Page 1

#462

Little Brother to the HAPPY TROLLER

®

For Outboard Motors Up To and Including 25 Horsepower

INSTALLATION INSTRUCTIONS

Step 1: Remove the four 1/4" (6.5 mm) mounting bolts, wash-

ers, and nuts from package and retain for installation.

Step 2: Pull control handle and allow troll plate to move down

into troll position. CAUTION: Troller is spring

loaded; don’t pinch your fingers.

Step 3: Locate the anti-cavitation plate on your motor or out-

drive. It’s the wide horizontal plate which extends just

above the propeller. Always select the flat side of the

anti-cavitation plate to mount the Lil’ Fella. Where

possible, mount the unit on the underside of the cavitation plate.

Step 4: With the troller plate locked in the troll (down) posi-

tion, place Troller on the anti-cavitation plate and

move as far forward as possible without causing interference with the Troller’s operating mechanism. Prior

to drilling, pull cord making sure the locking bar

moves all the way forward to the end of its slots, without any interference with the anti-cavitation plate,

fins, or ridges. Square up the Troller and use two

small “C” clamps to hold it securely in place for

drilling. Note: The two forward and two stern holes

are to be used for most outboard motor installations.

Step 5: Using a 1/4" (6.5 mm) drill bit, place drill in existing

hole in mounting plate. Using the hole as a drill guide

and keeping the drill square, drill straight through the

anti-cavitation plate (this plate is a solid casting and

no water jacket is involved). Before proceeding to the

next hole, insert a 1/4" (6.5 mm) bolt in the hole just

drilled. Position head of bolt on the mount plate side

and lightly tighten the nut and washer on the anticavitation plate side. Repeat this procedure for the

three remaining holes. Tighten all four bolts, but be

careful not to over-tighten.

If for some reason the hole pattern in the Lil’ Fella

does not work for your anti-cavitation plate, feel free

to drill new holes in the Lil’ Fella to obtain the best

possible fit and maximum strength. Do not attempt

to modify your anti-cavitation plate.

Step 6: Uncoil Troller control cord and tie off securely in a

convenient location, preferably in the center of the

stern of your boat. CAUTION: Allow sufficient slack

in the control cord to prevent accidental operation of the Troller during full turns of the boat.

Such inadvertent operation, going undetected,

could cause damage to the Troller or anti-cavitation plate. Excess slack may foul in the propeller,

also resulting in damage.

OPERATING INSTRUCTIONS

Always lubricate moving parts before each day’s

use.

Step 1: We recommend keeping your Troller in the troll

(down) position for storage and trailering.

Step 2: Before launching your boat, make certain the troll

plate is in the cruise (up) position. To accomplish this,

pull the control lever forward with one hand and lift up

the troll plate with the other hand. When troll plate is

against the stop (horizontal), release the control lever

and the Troller will lock in the cruise/travel position.

You are now ready to launch your boat. After launch-

ing, visually check to make sure the Troller is in

the cruise (up) position before getting underway.

Step 3: Ready to troll?

(a). Bring boat to a full stop.

(b). Place motor in neutral.

(c). Pull control cord to end of its travel and hold for a

few seconds while the springs move troll plate to the

locked down position, then release.

(d). Shift to forward gear and slowly adjust throttle for

proper trolling speed. Troll speed will normally be 50

to 75 RPM above dead idle. Caution: Damage will

occur if sudden throttle is applied or engine is

operated over 1200 RPM while in trolling position.

Step 4: Finished trolling?

(a). Reduce speed to dead idle.

(b). While still in forward gear, pull control cord. You

should feel a sudden movement forward as the troll

plate is released.

(c). Stop and visually check to make sure the troll

plate is released (locked in the up position).

(d). Slowly proceed to cruising speed. If drag is felt,

stop immediately and check Troller position.

(e). Visually check one more time. If in locked up

position, you may proceed to full power.

Be sure to carefully follow these instructions. Neither the manufacturer or re-seller are responsible for the correction of any

damage incurred to the boat, engine, anti-cavitation plate,

lower drive, propeller, or the Troller.

Save These Instructions

Page 2

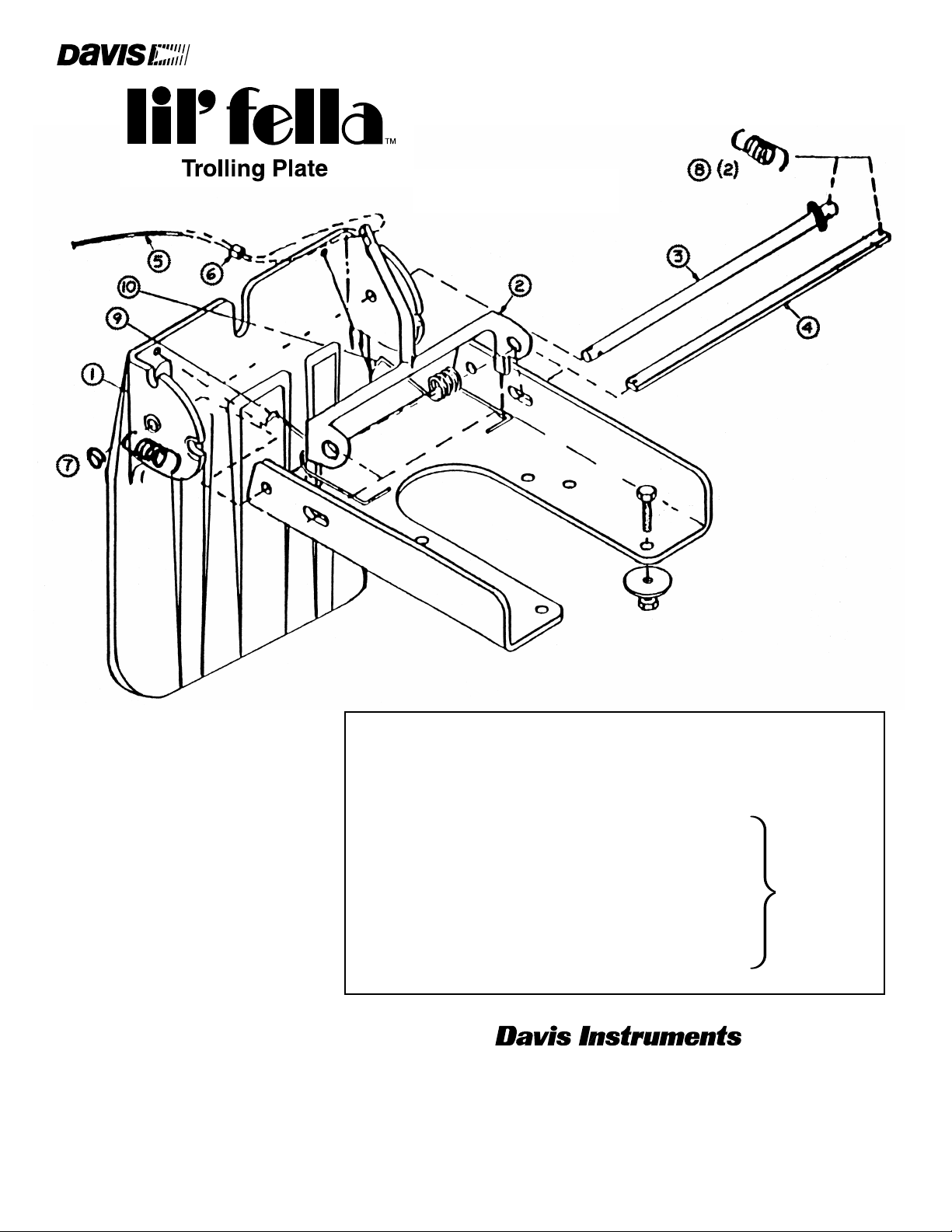

Part Order Description Qty.

Number per Unit

1 R462A Backplate 1

2 R462B Control Arm with Cord and Swedge 1

3 Pivot Rod

4 Locking Bar

5, 6 Control Cord and Swedge

7 Ring Pin,

stainless steel

8 Locking Bar Springs,

stainless steel (2)

9 Lowering Spring, LH

stainless steel

10 Lowering Spring, RH

stainless steel

PARTS LIST

Lil’ Fella™replacement parts may be

available through your local dealer. If not,

you may order directly from Davis

Instruments Corporation.

Lil’ Fella

™

Parts Kit,

order number

R462C

3465 Diablo Avenue, Hayward, CA 94545, U.S.A.

Phone (510) 732-9229 • Fax (510) 732-9188

info@davisnet.com

For information about our other fine products, visit www.davisnet.com

ONE-YEAR WARRANTY

We warrant our products to be free of defects

in material and workmanship for one year

from the date of original purchase. Write for

full warranty details.

462_Inst.pdf April 2006

Loading...

Loading...