Page 1

EASYLIFE

S U S T A I N A B L E C O M F O R T

®

MW-8200024-1

ALEZIO O HYBRID

en

User Guide

Hybrid air/water heat pump

ALEZIO O HYBRID

200 ESL HYBRID 4–8

200 ESL HYBRID 11–16

Page 2

Dear Customer,

Thank you very much for buying this appliance.

Please read through the manual carefully before using the product, and keep it in a safe place for later reference. In order to

ensure continued safe and efficient operation we recommend that the product is serviced regularly. Our service and customer

service organisation can assist with this.

We hope you enjoy years of problem-free operation with the product.

Page 3

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 Specific safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.1 Refrigerant fluid R410A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.2 Symbols used on the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.1 Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.2.1 Heat pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.2 Domestic hot water tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.3 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.4 Combination heaters with medium-temperature heat pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.5 Circulating pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.2 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.1 Description of the keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.2 Description of the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.1 Browsing in the menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.2 Description of the PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.3 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4.1 Switching off the heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4.2 Stopping domestic hot water production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4.3 Shutting down the cooling function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.5 Frost Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

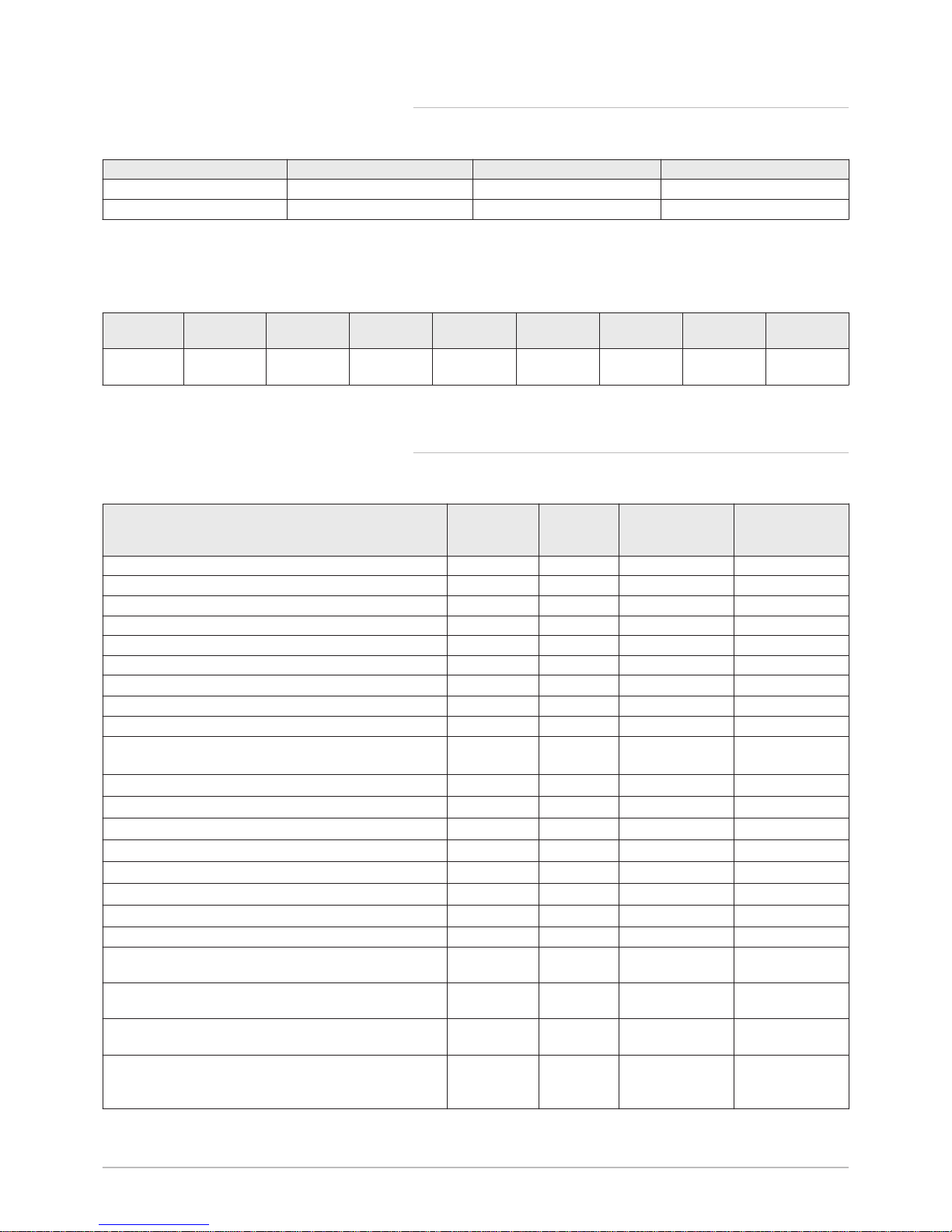

6.1 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1.1 User Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1.2 COUNTERS/TIME PROG/CLOCK menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.2 Setting the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2.1 Modifying the User parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2.2 Setting the room temperature set point in comfort mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.2.3 Setting the domestic hot water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.4 Activating Forcing of the cooling function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.5 Activating Manual Forcing for heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.6 Setting the timer programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3 Reading out measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.1 Control system sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Contents

7613346 - v05 - 13112018 200 ESL HYBRID 3

Page 4

7.1.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

7.2 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.1 Cleaning the casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

8.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

8.1.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1.2 Fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1.3 Alarm codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

8.2 Accessing the error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9 Decommissioning and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

9.1 Decommissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

9.2 Disposal and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1 Energy savings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.2 Terms of warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

12 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

12.1 Product fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

12.2 Product fiche - Temperature Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

12.3 Package fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Contents

4 200 ESL HYBRID 7613346 - v05 - 13112018

Page 5

1 Safety

1.1 General safety instructions

Danger

This appliance is not intended for use by persons

(including children) with reduced physical,

sensory or mental capabilities, or lack of

experience and knowledge, unless they have

been given supervision or instruction concerning

use of the appliance by a person responsible for

their safety. Children should be supervised to

ensure that they do not play with the appliance.

Danger of electric shock

Before any work, switch off all electricity supplies.

Caution

Installation of the heat pump must be done by a

qualified professional in accordance with

prevailing local and national regulations.

Warning

Do not touch the refrigeration connection pipes

with your bare hands while the heat pump is

running. Danger of burn or frost injury.

Warning

Do not touch the radiators for long periods.

Depending on the heat pump settings, the

temperature of the radiators may exceed 60°C.

Warning

In order to limit the risk of being scalded, the

installation of a thermostatic mixing valve on the

domestic hot water flow pipes is obligatory.

Take precautions with the domestic hot water.

Depending on the heat pump settings, the

domestic hot water temperature may exceed

65°C.

Caution

Only genuine spare parts may be used.

Warning

Only qualified professionals are authorised to

work on the domestic water storage tank and the

heating system.

1 Safety

7613346 - v05 - 13112018 200 ESL HYBRID 5

Page 6

Important

Insulate the pipes to reduce heat losses to a

minimum.

Caution

The system must satisfy each point in the rules in

force in the country that govern works and

interventions in individual homes, blocks of flats

or other buildings.

Important

Heating water and domestic water must not come

into contact with each other.

Important

Allow the space required to install the appliance

correctly: refer to the chapter Dimensions of the

Appliance (Installation and Service Manual).

Caution

Refrigerant safety

Danger

In the event of a refrigerant leakage:

1. Switch off the appliance.

2. Open the windows.

3. Do not use a naked flame, do not smoke, do

not operate electrical contacts.

4. Avoid contact with the refrigerant. Danger of

frost injuries.

5. Evacuate the property.

6. Contact a qualified professional.

Hydraulic safety

1 Safety

6 200 ESL HYBRID 7613346 - v05 - 13112018

Page 7

Caution

The appliance is intended to be permanently

connected to the domestic water mains network.

Caution

Respect the minimum and maximum water inlet

pressure to ensure correct operation of the

appliance: refer to the chapter Technical

Specifications.

Caution

Draining the appliance:

1. Shut off the domestic cold water inlet.

2. Open a hot water tap in the installation.

3. Open a valve on the safety unit.

4. When the water stops flowing, the appliance

has been drained.

See

For the domestic hot water operating temperature

limits: refer to the chapter Technical Data,

Domestic Hot Water Tank.

See

Setting the domestic hot water temperature set

point: refer to the chapter "Setting the domestic

hot water temperature set point".

Caution

Pressure limiter device: refer to the chapter

Special precautions to be taken when connecting

the domestic hot water circuit (Installation and

Service Manual).

The pressure limiter device (safety valve or

safety unit) must be regularly operated in order

to remove limescale deposits and ensure that it

is not blocked.

A pressure limiter device must be fitted to a

discharge pipe.

As water may flow out of the discharge pipe, the

pipe must be kept open to the open air, in a

frost-free environment, and at a continuous

downward gradient.

Caution

A pressure reducer (not provided) is required

when the supply pressure exceeds 80% of the

safety valve or safety unit calibration and must be

located upstream of the appliance.

1 Safety

7613346 - v05 - 13112018 200 ESL HYBRID 7

Page 8

Caution

There must be no cut-off devices between the

safety valve or unit and the domestic hot water

tank.

Electrical safety

Caution

A disconnection device must be fitted to the

permanent pipes in accordance with the

installation rules.

Caution

If a power cord comes with the appliance and it

turns out to be damaged, it must be replaced by

the manufacturer, its after sales service or

persons with similar qualifications in order to

obviate any danger.

Caution

Install the appliance in accordance with national

rules on electrical installation.

Caution

If the appliance is not wired in the factory, carry

out the wiring according to the wiring schematics

described in the chapter Electrical Connections

(Installation and Service Manual).

Caution

This appliance must be connected to the

protective earth.

Earthing must comply with prevailing installation

standards.

Earth the appliance before making any electrical

connections.

Type and calibre of the protective equipment:

refer to the chapter Recommended cable crosssections (Installation and Service Manual).

Caution

To connect the appliance to the mains electricity,

refer to the chapter Electrical Connections

(Installation and Service Manual).

Caution

This appliance must not be powered through an

external switch, such as a timer, or be connected

to a circuit which is regularly switched on and off

by the electricity provider.

1 Safety

8 200 ESL HYBRID 7613346 - v05 - 13112018

Page 9

Important

The Installation Manual for the appliance is also

available on our internet site.

1.2 Recommendations

Caution

Install the heat pump's indoor module in a frostfree location.

Important

Only qualified persons are authorised to

assemble, install and maintain the installation.

Caution

Maintenance work must be carried out by a

qualified professional.

Caution

After maintenance or repair work, check the

entire heating installation to ensure that there are

no leaks.

Caution

Only qualified professionals may carry out

electrical connections, always with the power off.

Caution

Separate the very low voltage cables from the

230/400 V circuit cables.

Important

The frost protection function does not work if the

heat pump is switched off.

Caution

If the home is unoccupied for a long period and

there is a risk of frost, drain the indoor module

and the heating system.

Important

Keep the heat pump accessible at all times.

Important

Never remove or cover labels and data plates

affixed to the appliances. Labels and data plates

must be legible throughout the entire lifetime of

the appliance.

Damaged or illegible instructions and warning

stickers must be replaced immediately.

1 Safety

7613346 - v05 - 13112018 200 ESL HYBRID 9

Page 10

Important

Remove the casing only to perform maintenance

and repair work. Put the casing back in place

after maintenance and repair work.

Caution

Give preference to the or mode rather than

switching off the system to leave the following

functions running:

Anti blocking of pumps

Frost Protection

Important

Regularly check the presence of water and

pressure in the heating installation.

Important

Keep this document close to the place where the

appliance is installed.

Caution

Do not make any modifications to the heat pump

without the written consent of the manufacturer.

Caution

To benefit from extended warranty cover, no

modifications must be made to the appliance.

Caution

Do not neglect to service the heat pump. Contact

a qualified professional or subscribe to a

maintenance contract for the annual servicing of

the heat pump.

1.3

Specific safety instructions

1.3.1 Refrigerant fluid R410A

Hazard identification

Effects harmful to health:

The vapours are heavier than air and may lead to

asphyxia owing to reduced oxygen levels.

Liquefied gas: contact with the liquid may cause

serious frost burn and eye injuries.

Product classification: this product is not classified as

a "hazardous preparation" according to European

Union regulations.

1 Safety

10 200 ESL HYBRID 7613346 - v05 - 13112018

Page 11

If the R410A refrigerant is mixed with air, it may cause

pressure surges in the refrigeration pipes and lead to an

explosion and other hazards.

Composition of / Information on the ingredients

Chemical nature: R-410A is composed of

Difluoromethane R32 and Pentafluoroethane R125

Tab.1 Composition of R-410A fluid

Name

Proportion Number CE Number CAS

Difluoromethane R32 50% 200–839–4 75-10-5

Pentafluoroethane

R125

50% 206-557-8 354-33-6

The Global Warming Potential of R410A gas is 2088.

Tab.2 Precautions for use

First aid If inhaled:

Evacuate the subject from the contaminated area and take him into

the open air.

If feeling unwell: call a doctor.

In the event of contact with the skin:

Treat frost injuries like burns. Rinse with copious amounts of tepid

water, do not remove clothing (risk of adhesion to the skin).

If skin burns appear, call a doctor immediately.

In the event of contact with the eyes:

Rinse immediately with water, holding the eyelids well apart (for at

least 15 minutes).

Consult an ophthalmologist immediately.

Fire prevention meas

ures

Appropriate extinguishing agents: All extinguishing agents can be

used.

Inappropriate extinguishing agents: none to our knowledge. In the

event of fire nearby, use the appropriate extinguishing agents.

Specific hazards:

Rise in pressure: in the presence of air, an inflammable mixture

may form under certain temperature and pressure conditions.

Toxic and corrosive vapours may be released by the effect of the

heat.

Special intervention methods: cool the volumes exposed to heat with

water spray.

Protection of the firemen:

Full self-contained breathing apparatus.

Complete body protection.

1 Safety

7613346 - v05 - 13112018 200 ESL HYBRID 11

Page 12

In the event of acci

dental spillage

Individual precautions:

Avoid contact with the skin and eyes.

Do not intervene without appropriate protective equipment.

Do not inhale the vapours.

Evacuate the hazardous area.

Stop the leakage.

Eradicate all sources of ignition.

Ventilate the spillage area mechanically.

Cleaning / decontamination: allow any residual product to evaporate.

In the event of contact with the eyes: Rinse immediately with water,

holding the eyelids well apart (for at least 15 minutes). Consult an oph

thalmologist immediately.

Handling Technical measures: ventilation

Precautions to be taken:

No smoking.

Prevent the build-up of electrostatic charges.

Work in a well ventilated place.

Personal protection

Respiratory protection:

If ventilation is insufficient: AX type cartridge mask.

In confined spaces: self-contained breathing apparatus.

Hand protection: protective gloves in leather or nitrile rubber.

Eye protection: safety glasses with side protection.

Skin protection: clothing made principally of cotton

Industrial hygiene: do not drink, eat or smoke at the place of work.

Considerations on dis

posal

Important

Disposal must be done in compliance with prevailing lo

cal and national regulations.

Product waste: consult the manufacturer or the supplier for informa

tion on recovery or recycling.

Soiled packaging: reuse or recycle after decontamination. Destroy in

authorised installations.

Regulation

Regulation (EU) No. 517/2014 of the European Parliament and of the

Council of 16 April 2014 on fluorinated greenhouse gases and re

pealing Regulation (EC) No. 842/2006.

1.4

Liabilities

1.4.1

Manufacturer's liability

Our products are manufactured in compliance with the

requirements of the various Directives applicable. They

are therefore delivered with the

marking and any

documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We

therefore reserve the right to modify the specifications

given in this document.

1 Safety

12 200 ESL HYBRID 7613346 - v05 - 13112018

Page 13

Our liability as manufacturer may not be invoked in the

following cases:

Failure to abide by the instructions on installing and

maintaining the appliance.

Failure to abide by the instructions on using the

appliance.

Faulty or insufficient maintenance of the appliance.

1.4.2 Installer's liability

The installer is responsible for the installation and initial

commissioning of the appliance. The installer must

observe the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Install the appliance in compliance with prevailing

legislation and standards.

Carry out initial commissioning and any checks

necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the

obligation to check the appliance and keep it in good

working order.

Give all the instruction manuals to the user.

1.4.3 User's liability

To guarantee optimum operation of the system, you

must abide by the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Call on a qualified professional to carry out installation

and initial commissioning.

Get your installer to explain your installation to you.

Have the required inspections and maintenance

carried out by a qualified installer.

Keep the instruction manuals in good condition close

to the appliance.

1 Safety

7613346 - v05 - 13112018 200 ESL HYBRID 13

Page 14

2 About this manual

2.1 General

This manual is intended for the user of a 200 ESL HYBRIDhybrid system.

2.2

Additional documentation

This manual contains all settings and information on the 200 ESL HYBRID

indoor module, as well as some information on the outdoor unit.

For information on the boiler, refer to the instruction manuals provided with

the boiler.

For additional information on the outdoor unit, refer to the manual provided

with the outdoor unit.

2.3

Symbols used

2.3.1

Symbols used in the manual

This manual uses various danger levels to draw attention to special

instructions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal

injury.

Caution

Risk of material damage.

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

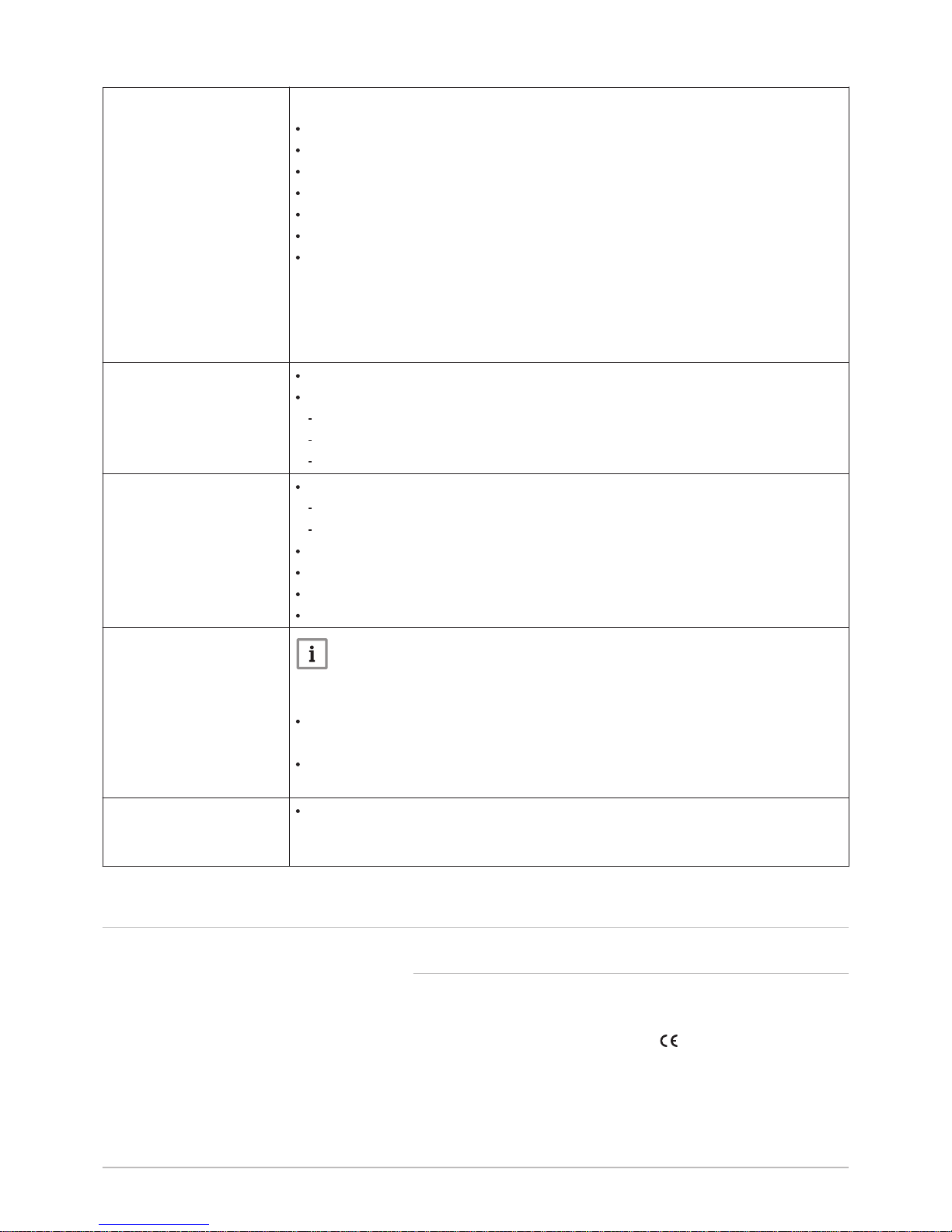

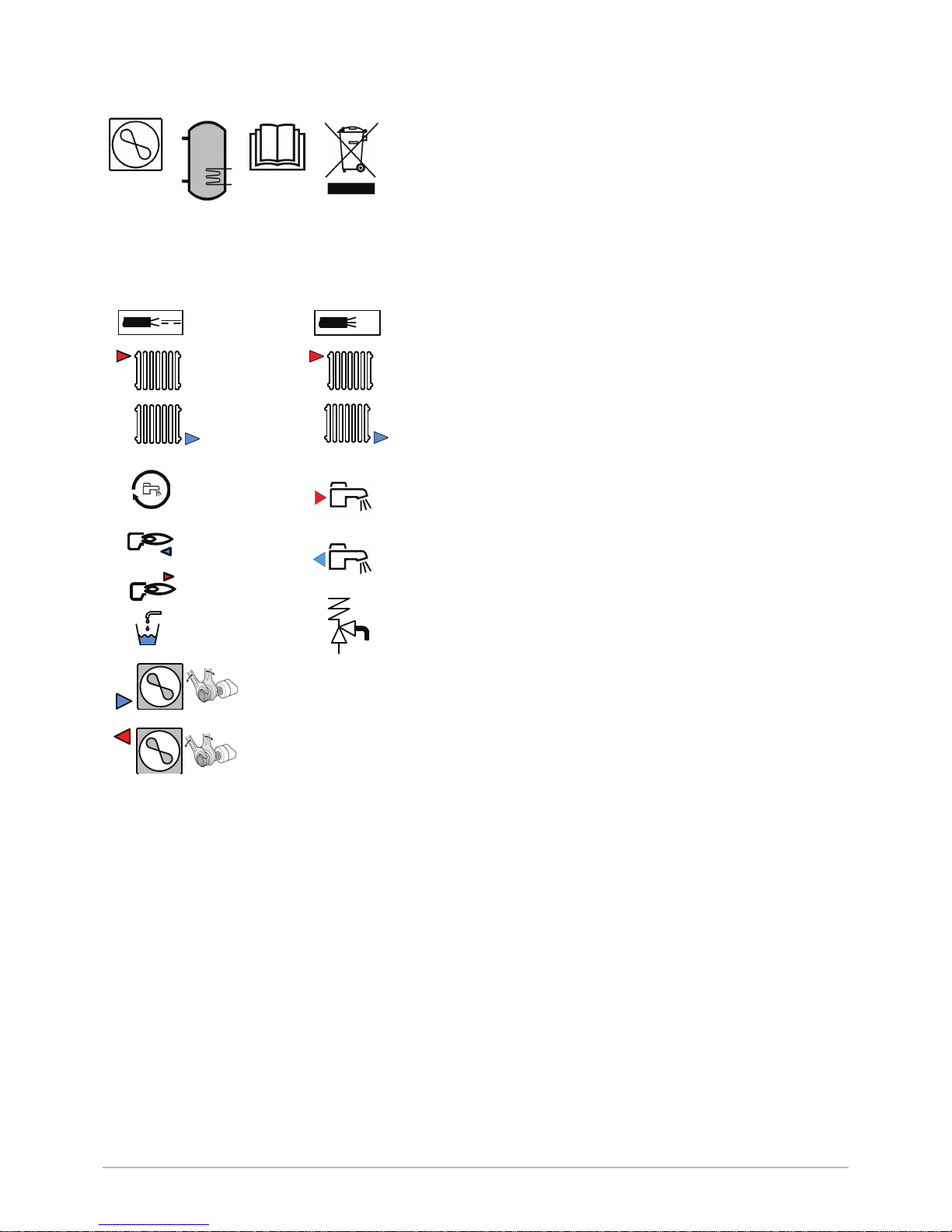

2.3.2 Symbols used on the appliance

1 Alternating current.

2 Protective earthing.

3 Caution: danger of electric shock, live parts. Disconnect the mains

power prior to carrying out any work.

Fig.1 Symbols used on the appliance

1 2

MW-6000066-1

1

2

3

2 About this manual

14 200 ESL HYBRID 7613346 - v05 - 13112018

Page 15

1 Information on the heat pump: Type of refrigerant fluid, maximum

operating pressure, maximum output absorbed by the indoor

module.

2 Information on the domestic hot water tank: Volume, maximum

operating pressure and standby losses of the domestic hot water

tank.

3 Before installing and commissioning the appliance, carefully read

the instruction manuals provided.

4 Dispose of used products through an appropriate recovery and

recycling structure.

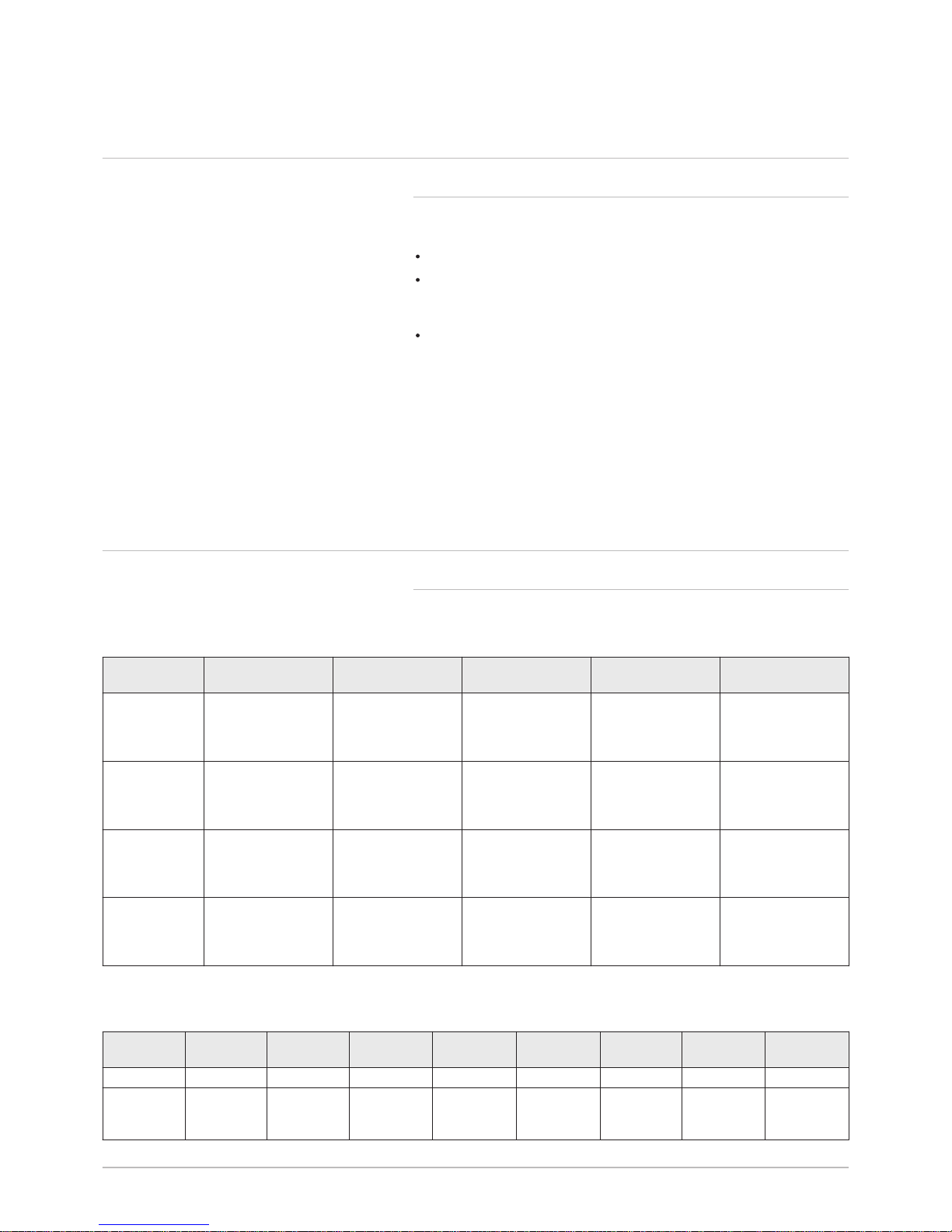

1 Sensor cable - low voltage

2 Power cord 230 V

3 Heating circuit flow

4 Circuit B flow

5 Heating circuit return

6 Circuit B return (optional)

7 Connection for recirculation

8 Domestic hot water outlet

9 Return from the indoor module to the boiler

10 Flow from the boiler to the indoor module

11 Domestic cold water inlet

12 Drain valve

13 Safety valve

14

3

/8" refrigerant fluid connection - liquid line

15

5

/8" refrigerant fluid connection - gas line

Fig.2 Symbols used on the data plate

1

2

4

3

MW-6000340-1

Fig.3 Symbols used on the connection

label

G3/4"

A

G1"

A

G1"

B

G1"

B

G1"

G3/4"

G3/4"

5/8

69-82 Nm

3/8

34-42 Nm

Ø13

1

2

4

6

8

10

12

3

5

7

9

11

13

MW-6000285-1

14

15

2 About this manual

7613346 - v05 - 13112018 200 ESL HYBRID 15

Page 16

3 Technical specifications

3.1 Homologations

3.1.1 Directives

This product complies with the requirements of the following European

Directives and Standards:

Pressure Equipment Directive 2014/68/EU

Low Voltage Directive 2014/35/EU

Generic standard: EN 60335-1

Relevant standard: EN 60335-2-40

Electromagnetic Compatibility Directive 2014/30/EU

Generic standards: EN 61000-6-3, EN 61000-6-1

Relevant Standard: EN 55014

This product conforms to the requirements of European Directive

2009/125/EC on the ecodesign of energy-related products.

In addition to the legal requirements and guidelines, the supplementary

guidelines in this manual must also be followed.

Supplements or subsequent regulations and guidelines that are valid at

the time of installation shall apply to all regulations and guidelines

specified in this manual.

3.2 Technical data

3.2.1 Heat pump

Maximum operating pressure: 0.3 MPa (3 bar)

Tab.3 Conditions of use

AWHP 4.5 MR AWHP 6 MR-3 AWHP 8 MR-2 AWHP 11 MR-2

AWHP 11 TR-2

AWHP 16 MR-2

AWHP 16 TR-2

Limit water op

erating temper

atures in heat

ing mode

+18 °C/+55 °C +18 °C/+60 °C +18 °C/+60 °C +18 °C/+60 °C +18 °C/+60 °C

Outdoor air op

erating temper

ature limits in

heating mode

-15° C/+35 °C -15° C/+35 °C -20° C/+35 °C -20° C/+35 °C -20° C/+35 °C

Water operat

ing temperature

limits in cooling

mode

+7°C / +25°C +7°C / +25°C +7°C / +25°C +7°C / +25°C +7°C / +25°C

Outdoor air op

erating temper

ature limits in

cooling mode

+7 °C/ +46 °C +7 °C/ +46 °C +7 °C/ +46 °C +7 °C/ +46 °C +7 °C/ +46 °C

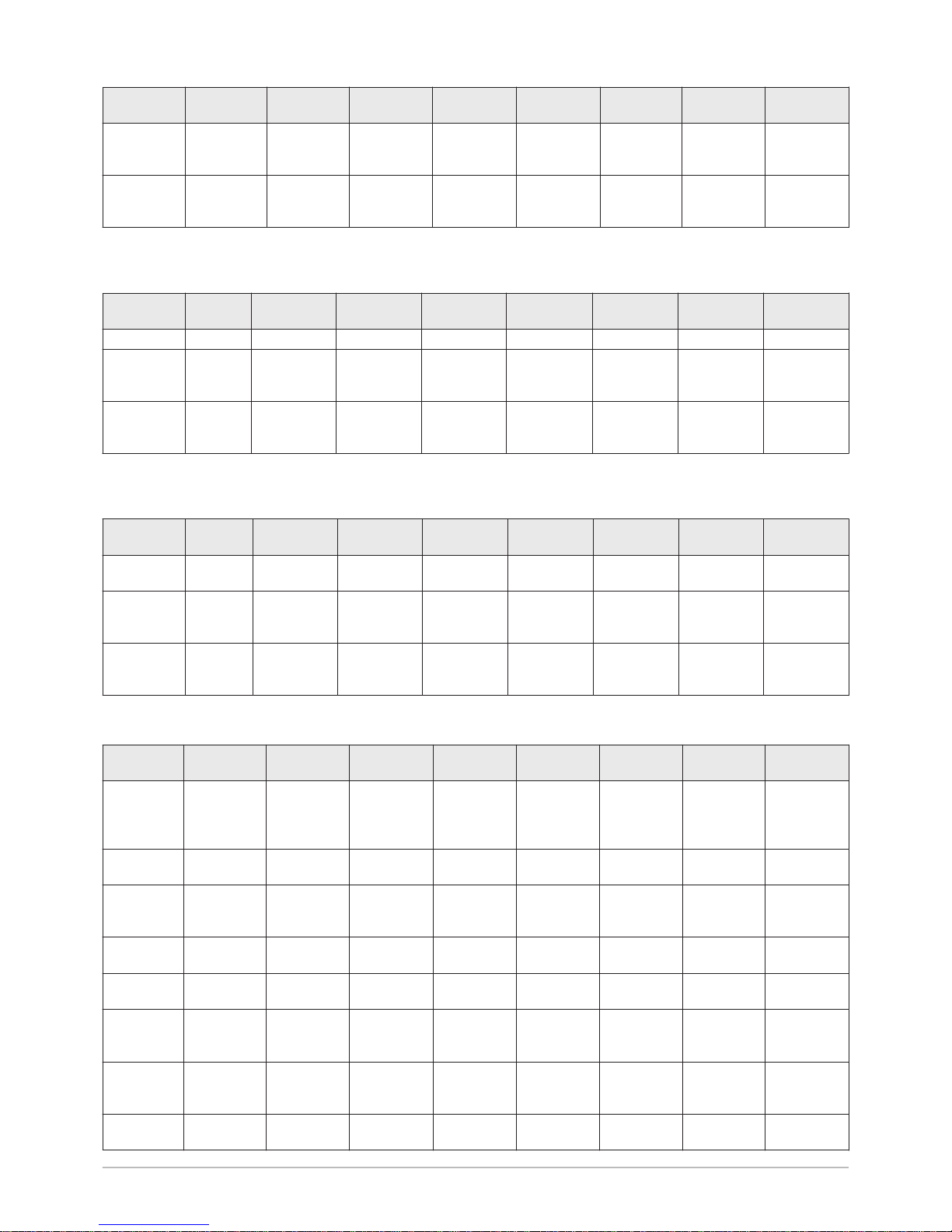

Tab.4 Heating mode: outside air temperature +7 °C, water temperature at the outlet +35 °C. Performances in accordance

with EN 14511-2.

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Heat output kW 4.6 5.82 7.9 11.39 11.39 14.65 14.65

Coefficient

of Perform

ance (COP)

5.11 4.22 4.34 4.65 4.65 4.22 4.22

3 Technical specifications

16 200 ESL HYBRID 7613346 - v05 - 13112018

Page 17

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Absorbed

electrical

power

kWe 0.90 1.38 1.82 2.45 2.45 3.47 3.47

Nominal wa

ter flow rate

(ΔT = 5 K)

m3/hour

0.80 1.00 1.36 1.96 1.96 2.53 2.53

Tab.5 Heating mode: outside air temperature +2 °C, water temperature at the outlet +35 °C. Performances in accordance

with EN 14511-2.

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Heat output kW 3.74 3.74 6.80 10.19 10.19 12.90 12.90

Coefficient

of Perform

ance (COP)

3.97 3.37 3.30 3.19 3.19 3.27 3.27

Absorbed

electrical

power

kWe 0.88 1.11 2.06 3.19 3.19 3.94 3.94

Tab.6 Cooling mode: outside air temperature +35 °C, water temperature at the outlet +18 °C. Performances in accordance

with EN 14511-2.

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Cooling out

put

kW 3.80 4.69 7.90 11.16 11.16 14.46 14.46

Energy effi

ciency ratio

(EER)

4.28 4.09 3.99 4.75 4.75 3.96 3.96

Absorbed

electrical

power

kWe 0.89 1.15 2.00 2.35 2.35 3.65 3.65

Tab.7 Common specifications

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Total dy

namic head

at nominal

flow rate

kPa 65 63 44 25 25 — —

Nominal air

flow rate

m3/h

2650 2700 3300 6000 6000 6000 6000

Power volt

age of the

outdoor unit

V 230 230 230 230 400 230 400

Start-up

amperage

A 5 5 5 5 3 6 3

Maximal

amperage

A 12 13 17 29.5 13 29.5 13

Acoustic

power - In

side

(1)

dB(A) 49 49 49 48 48 48 48

Acoustic

power Outside

(2)

dB(A) 61 65 67 69 69 70 70

Refrigerant

fluid R410A

kg 1.3 1.4 3.2 4.6 4.6 4.6 4.6

3 Technical specifications

7613346 - v05 - 13112018 200 ESL HYBRID 17

Page 18

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

R410A re

frigerant

(3)

tCO2e 2.714 2.923 6.680 9.603 9.603 9.603 9.603

Refrigerant

connection

(Liquid Gas)

inch 1/4 - 1/2 1/4 - 1/2 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8

Max. precharged

length

m 7 10 10 10 10 10 10

(1) Noise radiated by the envelope - Test run in accordance with the NF EN 12102 standard, temperature conditions: air 7°C, water 55°C

(2) Noise radiated by the envelope - Test run in accordance with the NF EN 12102 standard, temperature conditions: air 7 °C, water 45 °C

for AWHP 4.5 MR only (inner and outer sides).

(3) Quantity of refrigerant calculated in tonnes of CO2 equivalent

Important

The values in tonnes of CO2 equivalent are calculated using the

following formula: quantity (in kg) of refrigerant fluid x GWP /

1000.

The Global-Warming Potential (GWP) of R410A gas is 2088.

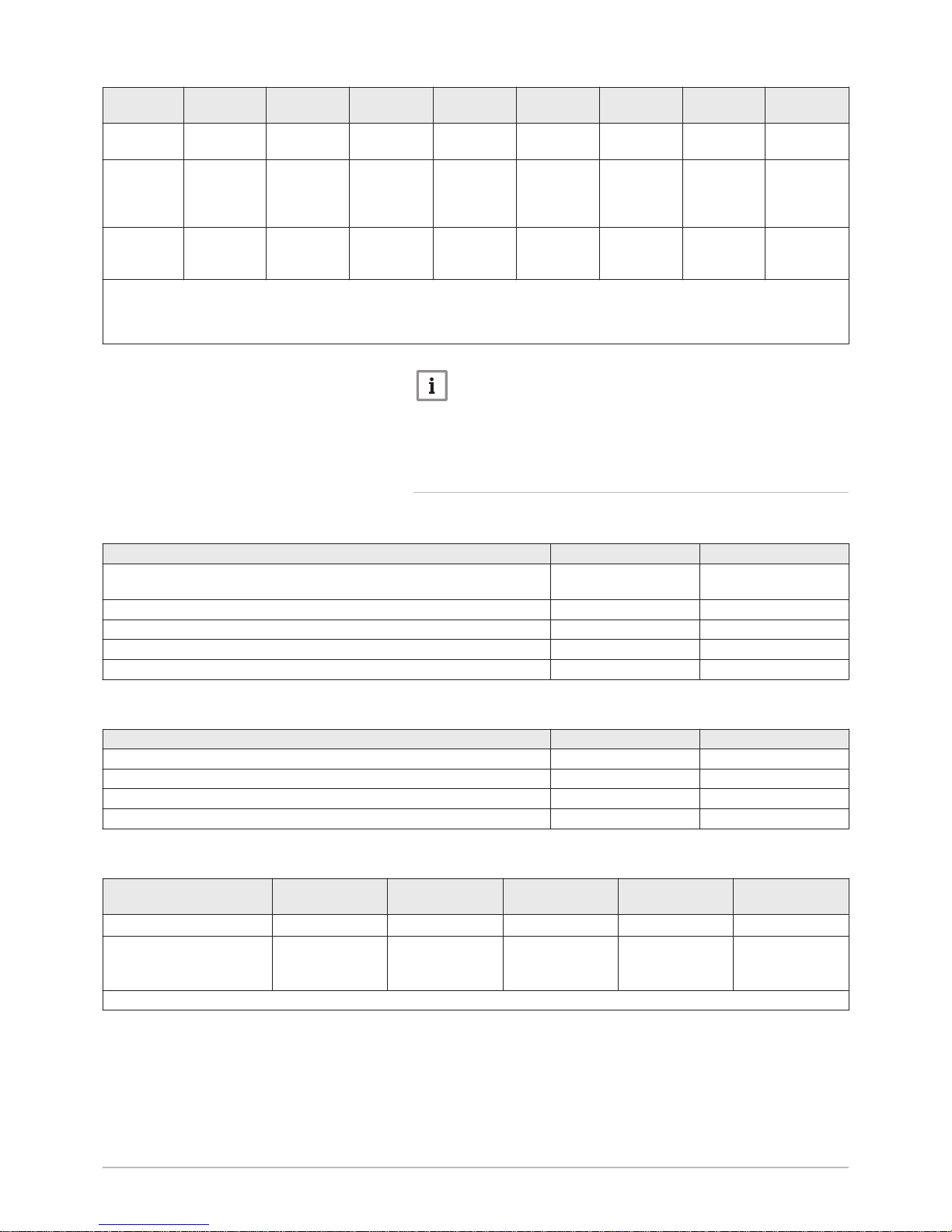

3.2.2 Domestic hot water tank

Tab.8 Technical specifications primary circuit (heating water)

Specification Unit Value

Maximum operating temperature

Version with hydraulic back-up

°C 90

Minimum operating temperature °C 7

Maximum operating pressure MPa (bar) 0.3 (3.0)

Exchanger capacity Litres 11.3

Exchange surface m² 1.7

Tab.9 Technical specifications secondary circuit (domestic water)

Specification Unit Value

Maximum operating temperature °C 80

Minimum operating temperature °C 10

Maximum operating pressure MPa (bar) 1.0 (10.0)

Water capacity Litres 177

Tab.10 Common specifications (in accordance with the PR-EN 13203–5 standard)

AWHP 4.5 MR AWHP 6 MR-3 AWHP 8 MR-2 AWHP 11 MR-2 ,

AWHP 11 TR-2

AWHP 16 MR-2 ,

AWHP 16 TR-2

Loading time

(1)

1 hour 21 minutes 1 hour 21 minutes 1 hour 21 minutes 1 hour 33 minutes 1 hour 11 minutes

Coefficient of performance

domestic hot water

(COP

DHW

)

0.75 0.75 0.75 1.07 1.07

(1) Water temperature set point: 57 °C – Outdoor temperature: 7°C – Inside air temperature: 20°C

3 Technical specifications

18 200 ESL HYBRID 7613346 - v05 - 13112018

Page 19

3.2.3 Weight

Tab.11 Indoor module

Indoor module Unit 200 ESL HYBRID 4–8 200 ESL HYBRID 11–16

Weight empty kg 129 131

Total weight with water kg 324 326

Refer to the boiler manual to calculate the total weight of the indoor

module combined with the boiler.

Tab.12 Outdoor unit

Outdoor

unit

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Weight

empty

kg 54 42 75 118 130 118 130

3.2.4 Combination heaters with medium-temperature heat

pump

Tab.13 Technical parameters for heat pump combination heaters (parameters declared for medium-temperature application)

Product name 200 ESL Hybrid

4.5MR

+ EFU C 19

200 ESL Hybrid

6MR-3

+ EFU C 24

Air-to-water heat pump Yes Yes

Water-to-water heat pump No No

Brine-to-water heat pump No No

Low-temperature heat pump No No

Equipped with a supplementary heater Yes Yes

Heat pump combination heater Yes Yes

Rated heat output under average conditions

(1)

Prated

kW 8 8

Rated heat output under colder conditions

(1)(1)

Prated

kW 6 6

Rated heat output under warmer conditions

(1)(1)

Prated

kW 4 5

Declared capacity for heating for part load at an indoor

temperature of 20 °C and outdoor temperature

T

j

T

j

= -7°C

Pdh

kW 3.8 3.5

T

j

= +2 °C

Pdh

kW 4.3 4.5

T

j

= +7 °C

Pdh

kW 4.5 4.8

T

j

= +12 °C

Pdh

kW 5.5 5.2

T

j

= bivalent temperature

Pdh

kW 4.3 4.5

T

j

= operation limit temperature

Pdh

kW 3.9 3.6

Bivalent temperature

T

biv

°C 2 2

Degradation co-efficient

(2)

Cdh

— 1.0 1.0

Seasonal space heating energy efficiency under average

conditions

ƞ

s

% 135 132

Seasonal space heating energy efficiency under colder

conditions

ƞ

s

% 122 121

Seasonal space heating energy efficiency under warmer

conditions

ƞ

s

% 172 166

Declared coefficient of performance or primary energy ra

tio for part load at an indoor temperature of 20 °C and

outdoor temperature

T

j

3 Technical specifications

7613346 - v05 - 13112018 200 ESL HYBRID 19

Page 20

Product name 200 ESL Hybrid

4.5MR

+ EFU C 19

200 ESL Hybrid

6MR-3

+ EFU C 24

T

j

= -7°C

COPd

or

%

1.64 1.86

T

j

= +2 °C

COPd

or

%

3.46 3.40

T

j

= +7 °C

COPd

or

%

4.96 4.52

T

j

= +12 °C

COPd

or

%

7.35 6.70

T

j

= bivalent temperature

COPd

or

%

3.46 3.40

T

j

= operation limit temperature

COPd

or

%

1.84 1.52

Operation limit temperature for air-to-water heat pumps

TOL

°C -10 -10

Heating water operating limit temperature

WTOL

°C 80 80

Electrical power consumption

Off mode

P

OFF

kW 0.009 0.009

Thermostat-off mode

P

TO

kW 0.049 0.049

Stand-by

P

SB

kW 0.013 0.019

Crankcase heater mode

P

CK

kW 0.055 0.055

Supplementary heater

Rated heat output

(1)(1)

Psup

kW 4.0 4.8

Type of energy input Oil Oil

Other specifications

Capacity control Variable Variable

Sound power level, indoors - outdoors

L

WA

dB 49 – 61 48 – 64

Annual energy consumption under average conditions

Q

HE

kWh

GJ

4045

6

4312

8

Annual energy consumption under colder conditions

Q

HE

kWh

GJ

4564

4

4236

3

Annual energy consumption under warmer conditions

Q

HE

kWh

GJ

1299

0

1544

0

Rated air flow rate, outdoors for air-to-water heat

pumps

—

m3/h

2100 2100

Declared load profile L L

Daily electricity consumption

Q

elec

kWh 4.020 4.816

Annual electricity consumption

AEC

kWh 845 968

Water heating energy efficiency

ƞ

wh

% 106.00 106.00

Daily fuel consumption

Q

fuel

kWh 0.000 0.000

Annual fuel consumption

AFC

GJ 0 0

(1) The rated heat output

Prated

is equal to the design load for heating

Pdesignh

, and the rated heat output of a supplementary heater

Psup

is equal to the supplementary capacity for heating

sup(Tj).

(2) If

Cdh

is not determined by measurement then the default degradation coefficient is

Cdh

= 0.9.

3 Technical specifications

20 200 ESL HYBRID 7613346 - v05 - 13112018

Page 21

Tab.14 Technical parameters for heat pump combination heaters (parameters declared for medium-temperature application)

Product name 200 ESL

Hybrid 8MR-2

+ EFU C 24

200 ESL

Hybrid 11MR-2

+ EFU C 19

200 ESL

Hybrid 16MR-2

+ EFU C 24

Air-to-water heat pump Yes Yes Yes

Water-to-water heat pump No No No

Brine-to-water heat pump No No No

Low-temperature heat pump No No No

Equipped with a supplementary heater Yes Yes Yes

Heat pump combination heater Yes Yes Yes

Rated heat output under average conditions

(1)

Prated

kW 11 15 22

Rated heat output under colder conditions

(1)(1)

Prated

kW 9 11 15

Rated heat output under warmer conditions

(1)(1)

Prated

kW 6 8 13

Declared capacity for heating for part load at an

indoor temperature of 20 °C and outdoor temper

ature

T

j

T

j

= -7°C

Pdh

kW 5.6 6.8 9.0

T

j

= +2 °C

Pdh

kW 6.1 8.2 11.8

T

j

= +7 °C

Pdh

kW 6.4 9.0 12.9

T

j

= +12 °C

Pdh

kW 6.5 10.1 15.4

T

j

= bivalent temperature

Pdh

kW 6.1 8.2 11.8

T

j

= operation limit temperature

Pdh

kW 5.6 6.2 8.3

Bivalent temperature

T

biv

°C 2 2 2

Degradation co-efficient

(2)

Cdh

— 1.0 1.0 1.0

Seasonal space heating energy efficiency under

average conditions

ƞ

s

% 134 132 129

Seasonal space heating energy efficiency under

colder conditions

ƞ

s

% 124 122 119

Seasonal space heating energy efficiency under

warmer conditions

ƞ

s

% 169 167 161

Declared coefficient of performance or primary

energy ratio for part load at an indoor tempera

ture of 20 °C and outdoor temperature

T

j

T

j

= -7°C

COPd

or

%

1.95 1.82 1.88

T

j

= +2 °C

COPd

or

%

3.49 3.43 3.33

T

j

= +7 °C

COPd

or

%

4.57 4.54 4.34

T

j

= +12 °C

COPd

or

%

6.33 6.24 5.82

T

j

= bivalent temperature

COPd

or

%

3.49 3.43 3.33

T

j

= operation limit temperature

COPd

or

%

1.63 1.45 1.54

Operation limit temperature for air-to-water

heat pumps

TOL

°C -10 -10 -10

Heating water operating limit temperature

WTOL

°C 80 80 80

Electrical power consumption

Off mode

P

OFF

kW 0.009 0.009 0.009

3 Technical specifications

7613346 - v05 - 13112018 200 ESL HYBRID 21

Page 22

Product name 200 ESL

Hybrid 8MR-2

+ EFU C 24

200 ESL

Hybrid 11MR-2

+ EFU C 19

200 ESL

Hybrid 16MR-2

+ EFU C 24

Thermostat-off mode

P

TO

kW 0.049 0.049 0.049

Stand-by

P

SB

kW 0.019 0.025 0.025

Crankcase heater mode

P

CK

kW 0.055 0.055 0.055

Supplementary heater

Rated heat output

(1)(1)

Psup

kW 5.8 9.0 13.7

Type of energy input Oil Oil Oil

Other specifications

Capacity control Variable Variable Variable

Sound power level, indoors - outdoors

L

WA

dB 48 – 66 47 – 69 47 – 69

Annual energy consumption under average

conditions

Q

HE

kWh

GJ

5859

9

7869

13

11525

21

Annual energy consumption under colder con

ditions

Q

HE

kWh

GJ

6548

6

8009

8

10810

10

Annual energy consumption under warmer

conditions

Q

HE

kWh

GJ

1904

0

2580

0

4120

0

Rated air flow rate, outdoors for air-to-water

heat pumps

—

m3/h

3300 6000 6000

Declared load profile L L L

Daily electricity consumption

Q

elec

kWh 4.816 4.816 4.816

Annual electricity consumption

AEC

kWh 968 968 968

Water heating energy efficiency

ƞ

wh

% 106.00 106.00 106.00

Daily fuel consumption

Q

fuel

kWh 0.000 0.000 0.000

Annual fuel consumption

AFC

GJ 0 0 0

(1) The rated heat output

Prated

is equal to the design load for heating

Pdesignh

, and the rated heat output of a supplementary heater

Psup

is equal to the supplementary capacity for heating

sup(Tj).

(2) If

Cdh

is not determined by measurement then the default degradation coefficient is

Cdh

= 0.9.

See

The back cover for contact details.

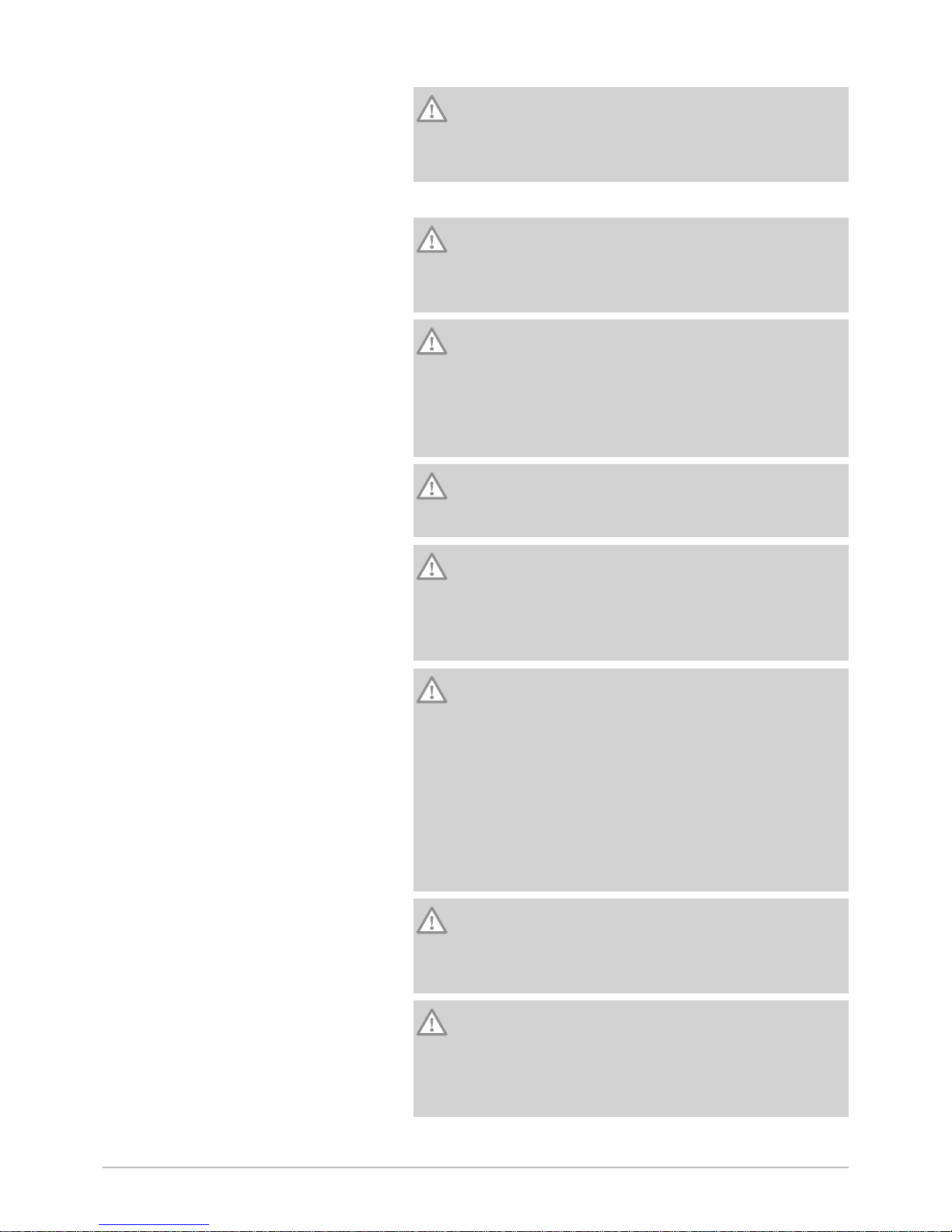

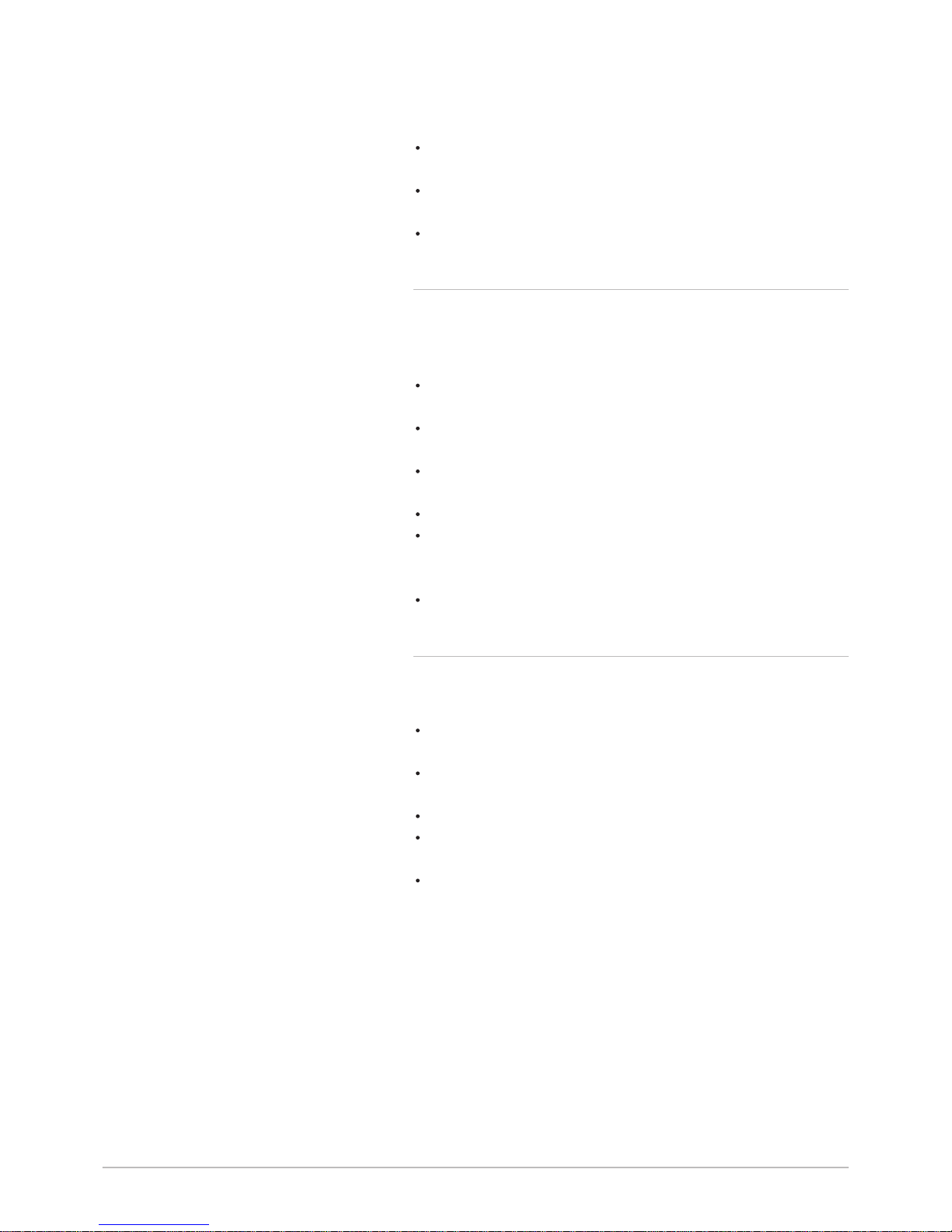

3.2.5

Circulating pump

Important

The benchmark for the most efficient circulating pumps is EEI ≤

0.20.

The circulating pump in the indoor module is a variable speed pump. It

adapts its speed to the distribution network.

1 Available pressure in metres of water column (mWc)

2

Water flow rate in cubic metres per hour (m3/h)

3 Available pressure for 4 to 8 kW outdoor units

4 Available pressure for the 11 and 16 kW outdoor units

Fig.4 Pressure available

MW-2000147-2

0

1

3

4

2

0.5

1.0 1.5 2.0 2.5

1

2

3

4

5

6

7

3 Technical specifications

22 200 ESL HYBRID 7613346 - v05 - 13112018

Page 23

4 Description of the product

4.1 General description

The hybrid heat pump comprises:

A 200 ESL HYBRID indoor module, including a domestic hot water tank.

A non-condensing oil boiler or a condensing oil boiler, installed on top of

or beside the indoor module.

A reversible outdoor unit for energy production in heating or cooling

mode.

Depending on the parameter settings of the hybrid heat pump, heating and

domestic hot water production are handled by:

The indoor module

The boiler

The indoor module and the outdoor unit are connected by means of

refrigerant and electrical connections.

The system offers the following advantages:

The heating circuit is housed in the insulated volume within the home.

Thanks to the "DC inverter" system, the heat pump modulates its output

to adapt to the needs of the home.

The temperature of the heating circuit is adjusted according to the

outside temperature.

The tank is protected against corrosion, on the one hand, by a

magnesium anode and, on the other, by a food quality lining vitrified at

850°C.

The heat exchanger in the hybrid domestic hot water tank is a coil

welded inside the tank, made of smooth piping. Its external surface,

which comes into contact with drinking water, is enamelled.

The indoor module is insulated by chlorofluorocarbon-free polyurethane

foam, which helps to keep heat losses to a minimum.

4.2 Operating principle

The heat pumps in the 200 ESL HYBRID range extract the heat found in

the air to restore it to the heating and/or domestic hot water circuit via the

refrigerant fluid. The efficiency of a heat pump is expressed in the form of

a coefficient of performance (COP), defined as the ratio between the heat

provided and the power consumed.

The heat pump comprises an evaporator, a compressor, a condenser and

an expansion valve. The indoor module includes the condenser. The other

components (evaporator, compressor and expansion valve) are located in

the outdoor unit.

1. The refrigerant fluid in the circuit is converted from the liquid state to

the gaseous state in the evaporator, making it possible to recover heat

from the air.

2. The compressor increases the fluid pressure, which thus increases

the temperature.

3. In the condenser, the fluid transfers the heat to the heating circuit

while converting to the liquid state.

4. The refrigerant passes through the thermostatic expansion valve and

returns to the initial state at low pressure and low temperature before

returning to the evaporator.

4 Description of the product

7613346 - v05 - 13112018 200 ESL HYBRID 23

Page 24

Fig.5 General operating principle

5

2

1

3

6

4

7

8

MW-6000391-1

1 Evaporator (fin battery in the outdoor unit)

2 Compressor

3 Condenser (plate exchanger in the indoor module)

4 Electronic expansion valve

5 Electrical energy

6 Heating water

7 Energy flow

8 Heat recovered from the environment

4.3 Main components

1

Heating generator control system PCB (EHC-02)

2

Immersion sleeve for the top domestic hot water sensor

3

Flow meter

4

Plate exchanger (condenser part of the heat pump)

5

Immersion sleeve for the bottom domestic hot water sensor

6

3-way valve motor reversing domestic hot water

7

Main circulating pump

8

Safety valve

9

Magnesium anode

10

Automatic air vent

11

Interface PCB for the outdoor unit

12

Magnetic sieve filter

13

Temperature sensor

Fig.6 Main components

MW-6000330-2

13

8

11

3

1

2

9

4

7

12

10

6

5

4 Description of the product

24 200 ESL HYBRID 7613346 - v05 - 13112018

Page 25

4.4 Control panel description

4.4.1 Description of the keys

1

h

: back to the previous level without saving the modifications

made

: manual reset

2

: accessing the heating parameters

: lowering the value

3

: accessing the domestic hot water parameters

: raising the value

4

: MODE display

: accessing the menu selected or confirming the value

modification

4.4.2

Description of the display

Hydraulic back-up

Hydraulic back-up in demand

Status of the Compressor

Steady symbol: compressing running

Operating modes

Steady symbol: heating function enabled

Flashing symbol: heating production running

Steady symbol: domestic hot water function enabled

Flashing symbol: domestic hot water production running

Heating or cooling function disabled

Domestic hot water function disabled

Hydraulic pressure in the system

The display alternates between the hydraulic pressure for the system and

the measured flow temperature.

Steady symbol: displayed when indicating the system's hydraulic

pressure value

Flashing symbol: pressure in the system too low

XXX Pressure value in the system (in bar) or flow temperature (in °C)

Fig.7

MW-1000043-5

1 2 3 4

Fig.8

MW-1000669-2

Fig.9

MW-5000012-3

Fig.10

MW-1000083-5

Fig.11

MW-5000037-4

4 Description of the product

7613346 - v05 - 13112018 200 ESL HYBRID 25

Page 26

Cooling mode

Steady symbol: cooling mode on

Flashing symbol: cooling request pending

Menu display

Information menu: displays the measured values and the statuses

of the appliance

User menu: provides access to the User level setting parameters

Installer menu: provides access to the Installer level setting

parameters

Manual Forcing menu: the appliance runs at the set point

displayed, the pumps operate and the three-way valves are not

controlled.

Malfunction menu: the appliance has malfunctioned. This

information is signalled by an error code and a flashing display.

Sub-Menu COUNTERS

TIME PROG sub-menu: Timer programming dedicated to

heating and domestic hot water production

Sub-Menu CLOCK

PCB selection menu: access to information on the additional PCBs

connected

Display of PCB names

The name of the PCB for which the parameters are displayed is

displayed in 3 characters.

Central unit PCB EHC-02 : direct circuit and domestic hot water

Central unit PCB CU-OH01 for the boiler

Additional PCB SCB–04: 2nd circuit

Fig.12

MW-5000015-3

Fig.13

Fig.14

MW-1000670-1

Fig.15

MW-1000754-1

...EHC / --02...

Fig.16

MW-1000683-1

...CUO / H01...

Fig.17

MW-1000687-1

...SCB / 04- / B...

4 Description of the product

26 200 ESL HYBRID 7613346 - v05 - 13112018

Page 27

COUNTERS / TIME PROG / Sub-Menus CLOCK

COUNTERS sub-menu (CNT)

TIME PROG sub-menu: Timer programming dedicated to

heating and domestic hot water production (CIRC A, CIRC B,

ECS)

Timer program for Monday

Timer program for Tuesday

Timer program for Wednesday

Timer program for Thursday

Timer program for Friday

Timer program for Saturday

Timer program for Sunday

CLOCK sub-menu (CLK)

Temperature sensors

Room temperature sensor connected:

fixed symbol for WINTER mode,

flashing symbol for SUMMER mode.

Outside temperature sensor connected:

fixed symbol for WINTER mode,

flashing symbol for SUMMER mode.

Other Information

Chimney Sweep Menu: forced operation in full load mode

Forced start-up: forced operation in heating mode

Three-way valve connected

Three-way valve closed

Three-way valve open

Pump running

Fig.18

MW-1000575-2

Fig.19

MW-5000014-4

Fig.20

MW-5000038-4

4 Description of the product

7613346 - v05 - 13112018 200 ESL HYBRID 27

Page 28

5 Operation

5.1 General

Once the indoor module has been connected to the boiler, the unit is

managed from the boiler control panel. No action need be taken directly

on the indoor module.

The boiler control panel:

displays every item of information on the hybrid heat pump as a whole

(indoor module, boiler and outdoor unit)

displays the PCB on which a parameter has to be set:

Heat pump control system PCB (EHC-02)

PCB for managing the second circuit (SCB-04)

is used to make the settings required for the hybrid heat pump to run.

5.2

Use of the control panel

5.2.1 Browsing in the menus

Press any key to turn on the backlight for the control panel screen.

If no key is pressed within 3 minutes, the control panel backlight will go

out.

Press the 2 right-hand keys together to access the different menus:

Tab.15 Menus available

Information menu

User menu

Installer menu

Manual Forcing menu

Malfunction menu

COUNTERS sub-menu

TIME PROG sub-menu

CLOCK sub-menu

PCB selection menu

Important

The icon is displayed only if an optional PCB has

been installed.

Important

The different menus are only accessible when the icons flash.

Press the key to:

access the next menu,

access the next sub-menu,

access the next parameter,

increase the value.

Press the key to:

access the previous menu,

access the previous sub-menu,

access the previous parameter

decrease the value.

Press the confirmation key to confirm:

a menu,

a sub-menu,

a parameter,

a value.

Fig.21

MW-2000369-1

Fig.22

MW-1000576-1

Fig.23

MW-2000370-1

Fig.24

MW-2000371-1

5 Operation

28 200 ESL HYBRID 7613346 - v05 - 13112018

Page 29

When the temperature is displayed, briefly pressing the back key h will

return to the time display.

5.2.2 Description of the PCBs

When commissioning the hybrid system with the boiler, the PCB displayed

in the main menu is EHC-02. The name of the PCB is displayed on the

screen: .

When commissioning the boiler, the PCB displayed is the CU-OH1.

The primary circuit is managed by the CU-OH1 central unit PCB. The

name of the PCB is displayed on the screen: .

See

Boiler instructions for setting the boiler parameters

Only the installer can access the parameters and settings for each PCB.

In order to control an installation that has an additional circuit, it will be

necessary to install the SCB-04 PCB. The name of the PCB is displayed

on the screen: .

Important

Given that numerous settings can be made on the 2 PCBs,

depending on the circuit concerned, the name of the PCB will be

represented by in the rest of the manual.

Selecting a PCB

1. Access the menus by pressing the two keys on the right

simultaneously.

2. Access the PCB selection menu (only when several PCBs are

present).

Important

The PCB selection menu is available only when the icon

flashes.

3. Scroll through the names of the connected additional PCBs by

pressing the or keys.

The names of the installed PCBs will be displayed in sequence.

4. Confirm the required PCB by pressing the key.

Important

The flow temperature for the selected PCB is displayed by default,

as well as the status of the pump(s) and the status of the valve

connected to the selected PCB.

5. Go back to the main display by pressing the h key.

5.3

Start-up

1. Switch on the outdoor unit and the indoor module.

2. The heat pump begins its start-up cycle.

If the start-up cycle runs normally, an automatic venting cycle is

initiated. Otherwise, an error message is displayed.

Fig.25 PCB managing the heat pump and

the hybrid functions

MW-1000591-2

Fig.26

MW-2000374-2

Fig.27

Management of a second circuit

MW-2000375-2

Fig.28

MW-2000369-1

Fig.29

MW-5000137-2

5 Operation

7613346 - v05 - 13112018 200 ESL HYBRID 29

Page 30

5.4 Shutdown

5.4.1 Switching off the heating

Important

Heating mode can be managed via the TIME PROG sub-menu

dedicated to timer programming.

Important

If the heating function is shut off, then the cooling will also be shut

off.

1. Go to stop mode by pressing the key.

2. Select the heating mode by pressing the key.

3. Confirm by pressing the key.

4. Select the heating shut-down pressing the key.

The screen displays: .

The frost protection function continues to run.

The heating has been shut down.

Important

Press the key to restart the appliance: the screen will

display .

5. Confirm by pressing the key.

6. Go back to the main display by pressing the h key.

Important

The display disappears after a few seconds of inactivity.

Fig.30

MW-5000027-4

Fig.31

MW-5000133-3

Fig.32

MW-5000134-3

5 Operation

30 200 ESL HYBRID 7613346 - v05 - 13112018

Page 31

5.4.2 Stopping domestic hot water production

Important

Domestic hot water production can be managed via the TIME

PROG sub-menu dedicated to timer programming.

1. Go to stop mode by pressing the key.

2. Select domestic hot water production mode pressing the key.

3. Confirm by pressing the key.

4. Select domestic hot water production shut-down by pressing the

key.

The screen displays: .

The frost protection function continues to run.

Production of domestic hot water has been shut down.

Important

Press the key to restart the appliance: the screen will

display .

5. Confirm by pressing the key.

6. Go back to the main display by pressing the h key.

Important

The display disappears after a few seconds of inactivity.

5.4.3 Shutting down the cooling function

Important

The cooling function can be managed using the parameter

in the timer programming sub-menu .

Important

If the heating function is shut off, then the cooling will also be shut

off.

5.5

Frost Protection

If the temperature of the heating water in the heat pump falls too much,

the integrated protection device switches itself on. This device functions as

follows:

If the water temperature is lower than 5°C, the circulating pump starts

up.

If the water temperature is lower than 3°C, the back-up starts up.

Fig.33

MW-5000135-3

Fig.34

MW-5000136-3

Fig.35

MW-5000028-4

5 Operation

7613346 - v05 - 13112018 200 ESL HYBRID 31

Page 32

If the water temperature is higher than 10°C, the back-up shuts down

and the circulating pump continues to run for a short time.

The radiator valves in rooms where there is a risk of frost must be fully

open.

5 Operation

32 200 ESL HYBRID 7613346 - v05 - 13112018

Page 33

6 Settings

6.1 List of parameters

6.1.1 User Menu

Fig.36

1

2

MW-2000435-1

3

2

1 Sub-menu available

2 Name of the PCB or circuit

3 Setting parameters

Tab.16

List of User sub-menus

Sub-menu Description Name of the PCB or cir

cuit

Main heating circuit

Additional heating circuit B

Domestic hot water circuit

Central unit PCB EHC-02

Central unit PCB CU-OH01

Additional PCB for circuit B

HMI control panel

See

Boiler user guide for parameters and user instructions.

Important

CP : Circuits Parameters= Heating circuit parameters

Tab.17

List of parameters in the / sub-menus of the User menu

Parameter Description

Factory setting Factory setting

Post-operation time of the circuit pump

Can be set from 0 to 20 minutes

4 minutes 4 minutes

Room temperature set point in reduced mode

Can be set from 5 to 30°C

16°C 16°C

Room temperature set point in comfort mode

Can be set from 5 to 30°C

20°C 20°C

Do not modify this setting. 6°C 6°C

Do not modify this setting. 21°C 21°C

Do not modify this setting. 22°C 22°C

Do not modify this setting. 20°C 20°C

Set point cooling activity zone 1

Can be set from 20 to 30°C

Do not modify this setting.

30°C 30°C

Set point cooling activity zone 2

Can be set from 20 to 30°C

Do not modify this setting.

25°C 25°C

Do not modify this setting. 25°C 25°C

6 Settings

7613346 - v05 - 13112018 200 ESL HYBRID 33

Page 34

Parameter Description

Factory setting Factory setting

Do not modify this setting. 25°C 25°C

Do not modify this setting. 25°C 25°C

Do not modify this setting. 25°C 25°C

Circuit operating mode:

= timer programming

= manual mode

= frost protection mode

0 0

Do not modify this setting. not available 55°C

Do not modify this setting. not available 10°C

Temperature set point for SWIMMING POOL mode not available 20°C

Do not modify this setting. 0 0

Important

DP : Direct Hot Water Parameters = Domestic hot water tank

parameters

Tab.18

List of parameters in the sub-menu of the User menu

Parameter Description

Factory setting

Number of timer programs selected for domestic hot water production mode

Can be set from 0 to 2

Do not modify this setting.

0

Domestic hot water temperature set point in comfort mode

Can be set from 40 to 65°C

54°C (4.5 kW)

54°C (6 kW)

53°C (8 kW)

54°C (11 kW)

54°C (16 kW)

Domestic hot water temperature set point in reduced mode

Can be set from 10 to 60°C

10°C

Domestic hot water production mode:

= timer programming

= manual mode

= frost protection mode

1

Important

AP : Appliance Parameters = Appliance parameters

Tab.19

List of parameters in the / / sub-menus of the User menu

Parameter Description Factory setting Factory setting Factory setting

Cooling mode operation:

= off

= on

not available 0 not available

Central heating operation:

= off (no heating or cooling)

= on

1 1 not available

Domestic hot water tank operation:

= off

= on

1 1 not available

6 Settings

34 200 ESL HYBRID 7613346 - v05 - 13112018

Page 35

Parameter Description Factory setting Factory setting Factory setting

SUMMER / WINTER set point switch:

Can be set from 15 to 30°C

set to 30.5°C = function deactivated

22°C 22°C 22°C

SUMMER override:

= off

= on

0 0 0

Important

HP : Heat-pump Parameters = Heat pump parameters

Tab.20

List of to parameters in the User menu

Parameter Description

Factory setting

Cost of peak time electricity

Can be set from 0.01 to 2.50 €/kWh

0.13 €/kWh

Cost of off-peak electricity

Can be set from 0.01 to 2.50 €/kWh

0.09 €/kWh

Cost of fossil energy (oil or gas) - price per litre or per m

3

Can be set from 0.01 to 2.50 €/kWh

0.90 €/kWh

Important

AP : Appliance Parameters = Appliance parameters

Tab.21

List of parameters in the sub-menu of the User menu

Parameter Description

Factory setting

Back-lighting

= off after 3 minutes of inactivity on the control panel

= on

0

Setting the LANGUAGE :

= no language

= French

= Dutch

= English

= German

= Spanish

= Italian

= Polish

= Portuguese

EN

Setting the CONTRAST :

Can be set from 0 to 3

0

Selecting the UNIT :

= °C

= °F

0

Applying summer/winter time :

= off

= on

1

6 Settings

7613346 - v05 - 13112018 200 ESL HYBRID 35

Page 36

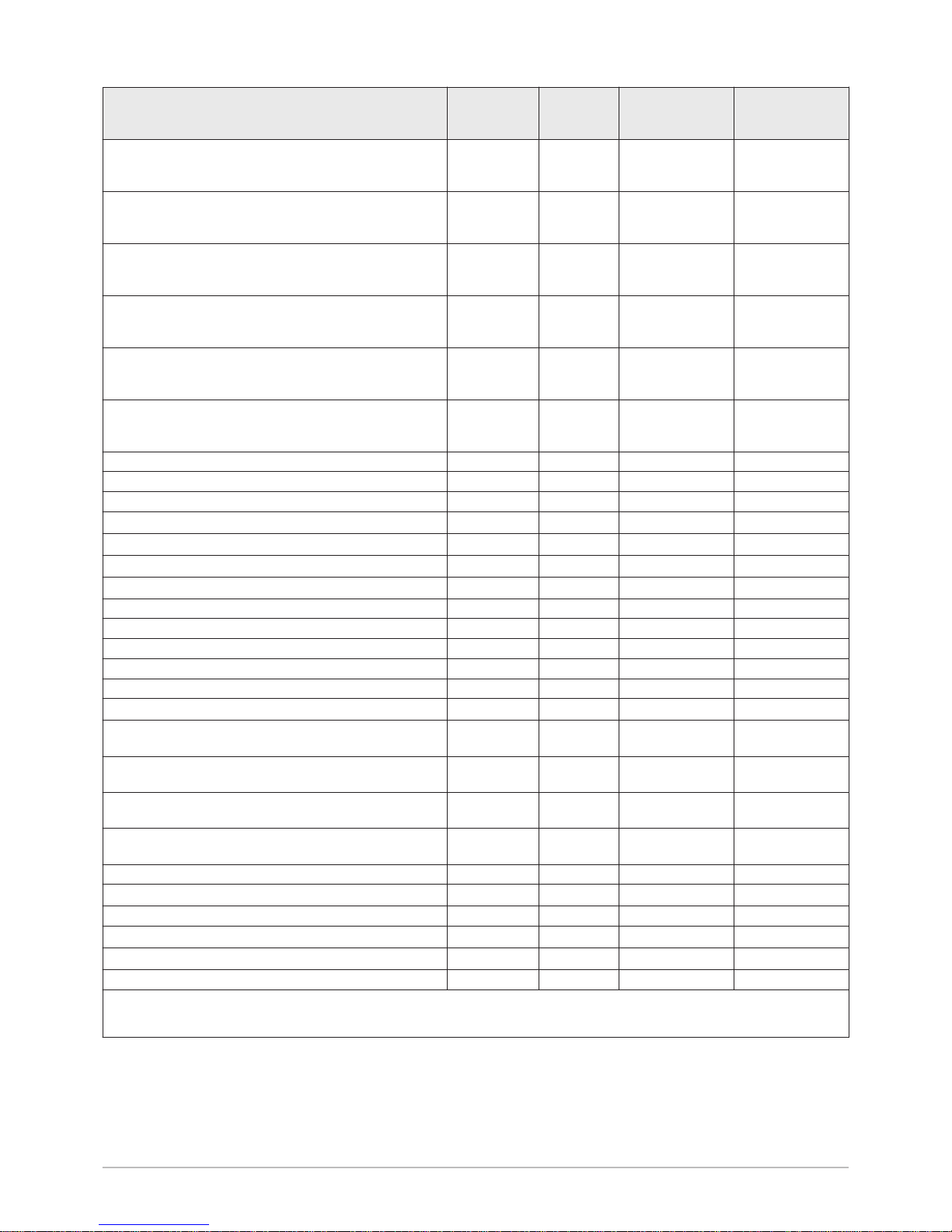

6.1.2 COUNTERS/TIME PROG/CLOCK menus

Tab.22

List of sub-menus

Sub-menu Description

COUNTERS

Timer programming for the main heating circuit

Timer programming for the additional heating circuit B

Timer programming for the domestic hot water circuit

Setting the clock and the date

COUNTERS sub-menu

Tab.23

Selections available in the sub-menu: names of associated PCBs

Adjustment parameter PCB Parameter

Central unit PCB EHC-02

Central unit PCB CU-OH01

Tab.24

List of hour run meters available (X) in the sub-menu

Parameter Description Unit

Number of hours' operation hours X X X

Number of hours' burner operation since

the last service

Number of hours' compressor operation

since the last service

hours X X

Number of hours' operation since the last

service

hours X X

Number of burner start-ups since the last

service

Number of compressor start-ups since the

last service

- X X

Consumption in heating mode kWh X X

Consumption in domestic hot water pro

duction mode

Wh X X

Consumption in cooling mode Wh X

Energy recovered in heating mode kWh X

Energy recovered in domestic hot water

mode

kWh X

Energy recovered in cooling mode kWh X

Seasonal coefficient of performance - X

Number of hours' pump operation hours X X

Number of pump start-ups - X X

Number of hours' operation of back-up 1 hours X

Number of hours' operation of back-up 2 hours X

Number of start-ups of back-up 1 - X

6 Settings

36 200 ESL HYBRID 7613346 - v05 - 13112018

Page 37

Parameter Description Unit

Number of start-ups of back-up 2 - X

Number of hours' pump operation hours X

Number of pump start-ups hours X

Number of reversal valve cycles - X X

Number of hours' reversal valve operation hours X X

Number of burner start-ups in domestic hot

water production mode

Number of compressor start-ups in domes

tic hot water mode

- X X

Number of hours of burner operation in do

mestic hot water production mode

Number of hours' compressor operation in

domestic hot water mode

hours X X

Number of burner start-ups

Number of compressor start-ups

- X X

Number of hours' burner operation

Number of hours' compressor operation

hours X X

Number of safety lock-downs (E36) - X

Resetting the maintenance service

: hour run meters ,

, are reset.

- X X

Tab.25

List of parameters in the sub-menu of the menu

Parameter Description

Timer programming for heating

Timer programming for cooling (only if cooling is activated)

Tab.26

List of parameters in the sub-menu of the menu

Parameter Unit

HOURS Can be set from 0 to 23 available

MINUTE Can be set from 0 to 59 available

DATE Can be set from 1 to 31 available

MONTH Can be set from 1 to 12 available

YEAR Can be set from 2000 to 2100 available

TIME PROG Sub-menu

Tab.27 List of parameters

Parameter Description Factory setting

Timer program for Mondays. 06:00 - 22:00

Timer program for Tuesdays. 06:00 - 22:00

Timer program for Wednesdays. 06:00 - 22:00

Timer program for Thursdays. 06:00 - 22:00

Timer program for Fridays. 06:00 - 22:00

Timer program for Saturdays. 06:00 - 22:00

Timer program for Sundays. 06:00 - 22:00

6 Settings

7613346 - v05 - 13112018 200 ESL HYBRID 37

Page 38

6.2 Setting the parameters

6.2.1 Modifying the User parameters

Caution

Altering the factory settings may impair operation of the appliance.

1. Access the User menu.

Important

The User menu is available only when the icon flashes.

2. Select the desired sub-menu by pressing the or key.

3. Confirm the selection by pressing the key.

4. Select the required parameter by pressing the or keys to scroll

through the list of adjustable parameters.

5. Confirm the selection by pressing the key.

6. Modify the value of the parameter using the or keys.

7. Confirm the new value of the parameter by pressing the key.

8. Go back to the main display by pressing the h key.

6.2.2 Setting the room temperature set point in comfort mode

Important

The room temperature set point can be managed via the TIME

PROG sub-menu dedicated to timer programming.

Important

To set the room temperature set point in reduced mode, it is

necessary to set parameter available in the User

menu.

When the setting is made in a reduced mode range, this setting

shortcut is used only to set the temperature set point in comfort

mode corresponding to .

1. Access the heating parameters by pressing the key twice.

2. Display the parameters for the required circuit by pressing the or

key.

3. Confirm by pressing the key.

The name of the circuit and the heating water temperature set point

are displayed alternately.

4. Access setting of the heating water temperature set point by pressing

the key.

5. Set the heating water temperature set point by pressing the or

key.

6. Confirm the new temperature set point by pressing the key.

Important

Press the h key to cancel all input.

Important

The setting for the room temperature set point in comfort mode

can also be accessed in the User menu, parameter .

Fig.37

MW-5000008-2

Fig.38

MW-5000040-6

Fig.39

MW-5000144-3

Fig.40

MW-3000249-4

6 Settings

38 200 ESL HYBRID 7613346 - v05 - 13112018

Page 39

6.2.3 Setting the domestic hot water temperature

Important

Domestic hot water production can be managed via the TIME

PROG sub-menu dedicated to timer programming.