Page 1

12S-SUB Manual (1.3 EN)

Page 2

General information

12S-SUB Manual

Version: 1.3 EN, 12/2011, D2615.EN .01

Copyright © 2011 by d&b audiotechnik GmbH; all rights

reserved.

Keep this manual with the product or in a safe place

so that it is available for future reference.

When reselling this product, hand over this manual to the new

customer.

d&b audiotechnik GmbH

Eugen-Adolff-Strasse 134, D-71522 Backnang, Germany

T +49-7191-9669-0, F +49-7191-95 00 00

docadmin@dbaudio.com, www.dbaudio.com

Page 3

Contents

1. Safety precautions......................................................... 4

1.1. Information regarding the use of loudspeakers......... 4

2. 12S-SUB loudspeaker................................................... 5

2.1. Product description...................................................... 5

2.2. Connections................................................................. 5

2.3. Operation.................................................................... 6

2.3.1. Controller settings.................................................... 7

2.4. Technical specifications............................................... 7

3. Manufacturer's Declarations...................................... 8

3.1. EU conformity of loudspeakers (CE symbol)............. 8

3.2. WEEE Declaration (Disposal)..................................... 8

d&b 12S-SUB Manual (1.3 EN) 3

Page 4

1. Safety precautions

1.1. Information regarding the use of loudspeakers

Potential risk of personal injury

Never stand in the immediate vicinity of loudspeakers driven at a

high level. Professional loudspeaker systems are capable of

causing a sound pressure level detrimental to human health.

Seemingly non-critical sound levels (from approx. 95 dB SPL) can

cause hearing damage if people are exposed to it over a long

period.

In order to prevent accidents when deploying loudspeakers on the

ground or when flown, please take note of the following:

– When setting up the loudspeakers or loudspeaker stands,

make sure they are standing on a firm surface. If you place

several systems on top of one another, use straps to secure

them against movement.

– Only use accessories which have been tested and approved

by d&b for assembly and mobile deployment. Pay attention to

the correct application and maximum load capacity of the

accessories as detailed in our specific "Mounting instructions"

or in our "Flying system and Rigging manuals".

– Ensure that all additional hardware, fixings and fasteners used

for installation or mobile deployment are of an appropriate

size and load safety factor. Pay attention to the manufacturers'

instructions and to the relevant safety guidelines.

– Regularly check the loudspeaker housings and accessories for

visible signs of wear and tear, and replace them when

necessary.

– Regularly check all load bearing bolts in the mounting devices.

Potential risk of material damage

Loudspeakers produce a static magnetic field even if they are not

connected or are not in use. Therefore make sure when erecting

and transporting loudspeakers that they are nowhere near

equipment and objects which may be impaired or damaged by an

external magnetic field. Generally speaking, a distance of 0.5 m

(1.5 ft) from magnetic data carriers (floppy disks, audio and video

tapes, bank cards, etc.) is sufficient; a distance of more than 1 m

(3 ft) may be necessary with computer and video monitors.

d&b 12S-SUB Manual (1.3 EN)4

Page 5

2. 12S-SUB loudspeaker

2.1. Product description

The 12S-SUB is a compact high performance subwoofer for use

with d&b xS-Series loudspeakers. The cabinet houses a long

excursion 12” neodymium driver in a bass-reflex design.

The 12S-SUB frequency response extends from 45 Hz to

130/100 Hz.

The enclosure is constructed from marine plywood with an impact

resistant black paint finish. The front of the cabinet is protected by

a rigid metal grill backed by an acoustically transparent foam.

Four rubber feet prevent cabinet movement and protect the bottom

panel against scratching.

The cabinet is Ball Impact Resistant according to DIN 18032-3.

Rigging components

The 12S-SUB side panels are each equipped with a pair of M10

threads to accept the Z5412 Horizontal bracket 12S-SUB. The

threaded inserts are covered by dummy caps in cabinet color. The

caps must be removed before mounting any accessories.

Fig. 1: 12S-SUB loudspeaker

Rigging example:

12S-SUB ceiling mounted with Z5412 Horizontal bracket 12S-SUB.

Fig. 2: Connector wiring

Cabinet options

The weather resistant version (WR) is suitable for outdoor use

(IP34, vertical aiming up to 0°). The cabinets have an impact and

weather protected black PCP (Polyurea Cabinet Protection) finish.

2.2. Connections

The cabinet is fitted with a pair of NL4 connectors and a two pole

screw terminal block (ST). All four pins of both NL4 connectors are

wired in parallel. The cabinet uses the pin assignments 2+/2–. Pins

1+/1– are designated to full range cabinets.

Cabinets with the weather resistant option (WR) are equipped with

a fixed input cable (PG type, H07-RN-F, 2 x 2.5 mm2 (AWG 13),

standard length 5.5 m (18 ft).

Pin equivalents of the applicable connector options are listed in the

table below.

NL4

ST

PG

1+ 1– 2+ 2–

n.a. n.a. + –

n.a. n.a. Brown (+) Blue (–)

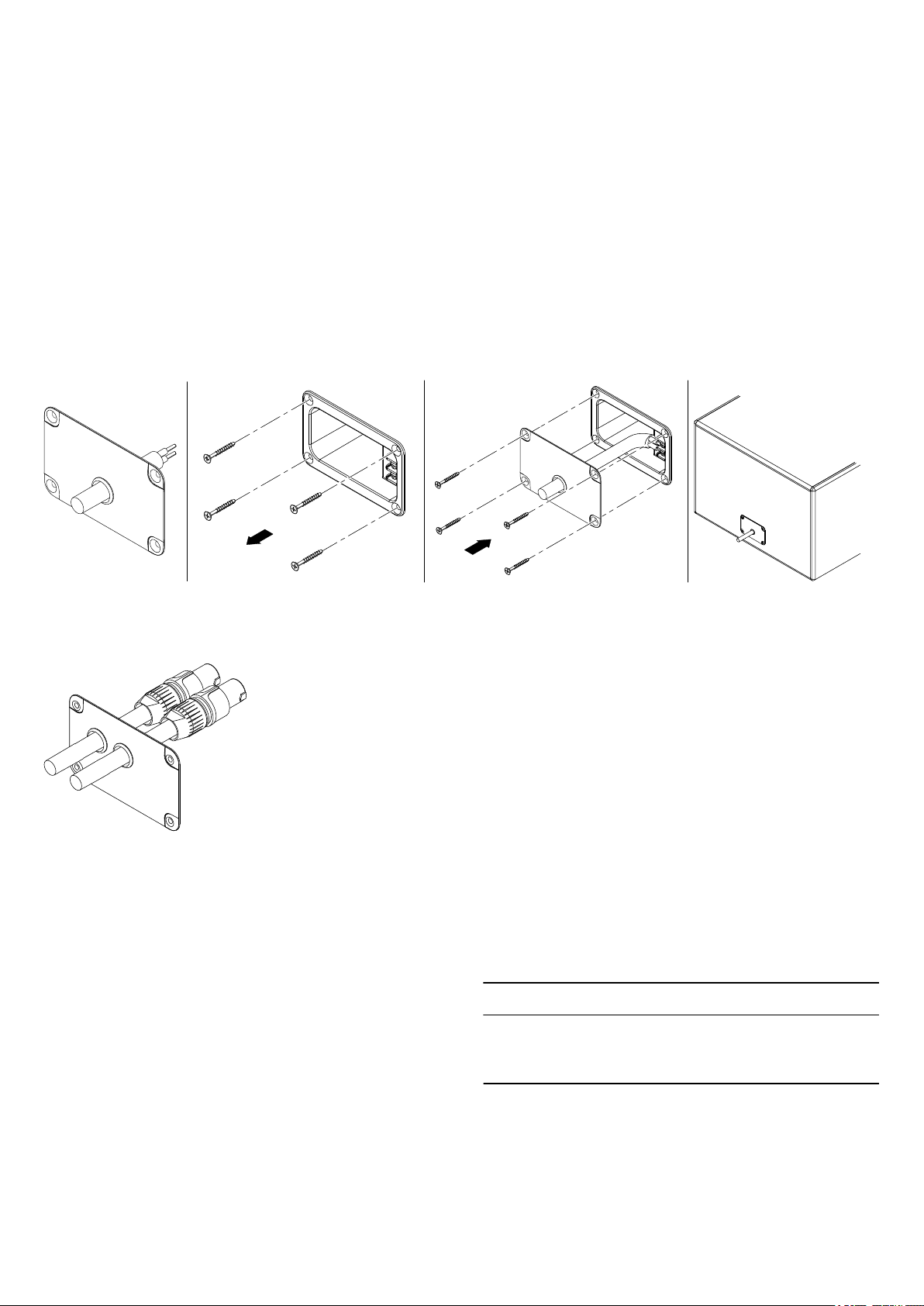

Fixed cable connection

The 12S-SUB loudspeaker is supplied with a cover plate [1] and a

rubber grommet feed through [2]. For indoor operation, these

items can be used to hide the connector panel, if required. For

unprotected outdoor operation, the connector panel must be

covered, i.e. both items must be used to achieve an IP degree of

protection of IP34.

To install the fixed cable connection, proceed as follows:

Fig. 3: Cover plate and rubber grommet

d&b 12S-SUB Manual (1.3 EN) 5

Tools required: Philips screw driver (#PH2).

Page 6

1. Prepare the rubber grommet and the connection cable.

2. Remove the knockout opening in the cover plate and attach

the rubber grommet correspondingly.

3. Insert the connection cable through the rubber grommet and

connect the cable wires to the screw terminal.

Þ Observe the correct polarity!

4. Undo the four screws of the connector panel.

5. Push the cover plate towards the connector panel until it fits

into place.

6. Finally fix the cover plate together with the connector panel

using the four screws.

Fig. 4: Installing the fixed cable connection

Fig. 5: NL4 cable connection with cover plate [1]

NL4 connection with cover plate

The two NL4 connector sockets of the cabinet's connector panel

are located in a recess to allow the use of the cover plate [1]

together with NL4 cable connectors, as shown in the graphic

opposite.

Note: Neutrik NL4FC type connectors must be used for this

option.

The cover plate is equipped with two knockout openings to allow

daisy chaining of the loudspeaker.

To use the NL4 connection, proceed in the same manner as

described above in the section entitled Þ "Fixed cable connection"

on page 5.

2.3. Operation

NOTICE!

Only operate d&b loudspeakers with a correctly configured d&b

amplifier, otherwise there is a risk of damaging the loudspeaker

components.

Operation with D6 or D12

Select the controller setup 12S-SUB.

d&b 12S-SUB Manual (1.3 EN)6

Page 7

Within the D12 amplifier it is available in "Dual Channel" and "Mix

TOP/SUB" mode. For combinations with full range systems fed by

a single 4-wire cable "Mix TOP/SUB" mode must be selected.

Up to a total of two 12S-SUB loudspeakers can be driven by each

channel of the D6 or D12 amplifiers.

2.3.1. Controller settings

For acoustic adjustment the 100 Hz function can be selected.

100 Hz circuit

If the 100 Hz circuit is selected, the upper operating frequency of

the system is reduced from 130 Hz to 100 Hz.

2.4. Technical specifications

12S-SUB system data

Frequency response (–5 dB standard) 45 Hz - 130 Hz

Frequency response (–5 dB 100 Hz mode) 45 Hz - 100 Hz

Max. sound pressure (single cabinet, 1 m, free field)

with D6 124 dB

with D12 127 dB

(SPLmax peak, pink noise test signal with crest factor of 4)

Fig. 6: 12S-SUB frequency response, standard and 100 Hz modes

Fig. 7: 12S-SUB cabinet dimensions in mm [inch]

12S-SUB loudspeaker

Nominal impedance 8 ohms

Power handling capacity (RMS/peak 10 ms) 300/1600 W

Components 1 x 12“ driver

Connections 2 x NL4

1 x screw terminal (ST - up to 4 mm2/AWG 11)

Optional fixed cable (PG):

H07-RN-F, 2 x 2.5 mm2 (AWG 13), 5.5 m (18 ft)

Pin assignment NL4: 2+/2–

Fixed cable (PG): brown + / blue –

Weight 16 kg (35 lb)

d&b 12S-SUB Manual (1.3 EN) 7

Page 8

3. Manufacturer's Declarations

3.1. EU conformity of loudspeakers (CE symbol)

This declaration applies to:

d&b 12S-SUB loudspeaker, Z1590

manufactured by d&b audiotechnik GmbH.

All production versions of these types are included, provided they

correspond to the original technical version and have not been

subject to any later design or electromechanical modifications.

We herewith declare that said products are in conformity with the

provisions of the respective EC directives including all applicable

amendments.

A detailed declaration is available on request and can be ordered

from d&b or downloaded from the d&b website at

www.dbaudio.com.

3.2. WEEE Declaration (Disposal)

Electrical and electronic equipment must be disposed of separately

from normal waste at the end of its operational lifetime.

Please dispose of this product according to the respective national

regulations or contractual agreements. If there are any further

questions concerning the disposal of this product, please contact

d&b audiotechnik.

d&b 12S-SUB Manual (1.3 EN)8

Page 9

D2615.EN .01, 12/2011 © d&b audiotechnik GmbH

www.dbaudio.com

Loading...

Loading...