Page 1

The Ultimate in Fall Protection

USER INSTRUCTION MANUAL

EZ-Stop™ Energy Absorbing Lanyards

EZ-Stop™ Force2™ Energy Absorbing Lanyards

EZ-Stop™ WrapBax™2 Lanyards

EZ-Stop™ Modular Lanyards

Shockwave™2 Force2™ Energy Absorbing Lanyards

Model numbers: See Table 2

DBI-SALA

ENERGY ABSORBING LANYARDS

Please read this User Manual

carefully before installing and

using this product.

LANYARDS WITH INTEGRAL ENERGY ABSORBERS AND ENERGY ABSORBER COMPONENTS

USED IN PERSONAL FALL ARREST SYSTEMS (ANSI Z359.13)

This manual is intended to meet the Manufacturer’s Instructions as required by ANSI Z359.13, and should be used as part of an

employee training program as required by OSHA.

DANGER: This product is part of a personal fall arrest, climbing, or rescue system. Working at height creates inherent

and unavoidable risks which can result in serious injury or death. The user must follow the manufacturer’s instructions for

each component of the system. These instructions must be provided to the user of this equipment. The user must read and

understand these instructions before using this equipment. Manufacturer’s instructions must be followed for proper use and

maintenance of this equipment. Alterations or misuse of this product or failure to follow instructions may result in serious

injury or death.

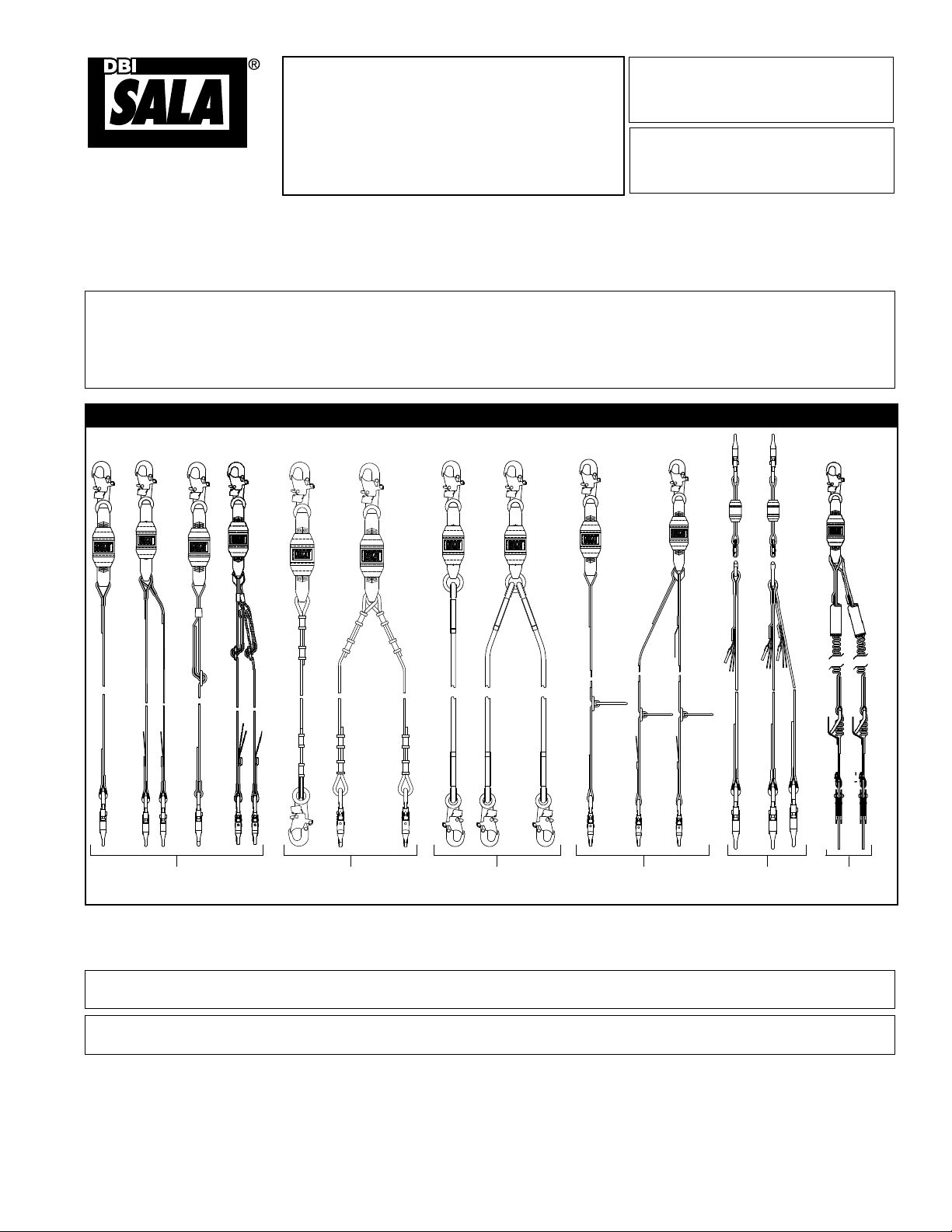

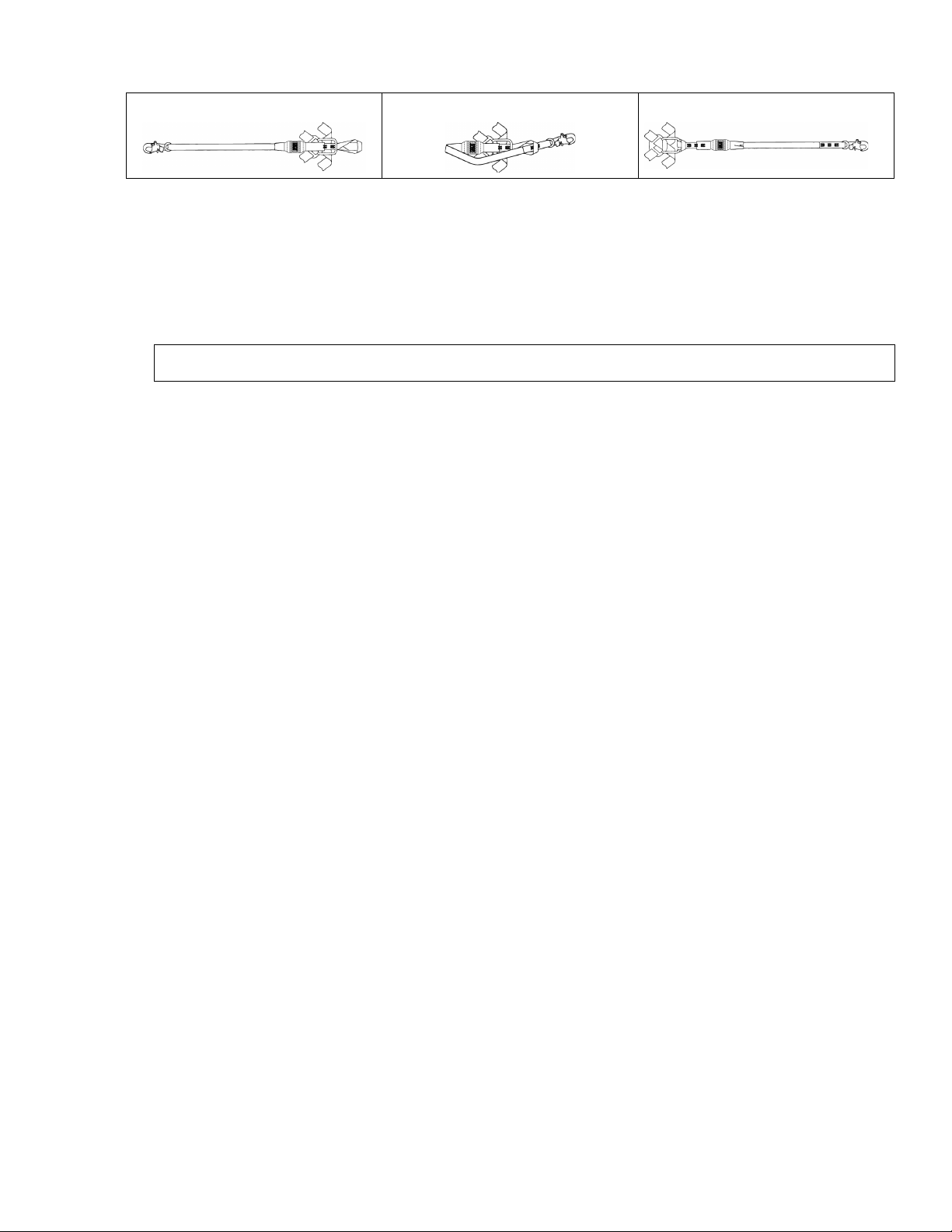

Figure 1 -

EZ-Stop™ Energy Absorbing Lanyards

Web Lanyards Tie-Back LanyardsRope Lanyards Modular

Cable Lanyards

Lanyards

Wind Energy

Lanyards

DESCRIPTION:

Figure 1 identifi es currently available DBI-Sala EZ-Stop Energy Absorbing Lanyard types.

IMPORTANT: If you have questions on the use, care, or suitability of this equipment for your application, contact

Capital Safety.

IMPORTANT: Before using this equipment, record the product identifi cation information from the ID label in the “Inspection

and Maintenance Log” in this instruction document.

Form No: 5903326 Rev: E

© Copyright 2014, DBI Industries, Inc.

Page 2

1.0 APPLICATIONS

1.1 PURPOSE: Energy absorbing lanyards are to be used as components in Personal Fall Protection Systems designed to

safely arrest a fall. See Figure 1 for the energy absorbing lanyard types covered by this instruction. Energy absorbing

lanyards are used in the following applications:

Fall Arrest: Fall arrest systems safely stop the user in a free fall from a height. The user can

then self-rescue or be rescued. Personal fall arrest systems typically include a full body harness

and an energy absorbing lanyard. Maximum arresting force must not exceed 1,800 lbs (8 kN).

Restraint: Restraint systems prevent the user from reaching a fall hazard (example: leading

edge roof work).

Rescue: The energy absorbing lanyard is used as a component of a back-up fall protection

system during rescue or as part of the primary rescue system.

1.2 LIMITATIONS AND REQUIREMENTS:

WARNING: Always consider the following application limitations and requirements before using this equipment.

A. CAPACITY: The EZ-Stop

Energy Absorbing Lanyard

is designed for use by persons with a combined weight (clothing,

tools, etc.) of no more than 310 lbs (141 kg)1. Make sure all of the components in your system are rated to a

capacity appropriate to your application.

B. FREE FALL: Personal fall arrest systems incorporating this equipment must be rigged to limit the free fall to 6 feet

(1.8 m) or less when using EZ-Stop energy absorbing lanyard models, or 12 feet (3.7 m) or less when using EZ-Stop

Force2 and EZ-Stop Leading Edge energy absorbing lanyard models.

C. FALL CLEARANCE: There must be suffi cient clearance below the user to arrest a fall before the user strikes the

ground or other obstruction. The clearance required depends on several factors:

• Deployment distance • Energy absorbing lanyard length • Movement of harness attachment element

• Free fall distance • Elevation of anchorage • Worker height

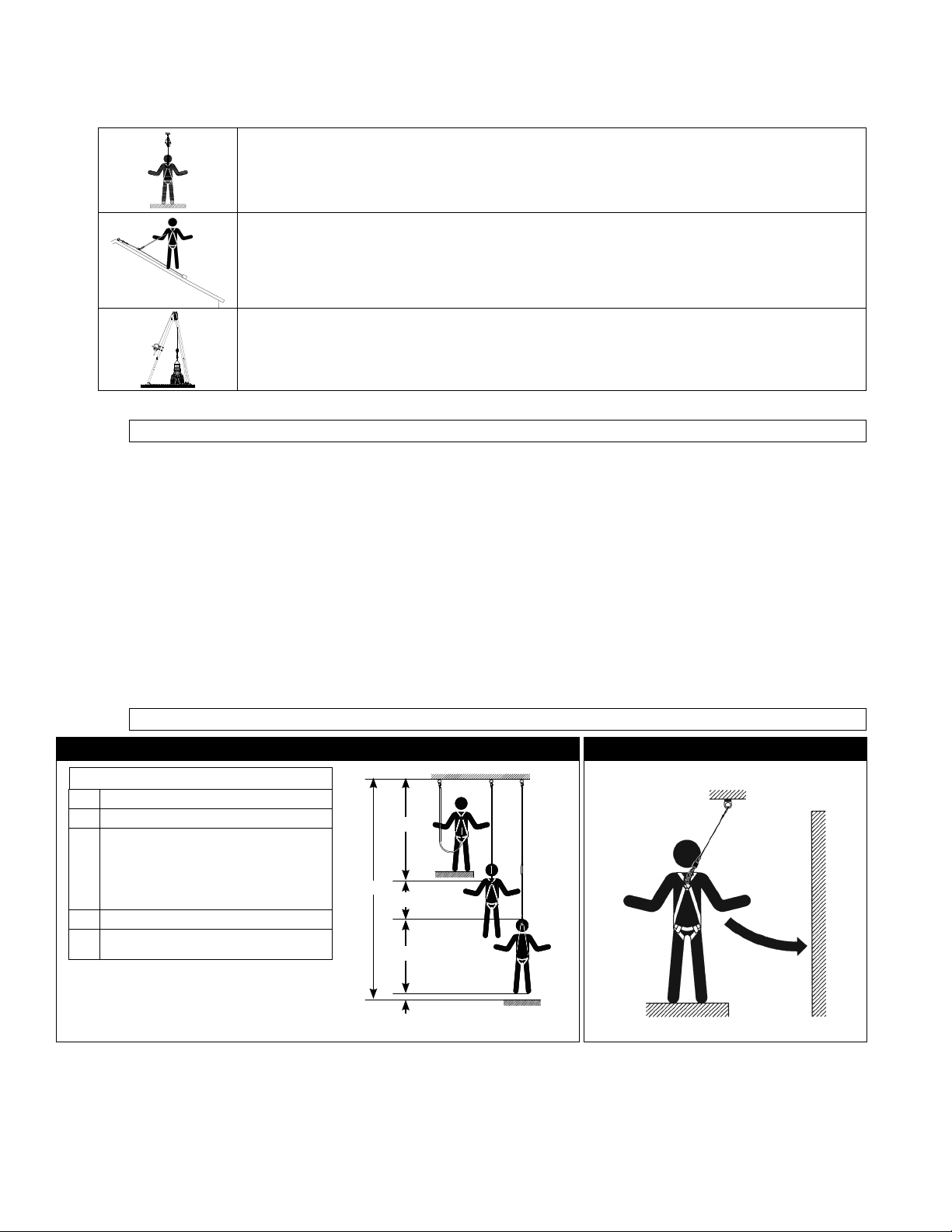

Figure 2 illustrates fall clearance calculation for an energy absorbing lanyard.

Figure 4 indicates the deployment distance of the personal energy absorber according to the user weight and free

fall distance.

D. SWING FALLS: Swing falls occur when the anchorage point is not directly above the point where a fall occurs (see

Figure 3). Minimize swing falls by working as close to and directly below the anchorage point as possible. Do not

permit a swing fall if injury could occur.

WARNING: The force of striking an object in a swing fall may cause serious injury or death.

Figure 2 – Fall Clearance Figure 3 – Swing Falls

RD = LL + DD + HH + C

RD Required Fall Clearance Distance

LL Length of Lanyard (Specifi ed on labeling)

DD Deployment Distance = 4 ft (1.2 m) except:

• for ANSI/OSHA Lanyards with Free Fall

greater than 6 ft (1.8 m) up to 12 ft (3.7

m), or user weights greater than 310 lbs

(141 kg) up to 420 lbs (191 kg), add 1 ft

(0.3 m): DD = 5 ft (1.5 m)

HH Height of Suspended Worker

C Safety Factor = 1.5 ft (0.5 m)

(Factors in D-Ring Slide and Harness Stretch.)

Example: Assuming a 6 ft (1.8 m) tall user with a

typical 6 ft (1.8 m) lanyard with 6 ft (1.8 m) Free Fall,

Fall Clearance calculation would be as follows:

RD = LL + DD + HH + C

RD = 6 ft + 4 ft + 6 ft + 1.5 ft = 17.5 ft

RD = 1.8 m + 1.2 m + 1.8 m + 0.5 m = 5.3 m

RD

LL

DD

HH

C

Swing

Fall

Hazard

E. ENVIRONMENTAL HAZARDS: Use of this equipment in areas with environmental hazards may require additional

precautions to prevent injury to the user or damage to the equipment. Hazards may include, but are not limited to;

heat, chemicals, corrosive environments, high voltage power lines, gases, moving machinery, and sharp edges.

F. LANYARDS FOR HIGH TEMPERATURE ENVIRONMENTS: Lanyards with Kevlar webbing are designed for use in

high temperature environments, with limitations: Kevlar webbing begins to char at 800° to 900° Fahrenheit. Kevlar

webbing can withstand limited contact exposure to temperatures up to 1,000° F. Polyester webbing loses strength at

300° to 400° F. PVC coating on hardware has a melting point of approximately 350° F.

1 Capacity: Most Capital Safety lanyards are factory tested to a maximum capacity of 310 lbs (141 kg). Force2 Lanyards are factory tested to a maximum capacity

of 420 lbs (191 kg).

2

Page 3

G. TRAINING: It is the responsibility of the user and the purchaser of this equipment to assure that they are familiar

with these instructions, trained in the correct care and use of, and are aware of the operating characteristics,

application limits, and the consequences of improper use of this equipment.

H. LEADING EDGE: EZ-Stop Leading Edge Energy Absorbing Lanyards have been successfully tested for horizontal

use and for falls over a steel edge without burrs (See Leading Edge models listed in Table 2). As a result, EZ-Stop

Leading Edge Energy Absorbing Lanyards may be used in situations where a fall may occur over similar edges such

as those found on steel shapes or metal sheeting. Avoid working where the lifeline will continuously or repeatedly

abrade against sharp or abrasive edges. Eliminate such contact or protect edges using a heavy pad or other means

I. ARC FLASH: Arc Flash lanyards

designed for use in environments where an arc fl ash (electrical explosion) could occur.

1.3 APPLICABLE STANDARDS: Refer to national standards including the ANSI Z359 family of standards on fall protection,

ANSI A10.32 and applicable local, state, and federal (OSHA) requirements governing occupational safety for more

information on Energy Absorbing Lanyards, Energy Absorbers and associated components.

in Table 2 meet the requirements of ASTM F887-13 for Type A Shock Absorbing Lanyards.

1.4 RESCUE PLAN: When using this equipment, the employer must have a rescue plan and the means at hand to implement

the rescue, as well as communicate that plan to users, authorized persons, and rescuers.

1.5 INSPECTION BEFORE USE: The energy absorbing lanyard must be inspected according to

instruction manual.

listed in Table 2

meet the test requirements of the ASTM F887-12 standard and are

EZ-Stop Arc Flash models listed

procedures in Section 4 of this

.

Figure 4 – Deployment Distance vs. Free Fall Distance, EZ-Stop™ Personal Energy Absorbers

EZ-STOP™ Personal Energy Absorbers

F

E

B

Deployment Distance (Feet)

A

Free Fall Distance (Feet)

FORCE2™ Personal Energy Absorbers

F

E

A 130 lb User Weight

B 220 lb User Weight

C 310 lb User Weight

D 420 lb User Weight

G

E Maximum Allowable Deployment Distance (OSHA)

C

F Maximum Allowable Deployment Distance (ANSI)

G Maximum Allowable Free Fall (OSHA/ANSI)

H Maximum Allowable Free Fall (OSHA)

I Maximum Allowable Free Fall (ANSI)

I

Deployment Distance (Feet)

D

H

C

B

A

Free Fall Distance (Feet)

3

Page 4

IMPORTANT: All distances shown in Figure 4 are based on results obtained during dynamic performance testing of EZ-Stop

energy absorbing lanyards in the ambient dry condition in accordance with ANSI Z359.13. Actual distances may vary depending

on environmental conditions, swing falls, etc. The maximum elongation of energy absorber value specifi ed on the product

labeling should be used when performing fall clearance calculations.

2.0 SYSTEM REQUIREMENTS

2.1 COMPATIBILITY OF COMPONENTS: Capital Safety equipment is designed for use with Capital Safety approved

components and subsystems only. Substitutions or replacements made with non-approved components or subsystems

may jeopardize compatibility of equipment and may effect the safety and reliability of the complete system.

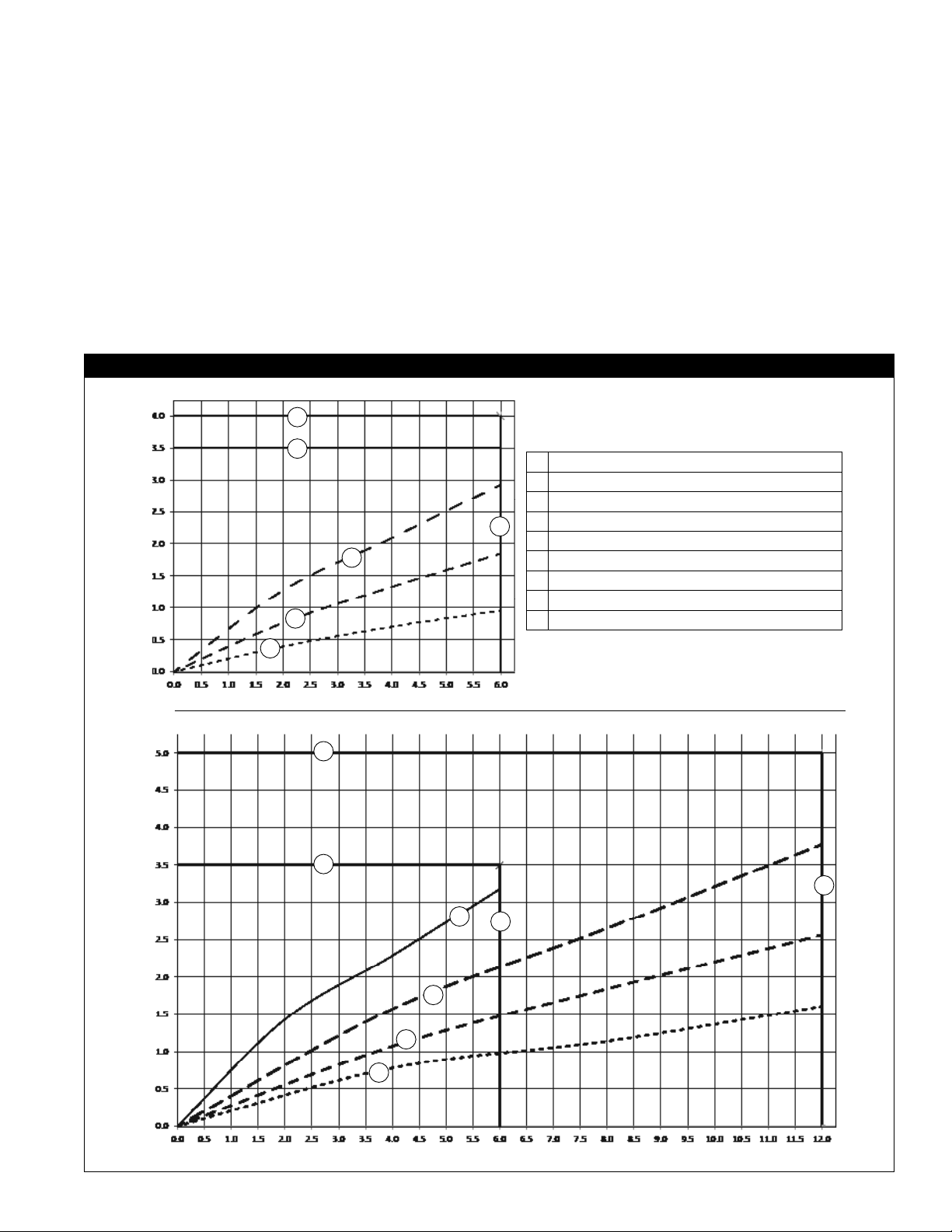

2.2 COMPATIBILITY OF CONNECTORS:

IMPORTANT: Use only connectors that are suitable to each application and are compatible with connecting elements.

• Connectors must be compatible with the anchorage or other system components.

• Connectors must be compatible in size, shape, and strength.

• Non-compatible connectors may unintentionally disengage (see Figure 5).

Connectors are considered to be compatible with connecting elements when they have been designed to work together in

such a way that their sizes and shapes do not cause their gate mechanisms to inadvertently open regardless of how they

become oriented. Contact Capital Safety if you have any questions about compatibility.

Self-locking snap hooks and carabiners are required by ANSI Z359.13 and OSHA. Connectors (hooks, carabiners, and

D-Rings) must be capable of supporting at least 5,000 lbs. (22.2 kN). Per ANSI Z359.12, connector gates must be able to

withstand a load of 3,600 lbs (16 kN).

Figure 5 – Unintentional Disengagement Figure 6 – Inappropriate Connections

If the connecting element to which a snap hook (shown) or carabiner attaches

is undersized or irregular in shape, a situation could occur where the connecting

element applies a force to the gate of the snap hook or carabiner. This force may

cause the gate (of either a self-locking or a non-locking snap hook) to open,

allowing the snap hook or carabiner to disengage from the connecting point.

Small ring or other

non-compatibly

shaped element

A. B. C. D.

E. F. G.

Force is applied to the

Snap Hook.

The Gate presses against

the Connecting Ring.

The Gate opens allowing

the Snap Hook to slip off.

2.3 MAKING CONNECTIONS: Capital Safety connectors (snap hooks and carabiners) are designed to be used only as

specifi ed in each product’s user’s instructions. See Figure 6 for inappropriate connections.

Capital Safety snap hooks and carabiners should not be connected:

A. To a D-Ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

WARNING: Large throat snap hooks should not be connected to standard size D-Rings or similar objects which will result in a

load on the gate if the hook or D-Ring twists or rotates, unless the snap hook complies with ANSI Z359.12 and is equipped with a

3,600 lb (16 kN) gate. Check the marking on your snap hook to verify that it is appropriate for your application.

C. In a false engagement, where features that protrude from the snap hook or carabiner catch on the anchor, and

without visual confirmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the manufacturer’s instructions for both the lanyard and

connector specifically allows such a connection).

F. To any object which is shaped or dimensioned such that the snap hook or carabiner will not close and lock, or that

roll-out could occur.

G. In a manner that does not allow the connector to align properly while under load (unless using Capital Safety snap

hooks that have been specifically designed and tested for these applications). Contact Capital safety for more

information.

CAUTION: Ensure all connectors are fully closed and locked.

2.4 EZ-STOP MODULAR ENERGY ABSORBING LANYARD MODELS: Refer to Operation and Use, Section 3.3 for

instructions on the assembly of the energy absorbing and lanyard components of the EZ-Stop Modular Energy Absorbing

Lanyard system.

4

Page 5

2.5 WEB LOOP CONNECTIONS: Some lanyards are designed to choke onto a web loop to provide a compatible connection.

To choke the lanyard on a web loop:

Insert the lanyard web loop through the

web loop or D-Ring on the harness.

Insert the appropriate end of the lanyard

through the lanyard web loop.

Pull the lanyard through the connecting web

loop to secure.

2.6 ANCHORAGE STRENGTH: Anchorages selected for use with the energy absorbing lanyards must have a strength capable

of sustaining the static load requirements of the intended fall protection application:

A. Fall Arrest: Anchorages selected for personal fall arrest systems (PFAS) shall have a strength capable of sustaining

static loads applied in the directions permitted by the system of at least:

1. Two times the average2 arresting force for certifi ed anchorages3, or

2. 5,000 pounds (22.2 kN) for non-certifi ed anchorages.

When more than one fall arrest system is attached to an anchorage, the strengths set forth in (1) and (2) above shall

be multiplied by the number of systems attached to the anchorage.

WARNING: Anchorages must be rigid. Large deformations of the anchorage will affect system performance, and may increase

the required fall clearance below the system, which could result in serious injury or death.

From OSHA 1926.500 and 1910.66: Anchorages used for attachment of PFAS must be independent of any anchorage

being used to support or suspend platforms and must be capable of supporting at least 5,000 lbs. (22.2 kN) per each

attached user. Or, be designed, installed, and used as part of a complete PFAS which maintains a safety factor of at

least two, and is supervised by a qualifi ed person.

B. Work Positioning: Anchorages selected for work positioning systems shall have a strength capable of sustaining

static loads applied in the directions permitted by the system of at least:

3. Two times the foreseeable force for certifi ed anchorages, or

4. 3,000 pounds (13.3 kN) for non-certifi ed anchorages.

When more than one work positioning system is attached to an anchorage, the strengths set forth in (3) and (4)

above shall be multiplied by the number of systems attached to the anchorage.

C. Restraint: Anchorages selected for restraint and travel restraint systems shall have a strength capable of sustaining

static loads applied in the directions permitted by the system of at least:

5. Two times the foreseeable force for certifi ed anchorages, or

6. 1,000 pounds (4.5 kN) for non-certifi ed anchorages.

When more than one restraint or travel restraint system is attached to an anchorage, the strengths set forth in (5)

and (6) above shall be multiplied by the number of systems attached to the anchorage.

D. Rescue: Anchorages selected for rescue systems shall have a strength capable of sustaining static loads applied in

the directions permitted by the system of at least:

7. Five times the foreseeable force for certifi ed anchorages, or

8. 3,000 pounds (13.3 kN) for non-certifi ed anchorages.

When more than one rescue system is attached to an anchorage, the strengths set forth in (7) and (8) above shall be

multiplied by the number of systems attached to the anchorage.

2

Average Arresting Force: ANSI Z359.13 requires 6 ft energy absorbers to have an average arresting force no greater than 900 lbs (4 kN) and a maximum deploy-

ment distance of 18 in. (1.2 m) without exceeding 1,800 (8 kN) maximum arresting force. 12 ft energy absorbers are required to have an average arresting force no

greater than 1,350 lbs (6 kN) and a maximum deployment distance of 60 in. (1.5 m) without exceeding 1,800 (8 kN) maximum arresting force.

3 Certifi ed Anchorage: An anchorage for fall arrest, positioning, or rescue systems that a qualifi ed person certifi es to be capable of supporting the potential fall forces

that could be encountered during a fall or that meet the criteria for certifi ed anchorage prescribed by the associated standard(s).

5

Page 6

3.0 OPERATION AND USE

WARNING: Do not alter or intentionally misuse this equipment. Consult Capital Safety when using this equipment in

combination with components or subsystems other than those described in this manual. Some subsystem and component

combinations may interfere with the operation of this equipment. Use caution when using this equipment around moving

machinery, electrical hazards, chemical hazards, sharp edges, or overhead materials that may fall onto the lanyard. Do not

loop the lanyard around small structural members. Failure to heed this warning may result in equipment malfunction, serious

injury, or death.

WARNING: Consult your doctor if there is reason to doubt your fi tness to safely absorb the shock from a fall arrest. Age and

fi tness seriously affect a worker’s ability to withstand falls. Pregnant women or minors must not use any DBI SALA full body

harness.

3.1 BEFORE EACH USE of this equipment, inspect it according to “Inspection Checklist” (Table 1).

3.2 PLAN your system before use. Consider all factors that will affect your safety during use of this equipment. The following

list gives important points to consider when planning your system:

A. ANCHORAGE: Select an anchorage that meets the requirements specified in “Limitations and Requirements”.

B. SHARP EDGES: Avoid working where system components may be in contact with, or abrade against, unprotected

sharp edges.

C. AFTER A FALL: Components which have been subjected to the forces of arresting a fall must be removed from

service and destroyed. See the “Inspection Checklist” (Table 1).

D. RESCUE: The employer must have a rescue plan when using this equipment. The employer must have the ability to

perform a rescue quickly and safely.

3.3 EZ-STOP MODULAR ENERGY ABSORBING LANYARD COMPONENTS ASSEMBLY: EZ-Stop Modular Energy Absorbing

Lanyard system components must be properly assembled. The system consists of an energy absorber (A) and a single or

twin leg lanyard (B) (See Figure 8).

Figure 8 – Modular EZ-Stop Energy Absorbing Lanyard Components

Figure 9 –

A B

TO ASSEMBLE EZ-STOP MODULAR LANYARD COMPONENTS:

Step 1: Figure 9: Orient the energy absorber female connector and the lanyard male connector as shown.

Step 2: Figure 10: Press the female connector locks (C) on each side of the connector to unlock the device. Insert

Step 3: Figure 11: Pull the energy absorber and lanyard in opposite directions to fully seat the male connector. The

the male connector and slide to the bottom of the female connector. Release both locks to capture the male

connector. The female connector locks must return to their fully extended position.

male connector must be securely locked in the position shown.

Figure 9 – Connector

Orientation

Figure 10 – Press Female

Connector Locks, Insert Male

Figure 11 – Fully Connected

Connector

C

C

WARNING: Do not use the modular lanyard

assembly if the locks do not return to the fully

extended position after following Steps 1, 2 and 3 in

Section 3.3.

An example of a failed connectiion is shown in

Figure 12. The lanyard male connector is not fully

inserted and locked within the energy absorber

female connector. This is an unsafe condition and the

modular lanyard components must not not be used.

Refer to Section 4.0 Inspection in this instruction

for procedures to determine unsafe or defective

component conditions.

Figure 12 – Failed Connection

6

Page 7

TO DISASSEMBLE EZ-STOP LANYARD MODULAR COMPONENTS:

Step 1: Figure 13: Press the female connector locks (C) on each side of the connector to unlock the device.

Step 2: Figure 14: While pressing the female connector locks, push the energy absorber and lanyard connectors

Step 3: Figure 15: Pull the male connector out of the female connector to separate the components.

toward each other.

Figure 13 –

Connector Locks

Figure 17 –

Press Female

Figure 14 – Push

Connectors Together

Figure 15 – Separate

Components

Figure 18 – Figure 19 –

C

C

3.4 CONNECTING TO BODY SUPPORT AND ANCHORAGE OR ANCHORAGE CONNECTOR: See Figure 16. Energy

absorbing lanyards should be connected to the body support fi rst and then connected to the rest of the system. Always

connect the energy absorber end of the lanyard to

body harness. DBI-SALA does not recommend using a body belt for fall arrest applications. If using a body belt, connect

the energy absorbing end of the lanyard to the D-Ring and position the belt so the D-Ring is located on the back side of the

body.

Connect the lanyard end to the anchorage or anchorage connector. Some anchorage connector devices may be supplied

with a permanently attached energy absorber. Use of an additional energy absorber or energy absorbing lanyard with this

lanyard system is not recommended.

the D-Ring on the back between the shoulders (dorsal D-Ring) on a full

Figure 16 – Anchorage Connection Examples

A Dorsal D-Ring, Full Body Harness

B Energy Absorbing Lanyard

C Anchorage Connector

D Fall Arrestor

C

C

C

D

B

3.5 A. 100% TIE-OFF LANYARD CONSIDERATIONS: Commonly known as 100% tie-off, “Y” type, twin leg, or double

Other practices that must be followed in order to use a 100% tie-off type lanyard safely include:

lanyards; these energy absorbing lanyards can be used to provide continuous fall protection while ascending,

descending, or moving laterally. With one lanyard leg attached, the worker can move to a new location, attach

unused lanyard leg, and disconnect attached leg. This procedure is repeated until a new location is reached.

1. The energy absorber portion of the lanyard must be connected to the dorsal D-Ring only. Use only the snap hook (or

other connector provided) to attach the energy absorber portion directly to the harness dorsal D-Ring. See Figures 17

and 18.

2. Do not connect the energy absorber to the anchorage. See Figure 19.

Figure 17 – Correct

Attachment

Energy

Absorber

attached to

dorsal D-Ring.

Figure 18 – Incorrect

Attachment

Energy

Absorber

not attached

to dorsal

D-Ring.

B

A AA

B

Figure 19 – Incorrect

Attachment

Do not attach

Energy

Absorber to

anchor.

7

Page 8

3. Do not attach the unused leg of the lanyard back to the harness at any location unless a specially designed lanyard

retainer is provided for this purpose. See Figure 20.

4. Connection of both lanyard legs to separate anchorage points is acceptable. See Figure 21.

5. When leapfrogging from one anchorage point to the next (such as traversing a horizontal or vertical structure) do not

connect to anchorage points that are further apart than the lanyard length (as marked on the lanyard label).

See Figure 22.

Figure 20 – Acceptable

Designed Retainers

Energy absorber attached to dorsal D-Ring. Lanyard legs conneced to

6. Never connect more than one person to a “Y” type lanyard at a time.

7. Do not allow any lanyard to pass under arms or legs during use.

Attaching a Tie-Back Lanyard: See Figure 23. Place

the tie-back lanyard over the anchoring structure. Ensure

the lanyard is not twisted. Adjust the floating D-Ring so it

hangs below the anchoring structure. Attach the lanyard

end hook to the floating D-Ring.

Ensure the lanyard is cinched tight around the anchorage

during use.

Figure 21 – Acceptable

Attachment

separate anchorage points.

Figure 22 – Maximum

Lanyard Reach

Do not attach to anchorage

points wider than lanyard length.

Figure 23 – Attaching Tie-Back

A

A Do not allow gate to contact anchorage member.

B Proper Connection.

C Improper connection.

Attaching a WrapBax

Lanyard: See Figure 24. Snap

hooks and WrapBax hooks

operate in the same manner.

Grip the hook handle in one

hand. With your index finger,

depress the locking mechanism

in. With your thumb, pull back

the gate latch. As the gate latch

is pulled back, the gate will

open. Release your grip and the

gate will close.

See Figure 25. Wrap the WrapBax lanyard around an appropriate

anchor (see section 2.6), then open the gate of the WrapBax

hook and pass the lanyard through the hook. The lanyard may

make more than one wrap around the anchor, but the lanyard

may only be passed through the WrapBax hook once. Make sure

the lanyard is captured and the gate closes completely.

WARNING: Only the WrapBax hook may be used to snap

back directly onto the WrapBax lanyard.

Figure 24 – Snap Hook and WrapBax Hook Operation

Pull back gate

with thumb

Depress locking

mechanism with

index finger

Step 1 Step 2 Step 1 Step 2

B

C

Figure 30 –

Pull back gate

with thumb

Depress locking

mechanism with

index finger

Figure 25 – Attaching WrapBax

8

Page 9

B. CONNECTING TO THE BODY SUPPORT:

Connect the energy absorbing lanyard or energy absorber to the D-Ring

on the back between the shoulders (dorsal D-Ring) on a full body harness. Connect so the energy absorber portion of

the lanyard is on the body support side. DBI-SALA does not recommend using a body belt for fall arrest applications. If

using a body belt, connect the energy absorbing lanyard or energy absorber to the D-Ring and position the belt so the

D-Ring is located on the back side of the body.

C. ATTACHING A LANYARD WITH WEB LOOPS: See Section 2.5.

D. CONNECTING TO A ROPE GRAB (FALL ARRESTOR): It is recommended the lanyard end (vs. the energy absorber

end) be attached to the rope grab. This recommendation is made to reduce possible interference with the operation

of the rope grab by the energy absorber “pack.” Attaching a component style energy absorber to a rope grab is not

recommended, with the exception of a “direct-coupling” between a rope grab and a harness. Some rope grabs may

be supplied with a permanently attached energy absorbing lanyard. For these cases, use of an additional energy

absorber connected between the rope grab and the body support is not recommended.

In some cases it may be permissible to couple an energy absorber component between the anchorage (or anchorage

connector) and the rope grab lifeline. In all cases, ensure the length of the energy absorber or energy absorbing

lanyard does not exceed the rope grab manufacturer’s recommended maximum connection length (3 feet [.9 m]

maximum per ANSI Z359.1).Consult the manufacturer’s instructions provided with the Rope Grab for further details.

E. CONNECTING TO SELF RETRACTING LIFELINE: DBI-SALA does not recommend connecting an energy absorbing

lanyard or energy absorber component to a self retracting lifeline. Special applications do exist where it may be

permissible. Contact DBI-SALA if considering connecting an energy absorbing lanyard to a self retracting lifeline.

3.6 AFTER USE, return the lanyard for cleaning or storage as described in section 5.0.

4.0 INSPECTION

4.1 i-Safe™ RFID TAG: Some lanyards include an i-Safe Radio

Frequency Identifi cation (RFID) tag (Figure 26). The RFID

tag can be used in conjunction with the i-Safe handheld

reading device to simplify inspection and inventory control

and provide records for your fall protection equipment.

If you are a fi rst-time user, contact a Capital Safety

Customer Service representative (see back cover); or if you

have already registered, go to isafe.capitalsafety.com. Follow

the instructions provided with your i-Safe handheld reader or

software to transfer your data to your database.

Figure 26 – i-Safe RFID Tag

IMPORTANT: The i-Safe Identifi cation Number on the RFID Tag is for purposes of electronic record keeping with the i-Safe system.

Where the Serial Number is printed on the product’s ID Label (see ‘Labeling”), the i-Safe Identifi cation Number and Serial Number may

be different numbers.

4.2 INSPECTION FREQUENCY:

The Energy Absorbing Lanyard shall be inspected by the user before each use and,

additionally, by a competent person4 other than the user at intervals of no more than one year5. Inspection procedures are

described in the “Inspection Checklist” (Table 1). Results of each Competent Person inspection should be recorded on copies

of the “Inspection and Maintenance Log” (lanyards) or tracked with the i-Safe system.

4.3 UNSAFE OR DEFECTIVE CONDITIONS: If inspection reveals an unsafe or defective condition, remove the lanyard from

service and destroy. Lanyards are not repairable.

4.4 PRODUCT LIFE: The functional life of the lanyard is determined by work conditions and maintenance. As long as the

lanyard passes inspection criteria, it may remain in service.

WARNING: Failure to properly inspect the lanyard could result in product failure and serious injury or death.

Table 1 – Inspection Checklist

Component: Inspection: (See Section 4.2 for Inspection Frequency) Pass Fail

Lanyard Hardware Inspect energy absorbing lanyard or energy absorber component hardware

Modular Lanyard

Hardware

(snap hooks, adjusters, swages, thimbles, etc.). These items must not be

damaged, broken, distorted, or have any sharp edges, burrs, cracks, worn

parts, or corrosion. Ensure the connecting hooks work properly. Hook gates

must move freely and lock upon closing. Ensure adjusters (if present) work

properly.

Inspect modular lanyard connection components for proper operation. Using

the procedures in Section 3.3 of this instruction, confi rm that female connector

locks move freely when depressed and that they securely capture male

connectors when the male and female components are assembled.

4 Competent Person: One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazard-

ous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

5 Inspection Frequency: Extreme working conditions (harsh environments, prolonged use, etc.) may require increasing the frequency of competent person

inspections.

9

Page 10

Table 1 – Inspection Checklist

Webbing & Stitching

(Figure 27)

Wire Rope

(Figure 28)

Energy Absorber &

Impact Indication

(Figure 29)

Labels All labels should be present and fully legible (see Section 7 ‘Labeling’).

The webbing material must be free of frayed, cut, or broken fi bers. Check

for tears, abrasions, mold, burns, or discoloration, etc. The webbing must be

free of knots, excessive soiling, heavy paint buildup, and rust staining. Check

for chemical or heat damage indicated by brown, discolored, or brittle areas.

Check for ultraviolet damage indicated by discoloration and the presence of

splinters or slivers on the webbing surface. All of the above factors are known

to reduce webbing strength. Inspect stitching for pulled or cut stitches. Broken

stitches may be an indication the energy absorbing lanyard or energy absorber

component has been impact loaded and must be removed from service.

Inspect entire length of the wire rope. Always wear protective gloves when

inspecting wire rope. Inspect for broken wires by passing cable through gloved

hands, fl exing it every few inches to expose breaks. Broken wires can be

removed by bending the wire back and forth parallel to the rope length. Do not

attempt to pull wires out of rope. Remove the energy absorbing lanyard from

service immediately and destroy if there are six or more randomly distributed

broken wires in one lay, or three or more broken wires in one strand in one lay.

A “lay” of wire rope is the length of wire rope that it takes for a strand (the

larger groups of wires) to complete one revolution or twist along the rope.

Remove the energy absorbing lanyard from service immediately and destroy

if there are any broken wires within 1 inch of the metal compression sleeves

(swages) at either end of the assembly. The wire rope should be free of

corrosion.

Inspect the energy absorber to determine if it has been activated. There

should be no evidence of elongation. Ensure energy absorber cover is secure

and not torn or damaged.

System & Subsystem

Components

Frayed

Heavily

Soiled

Welding

Burns

Inspect each system component or subsystem according to manufacturer’s

instructions and confi rm that it can continue to be used.

Figure 27 - Webbing

Cut

Figure 28 - Wire Rope

Kinked Wire Rope

Broken Wires

Bird-Caging

Welding Splatter

Figure 29 – Impact Indicators

The following items indicate the Energy Absorber

has been subjected to impact loading and has been

activated:

1. Torn webbing.

2. Torn or broken cover.

3. Open end or ripped out stitching.

4. Measured length is more than 15 cm (6 in.) longer

than the length marked on the label.

2

3

1

4

5.0 MAINTENANCE, SERVICING, STORAGE

5.1 Clean lanyard with water and a mild detergent solution. Wipe off hardware with a clean, dry cloth, and hang to air dry. Do

not force dry with heat. An excessive buildup of dirt, paint, etc., may prevent the lanyard from working properly, and in

severe cases degrade the webbing or rope to a point where it has become weakened and should be removed from service.

If you have any questions concerning the condition or cleaning of your lanyard, doubts about putting it into service or

require more information, contact Capital Safety.

5.2 Additional maintenance and servicing procedures (replacement parts) must be completed by a factory authorized service

center. Authorization must be in writing. Do not disassemble the unit. See Section 4.2 for inspection frequency.

5.3 Store the lanyard in a cool, dry, clean environment out of direct sunlight. Avoid areas where chemical vapors may exist.

Thoroughly inspect the lanyard or energy absorber component after extended storage.

10

Page 11

6.0 MODELS AND SPECIFICATIONS

Table 2 - EZ-Stop Lanyard Model Numbers Covered By This Instruction

WEB LANYARDS

1246010

1246011

1246012

1246013

1246014

1246015

1246016

1246017

1246018

1246019

1246021

1246022

1246023

1246024

1246025

1246026

1246027

1246028

1246029

1246037

1246038

1246039

1246053

1246054

1256055

1246056

1246070

1246071

1246072

1246073

1246074

1246075

1246077

1246078

1246079

1246080

1246081

1246083

1246085

1246086

1246087

1246088

1246089

1246090

1246091

1246093

1246094

1246098

1246099

1246100

1246101

1246102

1246103

1246104

1246107

1246109

1246110

1246113

1246116

1246120

1246121

1246122

1246123

1246124

1246125

1246130

1246138

1246139

1246140

1246141

1246142

1246143

1246144

1246145

1246147

1246148

1246149

1246150

1246151

1246152

1246153

1246155

1246156

1246157

1246158

1246159

1246160

1246161

1246162

1246163

1246164

1246165

1246166

1246167

1246168

1246169

1246170

1246171

1246172

1246173

1246174

1246176

1246177

1246180

1246192

1246193

1246194

1246196

1246197

1246198

1246199

1246200

1246201

1246202

1246203

1246204

1246205

1246206

1246207

1246208

1246212

1246213

1246214

1246215

1246216

1246217

1246218

1246221

1246222

1246223

1246225

1246226

1246227

1246228

1246229

1246230

1246231

1246232

1246233

1246234

1246235

1246236

1246239

1246240

1246241

1246242

1246243

1246245

1246246

1246247

1246249

1246246

1246248

1246250

1246251

1246252

1246255

1246256

1246264

1246265

1246266

1246267

1246268

1246269

5002045

ROPE LANYARDS

1246270

1246271

1246272

1246273

1246274

1246275

1246276

1246277

1246278

1246279

1246280

1246281

1246284

1246285

1246286

1246287

1246290

1246291

1246294

1246295

MODULAR LANYARDS

1246040

1246041

1246042

1246043

1246044

1246045

1246046

1246047

1246048

1246049

1246050

1246051

1246052

1246060

1246061

1246064

1246065

1246076

LEADING EDGE

LANYARDS

1246066

1246067

1246068

1246069

1246178

1246260

1246261

1246262

CABLE LANYARDS

1246135

1246136

1246181

1246182

1246183

1246184

1246186

1246187

1246188

1246189

1246190

1246244

1246185

ARC FLASH LANYARDS

1246263

1246298

1246299

1246300

1246301

1246302

1246303

1246304

1246305

1246306

1246307

1246308

1246309

1246310

1246311

1246313

1246314

1246315

1246316

1246317

1246318

1246319

1246320

1246321

1246322

1246323

1246324

1246337

1246340

1246341

1246312

WIND ENERGY

LANYARDS

1246030

1246032

Lanyard Model Energy Absorber Specifications Adjustable/

Fixed Length

EZ-Stop Energy

Absorber Component

Fixed Length EZ-Stop

Web Leg Lanyards

Adjustable Length

EZ-Stop Web Leg

Lanyards

EZ-Stop Cable Leg

Lanyards

EZ-Stop Rope Leg

Lanyards

EZ-Stop Elastic Leg

Lanyards

EZ-Stop Resist Web

Leg Lanyards

EZ-Stop Tie-Back Web

Leg Lanyards

EZ-Stop WrapBax2

Web Leg Lanyards

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

Fixed Not applicable.

Fixed

Adjustable

Fixed

Fixed

Fixed

Fixed

Fixed

Fixed

11

Lanyard Specifications

3/4 - 1 in. (1.9 - 2.5 cm) polyester

web, 8,000 - 9,800 lbs. (35.6 - 43.6

kN) tensile strength.

1 in. (2.5 cm) polyester web, 9,800

lbs. (43.6 kN) tensile strength.

1/4 in. (.64 cm) diameter steel cable,

galvanized, vinyl jacket, 7,000 lbs.

(31.1 kN) tensile strength.

1/2 in. (1.3 cm) nylon/polyester rope,

10,000 lbs. (44.5 kN) tensile strength.

1 3/8 in. (3.5 cm) tubular polyester

web, elastic web, 6,600 lbs. (29.4 kN)

tensile strength

1 in. (2.5 cm) polyester web,

polyurethane coated, 9,800 lbs. (43.6

kN) tensile strength.

1 in. (2.5 cm) polyester web, tubular

polyester web cover, 9,800 lbs. (43.6

kN) tensile strength.

1 3/6 in. (3.0 cm) nylon web, 13,000

lbs. (57.8 kN) tensile strength

Page 12

Lanyard Model Energy Absorber Specifications Adjustable/

Lanyard Specifications

Fixed Length

EZ-Stop Modular

Energy Absorber

EZ-Stop Modular

Lanyard Legs

EZ-Stop Arc Flash

Fixed Length Web Leg

Lanyards

Adjustable Length EZ-

Stop Arc Flash Web

Leg Lanyards

EZ-Stop Arc Flash

Tie Back Web Leg

Lanyards

Shockwave2 Force2

Wind Energy Web Leg

Lanyards

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular polyester web wear pad (both

ends), nylon outer cover, polyester thread, tensile strength

greater than 5000 lbs.

Not applicable.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular Nomex®/Kevlar® web wear

pad (both ends), Nomex®/Kevlar® outer cover, Kevlar®

thread, tensile strength greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular Nomex®/Kevlar® web wear

pad (both ends), Nomex®/Kevlar® outer cover, Kevlar®

thread, tensile strength greater than 5000 lbs.

1 1/4 - 1 1/2 in. (3.2 - 3.8 cm) aromatic polyester web

strength member, tubular Nomex®/Kevlar® web wear

pad (both ends), Nomex®/Kevlar® outer cover, Kevlar®

thread, tensile strength greater than 5000 lbs.

1 1/2 in. (3.8 cm) aromatic polyester web strength

member, tubular polyester web wear pad (both ends), nylon

outer cover, polyester thread, tensile strength greater than

5000 lbs.

Fixed Not applicable.

Fixed

Fixed

Adjustable

Fixed

Fixed

Specific to lanyard model; see

applicable lanyard leg specification.

1 in. (2.5 cm) Kevlar® or

polyurethane coated polyester web,

9,800 lbs. (43.6 kN) tensile strength.

1 in. (2.5 cm) Kevlar® web, 9,800

lbs. (43.6 kN) tensile strength.

1 in. (2.5 cm) Kevlar® web, 9,800

lbs. (43.6 kN) tensile strength.

2 in. (5.0 cm) tubular polyester web

strength member, 6,000 lbs. (26.7

kN) tensile strength.

6.1 LANYARD END HOOK SPECIFICATIONS

Hook Description Material Gate Strength Throat Size

2000023 Double Action Captive Eye Carabiner Anodized Aluminum Alloy 3,600 lbs (16 kN) 0.75 in (1.9 cm)

2000118 Double Action Lock Rebar Snap Hook Zinc Plated Steel 3,600 lbs (16 kN) 2.5 in (6.4 cm)

2000125 Double Action Lock Rebar Snap Hook Zinc Plated Steel 3,600 lbs (16 kN) 3.0 in (7.6 cm)

2000209 Double Action Lock Rebar Snap Hook Anodized Aluminum Alloy 3,600 lbs (16 kN) 2.5 in (6.4 cm)

2000210 Double Action Lock Rebar Snap Hook Zinc Plated Steel 3,600 lbs (16 kN) 2.5 in (6.4 cm)

2100044 Swiveling Self-Locking Snap Hook with Impact Indicator Stainless Steel 3,600 lbs (16 kN) 0.75 in (1.9 cm)

2109193 Double Action Lock Rebar Snap Hook Zinc Plated Steel 3,600 lbs (16 kN) 2.5 in (6.4 cm)

9501804 Double Action WrapBax2 Snap Hook Zinc Plated Steel 5,000 lbs (22 kN) 0.82 in (2.1 cm)

9502058 Double Action Lock Rebar Snap Hook Anodized Aluminum Alloy 3,600 lbs (16 kN) 2.25 in (5.7 cm)

9502116 Double Action Lock Snap Hook Zinc Plated Steel 3,600 lbs (16 kN) 0.75 in (1.9 cm)

9502573 Double Action Lock Snap Hook Zinc Plated Steel 3,600 lbs (16 kN) 0.71 in (1.8 cm)

9505254 Double Action Lock Snap Hook Anodized Aluminum Alloy 3,600 lbs (16 kN) 0.75 in (1.9 cm)

IMPORTANT: All systems, sub-systems and components marked with ANSI have been tested and qualifi ed/verfi ed in an

ISO 17025 accredited lab per ANSI Z359.7.

12

Page 13

7.0 LABELING

ALL EZ-STOP LANYARD MODELS: Warning, Use, Identifi cation and Inspection labels are located on and inside a protective

cover on the back side of the lanyard energy absorber. Pull Tab to open the cover and expose the labels.

A or B C

Tab

Tab

D

E

A: Warning/Use, ANSI models, EZ-Stop B: Warning/Use, ANSI models, EZ-Stop Force2

C: Warning/Inspection, on protective cover

D: Warning, on protective cover tab

Warning/Use, ANSI models, EZ-Stop Modular Lanyard Leg Component

E: iSafe RFID Tag, attached to protective cover;

also on some lanyard legs.

13

Page 14

INDIVIDUAL LABELS, IDENTIFIED BY MODEL TYPE:

Inspection Log Label, all models iSafe Label, all models

Front Back

Warning/Use, Twin Leg models Warning/Use, Tie-Back models

Warning/Use, WrapBax models

Front Back

Warning/Use, WrapBax models Warning/Use, Leading Edge models

Front Back

Warning/Use, Connecting Loop models Material Specifi cations, Shockwave2 Force2

Wind Energy models

14

Page 15

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 16

LIMITED LIFETIME WARRANTY

Warranty to End User: D B Industries, Inc., dba CAPITAL SAFETY USA (“CAPITAL SAFETY”) warrants to the

original end user (“End User”) that its products are free from defects in materials and workmanship under

normal use and service. This warranty extends for the lifetime of the product from the date the product is

purchased by the End User, in new and unused condition, from a CAPITAL SAFETY authorized distributor.

CAPITAL SAFETY’S entire liability to End User and End User’s exclusive remedy under this warranty is limited

to the repair or replacement in kind of any defective product within its lifetime (as CAPITAL SAFETY in its sole

discretion determines and deems appropriate). No oral or written information or advice given by CAPITAL

SAFETY, its distributors, directors, offi cers, agents or employees shall create any different or additional

warranties or in any way increase the scope of this warranty. CAPITAL SAFETY will not accept liability for defects

that are the result of product abuse, misuse, alteration or modifi cation, or for defects that are due to a failure to

install, maintain, or use the product in accordance with the manufacturer’s instructions.

CAPITAL SAFETY’S WARRANTY APPLIES ONLY TO THE END USER. THIS WARRANTY IS THE ONLY WARRANTY

APPLICABLE TO OUR PRODUCTS AND IS IN LIEU OF ALL OTHER WARRANTIES AND LIABILITIES, EXPRESSED

OR IMPLIED. CAPITAL SAFETY EXPRESSLY EXCLUDES AND DISCLAIMS ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND SHALL NOT BE LIABLE FOR INCIDENTAL,

PUNITIVE OR CONSEQUENTIAL DAMAGES OF ANY NATURE, INCLUDING WITHOUT LIMITATION, LOST PROFITS,

REVENUES, OR PRODUCTIVITY, OR FOR BODILY INJURY OR DEATH OR LOSS OR DAMAGE TO PROPERTY, UNDER

ANY THEORY OF LIABILITY, INCLUDING WITHOUT LIMITATION, CONTRACT, WARRANTY, STRICT LIABILITY, TORT

(INCLUDING NEGLIGENCE) OR OTHER LEGAL OR EQUITABLE THEORY.

CSG USA & Latin America

3833 SALA Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

solutions@capitalsafety.com

CSG EMEA

(Europe, Middle East, Africa)

Le Broc Center

Z.I. 1ère Avenue

5600 M B.P. 15 06511

Carros

Le Broc Cedex

France

Phone: + 33 4 97 10 00 10

Fax: + 33 4 93 08 79 70

information@capitalsafety.com

The Ultimate in Fall Protection

CSG Canada

260 Export Boulevard

Mississauga, ON L5S 1Y9

Phone: 905.795.9333

Toll-Free: 800.387.7484

Fax: 888.387.7484

info.ca@capitalsafety.com

CSG Australia & New Zealand

95 Derby Street

Silverwater

Sydney NSW 2128

AUSTRALIA

Phone: +(61) 2 8753 7600

Toll-Free : 1 800 245 002 (AUS)

Toll-Free : 0800 212 505 (NZ)

Fax: +(61) 2 87853 7603

sales@capitalsafety.com.au

www.capitalsafety.com

ISO

9001

CSG Northern Europe

5a Merse Road

North Moons, Moat

Reditch, Worcestershire, UK

B98 9HL

Phone: + 44 (0)1527 548 000

Fax: + 44 (0)1527 591 000

csgne@capitalsafety.com

CSG Asia

Singapore:

16S, Enterprise Road

Singapore 627666

Phone: +65 - 65587758

Fax: +65 - 65587058

inquiry@capitalsafety.com

Shanghai:

Rm 1406, China Venturetech Plaza

819 Nan Jing Xi Rd,

Shanghai 200041, P R China

Phone: +86 21 62539050

Fax: +86 21 62539060

Loading...

Loading...