Page 1

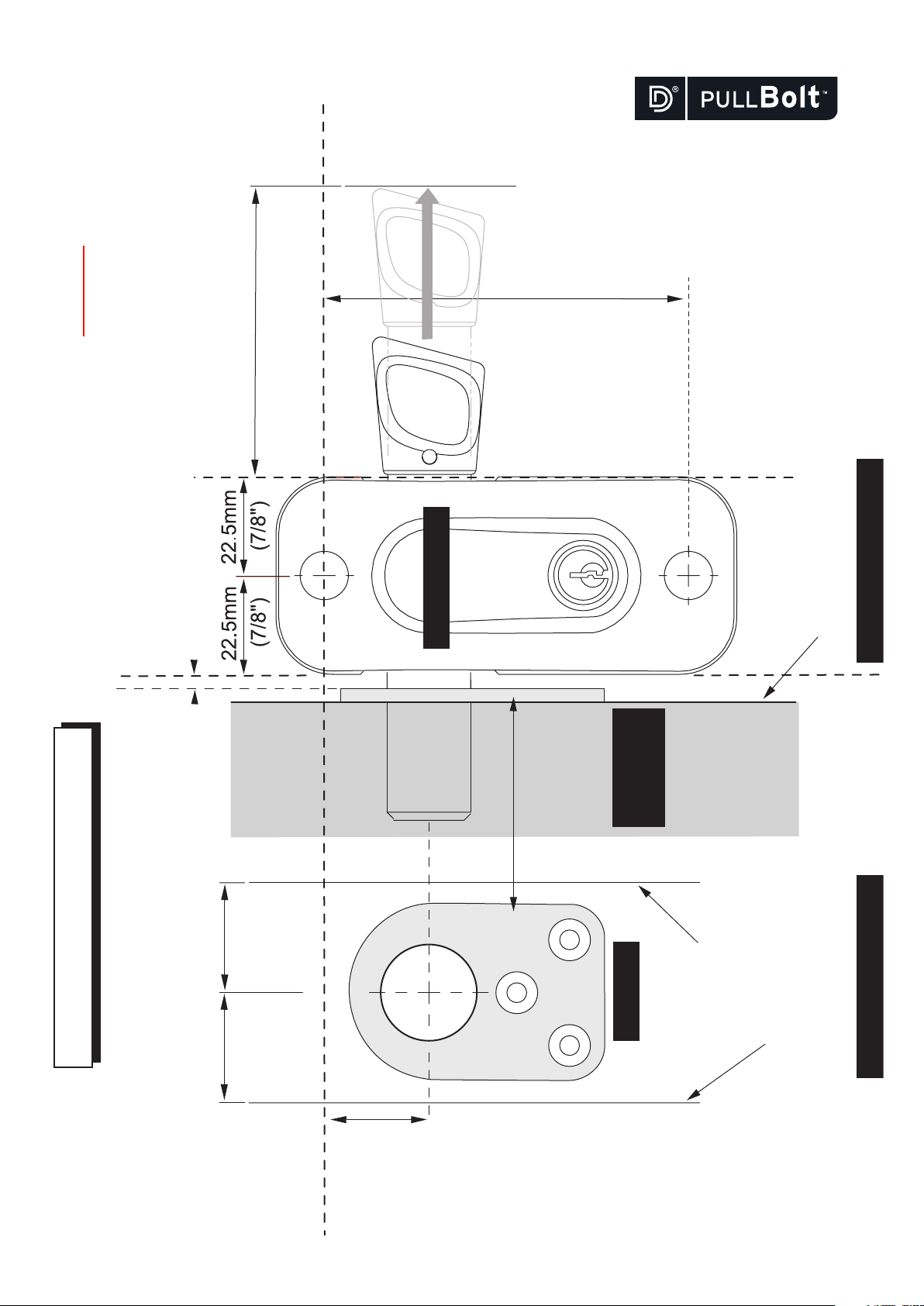

24mm

(15/16")

83mm (3.1/4")

LOCK BODY

KEEPER

FRONT TEMPLATESIDE TEMPLATE

Keeper in

side

position

WALL, FRAME

or POST

ALLOW 75mm (3") CLEARANCE

FOR HANDLE

25mm(1")

AND 13mm (1/2") MAXIMUM GAP

ALLOW 3 mm (1/8") MINIMUM GAP

FACE OF FRAME THAT

THE LOCK BODY IS

MOUNTED TO FOR A

LEFT-HAND OPENING

A

A

FACE OF POST THAT THE

SIDE-MOUNT KEEPER

IS MOUNTED TO

FACE OF FRAME

FOR A

RIGHT-HAND OPENING

D

E

D

E

25mm(1")

A

IMPORTANT: If printing these Instructions

from an electronic file (e.g. website download),

be sure to check that dimensions shown here

measure correctly, as differences in print-outs

may result in inaccurate template holes.

PULLBOLT SIDE-MOUNT MODEL

DRILLING TEMPLATE

PULLB000029PA •Instr_D&DPullBolt_SM (20/6/05)

Page 2

Changing from left- to right-hand fitting

1. Remove the key and

place the Lock Body

face down. Remove

the four corner screws

but DO NOT REMOVE

the two center screws

(shown at A).

Side-Mount model

2. Pick up the Lock Body

with both hands, being

careful to hold together

the front and back covers

(to prevent internal components moving). Turn over

the Lock Body and place

down on a at surface.

3. Lift the front cover and

place to one side. Lift the

bolt and ip it over as

shown, and place it back in

the cradle so that the pin

ts into the slot - either of

the two slots will work.

4. Replace the front cover and

re-t the four screws.

DO NOT use power screwdrivers;

use hand tools.

Optional: Blind Covers

Available separately

Steel washer

Plastic washer

Inside door

screw head dressing

Standard

Top view: Side-Mount model

Optional: Fixing Leg

Available separately

PULLB000028PA •Instr_D&DPullBolt_SM (14/12/11)

Page 3

FITTING INSTRUCTIONS SIDE-MOUNT MODEL

The D&D PullBolt™ is designed to provide added security to shop fronts, doors, frames and gates. The locking

mechanism is a “deadlock” design, meaning that it has to be locked in either the open or closed positions to

allow removal of the key. The PullBolt has a throw of 11/4” (32mm) and remains captured in the Lock Body

when locked in the open position. The PullBolt is designed to be mounted on the exterior of doors and gates, so

that the mounting-screw heads are concealed from manipulation.

Note: In the text below, the word “door” substitutes for “gate”.

Preparation: Before installing this D&D PullBolt™:

– ensure the maximum gap between the two mounting frames does not exceed

protrusion into the locking frame or ground of at least

3

/4” (19mm).

1

/2” (13mm). This will ensure a minimum bolt

– ensure there is at least 3” (75mm) of handle clearance to allow the bolt to retract when opening. Refer to the Drilling Template.

– ensure the handing is correct. The PullBolt is factory assembled to be mounted onto a left-hand opening door. To rotate the bolt to fit

right-hand opening see the instructions on the reverse side.

Tools required: Electric or cordless drill,

7

/16” dia. (11mm dia.), 7/8” dia. (22mm dia.) hole saw (or spade-bit for wood) and 1/8”

dia. (3.5mm dia.) drill bits, 6mm Allen key, square, hammer, centerpunch, pointed implement, pencil, adhesive tape (for temporarily

taping the template to the frame as required).

Installation procedure:

1. Determine the position on the door where you intend mounting the PullBolt, and, with the pencil, mark a fine, level centerline

across the face of the frame. This will be centerline ‘A’. Use the square to mark this centreline around to the side of the frame - and

then around to the rear of the frame. This is to ensure correct alignment of all drilled holes.

2. Transfer the line A across to the Wall Frame or Post. Mark a point

face (see ‘KEEPER’ on the drilling template). This is the center of the PullBolt hole. Centerpunch this point and drill a

dia.) hole to a maximum depth of 1

1

/4” (32mm).

15

/16” (24mm) down from this line and 1” (25mm) in from the

7

/8” dia. (22mm

3. Align the Keeper with this hole and mount it using the three screws provided.

4. Unlock the ‘LOCK BODY’ and fully retract the PullBolt handle. Place the Lock Body against the frame leaving a minimum gap of

1

/8” (3mm) between the edge of the Lock Body and the face of the Keeper. Ensure the door can open without any interference. Mark a

vertical “positioning line” on the frame using the outer edge of the Lock Body as a guide. Reproduce a corresponding line on the rear

face of the door frame by measuring.

5. Fold the template along line ‘D’ for left-hand mounting (or along line ‘E’ for right-hand mounting). Align the folded template line

with both the front positioning line and centerline ‘A’. Mark the two center points through the template using a pointed instrument,

then centerpunch these points. Now repeat this action at the rear positioning line using line ‘E’ (or line ‘D’ for left-hand mounting). This

ensures accurate, level drilling through the door section.

6. Drill holes of

7

/16” dia. (11mm dia.) through the frame - from both sides - in the places marked. (Smaller pilot holes may assist

drilling accuracy.)

7. Place the washers under the head of the M10 mounting screws and insert the screws into the rear drilled holes. A maximum thread

protrusion of

distributor for longer screws if required, or cut to

7

/8” (22mm) from the front of the door section and a minimum thread protrusion of 3/8” (10mm) applies. Contact your

3

/4” (19mm) if too long.

8. Take the 6mm Allen key and secure the mounting screws firmly into the Lock Body and Keeper.

Check to ensure that the PullBolt locks securely and that there is no interference when opening the door.

The D&D PullBolt™ is now ready for use.

MAINTENANCE: Lubricate the D&D PullBolt™ using only graphite powder. DO NOT use oil or grease.

For a downloadable Adobe Acrobat (.PDF) version of our Limited LIFETIME WARRANTY,

go to our website at www.ddtechglobal.com

AUSTRALIA: Unit 6, 4-6 Aquatic Dr, Frenchs Forest NSW 2086

USA: 7731 Woodwind Drive, Huntington Beach, CA 92647

www.ddtechglobal.com

PULLB000028PA •Instr_D&DPullBolt_SM (14/12/11)

Loading...

Loading...