DBI SALA 2200401, 2200403, 2200402, Vacuum Anchor Horizontal Lifeline System, 2200405 User Instruction

...Page 1

Instructions for the following series products:

Vacuum Anchor HLL System

(See back page for specific model numbers.)

User Instruction Manual

Vacuum Anchor

Horizontal Lifeline System

This manual is intended to be used as part of an

employee training program as required by OSHA.

WARNING: This product is part of a personal fall arrest system. The user must f ollow the manufacturer’ s instructions for

each component of the system. These instructions must be provided to the user of this equipment. The user must read

and understand these instructions before using this equipment. Manufacturer’s instructions must be f ollowed for proper

use and maintenance of this equipment. Alterations or misuse of this equipment, or failure to follow instructions, may result

in serious injury or death.

IMPORTANT: If you hav e questions on the use, care, or suitability of this equipment for your application, contact DBI/SALA.

IMPORTANT: Record the product identification information from the ID label in the inspection and maintenance log in

section 9.0 of this manual.

1.0 APPLICATION

1.1 PURPOSE: The V acuum Anchor Horizontal Lifeline System is designed f or use as an anchoring means for one or

two personal fall arrest systems. Use the V acuum Anchor Horizontal Lif eline System where horizontal mobility and

fall protection are required. The system is used in conjunction with v acuum anchors.

1.2 LIMITATIONS: The following limits apply to the installation and use of the Vacuum Anchor Horizontal Lif eline

System. Other limitations may apply:

IMPORTANT : OSHA regulations state that horizontal lif elines shall be installed and used under the supervision of a

qualified person (see below for definition) as part of a complete personal fall arrest system that maintains a saf ety factor

of at least two .

Qualified Person: An individual with a recognized degree or prof essional certificate, and extensive knowledge and

experience in the subject field, who is capable of design, analysis, evaluation, and specification in the subject work,

project, or product. Refer to OSHA 1910.66, 1926.32, and 1926.502.

A. HORIZONT AL LIFELINE SPAN: The maximum span distance is 40 ft. (12.2 m) f or a single span system. F or

multiple span systems, the maximum span distance is 80 ft. (24.4 m) with a maximum subspan length of 40 ft

(12.2 m). The span length must be reduced when clear ance is limited. See section 3.0 f or clearance information.

B. ANCHORAGE STR UCTURE: The surf ace to which the V acuum Anchors are attached must meet the limitations

and strength requirements specified in instruction 5902157.

C. SYSTEM CAP A CITY : The maximum capacity of the Vacuum Anchor Horizontal Lif eline is two persons. The

maximum weight of each person, including tools and clothing, is 310 lbs. (141 kg).

1

© Copyright 2005, DB Industries, Inc.

Page 2

Figure 1 - Typical Single Span Horizontal Lifeline Installation

2

Page 3

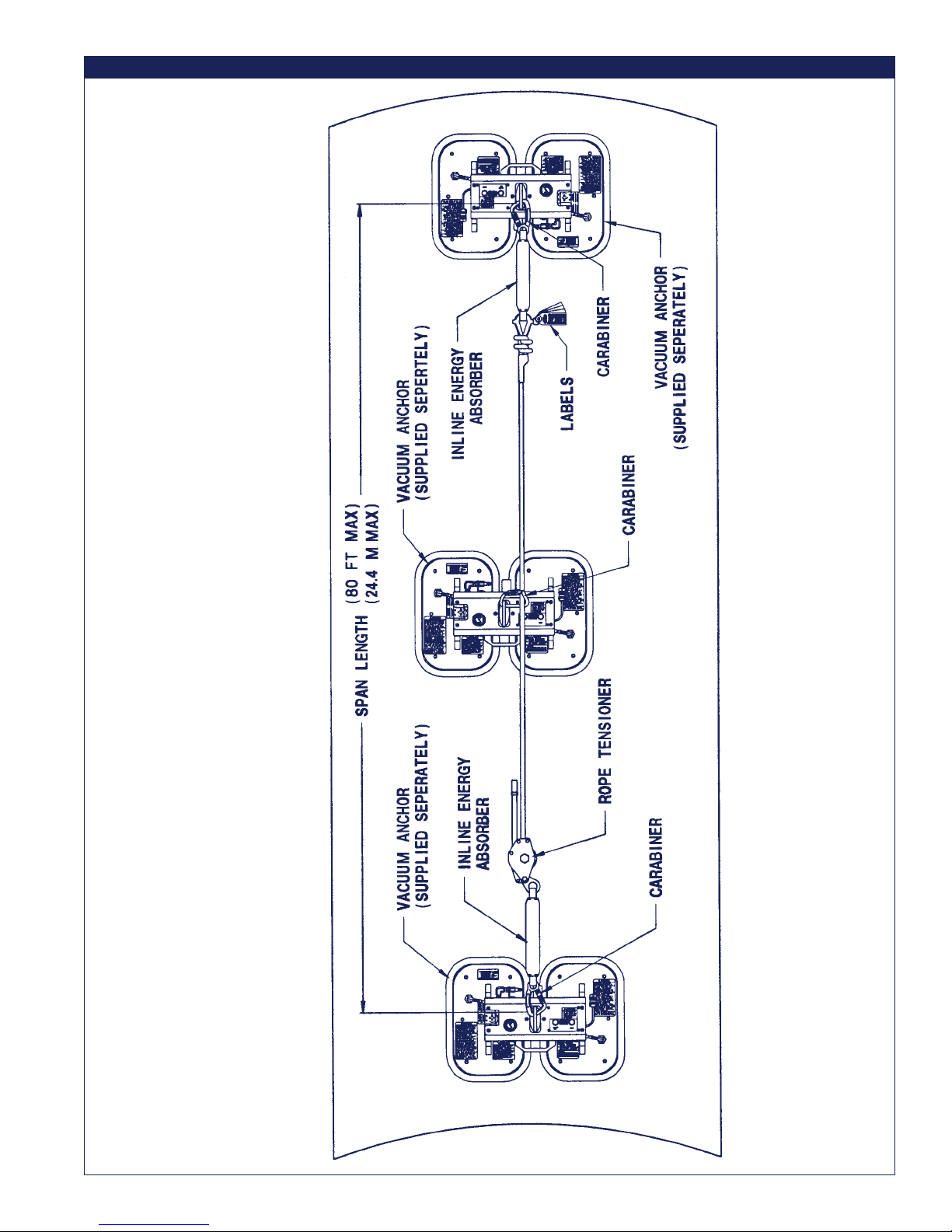

Figure 2 - Typical Multiple Span Horizontal Lifeline Installation

3

Page 4

D. CONNECTING SUBSYSTEM: A DBI/SALA Force 2 Energy Absorbing Lanyard must be used as the connecting

subsystem with the Vacuum Anchor Horizontal Lifeline .

E. FREE FALL: Whenev er possible , locate the horizontal lifeline such that the user is restrained from reaching a

fall hazard. If rigging as a restraint system is not possible, rig system such that the potential free fall is

minimized by positioning the horizontal lifeline as high and as far from the edge as possible, and by limiting the

lanyard length. P otential free f all m ust not e xceed 11 ft. (3.4 m).

F. SWING F ALLS: Swing falls occur when a w orker is positioned to the side of a horizontal lif eline when a fall

occurs. The force of striking an object in a swing f all may cause serious injury or death. Swing falls can be

minimized by working as close to the horizontal lifeline as possible.

G. F ALL CLEARANCE: There must be sufficient clearance below the w orker to arrest a fall bef ore striking the lower

level or obstruction. See section 3.0 for required clearance information.

H. BODY SUPPOR T : The Vacuum Anchor Horizontal Lif eline must be used as part of a personal fall arrest system

incorporating a full body harness.

I. ENVIRONMENT AL HAZARDS: Use of this equipment in areas with environmental hazards ma y require

additional precautions to reduce the possibility of injury to the user or damage to the equipment. Hazards may

include, but are not limited to; heat, chemicals, corrosive environments, high voltage power lines, gases, moving

machinery, and sharp edges. Contact DBI/SALA if y ou have questions about using this equipment where

environmental hazards exist.

J. TRAINING: This equipment must be installed and used by persons trained in its correct application and use . See

section 4.0.

1.3 APPLICABLE ST ANDARDS: Ref er to national standards, including ANSI Z359.1 and local, state, and f ederal

(OSHA 1910.66 and 1926.502) requirements for more information on personal fall arrest systems and associated

components.

2.0 SYSTEM REQUIREMENTS

2.1 PERSONAL F ALL ARREST SYSTEM COMPONENTS: The V acuum Anchor horizontal lif eline must be used with

DBI/SALA approved components and subsystems. Substitutions or replacements made with non-approved

components or subsystems may jeopardize compatibility of equipment and may effect the safety and reliability of

the complete system. Personal fall arrest components used with this system must meet all applicab le OSHA and

ANSI requirements. A full body harness must be used with this system.

2.2 PERSONAL FALL ARREST SYSTEM CONNECT ORS: Connectors are considered to be compatib le with

connecting elements when they have been designed to work together in such a way that their sizes and shapes do

not cause their gate mechanisms to inadvertently open regardless of how they become oriented. Contact DBI/SALA

if you have an y questions about compatibility.

Connectors (hooks, carabiners, and D-rings) must be capab le of supporting at least 5,000 lbs. (22kN). Connectors

must be compatible with the anchorage or other system components. Do not use equipment that is not compatible.

Non-compatible connectors may unintentionally disengage. See Figure 3. Connectors must be compatible in size,

shape, and strength. Self locking snap hooks and carabiners are required by ANSI Z359.1 and OSHA.

2.3 MAKING CONNECTIONS: Only use self-locking snap hooks and carabiners with this equipment. Only use

connectors that are suitable to each application. Ensure all connections are compatible in size, shape and strength.

Do not use equipment that is not compatible. Ensure all connectors are fully closed and locked.

DBI/SALA connectors (snap hooks and carabiners) are designed to be used only as specified in each product’s

user’s instructions. See Figure 4 f or inappropriate connections. DBI/SALA snap hooks and carabiners should not be

connected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

4

Page 5

Figure 3 - Unintentional Disengagement (Roll-out)

If the connecting element that a snap hook (shown) or carabiner attaches to is undersized or irregular in shape,

a situation could occur where the connecting element applies a force to the gate of the snap hook or carabiner .

This force may cause the gate (of either a self-locking or a non-locking snap hook) to open, allowing the snap

hook or carabiner to disengage from the connecting point.

Small ring or other

non-compatibly

shaped element

1. Force is applied to the

snap hook.

2. The gate presses against

the connecting ring.

3. The gate opens allowing the

snap hook to slip off.

NOTE: Large throat opening snap hooks should not be connected to standard size D-rings or similar objects which will

result in a load on the gate if the hook or D-ring twists or rotates. Large throat snap hooks are designed for use on fixed

structural elements such as rebar or cross members that are not shaped in a way that can capture the gate of the hook.

C. In a false engagement, where

Figure 4 - Inappropriate Connections

features that protrude from the

snap hook or carabiner catch on

the anchor and without visual

confirmation seems to be fully

engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope

lanyard or tie-back (unless the

manufacturer’ s instructions for

both the lanyard and connector

specifically allow such a

connection).

F. To any object which is shaped or

dimensioned such that the snap

hook or carabiner will not close and lock, or that roll-out could occur .

2.4 ANCHORAGE STRUCTURE: The anchorage structure must be rigid and capable of supporting at least 2,800 lbs.

(12.4 kN) along the axis of the horizontal lifeline. Anchorages m ust also support at least 2,800 lbs. (12.5 kn) applied

in all potential directions of fall arrest that are perpendicular to the axis of the horizontal lifeline. See Figure 5.

2.5 CONNECTING SUBSYSTEM: The connecting subsystem is the portion of the personal fall arrest system that

connects the horizontal lifeline subsystem to the harness fall arrest attachment element. A DBI/SALA Force 2

Energy Absorbing Lanyard must be used as the connecting subsystem with the V acuum Anchor Horizontal Lif eline.

3.0 OPERATION AND USE

WARNING: Do not alter or intentionally misuse this equipment. Consult DBI/SALA when using this equipment in

combination with components or subsystems other than those described in this manual. Some subsystem and component

combinations may interfere with the operation of this equipment. Use caution when using this equipment around moving

machinery , electrical hazards, chemical hazards, and sharp edges.

5

Page 6

Figure 5 - Anchorage Strength Requirements

WARNING: Consult your doctor if there is reason to doubt your fitness to saf ely absorb the shock from a fall arrest. Age

and fitness seriously affect a worker's ability to withstand falls. Pregnant women or minors must not use DBI/SALA self

retracting lifelines.

3.1 BEFORE EACH USE inspect this equipment according to section 5.0. Do not use this equipment if inspection

reveals an unsafe or defective condition. Plan your use of the fall protection system prior to exposing workers to

dangerous situations. Consider all factors affecting your safety before using this system.

A. Read and understand all manufacturer’s instructions for each component of the personal f all arrest system. All

DBI/SALA anchorage connectors, harnesses, and connecting subsystems are supplied with separate user

instructions. K eep all instructions for future ref erence.

B. Review sections 1.0 and 2.0 to ensure system limitations and other requirements have been followed. Review

applicable information regarding system clearance criteria. Ensure changes have not been made to the system

installation (i.e. length) or to the job site that could affect the required fall clearance. Do not use the system if

changes are required.

3.2 SYSTEM INST ALLA TION: Figures 1 and 2 show typical Single Span and Multiple Span V acuum Anchor horizontal

lifeline installations. The horizontal lif eline system should be positioned at a le v el that will minimiz e free f all while

allowing ease of use. The horizontal lif eline should be positioned near the work location to minimize swing f all

hazards. The connecting subsystem length should be k ept as short as possible to reduce the potential free fall and

required clearance distance. Both V acuum Anchors m ust be installed at approximately the same ele v ation so the

horizontal lifeline system is not sloped more than five degrees.

Step 1. Determine the locations of the Vacuum Anchors and evaluate the Anchorage Structure strength in

accordance with section 2.3. Determine the span length and evaluate the required clearance using Figures 6

and 7 along with Tables 1 and 2. F or Multiple Span Systems, use the length of the longest subsystem to

evaluate fall clearance.

Step 2. Attaching V acuum Anchors: Refer to the V acuum Anchor instruction 5902157 for complete installation

information.

Step 3. Secure each end of the horizontal lifeline to the Vacuum Anchors with the snap hook or carabiner. Loosen

and reposition the rope tensioner as required.

Step 4. Remov e the slack from the horizontal lif eline by pulling the rope through the tensioner b y hand. To tension

the horizontal lifeline, using a pointed bar or a 1-1/8 inch wrench, turn tensioning nut clockwise until

tensioning is no longer possible. Do not modify the rope tensioner to achieve greater lifeline tension. See

Figure 8. The final tension will be 300 to 450 lbs . (1.3 - 2.0 kN).

6

Page 7

Figure 6 - One Person

draynaLgnibrosbAygrenE2ecroFALAS/IBDahtiw

htgneLnapS

)m25.1(tf5)m38.1(tf6

)m75.4-m50.3(tf51-tf01)m83.6("11-'02)m86.6("11-'12

)m01.6-m75.4(tf02-tf51)m55.6("6-'12)m68.6("6-'22

)m26.7-m01.6(tf52-tf02)m19.6("8-'22)m12.7("8-'32

)m41.9-m26.7(tf03-tf52)m42.7("9-'32)m45.7("9-'42

)m76.01-m41.9(tf53-tf03)m06.7("11-'42)m09.7("11-'52

)m91.21-m76.01(tf04-tf53)m29.7("0-'62)m32.8("0-'72

3.3 OPERATION:

A. PERSONAL F ALL ARREST SYSTEM COMPONENTS: Inspect and don the full body harness according to

manufacturer’ s instructions. Attach the connecting subsystem (DBI/SALA F orce 2 Energy Absorbing Lany ard) to

the dorsal connection on the harness.

B. CONNECTING TO THE HORIZONT AL LIFELINE SYSTEM: Approach the work area using the appropriate

access equipment. Connect the carabiner or snap hook of your personal fall arrest system to the horizontal

lifeline. Connectors must meet all compatibility and strength requirements. See section 2.2.

C. HAZARDOUS SITUATIONS: Do not take unnecessary risks, such as jumping or reaching too far from the edge

of the working surface. Do not allow the connecting subsystem to pass under arms or between f eet. To avoid

swing fall hazards, do not work too far from either side of the horizontal lifeline.

metsySehtotdetcennoCrekroWenOrofecnaraelCderiuqeR-1elbaT

draynaLgnibrosbAygrenEfohtgneL

7

Page 8

Figure 7 - Two People

draynaLgnibrosbAygrenE2ecroFALAS/IBDahtiw

htgneLnapS

)m75.4-m50.3(tf51-tf01)m69.6("01-'22)m62.7("01-'32

)m01.6-m75.4(tf02-tf51)m61.7("6-'32)m74.7("6-'42

)m26.7-m01.6(tf52-tf02)m45.7("9-'42)m58.7("9-'52

)m41.9-m26.7(tf03-tf52)m29.7("0-'62)m32.8("0-'72

)m76.01-m41.9(tf53-tf03)m13.8("3-'72)m16.8("3-'82

)m91.21-m76.01(tf04-tf53)m96.8("6-'82)m99.8("6-'92

)m25.1(tf5)m38.1(tf6

D. TWO PERSONS CONNECTED T O THE HORIZONT AL LIFELINE SYSTEM: When a person falls while

connected to the horizontal lifeline, the system will deflect. If two persons are connected to the same horizontal

lifeline, and one person falls , the second person ma y be pulled off the working surface due to deflection. The

potential for the second person falling increases as the horizontal lif eline span length increases. The use of

independent horizontal lifeline systems for each person, or shorter span length, is recommended to minimize the

potential of the second person falling.

E. FREE FALL: Whenever possible , locate the

Figure 8 - T ensioner

horizontal lifeline such that the user is

restrained from reaching a fall hazard. If rigging

as a restraint system is not possible, rig

system such that the potential free fall is

minimized by positioning the horizontal lifeline

as high and as far from the edge as possible,

and by limiting the lanyard length. P otential free

fall must not exceed 11 ft. (3.4 m).

metsySehtotdetcennoCsrekroWowTrofecnaraelCderiuqeR-2elbaT

draynaLgnibrosbAygrenEfohtgneL

F. SHARP EDGES: Av oid working where the

connecting subsystem or other system

8

Page 9

components will be in contact with, or abrade against, unprotected sharp edges. If working around sharp edges

is unavoidable, a protective cover must be used to prevent cutting of the personal fall arrest system

components.

G. IN THE EVENT OF A F ALL: The responsible party must hav e a rescue plan and the ability to implement a

rescue. Tolerable suspension time in a full body harness is limited, so a prompt rescue is critical.

H. RESCUE: With the number of potential scenarios for a worker requiring rescue, an on-site rescue team is

beneficial. The rescue team is given the tools, both in equipment and technique, to perform a successful rescue.

3.4 SYSTEM REMOV AL: When no longer required, the horizontal lifeline system should be remo ved from the job site.

A. RELEASE TENSION ON THE HORIZONTAL LIFELINE:

Step 1. Lift the locking lever and position the pointed

bar under the locking lever as shown in Figur e 9.

Step 2. Push the pointed bar in a upward motion to

unlock the lev er.

Step 3. Loosen the tensioning nut by inserting the

pointed bar through the hole in the nut (or use a

1-1/8 inch wrench) and turn the tensioning nut

counterclockwise.

Step 4. Remove all knots and kinks in the rope before

storage.

Figure 9 - System Removal

4.0 TRAINING

4.1 It is the responsibility of the user to assure they are familiar with these instructions, and are trained in the correct

care and use of this equipment. User must also be aware of the operating characteristics, application limits, and the

consequences of improper use of this equipment. Training should be provided on a periodic basis to ensure rescuers

proficiency.

5.0 INSPECTION

5.1 BEFORE EACH INSTALLATION: Inspect all system components according to these or other manuf acturer’s

instructions. System components must be formally inspected by a qualified person, other than the user, at least

annually. Formal inspections should concentrate on visible signs of deterioration or damage to the system

components. Items found to be defective must be replaced. Do not use components if inspection reveals an unsafe

or defective condition. Record results of each inspection in the inspection and maintenance log in section 9.0 of this

manual.

5.2 INST ALLED SYSTEMS: An inspection of the horizontal lifeline system b y a qualified person must be conducted

after the system is installed. The system must be periodically inspected by a qualified person when left installed for

an extended period, and prior to each day’ s use. P eriodic inspections should be performed at least monthly , or more

frequently when site conditions and use warrant. Inspections of installed systems should include the inspection

steps listed in section 5.3.

5.3 BEFORE SYSTEM USE:

Step 1. Inspect all metal components (hooks, carabiners , rope tensioner , etc.) f or crac ks, def ormities, corrosion, or

other damage that may affect their strength or operation.

Step 2. Inspect rope for concentr ated wear . Material must be free of fra yed strands, brok en y arns, cuts, abrasions,

burns, and discoloration. The rope must be free of knots , e xcessiv e soiling, paint build-up , and rust staining.

Knots must be tight and thimbles must be held firmly in place. Check for chemical or heat damage;

indicated by brown, discolored, or brittle areas. Check for ultraviolet damage; indicated by discoloration and

splinters and slivers along the rope surface. All of the above factors are known to reduce rope strength.

9

Page 10

Step 3. Inspect the in-line energy absorber . Connecting hook must be free of cracks , corrosion, and other damage.

See Step 1. Inspect we bbing; material must be free of cuts, abrasions, b urns and discoloration. The

webbing should be free of excessive soiling, paint build-up, and rust staining. Check for chemical or heat

damage, indicated by brown, discolored or brittle areas. Check for ultraviolet damage, indicated by

discoloration and splinters and slivers along the web surface. Check for extension of the energy absorbing

device. Return the system for repairs if extended.

Step 4. Inspect system labels. The labels must be present and fully legible. See section 8.0.

IMPORTANT: If this equipment is subjected to the forces of a fall arrest, it must be remov ed from service and destroyed,

or returned to DBI/SALA fo r inspection or repair.

5.4 If inspection reveals an unsaf e or defective condition, remove unit from service and destroy, or contact DBI/SALA

for possible repair .

IMPORTANT: Only DBI/SALA or parties authorized in writing may make repairs to this equipment.

5.5 USER EQUIPMENT: Inspect harness and energy absorbing lanyard according to manufacturer’ s instructions.

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 CLEANING AND MAINTENANCE: Clean the horizontal lifeline system with water and a mild detergent. Wipe dry

with a clean, dry cloth and hang to air dry. Do not force dry with heat. An e xcessive build-up of dirt, paint, etc. may

prevent the system from w orking properly, and in severe cases, weaken the rope. A lubricant may be applied to the

moving parts of the rope tensioner. Do not allow lubricant to contact the rope tensioner teeth.

6.2 STORAGE: Store this horizontal lifeline system in a clean, dry environment, out of direct sunlight. A void areas where

chemical vapors are present. Thoroughly inspect the system after e xtended storage.

6.3 USER EQUIPMENT: Maintain, service, and store user equipment according to manufacturer’ s instructions.

7.0 SPECIFICATIONS

7.1 MATERIALS:

Rope Tensioner: Steel, plated

Lifeline Rope: Nylon

Carabiner: Aluminum Alloy

Energy Absorbers: Poly ester and Nylon

Snap Hooks: Alloy steel, plated

8.0 LABELING

8.1 These labels must be present and fully legible:

V acuum Anchor

Warning Label

V acuum Anchor

Clearance Label

10

Page 11

Vacuum Anc hor

ID Label

Inspection Log

Label

9.0 INSPECTION AND MAINTENANCE LOG

DA TE OF MANUF ACTURE: _______________________________________________________________________

MODEL NUMBER: ______________________________________________________________________________

DA TE PURCHASED: ____________________________________________________________________________

ETADNOITCEPSNISMETINOITCEPSNI

DETON

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

NOITCAEVITCERROCECNANETNIAM

DEMROFREP

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

11

Page 12

WARRANTY

Equipment offered by DBI/SALA is warranted against factory defects in workmanship and materials

for a period of two years from date of installation or use b y the owner , provided that this period shall

not exceed two years from date of shipment. Upon notice in writing, DBI/SALA will promptly repair

or replace all defective items. DBI/SALA reserves the right to elect to have any defective item

returned to its plant for inspection before making a repair or replacement. This warranty does not

cover equipment damages resulting from abuse, damage in transit, or other damage beyond the

control of DBI/SALA. This warranty applies only to the original purchaser and is the only one

applicable to our products, and is in lieu of all other warranties, expressed or implied.

This instruction applies to the following models:

2200401

2200402

2200403

2200404

2200405

2200406

2200425

Additional model numbers may appear on the next printing of these instructions

USA Canada

3833 SALA Way 260 Export Boulevard

Red Wing, MN 55066-5005 Mississauga, Ontario L5S 1Y9

Toll Free: 800-328-6146 Toll Free: 800-387-7484

Phone: (651) 388-8282 Phone: (905) 795-9333

Fax: (651) 388-5065 Fax: (905) 795-8777

www.salagroup.com www.salagroup.com

This manual is available for download at www.salagroup.com.

I S O

9 0 0 1

Certificate No. FM 39709

12

Form: 5902166

Rev: C

Loading...

Loading...