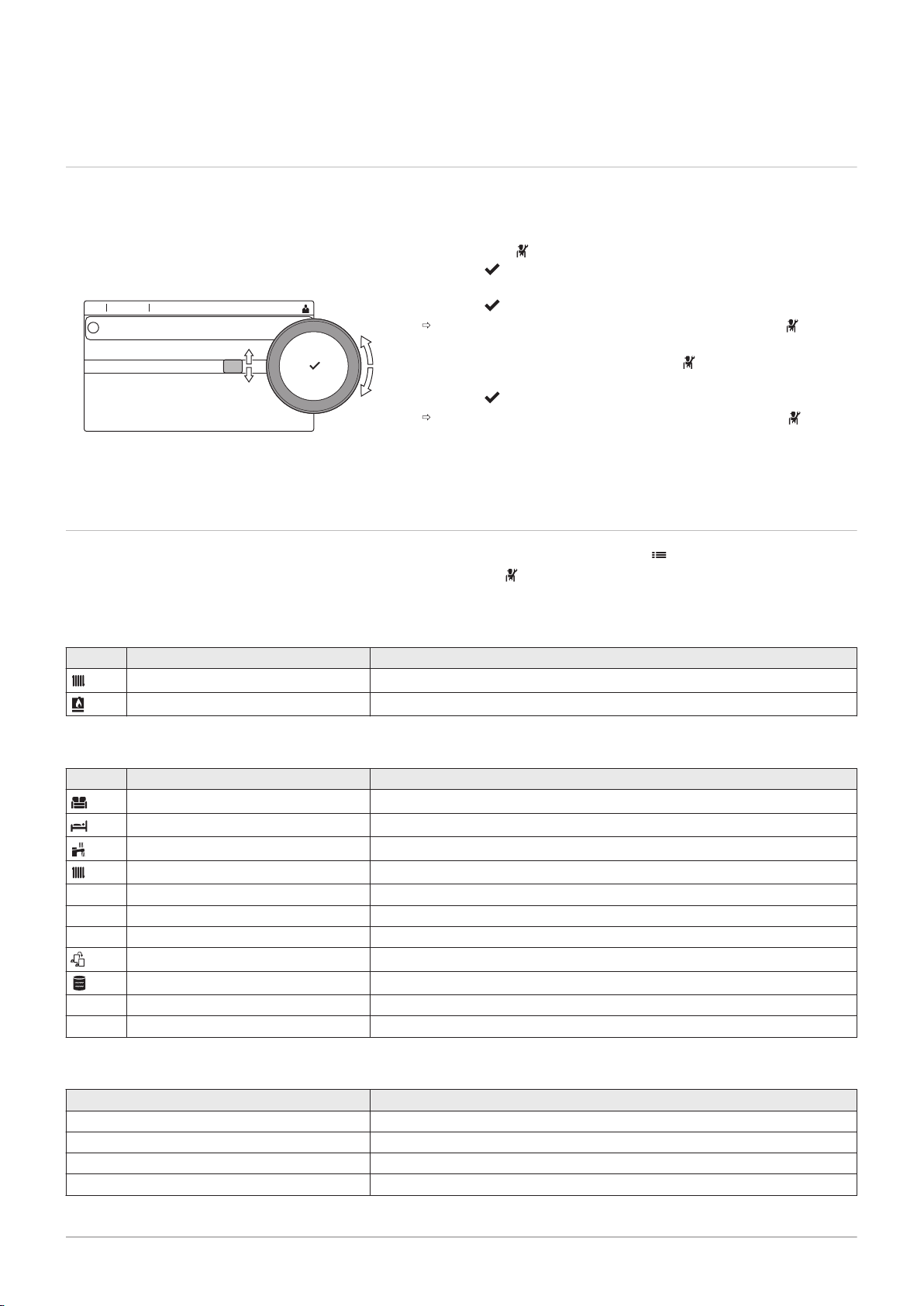

4.1 Control panel components

Fig.2 Control panel components

4.2

Description of the home screen

1 Rotary knob to select a tile, menu or setting

2

Confirm button to confirm the selection

3

Back button :

Short button press: Return to the previous level or previous

menu

Long button press: Return to home screen

4

Menu button to go to the main menu

5 Display

6 Status LED

This screen is shown automatically after start-up of the appliance. The

control panel goes automatically in standby mode (black screen) if the

screen is not touched for 5 minutes. Press one of the buttons on the

control panel to activate the screen again.

You can navigate from any menu to the home screen by pressing the back

button

for several seconds.

The tiles on the home screen provide quick access to the corresponding

menus. Use the rotary knob to navigate to the menu of your choice and

press the button to confirm the selection.

Fig.3 Icons on home screen

4.3

Fig.4 Items in the main menu

Description of the main menu

1 Tiles: the selected tile is highlighted

2 Date and time | Name of the screen (actual position in the menu)

3 Information about the selected tile

4 Error indicator (only visible if an error has been found)

5 Icon showing the navigation level:

: Chimney sweeper level

: User level

: Installer level

The installer level is protected by an access code. When this

level is active, the status of the tile [

] changes from Off into

On.

You can navigate from any menu directly to the main menu by pressing

the menu button

. The number of accessible menus depends on the

access level (user or installer).

A

Date and time | Name of the screen (actual position in the menu)

B

Available menus

C

Brief explanation of the selected menu

Tab.2

Available menus for the user

Description Icon

System Settings

Version Information

Page 9

4 Use of the control panel

7725087 - v.01 - 06062019 AMC Pro 9

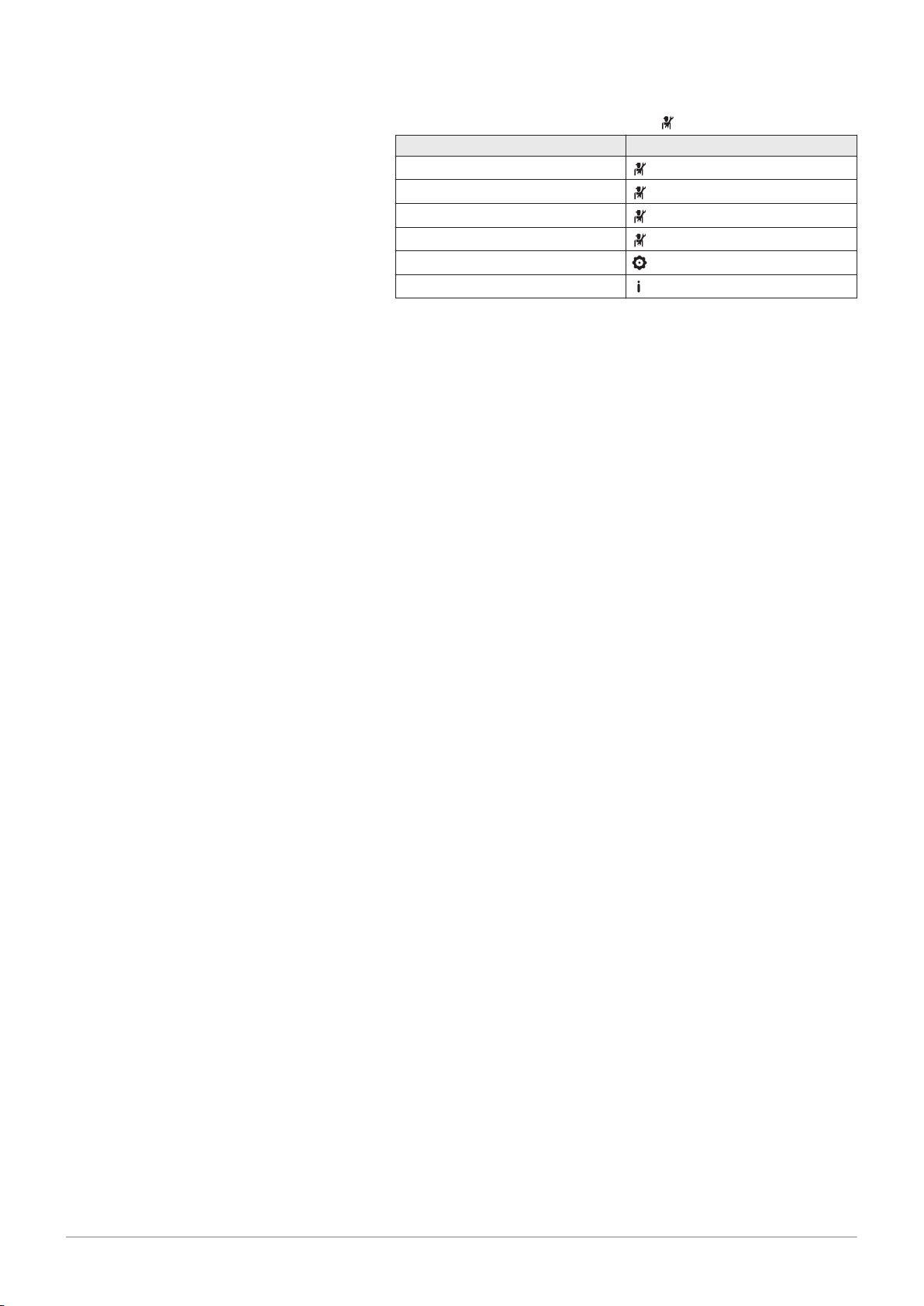

Tab.3

Available menus for the installer

Description Icon

Installation Setup

Commissioning Menu

Advanced Service Menu

Error History

System Settings

Version Information

Page 10

AD-3001387-01

Not set

Home Screen

22/02/2018 11:20

... ...

........ .......

........ .......

......

AD-3001388-01

... ...

........ .......

........ .......

......

Not set

Home Screen

22/02/2018 11:20

5 User instructions

10 AMC Pro 7725087 - v.01 - 06062019

5 User instructions

5.1 Changing the display settings

1. Press the button.

2. Select System Settings .

3. Perform one of the operations described in the table below:

Tab.4 Display settings

System Settings menu Settings

Set Date and Time Set the currrent date and time

Select Country and Language Select your country and language

Daylight Saving Time Enable or disable daylight saving time

Installer Details Read out the name and phone number of the installer

Set Heating Activity Names Create the names for the activities of the timer program

Set Screen Brightness Adjust the brightness of the screen

Set click sound Enable or disable the click sound of the rotary knob

License Information Read out detailed license information from the device platform application

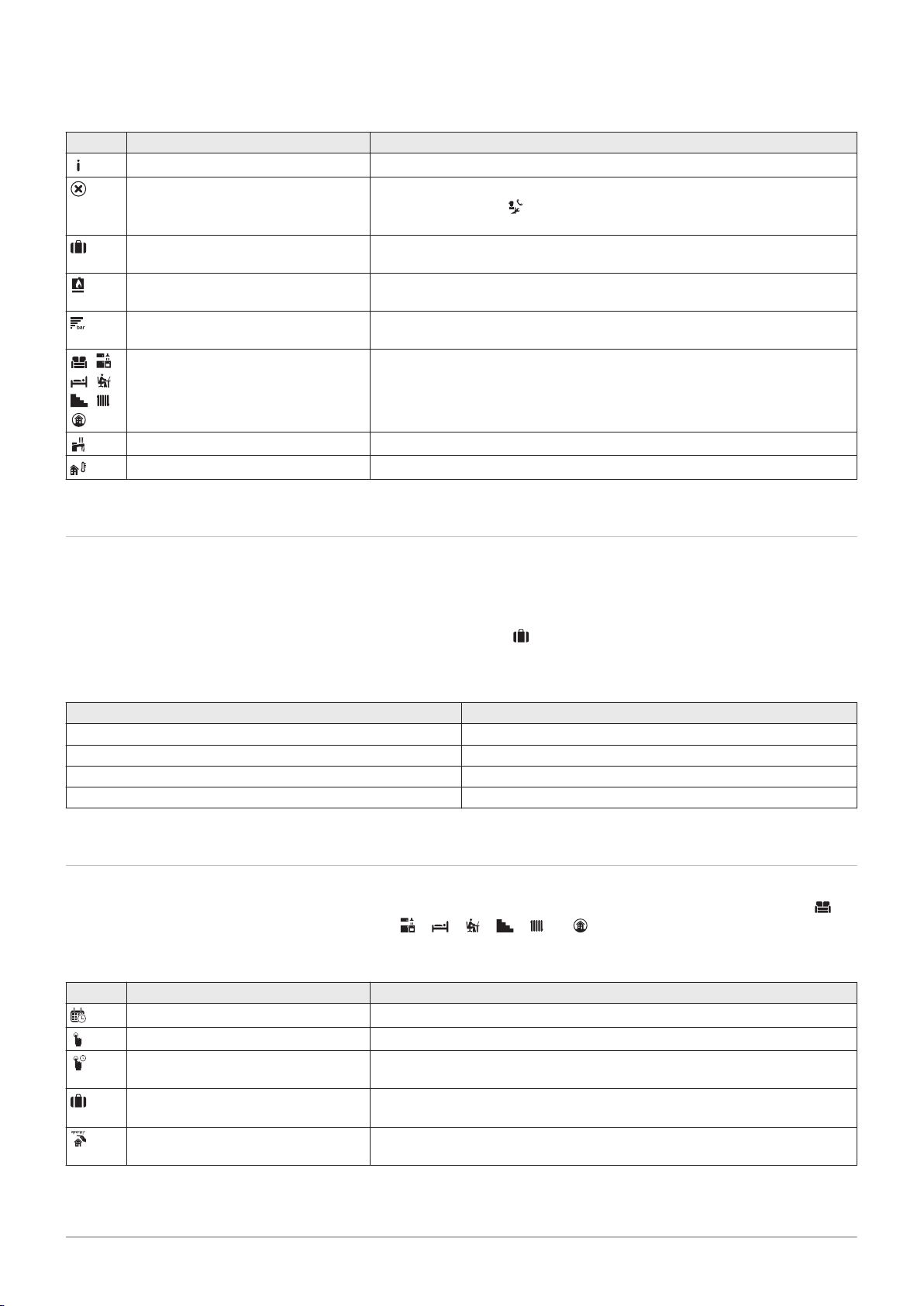

5.2 Accessing the user level menus

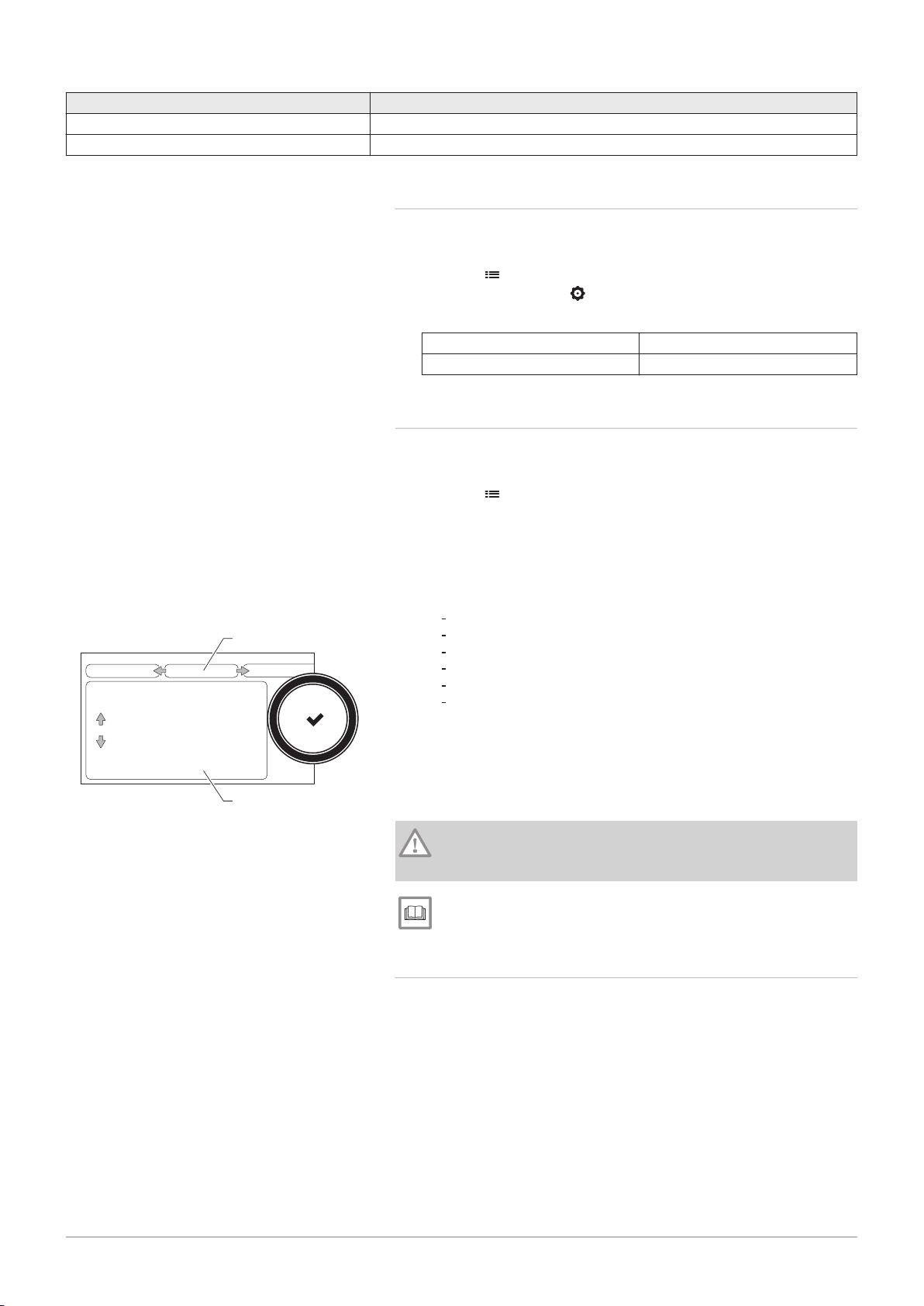

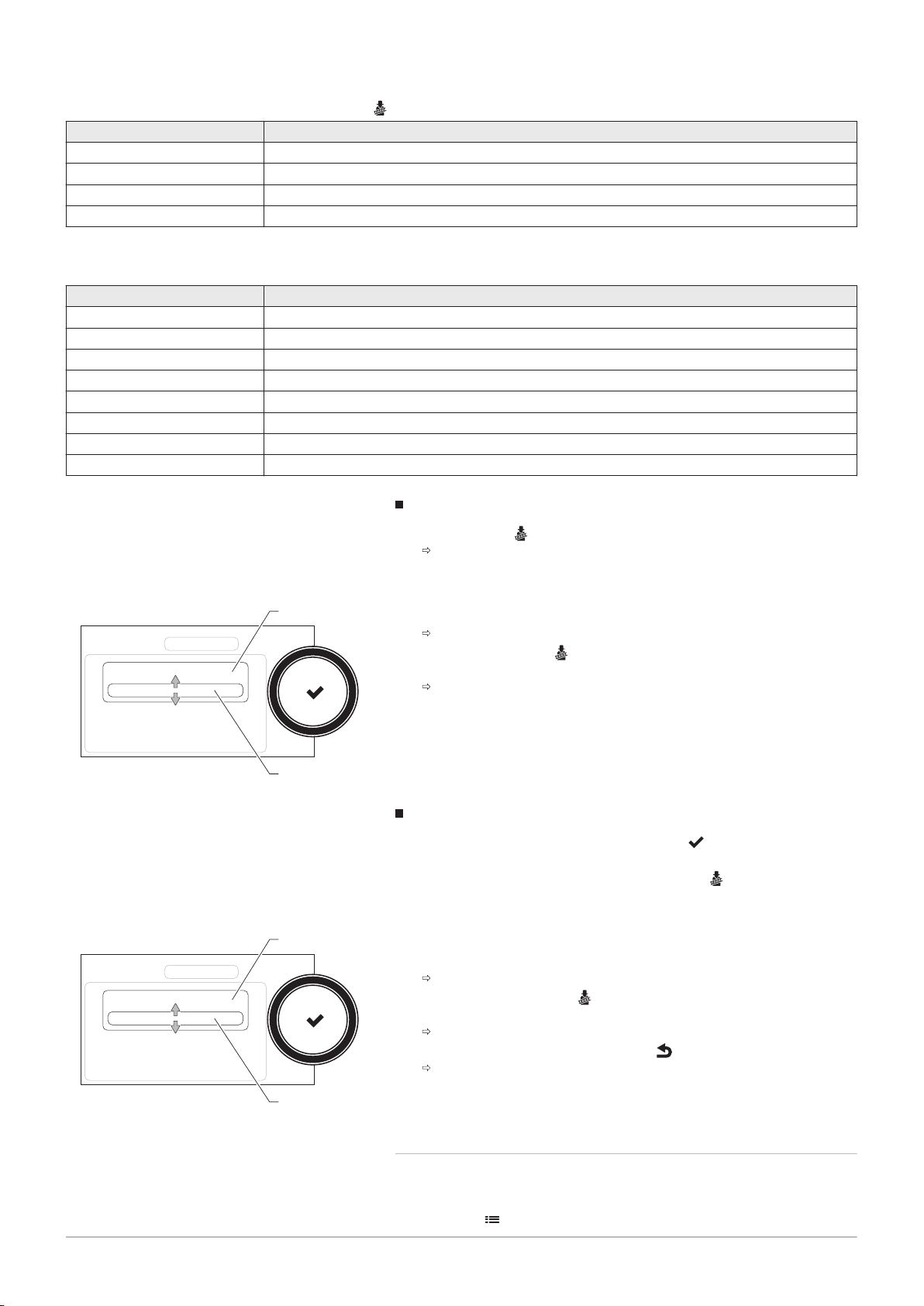

Fig.5

Fig.6 Confirm menu selection

Menu selection

The tiles on the home screen provide quick access for the user to the

corresponding menus.

1. Use the rotary knob to select the required menu.

2. Press the button to confirm the selection.

The available settings of this selected menu appear in the display.

3. Use the rotary knob to select the desired setting.

4. Press the button to confirm the selection.

All options for change will appear in the display (if a setting cannot

be changed, Cannot edit read-only datapoint will appear in the

display).

5. Use the rotary knob to change the setting.

6. Press the button to confirm the selection.

7. Use the rotary knob to select the next setting or press the button to

return to the home screen.

5.3

Home screen

The tiles on the home screen provide quick access to the corresponding

menus. Use the rotary knob to navigate to the menu of your choice and

press the button to confirm the selection. All options for change will

appear in the display (Cannot edit read-only datapoint will appear in the

display if a setting cannot be changed).

Page 11

Tab.5 Selectable tiles for the user

7725087 - v.01 - 06062019 AMC Pro 11

Tile Menu Function

Information menu. Read out various current values.

Error indicator. Read out details about the current error.

With some errors the icon will appear with installer contact details (when

filled in).

Holiday mode. Set the start and end date of your holiday to lower the room and domestic hot

water temperatures of all zones.

Gas boiler indicator. Read out burning details of the boiler and switch the heating function of the

boiler on or off.

Water pressure indicator. Shows the water pressure. Top up the installation when the water pressure is

too low.

Heating circuit set-up. Configure the settings per heating circuit.

, ,

, ,

, ,

DHW setup. Configure the domestic hot water temperatures.

Outdoor sensor setup. Configure the temperature regulation using the outdoor sensor.

5 User instructions

5.4 Activating holiday programs for all zones

If you go on holiday, the room temperature and domestic hot water

temperature can be reduced to save energy. With the following procedure

you can activate the holiday mode for all zones and domestic hot water

temperature.

1. Select the tile [ ].

2. Set the following parameters:

Tab.6 Holiday program settings

Parameter Description

Start date holiday Set the start time and date of your holiday

End date holiday Set the end time and date of your holiday

Wished room zone temperature on holiday period Set the room temperature for the holiday period

Reset Reset or cancel the holiday program

5.5 Heating circuit configuration

For every heating circuit there is a quick user settings menu available.

Select the heating circuit you want to configure by selecting the tile [ ],

[ ], [ ], [ ], [ ], [ ] or [ ]

Tab.7 Menu to configure a heating circuit

Icon Menu Function

Scheduling Set the scheduling mode and choose a timer program already created

Manual Set the manual mode; the room temperature setpoint is set to a fixed setting

Short temperature change Set the temporary mode; the room temperature setpoint is changed tempora

rily

Holiday Set the start and end date of your holiday to lower the room temperature set

point.

Antifrost Set the frost protection mode; the minimum room temperature protects your

system from freezing

Page 12

AD-3001404-01

1

2

5 User instructions

12 AMC Pro 7725087 - v.01 - 06062019

Icon Menu Function

Set Heating Activity Temperatures Set the room temperature setpoint for each activity of the timer program.

See: Timer program to control the room temperature, page 13

Zone configuration Access the settings for the configuration of the heating circuit.

Tab.8

Extended menu to configure a heating circuit Zone configuration

Menu Function

Short temperature change Change the room temperature temporarily, if required

OperatingZoneMode Select the heating operating mode: Scheduling, Manual or Antifrost

Manu ZoneRoomTempSet Set the room temperature manually to a fixed setting

Heating Schedule Create a timer program (up to 3 programs allowed). See: Creating a timer

program, page 13

Set Heating Activity Temperatures Set the room temperature for each activity of the timer program

ZoneTimeProg Select Select a timer program (3 options)

Holiday Mode Set the start and end date of your holiday and the reduced temperature for

this zone

Zone friendly Name Create or change the name of the heating circuit

Icon display zone Select the icon of the heating circuit

OperatingZoneMode Read the current operating mode of the heating circuit

5.6 Changing the room temperature of a zone

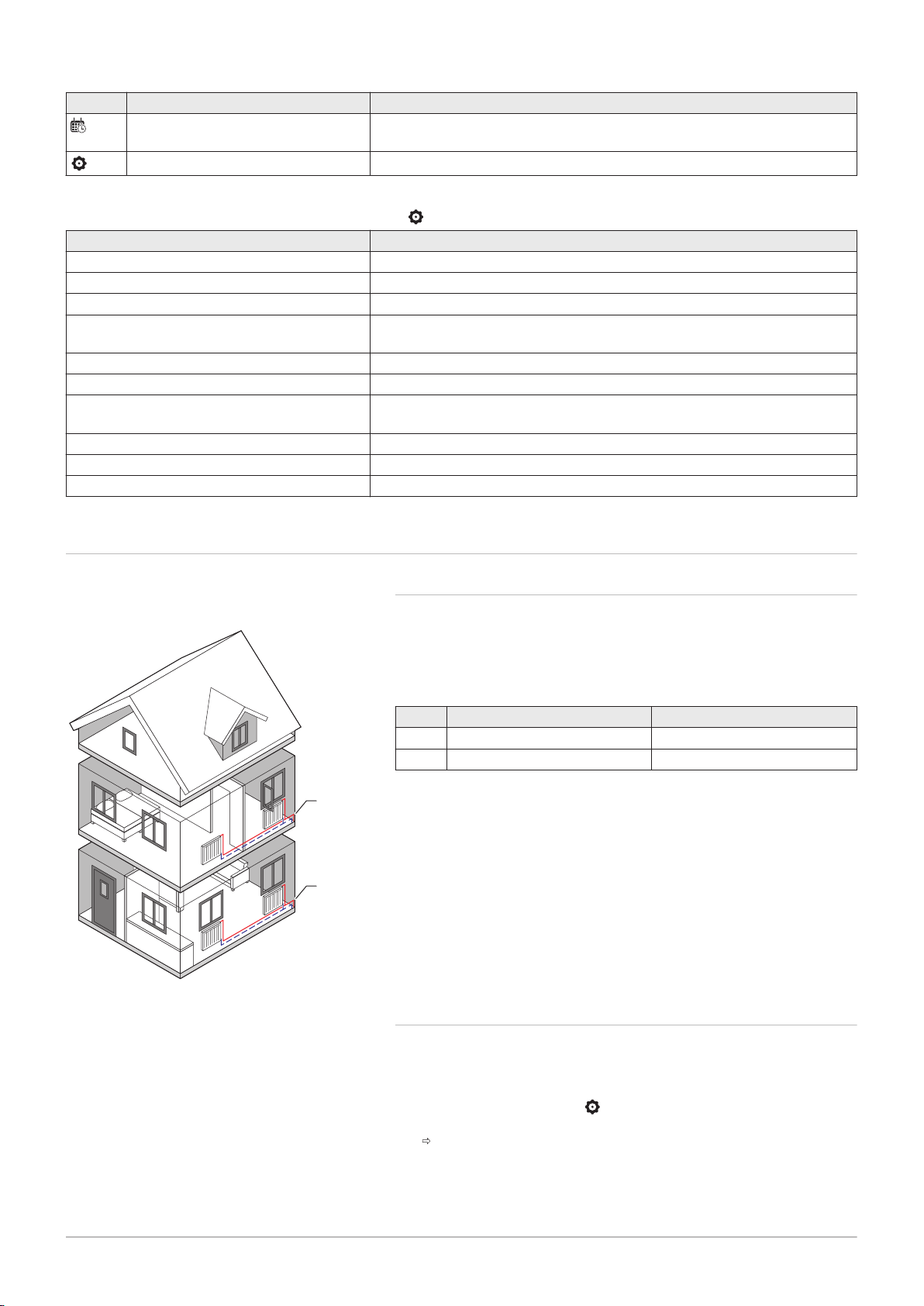

5.6.1 Definition of zone

Fig.7

Two zones

Zone is the term given to the different hydraulic circuits CIRCA, CIRCB

and so on. It designates several rooms of the house served by the same

circuit.

Tab.9 Example of two zones

Zone Factory name

1 Zone 1 CIRCA

2 Zone 2 CIRCB

5.6.2 Changing the name and symbol of a zone

The zones have a factory symbol and factory name. You can change the

name and symbol of a zone.

1. Select the tile of the zone you want to change.

2. Select Zone configuration

3. Select Zone friendly Name

A keyboard with letters, numbers and symbols is shown.

Page 13

AD-3001382-01

: .... ...... ........ ..............

11:20

xs t u v w

rm n o p q

fa b c d e

lg h i j k

y z

ÀÁÄabc ABC 123 !@# áäà

...

AD-3001383-01

: .... ...... ........ ..............

11:20

xs t u v w

rm n o p q

fa b c d e

lg h i j k

y z

ÀÁÄabc ABC 123 !@# áäà

...

5 User instructions

7725087 - v.01 - 06062019 AMC Pro 13

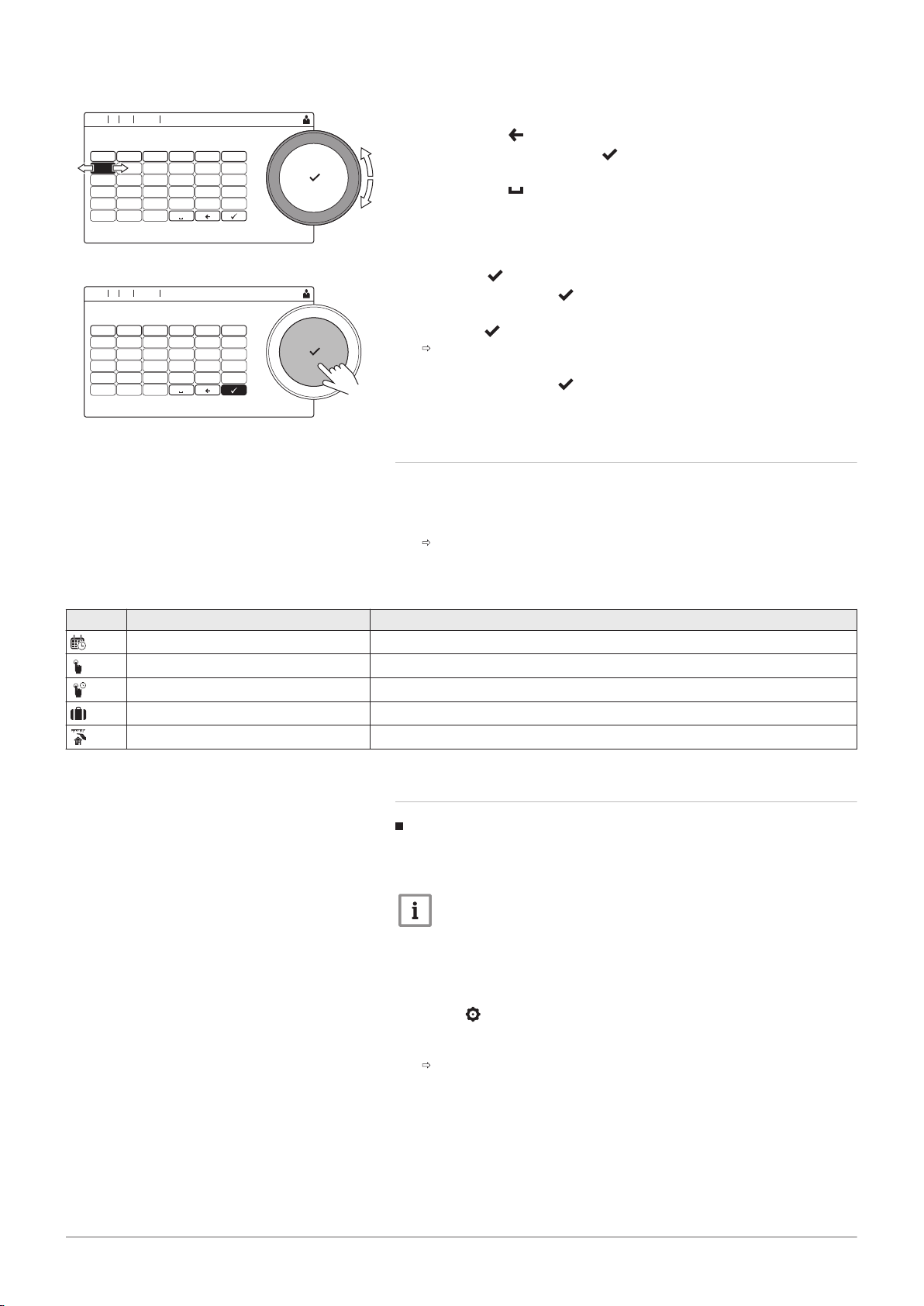

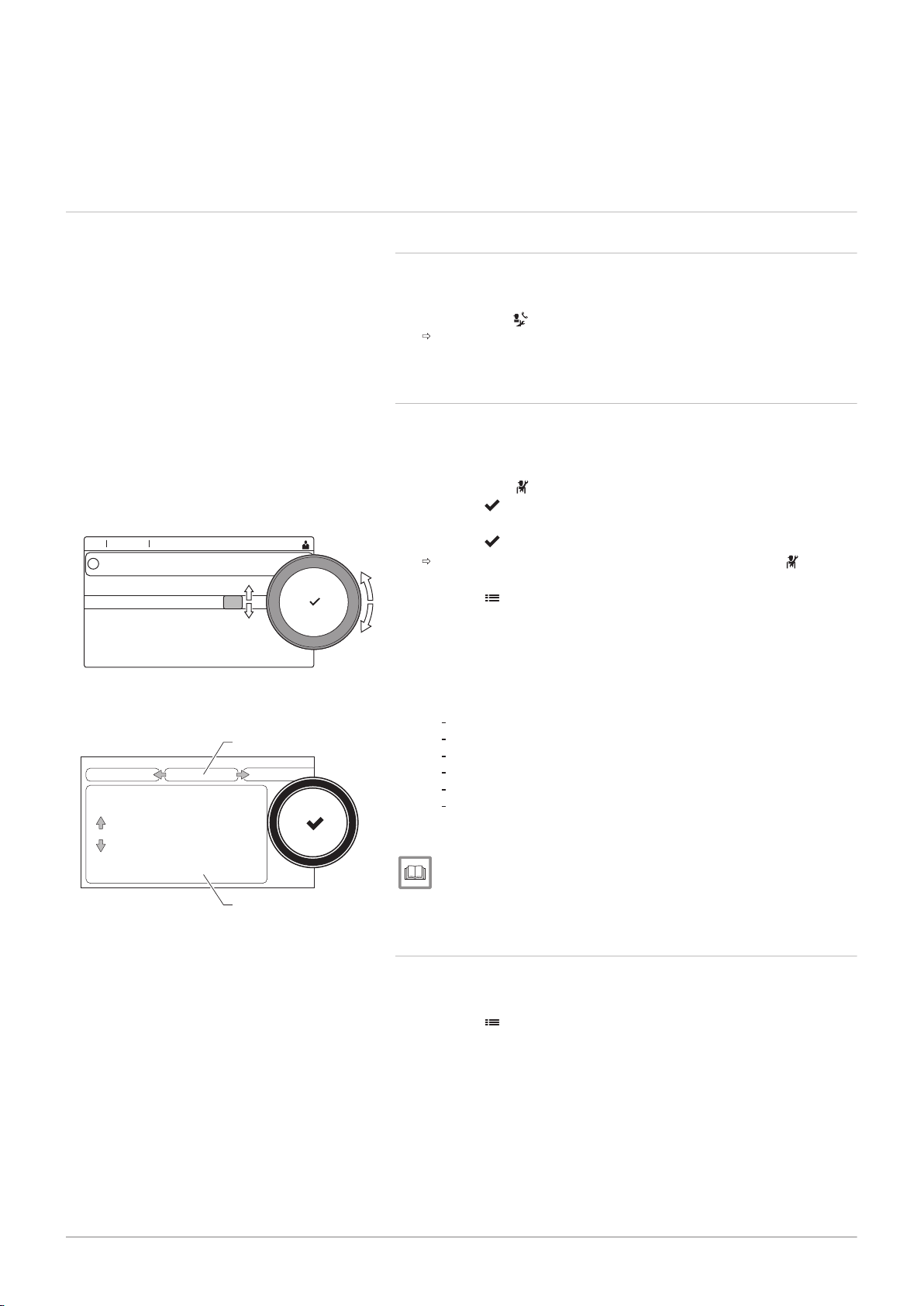

Fig.8

Letter selection

Fig.9 Confirm sign

4. Change the name of the zone (20 characters maximum):

4.1. Use the rotary button to select a letter, number or action.

4.2.

Select to delete a letter, number or symbol.

4.3.

Press the rotary knob to confirm or to repeat a letter,

number or symbol.

4.4.

Select to add a space.

5. Select the sign on the screen when the name is complete.

6. Press the rotary knob to confirm the selection.

7. Use the rotary button to select Icon display zone.

8. Press the knob to confirm the selection.

All available icons appear in the display.

9. Use the rotary knob to select the desired symbol of the zone.

10. Press the rotary knob to confirm the selection.

5.6.3 Changing the operating mode of a zone

To regulate the room temperature of the different areas of the house, you

can choose from 5 operating modes:

1. Select the tile of the zone you want to change.

The Zone QuickSelect menu opens.

2. Select the desired operating mode:

Tab.10 Operating modes

Icon Mode Description

Scheduling The room temperature is controlled by a timer program

Manual The room temperature is set to a fixed setting

Short temperature change The room temperature is changed temporarily

Holiday The room temperature is reduced during your holiday to save energy

Antifrost Protect the boiler and installation from freezing in winter

5.6.4 Timer program to control the room temperature

Creating a timer program

A timer program allows you to vary the room temperature per hour and per

day. The room temperature is linked to the activity of the timer program.

1. Select the tile of the zone you want to change.

2. Select Zone configuration > Heating Schedule.

3. Select the timer program you want to modify: Schedule 1, Schedule 2

or Schedule 3.

Important

You can create up to three timer programs per zone. For example,

you can create a program for a week with normal working hours

and a programme for a week when you are at home most of the

time.

Activities scheduled for Sunday are displayed. The last scheduled

activity of a day is active until the first activity of the next day. At

initial start-up, all weekdays have two standard activities; Home

starting at 6:00 and Sleep starting at 22:00.

Page 14

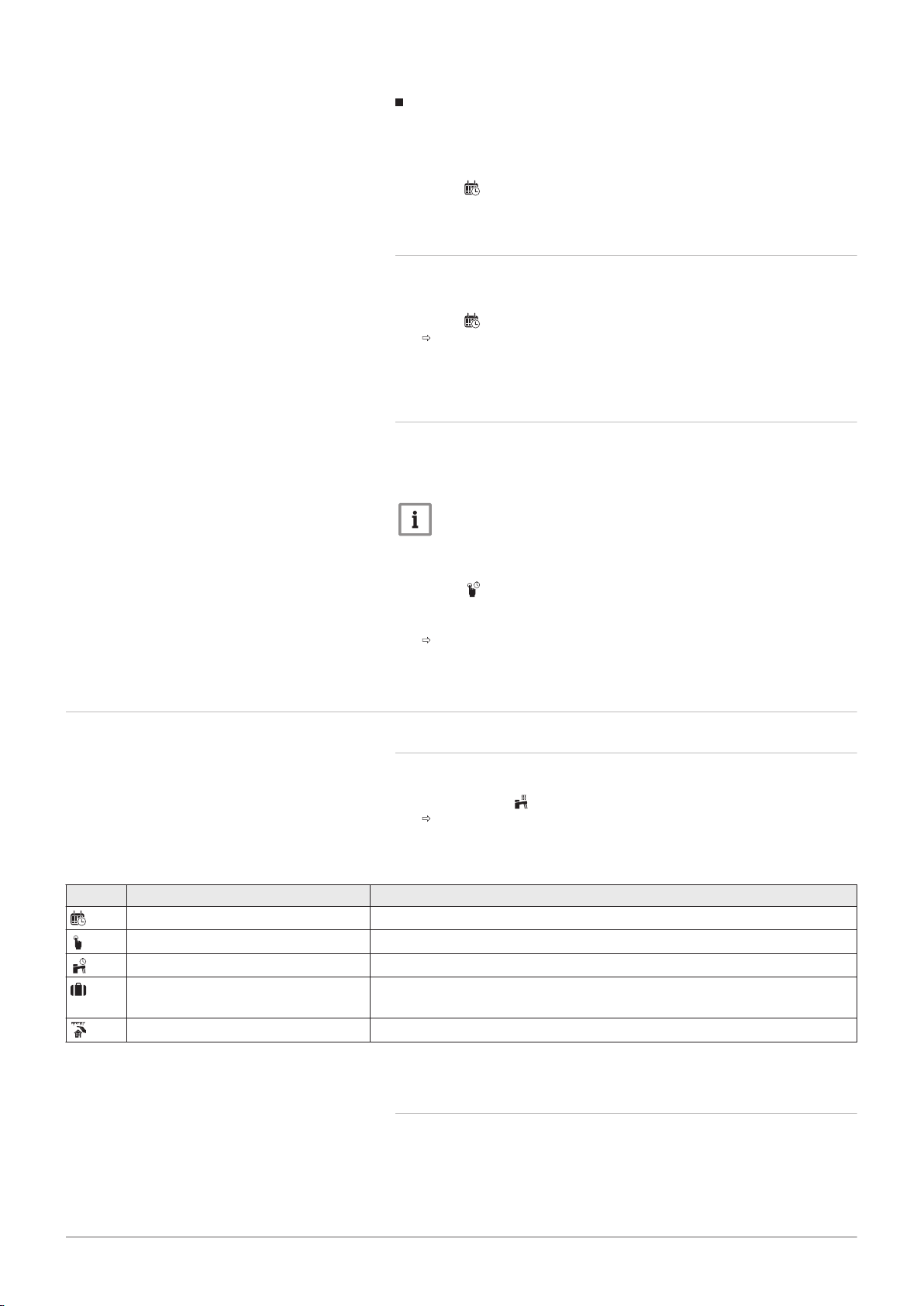

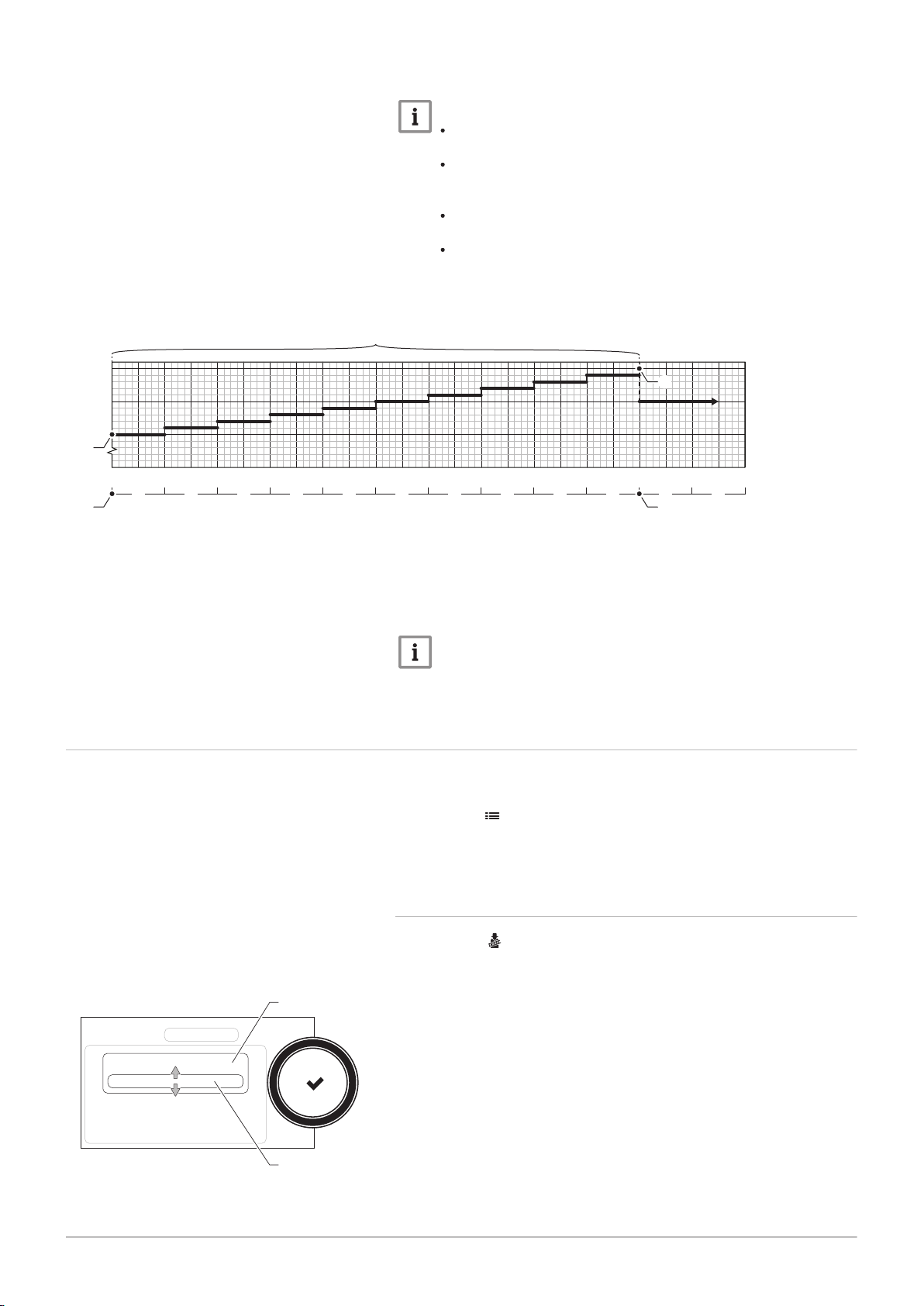

AD-3001403-01

0

15

20

25

°C

0:00 2:00 4:00 6:00 8:00 10:00 12:00h14:00 16:00 18:00 20:00 22:00 0:00

1

2

3

4

5

AD-3001384-01

........ .......

..... ... ....... ....

....... ...........

.... ...... ........ ..............

11:20

..:.. ........ ....

..:.. ........ ....

................ ..............

A

B

C

5 User instructions

14 AMC Pro 7725087 - v.01 - 06062019

Fig.10

Weekday

4. Select the weekday you want to modify.

A Weekday

B Overview of scheduled activites

C List of actions

5. Perform the following actions, if necessary:

5.1. Edit the start time and/or activity of a scheduled activity.

5.2. Add a new activity.

5.3. Delete a scheduled activity (select the activity Delete).

5.4. Copy the scheduled activities of the weekday to other days.

5.5. Change the temperature linked to an activity.

Definition of activity

Activity is the term used when programming time slots in a timer program.

The timer program sets the room temperature for different activities during

the day. A temperature setpoint is associated with each activity. The last

activity of the day is valid until the first activity of the next day.

Fig.11

Activities of a timer program

Tab.11 Example of activities

Start of the activity Activity Temperature setpoint

1 6:30 Morning 20 °C

2 9:00 Away 19 °C

3 17:00 Home 20 °C

4 20:00 Evening 22 °C

5 23:00 Sleep 16 °C

Changing the name of an activity

You can change the names of the activities in the timer program.

1. Press the button.

2. Select System Settings .

3. Select Set Heating Activity Names.

A list of 6 activities and their standard names is shown:

Activity 1 Sleep

Activity 2 Home

Activity 3 Away

Activity 4 Morning

Activity 5 Evening

Activity 6 Custom

4. Select an activity.

A keyboard with letters, numbers and symbols is shown.

5. Change the name of the activity:

5.1.

Press the rotary knob to repeat a letter, number or symbol.

5.2.

Select to delete a letter, number or symbol.

5.3.

Select to add a space.

6. Select the sign on the screen when the name is complete.

7. Press the rotary knob to confirm the selection.

Page 15

5 User instructions

7725087 - v.01 - 06062019 AMC Pro 15

Activating a timer program

In order to use a timer program, it is necessary to activate the operating

mode Scheduling. This activation is done separately for each zone.

1. Select the tile of the zone you want to change.

2. Select Scheduling.

3. Select timer program Schedule 1, Schedule 2 or Schedule 3.

5.6.5 Changing the heating activity temperatures

You can change the heating temperatures of each activity.

1. Select the tile of the zone you want to change.

2. Select Set Heating Activity Temperatures.

A list of 6 activities and their temperatures is shown.

3. Select an activity.

4. Set the heating activity temperature.

5.6.6 Changing the room temperature temporarily

Regardless of the operating mode selected for a zone, it is possible to

change the room temperature for a short period. After this period has

elapsed, the selected operating mode resumes.

Important

The room temperature can only be adjusted in this way if a room

temperature sensor/thermostat is installed.

1. Select the tile of the zone you want to change.

2. Select Short temperature change.

3. Set the duration in hours and minutes.

4. Set the temporary room temperature.

The Short temperature change menu shows the duration and the

temporary temperature.

5.7 Changing the domestic hot water temperature

5.7.1 Changing the domestic hot water operating mode

For hot water production, you can choose from 5 operating modes:

1. Select the tile [ ].

The DHW QuickSelect menu opens.

2. Select the desired operating mode:

Tab.12 DHW operating modes

Icon Mode Description

Scheduling The domestic hot water temperature is controlled by a timer program

Manual The domestic hot water temperature is set to a fixed setting

Hot water boost The domestic hot water temperature is increased temporarily

Holiday The domestic hot water temperature is reduced during your holiday to save

energy

Antifrost Protect the boiler and installation from freezing in winter

5.7.2

Increasing the domestic hot water temperature temporarily

Regardless of the operating mode selected for domestic hot water

production, it is possible to increase the domestic hot water temperature

for a short period. After this period the hot water temperature decreases to

the Reduced setpoint.

Page 16

AD-3001384-01

........ .......

..... ... ....... ....

....... ...........

.... ...... ........ ..............

11:20

..:.. ........ ....

..:.. ........ ....

................ ..............

A

B

C

5 User instructions

16 AMC Pro 7725087 - v.01 - 06062019

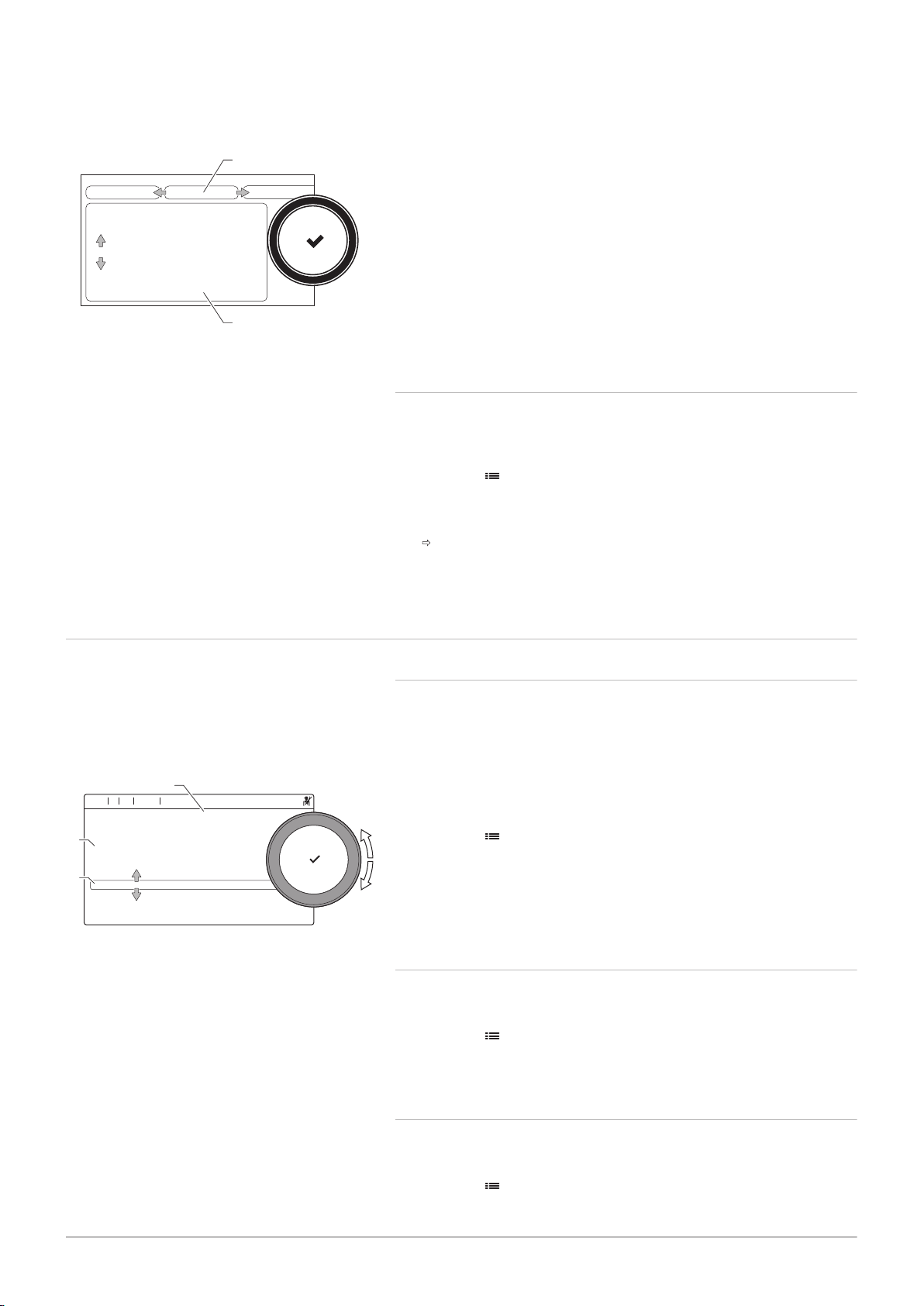

Fig.12

Weekday

Important

The domestic hot water temperature can only be adjusted in this

way if a domestic hot water sensor is installed.

1. Select the tile [ ].

2. Select Hot water boost.

3. Set the duration in hours and minutes.

The temperature is increased to the DHW comfort setpoint.

5.7.3 Timer program to control the DHW temperature

Creating a timer program

A timer program allows you to vary the domestic hot water temperature

per hour and per day. The hot water temperature is linked to the activity of

the timer program.

Important

You can create up to three timer programs. For example, you can

create a program for a week with normal working hours and a

programme for a week when you are at home most of the time.

1. Select the tile [ ].

2. Select Zone configuration > DHW Schedule.

3. Select the timer program you want to modify: Schedule 1, Schedule 2

or Schedule 3.

Activities scheduled for Sunday are displayed. The last scheduled

activity of a day is active until the first activity of the next day. The

scheduled activities are shown. At initial start-up, all weekdays have

two standard activities; Comfort starting at 6:00 and Reduced

starting at 22:00.

4. Select the weekday you want to modify.

A

Weekday

B Overview of scheduled activites

C List of actions

5. Perform the following actions, if necessary:

5.1. Edit the start time and/or activity of a scheduled activity.

5.2. Add a new activity.

5.3. Delete a scheduled activity (select the activity Delete).

5.4. Copy the scheduled activities of the weekday to other days.

5.5. Change the temperature linked to an activity.

Activating a DHW timer program

In order to use a DHW timer program, it is necessary to activate the

operating mode Scheduling. This activation is done separately for each

zone.

1. Select the tile [ ].

2. Select Scheduling.

3. Select DHW timer program Schedule 1, Schedule 2 or Schedule 3.

5.7.4 Changing the comfort hot water temperature

You can change the comfort hot water temperature in the timer program.

1. Select the tile [ ].

2. Select DHW comfort setpoint: The DHW temperature when the hot

water production is switched on.

3. Set the comfort hot water temperature.

You can also change the reduced hot water temperature via: Zone

configuration > Domestic Hot Water Setpoints > DHW reduced setpoint:

The DHW temperature when the hot water production is switched off.

Page 17

5.8 Switching the central heating on or off

7725087 - v.01 - 06062019 AMC Pro 17

You can switch off the central heating function of the boiler to save energy,

for example during the summer period.

5 User instructions

1. Select the tile [ ].

2. Select CH function on.

3. Select the following setting:

3.1. Off to switch off the central heating function.

3.2. On to switch the central heating function on again.

Important

Frost protection is not available when the central heating function

is switched off.

5.9

Reading the installer's name and phone number

The installer can set his name and phone number in the control panel. You

can read this information when you want to contact the installer.

1. Press the button.

2. Select System Settings > .Installer Details

The installer’s name and phone number is shown.

Page 18

AD-3001378-02

00:12

0 1 2

3

4

0

1

5

6

2

0

3

4

5

1

2

3

4

1

2

3

4

0

........ .......

........ .......

........ ......... ...

..... ... ....... .... .. ..... ....... .... ..... .......

i

6 Installer instructions

18 AMC Pro 7725087 - v.01 - 06062019

6 Installer instructions

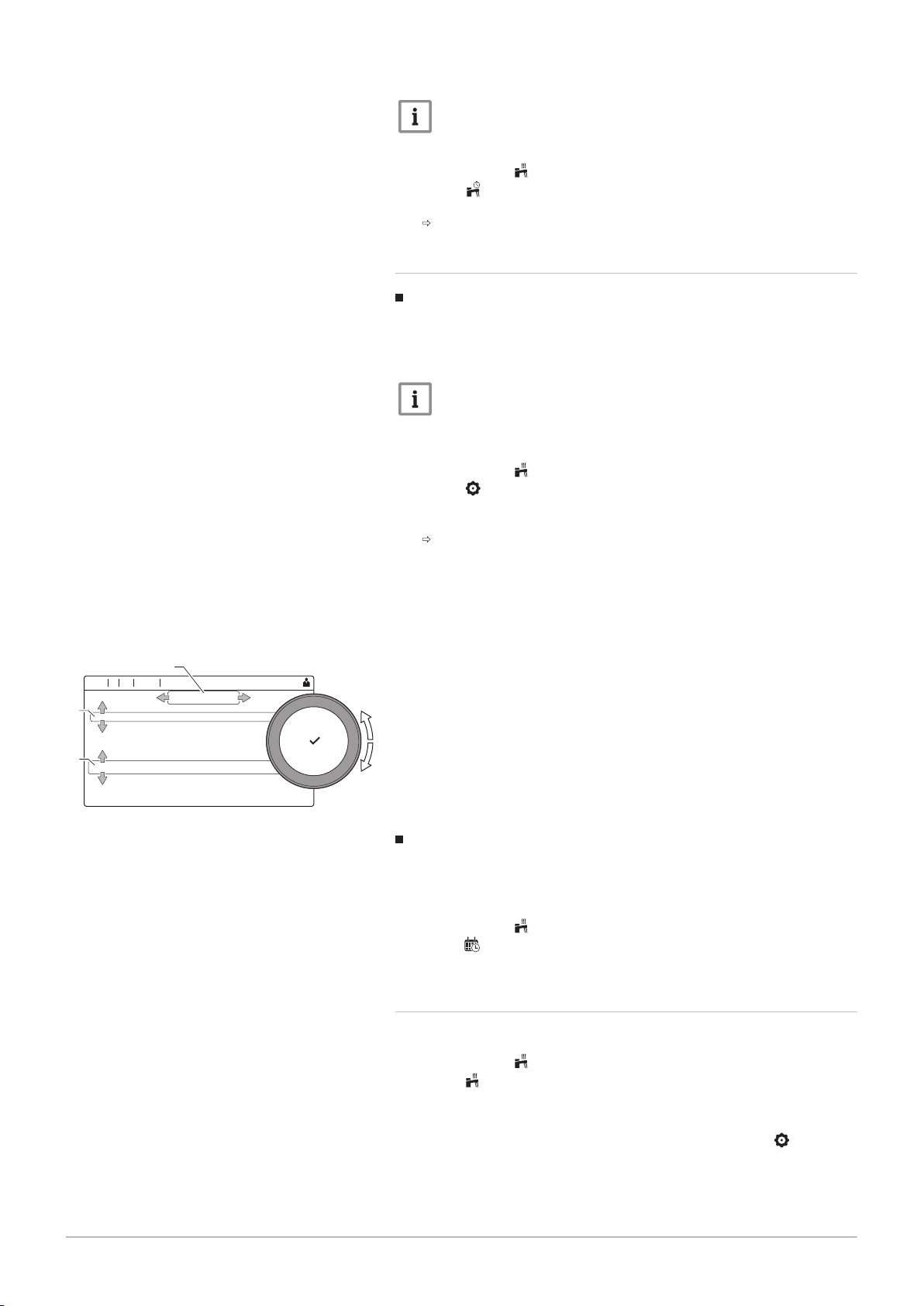

6.1 Accessing the installer level

Fig.13 Installer level

Some parameters that may affect the operation of the boiler are protected

by an access code. Only the installer is allowed to modify these

parameters.

1. Select the tile [ ].

2. Press the button to confirm the selection.

3. Use the rotary knob to select code: 0012.

4. Press the button to confirm the selection.

When the installer level is enabled, the status of the tile [ ]

changes from Off into On.

5. To leave the installer level, select the tile [ ] .

6. Use the rotary knob to select Confirm or Cancel.

7. Press the button to confirm the selection.

When the installer level is disabled, the status of the tile [ ]

changes from On into Off.

When the control panel is not used for 30 minutes, the installer level is left

automatically.

6.2 Configuring the installation at installer level

Configure the installation by pressing the button and selecting

Installation Setup . Select the control unit or circuit board you want to

configure:

Tab.13 CU-GH08

Icon Zone or function Description

CIRCA / CH Central heating circuit

Gas fired appliance Gas boiler

Tab.14 SCB-10

Icon Zone or function Description

CIRCA Central heating circuit A

CIRCB Central heating circuit B

DHW Domestic hot water external circuit

CIRCC Central heating circuit C

0-10 volt input 0–10 volt input signal

Digital Input Digital input signal

Analogue input Analogue input signal

Cascade management B Management of a cascade of multiple boilers

Buffer Tank Schedule Enable a buffer tank with one or two sensors

Outdoor temperature Outdoor sensor

Status information PCB SCB-10 status information

Tab.15 Configuring a zone or function of CU-GH08 or SCB-10

Parameters, counters, signals Description

Parameters Set the parameters at installer level

Counters Read the counters at installer level

Signals Read the signals at installer level

Adv. Parameters Set the parameters at advanced installer level

Page 19

Parameters, counters, signals Description

AD-3000936-01

A

B

7725087 - v.01 - 06062019 AMC Pro 19

Adv. Counters Read the counters at advanced installer level

Adv. Signals Read the signals at advanced installer level

6.2.1 Setting the installer details

You can store your name and phone number in the control panel to be

read by the user.

1. Press the button.

2. Select System Settings > Installer Details.

3. Enter the following data:

Installer name Name of the installer

Installer phone Phone number of the installer

6.2.2 Setting the parameters

You can change the parameters and settings of the appliance and the

connected control boards, sensors etc. to configure the installation.

1. Press the button.

2. Select > Installation Setup.

3. Select the zone or device you want to configure.

4. Select Parameters, counters, signals > Parameters to change a

parameter.

5. If available, select Adv. Parameters to change a parameter at the

advanced installer level.

A

Fig.14

Parameters, counters, signals

Parameters

Counters

Signals

Adv. Parameters

Adv. Counters

Adv. Signals

B List of settings or values

6 Installer instructions

The boiler’s control unit is set for the most common central heating

systems. These settings will ensure that virtually every central heating

system operates effectively. The user or the installer can optimise the

parameters as required.

Caution

Changing the factory settings may adversely affect the operation

of the boiler.

For more information, see

List of parameters, page 56

6.2.3 Changing boiler parameters when SCB-10 is fitted

When the boiler is fitted with the SCB-10 the following boiler CU-GH08

parameter(s) at installer level must be checked and adjusted, if necessary:

Page 20

AD-4100424-01

F

M

1500 2500 3500 4500 5500 6500 7500

0

20

R

Q

40

41,2

60

5400

AD-4100427-01

60

1500 2500 3500 4500 5500 6500 7500

0

20

R

Q

40

62

80

5600

F

M

6 Installer instructions

20 AMC Pro 7725087 - v.01 - 06062019

Tab.16 Installation Setup > CU-GH08 > CIRCA > Parameters, counters, signals > Parameters

Code Display text Description Range Adjust

ment

CP020 Zone Function Functionality of the zone 0 = Disable

0

1 = Direct

2 = Mixing Circuit

3 = Swimming pool

4 = High Temperature

5 = Fan Convector

6 = DHW tank

7 = Electrical DHW

8 = Time Program

9 = ProcessHeat

10 = DHW Layered

11 = DHW Internal tank

31 = DHW FWS EXT

Tab.17 Installation Setup > CU-GH08 > Gas fired appliance > Parameters, counters, signals > Parameters

Code Display text Description Range Adjust

ment

AP102 Boiler Pump function Configuration of the boiler pump as

zone pump or system pump (feed

0 = No

1 = Yes

0

lowloss header)

Tab.18 Installation Setup > CU-GH08 > Tank DHW > Parameters, counters, signals > Parameters

Code Display text Description Range Adjust

ment

DP007 Dhw 3wv Standby Position of three way valve during

standby

6.2.4

Setting the maximum load for CH operation

0 = CH position

1 = DHW position

0

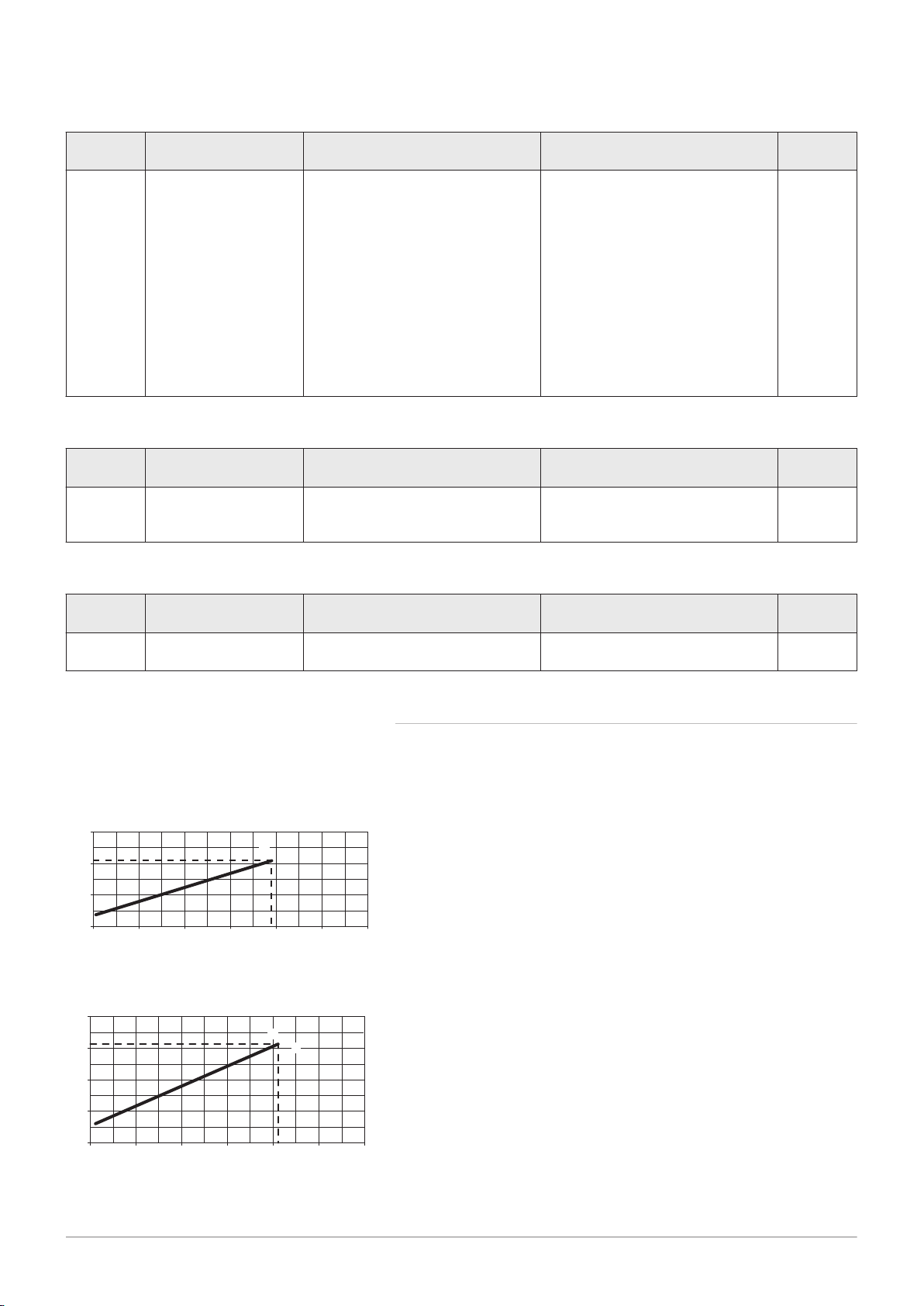

See the graphs for the relationship between load and speed for natural

gas. The speed can be changed using parameter GP007.

Fig.15 Load AMC Pro 45

Fig.16 Load AMC Pro 65

M

Maximum heat input

F

Factory setting

Q

Input (Hi) (kW)

R

Fan speed (rpm)

M

Maximum heat input

F

Factory setting

Q

Input (Hi) (kW)

R

Fan speed (rpm)

Page 21

AD-4100429-01

1500 2500 3500 4500 5500 6500 7500

0

20

R

Q

40

60

80

86

100

6300

F

M

AD-4100431-01

1500 2500 3500 4500 5500 6500 7500

0

20

R

Q

40

60

80

100

107

120

6800

F

M

AD-3001402-01

.... ...... ........ ..............

11:20

.... ...

... ....

...... ...

... ...

........ ...................

........ ...................

.... .....

D

B

A

C

6 Installer instructions

7725087 - v.01 - 06062019 AMC Pro 21

Fig.17

Load AMC Pro 90

Fig.18 Load AMC Pro 115

M

Maximum heat input

F

Factory setting

Q

Input (Hi) (kW)

R

Fan speed (rpm)

M

Maximum heat input

F

Factory setting

Q

Input (Hi) (kW)

R

Fan speed (rpm)

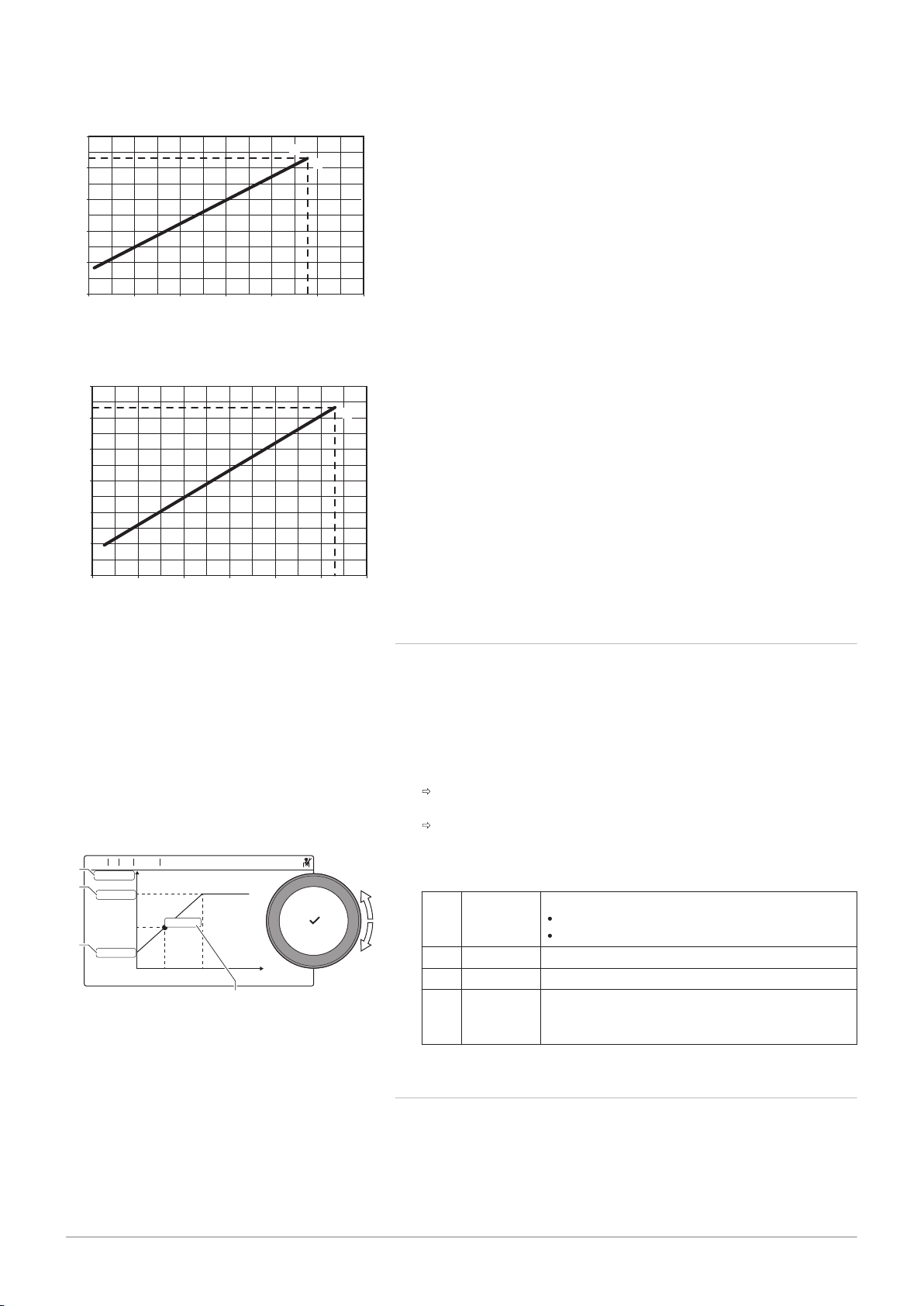

6.2.5 Setting the heating curve

When an outdoor temperature sensor is connected to the installation, the

relation between the outdoor temperature and the central heating flow

temperature is controlled by a heating curve. This curve can be adjusted

to the requirements of the installation.

1. Select the tile of the zone you want to configure.

2. Select Control strategy.

3. Select the setting Outdoor Temp. based or Outdoor & room based.

The option Heating Curve appears in the Zone setup menu.

4. Select Heating Curve.

A graphic display of the heating curve is shown.

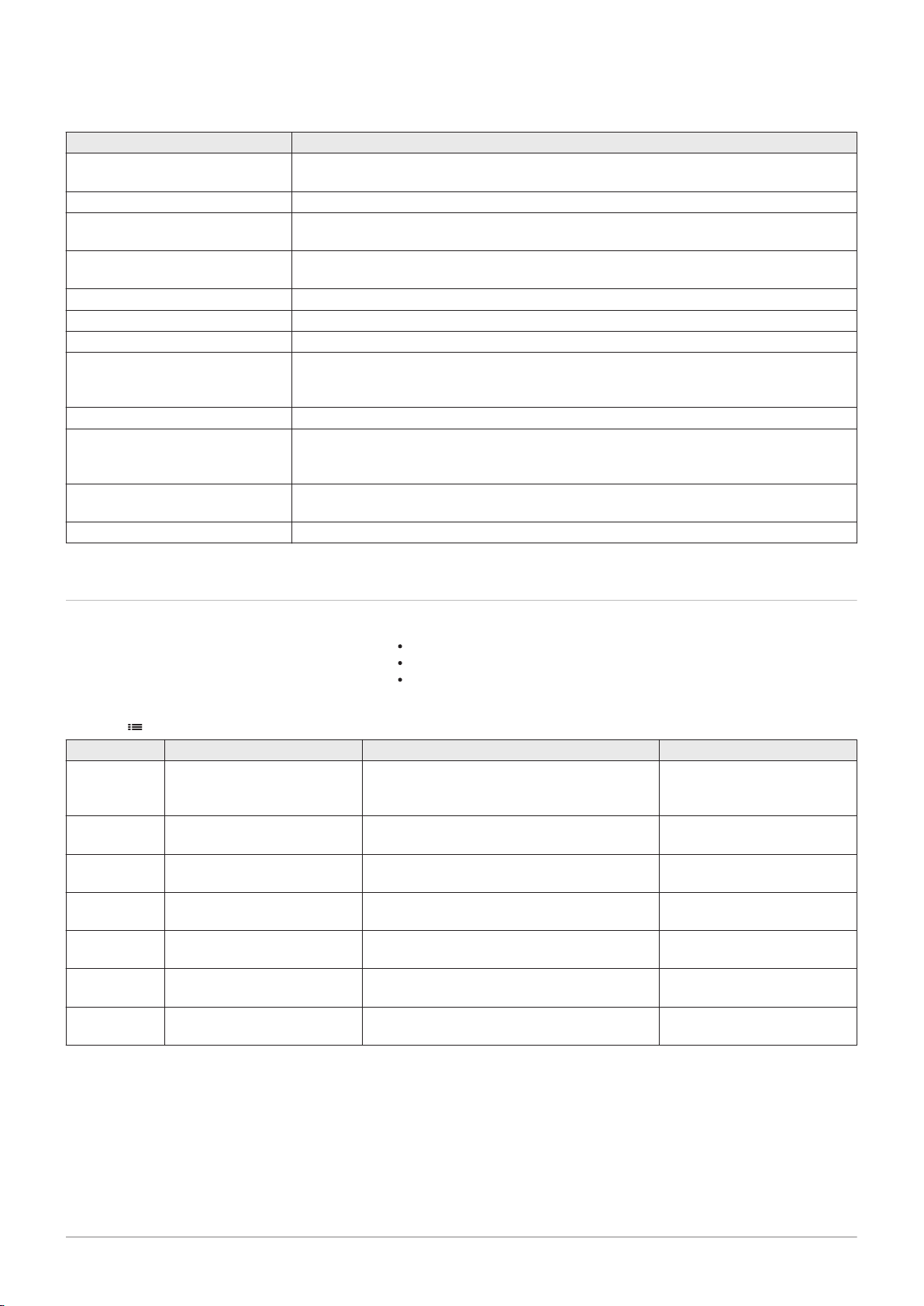

Fig.19 The heating curve

5. Adjust the following parameters:

Tab.19 Settings

A Slope: Slope of the heating curve:

Floor heating circuit: slope between 0.4 and 0.7

Radiator circuit: slope at approximately 1.5

B Max: Maximum temperature of the heating circuit

C Base: Ambient temperature setpoint

D xx°C ; xx°CRelationship between the heating circuit flow

temperature and the outdoor temperature. This

information is visible throughout the slope.

6.2.6 Screed drying

The screed drying function is used to force a constant flow temperature or

a series of successive temperature levels to accelerate screed drying on

underfloor heating.

Page 22

AD-3001406-01

0

20

35

50

T

0:00 0:00 0:00 0:00 0:00 0:00 0:00

d

0:00 0:00 0:00 0:00 0:00 0:00

10

9 8 7 6 5

4

3 2 1 x x

2

3

4 5

1

AD-3000941-02

A

B

6 Installer instructions

22 AMC Pro 7725087 - v.01 - 06062019

Fig.20 Screed drying curve

Important

The settings for these temperatures must follow the screed

layer's recommendations.

Activation of this function via the parameter CP470 forces the

permanent display of the screed drying function and deactivates

all other regulator functions.

When the screed drying function is active on one circuit, all

other circuits and the domestic hot water circuit continue to run.

It is possible to use the screed drying function on circuits A and

B. The parameter settings must be made on the PCB that

controls the circuit concerned.

d

Number of days

T

Heating set point temperature

1

Number of days on which the screed drying function

is activated (parameter CP470)

2

Screed drying start temperature (parameter CP480)

6.3 Commissioning the installation

Fig.21 Load test

3

Screed drying stop temperature (parameter CP490)

4

Start of the screed drying function

5

End of the screed drying function, back to normal

running

Important

Every day at midnight, the screed drying start temperature set

point is recalculated and the remaining number of days on which

the screed drying function is running decreases.

The commissioning menu shows submenus and tests needed for the

commissioning of the appliance.

1. Press the button.

2. Select Commissioning Menu.

3. Select the submenu with settings you want to change or the test you

want to perform.

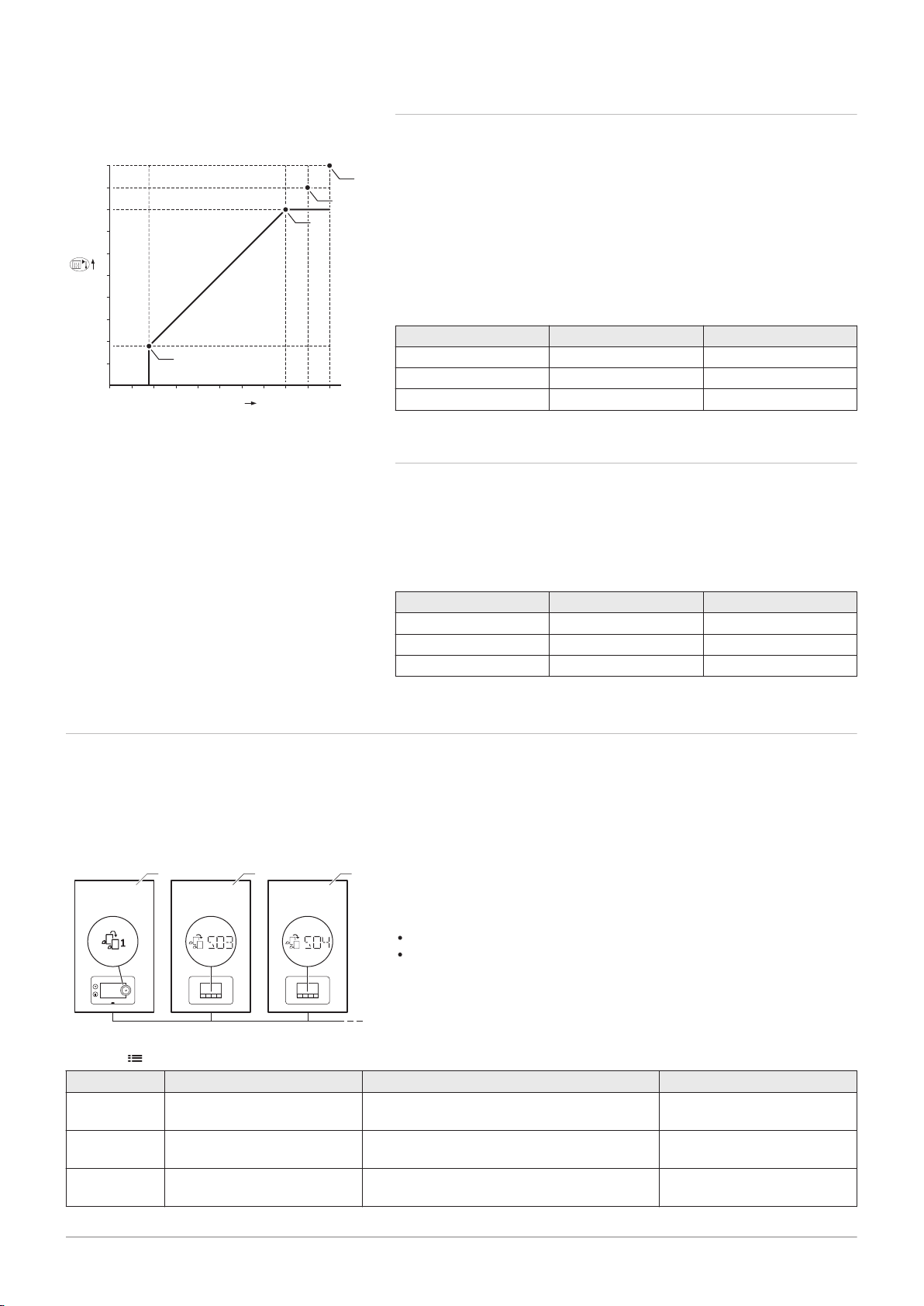

6.3.1

Chimney sweep menu

Select the tile [ ] to open the chimney sweep menu. The Change load

test mode menu will appear:

A Change load test mode

B Load test mode

Page 23

AD-3000941-02

A

B

AD-3000941-02

A

B

6 Installer instructions

7725087 - v.01 - 06062019 AMC Pro 23

Tab.20

Load tests in the chimney sweep menu

Change load test mode Settings

Off No test

MinimumPower Part load test

MaximumPowerCH Full load test for Central Heating mode

MaximumPowerDhw Full load test for Central Heating + Domestic Hot Water mode

Tab.21 Load test settings

Load Test menu Settings

ChimneyModeStatus Select the load test to start the test.

System Flow Temp Read the central heating flow temperature

T return Read the central heating return temperature

Actual fan RPM Read the actual fan speed

Actual flame current Read the actual flame current

Fan RPM Max CH Adjust the maximum fan speed during Central Heating mode

Fan RPM Min Adjust the minimum fan speed during Central Heating + Domestic Hot Water mode

Fan RPM Start Adjust the start fan speed

Performing the full load test

1. Select the tile [ ].

The Change load test mode menu appears.

2. Select the test MaximumPowerCH.

A

Fig.22

Full load test

Change load test mode

B MaximumPowerCH

The full load test starts. The selected load test mode is shown in the

menu and the icon appears in the top right of the screen.

3. Check the load test settings and adjust if necessary.

Only the parameters shown in bold can be changed.

Fig.23 Part load test

Performing the part load test

1. If the full load test is still running, press the button to change the

load test mode.

2. If the full load test was finished, select the tile [ ] to restart the

chimney sweep menu.

Change load test mode

A

B MinimumPower

3. Select the MinimumPower test in the menu Change load test mode.

The part load test starts. The selected load test mode is shown in

the menu and the icon appears in the top right of the screen.

4. Check the load test settings and adjust if necessary.

Only the parameters shown in bold can be changed.

5. End the part load test by pressing the button.

The message Running load test(s) stopped! is displayed.

6.3.2 Saving the commissioning settings

You can save all current settings on the control panel. These settings can

be restored if necessary, for example after replacement of the control unit.

1. Press the button.

Page 24

AD-3001378-02

00:12

0 1 2

3

4

0

1

5

6

2

0

3

4

5

1

2

3

4

1

2

3

4

0

........ .......

........ .......

........ ......... ...

..... ... ....... .... .. ..... ....... .... ..... .......

i

AD-3000936-01

A

B

6 Installer instructions

24 AMC Pro 7725087 - v.01 - 06062019

2. Select > Advanced Service Menu > Save as commissioning settings.

3. Select Confirm to save the settings.

When you have saved the commissioning settings, the option Revert

commissioning settings becomes available in the Advanced Service Menu.

6.4

Fig.24

Maintaining the installation

Installer level

Fig.25 Parameters, counters, signals

6.4.1 Viewing the service notification

When a service notification appears on the display, you can view the

details of the notification.

1. Select the tile [ ].

The View Service Notification menu opens.

2. Select the parameter or value you want to view.

6.4.2 Reading out measured values

The control unit continually registers various values from the boiler and the

connected sensors. These values can be read on the control panel of the

boiler.

1. Select the tile [ ].

2. Press the button to confirm the selection.

3. Use the rotary knob to select code: 0012.

4. Press the button to confirm the selection.

When the installer level is enabled, the status of the tile [ ]

changes from Off into On.

5. Press the button.

6. Select > Installation Setup.

7. Select the zone or device you want to read out.

8. Select Parameters, counters, signals > Counters or Signals to read

out a counter or signal.

9. If available, select Adv. Counters or Adv. Signals to read out counters

or signals at the advanced installer level.

A

Parameters

Counters

Signals

Adv. Parameters

Adv. Counters

Adv. Signals

B List of settings or values

For more information, see

List of measured values, page 77

6.4.3 Viewing production and software information

You can read details about the production dates, hardware and software

versions of the appliance and all connected devices.

1. Press the button.

2. Select Version Information.

Page 25

Fig.26

AD-3000936-01

A

B

AD-3001385-01

.... ...... ........ ..............

11:20

........

... .

... .

............ ....... ....... ....

......... ... .............. ...... .. .....

.......

.......

A

B

C

7725087 - v.01 - 06062019 AMC Pro 25

Version information

6 Installer instructions

3. Select the appliance, control board or any other device you want to

view.

A Select the appliance, control board or device

B List of information

4. Select the information you want to view.

6.4.4 Changing the domestic hot water temperature temporarily

When the timer program is active with a reduced domestic hot water

temperature, you can temporarily increase the hot water temperature for

e.g. testing of the hot water production.

1. Press the button.

2. Select Installation Setup > Internal DHW > Hot water boost.

3. Select Duration of temporary overwrite .

4. Set the duration in hours and minutes.

The hot water temperature is increased to the DHW comfort

setpoint.

You can delete or abort the temporary overwrite by selecting Reset.

6.5 Resetting or restoring settings

Fig.27 Configuration numbers

6.5.1

Resetting the configuration numbers CN1 and CN2

The configuration numbers must be reset when indicated by an error

message or when the control unit has been replaced. The configuration

numbers can be found on the data plate of the appliance.

A Select the control unit

B Extra information

C Configuration numbers

1. Press the button.

2. Select Advanced Service Menu > Set Configuration Numbers.

3. Select the control unit you want to reset.

4. Select and change the CN1 setting.

5. Select and change the CN2 setting.

6. Select Confirm to confirm the changed numbers.

6.5.2 Carrying out an auto-detect for the CAN matrix

When a control board has been replaced or removed from the boiler, this

function must be used to detect all devices connected to the CAN bus.

1. Press the button.

2. Select Advanced Service Menu > Auto Detect.

3. Select Confirm to carry out the auto-detect.

6.5.3

Restoring the commissioning settings

This option is only available when the commissioning settings were saved

on the control panel and allows you to restore these settings.

1. Press the button.

2. Select Advanced Service Menu > Revert commissioning settings.

3. Select Confirm to restore the commissioning settings.

Page 26

6 Installer instructions

26 AMC Pro 7725087 - v.01 - 06062019

6.5.4 Resetting to factory settings

You can reset the boiler to the default factory settings.

1. Press the button.

2. Select Advanced Service Menu > Reset to Factory Settings.

3. Select Confirm to restore the factory settings.

Page 27

7 Installation examples

AD-3001210-01

X2 X3

+TA-

TA

Tsyst Tsyst Tdhw Tflow Tflow Tflow

C AB21

R-Bus

Tout

R-Bus

R-Bus

12

3

4

+ -

Status

C AB

0-10V

N L

B

N

N L TS

N L

TS

A

N

23

2218 2019 21

5

14131211 15 16 17

43

21

109876

AD-4000062-01

x3

1

2

7725087 - v.01 - 06062019 AMC Pro 27

7.1 Access to the expansion box

7 Installation examples

Fig.28 Access to the expansion box

7.2

Connection options for the expansion PCB - SCB-10

If there is no space in the boiler’s instrument box to install an (optional)

expansion PCB, install the PCB in the electronics expansion box This is

available as an accessory.

1. Unclip the housing cover.

2. Remove the cover.

3. Install the expansion PCB in accordance with the instructions

supplied.

The following is installed in the expansion box:

the SCB-10 PCB.

Different heating zones can be connected to the SCB-10 PCB.

control of 2 (mixing) zones fitted on connector X15

control of a third (mixing) zone via an PCB (= accessory) fitted on

connector X8

control of one domestic hot water (DHW) zone

cascade layout (add sensor on sensor system 1 or 2)

Important

If the boiler is fitted with the SCB-10 PCB, then this is

automatically recognised by the automatic control unit of the

boiler.

On removing this control board, the boiler will show an error

code. To prevent this error, carry out an auto-detect immediately

after removing this board.

Fig.29 SCB-10 PCB

1 Outdoor temperature sensor

2 Programmable and 0-10 V input

3 Room temperature sensor - circuit C

4 Room temperature sensor - circuit B

Page 28

AD-3001318-01

X2 X3

7 Installation examples

28 AMC Pro 7725087 - v.01 - 06062019

5 Room temperature sensor - circuit A

6 Domestic hot water tank pump

7 Mixing valve - circuit B

8 Pump and safety thermostat - circuit B

9 Mixing valve - circuit A

10 Pump and safety thermostat - circuit A

11 System sensor 1

12 System sensor 2

13 Domestic hot water sensor

14 Flow sensor - circuit C

7.3

Zone functions of SCB-10

15 Flow sensor - circuit B

16 Flow sensor - circuit A

17 Impressed current anode

18 Connectors Mod-BUS

19 Coding wheel, selects the generator number in the

cascade in Mod-Bus

20 S-BUS connector

21 END connector for L-BUS connection

22 L-BUS connection to control unit (CU-GH08)

23 S-BUS cable connector

The SCB-10 with the AD249 option has following basic functions with

default zone settings:

CIRCA1 with parameter CP020 set as Direct circuit

CIRCB1 with parameter CP021 set as Disable

DHW1 with parameter CP022 set as Disable

CIRCC1 with parameter CP023 set as Disable

AUX1 with parameter CP024 set as Disable

To configure your specific installation, make sure to check and adjust the

parameter settings for the selected zones. The zone function table shows

which parameter settings are available for which zones.

Tab.22 Parameter setting for zone function

Zone

Parameter to set zone function

CIRCA 1

CP020

(1)

(3)

CIRCB 1

CP021

(1)

(3)

DHW 1

CP022

(1)

(3)

CIRCC 1

CP023

(1)(2)

(3)

AUX 1

CP024

0 = Disable x x x x x

1 = Direct x x x

2 = Mixing Circuit x x x

3 = Swimming pool x x x

4 = High Temperature x x x

5 = Fan Convector x x x

6 = DHW tank x x x x x

7 = Electrical DHW x x x

8 = Time Program x x x x x

9 = ProcessHeat x x x x x

10 = DHW Layered x

11 = DHW Internal tank x x x x x

(1) The number refers to the circuit number which can be set with the rotary dial on the SCB-10.

(2) With AD249 option.

(3) The last number of the parameter is related to the zone. The code can be used to identify the parameter settings in the connection

examples.

(1)(2)

(3)

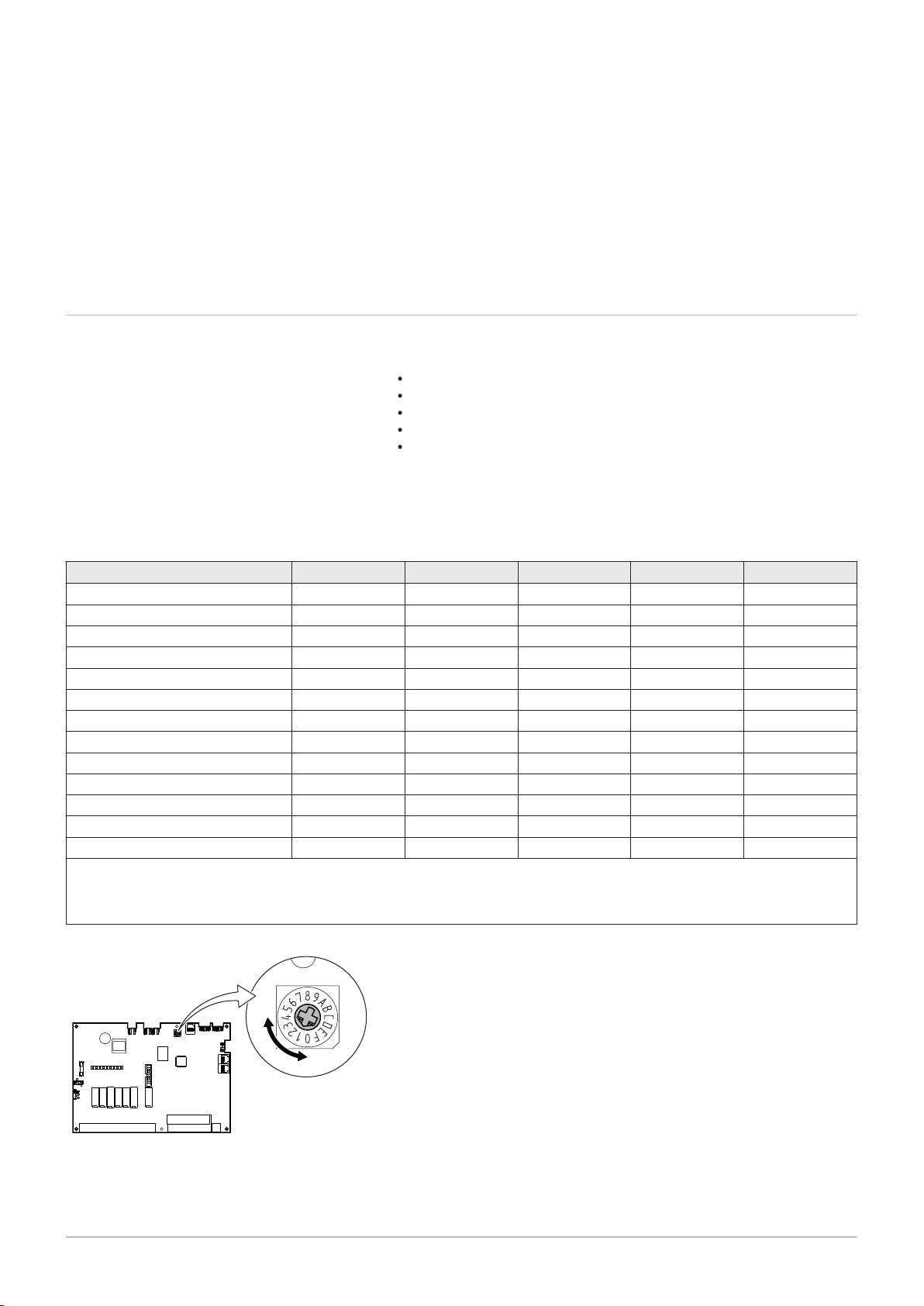

Fig.30

Rotary dial

You can use the rotary dial to identify multiple SCB-10s, for example in a

cascade situation. The default position of the rotary dial is 1. In this case

zone A will appear in the display as CIRCA1 (circuit A 1).

Page 29

7 Installation examples

7725087 - v.01 - 06062019 AMC Pro 29

Tab.23 Zone function settings explanation

Zone setting Explanation

0 = Disable Removes the circuit display, the circuit is not used, but its pump output can be used as a

status output.

1 = Direct Setting to manage a heating pump on the selected zone, cooling is not possible.

2 = Mixing Circuit Setting to manage a valve and a pump with the flow sensor, in heating or cooling (exam

ple underfloor heating).

3 = Swimming pool Setting to manage the pool heat pump according to the flow sensor (if the sensor is

present) and also the pool filter pump.

4 = High Temperature Setting to manage a pump, heats 365 days with program time, no stop in summer

5 = Fan Convector Setting to manage a pump, to warm and refresh

6 = DHW tank Setting to manage a pump and a sensor for domestic hot water

7 = Electrical DHW Setting to manage a pump, a sensor and to use the valve connector to control a relay for

the electric resistance of the tank. When switching to summer mode the tank automatical

ly switches to electric.

8 = Time Program Setting to create a time schedule on the pump connectors.

9 = ProcessHeat Setting to manage a pump, heats 365 days 24/24, no stop in summer, priority on all cir

cuits. The boiler will remove all protections to produce maximum power in a minimum of

time

10 = DHW Layered Setting to manage domestic hot water with 2 sensors, a tank top sensor (Tsyst 1 or 2)

triggers the load and the bottom sensor of the tank (Tdhw) triggers the stop of the charge.

11 = DHW Internal tank Setting to manage domestic hot water for boilers with internal tank.

7.4 Setting the 0-10 Volt input function of SCB-10

There are three options for the 0-10 Volt input control of the SCB-10 print:

disable the input function.

the input is temperature based.

the input is heat output based

Tab.24

Code Display text Description Range

EP014 SCB func. 10V PWMin Smart Control Board function 10 Volt PWM

EP030 Min Setp Temp 0-10V Sets the minimum set point temperature for 0

EP031 Max Setp Temp 0-10V Sets the maximum set point temperature for 0

EP032 Min Setp Power 0-10V Sets the minimum set point power for 0 - 10

EP033 Max Setp Power 0-10V Sets the maximum set point power for 0 - 10

EP034 Min Setp Volt 0-10V Sets the minimum set point voltage for 0 - 10

EP035 Max Setp Volt 0-10V Sets the maximum set point voltage for 0 - 10

button > Installation Setup > SCB-10 > 0-10 volt input > Parameters

input

- 10 volts for the Smart Control Board

- 10 volts for the Smart Control Board

volts for the Smart Control Board

volts

volts for the Smart Control Board

volts

0 = Off

1 = Temperature control

2 = Power control

0 °C - 100 °C

0.5 °C - 100 °C

0 % - 100 %

5 % - 100 %

0 V - 10 V

0 V - 10 V

Page 30

AD-0001156-02

0

1 2 3 4 5

6

7 8

9

10

0 - 10 V

10

20

30

40

50

60

70

80

90

100

2

3

4

1

AD-3000964-01

B CA

7 Installation examples

30 AMC Pro 7725087 - v.01 - 06062019

7.4.1 Analogue temperature regulation (°C)

Fig.31 Temperature regulation

1 Boiler on

2 Parameter CP010

3 Maximum flow temperature

4 Calculated value

The 0–10 V signal controls the boiler supply temperature. This control

modulates on the basis of flow temperature. The output varies between

the minimum and maximum value on the basis of the flow temperature set

point calculated by the controller.

Tab.25 Temperature regulation

Input signal (V) Temperature °C Description

0–1.5 0–15 Boiler off

1.5–1.8 15–18 Hysteresis

1.8–10 18–100 Desired temperature

7.4.2 Analogue output-based control

The 0 - 10 V signal controls the boiler output. This control modulates on

the basis of the heat output. The minimum output is linked to the boiler's

modulation depth. The output varies between the minimum and maximum

value on the basis of the value defined by the controller.

Tab.26 Control based on heat output

Input signal (V) Heat output (%) Description

0–2.0 0 Boiler off

2.0–2.2 0 Heat demand

2.0–10 0–100 Desired heat output

7.5 Cascade control

With the Diematic Evolution mounted in the master boiler it is possible to

manage up to 7 boilers equipped with the Inicontrol 2 in cascade. The

system sensor is connected to the master boiler. All the boilers in the

cascade are connected by an S-BUS cable. The boilers are automatically

numbered:

Fig.32 Cascade numbering

Tab.27

Code Display text Description Model series

NP006 Cascade Type Cascading boilers by adding successively or

NP009 CascInterStageTime Switch on and switch off timing for the

NP011 CascadeTypeAlgo Choice of Cascade Algorithm type, power or

> Installation Setup > SCB-10 > Cascade management B > Parameters, counters, signals > Parameters

in parallel, the boilers function simultaneously

producer of the cascade

temperature

A

The master boiler is number 1.

B

The first slave boiler is number 3 (number 2 does not exist).

C

The second slave boiler is number 4; and so on.

There are two options for cascade control management:

Adding supplementary boilers successively (traditional control).

Adding supplementary boilers simultaneously (parallel control).

0 = Traditional

1 = parallel

1 Min - 60 Min

0 = Temperature

1 = Power

Page 31

AD-3000960-01

40 8

4

x 8

-3K

+3K

6

5

4

1

2

3

AD-3000961-01

40 8

4

x 8

-3K

+3K

4

3

2

1

7 Installation examples

7725087 - v.01 - 06062019 AMC Pro 31

Fig.33 Traditional cascade control

management

Fig.34 Parallel cascade control

management

1

First boiler starts running when system temperature is 3°C below

set point.

2

After 4 minutes the second boiler starts running if ΔT< 6K and the

system temperature is still more than 3°C below set point.

3

After 8 minutes the third boiler starts running if ΔT< 6K and the

system temperature is still more than 3°C below set point.

4

First boiler stops running when system temperature is 3°C above

set point.

5

After 4 minutes the second boiler stops running if ΔT< 6K and the

system temperature is still more than 3°C above set point.

6

After 8 minutes the third boiler stops running if ΔT< 6K and the

system temperature is still more than 3°C above set point.

1

All boilers in cascade start running when system temperature is

3°C below set point.

2

First boiler stops running when system temperature is 3°C above

set point.

3

After 4 minutes the second boiler stops running if ΔT< 6K and the

system temperature is still more than 3°C above set point.

4

After 8 minutes the third boiler stops running if ΔT< 6K and the

system temperature is still more than 3°C above set point.

Temperature type cascade algorithm; the setpoint sent to the running

boiler is:

Output; requested by the zones.

Temperature; output setpoint requested by the zones + error calculation.

Output type cascade algorithm; the setpoint sent to the running boiler is: