Page 1

Instructions for the

following series products:

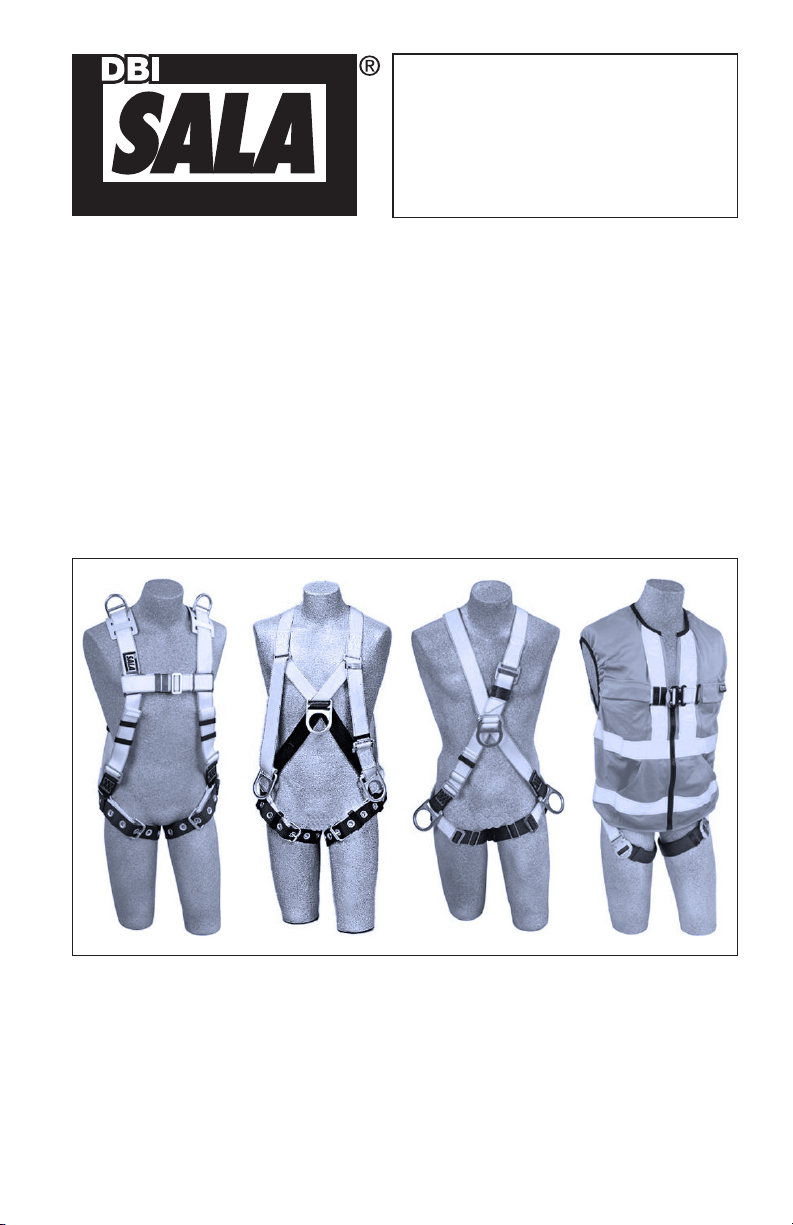

Full Body Harnesses

(See back pages for specic

model numbers.)

USER INSTRUCTION MANUAL

FULL BODY HARNESS

This manual is intended to meet the Manufacturer’s Instructions

as required by ANSIZ359 and CSA 259.10 and should be used as

part of an employee training program as required by OSHA

Form: 5908231

Rev: M

© Copyright 2009, DB Industries, Inc.

Page 2

Page 3

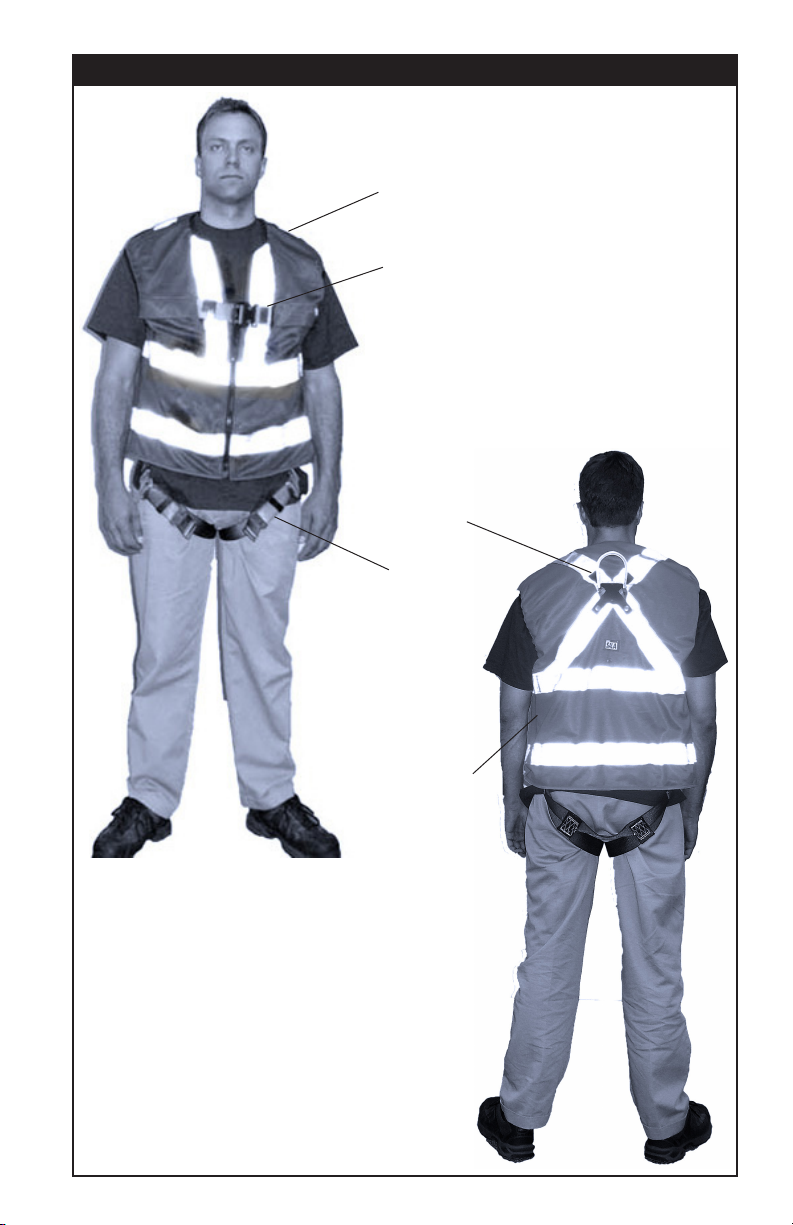

Figure 1 - Delta Vest™ Full Body Harness

Shoulder Strap

(inside vest)

Chest Strap

Attachment

Element for

Fall Arrest

(D-ring or

Web Loop)

Leg Strap

Labels and

RFID Tag

(inside vest)

3

Page 4

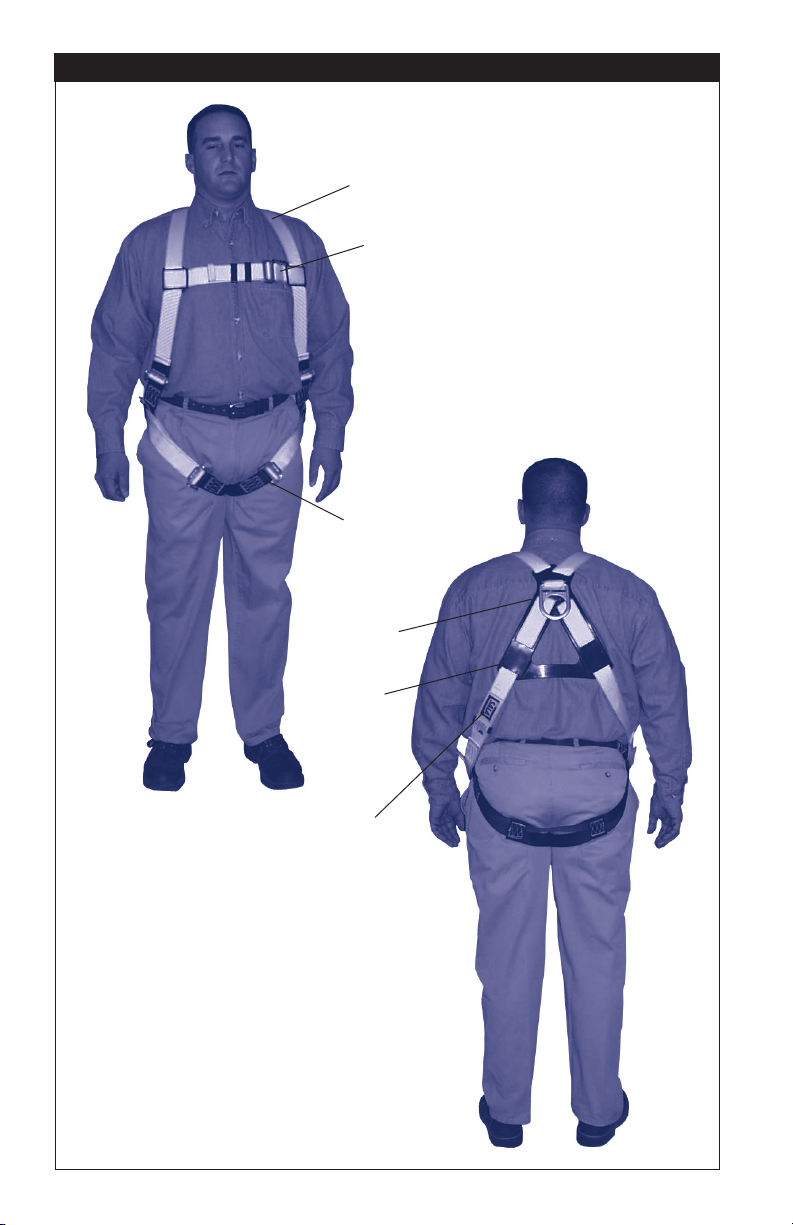

Figure 2 - Vest Style Full Body Harness

Shoulder Strap

Chest Strap

Leg Strap

Attachment

Element for

Fall Arrest

(D-ring or

Web Loop)

D-ring Pad

Labels and

RFID Tag

4

Page 5

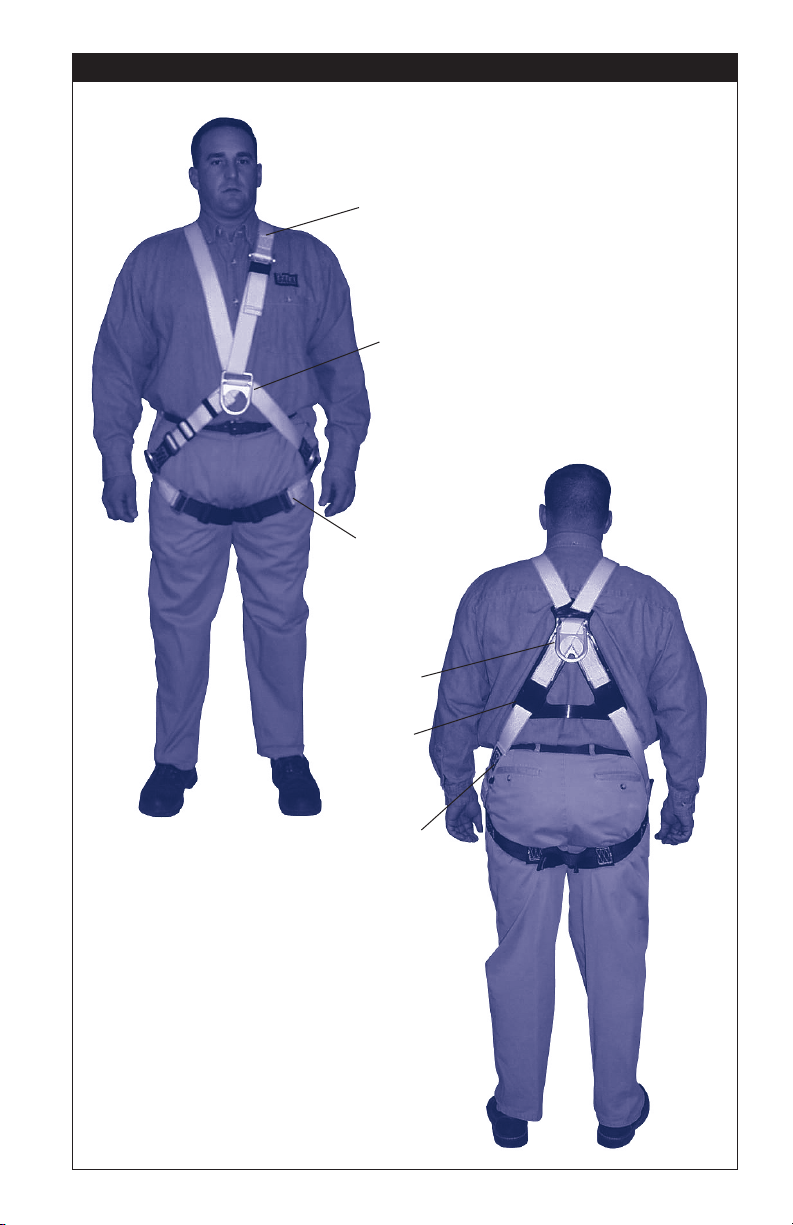

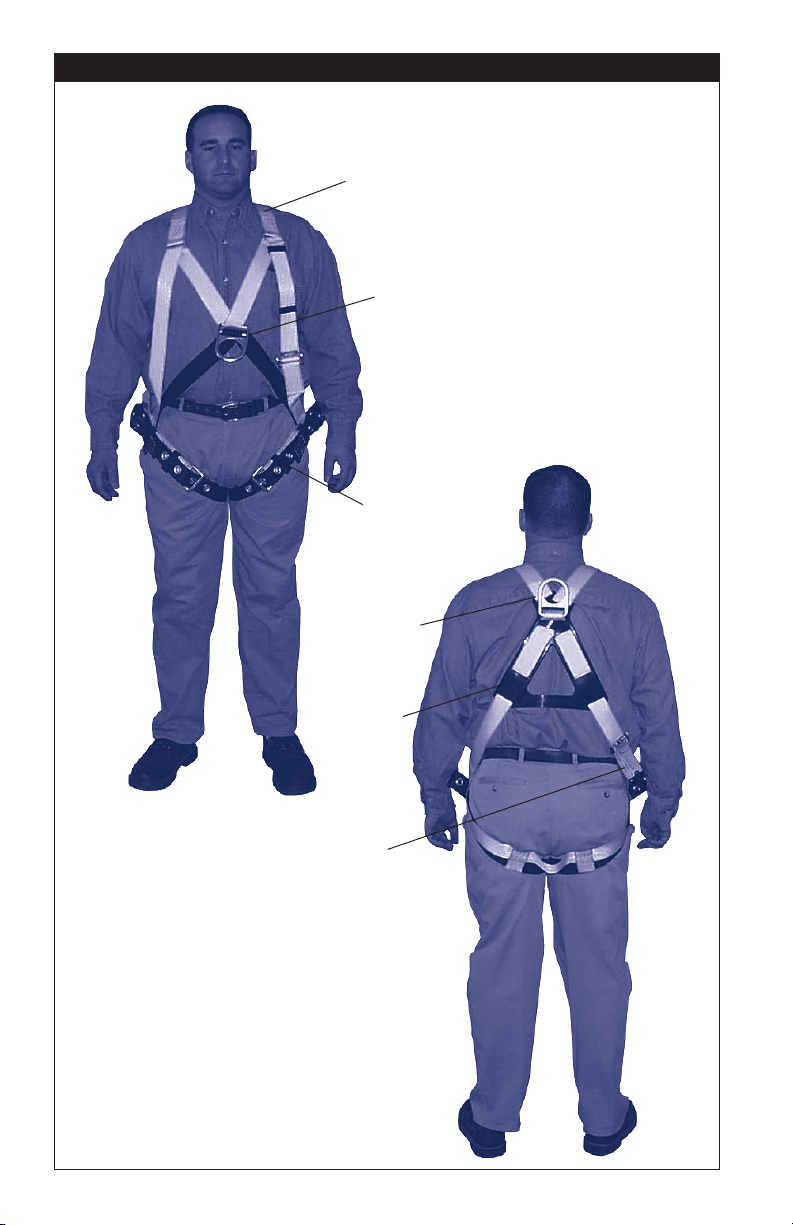

Figure 3 - Cross-over Style Full Body Harness

Shoulder Strap

Front Attachment Element

(D-ring or Web Loop)

Leg Strap

Attachment

Element for

Fall Arrest

(D-ring or

Web Loop)

D-ring Pad

Labels and

RFID Tag

5

Page 6

Figure 4 - Step-in Style Full Body Harness

Shoulder Strap

Front D-ring

Leg Strap

Attachment

Element for

Fall Arrest

(D-ring or

Web Loop)

D-ring Pad

Labels and

RFID Tag

6

Page 7

WARNING: This product is part of a personal fall arrest, restraint,

work positioning, personnel riding, climbing, or rescue system. The

user must follow the manufacturer’s instructions for each component

of the system. These instructions must be provided to the user of this

equipment. The user must read and understand these instructions

before using this equipment. Manufacturer’s instructions must be

followed for proper use and maintenance of this equipment. Alterations

or misuse of this product or failure to follow instructions may result in

serious injury or death.

IMPORTANT: If you have questions on the use, care, or suitability of

this equipment for your application, contact DBI‑SALA.

IMPORTANT: Before using this equipment, record the product

identication information from the ID label in the inspection and

maintenance log in section 9.0 of this manual.

DESCRIPTIONS

Delta Vest™ Full Body Harness: See Figure 1.

Vest Style Full Body Harness: See Figure 2.

Cross-Over Style Full Body Harness: See Figure 3.

Step-In Style Full Body Harness: See Figure 4.

OPTIONS:

DBI-SALA Full Body Harnesses are available with options and

accessories. Following is a partial list of commonly used options

and accessories (some options may not be available on all

harnesses):

• Shoulder D-rings

• Side D-rings

• Hip pad with side D-rings

• Quick Connect buckles

• Tongue buckle body belt

• Loops on harness for body belt

• Kevlar® webbing

• High visibility webbing

• Non-sparking/Non conductive PVC coated hardware

• Shoulder pads

• Tool belt support straps

• Seat sling

• Lanyard attached directly to D-ring or attachment element

• Snap fastener on shoulder strap for retaining lanyard

• Delta Vest™

• Tool holders

7

Page 8

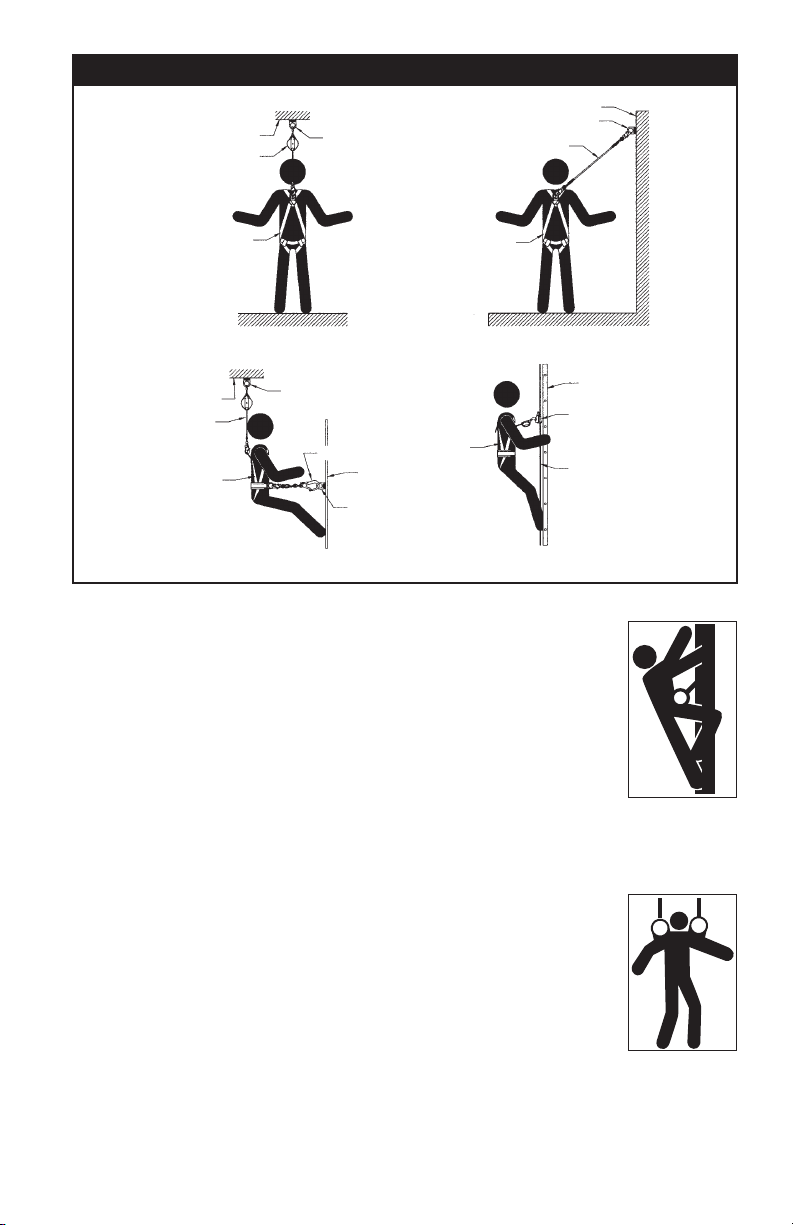

1.0 APPLICATIONS

1.1 PURPOSE: DBI-SALA full body harnesses are to be used as

components in personal fall arrest, restraint, work positioning, or

rescue systems. See Figures 1, 2, 3, and 4 for harness styles.

Harnesses included in this manual are full body harnesses and

meet ANSI Z359.1, OSHA, and CSA Z259.10 requirements. See

Figure 5 for application illustrations.

• Full body harnesses with Kevlar web should be used when

working with tools, materials, or environments of high

temperature (foundries, chemical manufacturing, steel

fabrication, emergency rescue services, re services, welders,

oil industry, nuclear industry, explosives).

• Harnesses with PVC coated hardware should be used when

working in explosive or electrically conductive environments, or

where surfaces must be protected from the hardware.

• Harnesses with high visibility webbing should be used when

increased visibility of the user is required.

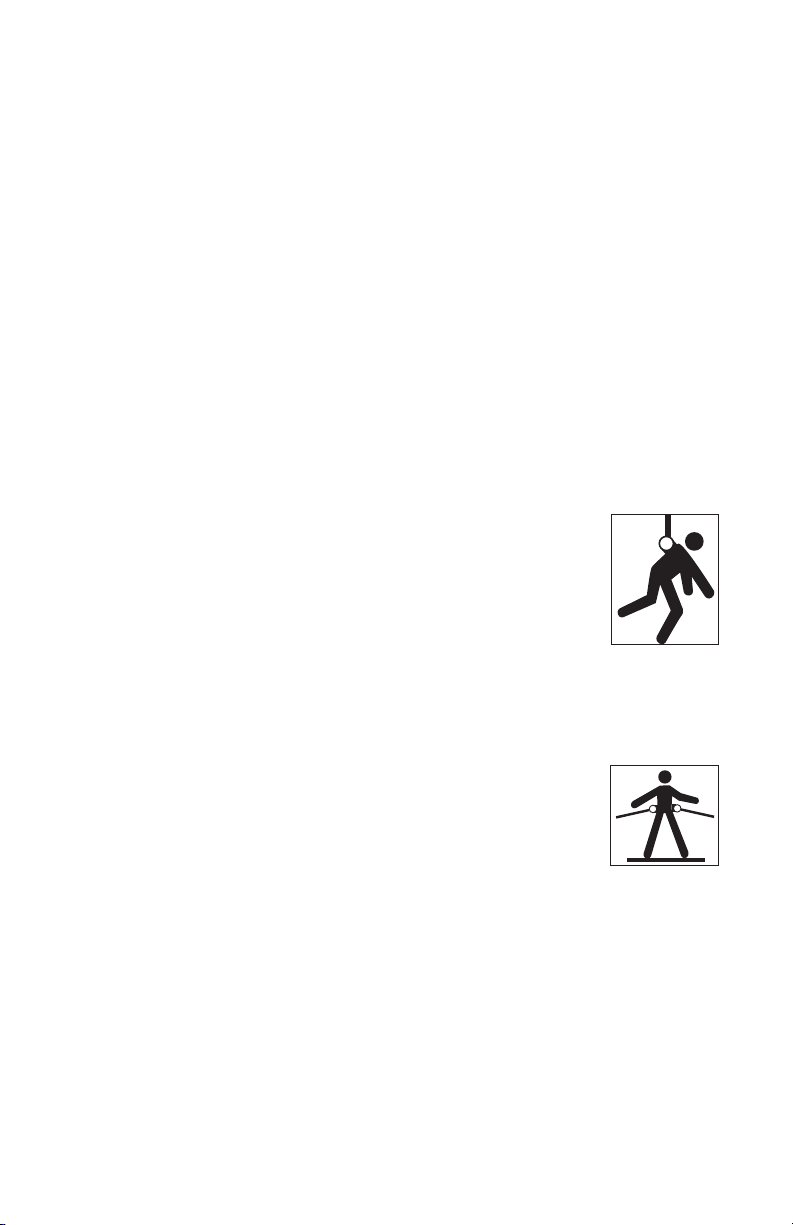

A. PERSONAL FALL ARREST: The full body harness

is used as a component of a personal fall arrest

system. Personal fall arrest systems typically

include a full body harness and a connecting

subsystem (energy absorbing lanyard). Maximum

arresting force must not exceed 1,800 lbs (8

kN).For fall protection applications connect the

fall arrest subsystem (example: lanyard, SRL,

energy absorber, etc.) to the D-ring or attachment

element on your back, between your shoulder

blades.

B. WORK POSITIONING: The full body harness

is used as a component of a work positioning

system to support the user at a work position.

Work positioning systems typically include a full

body harness, positioning lanyard, and a back-up

personal fall arrest system. For work positioning

applications, connect the work positioning

subsystem (example: lanyard, Y-lanyard, etc.)

to the lower (hip level) side or belt mounted

work positioning attachment anchorage elements

(D-rings). Never use these connection points for

fall arrest.

8

Page 9

Anchorage

Connecting Subsystem

(Self Retracting Lifeline

Shown)

Figure 5 - Applications

Anchorage Connector

Anchorage Connector

Restraint Lanyard

Anchorage

Full Body Harness

Fall Arrest

Anchorage

Back-up Fall

Arrest System

Full Body

Harness

Work Positioning

Anchorage

Connecto

Restraint Lanyard

r

Anchorage

Connector

Anchorage

Full Body Harness

Restraint

Cross-over

Full Body

Harness

Ladder Climbing

C. LADDER CLIMBING: The full body harness

is used as a component of a climbing system

to prevent the user from falling when climbing

a ladder or other climbing structure. Climbing

systems typically include a full body harness,

vertical cable or rail attached to the structure, and

climbing sleeve.For ladder climbing applications,

harnesses equipped with a frontal D-ring in the

sternal location may be used for fall arrest on

xed ladder climbing systems. These are dened

in Z259.2.1 in Canada and ANSI A14.3 in the

United States.

Ladder

Cable Sleeve

Cable

D. RESCUE: The full body harness is used as a

component of a rescue system. Rescue systems

are configured depending on the type of rescue.

For limited access (conned space) applications,

harnesses equipped with D-rings on the shoulders

may be used for entry and egress into conned

spaces where worker prole is an issue.

9

Page 10

E. CONTROLLED DESCENT: For controlled descent

applications, harnesses equipped with a single

sternal level D-ring, one or two frontal mounted

D-rings, or a pair of connectors originating below

the waist (such as a seat sling) may be used for

connection to a descender or evacuation system

(reference in Z259.10 in Canada).

F. RESTRAINT: The full body harness is used as a component

of a restraint system to prevent the user from reaching a fall

hazard. Restraint systems typically include a full body harness

and a lanyard or restraint line.

1.2 LIMITATIONS: Consider the following application limitations

before using this equipment:

A. CAPACITY: These full body harnesses are designed for use

by persons with a combined weight (clothing, tools, etc.) of no

more than 420 lbs. Make sure all of the components in your

system are rated to a capacity appropriate to your application

B. FREE FALL: Personal fall arrest systems used with this

equipment must be rigged to limit the free fall to 6 feet (1.8

M) (ANSI Z359.1). Restraint systems must be rigged so that

no vertical free fall is possible. Work positioning systems must

be rigged so that free fall is limited to 2 feet (.6 m) or less.

Personnel riding systems must be rigged so that no vertical

free fall is possible. Climbing systems must be rigged so that

free fall is limited to 18 in. (.46 cm) or less. Rescue systems

must be rigged so that no vertical free fall is possible. See

subsystem manufacturer’s instructions for more information.

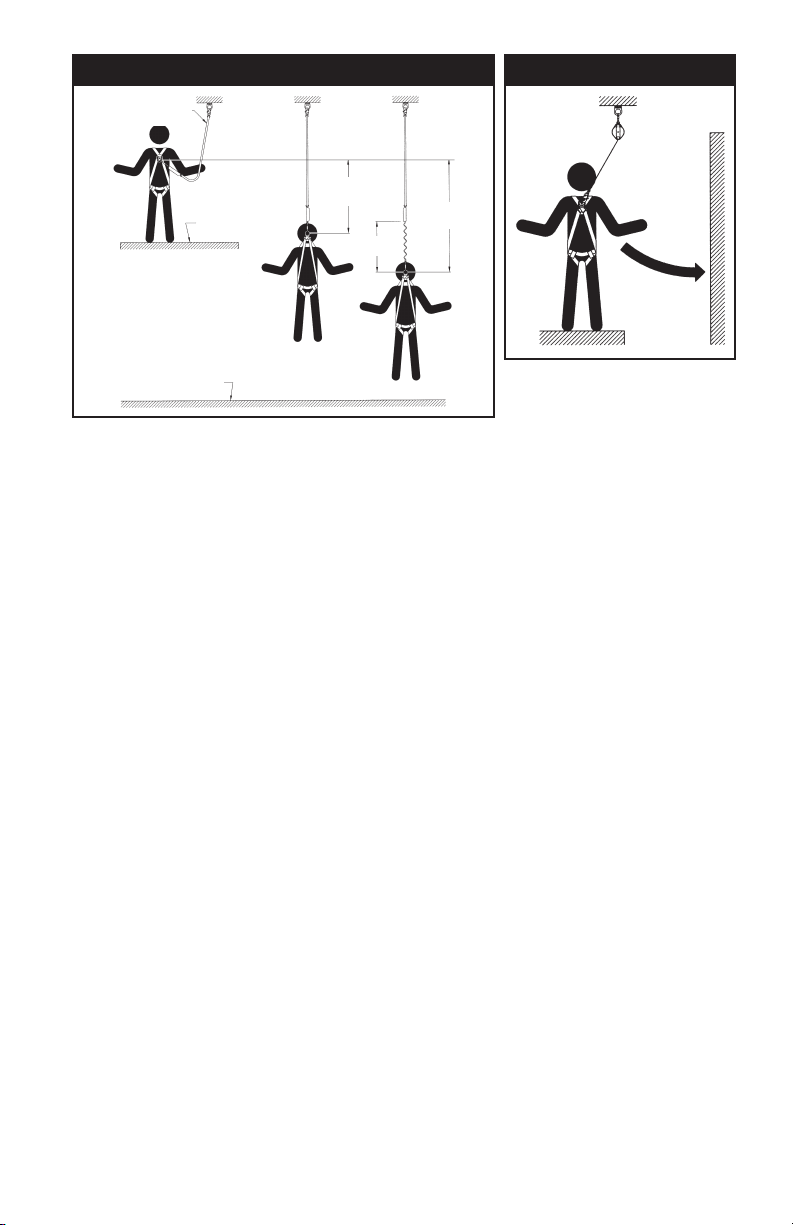

C. FALL CLEARANCE: See Figure 6. There must be sufcient

clearance below the user to arrest a fall before the user strikes

the ground or other obstruction. The clearance required is

dependent on the following factors:

• Elevation of anchorage

• Connecting subsystem length

• Deceleration distance

• Free fall distance

• Worker height

• Movement of harness attachment element

See subsystem manufacturer’s instructions for more information.

10

Page 11

Figure 6 - Fall Clearance

Connecting Subsystem

(Energy Absorbing Lanyard

NOTE: When calculating

fall clearance, an

additional 6 in. (15.3

cm) should be included

to allow for expected

harness stretch.

Lower Level or Obstruction

shown)

Working Level

Free Fall

6 ft. max

(ANSI Z359.1)

Deceleration

Distance

Total Fall Distance

(Free Fall +

Deceleration)

Figure 7 - Swing Fall

D. SWING FALLS: See Figure 7. Swing falls occur when the

anchorage point is not directly above the point where a fall

occurs. The force of striking an object in a swing fall may

cause serious injury or death. Minimize swing falls by working

as close to the anchorage point as possible. Do not permit

a swing fall if injury could occur. Swing falls will signicantly

increase the clearance required when a self-

retracting lifeline or

other variable length connecting subsystem is used.

E. EXTENDED SUSPENSION: A full body harness is not

intended for use in extended suspension applications. If the

user is going to be suspended for an extended length of time

it is recommended that some form of seat support be used.

DBI-SALA recommends a seat board, suspension workseat,

seat sling, or a boatswain chair. Contact DBI-SALA for more

information on these items.

Swing

Fall

Hazard

F. ENVIRONMENTAL HAZARDS: Use of this equipment in areas

with environmental hazards may require additional precautions

to prevent injury to the user or damage to the equipment.

Hazards may include, but are not limited to; heat, chemicals,

corrosive environments, high voltage power lines, gases,

moving machinery, and sharp edges.

G. HARNESSES FOR HIGH TEMPERATURE ENVIRONMENTS:

Harnesses with Kevlar webbing are designed for use in high

temperature environments, with limitations: Kevlar webbing

begins to char at 800° to 900° Fahrenheit. Kevlar webbing

can withstand limited contact exposure to temperatures up to

1,000° F. Polyester webbing loses strength at 300° to 400° F.

PVC coating on hardware has a melting point of approximately

350° F.

11

Page 12

IMPORTANT: When working with tools, materials, or in high

temperature environments, ensure that associated fall protection

equipment can withstand high temperatures, or provide protection for

those items.

IMPORTANT: Although PVC coated, cadmium, or zinc plated hardware

exhibit excellent corrosion resistance in chemical, acidic, alkaline, and

atmospheric conditions, frequent inspections may be required. Consult

with DBI‑SALA if you question the use of this equipment in hazardous

environments.

H. TRAINING: This equipment must be installed and used by

persons trained in its correct application and use. See section

4.0.

1.3 APPLICABLE STANDARDS: Refer to national standards, including

ANSI Z359 (.0, .1, .2, .3, and .4) family of standards on fall

protection, ANSI A10.32, CSA Z259.10, and applicable local, state

and federal (OSHA) requirements governing occupational safety for

more information about work positioning systems.

IMPORTANT: Harnesses with Kevlar webbing do not meet ANSI

Z359.1. Kevlar does not have equivalent abrasion resistance of

polyamides. Kevlar harnesses meet all other requirements of this

standard.

2.0 SYSTEM REQUIREMENTS

2.1 COMPATIBILITY OF COMPONENTS: DBI-SALA equipment

is designed for use with DBI-SALA approved components and

subsystems only. Substitutions or replacements made with nonapproved components or subsystems may jeopardize compatibility

of equipment and may effect the safety and reliability of the

complete system.

2.2 COMPATIBILITY OF CONNECTORS: Connectors are considered

to be compatible with connecting elements when they have been

designed to work together in such a way that their sizes and

shapes do not cause their gate mechanisms to inadvertently open

regardless of how they become oriented. Contact DBI-SALA if you

have any questions about compatibility.

Connectors (hooks, carabiners, and D-rings) must be capable

of supporting at least 5,000 lbs. (22.2 kN). Connectors must be

compatible with the anchorage or other system components.

Do not use equipment that is not compatible. Non-compatible

connectors may unintentionally disengage. See Figure 8.

Connectors must be compatible in size, shape, and strength. Selflocking snap hooks and carabiners are required by ANSI Z359.1

and OSHA.

12

Page 13

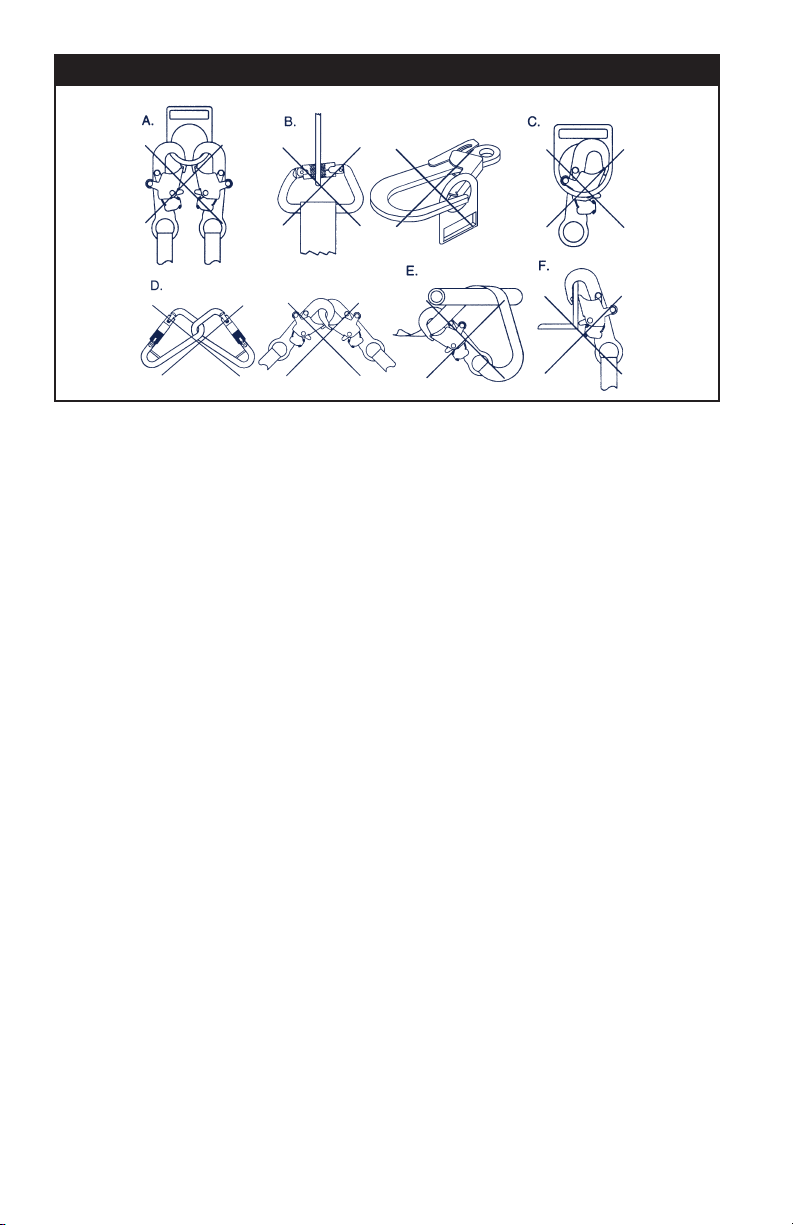

2.3 MAKING CONNECTIONS: Use only self-locking snap hooks and

carabiners with this equipment. Use only connectors that are

suitable to each application. Ensure all connections are compatible

in size, shape and strength. Do not use equipment that is not

compatible. Ensure all connectors are fully closed and locked.

DBI-SALA connectors (snap hooks and carabiners) are designed to

be used only as specied in each product’s user’s instructions. See

Figure 9 for inappropriate connections. DBI-SALA snap hooks and

carabiners should not be connected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

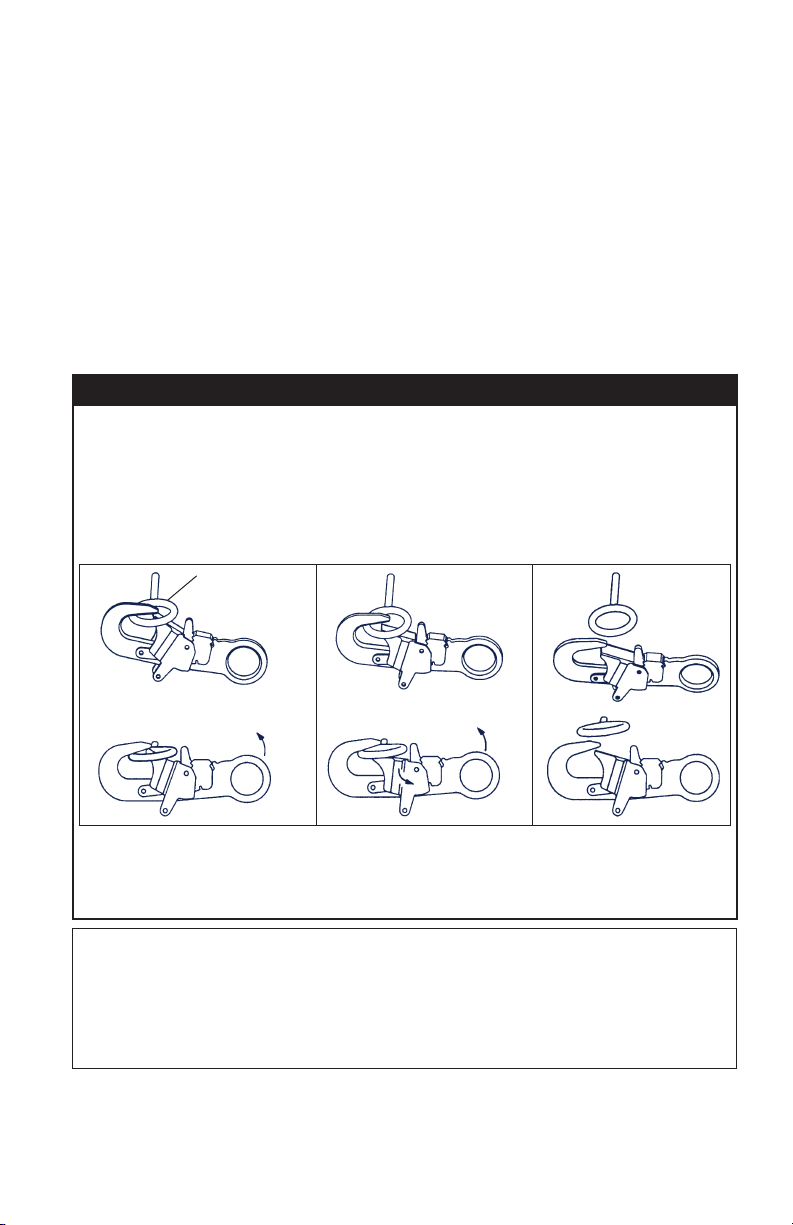

Figure 8 - Unintentional Disengagement (Rollout)

If the connecting element to which a snap hook (shown) or carabiner

attaches is undersized or irregular in shape, a situation could occur

where the connecting element applies a force to the gate of the snap

hook or carabiner. This force may cause the gate (of either a selflocking or a non-locking snap hook) to open, allowing the snap hook or

carabiner to disengage from the connecting point.

Small ring or

other noncompatibly

shaped element

1.FORCE IS APPLIED TO

THE SNAP HOOK.

2. THE GATE PRESSES

AGAINST THE

CONNECTING RING

3. THE GATE OPENS

ALLOWING THE

SNAP HOOK TO

SLIP OFF

NOTE: Large throat snap hooks should not be connected to standard

size D‑rings or similar objects which will result in a load on the gate

if the hook or D‑ring twists or rotates, unless the snap hook complies

with ANSI Z359.1‑2007 and is equipped with a 3,600 lb gate. Check

the marking on your snap hook to verify that it is appropriate for your

application.

C. In a false engagement, where features that protrude from the

snap hook or carabiner catch on the anchor, and without visual

conrmation seems to be fully engaged to the anchor point.

13

Page 14

Figure 9 - Inappropriate Connections

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the

manufacturer’s instructions for both the lanyard and connector

specically allows such a connection).

F. To any object which is shaped or dimensioned such that the

snap hook or carabiner will not close and lock, or that roll-out

could occur.

2.4 CONNECTING SUBSYSTEMS: Connecting subsystems (selfretracting lifeline, lanyard, rope grab and lifeline, cable sleeve)

must be suitable for your application. See section 1.1. See

subsystem manufacturer’s instructions for more information. Some

harness models have web loop connection points. Do not use

snap hooks to connect to web loops. Use a self-locking carabiner

to connect to a web loop. Ensure the carabiner cannot cross-gate

load (load against the gate rather than along the backbone of the

carabiner). Some lanyards are designed to choke onto a web loop

to provide a compatible connection. See Figure 10. Lanyards may

be sewn directly to the web loop forming a permanent connection.

Do not make multiple connections onto one web loop, unless

choking two lanyards onto a properly sized web loop.

2.5 ANCHORAGE STRENGTH: The anchorage strength required

is dependent on the application type. The following are the

requirements of ANSI 359.1 for these application types:

A. FALL ARREST: Anchorages selected for fall arrest systems

shall have a strength capable of sustaining static loads applied

in the directions permitted by the system of at least:

1. 5,000 lbs. (22.2 kN) for non-certified anchorages, or

2. Two times the maximum arresting force for certified

anchorages. When more than one fall arrest system is

14

Page 15

attached to an

anchorage, the

Figure 10 - Web Loop Connection

strengths set

forth in (1) and

(2) above shall

be multiplied

by the number

of systems

attached to the

Insert lanyard web loop through

web loop or D-ring on harness

Harness Web Loop

or D-ring

Energy Absorbing Lanyard

Web Loop on

anchorage.

B. RESTRAINT:

Anchorages

selected for

Insert appropriate end of lanyard

through the lanyard web loop

restraint and

travel restraint

systems shall

have a strength

capable of

sustaining

Pull the lanyard through the

connecting web loop to secure

static loads

applied in the

directions permitted by the system of at least:

1. 1,000 lbs. (4.5 kN) for non-certied anchorages, or

2. Two times the foreseeable force for certied anchorages.

When more than one restraint and travel restraint system

is attached to an anchorage, the strengths set forth in (1)

and (2) above shall be multiplied by the number of systems

attached to the anchorage.

C. WORKING POSITIONING: Anchorages selected for work

positioning systems shall have a strength capable of sustaining

static loads applied in the directions permitted by the system

of at least:

1. 3,000 lbs. (13.3 kN) for non-certied anchorages, or

2. Two times the foreseeable force for certied anchorages. When

more than one work positioning system is attached to an anchorage,

the strengths set forth in (1) and (2) above shall be multiplied by the

number of systems attached to the anchorage.

D. RESCUE: Anchorages selected for rescue systems shall have a

strength capable of sustaining static loads applied in the directions

permitted by the system of at least:

1 . 3,000 lbs. (13.3 kN) for non-certified anchorages, or

2. Five times the foreseeable force for certified anchorages. When

more than one rescue system is attached to an anchorage, the

strengths set forth in (1) and (2) above shall be multiplied by the

number of systems attached to the anchorage.

E. CLIMBING: The structure to which a climbing system is attached

must sustain the loads required by that particular system. See

instructions for climbing system for requirements.

15

Page 16

3.0 DONNING AND USE

WARNING: Do not alter or intentionally misuse this equipment. Consult

DBI‑SALA when using this equipment in combination with components or

subsystems other than those described in this manual. Some subsystem

and component combinations may interfere with the operation of this

equipment. Use caution when using this equipment around moving

machinery, electrical and chemical hazards, and sharp edges.

WARNING: Consult your doctor if there is reason to doubt your

tness to safely absorb the shock from a fall arrest. Age and tness

seriously affect a worker’s ability to withstand falls. Pregnant women

or minors must not use any DBI‑SALA full body harness.

3.1 BEFORE EACH USE of this equipment inspect it according to

section 5.0 of this manual.

3.2 PLAN your system before use. Consider all factors that will affect

your safety during use of this equipment. The following list gives

important points to consider when planning your system:

A. ANCHORAGE: Select an anchorage that meets the

requirements specied in sections 1.2 and 2.5.

B. SHARP EDGES: Avoid working where system components

may be in contact with, or abrade against, unprotected sharp

edges.

C. AFTER A FALL: Components which have been subjected to

the forces of arresting a fall must be removed from service and

destroyed.

D. RESCUE: The employer must have a rescue plan when using

this equipment. The employer must have the ability to perform

a rescue quickly and safely.

16

Page 17

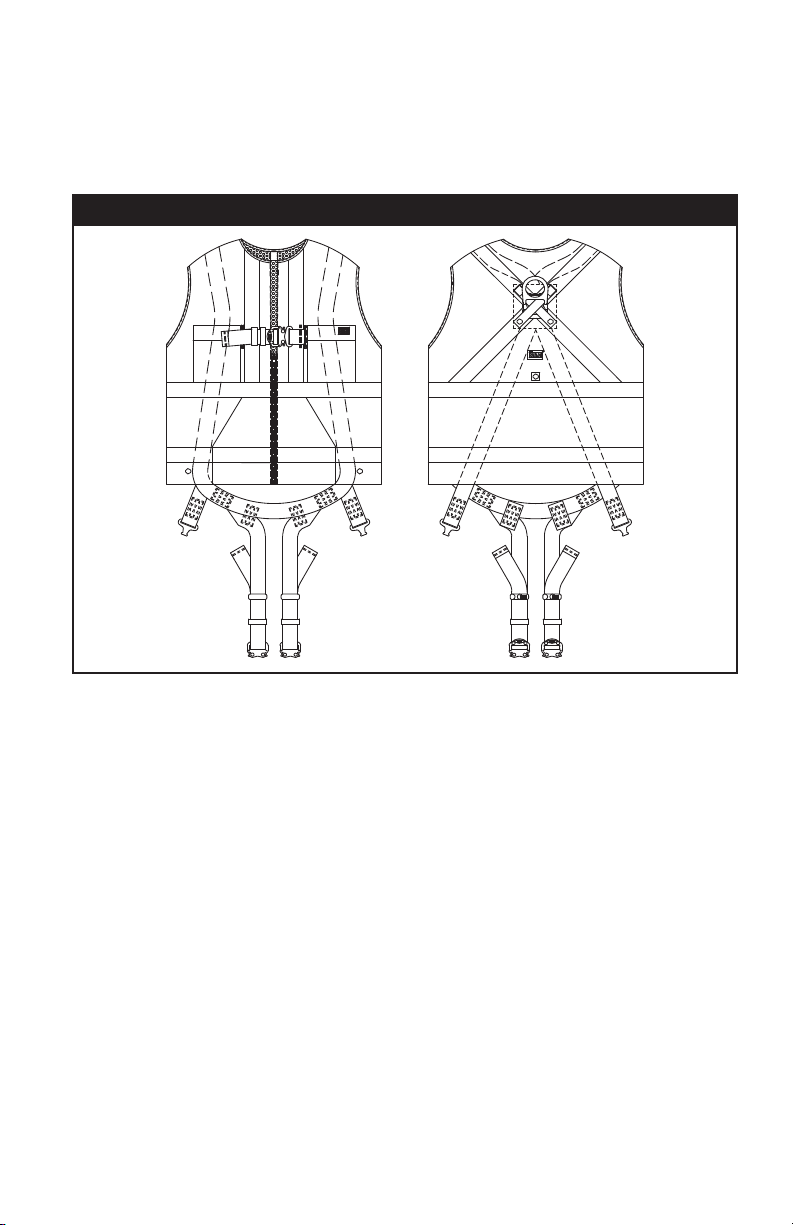

3.3 DONNING AND FITTING THE HARNESS:

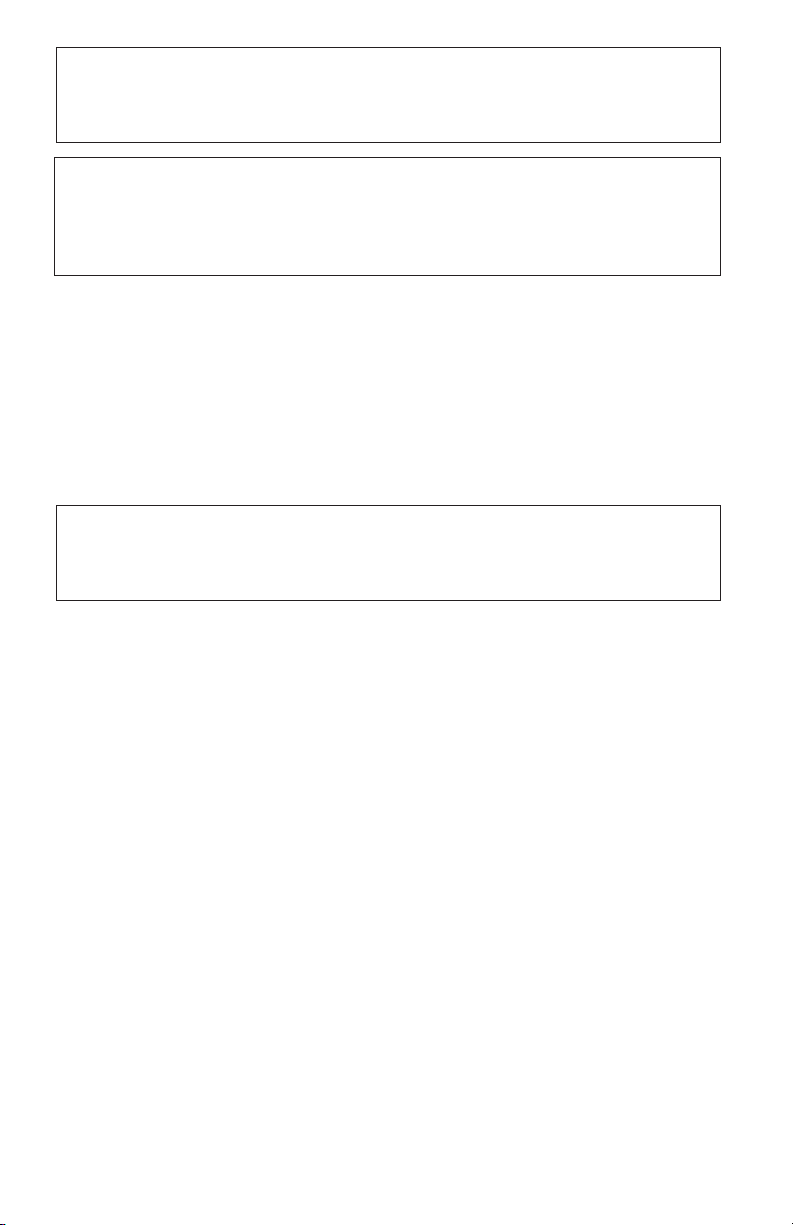

A. DELTA VEST™ HARNESS: See Figure 11 for front and back

views of the Delta Vest™ harness. Don the Delta Vest™ full

body harness by following these steps (see Figures 12 and 13).

Figure 11 - Front and Back View of Delta Vest™ Harness

Step 1. Lift harness by the back D-ring and untangle straps.

Allow leg straps to hang free.

Step 2. Don the Vest Harness as you would a jacket. Do not zip

the vest at this time.

Step 3. Connect chest strap by passing male buckle through

female buckle. Pass excess webbing through loop

keepers. See Figure 13.

Step 4. Reach between legs and grasp blue leg strap on your

left side. Bring strap up between legs and connect to

buckle attached to yellow strap (orange on high visibility

models, black on ame resistant models) as shown in

Figures 12 and 13. Connect right leg strap.

Step 5. Reach inside the vest and adjust shoulder straps to

a snug t. Left and right shoulder straps should be

adjusted to the same length. Readjust leg straps, chest

strap, and shoulder straps as necessary to a snug t.

Step 6. Zip the vest.

17

Page 18

Figure 12 - Donning the Delta Vest™ Harness

Delta Vest™ Harness

Step 1 Step 2 Step 3

Step 4 Step 5 Step 6

18

Page 19

Figure 13 - Delta Vest™ Harness Buckle Connections

Chest Strap: Pass male buckle

through female buckle and pull free

end of webbing to tighten.

Parachute Buckle: Pass webbing

under buckle and over roller and

down between roller and frame.

Pull web end to tighten. Three

inches of web must extend past

buckle.

B. VEST STYLE

HARNESS: If your

harness incorporates

loops for a removable

waist belt, the belt

should be installed

through the four loops

in the harness as shown

in Figure 14. The hip

pad, if used, is secured

to the belt by passing

the belt through the hip

pad loops. Don the vest

style full body harness

by following these steps

(see Figures 15 and

16):

Tongue Buckle: Pass webbing

through buckle and insert tongue

through grommet.

Pass Buckle: Pass male buckle

through female buckle and pull free

end of webbing to tighten.

Figure 14 - Removable Waist Belt

& Hip Pad

Step 1. Locate back D-ring held in position by the D-ring pad;

lift up harness and hold by this D-ring. Ensure the straps

are not twisted.

Step 2. Grasp the shoulder straps and slip harness onto one

arm. D-ring will be located on your back side. Ensure

19

Page 20

Figure 15 - Donning Vest Style Harness

Step 1

Step 3

Step 4 Step 5

Step 2

20

Page 21

Figure 16 - Vest Style Harness Buckle Connections

Chest Strap: Pass male buckle

through female buckle and pull free

end of webbing to tighten.

Parachute Buckle: Pass webbing

under buckle and over roller and

down between roller and frame.

Pull web end to tighten. Three

inches of web must extend past

buckle.

Pass Buckle: Pass male buckle

through female buckle and pull free

end of webbing to tighten.

straps are not tangled and hang freely. Slip free arm into

harness and position shoulder straps on top of shoulder.

Ensure straps are not tangled and hang freely. Chest

strap with pass through buckle will be positioned on front

side when worn properly.

Chest Strap: Attach chest strap by

inserting the tab of the buckle into

the receptor of the quick connect

buckle until a click is heard.

Tongue Buckle: Pass webbing

through buckle and insert tongue

through grommet.

Quick Connect Buckle: Insert the

tab of the buckle into the receptor of

the quick connect buckle until a click

is heard.

Step 3. Reach between your legs and grasp the leg strap on

your left side. Bring the strap up between your legs

and connect it by inserting the tab of the buckle into

the receptor of quick connect buckle on the left side as

shown in Figure 1. You will hear a click when the tab

engages properly. Pull the free end of the strap away

21

Page 22

from the buckle to make a snug t on each leg strap. To

loosen the leg strap, grasp the yellow plastic portion of

the buckle and pull away from your leg to allow the strap

to pull through the buckle. A plastic end keeper on the

end of the strap will stop it from pulling completely out

of the buckle. To release the buckle, press the silvercolored tabs on the buckle towards each other with one

hand, while pulling on the tab portion to the buckle with

the other hand. Repeat this procedure for the right side.

Step 4. Attach the chest strap by inserting the tab of the buckle

into receptor of quick connect buckle. See Figure 1.

You will hear a click when the tab engages properly.

Chest strap should be six inches down from the top of

shoulders. Pass excess strap through the loop keepers.

The strap may be tightened to a snug t by pulling the

free strap end to the left (away from the buckle). To

loosen the chest strap, grasp the yellow plastic portion

of the buckle and pull away from the body to allow the

strap to pull through the buckle. A plastic end keeper on

the end of the strap will stop it from pulling completely

out of the buckle. To release the buckle, press the silvercolored tabs on the buckle towards each other with one

hand, while pulling on the tab portion to the buckle with

the other hand.

Step 5. Adjust shoulder straps to a snug t by pulling excess

strap through the parachute buckles on each side of the

harness. Left and right sides of shoulder straps should

be adjusted to the same length and the chest strap

should be centered on your lower chest, six inches down

from shoulder. The front D-ring on vest style harness

is moved up or down by adjusting the shoulder straps

and leg straps.

Center the back

D-ring between

shoulder blades.

Adjust leg straps

to a snug t. At

least three inches

of webbing must

extend past

buckle on leg

straps. Adjust

the waist belt (if

present).

Figure 17 - Removable Waist Belt

and Hip Pad

C. CROSS-OVER STYLE

HARNESS: If your

harness incorporates

loops for a removable

waist belt, the belt

22

Page 23

Figure 18 - Donning Cross-over Style Harness

Step 1

Step 4

Step 2

Step 3

Step 5

23

Page 24

should be installed through the four loops in the harness as

shown in Figure 17. The hip pad, if used, is secured to the

belt by passing the belt through the hip pad loops. Don the

cross-over style full body harness by following these steps (see

Figures 18 and 19):

Step 1. Locate back D-ring held in position by the D-ring pad;

lift up harness and hold by this D-ring. Ensure the straps

are not twisted.

Step 2. Grasp shoulder straps between back and front D-ring and

slip harness over your head from the left side. Position

shoulder straps on top of shoulder. Ensure straps are not

tangled and hang freely. The D-ring will be positioned on

your back when worn properly.

Step 3. Grasp male pass-through buckle located on yellow

strap (orange on high visibility models, black on ame

resistant models) below front D-ring and connect to

female pass-through buckle (attached to blue or strap on

right hip). Male end of buckle must pass through female

end. Ensure straps are not tangled or crossed.

Step 4. Reach between legs and grasp blue leg strap on your

Figure 19 - Cross-over Style Harness Buckle Connections

Tongue Buckle: Pass webbing

through buckle and insert tongue

through grommet.

Quick Connect Buckle: Insert the

tab of the buckle into the receptor of

the quick connect buckle until a click

is heard

Pass Buckle: Pass male buckle

through female buckle and pull free

end of webbing to tighten.

Parachute Buckle: Pass webbing

under buckle and over roller and

down between roller and frame.

Pull web end to tighten. Three

inches of web must extend past

buckle.

24

Page 25

left side. Bring strap up between legs and connect to

buckle attached to yellow strap (orange on high visibility

models, black on ame resistant models). Connect right

leg strap.

Step 5. Adjust shoulder straps to a snug t. Left and right sides

of shoulder straps should be adjusted to the same length

and the front D-ring should be centered on your lower

chest. The back D-ring should be centered between your

shoulder blades. Adjust leg straps to a snug t. At least

three inches of webbing must extend past parachute

adjuster buckle when used on leg straps. Adjust the

waist belt (if present). Center retrieval D-rings (if

present) on top of each shoulder.

D. STEP-IN STYLE HARNESS: Don the step-in style full

harness by following these steps (see Figures 20 and 21):

Step 1. Locate back D-ring held in position by the D-ring pad;

lift up harness and hold by this D-ring. Ensure the straps

are not twisted.

Step 2. Step into harness by placing right leg over the seat sling

and then your left leg.

Step 3. Raise harness up and slip arms between front and back

shoulder straps. Slip the back D-ring pad over your head

with your head between the front shoulder straps and

the adjuster links.

Step 4. Reach between legs and grasp blue leg strap on your

left side. Bring strap up between legs and connect to

buckle attached to yellow strap (orange on high visibility

models, black on ame resistant models). Connect right

leg strap.

Step 5. Tighten shoulder straps through adjuster links and front

D-ring. Adjustment slack should be given out or taken

up through the buckle on the lower left shoulder strap.

Left and right shoulder straps should be adjusted to the

same length, and the front D-ring should be centered on

your lower chest. The back D-ring should be centered

between your shoulder blades. Adjust leg straps to a

snug ght.

body

3.4 USE OF FALL ARREST D-RING OR ATTACHMENT ELEMENT:

For fall protection applications connect to the D-ring or attachment

element on your back, between your shoulder blades. Side

D-rings, if present, are for positioning or restraint applications only.

Shoulder retrieval D-rings are for rescue or retrieval applications

only. Front D-ring is for ladder climbing or positioning. D-rings on

seat sling are for suspension or positioning applications only.

25

Page 26

Figure 20 - Donning Step-in Style Harness

Step 1

Step 4

Step 2

Step 3

Step 5

26

Page 27

Figure 21 - Step-in Style Harness Buckle Connections

Tongue Buckle: Pass webbing

through buckle and insert tongue

through grommet.

Parachute Buckle: Pass webbing

under buckle and over roller and

down between roller and frame. Pull

web end to tighten. Three inches of

web must extend past buckle.

Pass Buckle: Pass male buckle

through female buckle and pull free

end of webbing to tighten.

3.5 MAKING CONNECTIONS: When using a hook to connect to an

anchorage or when coupling components of the system together,

ensure roll-out cannot occur. Roll-out occurs when interference

between the hook and mating connector causes the hook gate

to unintentionally open and release. Self-locking snap hooks and

carabiners should be used to reduce the possibility of roll-out. Do

not use hooks or connectors that will not completely close over the

attachment object. See subsystem manufacturer’s instructions for

more information on making connections.

3.6 CONNECTING SYSTEM COMPONENTS: After tting the full body

harness the user may then connect to other system components.

Follow the guidelines in section 3.4 on selecting the correct

attachment element.

4.0 TRAINING

4.1 It is the responsibility of the user and the purchaser of this

equipment to assure that they are familiar with these instructions,

trained in the correct care and use of, and are aware of the

operating characteristics, application limits, and the consequences

of improper use of this equipment.

IMPORTANT: Training must be conducted without exposing the user

to a fall hazard. Training should be repeated on a periodic basis.

27

Page 28

5.0 INSPECTION

5.1 The i-Safe™ RFID tag on this harness can be used in conjunction

with the i-Safe handheld reading device and the web based portal

to simplify inspection and inventory control and provide records for

your fall protection equipment See Figure 22.

5.2 FREQUENCY: Before each use inspect the full body harness

according to sections 5.3 and 5.4. The harness must be inspected

by a competent person, other than the user, at least annually.

Record the results of each formal inspection in the inspection and

maintenance log in section 9.0, or use the i-Safe™ inspection

web portal to maintain your inspection records. If you are a rst-

time user, contact a Customer Service representative in the US

at 800-328-6146 or in Canada at 800-387-7484 or if you have

already registered, go to: www.capitalsafety.com/isafe.html. Follow

instructions provided with your i-Safe handheld reader or on the

web portal to transfer your data to your web log.

Figure 22 - i-Safe™ RFID Tag

i-Safe

RFID Tag

Wrap

Labels

Detail of Label Packet with

i-Safe RFID Tag

around

cover

IMPORTANT: If the full body harness has been subjected to fall

arrest or impact forces it must be immediately removed from service

and destroyed.

IMPORTANT: Extreme working conditions (harsh environments,

prolonged use, etc.) may require increasing the frequency of inspections.

28

Page 29

5.3 INSPECTION STEPS:

Step 1. Inspect harness hardware (buckles, D-rings, back pad,

loop keepers); These items must not be damaged,

broken, distorted, and must be free of sharp edges,

burrs, cracks, worn parts, or corrosion. PVC coated

hardware must be free of cuts, rips, tears, holes, etc. in

the coating to ensure non-conductivity. Ensure buckles

work smoothly. If present, inspect the quick connect

buckles by ensuring that the release tabs work freely and

that a click is heard when the buckle engages. Inspect

parachute buckle spring.

Step 2. Inspect webbing; material must be free of frayed, cut, or

broken bers. Check for tears, abrasions, mold, burns, or

discoloration. Inspect stitching; Check for pulled or cut

stitches. Broken stitches may be an indication that the

harness has been impact loaded and must be removed

from service.

IMPORTANT: On Delta Vest™ harnesses, inspection

should include the webbing inside the vest.

Step 3. Inspect labels; All labels should be present and fully

legible. See section 8.0.

Step 4. Inspect each system component or subsystem according

to manufacturer’s instructions.

Step 5. Impact Indicators: Fall arrest impact indicators give

a permanent, readily visible warning if the harness has

arrested a fall (or has been subjected to an equivalent

force). Impact indicators must be inspected before

each use. If the impact indicator has been activated the

harness must be removed from service and destroyed.

Each harness includes one of the following built-in fall

arrest impact indicators:

Stitched impact indicator: The stitched impact indicator

is a section of webbing that is lapped back on itself and

secured with a specific stitch pattern holding the lap. The

stitch pattern is designed to release when the harness

arrests a fall or has been subjected to an equivalent

force.

Dorsal D‑ring impact indicator: The dorsal D-ring

indicator (Figure 23) consists of a D-ring which is fitted

into a plastic housing. This is designed so that the D-ring

will be released from the housing exposing a red impact

indication label when the harness arrests a fall or has

been subjected to an equivalent force.

29

Page 30

Figure 23 - Impact Indicator

D-ring pulled

out of pivot

Red band

exposed

Normal Condition

D-ring seated

in pivot

Pivot

Indicated Condition

Remove harness from service

Step 6. Record the inspection date and results in the inspection

and maintenance log in section 9.0, or use the i-Safe™

inspection web portal.

NOTE: Some harnesses are equipped with a “stand up D‑ring” in the

dorsal (back) D‑ring location. If the spring in the D‑ring is damaged or

lost and the D‑ring no longer stands up, this does not compromise the

harness integrity. As long as the D‑ring passes inspection criteria in

Step 1, it is safe to use.

5.4 If inspection reveals a defective condition, remove unit from

service immediately and destroy.

NOTE: Only DBI‑SALA or parties authorized in writing may make

repairs to this equipment.

5.5 PRODUCT LIFE: The functional life of DBI-SALA harnesses is

determined by work conditions and maintenance. As long as the

product passes inspection criteria, it may remain in service.

30

Page 31

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 WASHING INSTRUCTIONS:

A. FULL BODY HARNESS: Clean full body harness with water and

a mild soap solution. Do not use bleach or bleach solutions.

Wipe off hardware with a clean, dry cloth, and hang to air

dry. Do not force dry with heat. An excessive buildup of dirt,

paint, etc. may prevent the full body harness from working

properly, and in severe cases degrade the webbing to a point

where it weakens and should be removed from service. More

information on cleaning is available from DBI-SALA. If you

have questions concerning the condition of your harness, or

have any doubt about putting it into service contact DBI-SALA.

B. FIRE RESISTANT PADDING:

• Remove pads from harness for laundering. Place the

harness in the supplied laundry bag. The bag is designed

to prevent entanglement of harness and to protect the

washing machine from damage. Use of the laundry bag to

wash the pads is optional.

• Launder ame resistant pads separately from harness

or other non-ame resistant garments. Lint from other

garments may affect ame resistance.

• Use a bleach-free detergent when washing both the harness

and the pads. Do not use soap; soap may leave a residue

which could affect ame resistance.

• Do not use chlorine bleach. Bleach may weaken fabric and

reduce product life.

• Oily or greasy stains may be pre-treated and washed in hot

water 140°F max (60°C max).

• Use delicate, permanent press, or cotton sturdy wash cycle

with cold or warm water. Hot water can be used on heavily

soiled items as long as it does not exceed 140°F (60°C).

Use extra rinse cycle to be sure all residual wash chemicals

are removed.

• Air dry or tumble dry using permanent press cycle and low

heat. Drying temp should not exceed 200°F (93°C). These

fabrics dry quickly, for lowest shrinkage, do not over dry.

6.2 Additional maintenance and servicing procedures must be

completed by a factory authorized service center. Authorization

must be in writing. Do not attempt to disassemble the unit.

6.3 Store full body harnesses in a cool, dry, clean environment out

of direct sunlight. Avoid areas where chemical vapors may exist.

Thoroughly inspect the full body harness after extended storage.

31

Page 32

7.0 SPECIFICATIONS

7.1 PERFORMANCE

Maximum Free Fall Distance: No greater than 6 feet (1.8 m),

per federal law and ANSI Z359.1.

Maximum Arresting Force: 1,800 lbs. (8 kN)

Capacity: 420 lbs. (191 kg)

Approximate Weight:

Harness only: 3 lbs. (1.4.kg)

Harness with Side D-rings: Add 1/2 lb. (.23 kg)

Harness with Back Pad or Belt: Add 1 lb. (.45 kg)

Cross-over Style Harness Patent numbers:

United States: 5,203,829

Canada: 2,080,643

All harnesses, excluding Kevlar harnesses, meet ANSI Z359.1 and

OSHA requirements.

7.1 MATERIALS

Standards: All harnesses marked with ASTM F887-2004 meet all

testing requirements of the standard.

Webbing Materials: 7000 lbs. Tensile strength Nylon

7000 lbs. Tensile strength Nomex* covered Kevlar*

Pad and Label Cover Materials:

• All outer fabric is Nomex and Kevlar blend fabric

• Fire resistant hook and loop fasteners

Optional Accessories:

• Hip Pad with side D-rings

• Nomex covered Kevlar webbing

• Non-sparking/ Non-conductive PVC coated hardware

• Arc-rated hip, leg, and back pads

• Polyurethane coated, arc-rated dorsal web loop

32

Page 33

8.0 LABELING

1

2

0

4

5

3

4

3

2

9

1

0

6

8

7

1

2

0

4

5

3

4

3

2

9

1

0

6

8

7

8.1 The following labels must be present and completely legible:

ANSI CSA

RFID Serial Number Label

Size Label Étiquette de taille

Warning Label Used on Nylon ASTM

F887-2004 Compliant Harnesses

Étiquette RFID

Étiquette de mise en garde du harnais

de nylon

Warning Label Used on Nomex/Kevlar

ASTM F887-2004 Compliant Harnesses

Étiquette de mise en garde du harnais

Nomex ou Kevlar

33

Page 34

ANSI CSA

Warning Label

Instruction Label (Vest Style)

Vignette de mise en garde

Étiquette couverture

Instruction Label (Cross-Over Style)

34

Page 35

ANSI CSA

Vignette d’inspection

Inspection Label

Web Loop Harness Label Étiquette de harnais de boucle de Web

35

Page 36

9.0 INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER: __________________________________________

MODEL NUMBER: ___________________________________________

DATE PURCHASED: ______________DATE FIRST USED: __________

INSPECTION

DATE

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

INSPECTION

ITEMS NOTED

CORRECTIVE

ACTION

MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

36

Page 37

This instruction applies to the following models:

1100092

1100181

1100195

1100230

1100231

1100232

1100233

1100245

1100246

1100247

1100299

1100406

1100482

1100520

1100521

1100522

1100540

1100541

1100542

1100543

1100550

1100675

1100676

1100700

1100701

1100702

1100703

1100726

1100727

1100750

1100756

1100762

1100767

1100768

1100769

1100775

1100776

1100777

1100778

1100779

1100780

1100781

1100840

1100841

1100842

1100925

1100926

1100927

1100928

1100929

1101021

1101022

1101116

1101117

1101118

1101119

1101120

1101121

1101214

1101215

1101216

1101217

1101218

1101219

1101240

1101241

1101250

1101251

2104180

1101252

1101252H

1101253

1101253H

1101254

1101254H

1101255

1101255H

1101256

1101257

1101258

1101259

1101260

1101261

1101262

1101266

1101267

1101268

1101269

1101270

1101271

1160008

1101272

1101273

1101274

1101340

1101341

1101420

1101421

1101422

1101423

1101424

1101436

1101437

1101438

1101439

1101440

1101441

1101450

1101451

1101452

1101453

1101455

1101456

1101457

1101458

1101459

1101460

1101461

1101462

1101463

1101464

1101465

1101466

1101467

1101468

1101469

1101470

1101471

1101472

1101473

1101474

1101511

1101512

1101513

1101514

1101515

1101516

1101611

1101625

1101626

1101627

1101628

1101629

1101630

1101631

1101632

1101633

1101634

1101635

1101636

1101637

1101638

1101639

1101640

1101641

1101642

1101643

1101644

1101645

1101646

1101647

1101649

1101650

1101651

1101653

1101654

1101654H

1101655

1101655H

1101656

1101656H

1101657

1101658

1101659

1101660

1101661

1101662

1101663

1101664

1101665

1101666

1101667

1101668

1101669

1101670

1101671

1101672

1101673

1101776

1101777

1101778

1101779

1101780

1101781

1101782

1101783

1101784

1101785

1101786

1101787

1101789

1101790

1101791

1101792

1101793

1101794

1101795

1101796

1101797

1101798

1101800

1101801

1101802

1101803

1101804

1101805

1101806

1101807

1101808

1101809

1101810

1101812

1101813

1101814

1101815

1101816

1101817

1101818

1101819

1101820

1101821

1101822

1101823

1101824

1101826

1101827

1101828

1101829

1101830

1101831

1101832

1101833

1101834

1101835

1101836

1101837

1101838

1101839

1101840

1101841

1101842

1101843

1101844

1101845

1101851

1101854

1101855

1101856

1101857

1101858

37

Page 38

1101859

1101860

1101861

1101862

1101863

1101864

1101866

1101867

1101869

1101870

1101871

1101872

1101873

1101874

1101890

1101891

1101892

1101893

1101909

1101910

1101911

1101912

1101913

1101977

1101978

1101979

1101980

1101981

1102000

1160002

1170002

1170003

2104177

2104181

2104182

1102000H

1102001

1160000

1102002

1102003

1102004

1102005

1102008

1102009

1102010

1170002

1170003

6100771

6100772

6100776

6100777

6116604

6116605

6116606

1102010ALT1

1102010

1170002

1170003

6100771

6100772

6100776

6100777

6116604

6116605

6116606

6116607

6116609

6116610

1102025

1102026

1102027

1102028

1102029

1102030

1102031

1102032

1102033

1102034

1102035

1102036

1102037

1102038

1102039

1102040

1102041

1102042

1102043

1102082

1102083

1102084

1102086

1102090

1102132

1102133

1102134

1102135

1102200

1102201

1102205

1102206

1102207

1102257

1102270

1102271

1102286

1102525

1102526

1102526H

1102527

1102528

1102529

1102529H

1102530

1102531

1102532

1102533

1102534

1102536

1102537

1102538

1102539

1102540

1102541

1102542

1102543

1102543H

1102546

1102548

1102549

1102556

1102557

1102558

1102559

1102560

1102561

1102562

1102563

1102564

1102565

1102566

1102875

1102875C

1102876

1102877

1102878

1102879

1102880

1102901

1102903

1102904

1102905

1102907

1102908

1102911

1102912

1102925

1102926

1102927

1102928

1102929

1102930

1102950

1102951

1102952

1102953

1102954

1102955

1102956

1102957

1102962

1102963

1102964

1102965

1102966

1102972

1102973

1103251

1103252

1103253

1103254

1103255

1103256

1103257

1103258

1103261C

1103262

1103262C

1103263

1103263C

1103264

1103265

1103266

1103267

1103270

1160001

1103270ALT1

1103270

1160001

1103321

1103350

1103351

1103352

1103353

1103354

1103355

1103356

1103357

1103358

1103359

1103360

1103361

1103375

1103376

1103377

1103378

1103379

1103383

1103384

1103385

1103386

1103393

1103394

1103395

1103510

1106725

1106726

1106727

1106728

1106729

1106730

1103511

1103512

1103513

2104168

2104169

2104170

2104171

2104172

2104173

2104174

2104175

2104176

2104178

2104179

1103611

1103612

1103800

1103801

1103802

1103803

1103803ALT

1103803

1103804

1103805

1103806

1103807

1103808

1103809

1103810

1103811

38

Page 39

1103812

1103813

1103814

1103825

1103826

1103827

1103828

1103829

1103831

1103836

1103837

1103852

1103853

1103854

1103855

1103856

1103860

1103861

1103875

1103876

1103877

1103878

1103879

1103880

1103882

1103884

1103885

1103886

1103888

1104125

1104126

1104625

AA7059A

AA7060A

1104626

1104627

1104628

1104629

1104630

1104632

1104633

1104635

1104636

1104650

1104725

1104729

1104730

1104731

1104732

1104733

1104734

1104735

1104736

1104739

1104740

1104741

1104742

1104743

1104744

1104745

1104746

1104747

1104748

1104749

1104775

1104776

1104777

1104778

1104779

1104780

1104781

1104782

1104783

1104800

1104801

1104803

1104804

1104805

1104806

1104850

1104851

1104852

1104853

1104854

1104855

1104856

1104857

1104858

1104859

1104860

1104861

1104863

1104866

1104871

1104872

1104873

1104874

1104875

1104876

1104877

1104878

1104879

1104880

1104881

1104882

1104885

1104886

1104890

1104891

1104892

1104893

1104894

1104900

1104901

1104902

1104903

1104904

1104905

1104906

1104907

1104908

1104909

1104910

1104911

1104912

1104914

1104915

1104916

1104917

1104918

1104919

1104920

1104921

1104924

1104950

1104952

1104953

1104954

1104955

1105000

1105001

1105002

1105003

1105004

1105005

1105300

1105301

1105325

1105326

1105327

1105328

1105329

1105330

1105331

1105350

1105375

1105375C

1105376

1105377

1105378

1105379C

1105382

1105383

1105384

1105400

1105401

1105405

1105406

1105407

1105408

1105409

1105410

1105411

1105450

1105475

1105476

1105477

1105478

1105479

1105480

1105481

1105482

1105483

1105484

1105487

1105488

1105489

1105490

1105491

1105500

1105555

1105556

1105577

1105650

1105651

1105652

1105675

1105676

1105677

1105678

1105679

1105680

1105681

1105682

1105683

1105725

1105726

1105727

1105728

1105729

1105732

1105733

1105734

1105735

1105750

1105751

1105752

1105753

1105754

1105755

1105801

1105802

1105803

1105804

1105825

1102353

1105825C

1105826

1102351

1105827

1102352

1105828

1102354

1105829

1105830

1102355

1105830C

1105831

1102350

1105832

1105833

1105834

1105835

1105836

1105837

1105838

1105840

1105850

1105851

1105852

1105853

1105854

1105900

1105901

1105925

1105926

1105950

1105951

1105952

1105953

39

Page 40

1105954

1105975

1106000

1106001

1106002

1106003

1106004

1106005

1106006

1106007

1106008

1106009

1106010

1106011

1106012

1106013

1106017

1106018

1106019

1106020

1106021

1106022

1106023

1106024

1106025

1106028

1106028H

1106029

1106030

1106031

1106032

1106033

1106034

1106035

1106036

1106037

1106039

1106040

1106041

1106048

1106055

1106056

1106057

1106058

1106059

1106063

1106066

1106067

1106068

1106069

1106070

1106071

1106072

1106074

1106076

1106077

1106078

1106079H

1106080H

1106081

1106082H

1106083H

1106100

1106101

1106102

1106103

1106104

1106105

1106106

1106107

1106108

1106109

1106110

1106111

1106114

1106115

1106116

1106117

1106118

1106119

1106120

1106125

1106126

1106127

1106150

1106151

1106152

1106175

1106180

1106200

1106201

1106203

1106204

1106205

1106207

1106208

1106209

1106210

1106211

1106275

1106279

1106300

1106301

1106302

1106303

1106304

1106305

1106306

1106307

1106308

1106309

1106310

1106325

1106326

1106327

1106328

1106329

1106330

1106331

1106332

1106333

1106334

1106350

1106351

1106352

1106354

1106355

1106356

1106357

1106365

1106366

1106367

1106368

1106369

1106370

1106375

1106376

1106377

1106378

1106379

1106380

1106381

1106382

1106383

1106384

1106385

1106386

1106400

1106401

1106403

1106404

1106405

1106406

1106407

1106408

1106409

1106410

1106411

1106414

1106425

1106426

1106427

1106450

1106450H

1106451

1106451H

1106452

1106452H

1106453

1106453H

1106454

1106455

1106456

1106476

1106477

1106478

1106479

1106480

1106481

1106482

1106550

1106675

1106676

1106677

1106679

1106680

1106681

1106682

1106683

1106684

1106687

1106688

1106700

1106701

1106702

1106703

1106704

1106750

1106751

1106754

1106755

1106756

1106800

1106801

1106802

1106900

1106901

1106902

1106903

1106904

1106905

1106950

1106951

1106952

1106953

1106954

1106975

1106976

1106977

1106978

1107000

1107001

1107002

1107003

1107025

1107026

1107027

1107075

1107125

1107126

1107127

1107128

1107129

1107150

1107151

1107152

1107153

1107154

1107200

1107201

1107202

1107203

1107204

1107205

1107206

1107207

1107225

1107250

1107251

1107252

1107275

1107276

1107277

1107278

1107279

1107400

1107400C

1107402

1107402C

1107403

40

Page 41

1107404

1107405

1107406

1107406C

1107407

1107407C

1107408

1107408C

1107409

1107410

1107415

1107416

1107417

1107418

1107419

1107420

1107421

1107422

1107425

1107425C

1107426

1107427

1107427C

1107428

1107428C

1107429

1107429C

1107430

1107430C

1107450

1107450C

1107451

1107451C

1107452

1107452C

1107453

1107453C

1107454

1107454C

1107455

1107455C

1107460

1107461

1107462

1107463

1107465

1107466

1107467

1107468

1107469

1107470

1107471

1107475

1107475C

1107476

1107476C

1107477

1107477C

1107478

1107478C

1107479

1107479C

1107480

1107480C

1107500

1107501

1107525

1107526

1107550

1107551

1107575

1107576

1107577

1107578

1107579

1107580

1107600

1107626

1107629

1107630

1107650

1107651

1107652

1107653

1107656

1107658

1107659

1107725

1107726

1107727

1107775

1107776

1107777

1107778

1107781

1107782

1107783

1107784

1107801

1107802

1107803

1107804

1107805

1107806

1107806H

1107807

1107807H

1107808

1107809

1107810

1107811

1107812

1107813

1107814

1107815

1107816

1107817

1107817H

1107818

1107819

1107820

1107821

1107822

1107823

1107824

1107825

1107828

1107829

1107830

1107831

1107832

1107833

1107834

1107836

1107850

1107851

1107855

1107875

1107926

1107950

1107951

1107952

1107954

1107957

1107958

1107959

1107960

1107962

1108000

1108001

1108002

1108003

1108025

1108026

1108034

1108100

1108101

1108102

1108103

1108104

1108105

1108106

1108107

1108108

1108109

1108125

1108126

1108127

1108128

1108129

1108130

1108131

1108132

1108133

1108134

1108175

1108176

1108177

1108178

1108179

1108184

1108185

1108186

1108187

1108188

1108189

1108190

1108225

1108226

1108227

1108228

1108229

1108300

1108301

1108302

1108305

1108307

1108308

1108309

1108310

1108311

1108375

1108376

1108377

1108378

1108379

1108380

1108400

1109000

1109002

1109062

1109075

1109076

1109077

1109078

1109079

1109080

1109102

1109105

1109106

1109107

1109108

1109109

1109110

1109111

1109121

1109125

1109126

1109127

1109128

1109129

1109130

1109142

1109143

1109144

1109145

1109150

1109151

1109152

1109400

1109425

1109426

1109427

1109429

1109431

1109441

1109446

1109447

1109448

1109449

1109450

1109451

1109475

1109500

1109501

1109502

1109503

1109550

1109551

1109552

41

Page 42

1109553

1109554

1109555

1109556

1109557

1109558

1109559

1109560

1109561

1109575

1109651

1109652

1109653

1109654

1109675

1109676

1109677

1109678

1109850

1109851

1109852

1109853

1109854

1109855

1109885

1109886

1109975

1109976

1109977

1110025

1110026

1110027

1110028

1110029

1110030

1110052

1110570

1110575

1110575H

1110576

1110576H

1110577

1110577H

1110578

1110578H

1110582

1110586

1110587

1110588

1110589

Additional Model Numbers may appear on the next printing.

1110590

1110591

1110600

2104205

1110601

1110602

1110603

1110604

1110605

1110606

1110608

1110618

1110625

1110626

1110675

1110700

1110701

1110702

1110704

1110725

1110727

1110750

1110751

1150054

1110752

1150058

1110753

1110754

1110755

1110760

1110761

1110762

1110770

1110771

1110772

1110773

1110774

1110780

1110781

1110782

1110783

1110784

1110785

1110786

1110787

1110792

1110793

1110800

1110801

1110802

1110803

1110810

1110811

1110812

1110813

1110814

1110820

1110830

1110831

1110832

1110850

1110851

1110852

1110853

1110854

1110855

1110856

1110857

1110858

1110859

1110930

1110935

1110942

1110950

1110951

1110952

1110953

1110954

1110955

1110956

1110990

1110992

1110994

1110995

1111000

1111001

1111002

1111003

1111004

1111275

1111276

1111277

1111278

1111279

1111280

1111325

1111326

1111327

1111330

1111331

1111332

1111500H

1111501H

1111502H

1111503H

1111504H

1111505H

1111506H

1111507H

1111508H

1111509H

1111575

1111577

1111578

1111579

1111580

1111581

1111582

1111583

1111584

1111585

1111586

1111591

1111592

1111593

1111594

1111595

1111610

1111611

1111612

1111613

1310065

1370111

1370112

3103300

3103301

3103330

3103331

3103332

3103333

3103334

3103335

3103336

3103337

3103350

3103351

3103375

3103386

3103387

3103388

3103389

3103390

3103395

3103420

3103450

3103451

3103452

3103453

3103471

3103515

3103520

3103521

3103522

3103523

3103524

3103543

3103544

3103547

3103549

4242

Page 43

Page 44

WARRANTY

Certificate No. FM 39709

ISO

9001

Equipment offered by DBI-SALA are warranted against factory

defects in workmanship and materials for a period of two years

from date of installation or use by the owner, provided that this

period shall not exceed two years from the date of shipment.

Upon notice in writing, DBI-SALA will promptly repair or replace

all defective items. DBI-SALA reserves the right to elect to have

any defective item returned to its plant for inspection before

making a repair or replacement. This warranty does not cover

equipment damages resulting from abuse, damage in transit, or

other damage beyond the control of DBI-SALA. This warranty

applies only to the original purchaser and is the only one

applicable to our products, and is in lieu of all other warranties,

expressed or implied.

USA Canada

3833 SALA Way 260 Export Boulevard

Red Wing, MN 55066-5005 Mississauga, Ontario L5S 1Y9

Toll Free: 800-328-6146 Toll Free: 800-387-7484

Phone: (651) 388-8282 Phone: (905) 795-9333

Fax: (651) 388-5065 Fax: (905) 795-8777

www.capitalsafety.com www.capitalsafety.com

This manual is available for download at www.capitalsafety.com.

A Capital Safety Company

Loading...

Loading...