Page 1

PROFESSIONAL DROP-IN COOKTOPS

• 36” – 5 BURNER COOKTOP

• 30” – 4 BURNER COOKTOP

Installation Manual

MODELS:

CT-365SS (shown)

CT-365BK

CT-365WT

CT-304SS

CT-304BK

CT-304WT

Page 2

A MESSAGE TO OUR CUSTOMERS

1

Thank you for selecting this DCS Professional Drop-In Cooktop. Because of this appliance’s unique features

we have developed this Installation Manual. It contains valuable information on how to install your new

appliance for years of safe and enjoyable cooking.

For your convenience, product questions can be answered by a DCS Customer Care Representative by

phone: 1-888-281-5698, by email: support@dcsappliances.com,

or by mail:

Fisher & Paykel Appliances,Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

www.dcsappliances.com

WAR NI NG

Improper installation, adjustment alteration,service or maintenance can cause

property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before use, installing or servicing this

equipment.

WAR NI NG

Do Not store or use gasoline or any other flammable vapors and liquids in the

vicinity of this or any other appliance.

FOR YOUR SAFETY

IF YOU SMELL GAS:

1. Do not turn on any electrical switch; do not use any phone in your building.

2. Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

3. If you cannot reach your gas supplier, call the fire department. Installation

and service must be performed by a qualified installer, service agency or the

gas supplier.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Page 3

TABLE OF CONTENTS

2

SAFETY PRACTICES AND PRECAUTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

PROPER VENTILATION REQUIREMENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION INSTRUCTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-10

Preparing for the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cabinet Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Gas Hook Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Recommended Grounding Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

INSTALLER FINAL CHECKLIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PRODUCT MEASUREMENT SPECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WIRING DIAGRAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

WAR RANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Page 4

SAFETY PRACTICES & PRECAUTIONS

3

When properly cared for, your new DCS Appliance has been designed to be a safe, reliable cooking

appliance. When using this restaurant caliber appliance, use it with extreme care, as

this type appliance provides intense heat and can increase the accident potential. Basic safety

precautions must be followed when using kitchen appliances,including the following:

Read the Use and Care Manual thoroughly before using your new appliance. This will help to

reduce the risk of fire,electric shock, or injury to persons.

Begin by insuring proper installation and servicing. Follow this installation instructions. Be sure

to have a qualified technician install and ground this appliance before using.

Have the installer show you where the gas supply shut-off valve is located so you will know how

and where to turn off the gas to the appliance.

If you smell gas, the installer has not done a proper job of checking for leaks.You can have a

small leak and therefore a faint gas smell if the connections are not completely sealed.Finding

a gas leak is not a “do-it-yourself” procedure. Some leaks can only be found with the burner

control in the ON position and for your protection it must be done by a qualified service

technician.

If by some chance a burner goes out and does not re-ignite and gas escapes, open a window or

a door to let the room air out.Do not attempt to use the appliance until the gas has had time to

dissipate.

This appliance has been factory assembled for Natural Gas or Liquid Propane as indicated by

model number.

Do not repair or replace any part of this appliance unless it is specifically recommended in this

manual. All other servicing should be referred to a qualified service technician.

WAR NING:

CHILDREN SHOULD NOT BE LEFT ALONE or unattended in an area where

appliances are in use. They should never be allowed to turn knobs, push

buttons, sit or stand on any part of an appliance.

WAR NING:

Do not store items of interest to children on or around the Drop-In Cooktop.

Children could be seriously injured if they should climb onto or reach across the

appliance to reach these items.

Never store anything on the cooktop. Flammable materials can accidently catch fire, plastic

items may melt or ignite and other types of items could be ruined.

Do not hang articles from any part of the appliance.Some fabrics are quite flammable and may

catch on fire.

If the appliance is near a window be certain the curtains do not blow over or near the cooktop

burners; they could catch on fire.

Never let clothing,pot holders, or other flammable materials come in contact with, or too close

to any burner or burner grate until it has cooled.Fabric may ignite and result in personal injury.

Page 5

SAFETY PRACTICES & PRECAUTIONS

4

Be certain to use only dry pot holders; moist or damp pot holders on hot surfaces may cause

burn injury from steam. Do not use a towel or other bulky cloth in place of pot holders. Do not

let pot holders touch hot burners, or burner grates.

For personal safety, wear proper apparel. Loose fitting garments or hanging sleeves should

never be worn while using this appliance. Some synthetic fabrics are highly flammable and

should not be worn while cooking.

Do not use aluminum foil to line any part of the cooktop. Using a foil liner could result in a

fire hazard.

WAR NING:

This appliance is for cooking. Based on safety considerations, never use the

cooktop to warm or heat a room.

WAR NING:

When using the cooktop: Do not touch the burner grates or the immediate

surrounding area. Areas adjacent to the burners may become hot enough to

cause burns.

Never leave the cooktop unattended when using high flame settings. A possible boil over

could cause smoking or greasy spill overs may ignite.More importantly,if the burner flames are

smothered by a severe boil over which effects the igniter, the unburned gas will escape into

the room, which would be extremely dangerous.

Only certain types of glass, heat-proof glass-ceramic, ceramic, earthen ware, or other glazed

utensils are suitable for use on the open flame of the cooktop. Utensils that are not thermally

heat safe may break with sudden temperature changes.

Do not heat unopened food containers; a build up of pressure may cause the container to burst.

During cooking, set the burner control so that the flame heats at the bottom of the pan and

does not curl around the bottom edges of the pan.This could heat and/or melt the handles.

Always use utensils that have flat bottoms large enough to cover the burner. The use of

undersized utensils will expose a portion of the flame to direct contact and may result in

ignition of clothing.

To minimize burns, ignition of flammable materials and accidental spill overs, position handles

of utensils inward so they do not extend over adjacent work areas,cooking areas,or the outside

edges of the cooktop.

Hold the handle of the pan to prevent movement of the utensil when stirring or turning food.

Grease is flammable.Do not use water on grease fires.Turn OFF the burner, then smother the

fire with baking soda or use a dry chemical or foam-type fire extinguisher. Let hot grease cool

before attempting to handle it. Avoid letting grease deposits collect around the base of the

cooktop burners. Clean after each use or boil over.

Use splatter screens over pans when frying foods to minimize possible grease burns. Be sure

not to use a flame that is too high.

For proper lighting and performance of the cooktop burners, keep the burner ports clean. It

may be necessary to clean these when there is a boil over or when the burner does not light,

even though the electronic igniters click.

Clean the cooktop with caution. Avoid steam burns; do not use a wet sponge or cloth to clean

the cooktop while it is hot. Some cleaners produce noxious fumes if applied to a hot surface.

Follow directions provided by the cleaner manufacturer.

Page 6

5

SAFETY PRACTICES & PRECAUTIONS

Be sure all the cooktop controls are turned off and the appliance is cool before using any type

of aerosol cleaner on or around the appliance.The chemical that produces the spraying action

could, in the presence of heat, ignite or cause metal parts to corrode.

Clean the ventilator hood and filters above the cooktop frequently so grease from cooking

vapor does not accumulate.

Turn the ventilator OFF in case of fire. The blower, if in operation, could unsafely spread the

flames.

Do not obstruct the flow of combustion or ventilation air to the appliance. Be sure a fresh air

supply is available.

For safety reasons and to avoid damage to the appliance never sit,stand, or lean on any part of

the appliance.

Service should only be done by authorized technicians. Service technicians must disconnect

the power supply before servicing this appliance.

California Proposition 65 - Warning: The burning of gas cooking fuel generates some by-

products which are known by the State of California to cause cancer or reproductive harm.

California law requires businesses to warn customers of potential exposure to such substances.

To minimize exposure to these substances, always operate this unit according to the

instructions contained in this booklet and provide good ventilation to the room when cooking

with gas.

NOTE:

This product must be installed by a licensed plumber or gas fitter when installed within

the Commonwealth of Massachusetts.

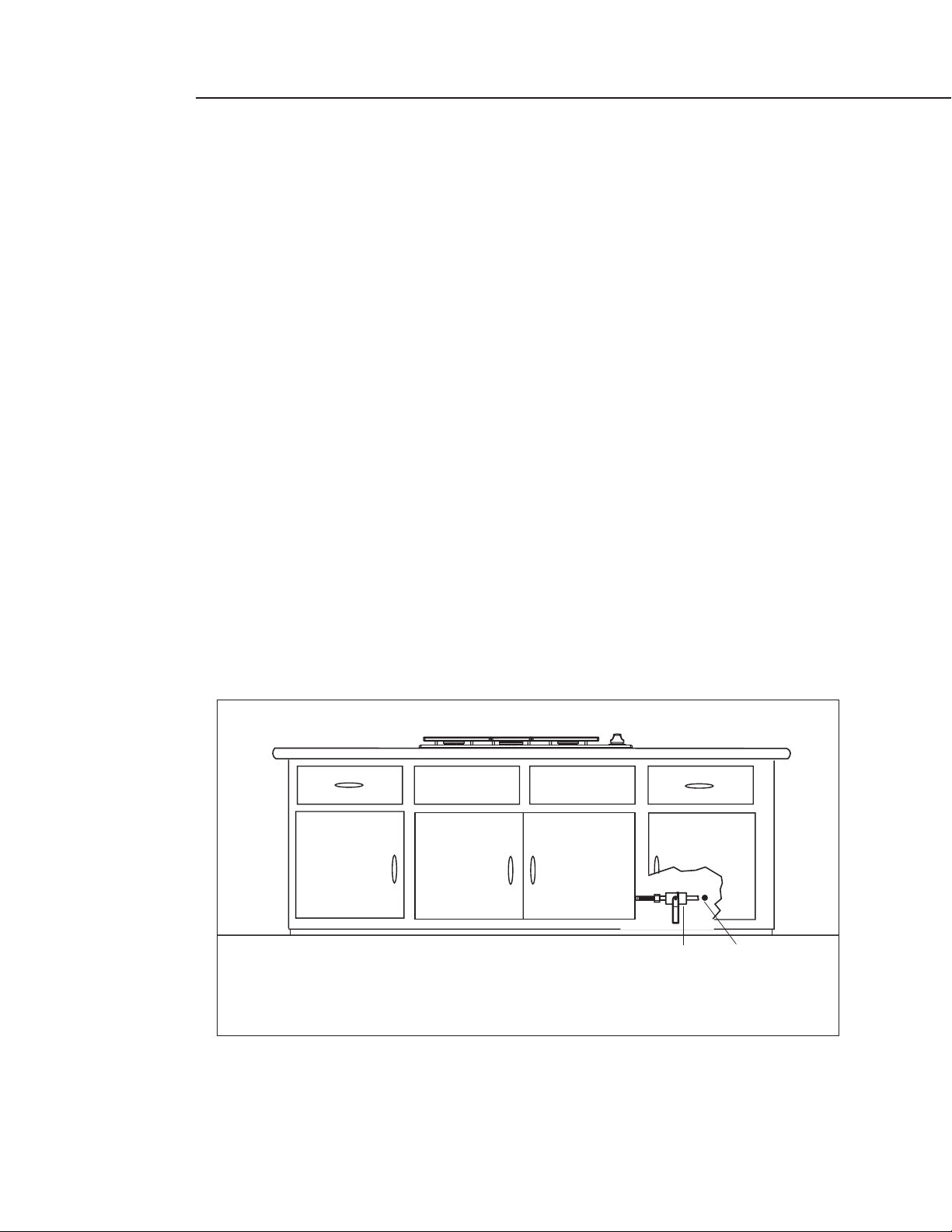

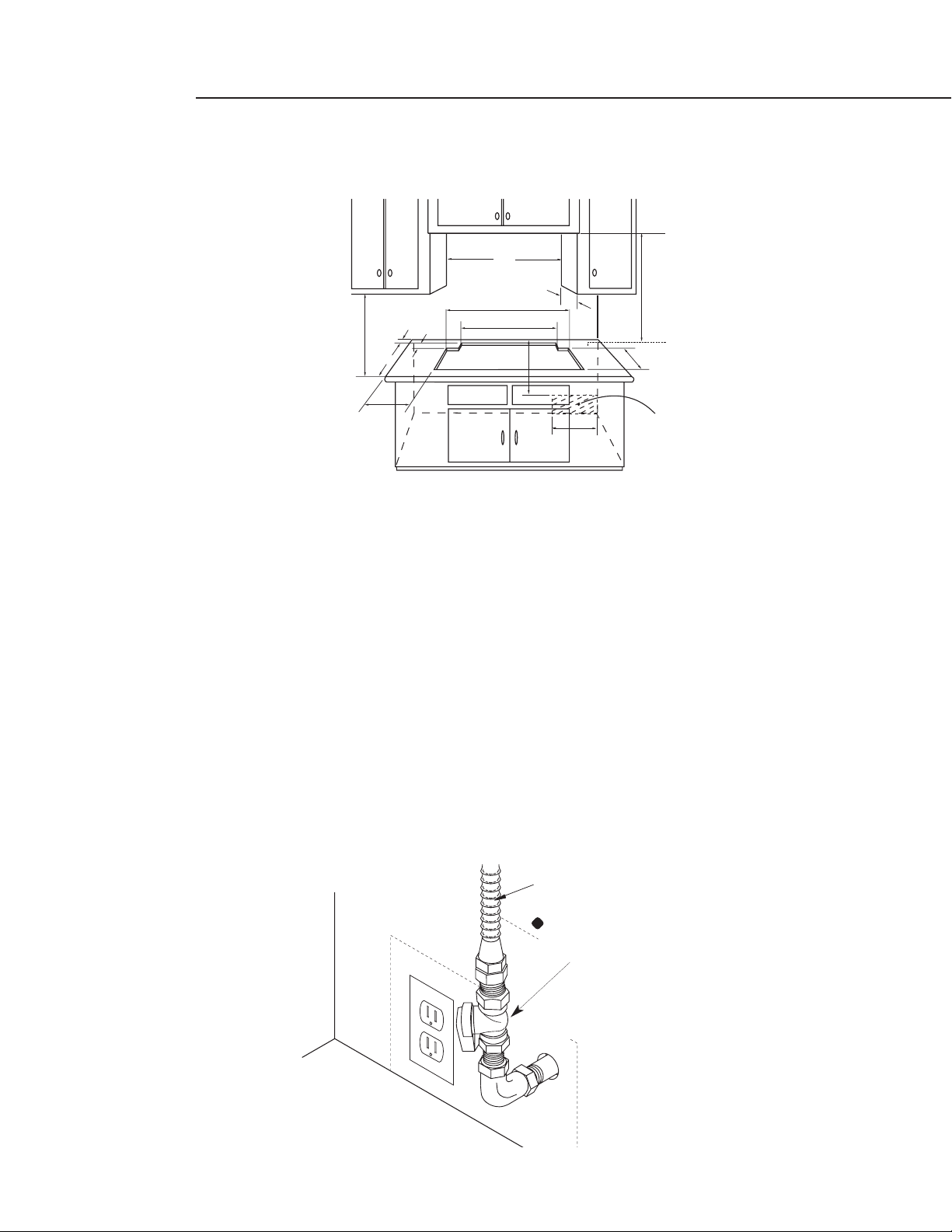

Installer supplied

shut-off valve

must be easily

accessible inside

cabinetry.

Gas Supply

Page 7

PROPER VENTILATION REQUIREMENTS

6

IMPORTANT INFORMATION:

CAUTION

:

Ventilation hoods and blowers are designed for use with single wall ducting.

However, some local building codes or inspectors may require double wall

ducting. Consult local building codes and/or local agencies before starting, to

ensure that hood and duct installation will meet local requirements. Hood

blower speeds should be variable to reduce noise and loss of heated or air

conditioned household air when maximum ventilation is not required.For best

smoke elimination, the lower edge of the hood should BE INSTALLED A

MINIMUM OF 30" TO A MAXIMUM OF 36" ABOVE THE COOKING SURFACE. If the

hood contains any combustible materials (i.e. a wood covering) it must be a

minimum of 36" above the cooking surface.Due to a high volume of ventilation

air, a source of outside replacement air is recommended. This is particularly

important for tightly sealed and insulated homes. A reputable heating and

ventilating contractor should be consulted.

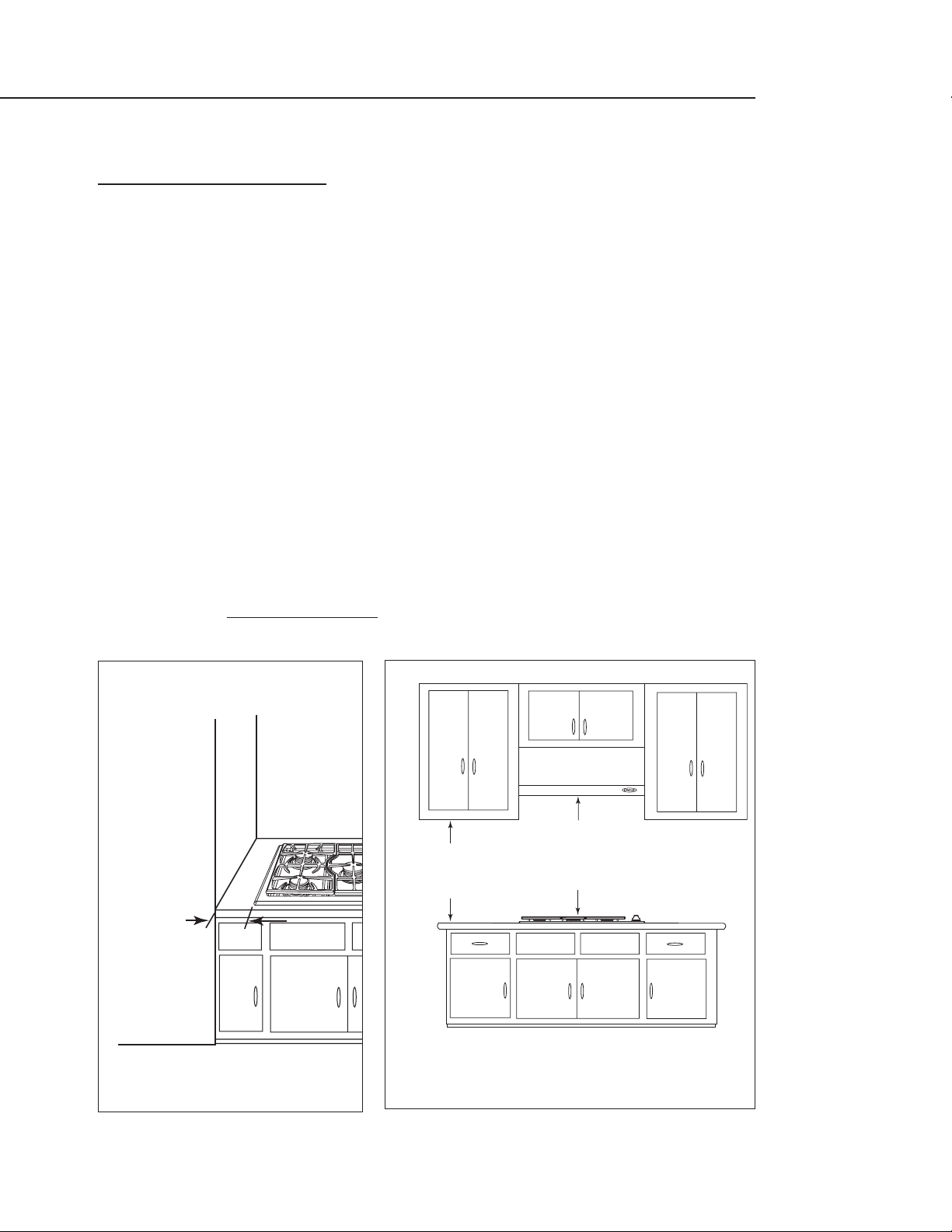

VENTILATION REQUIREMENTS:

STANDARD COUNTER INSTALLATION RECOMMENDATIONS

HOOD: (24" Deep x Unit Width)

BLOWER: 30”/36" COOKTOPS

600 CFM min.

3O" Min. clearance to

non-combustible surface,

36" Min. clearance to

combustible surface – from

cooktop cooking surface

18" Min. clearance to

combustible surface

from side of cooktop

outer edge

∆ As defined in the “National Fuel Gas Code”(ANSI Z223.1, lastest edition).

The horizontal surfaces of the range top (cooktop) trim must not be below

countertop level.

NOTE: See manufacture’s recommendations for ducting specifications.

5"

min. to

combustible

surface

Page 8

INSTALLATION INSTRUCTIONS

7

PREPARING FOR THE INSTALLATION:

Be sure to read page 6 for the proper ventilation requirements before you begin.

When making your CUTOUT refer to page 8-9 for cabinet preparation.

Step 1: Unpack the unit, the regulator, and remove all packing between all the burners, rings,

and caps. Remove the grates from their boxes.

Step 2: With the necessary tools and hardware ready, measure the distance from the back and

sides of the countertop and cabinet to locate the position of the cooktop Cutout.

Step 3: Make your Cutout according to the dimensions given on page 8 & 9.Square the cutout

to the countertop.

Step 4: Lower the cooktop into the countertop cutout, being careful not to damage the

counter, inlet pipe threads, or the power cord of the cooktop.

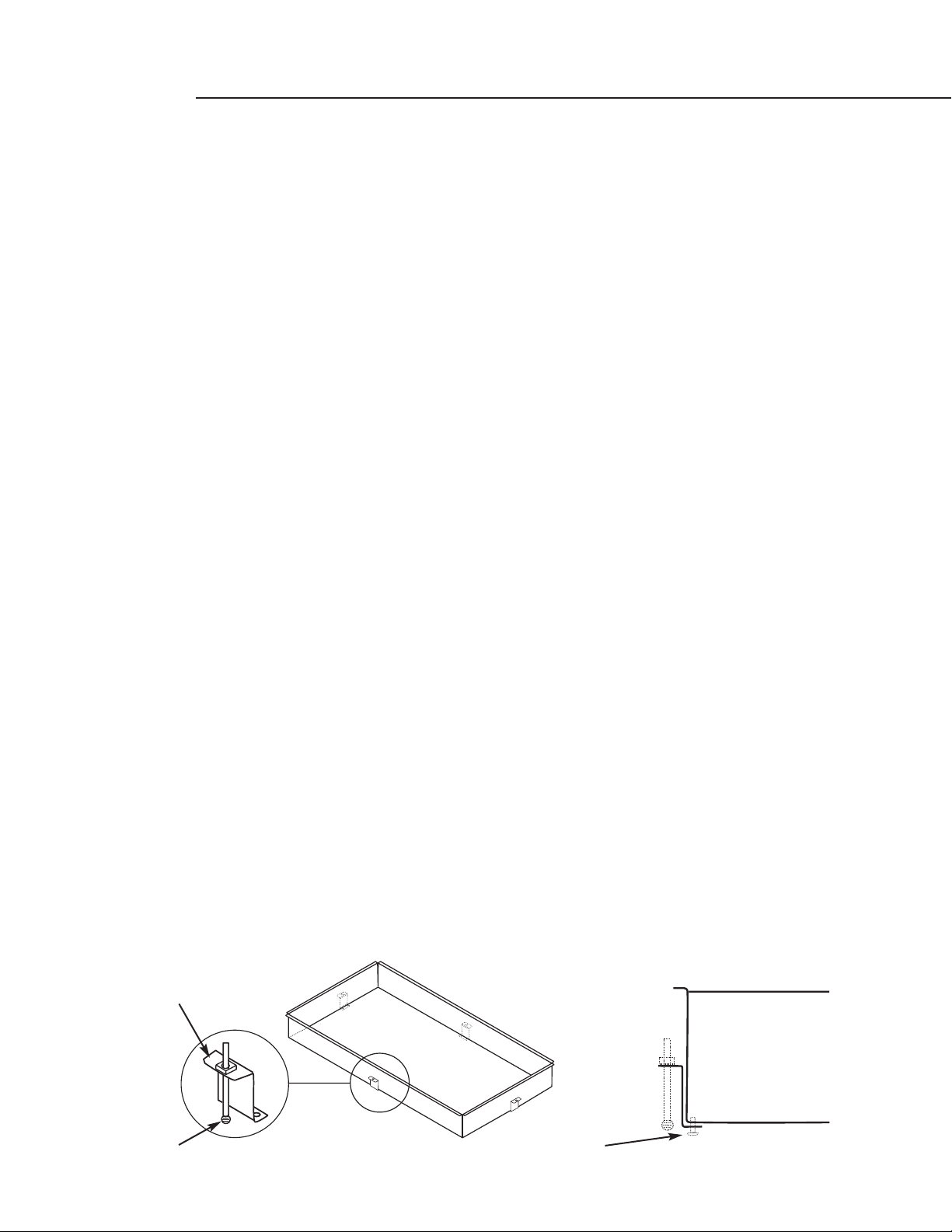

Step 5: Square the cooktop to the cutout and install the (4) retaining brackets onto the 8 holes

for CT-365 and (2) retaining brackets onto 4 holes for CT-304 located at the bottom of

the unit (See Figure 1 below). If hold down brackets are not installed, the cooktop will

not pull down to countertop.

Step 6: Tighten the 4 preloaded thumb screws which will keep the unit secured. Do Not Over-

tighten (See Figure 2 detail below).

NOTE: Some installations may not have adequate clearance at the front for the ‘Z’-shaped retain-

ing bracket.In those cases, use the ‘L’-bracket provided. Fasten the bracket to the bottom of

the cooktop chassis using one of the screw holes provided for the retaining brackets.Make

sure the bracket extends out far enough to contact the inside of the cabinet face.While pushing down on the front edge of the cooktop from above,attach the bracket to the cabinet.

This step wil insure that the edge of the cooktop is flush with the counter surface. Plug the

adjacent unused hole in the cooktop chassis with a screw.See Figure 3, page 8.

Step 7: Install the regulator with the arrow in the direction of the gas flow (towards the

cooktop) using a sealant on the male pipe threads. Put burner rings and burner caps in

place.

Step 8: Connect the gas line to the unit. Refer to page 9 for gas supply hookup.

Step 9: Turn ball valve to let the gas flow. Check for gas leak.

Step 10: Plug the unit into a wall outlet.

Step 11: Turn the front burner knob on first and apply a match to the burner until the gas lights,

being cautious not to burn your hand or other parts of your body.When the gas is first

activated,there is air present in the gas lines. The match applied to the burner makes it

easier and safer to clear the air/gas mixture. Use Caution to avoid burn injury.

Step 12: Put grates in place.

FIG.1

FIG.2

Bracket (p/n 91164)

Screw (p/n 15117-02)

Screw (p/n 15001-22)

Page 9

INSTALLATION INSTRUCTIONS

8

CABINET PREPARATION

The Drop-In Cooktop was designed for easy installation. However, for the best appearance, to conceal

the raw cutout edges and to ensure a snug and secure fit, the cutouts must be precise. Use the

cutout dimension information in the figures below for your installation. When preparing for installation, it is critical that the cabinet cutout matches the cutout dimensions provided for the cooktop for

a good fit. See illustrations below for specifications.

For proper performance,the Drop-In Cooktop must be level.To achieve a flush fit of the cooktop,

it will be necessary to have a flat countertop (front to back and left to right).

Be sure to check local building codes for the proper method of installation. Local codes may

vary.Installation, electrical connections, and grounding must comply with all applicable codes.

NOTE: The cooktop must be completely removed from cut-out to service. The lower firebox is not

supported by the counter.

Plug unused hole

with screw included.

(p/n 15001-22)

Fasten to inside of

cabinet face.

(p/n 91807)

Fasten bracket to

bottom of chassis.

(p/n 15001-22)

FIG. 3

A) 18” min.

B) 13” max.

C) 5” min. to combustibles∆

D) 19-3/4” depth

E) 34-3/4” for CT-365

28-5/8” for CT-304

F) 36” hood width min. for CT-365

30” hood width min. for CT-304

G) 2-1/2”

H) 5”

I) 18”

DROP-IN COOKTOP CUT-OUT DIMENSIONS

F

B

A

C

As defined in the “National Fuel Gas Code” (ANSI Z223.1, latest edition).

NOTE: See manufacturer's recommendations for ducting specifications.

E

H

I

CAUTION:

36" min. to

combustible

material ,

from cooking

G

surface

D

electrical

and

gas supply

Page 10

INSTALLATION INSTRUCTIONS

9

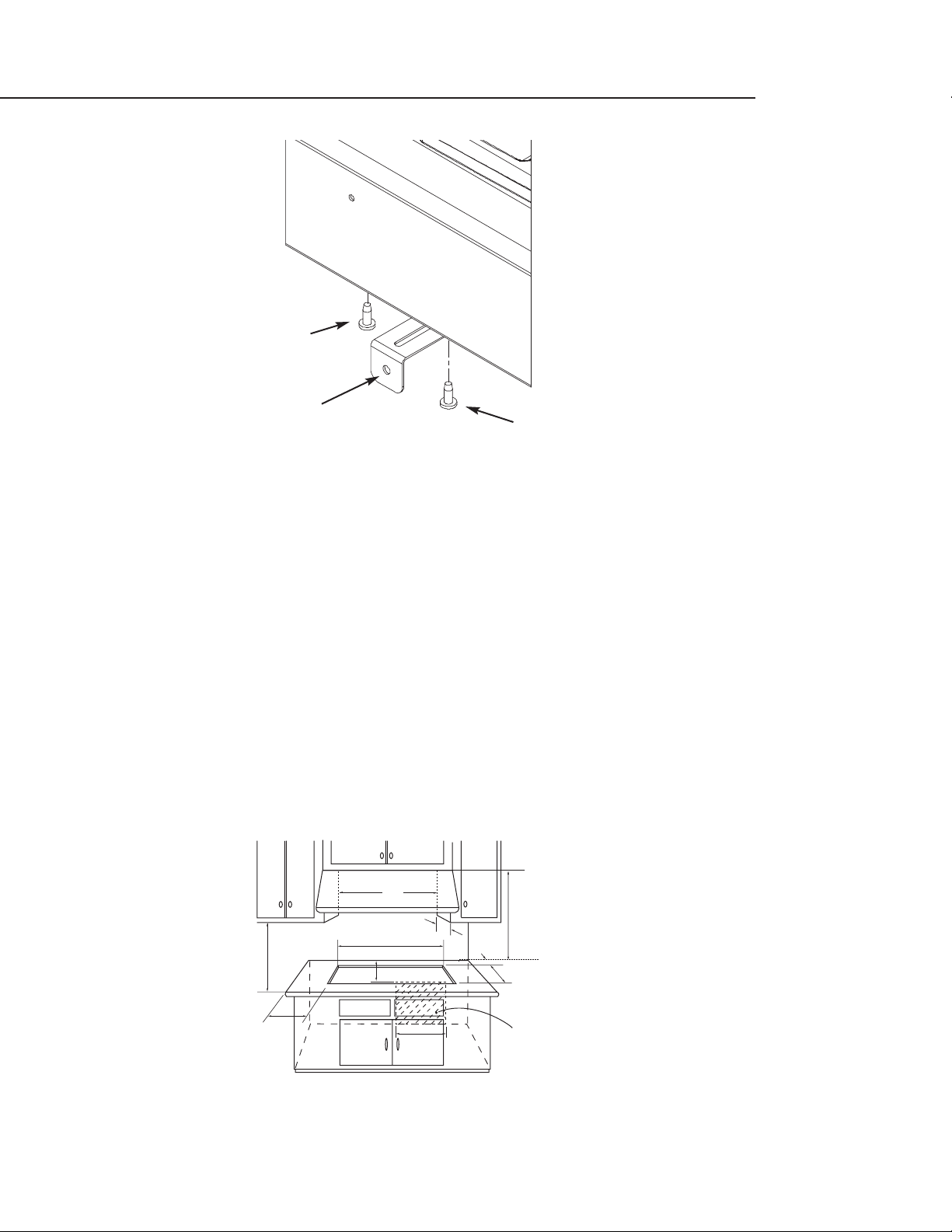

GAS HOOK UP:

Supply: Pressure Inches W.C.: 11.0~14.0”-LPG/6.0~9.0”-Natural Gas

Verify the type of gas supplied to the location. The cooktop is shipped from the factory set for Natural

Gas or LP (propane), depending on the specific model ordered. Verify that the cooktop is

compatible with the gas at the installation site before proceeding further.Return cooktop

to dealer if the unit is not set for site gas supply.

A manual valve must be installed external to the

appliance, in an accessible location from the front for the purpose of shutting off the gas supply.Make

sure the gas supply is turned off at the wall valve before connecting the appliance. The gas supply

connections should be made by a qualified technician and in accordance with local codes or

ordinances.

Locate Gas Supply and Electrical Supply, referring to the illustrations below.

Flex Line to Cooktop

Manual Shut-Off

Valve must be

Easily Accessible

!

B

CAUTION:

36" min. to

combustible

material ,

from cooking

surface

A

C

D

E

F

G

H

K

I

J

electrical

and

gas supply

As defined in the “National Fuel Gas Code” (ANSI Z223.1, latest edition).

NOTE: See manufacturer's recommendations for ducting specifications.

NOTE: When installing a 30" Cooktop with a Downdraft (DD-30SS), a minimum of

a 26" cabinetry depth is required.

L

DROP-IN COOKTOP CUT-OUT DIMENSIONS

(when installing with a DCS DD-36 or DD-30 Downdraft Ventilation System)

A) 18” min.

B) 13” max.

C) 5” min. to combustibles∆

D) 19-3/4” depth

E) 34-3/4” width for CT-365

28-5/8” width for CT-304

F) 33-1/2” width for DD36

27-1/2” width for DD30

G) 1/2” min.

H) 2-1/2”

I) 9”

J) 26-1/2”

K) Min. 36” for CT-365

Min. 30”for CT-304

Page 11

INSTALLATION INSTRUCTIONS

10

Power Requirements:

120 VAC, 60 Hz.,single phase.

CT-304/CT-365: 0.10 Amp. Max.

(Use 15 Amp.circuit minimum)

Always disconnect the electric supply cord from the wall outlet or turn off the electricity at the

service disconnect before servicing this appliance.

Observe all governing codes and ordinances when grounding, in the absence of which,observe

National Electrical Code ANSI/NFPA No. 70-1990.

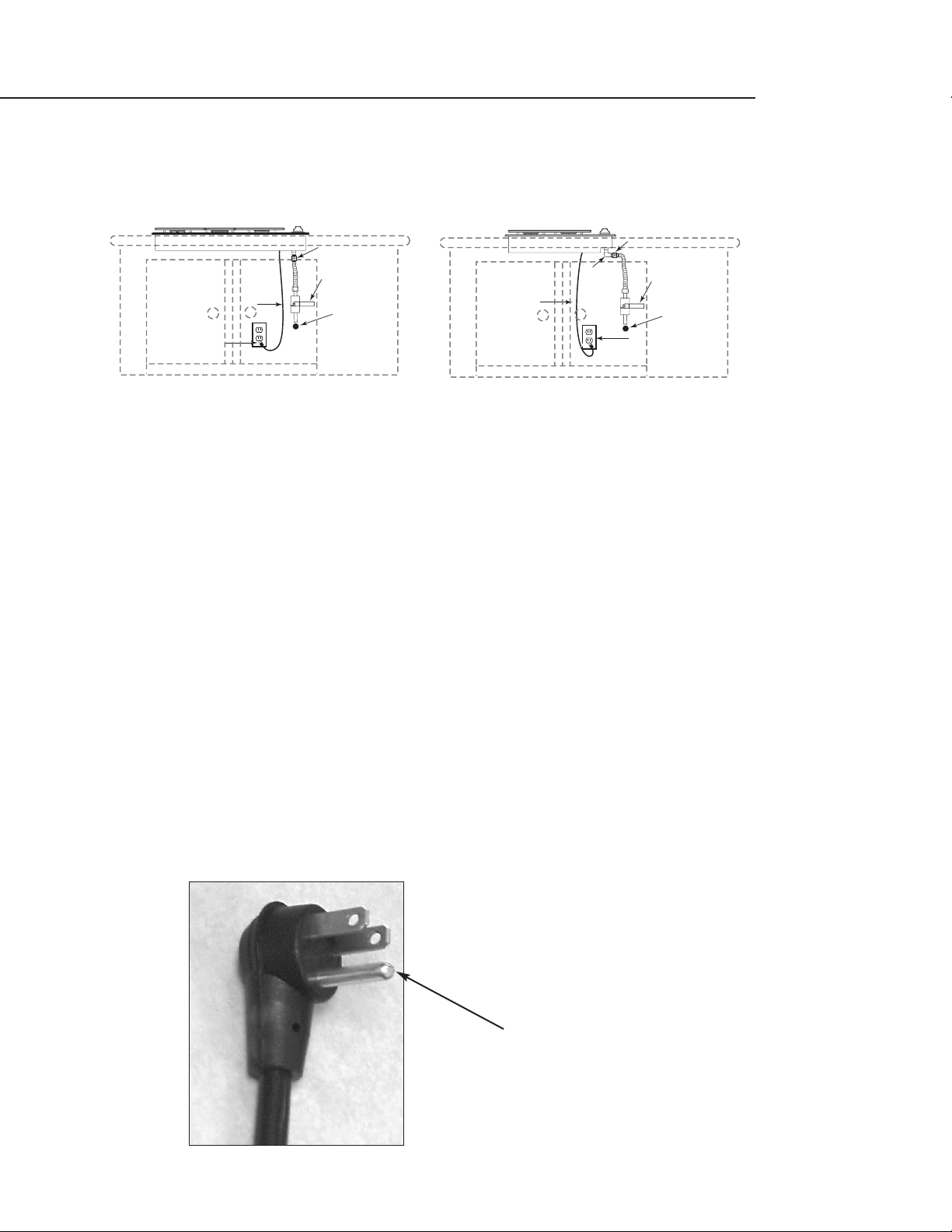

Recommended Grounding Method:

This appliance is factory equipped with a power supply cord with a three-prong grounding plug (with

polarized parallel blades). It must be plugged into a mating grounding-type receptacle, connected to

a correctly polarized 120 Volt circuit. If the circuit does not have a grounding type receptacle, it is the

responsibility and obligation of the installer or user to have the existing receptacle changed to a

properly grounded and polarized receptacle in accordance with all applicable local codes and

ordinances by a qualified electrician. In the absence of local codes and ordinances, the receptacle

replacement shall be in accordance with the National Electrical Code. THE THIRD GROUND PRONG

SHOULD NOT, UNDER ANY CIRCUMSTANCES, BE CUT OR REMOVED. The electrical supply must be a

120 volt, 60 Hz single phase, 15 AMP circuit. The power receptacle must be a NEMA 5-15R device to

accept the three prong plug supplied with the unit.

THIRD GROUND PRONG

COUNTER TOP

GAS SUPPLY

Installer supplied

shut-off valve must

be easily accessible

inside cabinetry

ELECTRIC SUPPLY

4 FOOT POWER CORD

COUNTER TOP

GAS SUPPLY

Installer supplied

shut-off valve must

be easily accessible

inside cabinetry

ELECTRIC SUPPLY

4 FOOT POWER CORD

900 Elbow

supplied*

(CT-304

only)

• Required when unit is installed over Wall Oven

REGULATOR

REGULATOR

GAS CONNECTION FOR CT-365

GAS CONNECTION FOR CT-304

Page 12

INSTALLER FINAL CHECKLIST

11

GENERAL

❏ Placement of Unit.

❏ Specified clearance maintained to cabinet

surfaces.

❏ Unit Level- front to back,side to side.

❏ All packaging material and tie straps

removed.

ELECTRICAL:

❏ Receptacle with 15 ampere circuit

protection is provided for service cord

connection.

❏ Adequate ground connection.

GAS SUPPLY:

❏ Connection: 1/2 NPT with a minimum 5/8”

diameter flex line.

❏ The pressure regulator which is connected

to the manifold is set for 4.0”W.C.for Natural

Gas or 10”W.C. for LP.

❏ Manual gas shut-off valve installed in an

accessible location.

❏ Unit tested and free of gas leaks.

OPERATION:

❏ All internal packing materials are removed,

i.e. below grates, around knobs, etc.

❏ Bezels centered on burner knobs and knobs

turn freely.

❏ Each burner lights satisfactorily, both

individually and with other burners

operating.

❏ Low flame operation verified.

❏ All burner caps, burner rings and burner

bases correctly seated in position, level, and

do not rock or slide.

❏ Burner grates correctly positioned,level, and

do not rock.

Page 13

PRODUCT MEASUREMENT SPECIFICATIONS

12

To be sure that the CUTOUT for the cooktop is correct and to insure a clean installation, REFER TO PAGE

8 FOR CABINET PREPARATION AND CUTOUT SPECIFICATIONS.

CT-365

CT-304

Top View

36"

Front View

34-1/2"

21"

2-3/4"

Top View

21"

30"

Front View

2-11/16"

28-5/16"

R Side View

4"

19-1/2"

5-1/2"

2-7/8"

4"

R Side View

5-1/2"

1-1/2"

19-1/2"

Page 14

WIRING DIAGRAM FOR CT-365

13

C

ELECTRODES

5

5 POINT

GAS RE-IGNITER

MODULE

G

N

SW5

LR

4

SW4

LF

3

SW3

RR

2

SW2

RF

1

SW1

120/230V

TRANSFORMER

230V

120V

C

LR

POWER CORD

120 VAC IN

LF

RR

RF

INDICATOR

LIGHTS

VALVE

SWITCHES

Page 15

WIRING DIAGRAM FOR CT-304

14

LR

ELECTRODES

4

4 POINT

GAS RE-IGNITER

MODULE

G

N

SW4

LF

3

SW3

RF

2

SW2

RR

1

SW1

INDICATOR

LIGHTS

120/230V

TRANSFORMER

230V

120V

LR

LF

POWER CORD

120 VAC IN

RF

RR

VALVE

SWITCHES

Page 16

15

SERVICE

HOW TO OBTAIN SERVICE:

For warranty service, contact DCS Customer Care Representative at (888) 281-5698. Before you call,

please have the following information ready:

Model Number (located at the bottom of chassis,right corner)

Serial Number (located at the bottom of chassis, right corner)

Date of installation

A brief description of the problem

Your satisfaction is of the utmost importance to us. If a problem cannot be resolved to your satisfaction,

please write to Customer Care or email:support@dcsappliances.com

Write:

Fisher & Paykel Appliances, Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

BEFORE YOU CALL FOR SERVICE:

1. Is the circuit breaker tripped?

2. Is the gas turned on?

3. Is the AC plugged in?

4. Is the burner cap in position?

5. Can the burner be lit with a match?

6. Is the gas type correct for the unit – LP or Natural? (Assume the gas type is natural unless

the model # has “L”which stands for LP.)

Page 17

16

WARRANTY

LENGTH OF WARRANTY

One (1) Year Full parts and Labor covers the entire product.

Five (5) Years Limited stainless steel main tops (parts only).

DCS WILL COVER:

All repair labor and parts found to be defective due to materials or workmanship for one full year “IN

HOME” warranty from date of purchase. This does not apply if the unit was subjected to other than

normal household use. Service must be provided by Authorized Factory Technician during normal

working hours. No charges will be made for repair or replacement at the location of initial installation

or factory for parts returned pre-paid, through the dealer and claimed within the warranty period, and

found by DCS to be defective.

Replacement will be F.O.B. DCS, and DCS will not be liable for any transportation costs, labor costs, or

export duties. This warranty shall not apply, nor can we assume responsibility for damage that might

result from failure to follow manufactures instructions or local codes, where the appliance has been

tampered with or altered in anyway or which, in our judgement, has been subjected to misuse,

negligence, or accident.

DCS WILL NOT COVER:

Installation or start-up.

Normal adjustment to burners,gas regulators, etc.

Cleaning of igniters and/or general maintenance.

Shipping damage.

Service by an unauthorized agency.

Damage or repairs due to service by an unauthorized agency or the use of unauthorized parts.

Service during other than normal working hours.

Improper installation, such as improper hook-up, etc.

Chipping of porcelain enamel grates.

Service visits to teach you how to use the appliance; correct the installation; reset circuit

breakers or replace home fuses.

Repairs due to other than normal household use.

Damage caused from accident,abuse, alteration, misuse,incorrect installation or installation not

in accordance with local codes.

Units installed in non-residential application such as day care centers,bed and breakfast centers,

churches, nursing homes, restaurants, hotels, schools, etc.

This warranty applies to appliances used in indoor residential applications; it does not cover their use

in commercial situations.

This warranty is for products purchased and retained in the 50 states of the U.S.A., the District of

Columbia and Canada. This warranty applies even if you should move during the warranty period.

Should the appliance be sold by the original purchaser during the warranty period, the new owner

continues to be protected until the expiration date of the original purchaser’s warranty period.

Page 18

WARRANTY

17

This warranty is in lieu of all other warranties, expressed or implied, and all implied warranties,

including warranties of merchantability and fitness for a particular purpose, are hereby disclaimed to

the full extent permitted by law. To the extent that implied warranties may not be disclaimed, the

duration of any implied warranties, including implied warranties of merchantability and fitness for a

particular purpose, are limited to the duration of this expressed warranty. This warranty gives you

specific legal rights. You may also have other rights which vary from state to state.

Page 19

NOTES

18

Page 20

TABLE DE CUISSON SUPENDUE

PROFESSIONNELLE

• 36 PO À 5 BRÛLEURS

• 30 PO À 4 BRÛLEURS

Manuel D'Installation

MODÈLES :

CT-365SS (indiqué)

CT-365BK

CT-365WT

CT-304SS

CT-304BK

CT-304WT

Page 21

À NOTRE CLIENTÈLE

1

Nous vous remercions d'avoir choisi cette table de cuisson suspendue professionnelle DCS. Nous avons

conçu ce Manuel d'installation pour expliquer ses fonctions uniques. Il contient des informations

extrêmement utiles sur la façon d'installer votre nouvel appareil de cuisson. Vous pourrez ainsi en profiter

pendant des années en toute sécurité.

Si vous avez des questions au sujet de notre produit,communiquez avec Centre de service à la clientèle DCS

par téléphone : 1-888-281-5698,email : support@dcsappliances.com,

or par courrier :

Fisher & Paykel Appliances,Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

États-Unis

VEUILLEZ CONSERVER CE MANUEL À TITRE DE RÉFÉRENCE.

AV ER TI SSEMENT

To ute installation,ajustement, altération ou entretien incorrect peut causer des

dommages matériels, des blessures ou la mort.Veuillez lire soigneusement ces

instructions d'installation, d'utilisation et d'entretien avant d'utiliser, installer

ou effectuer l'entretien de cet appareil.

AV ER TI SSEMENT

Évitez de stocker ou d'utiliser de l'essence ou tous autres liquides et vapeurs

inflammables à proximité de cet appareil ou de tout autre appareil.

POUR VOTRE SÉCURITÉ

SI VOUS SENTEZ UNE ODEUR DE GAZ :

1.N'allumez aucun interrupteur électrique; n'utilisez aucun téléphone dans

l'édifice.

2. Appelez immédiatement votre fournisseur de gaz de chez un voisin. Suivez

les instructions du fournisseur de gaz.

3. Si vous n'arrivez pas à joindre votre fournisseur de gaz,appelez les pompiers.

To ue entretien ou installation doit être confié à un installateur qualifié, un

organisme de service ou le fournisseur de gaz.

Page 22

TABLE DES MATIÈRES

2

MESURES DE SÉCURITÉ ET DE PRÉCAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

EXIGENCES EN MATIÈRE DE VENTILATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTRUCTIONS D’INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Préparation en vue de l'installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Préparation du boîtier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Branchement du gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Besoins en alimentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Méthode de mise à la terre recommandée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

LISTE DE CONTRÔLE FINALE DE L'INSTALLATEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SPÉCIFICATIONS DES DIMENSIONS DU PRODUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SCHÉMA DE CÂBLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

GARANTIE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Page 23

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

3

Votre nouvel appareil DCS fonctionnera de manière sûre et fiable pendant des années si vous en

prenez soin correctement.Faites extrêmement attention quand vous utilisez cet appareil de cuisson de

niveau professionnel car il dégage une chaleur intense et peut augmenter les risques d'accidents.Vous

devez respecter des consignes de sécurité élémentaires durant l'utilisation de cet appareil, dont

celles-ci :

Veuillez lire attentivement ce manuel d'utilisation et d'entretien avant d'utiliser votre nouvel

appareil. Ceci vous permettra de réduire les risques d'incendie, de chocs électriques ou de

blessures.

Commencez par vous assurer que l'installation et l'entretien sont effectués correctement.Suivez

les instructions d'installation fournies avec cet appareil.Confiez l'installation et la mise à la terre

de l'appareil à un technicien qualifié avant de l'utiliser.

Demandez-lui de vous montrer l'emplacement du robinet d'arrêt de l'alimentation de gaz afin

de savoir comment couper l'arrivée de gaz.

Si vous sentez une odeur de gaz,cela signifie que l'installateur n'a pas vérifié correctement s'il y

avait des fuites. Si les connexions ne sont pas complètement étanches, une petite fuite pourrait

se produire et laisser s'échapper une faible odeur de gaz. La détection des fuites n'est pas une

procédure à faire soi-même.Certaines fuites ne peuvent être détectées que si la commande du

brûleur est sur ON et, dans l'intérêt de votre sécurité, ceci doit être confié à un technicien

qualifié.

Si jamais un brûleur s'éteint sans se rallumer et laisse s'échapper le gaz, ouvrez la fenêtre ou la

porte pour évacuer l'air. N'essayez pas d'utiliser l'appareil avant que le gaz n'ait eu le temps de

se dissiper.

Cet appareil électroménager a été monté en usine pour être utilisé avec du gaz naturel ou

propane tel qu'indiqué par le numéro de modèle.

Ne réparez pas ni ne remplacez aucune pièce de cet appareil, sauf indication contraire du

manuel.Tout autre travail d'entretien doit être confié à un technicien qualifié.

AV ER TI SSEMENT :

LES ENFANTS NE DOIVENT PAS ÊTRE LAISSÉS SEULS OU sans surveillance dans

un endroit où est utilisé ce type d'appareil. Il ne faut jamais les laisser tourner

ou enfoncer des boutons,ni s'asseoir ou se tenir debout sur l'appareil.

AV ER TI SSEMENT :

ne rangez pas d'objets pouvant attirer les enfants sur ou autour de la table de

cuisson. Les enfants pourraient se blesser sérieusement s'ils grimpent sur

l'appareil ou s'étirent par dessus pour atteindre un objet particulier.

Ne rangez jamais rien sur la table de cuisson. Des matériaux inflammables pourraient

prendre feu accidentellement, des éléments en plastique pourraient fondre ou s'enflammer et

d'autres types d'objets pourraient être détruits.

Ne suspendez aucun objet sur aucune partie de l'appareil. Certains matériaux sont très inflam-

mables et pourraient prendre feu.

Si l'appareil se trouve près d'une fenêtre, assurez-vous que les rideaux sont suffisamment

éloignés des brûleurs de la table de cuisson; ils pourraient prendre feu sinon.

Page 24

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

4

Ne laissez jamais des vêtements, gants ou autres matériaux inflammables en contact ou à

proximité d'un brûleur ou d'une grille de brûleur tant que ceux-ci n'ont pas refroidi. Les tissus

peuvent s'enflammer et causer des blessures.

Utilisez seulement des gants isolants secs :les gants humides sur des surfaces chaudes peuvent

provoquer des brûlures causées par la vapeur. N'utilisez pas de serviette ou de chiffon épais à

la place de gants isolants. Ne laissez pas les gants isolants toucher les brûleurs ou leurs grilles.

Pour assurer votre propre sécurité, habillez-vous de façon appropriée. Ne portez jamais de

vêtements ou de manches lâches lorsque vous utilisez l'appareil. Certains tissus synthétiques

sont extrêmement inflammables et ne doivent pas être portés pendant la cuisson.

Ne recouvrez aucune partie de la table de cuisson avec du papier aluminium. L'utilisation de

papier aluminium peut créer un risque d'incendie.

AV ER TI SSEMENT :

cet appareil est destiné à la cuisson. Pour des raisons de sécurité, n'utilisez

jamais la table de cuisson pour chauffer une pièce.

AV ER TI SSEMENT :

Durant l'utilisation de la table de cuisson : ne touchez pas les grilles des

brûleurs ou les surfaces adjacentes. Celles-ci peuvent devenir suffisamment

chaudes pour provoquer des brûlures.

Ne laissez jamais la table de cuisson sans surveillance lorsque vous cuisinez à

flamme haute.

Un débordement par bouillonnement pourrait produire de la fumée ou un

déversement graisseux pourrait prendre feu. Et, surtout, si les flammes des brûleurs sont

étouffées par un débordement important affectant l'allumeur,le gaz non brûlé s'échappera

dans la pièce,ce qui serait extrêmement dangereux.

Seuls certains types d'ustensiles en verre, vitrocéramique calorifugée, céramique, poterie ou

émaillés sont appropriés pour être utilisés sur la flamme vive de la table de cuisson.Les ustensiles

non thermorésistants peuvent se briser à la suite de changements de température soudains.

Ne chauffez pas de contenant de nourriture fermé car la pression pourrait s'accumuler et le faire

exploser.

Durant la cuisson,réglez la commande du brûleur de sorte que la flamme ne chauffe que le fond

du récipient et ne lèche pas ses rebords inférieurs. Cela pourrait chauffer ou faire fondre les

poignées.

Servez-vous toujours d'ustensiles à fond plat suffisamment larges pour couvrir les brûleurs.

L'utilisation d'ustensiles trop petits risque d'offrir un contact direct à la flamme et de mettre le

feu aux vêtements

Afin de réduire le risque de brûlures,d'allumage de matériaux inflammables et de déversement

accidentel, tournez les poignées des ustensiles vers l'intérieur afin qu'elles ne surplombent pas

les surfaces de travail adjacentes, les zones de cuisson et les bords extérieurs de la table de

cuisson.

Tenez la poignée du récipient pour empêcher tout mouvement de l'ustensile lorsque vous

retournez ou remuez la nourriture.

La graisse est inflammable. Ne versez pas d'eau sur les feux de graisse. ÉTEIGNEZ le brûleur,

puis étouffez le feu avec du bicarbonate de soude ou à l'aide d'un extincteur à poudre ou à

mousse.Laissez toute graisse chaude refroidir avant d'essayer de la manipuler. Évitez de laisser la

graisse s'accumuler autour de la base des brûleurs de la table de cuisson.Nettoyez après chaque

utilisation ou déversement.

Page 25

5

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

Recouvrez les poêles à frire de grilles anti-éclaboussures pour éviter les risques de brûlures à

l'huile. Prenez soin de ne pas utiliser une flamme trop haute.

Pour assurer un bon allumage et une bonne performance des brûleurs de la table de cuisson,

gardez leurs ports dans un état propre. Il peut s'avérer nécessaire de nettoyer ceux-ci en cas de

débordement ou lorsque le brûleur ne s'allume pas, même si les allumeurs électroniques

cliquent.

Nettoyez la table de cuisson avec précaution. Évitez de vous brûler à la vapeur : n'utilisez pas

d'éponge ou de chiffon mouillé pour nettoyer l'appareil alors qu'il est encore chaud. Certains

produits de nettoyage produisent des vapeurs nocives s'ils sont appliqués à une surface chaude.

Suivez le mode d'emploi fourni par le fabricant du produit de nettoyage.

Assurez-vous que les boutons de l'appareil sont fermés et que celui-ci est froid avant d'utiliser

des nettoyants aérosol à proximité. L'élément chimique qui produit le jet de vaporisation peut,

en présence de chaleur,s'enflammer ou provoquer la corrosion des parties métalliques.

Nettoyez fréquemment la hotte et les filtres de ventilation surplombant la table de cuisson afin

d'empêcher toute accumulation de graisse provenant des vapeurs de cuisson.

ÉTEIGNEZ le ventilateur en cas d'incendie. Si la souffleuse est en marche, elle pourrait en effet

répandre les flammes.

Ne bloquez pas la circulation de l'air de combustion ou de ventilation. Assurez toujours un

apport d'air frais.

Pour des raisons de sécurité et pour ne pas endommager l'appareil, évitez de vous asseoir, de

vous tenir debout ou de vous appuyer contre la surface de cuisson.

Les réparations doivent être effectuées par des techniciens agréés uniquement.Ceux-ci doivent

débrancher le bloc d'alimentation avant de travailler sur l'appareil.

Avertissement concernant la proposition 65 de la Californie : l'incinération de gaz de cuisson

génère des sous-produits considérés par l'État de Californie comme pouvant causer le cancer

ou des malformations congénitales.Les lois de Californie exigent que les entreprises avertissent

leurs clients qu'ils risquent d'être exposés à de telles substances. Pour minimiser l'exposition à

ces substances,faites toujours fonctionner l'appareil conformément aux instructions contenues

dans ce manuel et assurez une bonne ventilation lorsque vous cuisinez au gaz.

REMARQUE :Ce produit doit être installé par un plombier ou ajusteur

d'appareils à gaz agréé si l'installation a lieu au sein du

Commonwealth du Massachusetts.

Le robinet d'arrêt fourni

par l'installateur doit

être facilement accessible de

l'intérieur du boîtier.

Alimentation en gaz

Page 26

EXIGENCES EN MATIÈRE DE

6

RENSEIGNEMENTS IMPORTANTS :

MISE EN GARDE :

les hottes et souffleuses de ventilation sont conçues pour être utilisées avec des

conduits à paroi simple. Toutefois, il se peut que certains codes du bâtiment

locaux ou des inspecteurs exigent des parois doubles. Consultez les codes du

bâtiment ou organismes locaux avant de commencer afin de vous assurer que

la hotte et les conduits sont conformes aux normes en vigueur.La vitesse de la

souffleuse de la hotte doit être variable afin de réduire le niveau de bruit et la

perte d'air chauffé ou conditionné de la pièce lorsqu'une ventilation maximum

n'est pas requise. Pour évacuer la fumée de la meilleure façon, le bord inférieur

de la hotte doit être INSTALLÉ À UN MINIMUM DE 76 CM (30 PO) ET UN

MAXIMUM DE 91 CM (36 PO) AU-DESSUS DE LA SURFACE DE CUISSON. Si la

hotte contient des matériaux combustibles (par ex.un revêtement en bois), elle

doit être placée à au moins 91 cm (36 po) au-dessus de la surface de cuisson. À

cause du volume élevé d'air de ventilation, il est recommandé d'assurer une

source d'air frais provenant de l'extérieur. Ceci est particulièrement important

pour les résidences très isolées. Consultez un spécialiste en chauffage et

aération réputé.

EXIGENCES EN MATIÈRE DE VENTILATION :

RECOMMANDATIONS CONCERNANT L'INSTALLATION D'UN COMPTOIR STANDARD

HOTTE : (profondeur 24 po x largeur de l'appareil)

SOUFFLEUSE : TABLE DE CUISSON 36 po

17 m3/min

Tel que défini dans le « National Fuel Gas Code » (norme ANSI Z223.1 dernière édition)

Le niveau des surfaces horizontales de la garniture de la cuisinière (table de cuisson) ne

doit pas être inférieur au niveau du comptoir.

REMARQUE :

Voir les recommandations du fabricant en ce qui concerne les dimensions des conduits.

Dégagement de 30 po min.

séparant surface non combustible

et table de cuisson.

Dégagement de 36 po min.

séparant surface combustible et

table de cuisson.

Dégagement

de 5 po min.

jusqu'à la

surface

combustible

Dégagement de

18 po min. séparant

surface combustible et

bord extérieur de

la table de cuisson

Page 27

INSTRUCTIONS D’INSTALLATION

PRÉPARATION EN VUE DE L'INSTALLATION :

Lisez attentivement la page 6 concernant les exigences en matière de ventilation avant de commencer.

Reportez-vous à la section de préparation du boîtier à la page 8 avant de pratiquer la DÉCOUPE.

Étape 1: Déballez l'appareil et le régulateur et enlevez tout l'emballage des brûleurs, des

couronnes et des capuchons. Retirez les grilles de leur boîtes.

Étape 2: À l'aide des outils et matériel nécessaires à portée de main, mesurez la distance entre

l'arrière et les côtés du comptoir et du boîtier afin de déterminer l'emplacement de la

découpe de la table de cuisson.

Étape 3: Effectuez la découpe selon les dimensions indiquées à la page 8. Alignez la découpe

contre le comptoir.

Étape 4: Abaissez la table de cuisson dans la découpe du comptoir en prenant soin de ne pas

endommager le comptoir, le filetage du tuyau d'admission ou le cordon d'alimentation

de la table de cuisson.

Étape 5: Alignez la table de cuisson contre la découpe et installez les (4) supports de retenue sur

les 8 trous situés au bas de l'appareil (voir Figure 1 ci-dessous). Si des supports de

retenue ne sont pas installés,la table de cuisson ne sera pas pressée contre le comptoir.

Étape 6: Serrez les 4 vis préinstallées pour bien fixer l'appareil.Évitez de trop serrer (voir Figure 2

ci-dessous).

REMARQUE : Il se peut que certaines installations ne disposent pas d'un dégagement suff-

isamment à l'avant pour le support de retenue en forme de Z. Dans ce cas,

utilisez le support en L fourni. Fixez le support au bas du châssis de la table de

cuisson à l'aide d'un des trous à vis prévus à cet effet. Assurez-vous que le support est suffisamment étendu pour qu'il touche l'intérieur de la face de l'armoire.

Fixez le support à l'armoire. Introduisez une vis dans le trou adjacent inutilisé du

châssis de la table de cuisson. Voir la figure 3.

Étape 7: Installez le régulateur, flèche orientée dans le sens du débit de gaz (pointant vers la

table de cuisson), et couvrez le filetage du tuyau mâle d'un enduit d'étanchéité. Mettez

en place les couronnes et capuchons des brûleurs.

Étape 8: Branchez la conduite de gaz à l'appareil. Reportez-vous à la page 9 en ce qui concerne

le branchement du gaz.

Étape 9: Tournez le robinet pour laisser passer le gaz. Regardez s'il y a des fuites de gaz.

Étape 10: Branchez l'appareil dans la prise murale.

Étape 11: Allumez d'abord le bouton du brûleur avant et allumez le gaz avec une allumette en

prenant soin de ne pas vous brûler la main ou d'autres parties du corps. Il y a de l'air

dans la conduite de gaz lorsque le gaz est activé initialement. L'utilisation d'une

allumette sur le brûleur permet de se débarrasser du mélange d'air et de gaz plus

facilement et de manière plus sécuritaire. Soyez prudent afin d'éviter tout risque de

brûlure.

Étape 12: Mettez les grilles en place.

7

FIG.2

FIG.1

le support (91164)

vis (15117-02)

vis (15001-22)

Page 28

INSTRUCTIONS D’INSTALLATION

8

PRÉPARATION DU BOÎTIER

La table de cuisson a été conçue pour permettre une installation facile. Toutefois, pour donner une

belle apparence à l'appareil, les découpes doivent être précises afin d'en dissimuler les bords bruts et

de permettre un ajustement serré et solide. Utilisez les dimensions de découpe des figures ci-dessous

pour votre installation.En préparation à l'installation, il est essentiel que la découpe du boîtier respecte

les dimensions de découpe fournies pour la table de cuisson afin d'assurer un bon ajustement.Voir les

spécifications indiquées sur les illustrations ci-dessous.

La table de cuisson doit être de niveau pour bien fonctionner. Le boîtier doit être plat (de l'avant

vers l'arrière et de gauche à droite) de manière à affleurer la table de cuisson.

Prenez soin de consulter les codes du bâtiment en vigueur au sujet de la méthode d'installation

à suivre.Les codes peuvent varier d'une région à l'autre.L'installation,les connexions électriques

et la mise à la terre doivent être conformes à tous les codes en vigueur.

REMARQUE : La table de cuisson doit être complètement retirée de la découpe pour toute

réparation ou entretien. La chambre de cuisson Inférieure n'est pas soutenue par le

comptoir.

F

B

A

C

D

E

G

H

Tel que défini dans le « National Fuel Gas Code » (norme ANSI Z223.1 dernière édition)

REMARQUE : Voir les recommandations du fabricant en ce qui concerne les dimensions des conduits.

MISE EN GARDE :

91,5 cm/ (36 po) min.

des matériaux

combustibles

à la surface de

cuisson

électrique

et en gaz

I

Introduisez une vis

dans le trou inutilisé.

(15001-22)

Fixez-la à l'intérieur de

la face de l'armoire.

(91807)

Fixez le support au

bas du châssis.

(15001-22)

FIG. 3

A) 45,7 cm (18 po) min.

B) 33 cm (13 po) max.

C) 12,7 cm (5 po) jusqu'aux matériaux

combustibles ∆

D) 50,2 cm (19-3/4 po) profondeur

E) 88,3 cm (34-3/4 po) pour le CT-365

72,7 cm (28-5/8 po) pour le CT-304

F) Largeur de hotte 91,4 cm (36 po) min.

pour CT-365

Largeur de hotte 76,2 cm (30 po) min.

pour CTR-304

G) 6,35 cm (2-1/2 po)

H) 12,7 cm (5 po)

I) 45,72 cm (18 po)

DIMENSIONS DE DÉCOUPE DE LA TABLE

DE CUISSON SUSPENDUE

Page 29

INSTRUCTIONS D’INSTALLATION

9

BRANCHEMENT DU GAZ :

Pression CE : 11,0~14,0 po - propane/6,0~9,0 po - gaz naturel

Vérifiez le type de gaz alimentant le site. La table de cuisson est réglée en usine pour fonctionner au

gaz naturel ou propane selon le modèle spécifique commandé.Avant d'aller plus loin, vérifiez que la

table de cuisson est compatible avec le gaz du site où elle doit être installée. Renvoyez la table de

cuisson au distributeur si elle n'est pas réglée pour fonctionner avec le gaz du site.Un robinet manuel

doit être installé à l'extérieur de l'appareil, sur le devant, dans un endroit accessible, afin de permettre

de couper le gaz.Avant de brancher l'appareil,prenez soin de couper le gaz par le robinet mural.Toutes

les connexions d'alimentation en gaz doivent être effectuées par un technicien qualifié conformément

aux codes et règlements en vigueur.

Reportez-vous aux illustrations ci-dessous pour repérer l'alimentation en gaz et l'alimentation

électrique.

Conduite flexible allant à

la table de cuisson

Le robinet d'arrêt

manuel doit être

facilement accessible

!

A) 45,7 cm (18 po) min.

B) 33 cm (13 po) max.

C) 12,7 cm (5 po) jusqu'aux matériaux

combustibles ∆

D) 50,2 cm (19-3/4 po) profondeur

E) 88,3 cm (34-3/4 po) pour le CT-365

72,7 cm (28-5/8 po) pour le CT-304

F) 33-1/2 po de largeur pour le DD36

27-1/2 po de largeur pour le DD30

G) 1,3 cm (1/2 po) min.

H) 6,35 cm (2-1/2 po)

I) 22,86 cm (9 po)

J) 67,3 cm (26-1/2 po)

K) Min. 91,4 cm (36 po) pour le CT-365

Min. 76,2 (30 po) pour le CT-304

L) 66,04 cm (26 po) min.

DIMENSIONS DE DÉCOUPE DE LA TABLE

DE CUISSON SUSPENDUE

(dans le cas d'une installation avec un système de ventilation par

aspiration descendante DCS DD-36 ou DD-30)

K

G

A

L

H

C

Tel que défini dans le « National Fuel Gas Code » (norme ANSI Z223.1 dernière édition)

REMARQUE : Voir les recommandations du fabricant en ce qui concerne les dimensions des conduits.

REMARQUE : Dans le cas de l'installation d'une table de cuisson de 30 po dotée d'un système de

ventilation par le bas (DD-30SS), prévoyez une profondeur d'armoire de 66 cm (26 po) minimum.

E

F

B

J

I

MISE EN GARDE :

91,5 cm/ (36 po) min.

des matériaux

combustibles

à la surface de

cuisson

D

électrique

et en gaz

Page 30

INSTRUCTIONS D’INSTALLATION

10

BESOINS EN ALIMENTATION :

120 V c.a.,60 Hz, courant monophasé

CT-365 : 0,10 A max.

(utilisez un circuit de 15 A minimum)

Débranchez toujours le cordon d'alimentation électrique de la prise murale ou coupez le

courant avant d'effectuer l'entretien de cet appareil.

Respectez tous les codes et réglementations en vigueur concernant la mise à la terre.S'il n'y en

a pas, respectez la norme ANSI/NFPA No. 70-1990 du National Electrical Code (Code national de

l'électricité).

MÉTHODE DE MISE À LA TERRE RECOMMANDÉE :

Cet appareil est équipé d'un cordon d'alimentation à fiche bipolaire avec terre dotée de lames

parallèles polarisées. La fiche doit être branchée dans une prise avec mise à la terre correspondante

connectée à un circuit correctement polarisé de 120 V. Si le circuit ne possède pas ce genre de prise,

l'installateur ou l'utilisateur a la responsabilité et le devoir de faire remplacer, par un technicien qualifié,

la prise existante par une prise polarisée correctement mise à la terre conformément aux codes et

réglementations en vigueur.En l'absence de tels codes et réglementations,le remplacement de la prise

doit être effectué conformément au Code national de l'électricité. LA TROISIÈME BROCHE DE

TERRE NE DOIT EN AUCUN CAS ÊTRE COUPÉE OU ENLEVÉE.

Assurez une alimentation

électrique à courant monophasé de 120 V, 60 Hz sur un circuit de 15 ampères.La prise de courant doit

être de type NEMA 5-15R compatible avec la fiche bipolaire avec terre fournie avec l'appareil.

Tro isième broche de terre

COMPTOIR

Le robinet d'arrêt

fourni par

l'installateur doit

être facilement

accessible de

l'intérieur du

boîtier

ALIMENTATION EN GAZ

CORDON D'ALIMENTATION

DE 1,2 M/4 PIEDS

ALIMENTATION ÉLECTRIQUE

COMPTOIR

RÉGULATEUR

Le robinet d'arrêt

fourni par

l'installateur doit

être facilement

accessible de

l'intérieur du

boîtier

ALIMENTATION EN GAZ

RÉGULATEUR

Coude à

90° fourni*

(CT-304

CORDON D'ALIMENTATION

DE 1,2 M/4 PIEDS

• Required when unit is installed over Wall Oven

uniquement)

ALIMENTATION ÉLECTRIQUE

Page 31

LISTE DE CONTRÔLE FINALE DE L'INSTALLATEUR

11

GÉNÉRALITÉS

❏ Emplacement de l'appareil.

❏ Dégagement spécifié respecté par rapport

aux surfaces du boîtier.

❏ Appareil de niveau - de l'avant à l'arrière,

d'un bord à l'autre.

❏ Matériel d'emballage et courroies d'attache

enlevés.

ALIMENTATION ÉLECTRIQUE :

❏ Prise avec protection de courant de 15

ampères pour brancher le cordon d'alimentation.

❏ Connexion de mise à la terre adéquate.

ALIMENTATION EN GAZ :

❏ Connexion : 1/2 NPT avec conduite flexible

de 5/8 po de diamètre minimum

❏ Le régulateur de pression connecté au

distributeur est réglé sur 4,0 po C.E. pour le

gaz naturel ou 10,0 po C.E. pour le gaz

propane.

❏ Robinet d'arrêt manuel installé dans un

endroit facile d'accès.

❏ Appareil testé et exempt de fuites.

FONCTIONNEMENT :

❏ Tout le matériel d'emballage interne est

enlevé, c'est-à-dire sous les grilles, autour

des boutons, etc.

❏ Cadrans centrés sur les boutons des brûleurs

et boutons tournant librement,

❏ Chaque brûleur s'allume correctement, qu'il

fonctionne seul ou avec les autres brûleurs.

❏ Réglage de flamme produisant une flamme

douce conique de 3/8 po sur les ports des

brûleurs supérieurs.

❏ Vérification de fonctionnement à faible

flamme.

❏ Tous les capuchons, couronnes et bases de

brûleur sont bien assis, de niveau, ne

remuent pas et ne glissent pas.

❏ Les grilles des brûleurs sont correctement

placées, de niveau et ne remuent pas.

Page 32

SPÉCIFICATIONS DES DIMENSIONS DU PRODUIT

12

Afin de vous assurer que la DÉCOUPE de la table de cuisson est correcte et que l'installation est bien

menée, CONSULTEZ LA PAGE 8 EN CE QUI CONCERNE LA PRÉPARATION DU BOÎTIER ET LES

SPÉCIFICATIONS DE DÉCOUPE.

CT-365

CT-304

Vue de dessus

36 po

Vue de face

34-1/2 po

21 po

Vue de dessus

21 po

30 po

Vue de face

2-11/16 po

28-5/16 po

Vue du côté droit alimentation

4"

19-1/2 po

5-1/2 po

Vue du côté droit alimentation

4"

19-1/2 po

5-1/2 po

1-1/2 po

Page 33

SCHÉMA DE CÂBLAGE – CT365

13

C

ÉLECTRODES

5

MODULE DE

RALLUMAGE DU

GAZ EN 5 POINTS

G

N

INT5

G. AR

4

INT4

G. AV

3

INT3

D. AR.

2

INT2

D. AV

1

INT1

120/230V

TRANSFORMATEUR

120V 230V

VOYANTS

C

G. AR

G. AV

CORDON

D'ALIMENTATION

120 V C.A. ENTRÉE

D. AR.

D. AV

DE ROBINET

INTERRUPTEURS

Page 34

SCHÉMA DE CÂBLAGE – CT304

14

R

G. A

ÉLECTRODES

4

MODULE DE

RALLUMAGE DU

GAZ EN 4 POINTS

G

N

INT4

G. AV

3

INT3

D. AV

2

INT2

D. AR

1

INT1

120/230V

TRANSFORMATEUR

230V

120V

G. AR

VOYANTS

G. AV

D. AV

D. AR.

DE ROBINET

INTERRUPTEURS

CORDON

D'ALIMENTATION

120 V C.A. ENTRÉE

Page 35

15

SERVICE

POUR L'OBTENTION DE SERVICE :

Pour le service sous garantie, contactez le centre DCS agréé le plus proche au (888) 281-5698. Avant

d'appeler,veuillez avoir les informations suivantes à portée de main :

Numéro de modèle (bas du châssis,coin droit)

Numéro de série (bas du châssis,coin droit)

Date d'installation

Brève description du problème

Votre satisfaction revêt la plus haute importance pour nous. Si un problème n'est pas résolu à votre

entière satisfaction, veuillez communiquer par courrier avec notre Centre de service à la clientèle ou

email : support@dcsappliances.com

Écrivez-nous à l'adresse suivante :

Fisher & Paykel Appliances, Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

AVANT D'APPELER LE SERVICE TECHNIQUE :

1. Est-ce que le disjoncteur s'est déclenché ou que le fusible est grillé?

2. Est-ce que le gaz est allumé?

3. Est-ce que la prise est branchée sur le courant?

4. Est-ce que le capuchon de brûleur est en place?

5. Peut-on allumer le brûleur avec une allumette?

6. Le type de gaz est-il correct pour cet appareil : gaz propane ou naturel? (Voir l'autocollant du

numéro de modèle.Vous pouvez supposer que le type de gaz est du gaz naturel à moins que le

numéro du modèle comporte un « L », ce qui signifie liquéfie, et donc propane.)

Page 36

16

GARANTIE

DURÉE DE LA GARANTIE

Un (1) an, pièces et main-d'œuvre sur tout le produit.

Cinq (5) ans de garantie limitée sur les pièces supérieures principales en acier inoxydable (pièces

seulement.)

DCS COUVRE LES FRAIS SUIVANTS :

Frais de main-d'œuvre et de réparation de pièces jugées défectueuses pour cause de vice de matière

ou de fabrication, et ce pendant une année complète avec garantie « À DOMICILE » pendant la

première année d'achat. Cette garantie ne s'applique pas si l'appareil a été soumis à une utilisation

autre qu'une utilisation domestique normale. Le service doit être fourni par un agent agréé de l'usine

durant les heures ouvrables normales. Il n'y aura pas de frais facturés pour les réparations ou

remplacements effectués sur le site de l'installation initiale ou en usine pour des pièces renvoyées port

payé, par l'intermédiaire du distributeur, pendant la période de garantie, et jugées défectueuses par

DCS.

Les remplacements sont effectués franco à bord DCS et DCS n'est pas responsable des frais de

transport, de main-d'œuvre ou des tarifs douaniers s'appliquant à l'exportation. Cette garantie ne

saurait s'appliquer,et nous n'assumons aucune responsabilité pour les dommages pouvant résulter du

fait de ne pas avoir respecté les consignes du fabricant ou des codes en vigueur, ou d'avoir trafiqué ou

altéré l'appareil de quelque façon, ou d'avoir,selon nous, soumis l'appareil à une mauvaise utilisation,à

de la négligence ou à un accident.

DCS NE COUVRE PAS LES FRAIS SUIVANTS :

Installation ou démarrage.

Réglage normal des brûleurs,régulateurs de gaz, etc.

Nettoyage des allumeurs et/ou entretien général.

Dommages subis durant le transport.

Service effectué par un centre non agréé.

Dommages ou réparations causés par un service effectué par un centre non agréé ou par l'util-

isation de pièces non autorisées.

Service effectué en dehors des heures ouvrables normales.

Mauvaise installation,telle qu'un branchement incorrect, etc.

Écaillement des grilles en émail- porcelaine.

Visites de service pour vous apprendre comment utiliser l'appareil, corriger l'installation,

réarmer les disjoncteurs ou remplacer les fusibles de la maison.

Réparations dues à une utilisation autre qu'une utilisation domestique normale.

Dommages causés par accident, abus, altération, mauvaise utilisation, installation incorrecte ou

installation non conforme aux codes en vigueur.

Appareils installés dans le cadre d'applications non résidentielles telles que garderies,auberges,

lieux de culte, maisons de soin, restaurants, hôtels, écoles,etc.

Cette garantie s'applique aux appareils utilisés dans des applications résidentielles. Elle ne couvre pas

les utilisations commerciales.

Cette garantie couvre les produits achetés et utilisés dans les 50 états des États-Unis, le District de

Columbia et au Canada.La garantie s'applique même si vous déménagez durant la période de garantie.

Si l'appareil est vendu par l'acheteur initial durant la période de garantie, le nouveau propriétaire

Page 37

17

GARANTIE

continue de bénéficier de la protection jusqu'à la date d'expiration de la période de garantie de

l'acheteur initial.

Cette garantie remplace toute autre garantie, explicite ou implicite. En outre, toutes les garanties

implicites, y compris les garanties de qualité marchande ou d'adaptation à un usage particulier,

sont déclinées par la présente dans toute la limite permise par la loi. Dans la mesure où les

garanties implicites ne peuvent être déclinées, la durée des garanties implicites, y compris les

garanties implicites de qualité marchande ou d'adaptation à un usage particulier, est limitée à la

durée de cette garantie expresse.Cette garantie vous donne des droits juridiques spécifiques.Il se

peut que vous ayez d'autres droits pouvant varier d'une juridiction à l'autre.

Page 38

Fisher & Paykel Appliances,Inc.

5900 Skylab Road, Huntington Beach, CA 92647

Customer Care: 888.281.5698

Fax: 714.372.7003

www.dcsappliances.com

As product improvement is an ongoing process at DCS, we reserve

the right to change specifications or design without notice.

Part No. 17736 Rev. D

Litho in USA 02/2005

DCS améliore constamment ses produits et se réserve le droit de

modifier les spécifications ou la conception de ses produits sans

aucun préavis.

Loading...

Loading...