Page 1

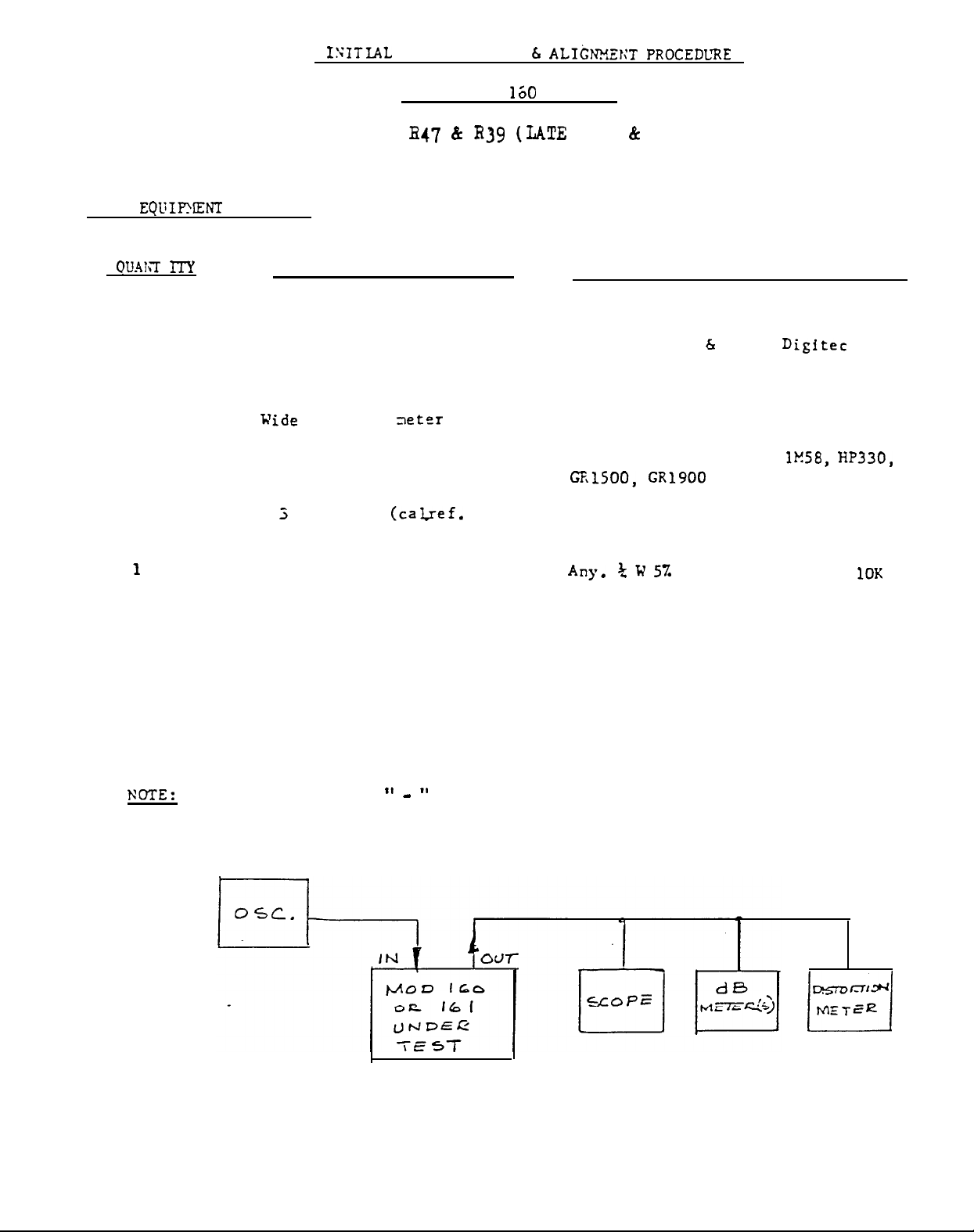

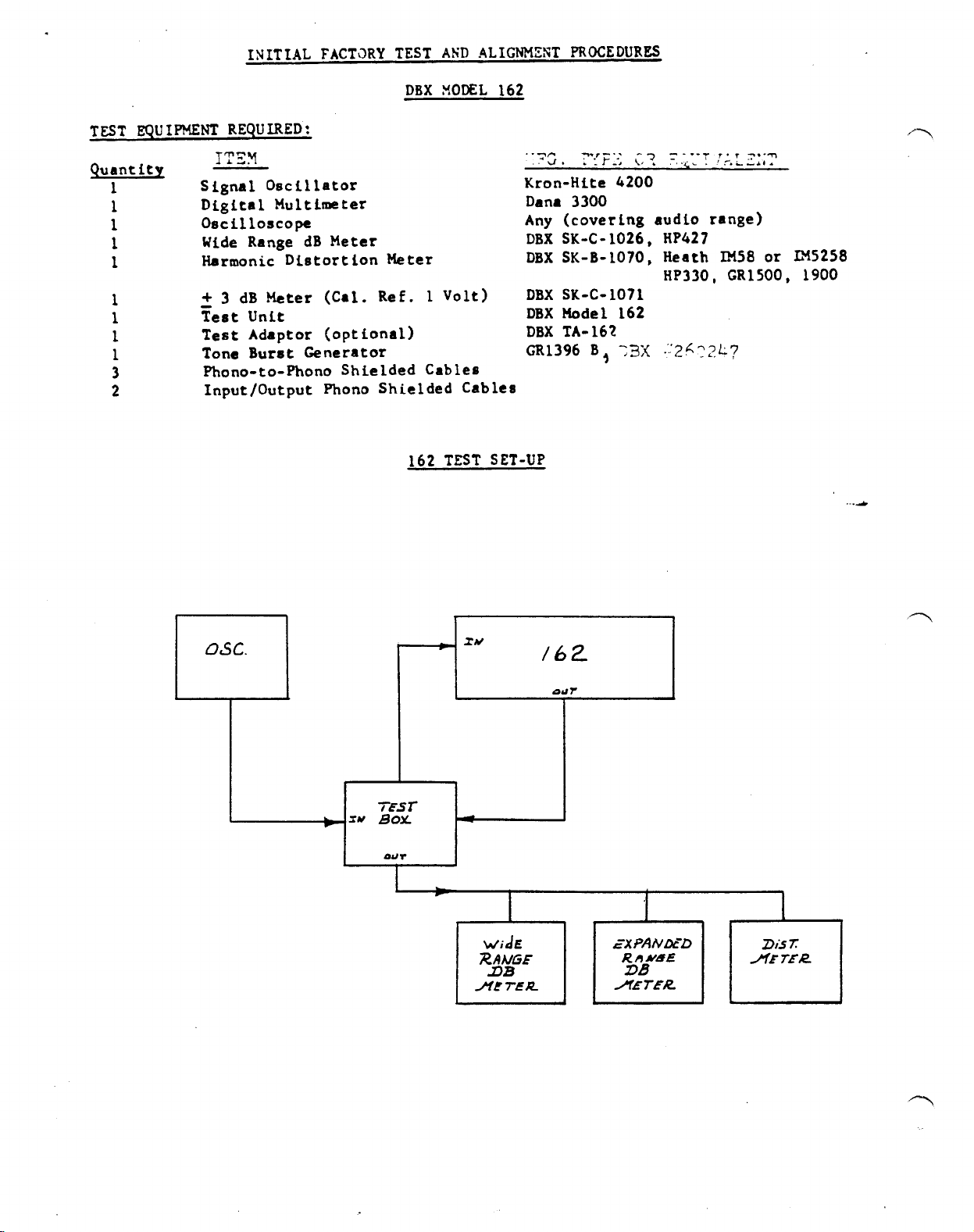

ISITIAL

FACTORY TEST 6

ALIGN?!ENT

PROCEDL7RE

TEST

EQUIWENT

QU_41\T l7-Y

1

1

1

1

1

1

DBX MODELS

WITHOUT

REQUIRED:

ITEM

Signal Oscillator

Digital Multimeter

Oscilloscope

Wide

.

Range db

Harmonic distortion meter

+ 3 db meter

(optional)

Ii47 & R39 (LATE

Deter

(cal_ref.

lb0

1 volt)

AND 161

160 & 161)

TYPE OR EQUIVALENT

Kron-Hite 4200, Heath 1272

Dana 3300, B

Any (covering audio band)

DBX

SK-C-1026, HP 427

DBX

SK-B-1070, Heath

GR1500, CR1900

DBX SKC-1071

&

K 282,

Digitec

lM58, HP330,

2110

1

NOTE:

Resistor Substitution Box

On model 160, tie It -

II

terminals to Gnd,

Any.

to 470K

k w 57.

values, typically

for normal testing.

10K

Revised 4-70-77

350325-03

Page 2

DBX MODELS 160 - 161

INITIAL TEST OUTLINE

SEQUENCE OF STEPS:

1) Supply Trim

2) RMS Trim

3) VCA & RMS Symmetry

4) Level Calibration

5) Threshold Calibration

6) Gain Change & input zero calibration

7) Output Calibration

8) Input Tracking

g)

Compression Circuit Calibration

10)

(R78)

Correct Value Test

11) Clipping

12) Response

13) Signal Clamping (Model 160 only)

14) Noise

15) Seal Pots

16) Burn-in

.

350025-03

Page 3

160/161

P-3 .

INITIAL PROCEDURE

Before

1)

2)

274)

3)

4)

applying

power to unit,

Supply Trim: Put resistance substitution box across R14 and measure

voltage at

+ 50 MV

place.

(+)

side of C7. Turn sub box until voltage is

(+14.950

to + 15.050).

Check (-) side of C8 to verify that it is -15 volts + 200

check mechanical zero of meter.

Solder appropriate resistor in

+15

-

DC

volts

MV

(-14.800 to -15.200)

RMS

Trim: (205) Connect sub box across the two RMS trim pins, and measure

the offset at the input pin of the RMS module.

voltage is zero + 15 MV,

-

(209) With input of 1.228 VRMS at 100 Hz,

the trim pin on the

RMS

and solder appropriate resistor in place.

place sub box between + v and

module.

Drop input level to - 60 db and adjust

sub box until a symmetrical waveform is observed on

Trim the sub box until

camp

pin, insert

value chosen in R36 spot (typ 8K to 75KR)

VCA & RMS Symmetry:

Set oscillator to 1.228 VRMS

a) 100 Hz (Tune for peak on distortion meter) Set front panel

compression knob to

control counter clockwise from

"0"

db.

Turn trim pots R27 and R34 until distortion reads minimum.

"3" and output gain to

"3~"

until external db meter reads

+20.

Turn threshold

Level Calibration:

Set oscillator to 1.228 VRMS

a)

100Hz

turn R63 until the voltage at the end of R79 (closest to

the center of unit) is

-.Oll

VDC

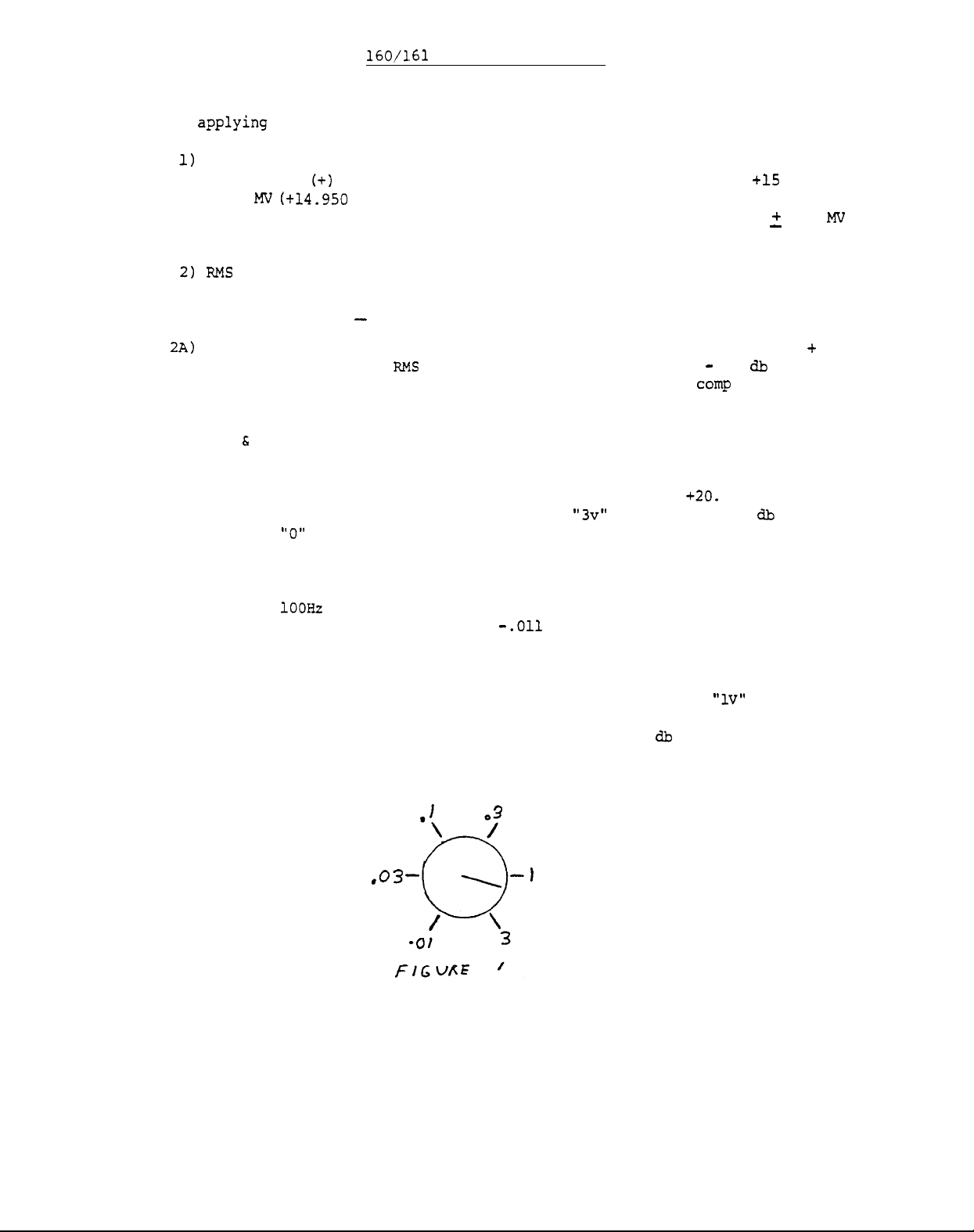

Threshold Calibration:

5)

Turn front panel

knob and position so that pointer indicates just past

"Threshold Control" until both led's are off.

"1V"

and retighten.

Loosen

(When both leds are off the input signal is at threshold level.) (See

fig. 1.)

Step the oscillator up and down in 10 db steps verifying that

the threshold level matches the input signal at successive calibration

marks on the threshold dial.

,03

350025-03

Page 4

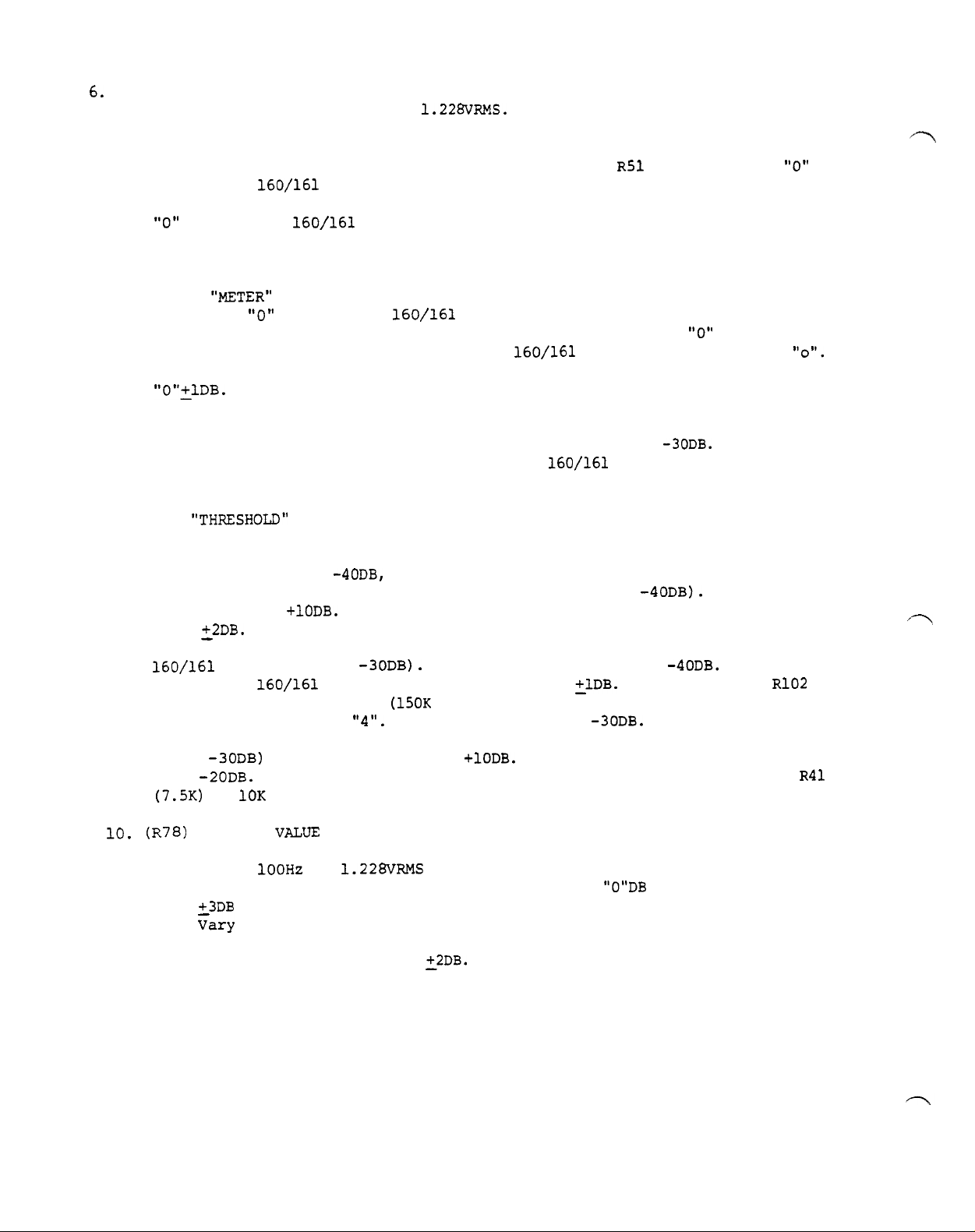

6.

GAIN CHANGE AND INPUT ZERO CALIBRATION

Set oscillator to 100 Hz at

6.1

Set "THRESHOLD" fully Cw.

6.2

"COMPRESSION" fully CCW.

Set

6.3

Place

6.4

on the DBX

Place

6.5

"0"

Repeat steps 6.4 and 6.5.

6.6

"METER" switch to

160/161

meter.

"METER" switch to "INPUT" and adjust rear panel pot R62 for precisely

on the DBX

160/161

meter.

1.228VRMS.

"GAIN CHANGE" and adjust

7. OUTPUT CALIBRATION

7.1 Place

precisely

"OUTPUT GAIN"

the

"MBTER"

switch to

"0"

on the DBX

control so that it points

"OUTPUT" and adjust

160/161

meter. If

overlay at the same time that the DBX

7.2 With the requirements of step 7.1 met,

"O+~lDB.

8. INPUT TRACKING

8.1 Place "METER" switch to

for a reading of precisely

"INPUT and step oscillator to

-30 on the DBX

P4

R51

for precisely

"0"

the "OUTPUT GAIN" control for

necessary adjust the knob on

"0"

precisely to

160/161

meter reads precisely

on the front

"0".

the external DB meter should read

Adjust R56

160/161

-3ODB.

meter.

/7

9. COMPRESSION CIRCUIT CALIBRATION

Set

9.1

9.2

9.3

9.4

"THRBSHOLD"

Set "COMPRESSION" fully CW.

Place "METER" switch to "OUTPUT"

Step oscillator to

fully CCW.

-4ODB,

and adjust the "OUTPUT GAIN" control for a

convenient reading on the external DB meter.

oscillator to

than

Adjust the

9.5

22DB.

160/161

on the DBX

meter.

+lODB.

"OUTPUT GAIN" control for a convenient reading on the DBX

160/161

to obtain this reading.

Set "COMPRESSION" to

9.6

(E.G.

The change on the External DB meter must be less

-3ODB).

meter should be less than

(150K

Nominal)

"4".

Step oscillator to

GAIN" control for a convenient reading on the External DB meter.

Step oscillator to

Adjust R43 to obtain this reading.

10K

(Recheck if R43 is adjusted1

VALUB

TEST

control fully CW.

1OOHz

at

1.228VRMS

"COMPRESSION" control from fully CCW to fully CW while

lo.

(~78)

read

10.1

10.2

10.3

10.4

(E.G.

-3ODB)

-2ODB.

(7.5K)

to

CORRECT

Set "THRESHOLD"

Apply

Set "OUTPUT GAIN" control for a reading of

+3DB

meter.

Vary

the

watching the External DB meter.

meter must be less than

+2DB.

(E.G.

-4ODB).

Step the oscillator to

Trim R58 with

Adjust "OUTPUT

+lODB.

+1DB.

-3ODB.

The External DB meter should

If necessary change

"0"DB

on the External

The change on the External DB

-4ODB.

Step the

j--Y

The change

RlO2

R41

Page 5

11) Clipping:

Step oscillator to +

output gain up until clipping is observed on the scope.

clean and should occur well after + 20

1Odb

and rotate compression control fully CCW.

Clipping should be

dbm

output for 160 and at

for 161.

12) Response:

Vary the frequency of the oscillator with

output of the unit is constant + 1 db from 30 hz to 20

Odb

output, and verify that the

KHZ.

13) Signal Clamping (Model 160 only)

For 160's turn power on and off,

does not contain a transient larger than the signal.

observing scope to check that the output

After power is switched

on the output should climb to normal, smoothly, in about a second.

14) Noise:

Short input terminals

and

observe noise output of unit.

With covers on,

noise should read less than -80 dbm.

15) Seal pots with wax (all except R62).

+18

P5

Turn

dbm

16) Burn-in:

Place in burn-in rack with appropriate power applied.

(120 or 240 volts).

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Loading...

Loading...