DEAN 100UFF Installation Manual

Super Cascade Filtration Systems

Installation & Operation Manual

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $6.00

819-5658

10-98

Please read all sections of this manual and retain for future reference.

Installation, maintenance, and repairs should be performed by your Dean Factory

Authorized Service Agency.

CAUTION

INSTRUCTIONS TO BE FOLLOWED IN CASE THE USER SMELLS GAS ARE TO

BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION SHALL BE

OBTAINED BY CONTACTING THE LOCAL GAS COMPANY OR GAS SUPPLIER.

CAUTION

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITYOF THIS OR ANY OTHER

GAS APPLIANCE.

WARNING!

SAFE AND SATISFACTORY OPERATION OF YOUR EQUIPMENT

DEPENDS ON ITS PROPER INSTALLATION.

INSTALLATION MUST CONFORM TO LOCAL CODES, OR IN THE ABSENCE OF

LOCAL CODES, WITH THE NATIONAL ELECTRIC CODE, NFPA 70-1984

(OR LATEST EDITIONS).

WARNING!

ELECTRICAL GROUNDING INSTRUCTIONS

THIS FILTER IS EQUIPPED WITH A THREE-PRONG, GROUNDED PLUG FOR

YOUR PROTECTION AGAINST SHOCK HAZARD AND SHOULD BE PLUGGED

DIRECTLY INTO A PROPERLY GROUNDED, THREE-HOLE RECEPTACLE. DO

NOT CUT OFF, REMOVE OR OTHERWISE BYPASS THE GROUNDING PRONG

ON THIS PLUG.

CAUTION

DO NOT FILTER MORE THAN ONE FRY TANK AT A TIME.

HOT FLUID – DO NOT FILL BEYOND MAXIMUM FILL LINE

LOCATED ON THE OIL CONTAINER.

COVER PHOTO

D60G Fryer with a 75SCF Super Cascade Filter

model installed.

SUPER CASCADE

FILTRATION SYSTEMS

INSTALLATION AND OPERATION MANUAL

TABLE OF CONTENTS

PAGE

1. PARTS ORDERING AND SERVICE INFORMATION 2

2. IMPORTANT INFORMATION 3

3. INSTALLATION 4

4. DAILY OPERATION 6

5. CLEANING AND MAINTENANCE 10

6. TROUBLESHOOTING 11

7. PARTS GUIDE 15

1. PARTS ORDERING AND SERVICE INFORMATION

1.1 ORDERING PARTS:

Customers may order parts directly from their

local Authorized Parts Distributor. For this

address and phone number, contact your

Maintenance & Repair Center or call the

factory. The factory address and phone number

are on the cover of this manual.

To speed up your order, the following

information is required:

Model Number

Type

Serial Number

With/Without Heater

Optional Equipment

Item Part Number

Quantity Needed

1.2 SERVICE INFORMATION:

Call the “800” number on the cover of this

manual for the location of your nearest

Maintenance & Repair Center or contact the

factory direct. Always give the model and serial

numbers of your filter and fryer.

To assist you more efficiently, the following

information will be needed:

Model Number

Type

Serial Number

With/Without Heater

Optional Equipment

Nature of Problem

Any other information which may be helpful in

solving your service problem

2

2. IMPORTANT INFORMATION

CLEANING OF THE FILTER.

2.1 GENERAL: The Super Cascade Oil

Filters are units that fit inside the Dean

Industries’ Super Marathon, Decathlon,

18UE, and Flatbottom fryers.

The used oil drains by gravity from the

fryer into the filter pan and then is pumped

back to the fryer vessel.

Filtering is accomplished through two

sheets of replaceable filter paper assisted

by a micro pre-coat filter powder or by

means of a Magnum Filter Leaf Assembly.

CAUTION

THE ON-SITE SUPERVISOR IS

RESPONSIBLE FOR ENSURING THAT

OPERATORS ARE MADE AWARE OF

THE INHERENT DANGERS OF

OPERATING A HOT OIL FILTER

SYSTEM, PARTICULARLY ASPECTS OF

OIL FILTRATION, DRAINING, AND

2.2 OPERATING CONTROLS: An

“ON/OFF” switch is mounted on the fryer.

If equipped with an optional in-line heater,

a three (3) position switch

(HEAT/OFF/PUMP) is mounted on the

fryer in lieu of the “ON/OFF” switch.

This optional heater probe is offered with

the 2424-SCF System.

2.3 SAFETY FEATURES: A 5-amp

(230V) or a 7-amp (115V) circuit breaker

switches the power OFF if an overload

occurs.

factory about a unit or ordering special

parts.

2.5 PRE-INSTALLATION:

a. GENERAL: These filters, when used

in combination with a fryer, require no

additional space for filter storage.

b. STANDARDS: Installation must be

in accordance with all applicable state

and local codes.

c. ELECTRICAL CONNECTIONS:

The filter may or may not be equipped

with an in-line heater. This filter

circuit is provided with an independent

electrical supply connection on the

fryer system.

2.6 UNPACKING THE FILTER:

Loose parts include starter kit and

accessories that may have been ordered.

These are packaged inside the filter tank.

The tank top is strapped to the shipping

frame. Do not discard or misplace these,

as they will be needed.

After unpacking, immediately check the

equipment for visible signs of shipping

damage. If such damage has occurred,

contact the carrier and file the appropriate

freight claims. Do not contact the factory,

the responsibility of shipping damage is

between the carrier and the dealer or enduser.

NOTE: IF CIRCUIT BREAKER IS

TRIGGERED, DEPRESS THE RESET

BUTTON TO ACTIVATE THE

CIRCUIT AFTER THE FAILURE

HAS BEEN DETECTED AND FIXED.

2.4 RATING PLATE: Information on

this plate includes the model and serial

numbers as well as electrical requirements.

This data is essential when contacting the

3

3. INSTALLATION:

3.1 GENERAL: On initial installation and

before each use, remove all loose parts from

the filter, wash the filter pan and all

accessories in hot, soapy water and dry

thoroughly.

1

4

2

WARNING!

DO NOT RUN WATER THROUGH

THE FILTERING SYSTEM. THE

FILTER PUMP IS NOT DESIGNED TO

HANDLE WATER. THIS WILL VOID

THE WARRANTY FOR THAT

SYSTEM, DAMAGE THE PUMP AND

CAUSE ACCIDENTS IF WATER

MIXES WITH HOT OIL.

3.2 ASSEMBLYING THE FILTER:

The Super Cascade Filter is available in two

configurations. The configurations differ in

the filtering medium used. The first

configuration uses filter paper and a holddown ring to secure that paper. The second

configuration, found on certain 2424SCFs

only, uses a Magnum Filter Leaf Kit instead

of filter paper as a filtering medium.

Filter Paper Configuration:

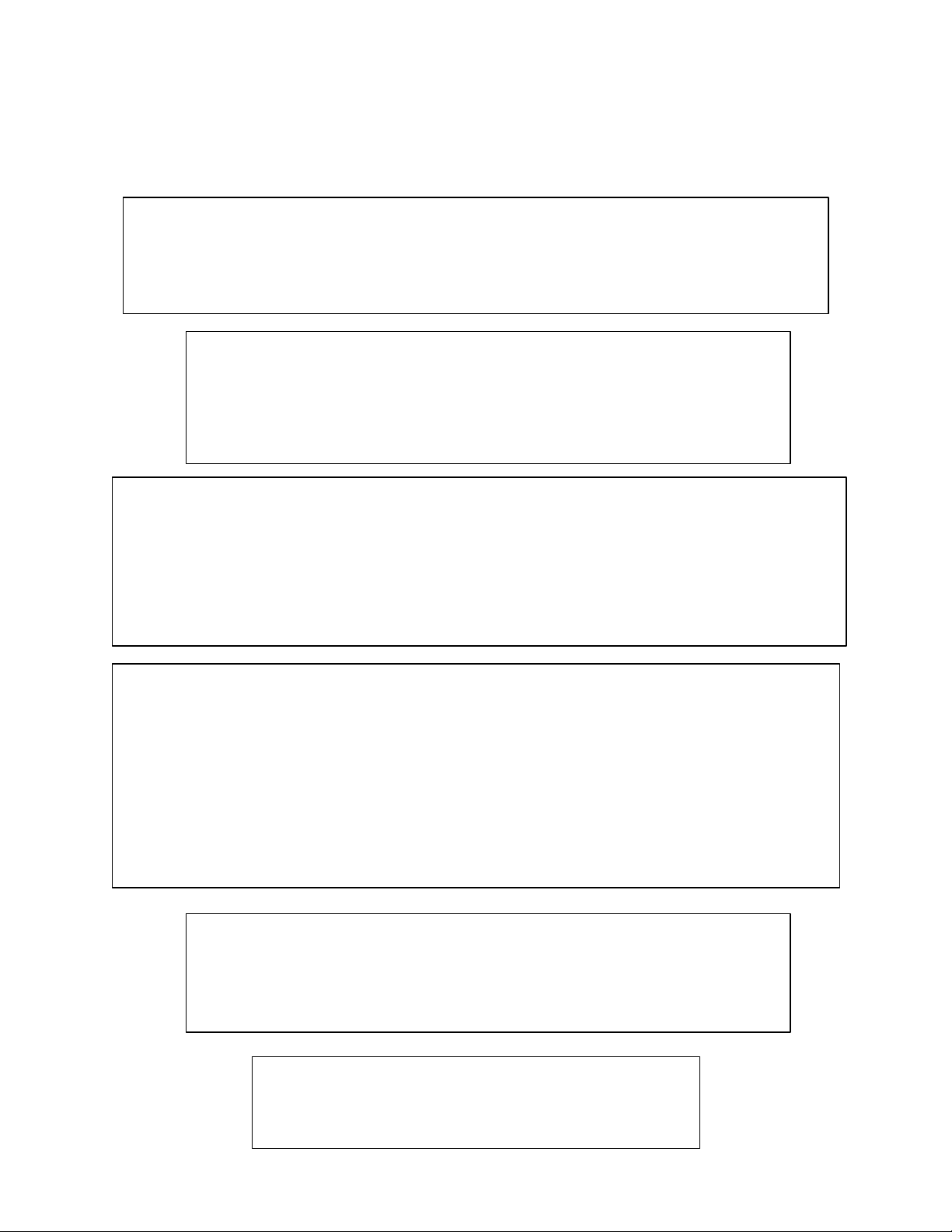

a. Figure 3-1 shows the proper assembly of

these parts:

1. Filter Pan Cover

2. Crumb Catcher Screen

3. Filter Paper (2 sheets)

4. Hold-Down Ring

5. Protective Screen/Support Grid

6. Filter Pan Assembly

3

5

6

Figure 3-1

b. First place the support grid in the bottom

of filter pan.

c. Put two filter paper sheets on top of the

support grid. Be sure the paper covers the

whole filter pan bottom.

d. Position the hold-down ring on top of the

filter papers and latch the hold-down ring

and filter papers securely against the filter

pan bottom. When positioning the holddown ring, do it evenly around the filter

pan and papers to create a good seal

around the support grid which prevents

any air from getting into the system.

e. Sprinkle 16 ounces of filter powder on the

top filter sheet. Ensure that the powder

covers the filter paper evenly.

f. Place the crumb catcher screen in the

filter pan. Allow the crumb catcher to

rest on the top edges of the hold-down

ring.

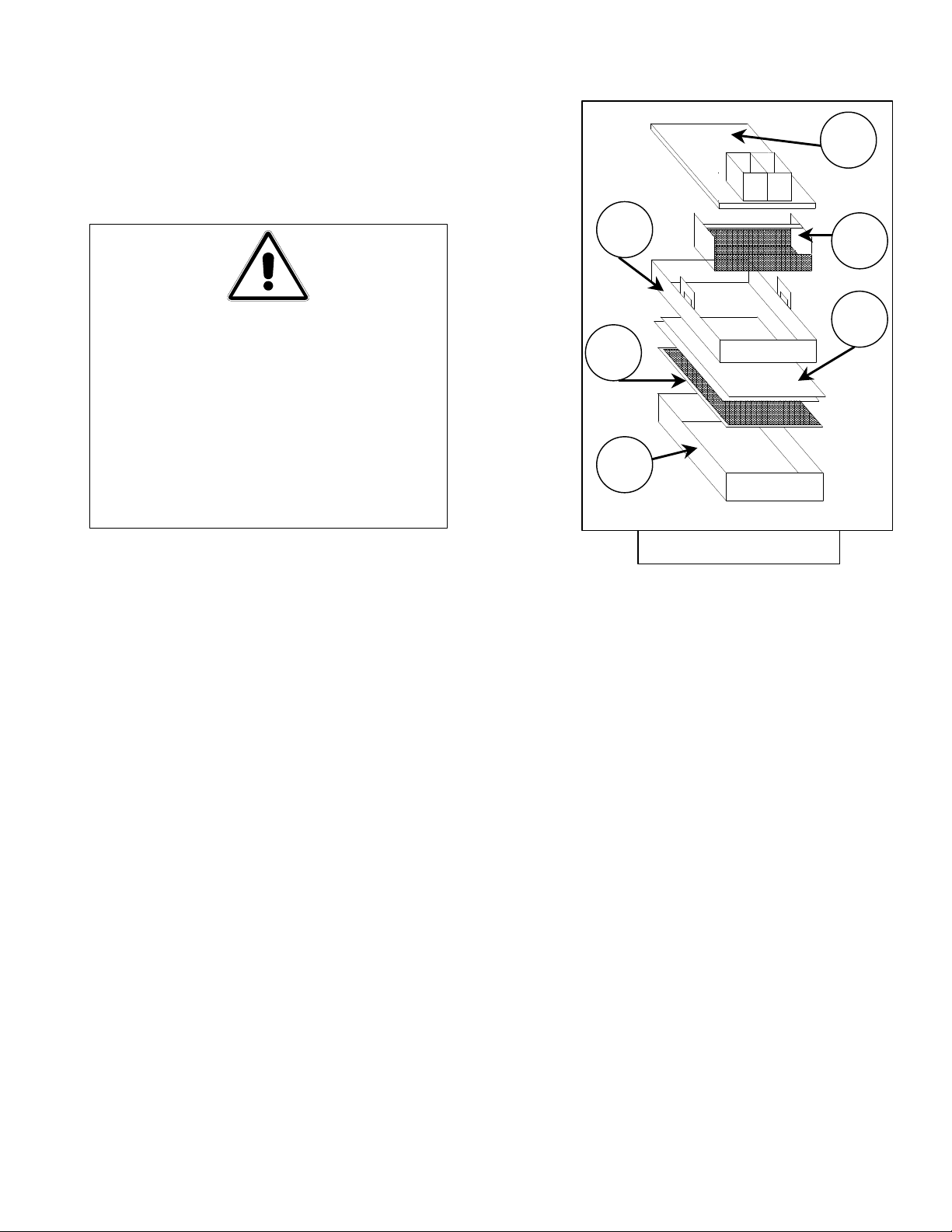

4

Installing crumb catcher screen.

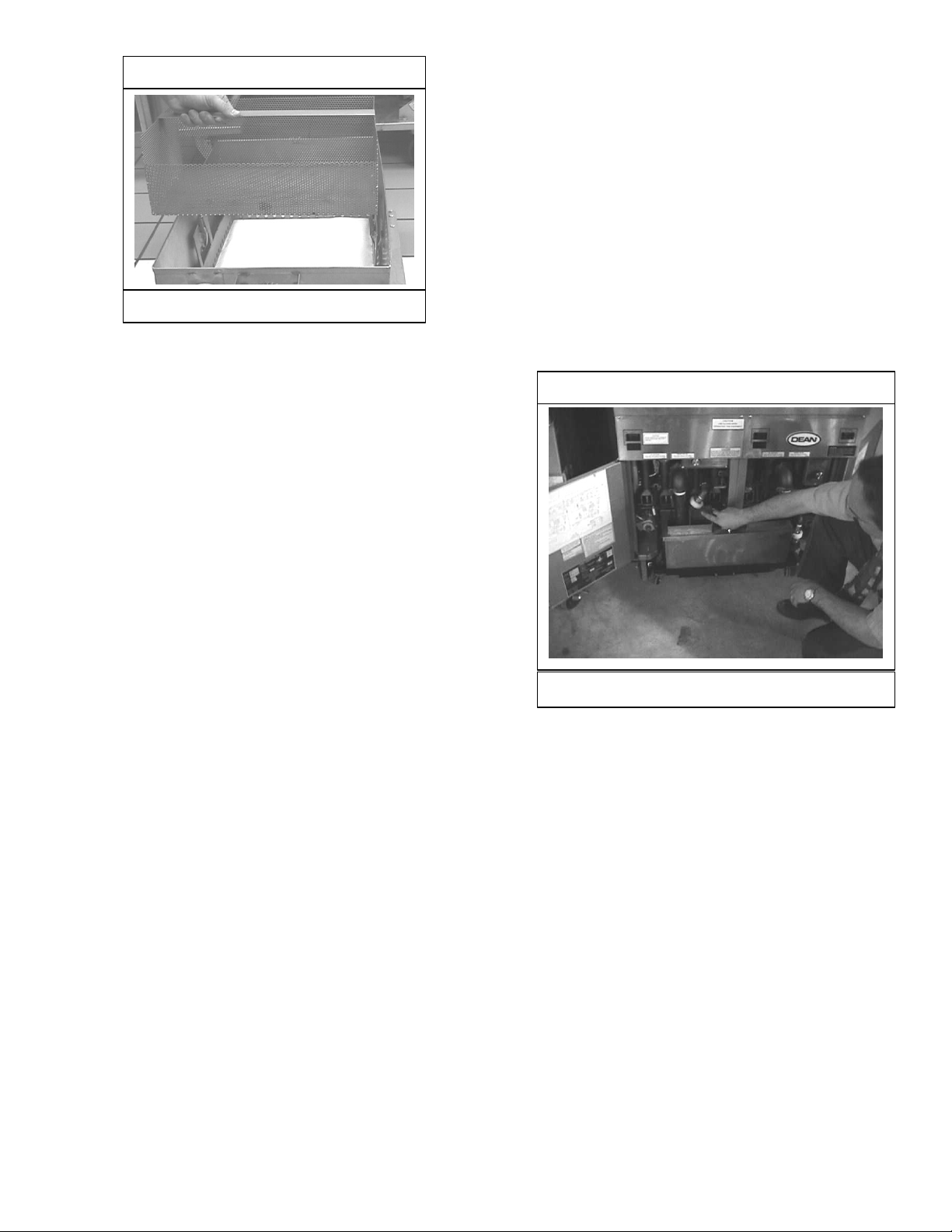

Location of Quick Disconnects

Figure 3-2

g. Place filter pan cover onto the filter pan

assembly.

h. Roll the filter into position, either inside

the fryer for built-in operations, or

position the filter underneath the fryer

drain valve for portable operations.

i. Prior to connecting the oil return lines,

ensure the filter switch is “OFF”.

f. Connect the oil return line connector to

the fryer’s oil return line quick disconnect

coupling.

3.3 INSTALLING THE FILTER IN

THE FRYER:

a. Slide the filter inside the fryer cabinet.

b. Connect the filter’s oil return line (male

quick disconnect) into the quick

disconnect (female) in the fryer’s return

line. See figure 3-3.

j. Then connect the oil return line to the

fryer’s oil return line quick disconnect

coupling.

Magnum Filter Leaf Kit:

a. Place the Magnum Filter Leaf in the

bottom of filter pan. Ensure oil intake

pipe is aligned properly with the opening

on the filter pan lid.

b. Sprinkle Magnasol powder into oil in the

fry vessel. Do not sprinkle Magnasol

powder in the filter unit as this will clog

the oil intake in the filter pan bottom.

c. Place filter pan cover onto the filter pan

assembly.

d. Roll the filter into position inside the

fryer.

Figure 3-3

e. Before connecting the oil return lines,

ensure the filter switch is “OFF” and the

power cord is disconnected from the

power source.

5

Loading...

Loading...