Page 1

Project

Dean

™

®

Item

Quantity

CSI Sec tion 11400

Approval

Cascade Filtration

Date

System for Dean Single Fryers

Models

50SU FF (HD50G, D50 G, SM40G,

SM50 G

CFD150

Cascade built-in oil filter shown

in cabinet of one D50G gas fryer

85SU FF (HD60G, HD6 3G, D60G,

SM60 G)

Standard Features

• Oil capacity:

50SUFF = 50 lbs. (25 liter); 85SUFF = 85 lbs.

(42 liter); 100SUFF = 100 lbs. (50 liter)

• Space-saving filter fits inside fryer cabinet

which houses one frypot

• Filter pan is lightweight and easy to remove

for cleaning

• Sloped drain pan leaves minimal oil in the

pan after filtering

• Filter cycle is complete from start to finish in

under 5 minutes

• 1-1/4” full-port drain valve standard on

HD50G, D50G, SM40G and SM50G.

1-1/2” full-port drain valve standard on

HD60G, HD63G, D60G, SM60G, SM80G,and

D80G

• Drain safety switch on all Dean filter systems

• Rear oil flush

• 1/3 H.P. filter motor

• 4 GPM (15 LPM) filter pump

1 00SUFF (SM8 0G, D80G)

• Stainless steel crumb catcher

• Filter starter kit

• Casters

Options & Accessories

Shortening Disposal Unit

See Dean fryer spec sheets for fryer

options.

See Dean Price List for filter paper

and optional accessories

Cascade Filtration System for Dean Single Fryers

Specifications

Designed for trouble-free filtering of

single fryers without wasting valuable

space

Dean’s renowned, built-in filtration puts

filtration where it’s most convenient to use

-- right within the fryer battery -- eliminating

the need for additional floor and storage

space.

The filtering process is fast and easy, encouraging frequent filtering -- a critical part of

maximizing oil life, especially with trans-fat

free oils. It is engineered with features that

allow added convenience and ease of use.

This system is enhanced with a gravity draining system that allows residual oil to drain

into the filter pan so that drain lines are

always open. The filter, housed beneath one

specially plumbed Dean fryer can filter one

fifty-pound fryer in about four minutes.

This filter comes standard with a powerful 4

GPM pump to maximize filtering efficiency

and minimize clogging. Large sump with

secure hold-down ring ensures proper vacuum and superior oil filtration. The stainless

steel filter pan is equipped with casters and

an automatic connection for ease of access.

Filtration process is two steps:

Step one: open drain valve, open return

valve to activate filter pump.

Step two: close drain valve; close return

valve to turn off pump.

5489 Campus Drive

Shreveport, LA 71129

USA

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@frymaster.com

www.frymast er.com

Bulletin N o. 830-0008

Printed 11/0 7

Revised 10 /11/11

Litho in U.S.A. ©Frymaster

Page 2

Dean

™

®

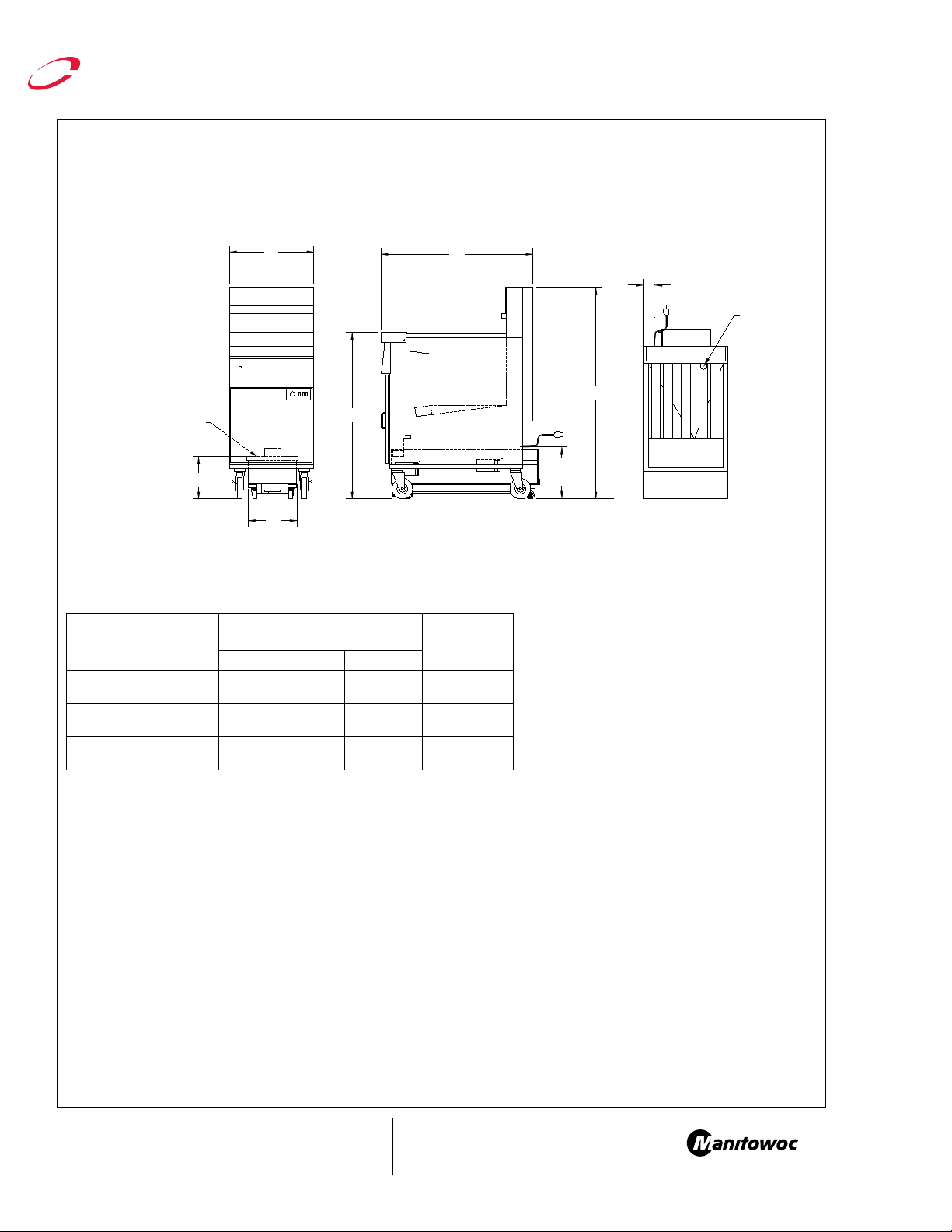

CASCADE FILTER PAN

(SM40, SM50, D50)

H

15.5 (39)

20” (51)

(SM60, D60)

22” (56)

(SM80, D80)

A

E

35” (89)

32-1/2” (83)

(SM40, SM50, D50)

36-1/2” (93)

(SM60, D60, SM80, D80)

B

DIMENSIONS

45” (114)

10.0

[25.4]

Cascade Filtration System for Dean Single Fryers

INCHES

[CM]

2.0

[5.1]

OIL RETURN

C

W

DIMENSIONS*

MO DEL

50SUF F 50 lb s. ( 25 L) 8” (20)

85SUF F 85 lb s. ( 39 L)

100SU FF 100 l bs. (45 L)

OI L

CA PACI TY

FI LTER D IME NSI ONS c m

W B H

34-1/ 2”

(88)

12-1/ 2”

(32)

14-1/ 2”

(37)

36-1/ 4

(92)

36-1/ 4”

(92)

11-1/ 4”

(28.6 )

11-7/ 8”

(30.2 )

11-7/ 8”

(30.2 )

POWER REQUIREMENTS FOR FILTER ONLY

(All Models): Domestic: 120V 8 A; Export/CE: 230/400V 4 A

HOW TO SPECIFY

The following description will assist with ordering the features

desired for this equipment:

50SUFF 50-lb oil capacity single ltration for models HD50G,

D50G, SM40G and SM50G

85SUFF 85-lb oil capacity single ltration for models HD60G,

HD63G, D60G, SM60G

100SUFF 100-lb oil capacity single ltration for models SM80G

and D80G

FI LTER

WE IGH T L BS.

kg

100 ( 45)

110 ( 49)

125 ( 57)

NOTES:

* Information on SUFF lters only -- for fryer specs and power

requirements, see individual fryer spec sheets.

The SUFF lter is completely contained inside the fryer cabinet;

for total oor space required, see individual fryer spec sheets.

DO NOT CURB MOUNT

Mode l #________ _______

CSI Section 11400

5489 Campus Drive

Shreveport, LA 71129

USA

We reserve the right to change specications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Check www.frymaster.com for updates.

Tel: 318-865-17 11

Tel: 1-800-221- 4583

Fax: 318-86 8-5987

E-mail: in fo@frymaster.com

www.frymast er.com

Bulletin N o. 830-0008

Printed 11/0 7

Revised 10 /11/11

Litho in U.S.A. ©Frymaster

Loading...

Loading...