DEAN MF90-12BI Installation Manual

10-01

Micro-Flo Built-In Series Filtration

Installation, Operation & Maintenance Manual

Systems

Models MF90-12BI, -14BI, -18BI & -20BI

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $6.00

819-5745

Please read all sections of this manual and retain for future reference.

Installation, maintenance, and repairs should be performed by your Dean

Factory Authorized Service Center.

CAUTION

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER COOKING APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

WARNING

SAFE AND SATISFACTORY OPERATION OF YOUR EQUIPMENT DEPENDS ON ITS

PROPER INSTALLATION. INSTALLATION MUST CONFORM TO LOCAL CODES, OR IN

THE ABSENCE OF LOCAL CODES, WITH THE LATEST EDITION OF THE NATIONAL

ELECTRIC CODE, N.F.P.A. 70.

i

Micro-Flo Series Built-In Filters

TABLE OF CONTENTS

Page #

1. DESCRIPTION AND SPECIFICATIONS 1-1

2. PRE-INSTALLATION 2-1

3. RECEIVING & INSTALLING THE FILTER 3-1

4. OPERATIONS 4-1

5. CLEANING AND MAINTENANCE 5-1

6. TROUBLESHOOTING 6-1

7. FACTORY SERVICE AND PARTS ORDERING 7-1

ii

MICRO-FLO BUILT-IN SERIES FILTRATION SYSTEMS

CHAPTER 1: DESCRIPTION AND SPECIFICATIONS

Micro-Flo Built-In Series filtration systems are available in sizes to handle quantities of oil up to 120

pounds. They can be fabricated to match Dean gas (Super Marathon & Decathlon) or electric fryers

(Cool Zone & Flatbottom Series), or in stand-alone cabinets. Micro-Flo filtration systems

incorporate a "gravity drain" design. The oil return line can be configured overhead (prior to 1994),

internally plumbed, or returned by the hose & nozzle.

Prior to 1994, handle-operated ball valves or optional "push-pull" linkage-operated ball valve

controls located in the filter cabinet were available. Current systems are configured with the oilreturn and drain valve controls located in each fryer cabinet.

1.1 Construction

Micro-Flo Built-In filters are constructed with the following features:

ø Fully welded, heavy gauge steel, with a removable stainless steel filter pan.

ø Internal oil return lines are plumbed with either a "push-pull" valve system in the filter

cabinet or manual drain valves at each fryer.

ø A 1/3 HP motor, coupled with a 5 GPM pump returns filtered oil to the fry vessel. An 8

GPM pump (optional) is also available.

1.2 Operating Controls

Micro-Flo Built-In filters are equipped with the following operating controls:

ø The "ON-OFF" power switch is mounted on the front control panel of the filter cabinet. If

the filter is equipped with an optional heater, a three-position switch (Heater/Off/Pump) is

included as the power switch.

ø Individual fryer drain valves control which fryer is filtered, reducing operator error.

ø Prior to 1994: Oil-return valves are either "push-pull" controls or "lever-operated" manual

ball valves; the push-pull controls are in the filter cabinet and the "lever-operated" valves are

at each individual fryer.

ø 1994 and later: Oil-return valves are push-pull controls, located within each individual fryer

cabinet. A manual "hose-disconnect" valve is located in the filter cabinet.

1-1

MICRO-FLO BUILT-IN SERIES FILTRATION SYSTEMS

CHAPTER 2: PRE-INSTALLATION

2.1 General

Micro-Flo Built-In filters are compatible with the following fryer models:

Cool Zone Fryers: Super Marathon and Decathlon Gas Fryers

Flatbottom Fryers: 1824G and 2424G (gas); 1824E and 2424E (electric)

Electric Fryers: 714E, 1414E, 1818E, 2020E and 18UE

2.2 Standards

Installation must be planned in accordance with all applicable state and local codes.

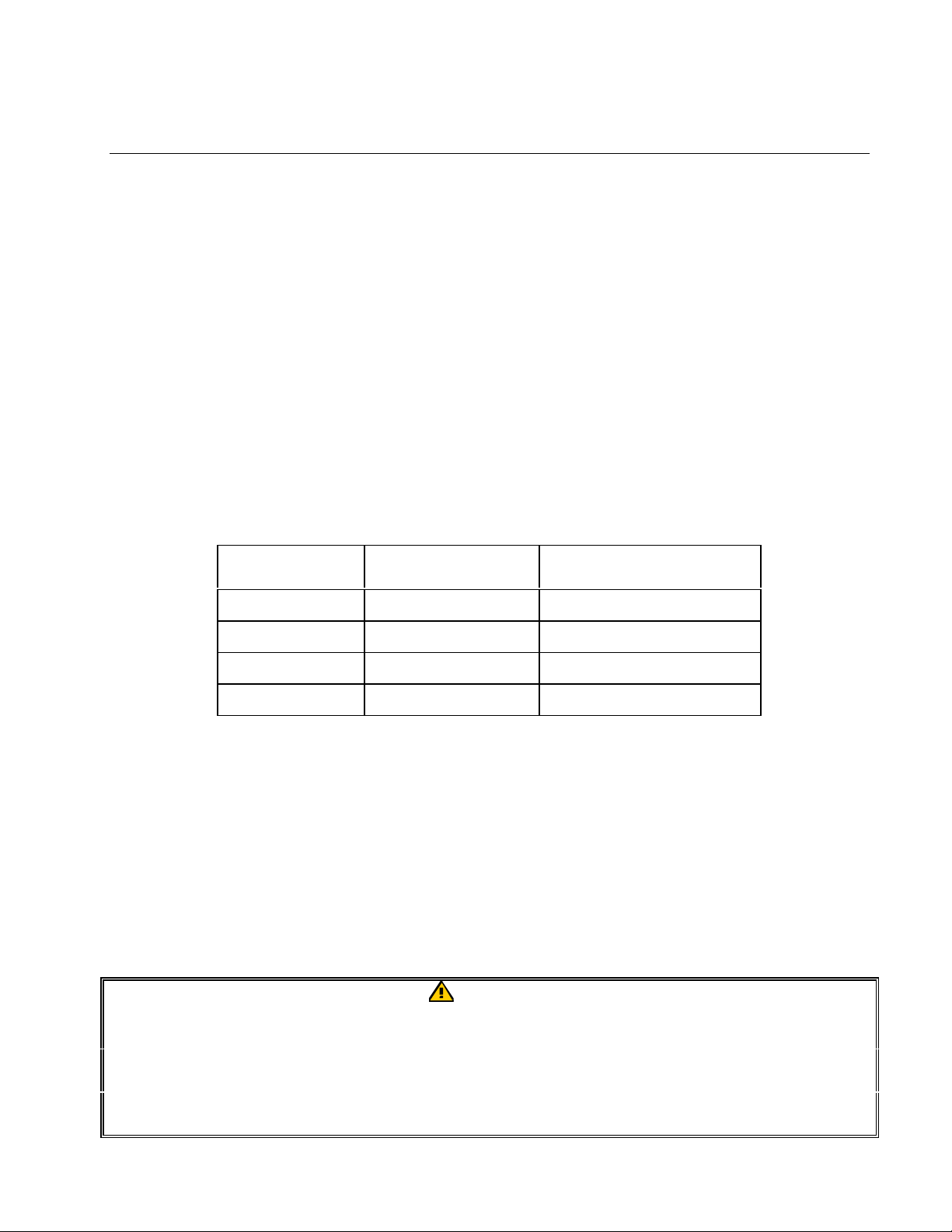

2.3 Dimensions & Capacities

Model Approximate Oil

Capacity (lbs hot)

MF90-BI-12 60 11 x 22-5/8"

MF90-BI-14 60 12-5/8 x 22-5/8"

MF90-BI-18 80 16-3/8 x 24-3/8"

MF90-BI-20 108 16-3/8 x 24-3/8"

Filter Paper Size

(W x L)

2.4 Electrical Connection

The wiring diagrams are in Section 7 of this manual; the filter may or may not be equipped with a

heater probe.

One connection only is required, to a 115v, 60 Hz, 15 amp electrical supply. The unit is equipped

with a flexible six foot, 16-3 SJT power cord; if an extension cord is required, it must be a threeconductor grounded cord of at least 16 gauge.

WARNING

Electrical Grounding Instructions

This filter is equipped with a three-prong, grounded plug for your protection against

shock hazard, and should be plugged directly into a properly grounded, three-hole

receptacle. Do not cut off, remove, or otherwise by-pass the grounding prong on this

plug.

2-1

MICRO-FLO BUILT-IN SERIES FILTRATION SYSTEMS

CHAPTER 3: RECEIVING & INSTALLING THE FILTER

3.1 General

Unpack the filter (or the fryer/filter combination) carefully and remove all filter parts from the

carton. Do not discard or misplace parts – they will be needed for final assembly.

After unpacking, immediately check the equipment for visible signs of shipping damage. If such

damage has occurred, do not refuse shipment. Contact the freight carrier and file the appropriate

damage claims. In case of shipping damage, do not contact the factory. The responsibility for

shipping damage is between the carrier and the dealer or end-user.

3.2 Installation Procedures

Installation must be planned in accordance with all applicable state and local codes, and as follows:

A. Install casters on fryers/cabinets prior to assembling filter components (where applicable).

B. Position all fryers/cabinets into their working position without joining, leaving enough space

for the filter.

C. Join fryers on either side of filter with the drain tube in front, and the oil return line in rear.

Note: Return oil line may be either rigid pipe or return hose with wand, depending on

arrangement ordered. Keep all oil-return line joints loose until full line-up is in place, and

then tighten finger tight only.

D. The drain tube from inboard fryers must terminate in an elbow, with the pipe nipple

extending into the filter pan.

E. Oil return lines are ½-inch steel tubing. Keep all joint fittings loose until the complete

fryer/filter battery is assembled and in place.

F. Connect power to the filter by plugging the filter power supply cord into the appropriate

power outlet, located inside the fryer.

G. Tighten the drain tube connections at the front and the nuts and bolts at the rear. Do not

over-tighten the oil return line connections.

H. Connect the fryer electrical supply to power source.

3-1

MICRO-FLO BUILT-IN SERIES FILTRATION SYSTEMS

CHAPTER 4: OPERATIONS

4.1 Initial Installation

On initial installation and before each use, remove all loose parts from the filter, wash the filter pan

and all accessories in hot, soapy water and dry thoroughly.

4.2 Assembling The Filter Pack

4.2.1 Models Prior to 1994

Micro-Flo filtration systems are shipped with a filter starter kit containing filter paper, filter powder

and other accessories. Remove the filter hold-down ring, place two papers on the grid, and then

replace the hold-down ring. It is essential that "Dean" filter papers are used; use of other than OEM

parts will void the warranty. The remaining filter papers should be stored away from moisture for

future use.

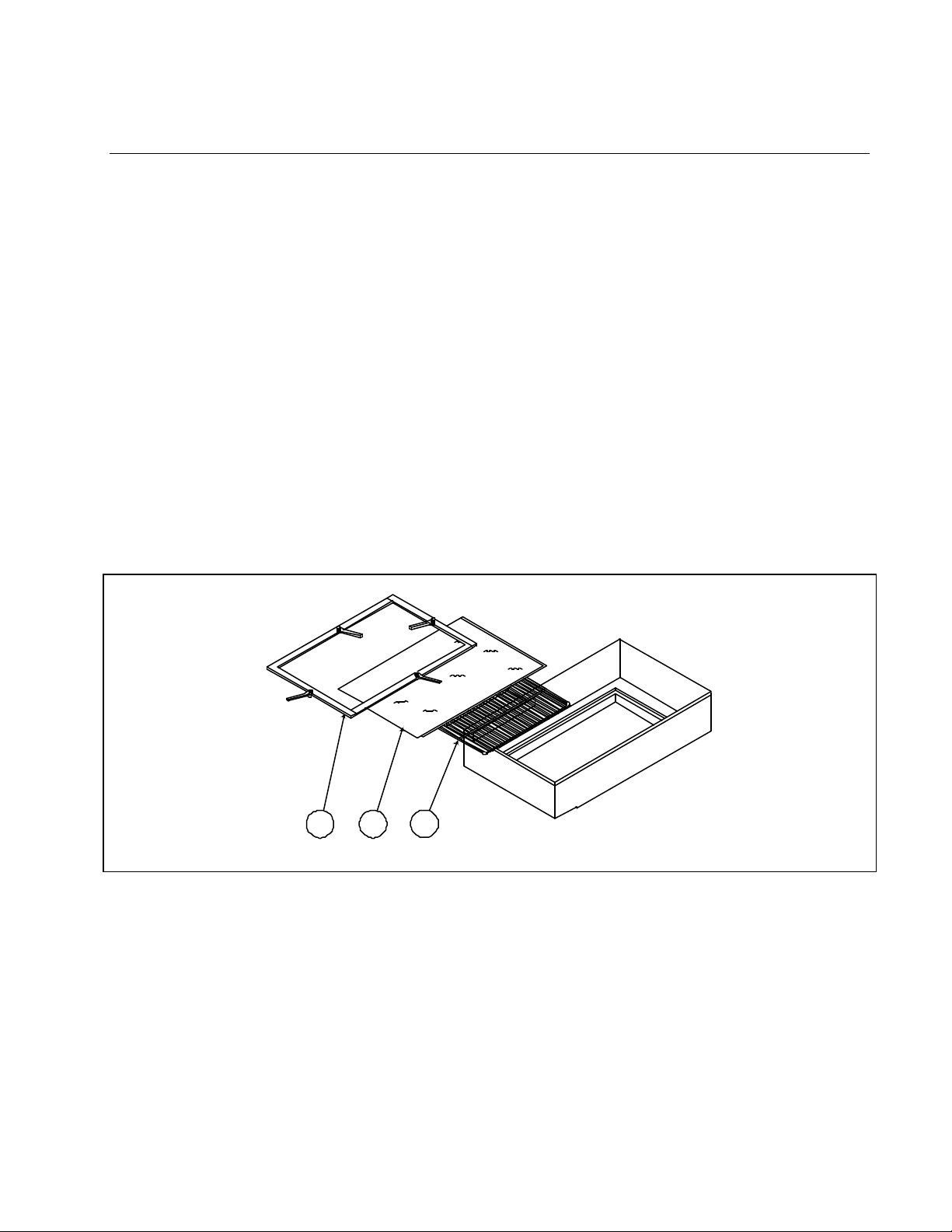

The illustration below shows the proper assembly of the filter.

123

1. Paper support grid

2. Filter paper (2 sheets)

3. Hold-down ring (4- or 6-latch design, according to model)

4-1

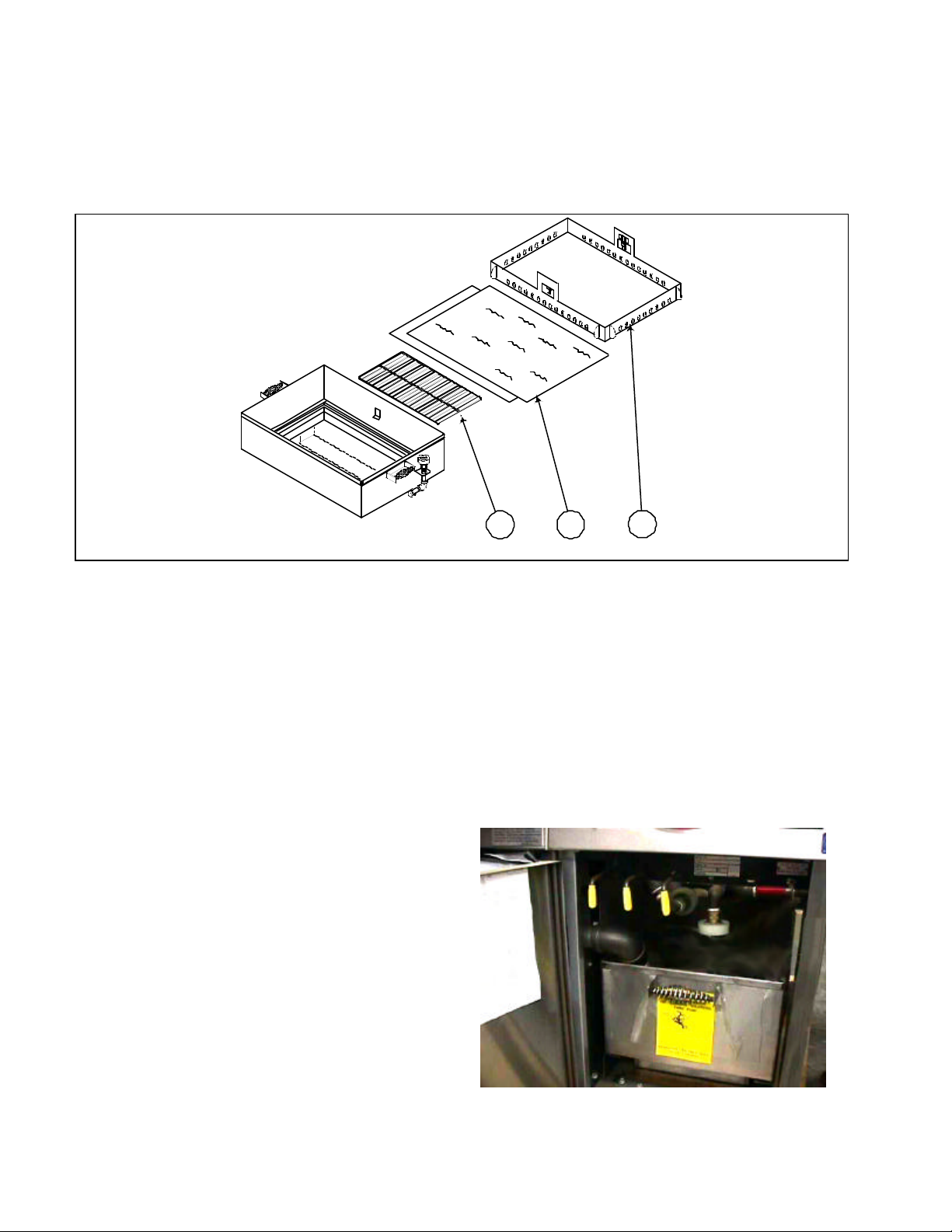

4.2.2 Models 1994 and After

See section 4.2.1 for filter pack assembly. The illustration below shows the proper assembly of the

filter pack.

1 2 3

1. Paper support grid

2. Filter paper (2 sheets)

3. Hold-down ring (2-latch design)

4.3 Normal Operation

4.3.1 Models Prior to 1994

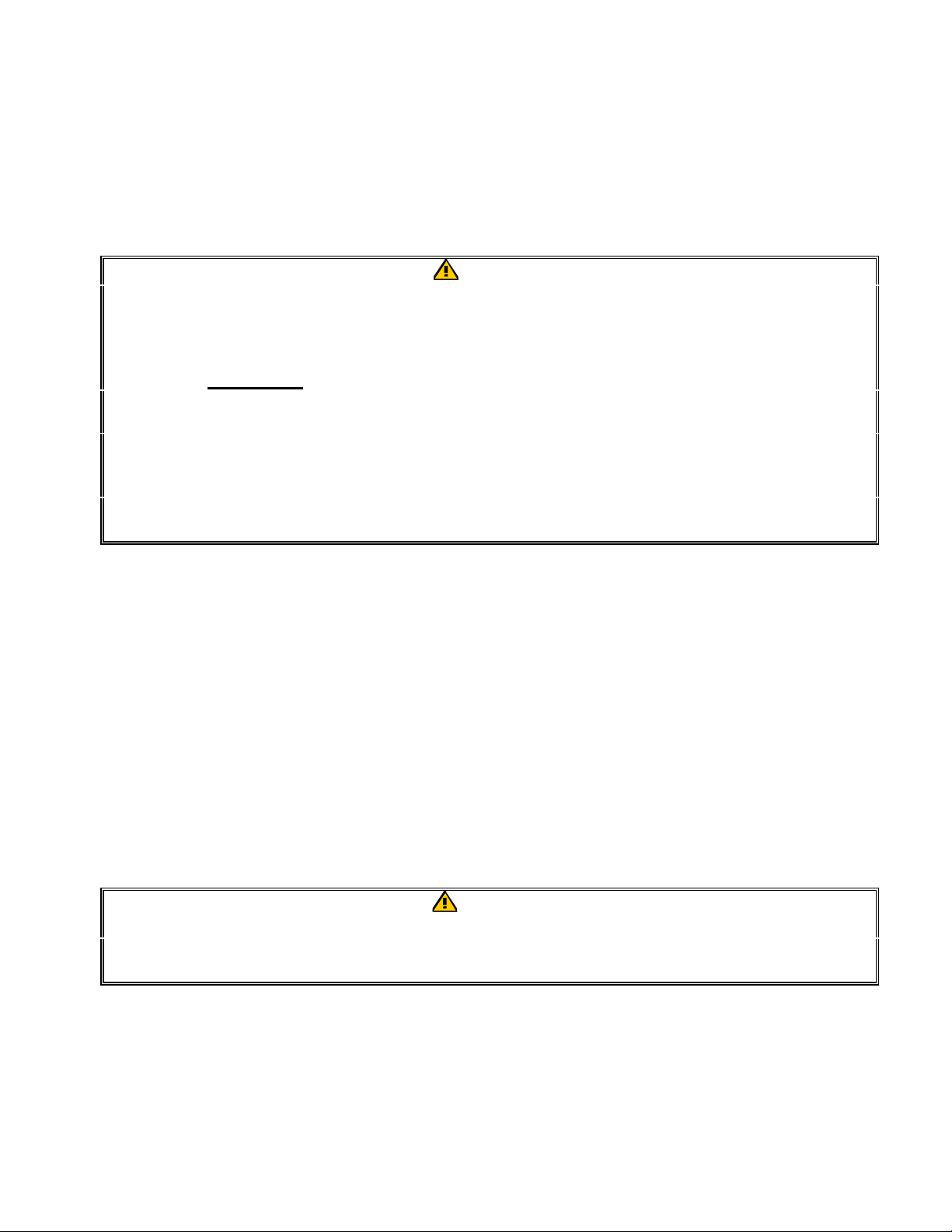

Micro-Flo Built-In filters come equipped with an

individual return valve at each fryer vessel, or

"push-pull" controls in the filter cabinet. The

"push-pull" version oil-return valves are located

inside of the filter cabinet. Manual-open valves

are replaced with a push-pull linkage actuated

valve.

Micro-Flo BI-Series with “Push-Pull” variation.

4-2

4.3.1 Models Prior to 1994 (cont.)

If filter is equipped to filter solid shortening, the "On-Off" switch will be a three-position switch

labeled "Pump/Off/Heat". The "Pump" position is used to operate the filter. The "Heat" position is

used to melt residual shortening from previous filter operations. Do not attempt to melt a block of

solid shortening with the filter heater. Damage to the heating elements will occur.

DANGER

EXTREME BURN HAZARDS

The temperature of oil to be filtered should be approximately 350°F (175°C). When

using flexible return hoses, hold the outlet nozzle securely in the frying vessel or

filter pan at all times before operating power switches or valves. Failure to do this

can result in severe burns.

Always wear oil-resistant, insulated gloves when working with hot oil!

Do not leave a filter machine unattended during operation. The action of the oil

moving through the lines could cause a flexible return hose to shake loose and

spray hot oil.

4.3.1.1 Filter Pan Setup

A. First, place the support grid in the bottom of filter pan.

B. Put two filter paper sheets on top of the support grid. Ensure the paper covers the whole

filter pan bottom.

C. Position the hold-down ring on top of the filter papers and latch the hold-down ring and filter

papers securely against the filter pan bottom, forming a tight seal.

D. Sprinkle 16 ounces of filter powder on the top filter sheet. Distribute the powder over the

filter paper as evenly as possible. If filtering a second frypot immediately after the first, add

only 8 ounces of filter powder for the second filtering.

CAUTION

The crumb tray (if applicable) in built-in filter systems must be emptied into a

fireproof container at the end of frying operations each day. Some food particles

can spontaneously combust if left soaking in certain shortening material.

E. Place the crumb screen (if used) in the filter pan. Ensure the crumb screen is clean, prior to

placement. Allow the crumb screen to rest on the top edges of the hold-down ring.

F. Slide filter pan back inside cabinet and close door.

4-3

4.3.1.2 Filter Operation

Push-pull variation valve control

A. Turn fryer "OFF".

B. Filter one fryer at a time.

C. Remove fry-baskets, crumb screen and/or drop-in grid from fryer.

D. Stir the oil below the heat transfer tubes or electric elements with an "L" shaped Teflon brush

(included with accessory pack) to loosen sediment.

E. Open the drain valve at the fryer and continue to stir and brush down the sides of the vessel

and tubes or electric elements.

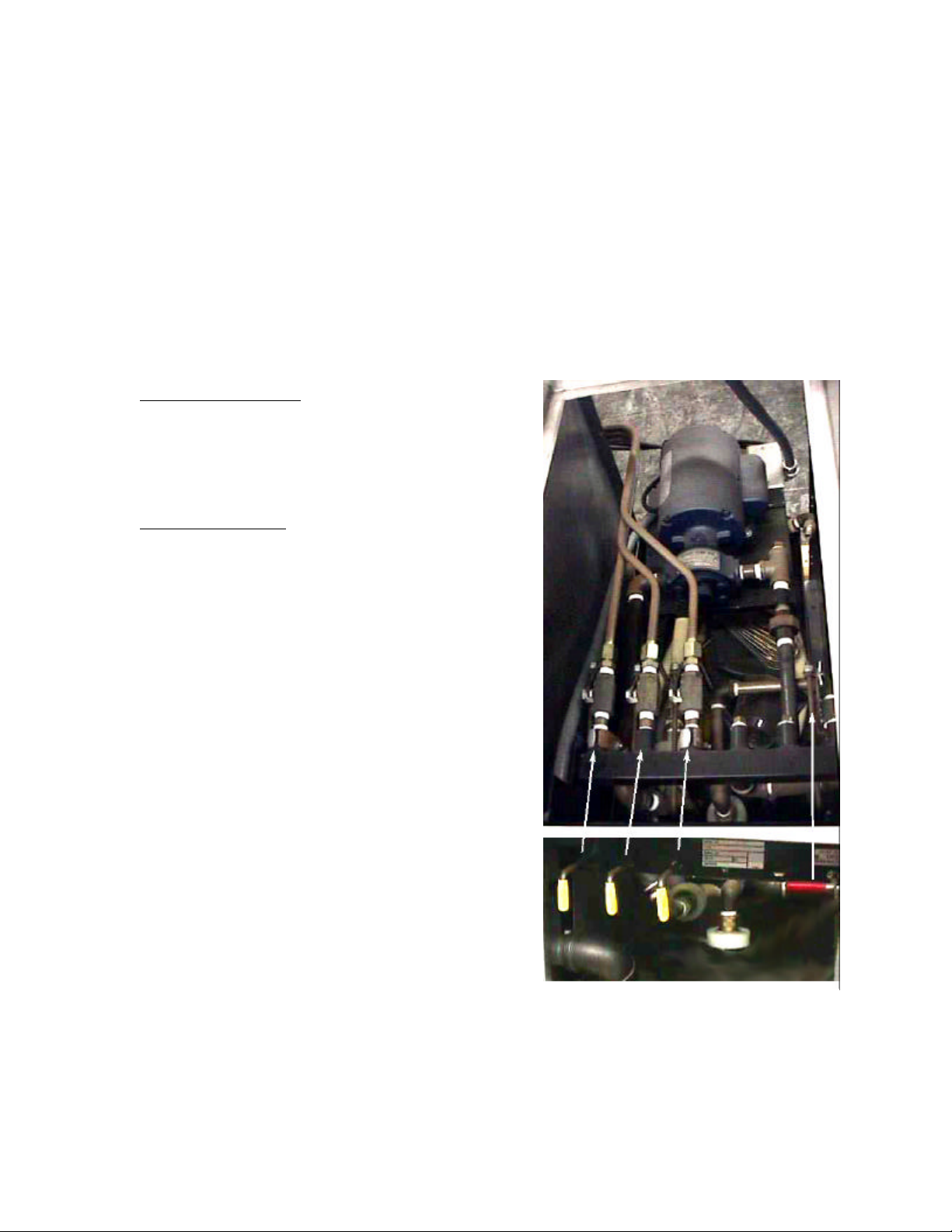

F. Push-Pull Variation: All oil-return valves are

located inside the filter cabinet. Open the filter

cabinet door. Pull the "Yellow" oil return valve

handle corresponding to the fry vessel being

filtered.

Standard Variation: Individual oil-return valves are

located within each fryer cabinet. Open the fryer

cabinet door at the fry vessel being filtered and

open the oil return valve.

G. Close the hose connect valve (or pull the red

handle) at the filter.

H. Turn the filter motor switch to "ON".

Oil/shortening will be circulated through the filter.

I. After filtering is complete, close the drain valve.

J. Replace drop-in grid in fryer.

K. Once the drop-in grid is covered with filtered

oil/shortening, turn on the fryer power switch and

push the reset switch (if applicable).

handles. Yellow handles operate oil

return valves, and the red handle

operates the hose connect valve.

4-4

Loading...

Loading...