Page 1

Oracle Dome Camera

Installation Manual

www.dedicatedmicros.com

Page 2

Dedicated Micros ©2008

2

Oracle

Whilst every attempt is made to ensure these manuals are accurate and current, Dedicated Micros reserve the right to

alter or modify the specication of the machine described herein without prejudice.

Contents

Introduction .......................................................3

Components supplied - External .......................5

Components supplied - Internal ........................6

Electrical Connections - External ......................7

Electrical Connections - Internal .......................9

Mounting Congurations - External ...................10

Mounting Congurations - Internal ....................13

Control Conguration - All Models.....................17

Upgrading Dome Software ................................22

Dome Conguration ..........................................24

Troubleshooting ................................................25

Notes .................................................................26

Page 3

Dedicated Micros ©2008

3

Oracle

Introduction

Congratulations on choosing a Dedicated Micros Oracle dome camera.

This manual will provide all the necessary information to install the Dedicated Micros Oracle Dome

Camera.

RF Interference warning

This is a class A product. In a domestic environment this product may cause radio frequency

interference, in which case the user may be required to take adequate measures.

Product Safety

WARNING

• Installation and servicing is only to be carried out by suitably qualied and

experienced personnel and should conform to all local codes.

• Only power low voltage cameras from the provided power supply. Use only a Class

2 power supply with a maximum current of 1.5 amps and the wiring as specied in

the National Electrical Code ANSI/NFPA 70.

This camera range is designed for use in general purpose CCTV applications and has no other

purpose.

Only operate your camera between the temperatures of -10°C and +40°C. This low voltage camera

must be powered with either a 12V DC or a 24V AC power supply. Do not operate your camera

outside its specied power supply range.

FCC CLASS B REGULATORY NOTICE

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired This equipment has been

tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a different circuit different to the receiver.

Consult the dealer or an experienced radio/TV technician for help.

Modications not expressly approved by the manufacturer could void the user’s authority to

operate the equipment under FCC rules.

Page 4

Dedicated Micros ©2008

4

Oracle

Camera Care

In order to avoid damaging your camera, note the following points:

CAUTION

• Remove all packaging inserts and the protective lm from the dome cover before

using the camera.

• This installation should be made by a qualied service person and should conform

to all local codes.

CE NOTICE (EUROPEAN UNION).

Marking by the symbol CE indicates compliance of this DM product to the Electromagnetic

Compatibility Directive 89/336/EEC, and the Low Voltage Directive 73/23/EEC of the European

Union. Such marking is indicative that this system meets the following technical standards.

• EN 61000-6-3 EMC Standard Residential, Commercial and Light Industry.

• EN 61000-3-3 Limitations of voltage changes, uctuations and icker in public lowvoltage supply systems for equipment with rated current up to 16A.

• EN 61000-3-2 Limits for harmonic current emissions for equipment with rated

current up to 16A.

• EN 50130-4 Immunity requirements for components of re, intruder and social

alarm systems.

• EN 60950 Safety of IT and related equipment.

• EN 55022 Class B. Radiated Emissions Standard, suitable for Commercial or

Residential use.

• EN 60825-1 Safety standard for LED’s and Lasers.

Further details about these applicable standards can be obtained from Dedicated Micros Ltd. 1200

Daresbury Park, Daresbury, Cheshire, WA44HS.

A “Declaration of Conformity” with all relevant European Union Directives has been made, is on le

and is available from the Dedicated Micros address above.

This product is marked with the CE symbol and indicates compliance with all applicable directives.

Directive 89/336/EEC.

A “Declaration of Conformity” is held at Dedicated Micros Ltd., 1200 Daresbury Park, Daresbury,

Cheshire, WA44HS.

Page 5

Dedicated Micros ©2008

5

Oracle

Components supplied - External

Before installing the dome, please remove the components from the packaging and verify that all

items listed below have been supplied:

1 x Dedicated Micros Oracle Dome enclosure and camera (with incorporated safety bond)

1 x Oracle Dome Power Supply (except USA)

1 x Dedicated Micros Oracle Dome manual

Note for US Customers: The PSU must be a UL2044 approved Class 2 current limited 24VAC

Power Supply with a maximum current of 1.5 amps and the wiring as

specied in the National Electrical Code ANSI/NFPA 70.

Note: Mounting brackets may have been ordered and delivered separately.

Important: The Advanced Programming and Control features on the Oracle Dome are only

available when used with the latest Dedicated micros DVRs. These include DV-IP

Server, DV-IP HD, DV-IP RT and HighVu Excel. Standard functionality will still be

available with other control equipment.

Page 6

Dedicated Micros ©2008

6

Oracle

Components supplied - Internal

Before installing the dome, please remove the components from the packaging and verify that all

items listed below have been supplied:

1 x Dedicated Micros Oracle Dome enclosure and camera (with incorporated safety bond)

1 x Dedicated Micros Oracle Dome manual

Note: The PSU must be a UL2044 approved Class 2 current limited 24VAC Power Supply with

a minimum current of 1.5 amps and the wiring as specied in the National Electrical Code

ANSI/NFPA 70. Dedicated Micros recommends the DM/94012 for indoor dome.

Note: Mounting brackets may have been ordered and delivered separately.

Important: The Advanced Programming and Control features on the Oracle Dome are only

available when used with the latest Dedicated micros DVRs. These include DV-IP

Server, DV-IP HD, DV-IP RT and HighVu Excel. Standard functionality will still be

available with other control equipment.

Page 7

Dedicated Micros ©2008

7

Oracle

Electrical Connections - External

Multiway Connector

The dome receives power and data, and sends video and data via the multiway connector.

This feeds into the PCB housed in the terminal box, which provides wiring breakout and interconnectivity.

Note: The terminal box is not supplied in the USA.

Dome connector

C

V

D

R

E

U

K

J

H

B P A N M L

F S G T

Note: Viewed from wiring side

The 15 core cable connections are as follows:

Cable Function Connector Pin

Green/Yellow Earth F

Green/Yellow Earth G

Coax Video Signal C

Coax Vid Screen P

Yellow RS485A E

Green RS485B T

Brown 24VAC D

Blue 24VAC U

Violet Alarm 1 H

Pink Alarm 2 S

Grey Alarm 3 J

Orange Alarm 4 R

Black Alarm Ground K

White Relay A N

Red Relay B L

Page 8

Dedicated Micros ©2008

8

Oracle

PCB

1

9

Alm 1

Alm Gnd

Alm 2

Alm Gnd

Alm 3

Alm Gnd

Alm 4

Alm Gnd

Relay A

Relay B

Vid In +

Vid In -

Tx/Rx +A

Tx/Rx -B

PWR +

Pwr -

Alm 1

Alm 2

Alm 3

Alm 4

Alm Gnd

Relay A

Relay B

Shield Gnd

Shield Gnd

24V AC +

24VAC-

J1

J2

+ UTP

- UTP

Tx/Rx +A

Tx/Rx -B

Optional

Alarm/Relay

Inputs

To Dome

Multiway

Connector

DVR Video

Output

DVR RS485

Telemetry

Future

development

TEL

TERM

Minimum conguration

The simplest connection possible to the Oracle Dome would require the following;

The Mains supply (live, earth and neutral) is connected to the heavy duty connector block

mounted in the Power Supply Unit next to the PCB. Power select links (J1 & J2) should be

set to 24VAC (centre and arrowed pin bridged as shown above). Telemetry termination (TEL

TERM) link is normally not tted (as shown above).

Function Colour PCB Connector

Safety (Earth) Green/Yellow Shield Gnd

Power Brown PWR+

Power Blue PWR-

Video Coax BNC

RS485A Yellow Tx/Rx +A

RS485B Green Tx/Rx -B

Note: Whilst the Alarm and Relay inputs are not essential for minimum conguration, it is

recommended that they are connected to the PCB in case they are required in the future.

Note: The Multiway cable should be securely clamped to the chassis using the screw clamp

provided. The insulation should be stripped back to allow the clamp to contact the cable

foil sheath. All glands into the PSU should be securely tightened to prevent the ingress

of moisture.

Connecting the DVR to the Oracle Dome (via PCB)

Video to the DVR is sent via the BNC Video/Control Output connection shown above.

Telemetry control is via the DVR RS485 Telemetry Inputs/Outputs connection shown above.

RS485A connects to Pin 1 on the serial connector of the DVR.

RS485B connects to Pin 9 on the serial connector of the DVR.

Alternatively the Oracle supports either up the coax (UTC) control via the video output BNC

connector or un-shielded twisted pair (UTP) via the UTP video/UTP net connectors (available via

future software upgrade).

Page 9

Dedicated Micros ©2008

9

Oracle

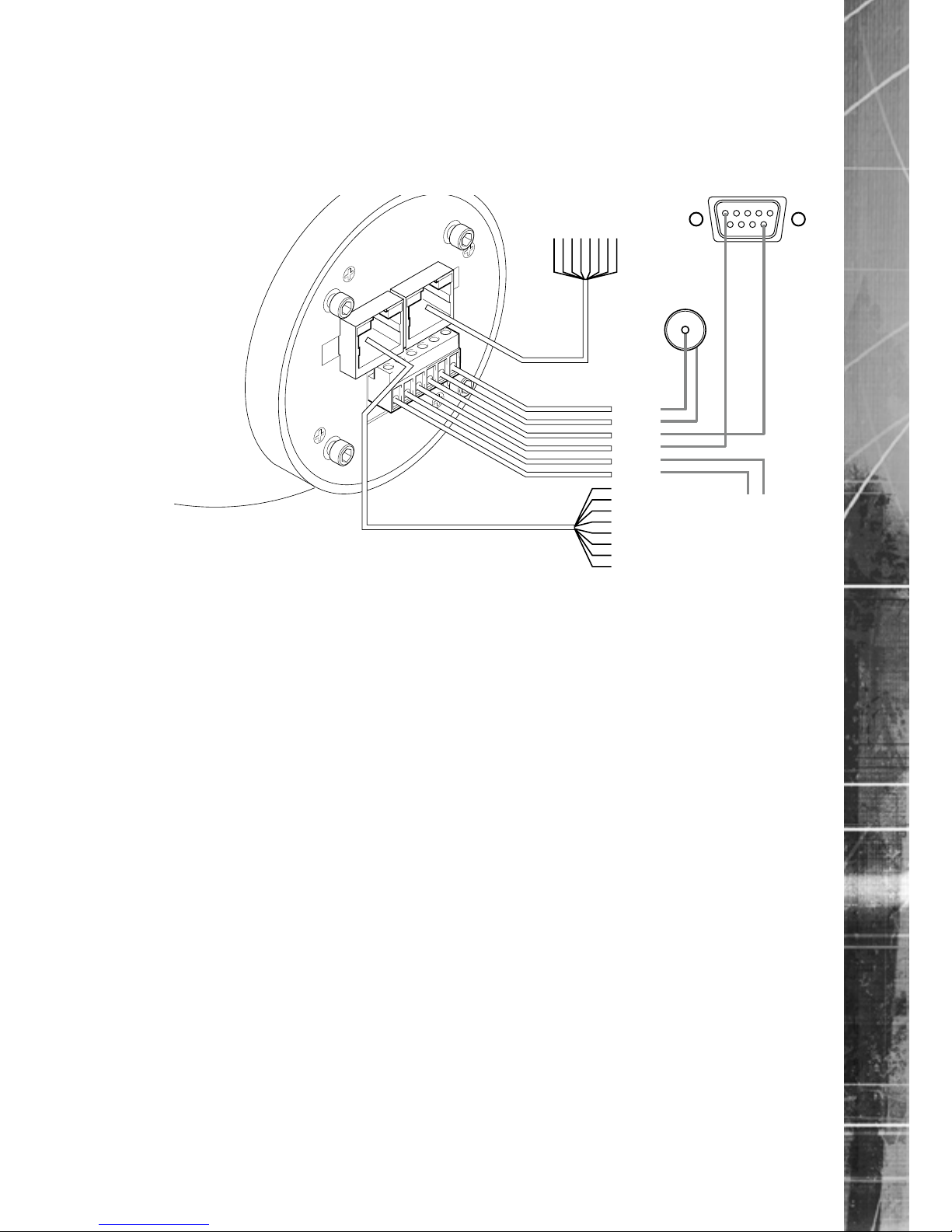

Electrical Connections - Internal

The dome requires connection to the power supply and to the BNC connection of the DVR. Use

the serial port connection if serial telemetry is required. There is no prepared cable included, the

connector for the camera is included.

Vid Sig

Vid GND

485B

485A

24VAC

24VAC

Reserved for

UTP/Ethernet

versions

Pin 1 - Alarm 1

Pin 2 - Alarm 2

Pin 3 - Alarm 3

Pin 4 - Alarm 4

Pin 5 - Alarm Ground

Pin 6 - NC

Pin 7 - Relay A

Pin 8 - Relay B

1

9

TX+

BNC

TX-

24V Power

Supply

+ -

The two RJ45 connectors are used for alarms and UTP control. The serial connector provides the

serial telemetry interface. The dome will also be capable of accepting future software upgrades via

this serial connection. This will ensure the dome can be incorporated into any upgraded network.

RJ45 connectors

Pin Connection

1 Alarm 1

2 Alarm 2

3 Alarm 3

4 Alarm 4

5 Alarm Ground

6 Not connected

7 Relay A

8 Relay B

Note: The relay is suitable for switching DC only and is rated at 0.7A.

Multiway connector

The serial connection is not required when using UTC Control.

Connector Function

24VAC 24VAC+ from UL2044 approved Class 2 current limited 24VAC 1A

24VAC 24VAC- from UL2044 approved Class 2 current limited 24VAC 1A

485A Pin 1 on Serial Connection to appropriate DVR

485B Pin 9 on Serial Connector to appropriate DVR

Vid GND BNC Earth (screen connection)

Vid Sig BNC Signal (centre pin connection)

Note: Refer to ‘Dome Conguration’ for a list of appropriate DVRs.

Page 10

Dedicated Micros ©2008

10

Oracle

Mounting Congurations - External

With appropriate brackets this dome enclosure can be mounted in any of the orientations

shown below.

Note: Mounting brackets may have been ordered and delivered separately.

1

4

5

3

2

1. Wall/Pendant Mount (order code DM/90002) giving pendant or wall mount options.

2. Extended Wall Mount (order code DM/90009) for more exibility in wall mounting.

3. Corner Bracket (order code DM/90007) for mounting to corners of buildings in

conjunction with DM/90002.

4. Snowdrop mount bracket (order code DM/90004) for mounting at the top of a pole

or column.

5. Pendant Mount (order code DM/90003 - 250mm; order code DM/90012 - 500mm;

order code DM/90013 - 1000mm; order code DM/90014 - 1500mm) for roof or

parapet mounting.

Page 11

Dedicated Micros ©2008

11

Oracle

Safety Bond

The safety bond is designed to prevent damage to the dome if it is dropped during installation or

maintenance. It should be connected between the mounting point on the dome and a suitable

secure position, either on the bracket or within the ceiling void. Selection of this suitable point should

consider that it will receive the full force of the dome should it be dropped.

For wall, pendant & snowdrop mounted domes;

1. Clip safety bond to the mounting bracket eyelet on ange of bracket to secure.

For standard ceiling mounted domes attach the supplied safety bond;

1. Attach bond to a suitable secure position in the ceiling void.

Note: Always support dome with bond prior to mating connector. The weight of dome should be

supported by bond ensuring no stress is placed on centre connector at any time.

Page 12

Dedicated Micros ©2008

12

Oracle

Dome Mounting

A. Secure & hang dome to bracket by attaching safety bond spring clip to eyelet.

Note: Procedure is the same for all installations.

Note: Ceiling installation is made easier by removing an adjacent ceiling tile during installation.

B. Lift dome to bracket ange ensuring head of screws (previously tted cap head

screw) pass through keyhole slots. Twist to locate.

C. Mate the previously prepared central connector, refer to ‘Electrical Connections’

for more information, supplying power & control to dome (ensure power is off when

connecting).

D. Tighten 4 top mounting xings with Hexagonal key supplied to secure.

E. Secure any plastic covers or trim (wall/pendant installations only).

Page 13

Dedicated Micros ©2008

13

Oracle

Mounting Congurations - Internal

With appropriate brackets this dome enclosure can be mounted in any of the orientations

shown below.

Note: Mounting brackets may have been ordered and delivered separately.

1

4

3

2

1. Wall/Pendant Mount (order code DM/90002) giving pendant or wall mount options.

2. Corner Bracket (order code DM/90007) for mounting to corners of buildings in

conjunction with DM/90002.

3. Tile mount (order code DM/CSD/TMR) for suspended ceilings.

4. Snowdrop mount bracket (order code DM/90004) for mounting at the top of a pole

or column.

Page 14

Dedicated Micros ©2008

14

Oracle

Safety Bond

The safety bond is designed to prevent damage to the dome if it is dropped during installation or

maintenance. It should be connected between the mounting point on the dome and a suitable

secure position, either on the bracket or within the ceiling void. Selection of this suitable point should

consider that it will receive the full force of the dome should it be dropped.

For wall, pendant & snowdrop mounted domes;

1. Clip safety bond to the mounting bracket eyelet on ange of bracket to secure.

For standard ceiling mounted domes attach the supplied safety bond;

1. Attach bond to a suitable secure position in the ceiling void.

Note: Always support dome with bond prior to mating connector. The weight of dome should be

supported by bond ensuring no stress is placed on centre connector at any time.

Page 15

Dedicated Micros ©2008

15

Oracle

Dome Mounting

Pendant Mount

A. Secure and hang dome to bracket by attaching safety bond spring clip to eyelet.

B. Lift dome to bracket ange ensuring head of screws (previously tted Cap head

Screw) pass through keyhole slots. Twist to locate.

C. Mate the previously prepared central connector, refer to ‘Electrical Connections’

for more information, supplying power & control to dome (ensure power is off when

connecting).

D. Tighten 4 top mounting xings with Hexagonal key supplied to secure.

E. Secure any plastic covers or trim (wall/pendant installations only).

Page 16

Dedicated Micros ©2008

16

Oracle

Tile Mount

Ø190mm

3 x Ø6mm

204mm PCD

A

C

E

F

D

B

A. Remove the selected tile that will have the dome mounted in it. Use the mounting

ring (B) as a template to mark the drilling positions of the 3 x supporting holes on

a 204mm pitch circle diameter (6mmØ holes, if using the supplied cavity plugs (A))

and the 190mmØ hole for the dome. Fit the cavity plugs (A) to the holes.

Note: The installer is responsible for ensuring the xings used to mount the dome are suitable for

the material and will adequately support the weight of the dome.

B. Attach the mounting ring to the dome using the provided 6 x M3x8 xings (C).

C. Re-install the tile in the ceiling. Secure and hang dome to a suitable mounting point

in the ceiling void by attaching safety bond spring clip to eyelet through the large

centre hole in the tile.

Note: Ceiling installation is made easier by removing an adjacent ceiling tile during installation.

D. Fasten the dome to the mounting ring (B) using the provided 3 x No.8x1”(25.4mm)

self tapping screws (D) (or suitable xings provided by the installer).

E. Snap t the provided tile mount bezel (E). This replaces the standard bezel (F)

provided with the camera. Discard the standard bezel (F).

Page 17

Dedicated Micros ©2008

17

Oracle

Control Conguration - All Models

Switch settings

Different controllers require different protocols and a red rotary switch is provided to select

the desired protocol. These are accessed by removing the outer hemisphere, refer to ‘Switch

Conguration’ for more information. There are three color coded switches, red, blue and yellow,

which are all located inside the dome camera housing. The blue and yellow switches have different

functions, depending on the protocol selected by the red switch.

Switch Conguration

To access the address switches and termination switch, remove the outer hemisphere by

unscrewing the six hemisphere securing screws. The location of the switches is shown. Access to

the switches is improved if the inner shroud is removed by taking out the four securing screws. This

operation should be carried out in an ofce type environment to avoid ingress of moist air.

RED SWITCH LOCATION

Function - Protocol Selection

Position Protocol

0 Auto Sense (under development)

1 DM UTC (under development)

2 DM RS485

3 DM Current Loop (under development)

4 BBV UTC

Note: The selected protocol will be displayed on screen at power-up for a few seconds each time

the rotary switches are changed.

Page 18

Dedicated Micros ©2008

18

Oracle

BLUE SWITCH LOCATION

Function - Dependant on Red Switch Conguration

UTC/Current Loop - Not Used

Serial - Referenced by Camera Number on the DVR, refer to ‘Address

chart’ in section ‘RS485 Serial Connection’.

YELLOW SWITCH LOCATION

Function - Dependant on Red Switch Conguration

UTC/Current Loop - Not Used

Serial - Referenced by Camera Number on the DVR, refer to ‘Address

chart’ in section ‘RS485 Serial Connection’.

TERMINATION SWITCH LOCATION (SW1)

Note: SW1 should be set towards the centre of PCB to turn RS485 termination ON or set away

from the centre of the PCB to turn RS485 termination OFF.

Page 19

Dedicated Micros ©2008

19

Oracle

RS485/CURRENT LOOP TELEMETRY SWITCH LOCATION (SW2)

Note: SW2 should be set towards the centre of the PCB (RS485)

COAX OR DIFFERENTIAL VIDEO SWITCH LOCATION (SW3)

Note: SW3 should be set towards the centre of the PCB (coax).

RS485 Serial Connection

The coax cable and power wires are always connected.

The RS485 wires are only connected when an RS485 controller is being used.

The dome supports the DM RS485 PTZ protocols. The desired protocol and the node address for

the dome are selected by the rotary hex switches (red, blue and yellow) inside the dome. These

are accessed by removing the outer hemisphere and inner shroud, refer to Switch Conguration for

more information.

RS485 protocol allows multiple domes to be connected via the serial connection on the back of the

DVR. Each dome in the chain should have a unique individual address, to enable it to be called by

the DVR. The switch settings for the protocols and node addresses are shown in the table below.

Page 20

Dedicated Micros ©2008

20

Oracle

Address chart

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63

64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79

80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95

96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111

112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127

128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143

144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159

160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175

176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191

192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207

208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223

224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239

240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255

Yellow

Blue

0 1 2 3 4 5 6 7 8 9 A B C D E F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

To congure the Dome using DM RS485;

1. Select DM RS485 by setting the red switch to position 2.

2. Select a node address for the dome to be congured. Scan across the table to

identify the values for the blue and yellow switches; blue switch setting is shown

on the left, yellow switch setting on the right. For example, if the dome is to be

used with node address ID#5 the switches should be set to ‘05’. i.e. the blue switch

should be set to ‘0’ and the yellow switch set to ‘5’.

3. Set the individual RS485 address for the dome on the blue and yellow switches

tted inside the dome housing.

Note: The dome will display its protocol and address setting when rst powered on as the screen

will show (in the example above) “Node Address 05”. It will also display briey after each

time the setting is changed.

All Dedicated Micros Oracle domes are tted with a termination switch (SW1), shown above. If a

single dome is connected on the RS485 line, or if a star conguration is used, the termination switch

should be switched to ‘ON’ (Switch towards the centre of the PCB).

If multiple domes are connected in a ‘daisy chain’ conguration, then only the last dome in the chain

should be switched to ‘IN’. All other domes in the chain should be switched to “OFF’ (Switch set

away from the centre of the PCB).

Page 21

Dedicated Micros ©2008

21

Oracle

Up-The-Coax PTZ control

Note: Only basic PTZ and preset functionality is available currently using UTC control. For full

programming and control including point&go and Absolute Positioning use RS485 control.

Commands to control the position of the dome can be transmitted up the same co-ax cable used to

transmit the video signal to the recorder station. Individual addresses do not need to be congured

within the dome because the instruction is sent directly to the dome.

Note: The serial connection is not required when using Up-The-Coax control.

Up the Coax Switch Settings

Switch Setting

Red 4

Yellow/Blue Not required.

RED SWITCH LOCATION

BLUE SWITCH LOCATION

YELLOW SWITCH LOCATION

Page 22

Dedicated Micros ©2008

22

Oracle

Upgrading Dome Software

The Oracle dome has an expanded feature and control set over other domes, which are only

available through the Dedicated Micros PTZ protocol.

These features are accessed through a set of web pages available on the latest Dedicated Micros

machines (DV-IP Server, DV-IP RT, DV-IP HD and HighVu Excel) and that will have access to

this dome. These pages will be available through the familiar unit interface and will allow easy

conguration of the domes features.

To upgrade dome software via RS485;

Note: The dome must be congured to RS485 telemetry to perform the software upgrade (Red

Switch to position 2).

Software is downloaded via the RS485 telemetry link on the dome, using a USB to RS485 converter

on the PC.

1. Download the software ‘domecfg’ and the application upgrade software from the

Dedicated Micros website.

2. Connect a USB to 485 converter to a USB port on your PC (see note below for

details of pin out for 9way Dtype connector).

3. Connect the RS485 serial lead from the Oracle dome to the output of the USB to

485 converter.

4. Launch the ‘Domecfg’ application.

5. Select ‘Setup’ (tab top left of window) in ComPorts window select drop-down

menu and select the PC COM port that has been assigned to the USB to RS485

converter.

7. Ensure the following settings are selected:

Baud rates: 9600

Parity: None

Data bits: 8

Stop bits: 1

Flow control: Xon char 17

Xoff char 19

8. Select ‘OK’

9. Select the Camera number (Cam box top left window) to ensure the upgrade

program addresses the packets to the relevant dome.

10. Conrm that correct COM port has been selected by using the Up (U), Down (D),

Left (L) and Right (R) buttons to move the dome.

If settings are correct the dome should move when requested.

If not, check; The camera number equates to the dome address switch settings and

that the USB to RS485 converter is correctly congured.

11. Select ‘File->Open’ and navigate to the downloaded application upgrade software

zip le. Left click the le and then press ‘Open’.

12. Select ‘Upload’ to transfer the le to the dome. Upgrade takes approximately

twenty minutes, the progress can be monitored using the ‘Domecfg’ application or

by viewing the camera that is being upgraded via the unit it is connected to.

Important: The dome must not be powered down whilst a software download is in progress.

Powering down the dome could permanently corrupt the dome software.

13. When the upgrade is complete, the ‘Domecfg’ application will display ‘Finished’.

14. Disconnect the RS485 telemetry cable from the USB to 485 converter and

reconnect to the serial port of the DVR.

15. Conrm correct operation using telemetry control of the DVR

Page 23

Dedicated Micros ©2008

23

Oracle

Note: Pin out for 9-way D-type connector to the DVR is normally Pin 1 for RS485+A and pin 9 for

RS485B. If the converter used is different then an intermediate cable may be needed to

transpose the wires (see converter’s documentation for pin out details).

16. Conrm the upgrade has been successful by checking the software version number

on the startup screen (This screen can also be displayed by special preset G4)

Page 24

Dedicated Micros ©2008

24

Oracle

Dome Conguration

The Dome is congured via the attached DVR. The special software features are available via the

interface on DVR’s capable of accessing them (DV-IP Server, DV-IP RT, DV-IP HD and HighVu

Excel), refer to the documentation for your individual DVR for further details.

The Dome has advanced features that include Point and Go, Privacy masking, Presets, Sectors and

Patrols. along with Camera and Event settings. Some of these will be available to standard DVR’s.

List of DVR’s required to utilise advanced programming features

• DV-IP Server, DV-IP HD, DV-IP RT and HighVu Excel running Gen3 pages.

Note: Standard functionality will still be available with all other control equipment.

Page 25

Dedicated Micros ©2008

25

Oracle

Troubleshooting

No picture

Cause

1. Check the Input voltage

2. Check the continuity on the dome cable, refer to ‘Electrical Connections’ for more information.

Picture with intermittent control

Cause

This is most likely due to too much or too little video gain whilst using UTC telemetry.

Solution

Adjust using the Oracle dome settings page on the DVR.

Dome spins continuously (DM controllers)

Cause

No joystick dead band recognized as joystick was off centre during power-up.

Solution

Reboot the controller with the joystick self centred.

No telemetry control

Cause

Check the telemetry and address switch settings.

Note: Any changes to the switch settings are briey displayed on the video output from the dome as

conrmation.

Page 26

Dedicated Micros ©2008

26

Oracle

Notes

Page 27

Dedicated Micros ©2008

27

Oracle

Index

Address chart ..............................................................................................................................................20

BLUE SWITCH LOCATION ......................................................................................................................... 18

Camera Care ................................................................................................................................................. 4

CE NOTICE (EUROPEAN UNION). .............................................................................................................. 4

COAX OR DIFFERENTIAL VIDEO SWITCH LOCATION (SW3) ................................................................ 19

Components supplied - External ...................................................................................................................5

Components supplied - Internal..................................................................................................................... 6

Connecting the DVR to the Oracle Dome (via PCB) ..................................................................................... 8

Control Conguration - All Models ............................................................................................................... 17

Dome Conguration..................................................................................................................................... 24

Dome connector ............................................................................................................................................ 7

Dome Mounting ........................................................................................................................................... 12

Dome Mounting ........................................................................................................................................... 15

Dome spins continuously (DM controllers) .................................................................................................. 25

Electrical Connections - External................................................................................................................... 7

Electrical Connections - Internal .................................................................................................................... 9

FCC CLASS B REGULATORY NOTICE ....................................................................................................... 3

For standard ceiling mounted domes attach the supplied safety bond; ...................................................... 11

For standard ceiling mounted domes attach the supplied safety bond; ......................................................14

For wall, pendant & snowdrop mounted domes; ......................................................................................... 11

For wall, pendant & snowdrop mounted domes; ......................................................................................... 14

Function - Dependant on Red Switch Conguration ...................................................................................18

Function - Dependant on Red Switch Conguration ...................................................................................18

Function - Protocol Selection....................................................................................................................... 17

List of DVR’s required to utilise advanced programming features ............................................................... 24

Minimum conguration .................................................................................................................................8

Mounting Congurations - External ............................................................................................................. 10

Mounting Congurations - Internal ..............................................................................................................13

Multiway Connector ....................................................................................................................................... 7

Multiway connector ........................................................................................................................................ 9

No picture .................................................................................................................................................... 25

No telemetry control ....................................................................................................................................25

Notes ........................................................................................................................................................... 26

PCB ............................................................................................................................................................... 8

Pendant Mount ............................................................................................................................................ 15

Picture with intermittent control ...................................................................................................................25

Product Safety ............................................................................................................................................... 3

RED SWITCH LOCATION ........................................................................................................................... 17

RED SWITCH LOCATION ........................................................................................................................... 21

RF Interference warning ................................................................................................................................ 3

RJ45 connectors............................................................................................................................................ 9

RS485/CURRENT LOOP TELEMETRY SWITCH LOCATION (SW2) ........................................................ 19

RS485 Serial Connection ............................................................................................................................ 19

Switch Conguration.................................................................................................................................... 17

Switch settings............................................................................................................................................. 17

TERMINATION SWITCH LOCATION (SW1)............................................................................................... 18

Tile Mount .................................................................................................................................................... 16

To congure the Dome using DM RS485; ................................................................................................... 20

To upgrade dome software via RS485; .......................................................................................................22

Troubleshooting ........................................................................................................................................... 25

Up-The-Coax PTZ control ...........................................................................................................................21

Upgrading Dome Software .......................................................................................................................... 22

Up the Coax Switch Settings ....................................................................................................................... 21

YELLOW SWITCH LOCATION ................................................................................................................... 18

YELLOW SWITCH LOCATION ................................................................................................................... 21

Page 28

Dedicated Micros Europe

Neckarstrae 15,

41836 Hückelhoven, Germany

Dedicated Micros France

9-13 rue du Moulinet

75013 Paris, France

Dedicated Micros Slovenia

Delavska cesta 26,

4208 Sencure, Slovenia

Dedicated Micros Benelux

Joseph Chantraineplantsoen 1,

3070 Kortenberg, Belgium

Dedicated Micros USA.

14434 Albemarle Point Place, Suite 100,

Chantilly, Virginia 20151 USA

Dedicated Micros, Australia PTY.

5/3 Packard Avenue, Castle Hill,

NSW 2154, Australia

Dedicated Micros, Asia PTY

16 New Industrial Road,

#03-03 Hudson Techno Centre,

Singapore 536204

Dedicated Micros Middle East

Building 12, Suite 302, P.O. Box 500291, Dubai Internet

City, Dubai, United Arab Emirates

Dedicated Micros Ltd.

1200 Daresbury Park, Daresbury,

Cheshire, WA4 4HS, UK

Installed by

MI-I-OD/E1-1

PN. 740408

Dedicated Micros (Malta) Ltd.

BLB017, Bulebel Industrial Estate,

Zejtun, ZTN08, Malta

Loading...

Loading...