Page 1

Instructions for the following series products:

EZ Stop Lanyards

ShockWave Lanyards

EZ Stop Retrax Lanyards

(See back pages for specifi c model numbers.)

USER INSTRUCTION MANUAL

LANYARDS WITH INTEGRAL ENERGY ABSORBERS AND ENERGY ABSORBER

COMPONENTS USED IN PERSONAL FALL ARREST SYSTEMS (ANSI Z359.1)

This manual is intended to meet the Manufacturer’s Instructions as required by ANSI Z359.1, and should be used

as part of an employee training program as required by OSHA.

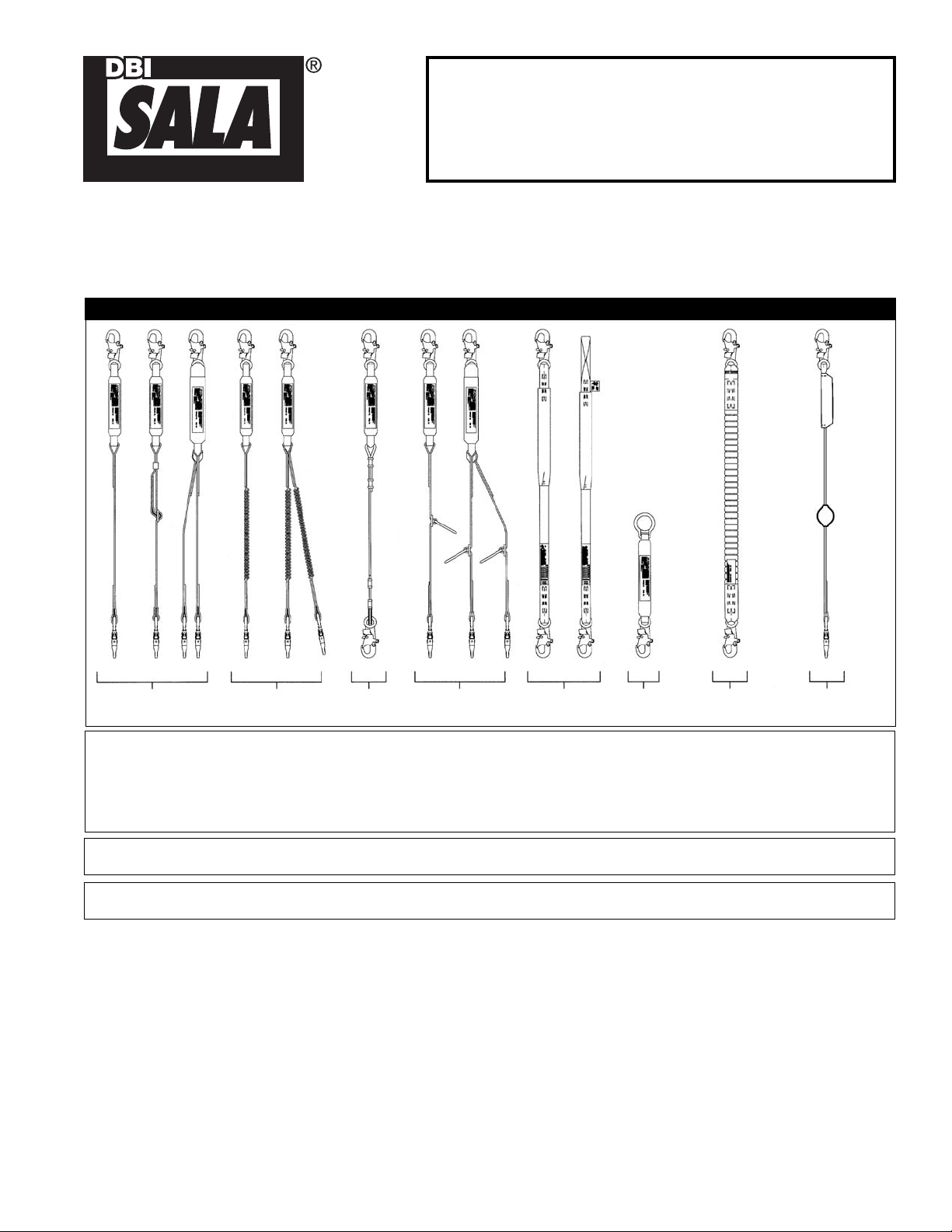

Figure 1 - EZ STOP® Lanyards

EZ Stop II

Web Lanyards

EZ Stop II

Shockwave Lanyards

EZ Stop II

Cable Lanyards

EZ Stop II

Tie-back Lanyards

EZ Stop III

Web Lanyards

EZ Stop III

Energy Absorber

Component

Shockwave 2

Lanyard

EZ Stop Retrax

Retracting Lanyard

WARNING: This product is part of a personal restraint, work positioning, suspension, or rescue system. These

instructions must be provided to the user and rescuer (see section 8 Terminology). The user must read and

understand these instructions or have them explained to them before using this equipment. The user must read

and follow the manufacturer’s instructions for each component or part of the complete system. Manufacturer’s

instructions must be followed for proper use and maintenance of this product. Alterations or misuse of this

product or failure to follow instructions may result in serious injury or death.

IMPORTANT: If you have any questions on the use, care, application, or suitability for use of this equipment,

contact DBI-SALA.

IMPORTANT: Before using this equipment record the product identifi cation information (found on the I.D. label)

in the inspection and maintenance log in section 10.0 of this manual.

DESCRIPTIONS

EZ STOP® II WEB LANYARDS

1-in. (2.5 cm) web, 9503175 hook each end.

1-in. (2.5 cm) web, 9503175 hook one end, 2007153 hook other end.

1-in. (2.5 cm) web, 9503175 hook one end, 1200049 wire pipe clamp other end.

1-in. (2.5 cm) web, 9503175 hook one end, 2000108 carabiner other end.

1-in. (2.5 cm) web, web loop one end, 2007153 hook other end.

1-in. (2.5 cm) web, web loop one end, 9503175 hook other end.

1-in. (2.5 cm) web, adjustable, 9503175 hook each end.

1-in. (2.5 cm) web, 100% tie-off, 9503175 hook center, 2007153 hook leg ends.

1-in. (2.5 cm) web, 100% tie-off, 9503175 hook center and leg ends.

1-in. (2.5 cm) web, 100% tie-off, 9503175 hook center, 2000108 carabiner leg ends.

1-in. (2.5 cm) web, 100% tie-off, web loop center, 2007153 hook leg ends.

1-in. (2.5 cm) web, 100% tie-off, web loop center, 9503175 hook leg ends.

Form: 5902143 Rev: K

© Copyright 2009, DB Industries, Inc.

Page 2

EZ STOP® II SHOCKWAVE™ WEB LANYARDS

1-in. (2.5 cm) elastic web, 9503175 hook each end.

1-in. (2.5 cm) elastic web, 9503175 hook one end, 2007153 hook other end.

1-in. (2.5 cm) elastic web, web loop one end, 2007153 hook other end.

1-in. (2.5 cm) elastic web, web loop one end, 9503175 hook other end.

1-in. (2.5 cm) elastic web, 100% tie-off, 9503175 hook center and both ends.

1-in. (2.5 cm) elastic web, 100% tie-off, 9503175 hook center, 2007153 hook leg ends.

1-in. (2.5 cm) elastic web, 100% tie-off, web loop center, 2007153 hook leg ends.

1-in. (2.5 cm) elastic web, 100% tie-off, web loop center, 9503175 hook leg ends.

EZ STOP® II CABLE LANYARDS

7/32-in. (.6 cm) cable, 9503175 snap hook each end.

7/32-in. (.6 cm) cable, 9503175 snap hook one end, 2007153 snap hook other end.

7/32-in. (.6 cm) cable, 9503175 snap hook one end, 2000108 carabiner other end.

EZ STOP® II TIE-BACK LANYARDS

1-in. (2.5 cm) web, 9503175 hook both ends, fl oating D-ring.

1-in. (2.5 cm) web, 100% tie-off, 9503175 hook center and leg ends, fl oating D-rings.

EZ STOP

1 3/8-in. (3.5 cm) web, 9503175 hook each end.

1 3/8-in. (3.5 cm) web, 9503175 hook one end, 2007153 hook other end.

1 3/8-in. (3.5 cm) web, 9503175 hook one end, 2000108 carabiner other end.

1 3/8-in. (3.5 cm) web, 9503175 hook one end, 1200049 wire pipe hook other end.

1 3/8-in. (3.5 cm) web, web loop one end, 2007153 hook other end.

1 3/8-in. (3.5 cm) web, web loop one end, 9503175 hook other end.

®

III WEB LANYARDS

EZ STOP® II ENERGY ABSORBER COMPONENT

9503175 hook one end, D-ring one end, 24-in. length.

SHOCKWAVE 2™ WEB LANYARD

1 15/16-in. (4.9 cm) web, 9503175 hook each end.

1 7/8-in. (4.8 cm) web, 9502116 hook one end, 9500810 hook other end

EZ STOP® RETRAX™ RETRACTING WEB LANYARD

1 3/8-in. (3.5 cm) web, 9503175 hook each end.

1 3/8-in. (3.5 cm) web, 9503175 hook one end, 9510057 hook other end.

1 3/8-in. (3.5 cm) web, 9503175 hook one end, 2007153 hook other end.

1 3/8-in. (3.5 cm) web, 100% tie-off, 9503175 hook each end.

Note: Other hook and lanyard options are available.

1.0 APPLICATIONS

1.1 PURPOSE: DBI-SALA Energy Absorbing Lanyards and Energy Absorbers are intended to be used as part of a personal

fall arrest system. Applications for these products include inspection work, construction and demolition, maintenance, oil

production, confi ned space rescue, and similar activities where there exists the possibility of a fall. This equipment is specially

designed to dissipate fall energy and limit fall arrest forces transferred to the body.

1.2 LIMITATIONS: The following application limitations must be considered before using this product:

A. CAPACITY: This equipment is for use by persons with a combined weight (person, clothing, tools, etc.)

of no more than 310 lbs. (140.6 kg). CSA models meet Z25911-05 E4 or E6 classifications. See back

cover for associated capacities and model numbers.

B. PHYSICAL AND ENVIRONMENTAL HAZARDS: Use of this equipment in areas containing physical

or environmental hazards may require that additional precautions be taken to reduce the possibility

of damage to this equipment or injury to the user. Hazards may include, but are not limited to: high

heat, strong or caustic chemicals, corrosive environments, the possibility of electric current flowing

through this equipment when working near high voltage power lines, explosive or toxic gases,

moving machinery, sever cold, or sharp edges. Contact DBI-SALA if you have any questions about the

application of this equipment in areas where physical or environmental hazards are present.

C. TRAINING: This equipment is intended to be installed and used by persons who have been properly

trained in its correct application and use.

1.3 Refer to national standards including ANSI Z359 (.0, .1, .2, .3, and .4), family of standards on fall protection, ANSI A10.32,

and applicable local, state, and federal (OSHA) requirements governing occupational safety for more information on Energy

Absorbing Lanyards, Energy Absorbers and associated components. In Canada, see the Z259 group of CSA Standards.

2

Page 3

2.0 SYSTEM REQUIREMENTS

2.1 COMPATIBILITY OF CONNECTORS: DBI-SALA equipment is designed for use with DBI-SALA approved

components and subsystems only. Substitutions or replacements made with non-approved components

or subsystems may jeopardize compatibility of equipment and may effect the safety and reliability of the

complete system.

COMPATIBILITY:

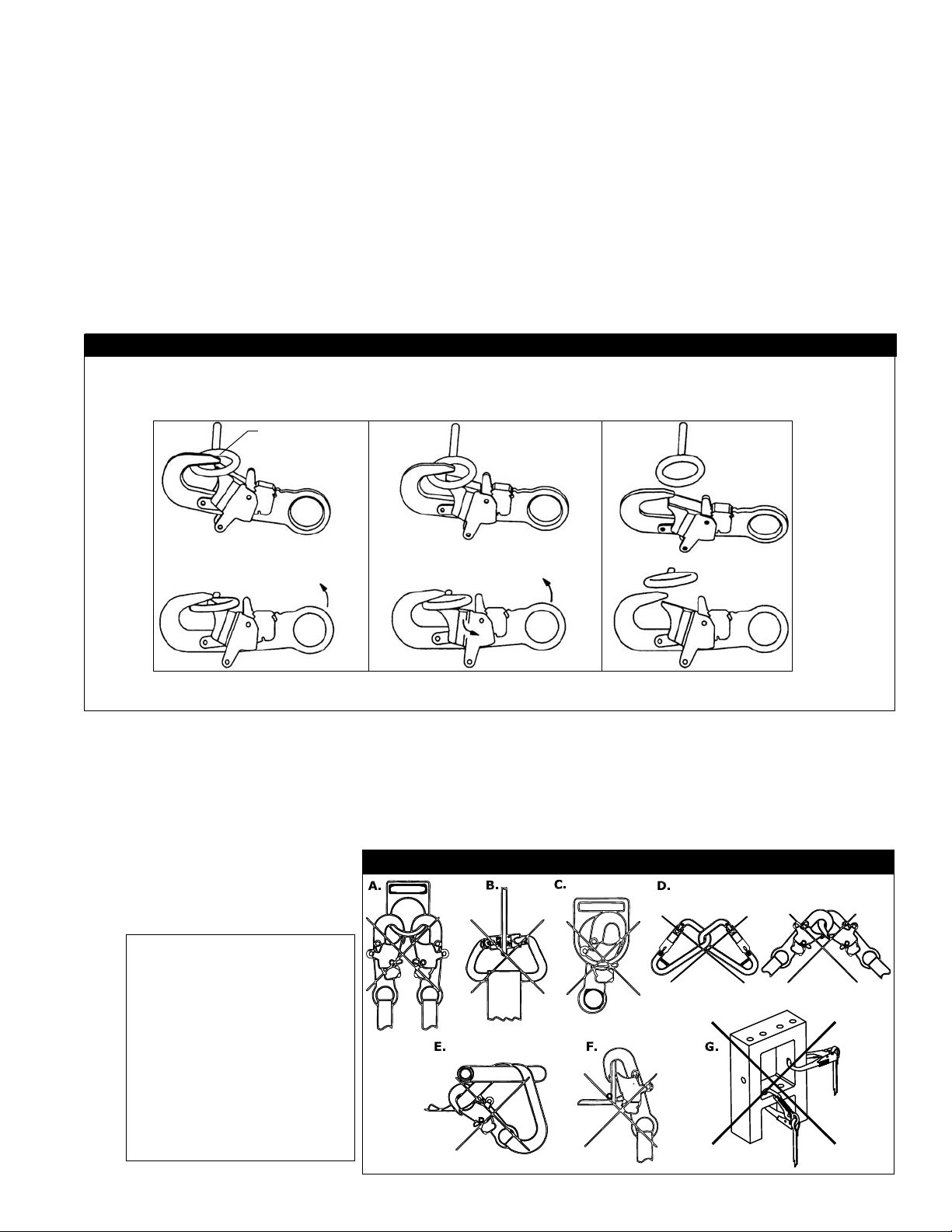

use equipment that is not compatible. Non-compatible connectors may unintentionally disengage. See Figure 2.

Connectors must be compatible in size, shape, and strength regardless of orientation. Self-locking snap hooks

and carabiners are required by ANSI Z359.1 and OSHA

compatibility.

Connectors ( hooks, carabiners, and D-rings) must be capable of supporting a tensile load of at least 5,000 lbs. (22.2

kN). Per ANSI Z359.1, connector gates must be able to withstand a load of 3,600 lbs (16 kN): the face of the gate

must withstand 3,600 lbs (16 kN); the side of the gate must withstand 3,600 lbs (16kN), and the minor axis of a

snap hook or carabiner must withstand 3,600 lbs (16 kN), except for those with captive eyes.

If the connecting element that a snap hook (shown) or carabiner attaches to is undersized or irregular in shape, a situation

could occur where the connecting element applies a force to the gate of the snap hook or carabiner. This force may cause

the gate (of either a self-locking or a non-locking snap hook) to open, allowing the snap hook or carabiner to disengage

from the connecting point.

Connectors must be compatible with the anchorage or other system components. Do not

. Contact DBI-SALA if you have any questions about

Figure 2 - Unintentional Disengagement (Roll-out)

Small ring or

other

non-compatibly

shaped element

1. Force is applied to the

snap hook.

2. The gate presses against

the connecting ring.

3. The gate opens allowing the

snap hook to slip off.

2.2 MAKING CONNECTIONS: Only use self-locking snap hooks and carabiners with this equipment. Only use

connectors that are suitable to each application. Ensure all connections are compatible in size, shape and

strength. Do not use equipment that is not compatible. Ensure all connectors are fully closed and locked.

DBI-SALA connectors (snap hooks and carabiners) are designed to be used only as specifi ed in each

product’s user instructions. See Figure 3 for inappropriate connections. DBI-SALA snap hooks and carabiners

should not be connected:

A. To a D-ring to which another

connector is attached.

Figure 3 - Inappropriate Connections

B. In a manner that would

result in a load on the gate.

NOTE: Large throat-opening

snap hooks should not be

connected to standard size

D-rings or similar objects

which will result in a load on

the gate if the hook or D-ring

twists or rotates. Large throat

snap hooks are designed

for use on fi xed structural

elements such as rebar or

cross members that are not

shaped in a way that can

capture the gate of the hook.

3

Page 4

C. In a false engagement, where features that protrude from the snap hook or carabiner catch on the

anchor, and without visual confirmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the manufacturer’s instructions for both the

lanyard and connector specifically allows such a connection).

F.

To any object which is shaped or dimensioned such that the snap hook or carabiners will not close and lock,

or that roll-out could occur.

G. In a manner that does not allow the connector to align with the fall arrest device (i.e., lanyard) while under

load.

2.3 ANCHORAGE STRENGTH:

have a strength capable of sustaining static loads applied in the directions permitted by the system of at least:

A. 5,000 pounds (22.2kN) for non-certified anchorages, or

B. Two times the maximum arresting force for certified anchorages.

When more than one fall arrest system is attached to an anchorage, the strengths set forth in (A) and (B)

above shall be multiplied by the number of systems attached to the anchorage.

WARNING: Anchorages must be rigid. Large deformations of the anchorage will affect system performance,

and may increase the required fall clearance below the system, which could result in serious injury or death.

From OSHA 1926.500 and 1910.66: Anchorages used for attachment of PFAS shall be independent of

any anchorage being used to support or suspend platforms, and capable of supporting at least 5,000 lbs.

(22.2 kN) per user attached, or be designed, installed, and used as part of a complete PFAS which maintains

a safety factor of at least two, and is supervised by a qualifi ed person

Anchorages selected for work positioning systems shall have a strength capable of sustaining static loads

applied in the directions permitted by the system of at least:

A. 3,000 pounds (13.3kN) for non-certified anchorages, or

B. Two times the foreseeable force for certified anchorages.

When more than one work positioning system is attached to an anchorage, the strengths set forth in (A) and

(B) above shall be multiplied by the number of systems attached to the anchorage.

In accordance with ANSI Z359.1, anchorages selected for fall arrest systems shall

3.0 OPERATION AND USE

WARNING: Do not alter or intentionally misuse this equipment. Consult DBI-SALA when using this equipment

in combination with components or subsystems other than those described in this manual. Some subsystem

and component combinations may interfere with the operation of this equipment. Use caution when using this

equipment around moving machinery, electrical hazards, chemical hazards, and sharp edges. Do not loop the

lanyard around small structural members

WARNING: Working at height has inherent risks. Some risks are noted here but are not limited to the following:

falling, suspension/prolonged suspension, striking objects, and unconsciousness. In the event of a fall arrest and/

or subsequent rescue (emergency) situation, some personal medical conditions may affect your safety. Medical

conditions identifi ed as risky for this type of activity include but are not limited to the following: heart disease,

high blood pressure, vertigo, epilepsy, drug or alcohol dependence, psychiatric illness, impaired limb function

and balance issues. We recommend that your employer/physician determine if you are fi t to handle normal and

emergency use of this equipment

3.1 BEFORE EACH USE of this equipment, carefully inspect it to assure that it is in good working condition.

Check for worn or damaged parts. Ensure all hardware is present and secure, and is not distorted or have

any sharp edges, burrs, cracks, or corrosion. Ensure self-locking snap hooks or carabiners work properly.

Inspect rope or webbing for wear, cuts, burns, frayed edges, breaks, or other damage. See section 5.0 for

further inspection details. Do not use if inspection reveals an unsafe condition.

3.2 PLAN your fall protection system before starting your work. Take into consideration factors that affect

your safety before, during, and after a fall. The following list gives some important points to consider when

planning your system:

A. ANCHORAGE: Select a rigid anchorage point that is capable of supporting the required loads. See

section 2.3. The anchorage location must be carefully selected to reduce possible free fall and swing

fall hazards and to avoid striking an object during a fall. The anchorage should be generally level

(horizontal) to prevent the anchorage connector from sliding down an incline when in use, which could

cause serious injury to the user.

.

4

Page 5

B. FREE FALL: Personal fall arrest systems must be rigged such that the potential free fall is never greater

than 6 ft. (1.8 m). Avoid working above your anchorage level to avoid an increased free fall distance.

IMPORTANT: Some energy absorbing lanyards, such as EZ Stop® Retrax™ and the Shockwave lanyards, make

use of retracting devices designed to shorten their free length. These devices do not decrease free fall distance

C. FALL ARREST FORCES: The assembled fall arrest system must keep fall arrest forces below 1,800 lbs.

(8.0 kN) when used with a full body harness.

D. FALL CLEARANCE: Should a fall occur, there

must be sufficient clearance in the fall area to

arrest the fall before striking the ground or other

object. Energy absorbers can extend the fall

arrest distance by up to 42 inches (106.7 cm).

Figure 4 shows how to estimate fall clearance

distance when using an energy absorbing lanyard

Figure 4 - Estimating Fall Clearance

“FFD” = Free Fall Distance

“DD” = Energy Absorber Deceleration

distance (3 1/2 ft. [1.1 m])

“H” = Height to dorsal connector when

worker is suspended

“C” = Clearance to obstruction during

fall arrest (1 1/2 ft. [.5 m] required)

“RD” = Required distance below working

surface to nearest obstruction

“RD” = “FFD” + “DD” + “H” + “C”

or energy absorber subsystem. Other factors

may influence the required clearance distances.

For example, using an energy absorbing lanyard

Working Surface

Free Fall Distance “FFD”

6 ft. (1.6 m) maximum allowed

or energy absorber with a rope grab (fall

arrestor) may require additional clearance due to

stretch in the lifeline or sliding of the rope grab

on the lifeline during fall arrest. Some full body

harness models incorporate a sliding (positional)

D-ring in the back as the fall arrest attachment,

movement of this D-ring during fall arrest can

increase the fall clearance distance required. Use

caution when assembling system components

that could act to extend the fall arrest distance

Required Distance below

working surface to nearest

obstruction “RD”

Nearest Obstruction

Energy Absorber

Deceleration Distance

“DD”

Height to Dorsal Connector

when worker is suspended “H”

(and therefore fall clearance required). Refer to

manufacturer’s instructions for each part of the

system for more information on fall clearance.

E. SWING FALLS: Swing falls occur when the anchorage point is not

Clearance to obstruction “C”

1 1/2 ft. (.5 m) minimum required

Figure 5 - Swing Fall Hazard

directly above the point where a fall occurs. The force of striking an

object while swinging (horizontal speed of the user due to the pendulum

affect) can be great and may cause serious injury. In a swing fall

situation, the total vertical fall distance of the user will be greater than if

the user had fallen vertically directly below the anchorage point. The user

must therefore account for an increase in the total free fall distance and

the area needed to safely arrest the fall. Swing falls can be minimized by

working as directly below the anchorage point as possible. Never permit

Swing Fall

Hazard

a swing fall if injury could occur. If a swing fall situation exists in your

application contact DBI-SALA before proceeding. See Figure 5.

F. SHARP EDGES

: Avoid working where the lanyard, subsystem, or other

system components will be in contact with, or abrade against, unprotected

sharp edges.

Do not loop lanyard around small diameter structural members.

If working with this equipment near sharp edges is unavoidable, protection

against cutting must be provided by using a heavy pad or other means over the exposed sharp edge.

G. RESCUE

: The user (employer) must have a rescue plan and the ability to implement it when using this

equipment

H. AFTER A FALL: Lanyards with integral energy absorbers, or energy absorber components which have

been subjected to the forces of arresting a fall must be removed from service and destroyed. See

Figure 18.

WARNING: Read and follow manufacturer’s instructions for associated equipment (full body harness, rope grab,

etc.) used in your fall protection system.

IMPORTANT: For special (custom) versions of this product, follow the instructions herein. If included, see

supplement for additional instructions.

3.3 MAKING CONNECTIONS: See Figure 6 for hook operation. When using a hook to connect to an anchorage,

or when coupling components of the system together, ensure accidental disengagement (roll-out) cannot

occur. Roll-out occurs when interference between a hook and the mating connector causes the hook’s gate

or keeper to accidentally open and release. Roll-out may occur when a hook is connected to an undersized

ring such as an eye bolt or other non-compatible shaped connector. Self-locking snap hooks or selflocking and self-closing gate carabiners should be used to reduce the possibility of roll-out when making

connections. Do not use hooks or connectors that will not completely close over the attachment object. For

5

Page 6

these situations, use a tie-off adaptor or other anchorage connector to allow a compatible connection. Do

not knot the lanyard in any manner, and do not hook the lanyard back into itself (choker style). Snap hooks

and carabiners must not be connected to each other. Do not attach snap hooks to web loops.

Figure 6 - Making Connections

Push

Pull Back Gate

with Thumb

Depress Locking

Mechanism with

Index Finger

Step 1 Step 2

Up

Rotate

Clockwise

Step 1 Step 2 Step 3

Push

Rotate

Clockwise

Inward

Step 1 Step 2 Step 1 Step 2

Push

Inward

Push

Inward

Depress Locking

Mechanism with

Palm of Hand

A. CONNECTING TO ANCHORAGE OR

ANCHORAGE CONNECTOR: See Figure 7.

Always connect the energy absorber end of

the lanyard to the body support (harness).

Connect the lanyard end to the anchorage

Anchorage

Connector

or anchorage connector. Component style

energy absorbers should be connected to

the body support first, then coupled to

the rest of the system. Some anchorage

connector devices may be supplied with

permanently attached energy absorber. Use

of an additional energy absorber or energy

absorbing lanyard with these types of

subsystems is not recommended.

100% Tie-off Lanyard Considerations:

Commonly known as 100% tie-off, “Y”

type, twin leg, or double lanyards; these energy absorbing

lanyards can be used to provide continuous fall protection

while ascending, descending, or moving laterally. With one

lanyard leg attached, the worker can move to a new location,

attach unused lanyard leg, and disconnect attached leg. This

procedure is repeated until a new location is reached. With

the EZ Stop® II Shockwave 100% tie-off type lanyard, only

one leg of the lanyard shall be attached to the anchorage or

anchorage connector once a working location is reached. Other

practices that must be followed in order to use a 100% tie-off

type lanyard safely include:

Figure 10 - Incorrect

Attachment

1. The energy absorber portion of the lanyard

must be connected to the dorsal D-ring only.

Use only the snap hook (or other connector

Do not attach

Energy Absorber

to anchor

provided) to attach the energy absorber portion directly to the

harness dorsal D-ring. See Figures 8 and 9.

2. Do not connect the energy absorber to the anchorage. See Figure 10.

3. Do not attach the unused leg of the lanyard back to the harness at any location unless

a specially designed lanyard retainer is provided for this purpose. See Figure 11.

Figure 7 - Connecting to Anchorage

Anchorage

Connector

Energy Absorbing

Lanyard

Energy Absorbing

Lanyard

Figure 8 - Correct

Attachment

Connecting

Subsystem

(Rope Grab)

Energy Absorber

attached to

dorsal D-ring

Figure 9 - Incorrect

Attachment

Anchorage

Connector

Energy

Absorbing

Lanyard

Energy Absorber

not attached

to dorsal D-ring

4. Connection of both lanyard legs to separate anchorage points is acceptable. See

Figure 12.

6

Page 7

Figure 11 - Acceptable Designed Retainers

Figure 12 - Acceptable

Attachment

5. When leapfrogging from one anchorage point to the next (such as traversing a

horizontal or vertical structure) do not connect to anchorage points that are further

apart than the lanyard length (as marked on the lanyard label). See Figure 13.

6. Never connect more than one person to a “Y” type lanyard at a time.

7. Do not allow any lanyard to pass under arms or legs during use.

Attaching a Tie-Back Lanyard: See Figure 14. Place the tie-back lanyard over the

Figure 14 - Attaching Tie-Back

Do not allow gate to

contact anchorage

member

anchoring structure. Ensure the lanyard is not twisted.

Adjust the floating D-ring so it hangs below the anchoring

structure. Attach the lanyard end hook to the floating

D-ring.

Attaching a Shockwave 2 Tie-Back Lanyard

Shockwave 2 Tie-back lanyards (model no. 1244650 and

1244675) are the only Shockwave

Figure 15 - Shockwave 2 Tie-Back

models suitable for tie back

applications. Do not use regular

Shockwave 2 models for tie back

applications.

Tie back using the captive eye

Proper Connection

Improper Connection

carabiner only. Do not tie back using

the snap hook. The snap hook must

Figure 16 - Attaching Wire Form

be connected to the user’s harness.

Anchorage size limit: The red

stitching must be outside of the

captive eye carabiner when the

lanyard is tight around the anchorage (under hand tension). See fi gure 15.

Proper Connection

WARNING: Tying back beyond the red stitching will limit the amount of

energy absorption in the event of a fall and could result in serious injury or

death

Load Direction

If the stitching is located outside of the carabiner, choose an anchorage of

smaller size (in accordance with the requirements in section 2.3) to prevent

tying back beyond the red stitching.

Improper

Connection

Load Direction

Ensure the lanyard is cinched tight around the anchorage during use.

ATTACHING A LANYARD WITH WIRE FORM PIPE HOOK: The wire form

Load Direction

Improper

Connection

pipe hook is intended for use with pipes up to 3 inches (7.6 cm) in diameter.

The anchorage must be geometrically compatible in size and shape. See Figure 16 for examples of

proper and improper connections and intended load directions. Do not side load the pipe hook. Do

not allow the pipe hook to contact electrical sources. Squeeze the handle to open the hook. Place

hook around the anchorage and release handle. Only use a carabiner as the connecting element when

attaching a personal fall arrest system to a pipe hook. When connecting to an anchorage, ensure the

hook fully closes and closure hooks engage eye loops on hook body.

B. CONNECTING TO THE BODY SUPPORT:

Connect the energy absorbing lanyard or energy absorber

to the D-ring on the back between the shoulders (dorsal D-ring) on a full body harness. Connect so the

energy absorber portion of the lanyard is on the body support side. DBI-SALA does not recommend using

a body belt for fall arrest applications. If using a body belt, connect the energy absorbing lanyard or

energy absorber to the D-ring and position the belt so the D-ring is located on the back side of the body.

OK NO

Red

Stitch

Figure 13 - Max Lanyard

Max ≤

Reach

Lanyard

Length

Red

Stitch

7

Page 8

ATTACHING A LANYARD WITH WEB LOOPS: See Figure 17.

Figure 17 - Web Loop Connection

1. Insert the energy absorbing lanyard web loop through the

harness web loop or D-ring.

Insert lanyard web loop through

2. Insert the opposite end of the energy absorbing lanyard through

web loop or D-ring on harness

the connecting web loop.

3. Pull the attached energy absorbing lanyard through the

connecting web loop to secure.

C. CONNECTING TO A ROPE GRAB (FALL ARRESTOR): It is

recommended the lanyard end (vs. the energy absorber end)

be attached to the rope grab. This recommendation is made

Insert opposite end of lanyard

through the lanyard web loop

to reduce possible interference with the operation of the rope

grab by the energy absorber “pack”. Attaching a component

style energy absorber to a rope grab is not recommended, with

the exception of a “direct-coupling” between a rope grab and a

Pull the lanyard through the

connecting web loop to secure

harness. Some rope grabs may be supplied with a permanently

attached energy absorbing lanyard. For these cases, use of an additional energy absorber connected

between the rope grab and the body support is not recommended. In some cases it may be permissible

to couple an energy absorber component between the anchorage (or anchorage connector) and the

rope grab lifeline. In all cases, ensure the length of the energy absorber or energy absorbing lanyard

does not exceed the rope grab manufacturer’s recommended maximum connection length (3 feet [.9 m]

maximum per ANSI Z359.1).

D. CONNECTING TO SELF RETRACTING LIFELINE: DBI-SALA does not recommend connecting an

energy absorbing lanyard or energy absorber component to a self retracting lifeline. Special applications

do exist where it may be permissible. Contact DBI-SALA if considering connecting an energy absorbing

lanyard to a self retracting lifeline.

3.4 ADJUSTING THE RETRAX™ LANYARD: The amount of

the lanyard that is retracted into the Retrax housing can

Figure 18 - Adjusting the Retrax Lanyard Length

be adjusted by completely extending the lanyard from the

housing, then sliding the housing up or down the lanyard.

1. Fully extend the lanyard from the Retrax housing

See Figure 18. Adjusting the length of lanyard that is

retracted into the housing will not reduce the amount of fall

clearance needed to arrest a fall. See section 3.2.

WARNING: The Retrax lanyard is designed to retract and

store the lanyard strap. It is not designed to “lock” or limit the

2. Slide the Retrax housing away from the center of the lanyard

lanyard length in a fall.

3.5 After use, return the lanyard for cleaning or storage as described in section 6.0

Harness web loop

or D-ring

Energy Absorbing Lanyard

Web loop on

4.0 TRAINING

4.1

It is the responsibility of all users of this equipment to understand these instructions, and to be trained in the correct

installation, use, and maintenance of this equipment. These individuals must be aware of the consequences of improper

installation or use of this equipment. This user manual is not a substitute for a comprehensive training program. Training

must be provided on a periodic basis to ensure profi ciency of the users.

IMPORTANT: Training must be conducted without exposing the trainee to a fall hazard. Training should be

repeated on a periodic basis.

5.0 INSPECTION

5.1 FREQUENCY

• Before each use visually inspect per steps listed in sections 5.2 and 5.3.

• Annually: The lanyard must be inspected by a competent person (see section 8 Terminology) other

than the user at least annually. See sections 5.2 and 5.3 for guidelines. Record the results of each

inspection in the inspection and maintenance log in section 9.0, or use the inspection web portal if an

i-Safe™ RFID tag is present (see Figure 19). If you are registered i-Safe user, go to www.capitalsafety.

com/isafe. For more information contact a Customer Service representative in the US at 1-800-3286146 or in Canada at 1-800-387-7484.

IMPORTANT

impact forces, the user, authorized person, or rescuer must remove it from service immediately and destroy it.

IMPORTANT: Extreme working conditions (harsh environment, prolonged use, etc.) may require increasing the

frequency of inspections.

: If the energy absorbing lanyard or energy absorber component has been subjected to fall arrest or

8

Page 9

Figure 19 - i-Safe RFID Tag

Figure 20 - Inspecting the Energy Abosrber for Activation

i-Safe

RFID Tag

The following inspection items are indications

that the Energy Absorber has been subjected

to impact loading and has been activated.

Open end or ripped

out stitching

more than 6 in. (15 cm) longer than the

Torn or broken cover

Measured length is

length marked on the label.

Torn webbing

5.2 INSPECTION STEPS

Step 1. Inspect energy absorbing lanyard or energy absorber component hardware (snap hooks, adjusters,

swages, thimbles, etc.). These items must not be damaged, broken, distorted, or have any sharp

edges, burrs, cracks, worn parts, or corrosion. Ensure the connecting hooks work properly. Hook

gates must move freely and lock upon closing. Ensure adjusters (if present) work properly.

Step 2. Inspect the energy absorbing lanyard or energy absorber component per the following as

applicable:

WEBBING AND STITCHING: The webbing material must be free of frayed, cut, or broken

fi bers. Check for tears, abrasions, mold, burns, or discoloration, etc. The webbing must be free

of knots, excessive soiling, heavy paint buildup, and rust staining. Check for chemical or heat

damage indicated by brown, discolored, or brittle areas. Check for ultraviolet damage indicated

by discoloration and the presence of splinters or slivers on the webbing surface. All of the above

factors are known to reduce webbing strength. Damaged or questionable webbing should be

replaced. Inspect stitching for pulled or cut stitches. Broken stitches may be an indication the

energy absorbing lanyard or energy absorber component has been impact loaded and must be

removed from service.

WIRE ROPE: Inspect entire length of the wire rope. Always wear protective gloves when

inspecting wire rope. Inspect for broken wires by passing cable through gloved hands, fl exing it

every few inches to expose breaks. Broken wires can be removed by bending the wire back and

forth parallel to the rope length. Do not attempt to pull wires out of rope. Remove the energy

absorbing lanyard from service immediately and destroy if there are six or more randomly

distributed broken wires in one lay, or three or more broken wires in one strand in one lay.

A “lay” of wire rope is the length of wire rope that it takes for a strand (the larger groups of

wires) to complete one revolution or twist along the rope. Remove the energy absorbing lanyard

from service immediately and destroy if there are any broken wires within 1 inch of the metal

compression sleeves (swages) at either end of the assembly. The wire rope should be free of

corrosion.

Step 3. ENERGY ABSORBING COMPONENT: Inspect energy absorber to determine if it has been

activated. There should be no evidence of elongation. See Figure 20. Ensure energy absorber

cover is secure and not torn or damaged. On the Shockwave 2™ Lanyard models, the lanyard

webbing will tear out to reveal the warning on the impact indicator label. See section 8.2 for label

illustration.

Step 4. All labels should be present and fully legible. See section 8.0.

Step 5. Inspect each system component or subsystem per associated manufacturer’s instructions.

Step 6. Record the inspection date and results in the inspection log in section 9.0.

5.3 If inspection reveals an unsafe condition, remove unit from service immediately and destroy, or contact an

authorized service center for repair.

NOTE: Only DBI-SALA or parties authorized in writing may make repairs to this equipment.

9

Page 10

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 Clean lanyard with water and a mild detergent solution. Wipe off hardware with a clean, dry cloth, and

hang to air dry. Do not force dry with heat. If you have any questions regarding cleaning of this equipment,

or require more information, contact DBI-SALA. An excessive buildup of dirt, paint, etc., may prevent the

lanyard from working properly, and in severe cases degrade the webbing or rope to a point where it has

become weakened and should be removed from service. If you have any questions concerning the condition

of your lanyard, or have any doubt about putting it into service, contact DBI-SALA.

6.2 Additional maintenance and servicing procedures (replacement parts) must be completed by a factory

authorized service center. Authorization must be in writing. Do not disassemble the unit. See section 5.1 for

inspection frequency.

6.3 Store the lanyard in a cool, dry, clean environment out of direct sunlight. Avoid areas where chemical vapors

may exist. Thoroughly inspect the lanyard or energy absorber component after extended storage.

7.0 SPECIFICATIONS

- The maximum arresting force of DBI-SALA Energy Absorbing Lanyards and components when

dynamically tested in accordance with ANSI Z359.1 is 900 lbs. (4 kN). (EZ STOP® III and

ShockWave 2 models less than 6 ft. [1.8 m] in length, maximum arresting force is 1800 lbs. [8 kN],

Shockwave 2 Tie-back, maximum arrresting force is 1350 lbs [6 kN]).

- The maximum elongation of the Energy Absorbing Lanyard or Energy Absorber component when

dynamically tested in accordance with ANSI Z359.1 is 42 in. (1 m).

- Maximum free fall distance must be no greater than 6 ft. (1.8 m) per federal law and ANSI Z359.1

- EZ STOP® II U.S. Patent Number 5,174,410

- 9503175 Self-closing and self-locking snap hook U.S. Patent Number 4,977,647, Can. 2,027,784.

Lanyard Model Energy Absorber Specifications Adjustable/

Fixed Length

EZ Stop II Web Lanyards

Adjustable Length

EZ Stop II Web Lanyards

100% Tie-off

EZ Stop II Web Lanyards

EZ Stop II Energy

Absorber Component

EZ Stop II

Cable Lanyards

EZ Stop III

Web Lanyards

EZ Stop II Tie-back

Web Lanyard

EZ Stop II Tie-back

100% Tie-off Web Lanyard

EZ Stop II Shockwave

Shockwave 2

Shockwave 2 Tie Back

EZ Stop II Retrax

Web Lanyard

1 3/4 in. (4.4 cm) polyester web strength

member, tubular nylon web wear pads both ends,

nylon outer cover, polyester thread, 8,800^lb.

(39.1^kN) tensile strength.

1 3/4 in. (4.4 cm) polyester web strength

member, tubular nylon web wear pads both ends,

nylon outer cover, polyester thread, 8,800^lb.

(39.1^kN) tensile strength.

1 3/4 in. (4.4 cm) polyester web strength

member, tubular nylon web wear pads both ends,

nylon outer cover, polyester thread, 8,800^lb.

(39.1 kN) tensile strength.

1 3/4 in. (4.4 cm) polyester web strength

member, tubular nylon web wear pads both ends,

nylon outer cover, polyester thread, 8,800^lb.

(39.1^kN) tensile strength.

1 3/4 in. (4.4 cm) polyester web strength

member, nylon web wear pads both ends,

nylon outer cover, polyester thread, 8,800^lb.

(39.1^kN) tensile strength.

1 3/8 in. (3.5 cm) tubular polyester web strength

member, nylon web wear pads both ends,

polyester thread, 8,800^lb. (39.1^kN) tensile

strength.

1 3/4 in. (4.4 cm) polyester web strength

member, tubular nylon web wear pads both ends,

nylon outer cover, polyester thread, 8,800^lb.

(39.1^kN) tensile strength.

1 3/4 in. (4.4 cm) polyester web strength

member, tubular nylon web wear pads both ends,

nylon outer cover, polyester thread, 8,800^lb.

(39.1^kN) tensile strength.

1 3/4 in. (4.4 cm) polyester web strength

member, tubular nylon web wear pads both ends,

nylon outer cover, polyester thread, 8,800^lb.

(39.1^kN) tensile strength.

1 15/16 in. (4.9 cm) polyester web strength

member, nylon web wear pads both ends,

polyester thread, 6,000 lb. (26.7^kN) tensile

strength.

1 7/8 in. (4.8 cm) polyester web strength

member, nylon web wear pads both ends,

polyester thread, 8,500 lb. (37.7^kN) tensile

strength.

1 3/4 in. (4.4 cm) polyester web strength

member, nylon web wear pads both ends, nylon

outer cover, polyester thread, 6,000 lb. (26.7 kN)

tensile strength.

Fixed Length

Lanyard Specifications

Fixed

Adjustable

Fixed

Fixed Not Applicable

Fixed

Fixed

Fixed

Fixed

Fixed

Fixed Lanyard and energy absorber are the same material.

Fixed Lanyard and energy absorber are the same material.

Fixed

1 in. (2.5 cm) polyester web, 8,800^lb. (39.1^kN)

1 in. (2.5 cm) polyester web, 8,800^lb. (39.1^kN)

1 in. (2.5 cm) polyester web, 100% tie-off, 8,800^lb.

7/32 in. (.6 cm) 7x9 galvanized cable, vinyl covered.

5,600 lb. (24.9 kN) tensile strength

1 3/8 in. (3.5 cm) tubular polyester web strength

member, 6,000 lb. (26.7 kN) tensile strength

1 in. (2.5 cm) polyester web strength member,

8,800^lb. (39.1^kN) tensile strength with 1 3/8 in.

(3.5 cm) tubular polyester web cover

1 in. (2.5 cm) polyester web strength member,

8,800^lb. (39.1^kN) tensile strength with 1 3/8 in.

(3.5 cm) tubular polyester web cover

1 15/16 in. (4.9 cm) tubular polyester web strength

member, 6,000 lb. (26.7 kN) tensile strength

1 3/8 in. polyester web, 6,000 lb. (26.7 kN) tensile

tensile strength

tensile strength

(39.1^kN) tensile strength

strength

10

Page 11

8.0 TERMINOLOGY

Authorized Person: A person assigned by the employer to perform duties at a location where the person will

be exposed to a fall hazard (otherwise refered to as “user” for the purpose of these instructions).

Rescuer: Person or persons other than the rescue subject acting to perform an assisted rescue by operation

of a rescue system.

Certified Anchorage: An anchorage for fall arrest, positioning, restraint, or rescue systems that a qualified

person certifies to be capable of supporting the potential fall forces that could be encountered during a fall

or that meet the criteria for a certified anchorage prescribed in this standard.

Qualified Person: A person with a recognized degree or professional certificate and with extensive

knowledge, training, and experience in the fall protection and rescue field who is capable of designing,

analyzing, evaluating and specifying fall protection and rescue systems to the extent required by this

standard.

COMPETENT PERSON: One who is capable of identifying existing and predictable hazards in the surroundings

or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has

authorization to take prompt corrective measures to eliminate them.

9.0 LABELING

9.1 This label must be attached to all lanyards and be fully legible.

All Lanyards - Inspection Log

9.2 These labels must be securely attached to all Shock Wave 2™ Lanyards and be fully legible.

All ShockWave 2 Lanyards - I.D. / Warning Label

11

Page 12

9.3 These labels must be securely attached to the noted CSA approved lanyards and be fully legible.

Warning Label - All CSA Approved Lanyards

ID / Warning Label - CSA Approved EZ Stop® II Web Lanyards

ID Label - CSA Approved EZ Stop® III Web Lanyards

9.4 These labels must be attached to the noted Energy Absorbing Lanyards or Energy Absorber components

and be fully legible.

ID Label - EZ Stop® II Web Lanyards

Warning Label - All Web Loop

Energy Absorbing Lanyards Not

Permanently Attached to Harness

Warning Label EZ Stop® II

Tie-Back Lanyards

Warning Label - All Web Loop

Energy Absorbing Lanyards

Permanently Attached to Harness

12

Page 13

9.4 CONTINUED . . .

These labels must be attached to the noted Energy Absorbing Lanyards or Energy Absorber components and

be fully legible.

Impact Indicator Label

EZ Stop® Shock Wave 2 Tie-Back Lanyards

And

EZ Stop® Shock Wave III Lanyards

Shockwave 2 Tie Back Lanyards ID Label Front and Back

Retrax Warning Label

100% Tie-off Lanyard

Warning Label

Shockwave 2 Tie

Back Lanyards

Warning Label

All EZ Stop III ANSI Approved Lanyards - I.D. / Warning Label

Shockwave 2 Tie Back Lanyards

Impact Indicator Label

13

Page 14

10.0 INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

14

Page 15

Models - ANSI:

1100456

1100750

1100756

1100762

1100767

1100768

1100769

1101240

1101241

1101272

1101340

1101341

1101633

1101635

1101645

1101646

1101647

1101775

1101789

1101790

1101792

1101793

1101795

1101832

1101835

1101836

1101837

1101851

1101859

1101866

1101869

1102525

1103886

1104729

1104744

1104745

1104746

1104747

1104748

1104912

1104918

1104924

1105376

1105491

1106002

1106003

1106005

1106007

1106008

1106016

1106017

1106033

1106040

1106041

1106058

1106059

1106063

1106064

1106074

1106150

1106151

1106152

1106203

1106211

1106212

1106325

1106326

1106327

1106328

1106329

1106330

1106331

1106332

1106333

1106334

1106679

1106682

1106683

1106684

1106687

1106900

1106901

1106902

1106903

1106904

1106905

1107026

1107575

1107576

1107650

1107652

1107725

1107727

1107875

1107951

1107952

1107958

1107959

1107962

1107991

1107992

1108033

1108034

1108301

1108310

1109105

1109106

1109111

1110792

1110793

1220002

1220003

1220004

1220005

1220006

1220007

1220011

1220013

1220014

1220016

1220017

1220019

1220022

1220024

1220026

1220027

1220028

1220029

1220030

1220033

1220034

1220035

1220037

1220038

1220040

1220043

1220045

1220046

1220048

1220053

1220066

1220067

1220068

1220070

1220071

1220074

1220077

1220078

1220079

1220081

1220083

1220086

1220087

1220091

1220098

1220103

1220105

1220108

1220111

1220115

1220120

1220123

1220124

1220127

1220132

1220135

1220140

1220146

1220148

1220153

1220154

1220156

1220157

1220170

1220175

1220178

1220186

1220194

1220197

1220200

1220201

1220203

1220207

1220251

1220253

1220256

1220258

1220259

1220262

1220265

1220267

1220268

1220269

1220271

1220272

1220274

1220275

1220277

1220279

1220285

1220286

1220288

1220289

1220291

1220292

1220295

1220298

1220299

1220300

1220352

1220354

1220358

1220359

1220362

1220363

1220364

1220365

1220366

1220368

1220399

1220405

1220406

1220409

1220411

1220412

1220413

1220414

1220416

1220417

1220419

1220421

1220424

1220427

1220428

1220433

1220436

1220437

1220446

1220447

1220448

1220452

1220453

1220462

1220463

1220464

1220465

1220466

1220467

1220469

1220471

1220472

1220473

1220474

1220475

1220509

1220510

1220511

1220525

1220526

1220535

1220536

1220537

1220538

1220540

1220551

1220553

1220557

1220558

1220559

1220562

1220563

1220564

1220566

1220567

1220568

1220570

1220571

1220573

1220574

1220601

1220620

1220626

1220680

1220681

1220682

1220701

1220704

1220705

1220706

1220707

1220708

1220712

1220713

1220716

1220718

1220720

1220722

1220724

1220725

1220726

1220727

1220729

1220739

1220740

1220745

1220746

1220748

1220749

1220751

1220753

1220757

1220775

1220803

1220804

1220806

1220808

1220809

1220845

1220846

1220847

1220848

1220849

1220850

1220852

1220854

1220855

1220856

1220857

1220859

1220860

1220861

1220862

1220863

1220865

1220870

1220871

1220872

1220873

1220874

1220880

1220902

1220903

1220905

1220906

1220909

1220914

1220915

1220917

1220922

1220925

1220929

1220932

1220975

1221001

1221002

1221003

1221004

1221005

1221006

1221008

1221009

1221013

1221016

1221030

1221031

1221032

1221033

1221101

1221102

1221104

1221105

1221106

1221107

1221108

1221112

1221114

1221115

1221116

1221117

1221119

1221120

1221205

1221206

1221209

1221210

1221211

1221215

1221216

1221217

1221251

1221276

1221327

1221401

1221451

1221460

1221461

1221462

1221463

1221464

1221480

1221481

1221482

1221702

1221751

1221752

1222300

1223026

1224003

1224005

1224006

1224007

1224008

1224009

1224011

1224012

1224013

1224014

1224016

1224018

1224023

1224024

1224026

1224027

1224029

1224031

1224034

1224036

1224038

1224041

1224043

1224047

1224101

1224102

1224103

1224107

1224110

1224111

1224252

1224253

1224301

1224302

1224305

1224306

1224307

1224308

1224309

1224310

1224311

1224312

1224313

1224314

1224319

1224321

1224322

1224323

1224324

1224325

1224327

1224329

1224330

1224331

1224335

1224336

1224337

1224338

1224339

1224344

1224345

1224346

1224347

1224349

1224350

1224354

1224355

1224356

1224402

1224404

1224405

1224406

1224409

1224410

1224411

1224412

1224413

1224414

1224416

1224418

1224419

1224420

1224421

1224424

1224425

1224430

1224431

1224433

1224434

1224435

1224436

1224437

1224439

1224440

1224441

1224442

1224443

1224444

1224445

1224447

1224455

1224456

1224457

1224458

1224475

1224476

1224510

1224610

1224611

1224612

1224613

1224630

1224631

1224632

1224633

1224634

1226000

1226001

1226003

1229000

1240004

1240005

1240006

1240007

1240011

1240012

1240013

1240016

1240017

1240018

1240019

1240020

1240023

1240024

1240027

1240028

1240029

1240030

1240034

1240035

1240038

1240039

1240040

1240041

1240043

1240046

1240048

1240053

1240054

1240057

1240058

1240059

1240060

1240062

1240063

1240066

1240067

1240068

1240071

1240074

1240077

1240080

1240082

1240083

1240084

1240086

1240088

1240089

1240090

1240091

1240092

1240093

1240097

1240098

1240101

1240102

1240103

1240105

1240108

1240111

1240113

1240114

1240115

1240117

1240118

1240120

1240122

1240123

1240124

1240125

1240126

1240127

1240128

1240129

1240130

1240131

1240132

1240135

1240136

1240137

1240139

1240140

1240141

1240142

1240143

1240144

1240147

1240150

1240153

1240154

1240155

1240156

1240157

1240158

1240168

1240170

1240175

1240178

1240179

1240186

1240188

1240193

1240194

1240197

1240200

1240201

1240202

1240205

1240208

1240209

1240210

1240211

1240251

1240253

1240256

1240257

1240258

1240259

1240262

1240263

1240264

1240265

1240266

1240267

1240268

1240269

1240271

1240272

1240273

1240274

1240276

1240277

1240278

1240279

1240280

1240281

1240282

1240291

1240292

1240294

1240295

1240299

1240351

1240354

1240357

1240359

1240362

1240368

1240399

1240405

1240406

1240409

1240411

1240412

1240414

1240415

1240416

1240419

1240421

1240424

1240427

1240428

1240430

1240431

1240432

1240433

1240436

1240440

1240441

1240445

1240446

1240447

1240448

1240452

1240453

1240458

1240460

1240462

1240463

1240464

1240465

1240466

1240467

1240469

1240470

1240471

1240472

1240473

1240474

1240475

1240476

1240477

1240505

1240506

1240508

1240509

1240510

1240511

1240525

1240526

1240535

1240536

1240537

1240538

1240540

1240551

1240552

1240553

1240554

1240555

1240556

1240557

1240558

1240560

1240561

1240565

1240566

1240567

1240568

1240570

1240573

1240574

1240601

1240603

1240604

1240620

1240626

1240627

1240680

1240681

1240682

1240683

1240702

1240703

1240704

1240705

1240706

1240707

1240708

1240710

1240711

1240712

1240713

1240714

1240715

1240716

1240717

1240718

1240719

1240720

1240722

1240723

1240724

1240725

1240726

1240727

1240729

1240730

1240731

1240732

1240733

1240734

1240735

1240736

1240737

1240738

1240739

1240740

1240741

1240742

1240743

1240744

1240745

1240746

1240748

1240749

1240750

1240752

1240753

1240754

1240755

1240756

1240757

1240801

1240802

1240803

1240804

1240805

1240806

1240807

1240808

1240809

1240845

1240846

1240847

1240848

1240849

1240850

1240852

1240854

1240855

1240856

1240857

1240859

1240860

1240861

1240862

1240863

1240865

1240870

1240871

1240872

1240873

1240874

1240875

1240876

1240877

1240878

1240879

1240880

1240901

1240902

1240903

1240904

1240905

1240906

1240907

1240909

1240910

1240911

1240912

1240913

1240914

1240915

1240916

1240922

1240923

1240924

1240926

1240927

1240928

1240929

1240930

1240932

1240935

1240975

1241001

1241002

1241003

1241004

1241005

1241006

1241008

1241009

1241010

1241013

1241014

1241016

1241018

1241020

1241022

1241023

1241024

1241025

1241029

1241030

1241031

1241032

1241033

1241101

1241102

1241103

1241105

1241106

1241108

1241109

1241110

1241111

1241112

1241113

1241114

1241117

1241118

1241120

1241122

1241124

1241125

1241201

1241204

1241205

1241206

1241207

1241210

1241211

1241213

1241214

1241215

1241216

1241217

1241218

1241219

1241220

1241250

1241251

1241276

1241277

1241326

1241327

1241460

1241461

1241462

1241463

1241464

1241465

1241480

1241481

1241482

1241483

1241701

1241702

1241751

1241752

1241761

1241763

1242475

1242476

1242500

1243026

1244001

1244003

1244004

1244006

1244007

1244008

1244009

1244010

1244011

1244012

1244013

1244014

1244016

1244018

1244021

1244023

1244024

1244026

1244027

1244028

1244029

1244030

1244031

1244032

1244033

1244034

1244035

1244036

1244037

1244038

1244039

1244040

1244041

1244043

1244047

1244101

1244102

1244103

1244104

1244106

1244107

1244112

1244205

1244213

1244251

1244252

1244253

1244254

1244301

1244302

1244303

1244304

1244305

1244306

1244307

1244308

1244309

1244310

1244311

1244312

1244313

1244314

1244317

1244318

1244319

1244321

1244324

1244325

1244326

1244327

1244329

1244331

1244332

1244335

1244338

1244340

1244344

1244346

1244349

1244351

1244353

1244354

1244355

1244356

1244357

1244358

1244359

1244360

1244402

1244403

1244404

1244406

1244409

1244410

1244411

1244412

1244413

1244414

1244415

1244417

1244420

1244424

1244425

1244426

1244430

1244433

1244434

1244435

1244436

1244439

1244440

1244441

1244442

1244443

1244444

1244445

1244446

1244448

1244455

1244456

1244457

1244458

1244475

1244476

1244510

1244601

1244610

1244611

1244612

1244613

1244614

1244630

1244631

1244632

1244633

1244634

1244650

1244675

1244676

1244700

1244725

1244750

1244751

1246001

1246002

1330025

1330035

1330055

1330065

1330100

5002040

5002041

5002042

5002050

5900876

5900877

Additional model numbers may appear on the next printing of these instructions.

15

Page 16

Models - CSA:

CSA Class Model Numbers

E4:

E6:

Max. Arresting Force Max. Elongation Min. Mass of Worker Max. Mass of Worker

900 lbf (4.0 kN) 3.9 ft (1.2 m) 100 lbs (45 kg) 254 lbs (115 kg)

1100320C

1100321C

1100322C

1100323C

1100447C

1100448C

1100449C

1100450C

1100890C

1100891C

1100892C

1100893C

1100894C

1100980C

1100981C

1100982C

1100983C

1101166C

1101167C

1101168C

1101169C

1101170C

1101535C

1101536C

1101537C

1101538C

1101540C

1101851C

1101859C

1101871C

1102319C

1102320C

1102321C

1102967C

1102968C

1102969C

1102970C

1102971C

1103266C

1103268C

1103269C

1103387C

1103388C

1103389C

1103390C

1103391C

1103392C

1105855C

1106015C

1106040C

1106041C

1106042C

1106053C

1106054C

1106060C

1106061C

Max. Arresting Force Max. Elongation Min. Mass of Worker Max. Mass of Worker

1,300 lbf (6.0 kN) 5.7 ft (1.75 m) 200 lbs (90 kg) 386 lbs (175 kg)

1242225C

1242226C

1242227C

1242228C

1106062C

1106075C

1106203C

1106684C

1106685C

1106689C

1106690C

1106698C

1106699C

1107160C

1107161C

1107162C

1107163C

1107164C

1107165C

1107837C

1107838C

1107839C

1107840C

1107961C

1108028C

1108355C

1108356C

1108357C

1108358C

1108359C

1108528C

1108529C

1242229C

1242230C

1108530C

1108534C

1108539C

1108540C

1108541C

1108542C

1108603C

1108678C

1108679C

1108680C

1108684C

1108685C

1108686C

1108710C

1108711C

1108712C

1108713C

1108714C

1108715C

1109025C

1109037C

1109038C

1109045C

1109057C

1109058C

1109061C

1109141C

1109432C

1242250C

1242275C

1109433C

1109434C

1109435C

1109436C

1109437C

1110310C

1110311C

1110312C

1110313C

1110612C

1110613C

1110614C

1110619C

1110705C

1110706C

1220006C

1220007C

1220012C

1220016C

1220017C

1220024C

1220028C

1220030C

1220035C

1220038C

1220040C

1220042C

1220043C

1242325C

1242326C

1220046C

1220048C

1220054C

1220058C

1220068C

1220071C

1220074C

1220079C

1220080C

1220086C

1220091C

1220092C

1220093C

1220098C

1220105C

1220108C

1220115C

1220132C

1220139C

1220180C

1220181C

1220182C

1220195C

1220204C

1220206C

1220256C

1220259C

1220269C

1242350C

1242375C

1220296C

1220297C

1220299C

1220300C

1220301C

1220359C

1220362C

1220364C

1220369C

1220406C

1220409C

1220450C

1220451C

1220455C

1220459C

1220461C

1220466C

1220468C

1220526C

1220527C

1220535C

1220536C

1220539C

1220540C

1220553C

1220558C

1220572C

1220601C

1220680C

1220681C

1220850C

1220851C

1220852C

1220853C

1220857C

1220858C

1220861C

1220863C

1220864C

1220866C

1220870C

1220871C

1220873C

1220880C

1220906C

1220937C

1220938C

1220939C

1220940C

1221001C

1221006C

1221028C

1221034C

1221104C

1221106C

1221206C

1221425C

1221426

1221426C

1221460C

1221461C

1221480C

1221481C

1221484C

1221801C

1221802C

1221803C

1221804C

1221805C

1221806C

1221807C

1221808C

1221809C

1221810C

1221811C

1221812C

1221813C

1221814C

1221815C

1221816C

1221851C

1221852C

1221853C

1221854C

1224006C

1224306C

1224341C

1224343C

1224348C

1224405C

1224406C

1224409C

1224427C

1224428C

1224431C

1224438C

1240210C

1240211C

1240256C

1240325C

1240477C

1240559

1244610C

1244611C

1244630C

1244631C

Additional model numbers may appear on the next printing of these instructions.

A Capital Safety Company

CSG USA

3833 Sala Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

solutions@capitalsafety.com

CSG EMEA (France)

Le Broc Center

Z.I. 1ère Avenue-5600 M

BP 15 • 06511 Carros Cedex

Phone: +33 (0)4 97 10 00 10

Fax: +33 (0)4 93 08 79 70

information@capitalsafety.com

CSG Canada Ltd.

260 Export Boulevard

Mississauga, Ontario L5S 1Y9

Canada

Toll Free: 800.387.7484

Phone: 905.795.9333

Fax: 905.795.8777

sales.ca@capitalsafety.com

CSG Asia Pte Ltd.

No. 6, Tuas Avenue 18

Singapore 638892

Phone: +65 6558 7758

Fax: +65 6558 7058

inquiry@capitalsafety.com

CSG Northern Europe Ltd.

7 Christleton Court • Stuart Rd.

Manor Park • Runcorn

Cheshire WA7 1ST • UK

Phone: +44 (0) 1928 571324

Fax: +44 (0) 1928 571325

csgne@csgne.co.uk

CSG (Aust) Pty Ltd.

20 Fariola Street • Sliverwater

Sydney, NSW 2128

Australia

Phone: +61 (2) 9748 0335

Fax: +61 (2) 9748 0336

sales@capitalsafety.com.au

www.capitalsafety.com

ISO

9001

Certificate No. FM 39709

Loading...

Loading...