Page 1

The Ultimate in Fall Protection

Approved by the

National Fire Protection Association

Use this Supplemental Instruction with the

ExoFit NEX User Instruction Manual 5903027.

This supplement includes information for the

following sections: 1.0 Application, 2.0 System

Limitations and Requirements, 3.0 Donning

and Use, 7.0 Specications, and 8.0 Labels.

Permanently retain this Supplemental

Instruction and the ExoFit NEX User

Instruction Manual 5903027. Keep a copy of

both Instructions with the ExoFit NEX harness.

Full Body Suspension Harness

1113283 1113283C

1113284 1113284C

1113289 1113289C

1113304 1113304C

1113348 1113348C

1113370 1113370C

1113371 1113371C

1113372 1113372C

1113373 1113373C

1113557 1113557C

1113558 1113558C

1113559 1113559C

1113560 1113560C

1113561 1113561C

1113562 1113562C

1113563 1113563C

1113564 1113564C

1113565 1113565C

1113566 1113566C

1113567 1113567C

1113568 1113568C

1113569 1113569C

1113570 1113570C

1113571 1113571C

1113572 1113572C

1113573 1113573C

1113574 1113574C

ExoFit NEX™

Model Numbers:

1113575 1113575C

1113576 1113576C

1113577 1113577C

1113578 1113578C

1113579 1113579C

1113580 1113580C

1113590 1113590C

1113591 1113591C

1113644 1113644C

1113645 1113645C

1113646 1113646C

1113647 1113647C

1113648 1113648C

1113649 1113649C

1113650 1113650C

1113651 1113651C

1113652 1113652C

1113653 1113653C

1113654 1113654C

1113655 1113655C

1113656 1113656C

1113657 1113657C

1113658 1113658C

1113659 1113659C

1113660 1113660C

1113661 1113661C

1113662 1113662C

1113663 1113663C

1113664 1113664C

1113665 1113665C

1113666 1113666C

1113667 1113667C

1113668 1113668C

1113669 1113669C

1113699C 1113700C

1113701C 1113702C

1114000 1114000H

1114001 1114001H

1114002 1114002H

1114003 1114003H

1114004 1114004H

1114005 1114005H

1114006 1114006H

1114007 1114007H

1114008 1114008H

1114009 1114009H

1114010 1114010H

1114011 1114011H

1114012 1114012H

1114013 1114013H

1114014 1114014H

1114030 1114031

1114032 1114033

1114034 1114035

1114036 1114037

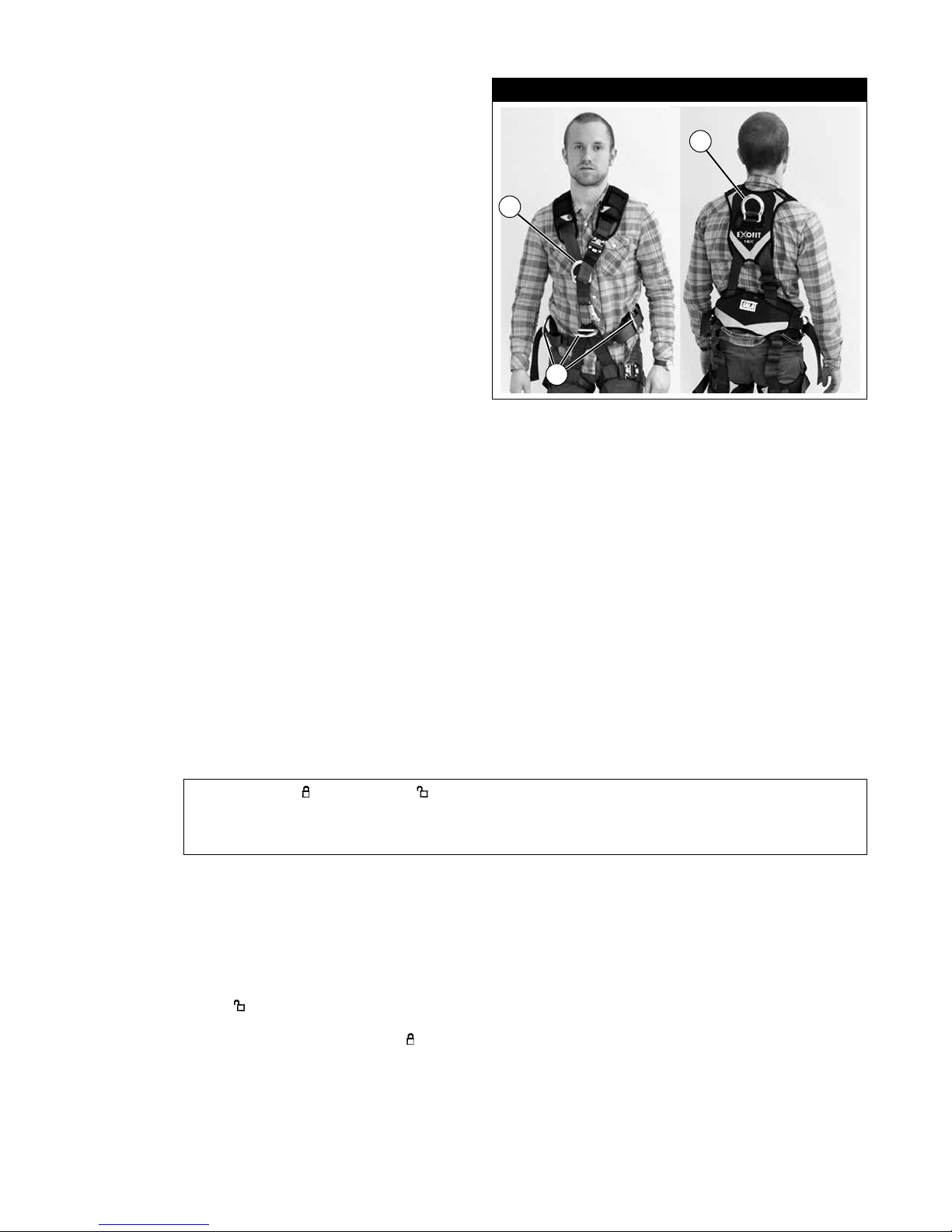

Figure 1 - ExoFit NEX™ Full Body Suspension Harness

A

E

B

C

B

C

D

D

A. Shoulder Strap w/Hybrid Padding B. Duo-Lok™ Quick Connect Buckle C. Tech-Lite™ Side, Front and Pelvic D-Rings

D

D. Leg [Suspension] Strap E. Tech-Lite™ Dorsal D-Ring

D

Page 2

1.0 application

1.1.1 PURPOSE: Suspension harness used for Fall

Arrest (D-Ring connections A, Figure 2) and Work

Positioning (D-Ring connections B, Figure 2).

Figure 2 - Applications

A

1.2.1 STANDARDS: Refer to life safety harness

information found in NFPA 1500, Standard on

Fire Department Occupational Safety and Health

Program, and NFPA 1983, Standard on Life Safety

Rope and Equipment for Emergency Services.

A

B

2.0 system limitations & RequiRments

2.7.1 ENVIRONMENTAL HAZARDS: Do not expose the harness to flame or high temperature. Such exposure

could cause the harness to melt or burn and fail during use. Harnesses that meet the optional flame

resistance requirements specified in NFPA 1983 are designed for use in environments where exposure to

flame or high temperature could occur.

3.0 Donning anD use

3.9 DONNING AND FITTING THE SUSPENSION HARNESS: The ExoFit NEX™ Suspension Harness includes

leg straps for work positioning. Don the Full Body Suspension Harness using the following steps and the

corresponding images in Figure 3.

Step 1. Locate the front of the harness. The front has two D-rings. Lift up the harness and hold by the

shoulder straps. Ensure all straps are not twisted.

Step 2. With the front of the harness facing forward, step through the right side of the harness with

your right leg. Then, step through the left side of the harness with your left leg.

shoulder strap and place it on the top of your right shoulder. Ensure that the straps are not

tangled and hang freely.

Step 3. Grasp the left shoulder strap and place it over your left shoulder.

positioned on the front of your body if the harness has been donned properly.

Step 4. Grasp the tab of the buckle located at the bottom of the strap that you placed over your left

shoulder. Insert the tab into the receptor of the quick connect buckle on the left side of the

harness. You will hear a click when the tab engages properly.

note: Locking and unlocking the webbing lock prevents or allows the strap to slide

between the sliding bar and slot on the female end of the quick connect buckle. It does

not control engagement or disengagement of the buckle ends and will not affect the buckle

connection in the event of a fall.

Step 5. Grasp the waist-level strap ends on right and left sides of the harness. Pull both ends forward

until all slack is removed from the waist strap and the strap is comfortably tight around your

waist. Insert strap ends into the waist strap keeper loops on the right and left sides of the

harness.

Step 6. Reach between your legs and grasp the leg strap on your right side. Bring the strap up and

insert the tab of the buckle into the receptor of the buckle on the right side. You will hear a click

when the tab engages properly.

Step 7. Connect the right leg strap using the same procedure as in Step 6. To adjust the leg straps,

unlock

keeper on the end of the strap will stop it from pulling completely out of the buckle. When the

strap is properly adjusted, lock

tabs on the buckle towards each other with one hand, while pulling on the tab portion of the

buckle with the other hand.

Step 8. Adjustshoulderstrapstoasnugtusingthestrapadjustmentproceduredescribedbetween

Steps 4 and Step 5 on the following page. Left and right sides of the shoulder straps should be

adjusted to the same length and the upper front D-ring should be centered on your lower chest.

The back D-ring should be centered between your shoulder blades. Adjust the leg straps to a

snugt.Atleast3in.(8cm)ofwebbingmustextendpastthebuckleonthelegstraps.Adjust

thewaistbeltagainasnecessaryforasecure,comfortablet.

the webbing lock on the quick connect buckle and pull on the strap. A plastic end

the webbing lock.

To release the buckle, press the silver-colored

The two D-rings will be

Grasp the right

Page 3

Figure 3 - Donning Suspension Harness

Step 1

Step 4

Step 2

Duo-Lok™ Quick Connect Buckles

Connection: Connect buckle ends by inserting

the tab into the receptor until a click is heard.

Strap Adjustment: Rotate Webbing Lock

to unlocked position . Pull strap to adjust.

Rotate Webbing Lock to locked position .

note: The Webbing Lock does not control

engagement or disengagement of the buckle ends.

Step 3

Step 5

Step 6 Step 7 Step 8

Page 4

3.10 DONNING AND FITTING THE FIRE AND RESCUE HARNESS. The Fire and Rescue Harness can be used

for work positioning or for rescue worker applications. The Class II harness assembly must be donned

appropriatelyforthespecicapplication.AftertheClassIIharnesshasbeendonnedforworkpositioning

or for rescue, the Class III portion of the harness can be donned. See Section 3.11 for work positioning,

Section 3.12 for rescue and 3.13 for the shoulder straps.

waRning: The Fire and Rescue Harness meets the requirements of NFPA 1983, Standard on Life

Safety Rope and Equipment for Emergency Services, 2012 Editions, and the Optional Flame Resistance

Requirements of NFPA 1983, Class II. When used in conjunction with DBI/SALA part numbers 1114000,

1114000H, 1114001, 1114001H 1114002, or 1114002H, the Fire and Rescue Harness meets the

requirements of Class III but IS NOT FLAME RESISTANT. See Harness labels 5909121 and 5909122.

3.11 FIRE AND RESCUE CLASS II HARNESS DONNING FOR WORK POSITIONING: The ExoFit NEX™ Fire

and Rescue Harness includes leg straps that permit the harness to be used for work positioning. To configure

the harness for work positioning, follow Figure 4, Steps 1 through 5, to fit the leg straps to the user. Follow

the steps in Figure 6 to convert the harness to Class III.

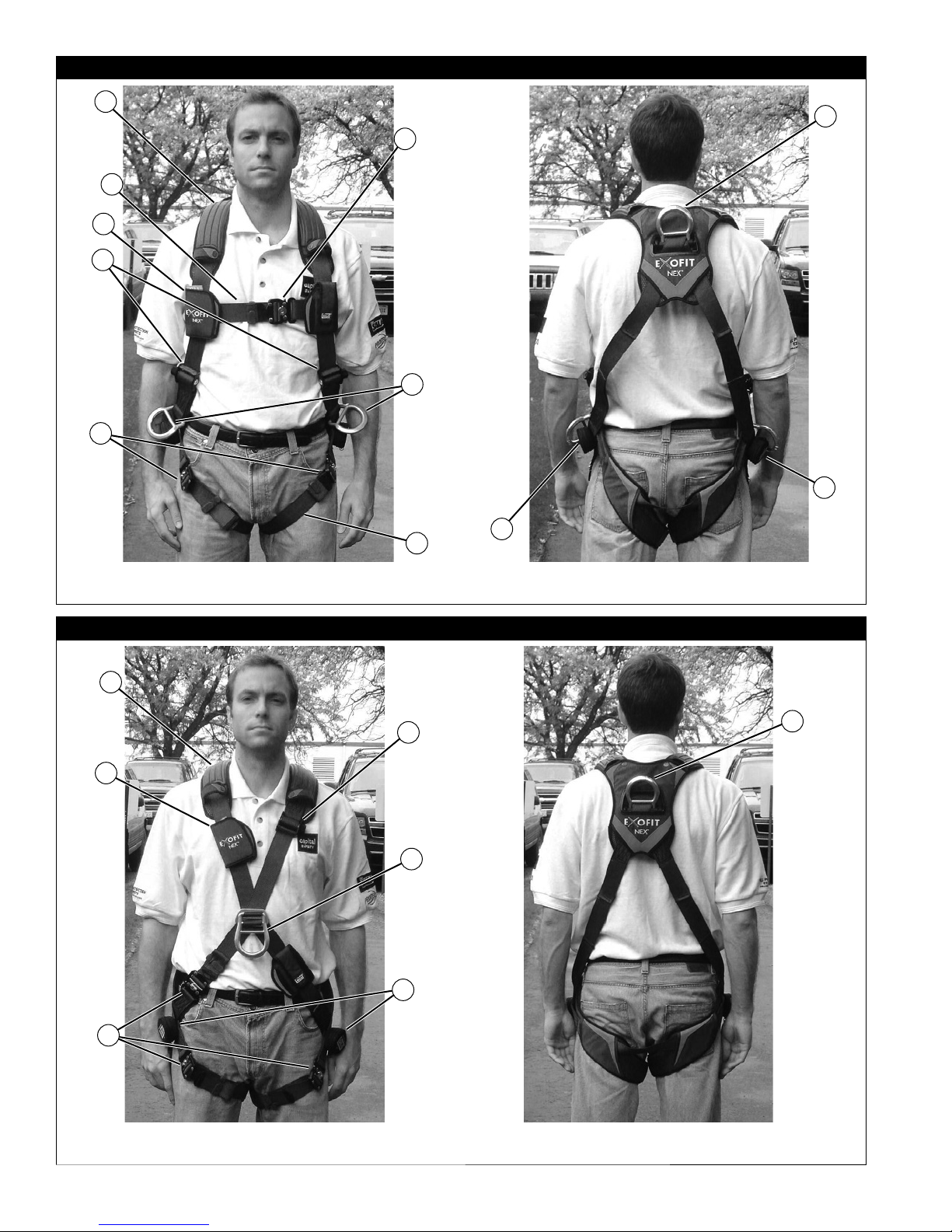

Figure 4 - Fire And Rescue Harness Belt Donning For Work Positioning

Work Positioning, Step 1

Work Positioning, Step 2 Work Positioning, Step 3

Proceed to Figure 6, steps 1 - 6

Work Positioning, Step 4 Work Positioning, Step 5

Figure 4

Step 1. Suspend the harness by holding each end. D-Rings and the carabiner should be facing forward.

Ensure all straps are not twisted.

Step 2. Grasp the quick connect buckle at the end of the web belt and bring it around your waist so that

the buckle is just behind your left hip. Lock the tab located at the opposite end of the web belt

into the quick connect buckle. You will hear a click when the tab engages properly.

Step 3. Grasp the quick connect buckle located at the bottom of the strap that is hanging nearest your

left leg. Bring that quick connect buckle around the back of your left leg. Lock the tab located

at the end of the short web strap on your left hip into the quick connect buckle. You will hear a

click when the tab engages properly.

Step 4. Grasp the quick connect buckle located at the bottom of the strap that is hanging nearest your

right leg. Bring that quick connect buckle around the back of your right leg. Lock

the tab

located at the end of the short web strap on your right hip into the quick connect buckle. You

will hear a click when the tab engages properly.

note: Locking and unlocking the webbing lock prevents or allows the strap to slide

between the sliding bar and slot on the female end of the quick connect buckle. It does

not control engagement or disengagement of the buckle ends and will not affect the

buckle connection in the event of a fall.

Page 5

Step 5. Grasp the waist-level strap ends on right and left sides of the harness. Pull both ends forward

until all slack is removed from the waist strap and the strap is comfortably tight around your

waist. Insert strap ends into the waist strap keeper loops on the right and left sides of the

harness.

3.12 FIRE AND RESCUE CLASS II HARNESS DONNING FOR RESCUE: The ExoFit NEX™ Fire and Rescue

Harness includes leg straps that permit the harness to be used for rescue work. To configure the harness for

rescue, follow Figure 5, Steps 1 through 5, to fit the leg straps to the user. Follow the steps in Figure 6 to

convert the harness to Class III.

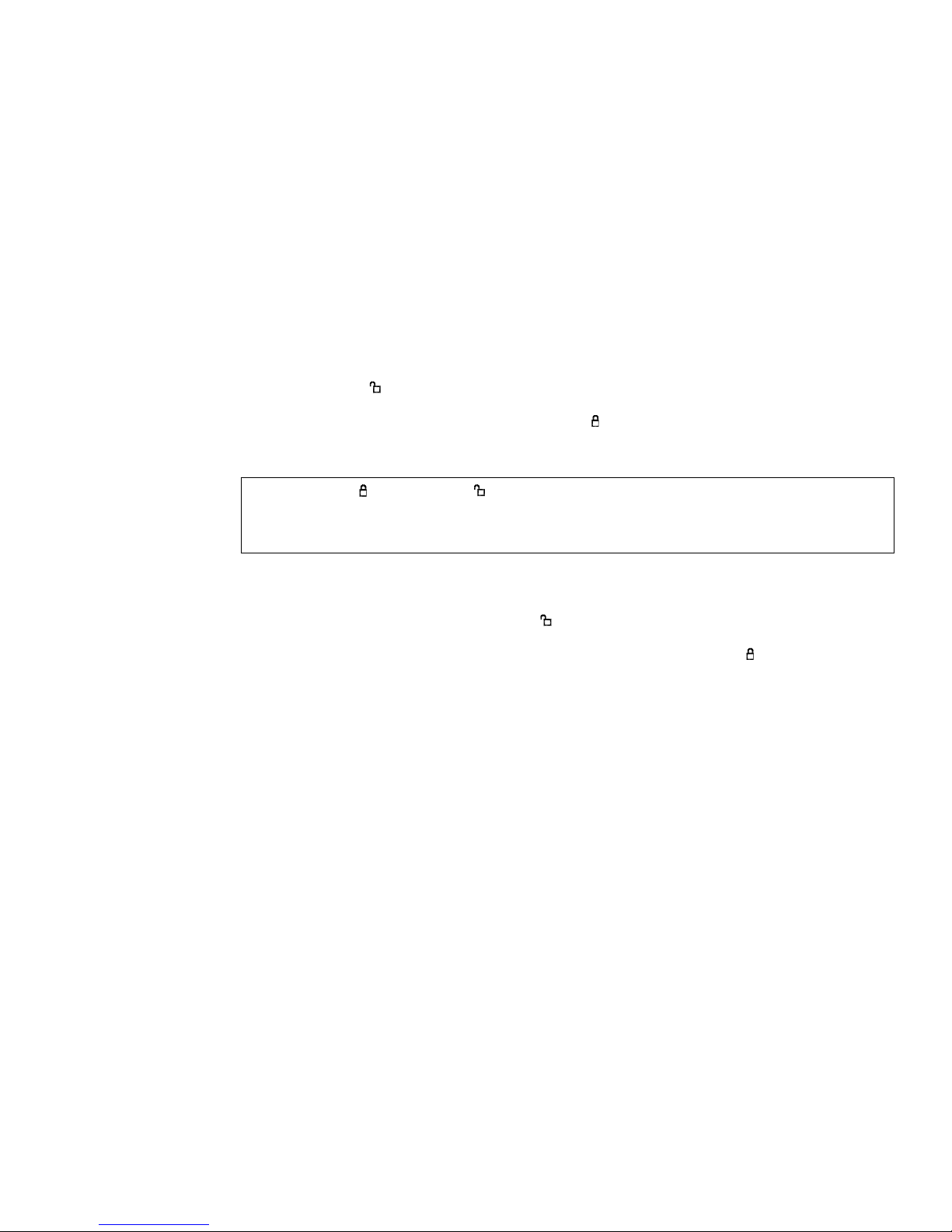

Figure 5 - Fire And Rescue Harness Belt Donning For Rescue

Rescue, Step 1

Rescue, Step 2 Rescue, Step 3

Proceed to Figure 6, steps 1 - 6

Rescue, Step 4

Rescue, Step 5

Figure 5

Step 1. Suspend the harness by holding each end. D-Rings and the carabiner should be facing forward.

Ensure all straps are not twisted.

Step 2. Grasp the quick connect buckle at the end of the web belt and bring it around your waist so that

the buckle is just behind your left hip. Lock the tab located at the opposite end of the web belt

into the quick connect buckle. You will hear a click when the tab engages properly.

Step 3. Reach between your legs and grasp the leg strap on your left side. Bring the strap up around the

back of your left leg. Insert the tab on the strap handing from the left side of the belt into the

quick connect buckle of the strap. You will hear a click when the tab engages properly.

Step 4. Reach between your legs and grasp the leg strap on your right side. Bring the strap up around

the back of your right leg. Insert the tab on the strap handing from the right side of the belt into

the quick connect buckle of the strap. You will hear a click when the tab engages properly.

To adjust the leg straps, unlock

the webbing lock on the quick connect buckle and pull on the

strap. A plastic end keeper on the end of the strap will stop it from pulling completely out of

the buckle. When the strap is properly adjusted, lock

the webbing lock.

To release the buckle,

press the silver-colored tabs on the buckle towards each other with one hand, while pulling on the

tab portion of the buckle with the other hand.

Step 5. Grasp the waist-level strap ends on right and left sides of the harness. Pull both ends forward

until all slack is removed from the waist strap and the strap is comfortably tight around your

waist. Insert strap ends into the waist strap keeper loops on the right and left sides of the

harness.

waRning: The Fire and Rescue Harness meets the requirements of NFPA 1983, Standard on Life

Safety Rope and Equipment for Emergency Services, 2012 Editions, and the Optional Flame Resistance

Requirements of NFPA 1983, Class II. When used in conjunction with DBI/SALA part numbers 1114000,

1114000H, 1114001, 1114001H 1114002, or 1114002H, the Fire and Rescue Harness meets the

requirements of Class III but IS NOT FLAME RESISTANT. See Harness labels 5909121 and 5909122.

Page 6

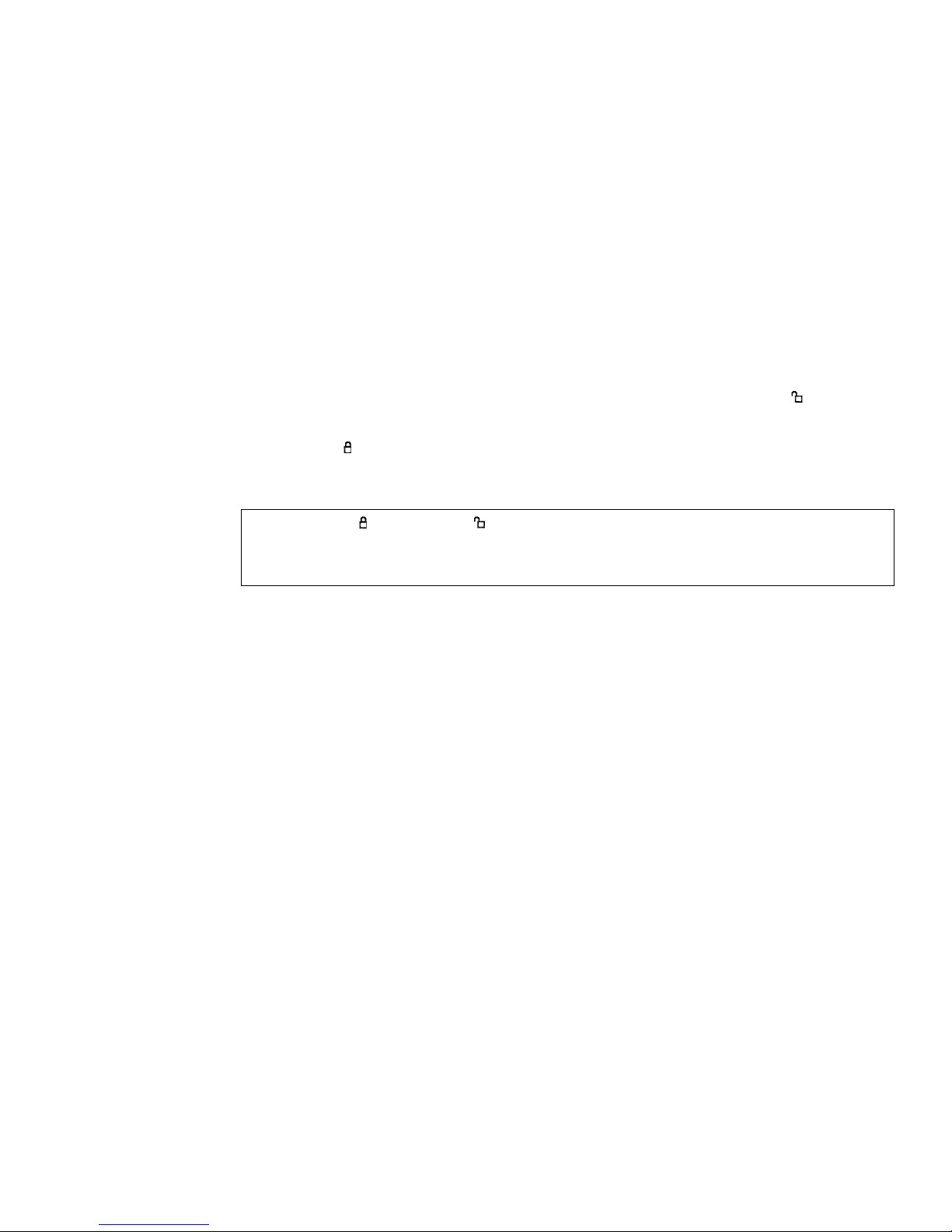

3.13 SHOULDER STRAPS: Complete donning of the ExoFit NEX™ Fire Rescue Class III harness by following

Figure 6, Steps 1 through 6.

Figure 6 - Fire And Rescue Harness Shoulder Strap Donning

Step 1

Step 4

Step 2

Step 5

Step 3

A

B

Step 6

Figure 6

Step 1. Suspend the shoulder harness. The D-Ring and Yoke should be facing forward. Ensure all straps

are not twisted. Place the opening in the Yoke over your head and rest the straps on your

shoulders.

Step 2. Open the carabiner at the bottom of the Yoke. Insert the carabiner through the strap that holds

the D-Ring on the harness belt. Close the carabiner. The gate of the carabiner must not be

inside the D-Ring loop.

Step 3. Bring the strap on the right side of your back around to your right hip. Open the carabiner and

insert it through the red loop on the top of the belt. The carabiner gate must not be inside the

belt loops.

Step 4. Bring the strap on the left side of your back around to your left hip. Open the carabiner and

insert it through the blue loop on the top of the belt. The carabiner gate must not be inside the

beltloops.Orientthecarabinersasshowninthegures.Thecarabinergatemustnotbeinside

the belt loop.

Step 5. Conrmthatthefrontstrapissecuredbythecarabinerandthatthestrapslieatonyour

chest. Left and right sides of the shoulder straps should be adjusted to the same length and the

upper front D-ring should be centered on your lower chest, facing outward and free to swivel up

and down.

Page 7

Step 6. Conrmthatthebackstrapsaresecuredbythecarabiners(A - blue strap end secured by

carabiner to blue loop; B - red strap end end secured by carabiner to red loop) and that the

strapslieatacrossyourback.TheD-Ringatthecenteroftheharnesspaddingbetweenyour

shoulders must be facing outward and free to swivel up and down. Adjust shoulder straps to a

snugt.

Beforeuse,adjusttheharnesslegstrapstoasnugt.Atleast3in.(8cm)ofwebbingmustextendpastthe

buckleonthelegstraps.Adjustthewaistbeltagainasnecessaryforasecure,comfortablet.

7.0 speciFications

7.3.1 STANDARDS: When installed and used per the requirements and recommendations in the manual,

the ExoFit NEX™ Full Body Suspension Harness meets the requirements of the National Fire Protection

Association 1983 Standard on Life Safety Rope and Equipment for Emergency Services, 2012 Edition.

Page 8

USER INSTRUCTION MANUAL

EXOFIT NEX™ FULL BODY HARNESS

This manual is intended to meet the Manufacturer’s Instructions as required by ANSI Z359 and

CSA 259.10 and should be used as part of an employee training program as required by OSHA

WARNING: This product is part of a personal fall arrest,

restraint, work positioning, climbing, controlled descent,

or rescue system. The user must follow the manufacturer’s

instructions for each component of the system. These

instructions must be provided to the user of this equipment.

The user must read and understand these instructions before

using this equipment. Manufacturer’s instructions must be

followed for proper use and maintenance of this equipment.

Alterations or misuse of this product or failure to follow

instructions may result in serious injury or death.

IMPORTANT: If you have questions on the use, care, or

suitability of this equipment for your application, contact

Capital Safety.

ExoFit NEX™

Full Body Harness

Model Numbers: (See back pages.)

IMPORTANT: Record the product identifi cation information

from the ID label in the inspection and maintenance log in

Section 9 of this manual.

DESCRIPTIONS:

The ExoFit NEX™ Full Body Harness is available in Vest (Figure 1)

and Cross-Over (Figure 2) styles confi gured with a variety of

features including the following:

• Tech-Lite™ Aluminum D-Rings - Varied Locations: Front, Back,

Hips, Shoulders

• Duo-Lok™ Quick Connect Buckles

• Repel Technology Webbing

• Hybrid Comfort Padding

• Revolver™ Vertical Torso Adjusters

• Tongue Buckle Body Belt

• Suspension Trauma Straps

NOTE: Some features may not be available on all models of

the ExoFit NEX™ Full Body Harness.

Page 9

Figure 1 - ExoFit NEX™ Vest Style Full Body Harness

A

H

B

C

D

E

F

B

I

G

A. Shoulder Strap w/Hybrid Padding B. Duo-Lok™ Quick Connect Buckle C. Chest Strap D. Hybrid Chest Pad with i-Safe™ RFID Tag &

Labels E. Revolver™ Torso Adjustor F. Tech-Lite™ Side D-Ring G. Leg Strap H. Tech-Lite™ Dorsal D-Ring I. Trauma Strap

I

Figure 2 - ExoFit NEX™ Cross-Over Style Full Body Harness

A

B

C

D

G

E

A. Shoulder Strap w/Hybrid Padding B. Revolver™ Adjustor C. Hybrid Chest Pad with i-Safe™ RFID Tag & Labels D. Tech-Lite™ Front

D-Ring E. Duo-Lok™ Quick Connect Buckle F. Trauma Strap G. Tech-Lite™ Dorsal D-Ring

F

Page 10

1.0 APPLICATION

1.1 PURPOSE: The DBI-SALA ExoFit NEX™™ Full Body Harness (Figure 1 and Figure 2) should be used as a component

in personal fall arrest, restraint, work positioning, climbing, controlled descent, or rescue systems (see

Table 1).

ExoFit NEX™ Harnesses included in this manual are full body harnesses and meet ANSI Z359.1, OSHA, and

CSA Z259.10 requirements. See Figure 3 for application illustrations.

WARNING: Working at height has inherent risks. Some risks are noted here but are not limited to:

falling, suspension/prolonged suspension, striking objects, and unconsciousness. In the event of a fall

arrest and/or subsequent rescue (emergency) situation, some personal medical conditions may affect your

safety. Medical conditions identifi ed as risky for this type of activity include, but are not limited to: heart

disease, high blood pressure, vertigo, epilepsy, drug or alcohol dependence, psychiatric illness, impaired

limb function and balance issues. We recommend that your employer/physician determine if you are fi t to

handle normal and emergency use of this equipment.

Table 1 - ExoFit NEX™ Full Body Harness Applications

Application CSA Class Description

Personal Fall Arrest Class A

Controlled Descent Class D

The full body harness is used as a component of a personal fall arrest system.

Personal fall arrest systems typically include a full body harness and a connecting

subsystem (energy absorbing lanyard). Maximum arresting force must not exceed

1,800 lbs (8 kN). For fall arrest applications connect the fall arrest subsystem

(example: lanyard, SRL, energy absorber, etc.) to the D-ring or attachment element

on your back, between your shoulder blades.

For controlled descent applications, harnesses equipped with a single sternal level

D-ring, one or two frontal mounted D-rings, or a pair of connectors originating

below the waist (such as a seat sling) may be used for connection to a descender or

evacuation system (reference in Z259.10 in Canada).

Rescue Class E The full body harness is used as a component of a rescue system. Rescue systems

Ladder Climbing Class L

Work Positioning Class P

Restraint None The full body harness is used as a component of a restraint system to prevent the

are confi gured depending on the type of rescue. For limited access (confi ned space)

applications, harnesses equipped with D-rings on the shoulders may be used for

entry and egress into confi ned spaces where worker profi le is an issue.

The full body harness is used as a component of a climbing system to prevent

the user from falling when climbing a ladder or other climbing structure. Climbing

systems typically include a full body harness, vertical cable or rail attached to the

structure, and climbing sleeve. For ladder climbing applications, harnesses equipped

with a frontal D-ring in the sternal location may be used for fall arrest on fi xed

ladder climbing systems. These are defi ned in CSA Z259.2.1 in Canada and ANSI

A14.3 in the United States.

The full body harness is used as a component of a work positioning system to

support the user at a work position. Work positioning systems typically include a full

body harness, positioning lanyard, and a back-up personal fall arrest system. For

work positioning applications, connect the work positioning subsystem (example:

lanyard, Y-lanyard, etc.) to the lower (hip level) side or belt mounted work

positioning attachment anchorage elements (D-rings). Never use these connection

points for fall arrest.

user from reaching a fall hazard. Restraint systems typically include a full body

harness and a lanyard or restraint line.

1.2 STANDARDS: Refer to local, state, and federal (OSHA) requirements governing occupational safety for

additional information regarding Personal Fall Arrest Systems. Refer to the following national standards on fall

protection:

ANSI Z359.0 Defi nitions and Nomenclature Used for Fall Protection and Fall Arrest

ANSI Z359.1 Safety Requirements for Personal Fall Arrest Systems, Subsystems, and Components

ANSI Z359.2 Minimum Requirements for a Comprehensive Managed Fall Protection Program

ANSI Z359.3 Safety Requirements for Positioning and Travel Restraint Systems

ANSI Z359.4 Safety Requirements for Assisted-Rescue and Self-Rescue Systems, Subsystems, and Components

ANSI A10.32 Fall Protection Systems for Construction and Demolitions

CSA Z259.10 Full Body Harnesses

ASTM F887-2011 Standard Specifi cations for Personal Climbing Equipment

Page 11

Figure 3 - Applications

1 Fall Arrest

2 Restraint

3 Ladder Climbing

4a Work Positioning

4b Work Positioning or

Controlled Descent,

with Seat Sling

4c Work Positioning,

with Seat Sling

4d Work Positioning,

with Seat Sling -

Tower Climbing

A Anchorage

B Anchorage

Connector

C Connecting

Subsystem (SRL

shown)

D Full Body Harness

E Restraint Lanyard

F Backup Fall Arrest

System

G Ladder

H Cable Sleeve

I Cable

J Seat Sling

K Tower Structure

A

C

D

B

1

A

B

F

D

A

4a 4b 4c 4d

A

B

F

E

D

B

J

A

E

B

D

A

2

A

B

A

F

D D

J

E

E

J

G

H

I

3

K

E

1.3 TRAINING: This equipment is intended to be used by persons trained in its correct application and use. It is the

responsibility of the user to assure they are familiar with these instructions and are trained in the correct care and use

of this equipment. Users must also be aware of the operating characteristics, application limits, and the consequences of

improper use.

2.0 SYSTEM LIMITATIONS & REQUIREMENTS

Consider the following limitations/requirements prior to installing or using this equipment:

2.1 CAPACITY: ExoFit NEX™ Full Body Harnesses are designed for use by persons with a combined weight

(clothing, tools, etc.) of no more than 420 lbs. (191 kg) per OSHA, 310 lbs. (141 kg) per ANSI Z359.1,

or 352 lbs. (160 kg) per CSA Z259.10-06. Make sure all of the components in your system are rated to a

capacity appropriate to your application.

2.2 FREE FALL: Personal fall arrest systems used with this equipment must be rigged to limit the free fall to 6

feet (1.8 M) per ANSI Z359.1 (see Section 7.1). Restraint systems must be rigged so that no vertical free

fall is possible. Work positioning systems must be rigged so that free fall is limited to 2 feet (.6 m) or less.

Personnel riding systems must be rigged so that no vertical free fall is possible. Climbing systems must

be rigged so that free fall is limited to 18 in. (.46 cm) or less. Rescue systems must be rigged so that no

vertical free fall is possible. See subsystem manufacturer’s instructions for more information.

2.3 FALL CLEARANCE: Figure 4 illustrates fall clearance requirements. There must be suffi cient clearance

below the user to allow the system to arrest a fall before the user strikes the ground or other obstruction.

Clearance required is dependent on the following factors:

• Elevation of Anchorage • Connecting Subsystem Length

• Deceleration Distance • Free Fall Distance

• Worker Height • Movement of Harness Attachment Element

Page 12

Figure 4 - Fall Clearance (Lanyards)

Figure 5 - Swing Falls

RD = LL + DD + HH + C

RD Required Fall Clearance Distance

LL Length of Lanyard (Specifi ed on labeling)

DD Deceleration Distance = 4 ft (1.2 m) except:

• for ANSI/OSHA Lanyards with Free Fall

greater than 6 ft (1.8 m) up to 12 ft (3.7

m), or user weights greater than 310 lbs

(141 kg) up to 420 lbs (191 kg); add 1 ft

(0.3 m): DD = 5 ft (1.5 m)

• for CSA E6 Lanyards, add 1.7 ft. (0.5 m):

DD = 5.7 ft (1.7 m)

HH Height of Suspended Worker

C Safety Factor = 1.5 ft (0.5 m)

(Factors in D-Ring Slide and Harness Stretch.)

Example: Assuming a 6 ft (1.8 m) tall user with a

typical 6 ft (1.8 m) lanyard with 6 ft (1.8 m) Free Fall,

Fall Clearance calculation would be as follows:

RD = LL + DD + HH + C

RD = 6 ft + 4 ft + 6 ft + 1.5 ft = 17.5 ft

RD = 1.8 m + 1.2 m + 1.8 m + 0.5 m = 5.3 m

LL

RD

DD

HH

C

2.4 SWING FALLS: Swing falls occur when the anchorage point is not directly above the point where a fall

occurs. The force of striking an object in a swing fall may cause serious injury or death. Minimize swing

falls by working as close to the anchorage point as possible. Do not permit a swing fall if injury could occur.

Swing falls will signifi cantly increase the clearance required when a self-

retracting lifeline or other variable

length connecting subsystem is used.

2.5 EXTENDED SUSPENSION:

A full body harness is not intended for use in extended suspension applications.

If the user is going to be suspended for an extended length of time it is recommended that some form of

seat support be used. DBI-SALA recommends a seat board, suspension work seat, seat sling, or a boatswain

chair. Contact Capital Safety for more information on these items.

2.6 ENVIRONMENTAL HAZARDS: Use of this equipment in areas with environmental hazards may require

additional precautions to prevent injury to the user or damage to the equipment. Hazards may include,

but are not limited to: heat, chemicals, corrosive environments, high voltage power lines, gases, moving

machinery and sharp edges.

2.7 COMPATIBILITY OF COMPONENTS: Unless otherwise noted, DBI-SALA equipment is designed for use with

DBI-SALA approved components and subsystems only. Substitutions or replacements made with non approved

components or subsystems may jeopardize compatibility of equipment and may affect safety and reliability of the

complete system.

2.8 COMPATIBILITY OF CONNECTORS: Connectors are considered to be compatible with connecting

elements when they have been designed to work together in such a way that their sizes and shapes do not

cause their gate mechanisms to inadvertently open regardless of how they become oriented. Connectors

(hooks, carabiners, and D-rings) must be capable of supporting at least 5,000 lbs. (22 kN). Connectors

must be compatible with the anchorage or other system components. Do not use equipment that is not

compatible. Non-compatible connectors may unintentionally disengage (see Figure 6). Connectors must

be compatible in size, shape, and strength. Self-locking snap hooks and carabiners are required by ANSI

Z359.1 and OSHA.

Page 13

2.9 MAKING CONNECTIONS: Use only self-locking snap hooks and carabiners with this equipment. Only use

connectors that are suitable to each application. Ensure all connections are compatible in size, shape and

strength. Do not use equipment that is not compatible. Ensure all connectors are fully closed and locked.

DBI-SALA connectors (snap hooks and carabiners) are designed to be used only as specifi ed in each

product’s user’s instructions. See Figure 7 for illustration of the inappropriate connections stated below. DBISALA snap hooks and carabiners should not be connected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

C. In a false engagement, where features that protrude from the snap hook or carabiner catch on the

anchor and without visual confi rmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the manufacturer’s instructions for both the

lanyard and connector specifi cally allow such a connection).

F. To any object which is shaped or dimensioned such that the snap hook or carabiner will not close and

lock, or that roll-out could occur.

G. In a manner that does not allow the connector to align with the fall arrest device (i.e., lanyard) while

under load.

NOTE: Other than 3,600 lb. (16 kN) gated hooks, large throat opening snap hooks should not be

connected to standard size D-rings or similar objects which will result in a load on the gate if the hook or

D-ring twists or rotates. Large throat snap hooks are designed for use on fi xed structural elements such as

rebar or cross members that are not shaped in a way that can capture the gate of the hook.

Other Restrictions:

• Do not make connections where the hook locking mechanism can come into contact with a structural

member or other equipment and potentially release the hook.

• Do not connect a snap hook into a loop or thimble of a wire rope or attach in any way to a slack wire

rope.

• The snap hook must be free to align with the applied load as intended (regardless of the size or shape of

the mating connector).

• A carabiner may be used to connect to a single or pair of soft loops on a body support such as a body

belt or full body harness, provided the carabiner can fully close and lock. This type of connection is not

allowed for snap hooks.

• A carabiner may be connected to a loop or ring connector that is already occupied by a choker style

connector. This type of connection is not allowed for snap hooks.

Figure 6 - Unintentional Disengagement (Rollout)

If the connecting element to which a snap hook (shown) or carabiner

attaches is undersized or irregular in shape, a situation could occur

where the connecting element applies a force to the gate of the snap

hook or carabiner. This force may cause the gate (of either a selflocking or a non-locking snap hook) to open, allowing the snap hook

or carabiner to disengage from the connecting point.

Small ring or other

non-compatibly

shaped element

Figure 7 - Inappropriate Connections

1. Force is applied

to the Snap

Hook.

2. The Gate

presses against

the Connecting

Ring.

3. The Gate opens

allowing the

Snap Hook to

slip off.

Page 14

2.10 CONNECTING SUBSYSTEMS: Connecting subsystems (self-retracting lifeline, lanyard, rope grab and

lifeline, cable sleeve) must be suitable for your application (see Table 1). See subsystem manufacturer’s

instructions for more information. Some harness models have web loop connection points. Do not use snap

hooks to connect to web loops. Use a self-locking carabiner to connect to a web loop. Ensure the carabiner

cannot cross-gate load (load against the gate rather than along the backbone of the carabiner). Some

lanyards are designed to choke onto a web loop to provide a compatible connection. See Figure 8. Lanyards

may be sewn directly to the web loop forming a permanent connection. Do not make multiple connections

onto one web loop, unless choking two lanyards onto a properly sized web loop.

Figure 8 - Web Loop Connection

1. Insert Lanyard Web Loop (A) through Web Loop

or D-ring on harness (B).

1

2. Insert opposite end of Lanyard through the

Lanyard Web Loop.

3. Pull the Lanyard through the connecting Web

B

A

Loop to secure.

2

3

2.11 ANCHORAGE & ANCHORAGE STRENGTH: Anchorage and anchorage strength requirements are dependent

on the full body harness application (see Figure 3). In accordance with ANSI Z359.1, anchorages selected for Fall

Arrest Systems must meet the anchorage strength requirements defi ned in Table 2.

Table 2 - Anchorage Strength Requirements

Fall Arrest

Restraint

Work Positioning

Rescue

Climbing The structure to which a climbing system is attached must sustain the loads required by that

1 Multiple Systems:

or Certifi ed anchorages shall be multiplied by the number of systems attached to the anchorage.

2 Certifi ed Anchorage: An anchorage for fall arrest, positioning, restraint, or rescue systems that a qualifi ed person certifi es to be

capable of supporting the potential fall forces that could be encountered during a fall or that meet the criteria for a certifi ed anchor-

age prescribed in this standard.

1

Non-Certifi ed Anchorages: 5,000 lbs (22.2 kN)

2

Certifi ed Anchorages

: 2 times the Maximum Arresting Force for Certifi ed

Anchorages

1

1

1

Non-Certifi ed Anchorages 1,000 (4,5 kN)

2

Certifi ed Anchorages

: 2 times the foreseeable force for certifi ed anchorages.

Non-Certifi ed Anchorages 3,000 lbs (13.3 kN)

2

Certifi ed Anchorages

: 2 times the foreseeable force for certifi ed anchorages.

Non-Certifi ed Anchorages 3,000 lbs (13.3 kN)

2

Certifi ed Anchorages

: 5 times the foreseeable force for certifi ed anchorages.

particular system. See the instructions for the climbing system for requirements.

When more than one of the defi ned system is attached to an anchorage, the strength defi ned for Non-Certifi ed

Page 15

3.0 DONNING AND USE

WARNING: Do not alter or intentionally misuse this equipment. Consult Capital Safety when using this

equipment in combination with components or subsystems other than those described in this manual. Some

subsystem and component combinations may interfere with the operation of this equipment. Use caution when

using this equipment around moving machinery, electrical and chemical hazards, and sharp edges.

3.1 BEFORE EACH USE: Before each use of this equipment inspect the ExoFit NEX™ Full Body Harness

according to Section 5 of this manual.

3.2 PLANNING: Plan your system before use. Consider all factors that will affect your safety during use of this

equipment. Consider the following aspects when planning your system:

• ANCHORAGE: Select an anchorage that meets the anchorage requirements specifi ed in Section 2.

• SHARP EDGES: Avoid working where system components may be in contact with, come in contact with,

or abrade against, unprotected sharp edges.

• AFTER A FALL: Any equipment which has been subjected to the forces of arresting a fall, or exhibits

damage consistent with the effect of fall arrest forces as described in Section 5, must be removed from

service immediately and destroyed by the user, the rescuer

• RESCUE: The employer must have a rescue plan when using this equipment. The employer must have

the ability to perform a rescue quickly and safely.

3.3 DONNING AND FITTING THE HARNESS: The ExoFit NEX™ Full Body Harness is available in Vest

(Figure 1) and Cross-Over (Figure 10) styles. Donning procedures will vary with the harness style.

WARNING: Do not alter or intentionally misuse this equipment. Consult Capital Safety when using this

equipment in combination with components or subsystems other than those described in this manual. Some

subsystem and component combinations may interfere with the operation of this equipment. Use caution when

using this equipment around moving machinery, electrical and chemical hazards, and sharp edges.

1

, or an authorized person2.

Figure 9 - Vest Style Harness Figure 10 - Cross-Over Style Harness

A

A

A. Belt Loops A. Belt Loops

1 Rescuer: Person or persons other than the rescue subject acting to perform an assisted rescue by operation of a rescue

system.

2 Authorized Person: A person assigned by the employer to perform duties at a location where the person will be exposed to

a fall hazard (otherwise referred to as “user” for the purpose of these instructions).

Page 16

A. EXOFIT NEX™ VEST STYLE FULL BODY HARNESS: The ExoFit NEX™ Vest Style Harness

incorporates loops for a removable waist belt (see Figure 9). The belt can be installed through the two

loops in the harness located in the lower back shoulder straps. The belt will pass through the harness

just below the padded area. The hip pad, if used, is secured to the belt by passing the belt through the

hip pad loops. Don the Vest Style Full Body Harness per the following steps and corresponding images in

Figure 11:

Step 1. Locate back D-ring held in position by the D-ring pad; lift up harness and hold by this

D-ring. Ensure the straps are not twisted.

Step 2. Grasp the shoulder straps and slip the harness onto one arm. The D-ring will be located on

your back side. Ensure that the straps are not tangled and hang freely. Slip your free arm

into the harness and position the shoulder straps on top of your shoulder. Ensure that the

straps are not tangled and hang freely. The chest strap, with quick connect buckle, will be

positioned on the front side when worn properly.

Step 3. Reach between your legs and grasp the gray leg strap on your left side. Bring the strap up

between your legs and connect it by inserting the tab of the buckle into receptor of quick

connect buckle on the left side as shown in Figure 11. You will hear a click when the tab

engages properly. Connect the right leg strap using the same procedure. To adjust the

leg straps, unlock

the webbing lock on the quick connect buckle and pull on the strap.

A plastic end keeper on the end of the strap will stop it from pulling completely out of the

buckle. When the strap is properly adjusted, lock the webbing lock. To release the buckle,

press the silver-colored tabs on the buckle towards each other with one hand, while pulling

on the tab portion of the buckle with the other hand.

NOTE: Locking and unlocking the webbing lock prevents or allows the strap to slide

between the sliding bar and slot on the female end of the quick connect buckle. It does

not control engagement or disengagement of the buckle ends and will not affect the

buckle connection in the event of a fall.

Step 4. Attach the chest strap by inserting the tab of the buckle into the receptor of the quick

connect buckle. You will hear a click when the tab engages properly. The chest strap should

be 6 in. (15 cm) down from the top of your shoulders. Pass excess strap through the loop

keepers. To adjust the chest strap, unlock

the webbing lock on the quick connect buckle

and pull on the strap. A plastic end keeper on the end of the strap will stop it from pulling

completely out of the buckle. When the strap is properly adjusted, lock the webbing lock.

To release the buckle, press the silver-colored tabs on the buckle toward each other with

one hand, while pulling on the tab portion of the buckle with the other hand.

Step 5. Adjust shoulder straps to a snug fi t with the Vertical Torso Adjusters (see Figure 11): Left

and right sides of shoulder straps should be adjusted to the same length and the chest strap

should be centered on your lower chest, 6 in. (15 cm) down from shoulder. The front D-ring

on the vest style harness is moved up or down by adjusting the shoulder straps and leg

straps. Center the back D-ring between your shoulder blades. Note: On applicable models,

the back (dorsal) D-ring can be repositioned up or down as needed for a correct fi t. Adjust

leg straps to a snug fi t. At least 3 in. (8 cm) of webbing must extend past the buckle on the

leg straps. Adjust the waist belt (if present).

Page 17

Figure 11 - Donning the ExoFit NEX™ Vest Style Full Body Harness

Step 1 Step 2 Step 3

Duo-Lok™ Quick Connect Buckles

Connection: Connect buckle ends by inserting

the tab into the receptor until a click is heard.

Step 4

Strap Adjustment: Rotate Webbing Lock

to unlocked position

Rotate Webbing Lock to locked position

NOTE: The Webbing Lock does not control

engagement or disengagement of the buckle ends.

Revolver™ Vertical Torso Adjusters

Right

To Tighten: Turn

Ratchet Knob in

direction A.

A

To Loosen: Pull

Ratchet Knob

out and turn in

direction B.

NOTE: After

adjustment, tug

upwards on the

B

shoulder straps to

ensure that each

adjustor is locked in

place.

. Pull strap to adjust.

.

Left

A

Step 5

B

Page 18

B. EXOFIT NEX™ CROSS-OVER STYLE FULL BODY HARNESS: The ExoFit NEX™ Cross-Over Style

Harness incorporates loops for a removable waist belt. The belt can be installed through the two loops

in the harness located in the lower back shoulder straps (see Figure 10). The belt will pass through the

harness just below the padded area. The hip pad, if used, is secured to the belt by passing the belt

through the hip pad loops. Don the Cross-Over Style Full Body Harness per the following steps and

corresponding images in Figure 12:

Step 1. Locate the back D-ring held in position by the D-ring pad; lift up the harness and hold by

this D-ring. Ensure the straps are not twisted.

Step 2.

Grasp the shoulder straps between the back and front D-ring and slip the harness over your

head from the left side. Position the shoulder straps on top of your shoulders. Ensure that

the straps are not tangled and hang freely. The D-ring will be positioned on your back when

worn properly.

Step 3. Grasp the tab of the buckle located at your right hip and insert it into the receptor of the

quick connect buckle (see Figure 12). You will hear a click when the tab engages properly.

Step 4. Reach between your legs and grasp the gray leg strap on your left side. Bring the strap up

between your legs and insert the tab of the buckle into the receptor of the buckle on the left

side as shown in Figure 12. You will hear a click when the tab engages properly. Connect

the right leg strap using the same procedure. To adjust the leg straps, unlock the webbing

lock on the quick connect buckle and pull on the strap. A plastic end keeper on the end of

the strap will stop it from pulling completely out of the buckle. When the strap is properly

adjusted, lock the webbing lock.

To release the buckle, press the silver-colored tabs on the

buckle towards each other with one hand, while pulling on the tab portion of the buckle with

the other hand.

NOTE: Locking and unlocking the webbing lock prevents or allows the strap to slide

between the sliding bar and slot on the female end of the quick connect buckle. It does

not control engagement or disengagement of the buckle ends and will not affect the

buckle connection in the event of a fall.

Step 5. Adjust shoulder straps to a snug fi t with the Vertical Torso Adjusters (see Figure 12):

Left and right sides of the shoulder straps should be adjusted to the same length and the

front D-ring should be centered on your lower chest. The back D-ring should be centered

between your shoulder blades. Note: On ExoFit XP models, the back (dorsal) D-ring can

be repositioned up or down as needed for a correct fi t. Adjust the leg straps to a snug fi t.

At least 3 in. (8 cm) of webbing must extend past the buckle on the leg straps. Adjust the

waist belt (if present).

3.4 USE OF FALL ARREST D-RING OR ATTACHMENT ELEMENT: For fall arrest applications connect to the

D-ring or attachment element on your back, between your shoulder blades. Side D-rings, if present, are for

positioning or restraint applications only. Front D-ring, if present, is for ladder climbing, positioning, or other

applications with a limited free fall not exceeding 2 feet (0.6 m) with a 900 MAF requirement. For rescue,

back, shoulder, or front D-rings may be used. D-rings on seat sling are for work positioning or personnel

riding.

3.5 MAKING CONNECTIONS: When using a hook to connect to an anchorage or when coupling components

of the system together, ensure roll-out cannot occur. Roll-out occurs when interference between the hook

and mating connector causes the hook gate to unintentionally open and release. Self-locking snap hooks

and carabiners should be used to reduce the possibility of roll-out. Do not use hooks or connectors that

will not completely close over the attachment object. See subsystem manufacturer’s instructions for more

information on making connections.

3.6 CONNECTING SYSTEM COMPONENTS: After properly fi tting the full body harness, the user may then

connect to other system components. Follow the guidelines in Section 3.4 when selecting the correct

attachment element.

Page 19

Figure 12 - Donning the ExoFit NEX™ Cross-Over Style Full Body Harness

Step 1 Step 2 Step 3

Duo-Lok™ Quick Connect Buckles

Connection: Connect buckle ends by inserting the

tab into the receptor until a click is heard.

Step 4

Strap Adjustment: Rotate Webbing Lock to

unlocked position

Webbing Lock to locked position

NOTE: The Webbing Lock does not control

engagement or disengagement of the buckle ends.

Revolver™ Vertical Torso Adjusters

To Tighten: Turn Ratchet Knob in

direction A.

To Loosen: Pull Ratchet Knob out

and turn in direction B.

NOTE: After adjustment, tug

upwards on the shoulder straps to

ensure that each adjustor is locked

in place.

. Pull strap to adjust. Rotate

.

Left

A

Step 5

B

Page 20

3.7 SUSPENSION TRAUMA STRAP: The

ExoFit NEX™ Full Body Harness is equipped with

a Suspension Trauma Strap (Figure 13) to help

prolong allowable suspension time in the event

of a fall from height. It should only be used

in situations where a fall has occurred or for

training. To use the Suspension Trauma Strap:

Step 1. Unzip the Trauma Strap Pouch on each

hip of the harness and deploy the

Suspension Straps (Figure 13A).

Step 2. Raise the ends of the straps to access

the hook and loops. Insert the hook

into the loop that provides the desired

strap length.

Step 3. Lower the Suspension Strap and step

onto the strap to alleviate pressure

of the harness leg straps on the legs

(Figure 13B). Adjust the hook/loop

combination for optimal comfort.

WARNING: Maintain an upright position

following suspension. Do not lay down. Seek

medical attention following a suspension.

Figure 13 - Suspension Trauma Straps

A

B

3.8 EXOFIT NEX GLOBAL WIND ENERGY

HARNESS MODEL REPLACEABLE LUMBAR

PROTECTOR: The Lumbar Protector (A) can be

replaced in the fi eld when worn or damaged. (See

Figure 14)

Place the ExoFit harness on a fl at surface. Pull the

hip belt (B) completely out of the harness to free

the worn/damaged Lumbar Protector (A) and tool

loops (D, if installed).

To install the replacement Lumbar Protector:

Step 1. Reinsert the hip belt through the left

D-Ring (C), the end of the fi rst tool

loop (D, if installed), belt loops (E) and

(F), and the end of the tool loop (D).

Step 2. Insert the hip belt through the

replacement Lumbar Protector (G), the

second tool loop (H, if installed), the

next two belt loops (I) and (K), the

end of the tool loop (H) and the right

D-Ring.

Figure 14 - Replaceable Lumbar Protector

A

C

G

I

H

D

E

B

F

K

D

H

Completed installation of replacement Lumbar

Protector.

Page 21

4.0 TRAINING

It is the responsibility of the purchaser and the user of this equipment to assure that they understand these

instructions and are trained in the correct care and use of this equipment. They must also be aware of the

operating characteristics, application limits, and the consequences of improper use of this equipment.

IMPORTANT: Training must be conducted without exposing the user to a fall hazard. Training should be

repeated on a periodic basis.

5.0 INSPECTION

5.1 i-Safe™ RFID TAG: The i-Safe™ RFID tag on the ExoFit NEX™ Harness (see “Figure 15 i-Safe™ RFID Tag”)

can be used in conjunction with the i-Safe handheld reading device and the web based portal to simplify

inspection and inventory control and provide records for your fall protection equipment.

Figure 15 i-Safe™ RFID Tag

A Wrap-Around Cover

B i-Safe™ RFID Tag

C Product Labels

A

B

C

5.2 FREQUENCY: Before each use inspect the full body harness according to Section 5.3. The harness must

be inspected by a competent person3, other than the user, at least annually. Record the results of each

formal inspection in the inspection and maintenance log in section Section 9, or use the i-Safe™ inspection

web portal to maintain your inspection records.

IMPORTANT: If the full body harness has been subjected to fall arrest or impact forces it must be

immediately removed from service and destroyed.

IMPORTANT: Extreme working conditions (harsh environments, prolonged use, etc.) may require

increasing the frequency of inspections.

5.3 INSPECTION: Inspect the ExoFit NEX™ Full Body Harness as follows:

Step 1. Inspect harness hardware (buckles, D-rings, pads, loop keepers, vertical torso

adjusters): These items must not be damaged, broken, distorted, and must be free of sharp

edges, burrs, cracks, worn parts, or corrosion. PVC coated hardware must be free of cuts, rips,

tears, holes, etc. in the coating to ensure non-conductivity. Ensure that release tabs on buckles

work freely and that a click is heard when the buckle engages. Inspect vertical torso adjusters for

proper operation. Ratchet knobs should turn with ease in a clockwise direction and should only

turn counterclockwise when the knob is pulled out.

Step 2. Inspect webbing: Material must be free of frayed, cut, or broken fi bers. Check for tears,

abrasions, mold, burns, or discoloration. Inspect stitching; check for pulled or cut stitches. Broken

stitches may be an indication that the harness has been impact loaded and must be removed

from service. When performing the annual formal inspection, unsnap and open the back pad to

facilitate inspection of the webbing.

Step 3. Inspect the labels: All labels should be present and fully legible (see Section 8).

Step 4. Inspect system components and subsystems: Inspect each system component or subsystem

according to manufacturer’s instructions.

3 Competent Person: One who is capable of identifying existing and predictable hazards in the surroundings or working

conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective

measures to eliminate them.

Page 22

Step 5. Record inspection data: Record the inspection date and results in the Inspection and

Maintenance Log (see Section 9).

Step 6. Inspect the Stitched Impact Indicator: The stitched impact indicator is a section of webbing

that is lapped back on itself and secured with a specifi c stitch pattern holding the lap (see

Figure 16). The stitch pattern is designed to release when the harness arrests a fall or has been

subjected to an equivalent force If the impact indicator has been activated the harness must be

removed from service and destroyed.

Step 7. Inspect Suspension Trauma Straps: Check the trauma strap pouches for damage and secure

connection to the harness. Unzip the trauma strap pouch on each hip of the harness and inspect

suspension trauma straps. Webbing and pouch material must be free of frayed, cut, or broken

fi bers. Check for tears, abrasions, mold, burns, discoloration, or knots. Verify that one pouch is

marked ‘Hook’ and the other marked ‘loop’.

IMPORTANT: If inspection reveals a defective condition, remove the unit from service immediately and

destroy it.

NOTE: Only DBI-SALA or parties authorized in writing may make repairs to this equipment.

Figure 16- Stitched Impact Indicator

A. Stitched Impact Indicator

A

A

6.0 MAINTENANCE, SERVICING, AND STORAGE

6.1 WASHING INSTRUCTIONS: Washing procedures for the ExoFit NEX™ Full Body Harness are as follows:

Step 1. Spot clean the ExoFit NEX™ full body harness with water and a mild soap solution.

IMPORTANT: Use a bleach-free detergent when washing the harness and pads. Fabric softener or dryer

sheets SHOULD NOT be used when laundering and drying the harness and pads.

Step 2. Water temperature for wash and rinse must not exceed 160° F (70° C).

Step 3. The harness and pads may be air dried or tumble dried on low heat not exceeding 200° F (90° C).

NOTE: More information on cleaning is available from Capital Safety. If you have questions concerning the

condition of your harness, or have any doubt about putting it into service, contact Capital Safety.

6.2 ADDITIONAL MAINTENANCE AND SERVICING: Additional maintenance and servicing procedures must

be completed by a factory authorized service center. Authorization must be in writing. Do not attempt to

disassemble the unit.

6.3 STORAGE: Store the ExoFit NEX™ Full Body Harness in a cool, dry, clean environment out of direct sunlight.

Avoid areas where chemical vapors may exist. Thoroughly inspect the full body harness after extended

storage.

Page 23

7.0 SPECIFICATIONS

7.1 PERFORMANCE:

• Maximum Free Fall Distance: No greater than 6 ft (1.8 m), per federal law and ANSI Z359.1.

NOTE: Harness is acceptable for use with free fall distances exceeding 6 feet (1.8 m) if used with

appropriate connecting system.

• Maximum Arresting Force: 1,800 lbs. (13 kN)

• Maximum Capacity:

• 420 lbs. (191 kg) per OSHA

• 310 lbs. (141 kg) per ANSI Z359.1

• 352 lbs. (160 kg) per CS

• Approximate Weight:

Harness only: 3 lbs. (1.4 kg)

Harness with Side D-rings: Add 1/2 lb. (.23 kg)

Harness with Front D-ring: Add 1/4 lb. (.11 kg)

Harness with Back Pad or Belt: Add 1 lb. (.45 kg)

7.2 MATERIALS:

A Z259.10-06

• Webbing Materials: 6,000 lbs (27 kN) Polyester; 7,000 lbs (31 kN) Tensile Strength Nylon; 7,000 lbs

Tensile Strength Nomex4 covered Kevlar

4

• Pad and Label Cover Materials:

• Blend of Nylon and Polyester.

• All outer fabric is Nomex and Kevlar blend fabric. (Arc Flash models only)

• Fire Resistant Hook and Loop Fasteners. (Arc Flash models only)

• Optional Accessories:

• Hip Pad with side D-rings

• Nomex® covered Kevlar® webbing

• Non-sparking/ Non-conductive PVC coated hardware

• Arc-rated hip, leg, and back pads

• Polyurethane coated, arc-rated dorsal web loop

7.3 STANDARDS: When installed and used per the requirements and recommendations in the manual, the

ExoFit NEX™ Full Body Harness meets local, state, and federal requirements defi ned in Section 1.2.

4 ®: Nomex® and Kevlar® are registered trademarks of DuPont.

Page 24

9.0 INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 25

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 26

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 27

1100381

1100382

1100383

1100384

1100385

1100386

1100387

1100388

1100397

1100398

1100920

1100921

1100922

1100923

1101739

1101742

1101743

1101744

1101749

1101759

1101919

1101921

1101922

1101923

1101924

1102016

1102017

1102018

1102019

1102023

1102705

1102706

1102707

1102708

1102709

1103070

1103071

1103072

1103072H

1103073

1103073H

1103074

1103084

1103085

1103086

1103087

1103088

1103089

1103094

1103095

1113000

1113001

1113001H

1113004

1113004H

1113007

1113007H

1113008

1113008H

1113009

1113009H

1113010

1113010H

1113011

1113011H

1113012

1113012H

1113013

1113013H

1113014

1113014H

1113015

1113016

1113016C

1113018

1113019

1113020

1113021

1113022

1113023

1113024

1113025

1113026

1113027

1113028

1113030

1113031

1113032

1113033

1113034

1113036

1113037

1113038

1113039

1113040

1113043

1113045

1113046

1113046H

1113049

1113049H

1113052

1113052H

1113055

1113055H

1113058

1113058H

1113060

1113061

1113061H

1113064

1113064H

1113067

1113067H

1113068

1113069

1113070

1113070H

1113071

1113072

1113073

1113073H

1113075

1113076

1113076H

1113077

1113078

1113079

1113079H

1113080

1113081

1113082

1113082H

1113083

1113085

1113085H

1113088

1113088H

1113090

1113091

1113092

1113093

1113094

1113095

1113096

1113097

1113098

1113100

1113103

1113105

1113106

1113106H

1113109

1113109H

1113112

1113115

1113118

1113120

1113121

1113124

1113124H

1113127

1113130

1113133

1113135

1113136

1113137

1113138

1113139

1113140

1113142

1113143

1113145

1113148

1113150

1113151

1113151H

1113154

1113154H

1113157

1113157H

1113160

1113160H

1113162

1113163

1113164

1113165

1113166

1113167

1113168

1113169

1113170

1113171

1113172

1113173

1113180

1113181

1113182

1113183

1113184

1113185

1113186

1113187

1113188

1113189

1113190

1113190H

1113191

1113191H

1113192

1113192H

1113193

1113193H

1113194

1113195

1113196

1113197

1113198

1113199

1113200

1113201

1113202

1113203

1113204

1113205

1113206

1113207

1113208

1113220

1113225

1113226

1113227

1113228

1113229

1113230

1113231

1113232

1113233

1113234

1113240

1113241

1113242

1113243

1113244

1113245

1113246

1113247

1113248

1113249

1113250

1113251

1113252

1113253

1113254

1113255

1113256

1113257

1113258

1113259

1113260

1113261

1113262

1113263

1113264

1113269

1113270

1113271

1113272

1113273

1113274

1113275

1113276

1113277

1113278

1113279

1113280

ANSI Models

1113281

1113282

1113285

1113286

1113287

1113288

1113290

1113291

1113291H

1113292

1113292H

1113293

1113293H

1113294

1113295

1113296

1113297

1113298

1113303

1113305

1113306

1113307

1113308

1113309

1113310

1113311

1113312

1113313

1113314

1113315

1113316

1113317

1113318

1113319

1113320

1113321

1113322

1113323

1113324

1113325

1113326

1113327

1113328

1113329

1113330

1113331

1113332

1113333

1113334

1113335

1113336

1113337

1113338

1113339

1113345

1113346

1113347

1113348

1113350

1113351

1113352

1113353

1113354

1113355

1113356

1113357

1113358

1113359

1113360

1113361

1113362

1113363

1113364

1113365

1113366

1113367

1113368

1113369

1113370

1113371

1113372

1113373

1113374

1113375

1113375H

1113376

1113376H

1113377

1113377H

1113378

1113378H

1113379

1113380

1113381

1113382

1113383

1113384

1113385

1113386

1113387

1113388

1113389

1113390

1113391

1113392

1113393

1113394

1113395

1113396

1113397

1113398

1113399

1113400

1113401

1113402

1113403

1113404

1113405

1113406

1113407

1113408

1113409

1113410

1113411

1113412

1113413

1113414

1113415

1113416

1113417

1113418

1113419

1113420

1113421

1113422

1113423

1113424

1113425

1113426

1113427

1113428

1113434

1113435

1113436

1113437

1113438

1113439

1113445

1113446

1113447

1113448

1113459

1113460

1113461

1113462

1113463

1113464

1113465

1113466

1113467

1113468

1113469

1113470

1113471

1113472

1113473

1113474

1113475

1113476

1113477

1113478

1113479

1113480

1113481

1113482

1113483

1113484

1113485

1113486

1113487

1113490

1113491

1113492

1113493

1113494

1113495

1113496

1113497

1113498

1113499

1113500

1113501

1113502

1113503

1113504

1113505

1113506

1113507

1113508

1113509

1113510

1113511

1113512

1113513

1113514

1113515

1113516

1113517

1113518

1113519

1113520

1113521

1113522

1113523

1113524

1113525

1113526

1113527

1113528

1113529

1113530

1113531

1113532

1113533

1113534

1113535

1113536

1113537

1113538

1113539

1113540

1113541

1113542

1113543

1113544

1113545

1113546

1113547

1113548

1113549

1113550

1113551

1113552

1113553

1113554

1113555

1113556

1113557

1113558

1113559

1113560

1113561

1113562

1113563

1113564

1113565

1113566

1113567

1113568

1113569

1113570

1113571

1113572

1113573

1113574

1113575

1113576

1113577

1113578

1113579

1113580

1113581

1113582

1113583

1113584

1113585

1113586

1113587

1113588

1113589

1113590

1113591

1113592

1113593

1113594

1113595

1113596

1113597

1113598

1113599

1113600

1113601

1113602

1113603

1113604

1113605

1113606

1113607

1113608

1113609

1113610

1113611

1113612

1113613

1113614

1113615

1113616

1113617

1113618

1113619

1113620

1113621

1113622

1113623

1113624

1113625

1113626

1113627

1113628

1113629

1113630

1113631

1113632

1113633

1113634

1113635

1113636

1113637

1113638

1113639

1113640

1113641

1113642

1113643

1113644

1113645

1113646

1113647

1113648

1113649

1113650

1113651

1113652

1113653

1113654

1113655

1113656

1113657

1113658

1113659

1113660

1113661

1113662

1113663

1113664

1113665

1113666

1113667

1113668

1113669

1113670

1113671

1113672

1113673

1113674

1113675

1113676

1113677

1113678

1113679

1113680

1113681

1113682

1113683

1113684

1113685

1113686

1113687

1113688

1113689

1113690

1113691

1113692

1113693

1113694

1113695

1113696

1113697

1113698

1113703

1113704

1113705

1113706

1113707

1113708

1113709

1113710

1113711

1113712

1113713

1113714

1113715

1113716

1113717

1113718

1113719

1113720

Page 28

1103070C

1103071C

1103072C

1103073C

1103074C

1103085C

1103086C

1103087C

1103088C

1103089C

1113000C

1113001C

1113001CH

1113002C

1113003C

1113004C

1113004CH

1113005C

1113006C

1113007C

1113007CH

1113010C

1113013C

1113015C

1113019C

1113022C

1113025C

1113028C

1113029C

1113030C

1113031C

1113034C

1113037C

1113040C

1113043C

1113045C

1113046C

1113049C

1113052C

1113055C

1113058C

1113060C

1113061C

1113061CH

1113064C

1113064CH

1113067C

1113067CH

1113070C

1113070CH

1113073C

1113075C

1113076C

1113079C

1113082C

1113085C

1113088C

1113090C

1113090CH

1113091C

1113091CH

1113094C

1113094CH

1113097C

1113100C

1113103C

1113105C

1113106C

1113109C

1113112C

1113115C

1113118C

1113120C

1113121C

1113124C

1113125C

1113126C

1113127C

1113128C

1113130C

1113133C

1113135C

1113136C

1113139C

1113142C

1113145C

1113148C

1113150C

1113151C

1113152C

1113153C

1113154C

1113155C

1113156C

1113157C

1113160C

1113163C

1113174

1113175

1113176

1113177

1113178

1113179

1113190C

1113190CH

1113191C

1113191CH

1113192C

1113192CH

1113193C

1113193CH

1113194C

1113195C

1113196C

1113197C

1113199C

1113210

1113211

1113212

1113213

1113214

1113215

1113216

1113217

1113218

1113219

1113220C

1113221C

1113222C

1113223C

1113224C

1113235C

1113236C

1113237C

1113238C

1113239C

1113264

1113265C

1113266C

1113267C

1113268C

1113290C

1113291C

1113292C

1113293C

1113295C

1113296C

1113297C

1113298C

1113299C

1113300C

1113301C

1113302C

1113315C

1113316C

1113317C

1113318C

1113319C

1113320C

1113321C

1113322C

1113323C

1113324C

1113325C

CSA Models

1113326C

1113327C

1113328C

1113329C

1113330C

1113331C

1113332C

1113333C

1113334C

1113335C

1113336C

1113337C

1113338C

1113339C

1113340C

1113341C

1113345C

1113346C

1113347C

1113348C

1113370C

1113371C

1113372C

1113373C

1113385C

1113386C

1113387C

1113388C

1113430C

1113431C

1113432C

1113433C

1113440C

1113441C

1113442C

1113449

1113450

1113451

1113452

1113453

1113454

1113455

1113456

1113457

1113458

1113459C

1113460C

1113467C

1113468C

1113509C

1113510C

1113511C

1113512C

1113513C

1113514C

1113515C

1113516C

1113517C

1113518C

1113519C

1113520C

1113521C

1113522C

1113523C

1113524C

1113525C

1113526C

1113527C

1113528C

1113529C

1113530C

1113531C

1113532C

1113557C

1113558C

1113559C

1113560C

1113561C

1113562C

1113563C

1113564C

1113565C

1113566C

1113567C

1113568C

1113569C

1113570C

1113571C

1113572C

1113573C

1113574C

1113575C

1113576C

1113577C

1113578C

1113579C

1113580C

1113581C

1113582C

1113590C

1113591C

1113592C

1113593C

1113594C

1113595C

1113596C

1113597C

1113598C

1113599C

1113600C

1113601C

1113602C

1113603C

1113604C

1113605C

1113606C

1113607C

1113608C

1113609C

1113610C

1113611C

1113612C

1113613C

1113614C

1113615C

1113616C

1113617C

1113644C

1113645C

1113646C

1113647C

1113648C

1113649C

1113650C

1113651C

1113652C

1113653C

1113654C

1113655C

1113656C

1113657C

1113658C

1113659C

1113660C

1113661C

1113662C

1113663C

1113664C

1113665C

1113666C

1113667C

1113668C

1113669C

1113670C

1113671C

1113672C

1113673C

1113674C

1113675C

1113676C

1113677C

1113678C

1113679C

1113680C

1113681C

1113682C

1113683C

1113684C

1113685C

1113686C

1113687C

1113688C

1113689C

1113690C

1113691C

1113692C

1113693C

1113694C

1113695C

1113696C

1113697C

1113698C

1113699C

1113700C

1113701C

1113702C

1121118C

1121119C

1121120C

1121218C

1121219C

1121220C

1122118C

1122119C

1122120C

1122121C

1122122C

1122123C

1122124C

1122218C

1122219C

1122220C

1122221C

1122222C

1122223C

1122224C

1123121C

1123122C

1123123C

1123124C

1123125C

1123126C

1123221C

1123222C

1123223C

1123224C

1123225C

1123226C

1124123C

1124124C

1124125C

1124126C

1124127C

1124223C

1124224C

1124225C

1124226C

1124227C

1125125C

1125126C

1125127C

1125128C

1125225C

1125226C

1125227C

1125228C

1126127C

1126128C

1126129C

1126130C

1126227C

1126228C

1126229C

1126230C

View other clothing & work wear made by DBI-Sala on our website.

Loading...

Loading...