Page 1

Davey® Repair or Replacement Guarantee

In the unlikely event in Australia or New Zealand that this Davey product develops any malfunction

within two years of the date of original purchase due to faulty materials or manufacture, Davey will at

our option repair or replace it for you free of charge, subject to the conditions below.

Should you experience any difculties with your Davey product, we suggest in the rst instance that

you contact the Davey Dealer from which you purchased the Davey product. Alternatively you can

phone our Customer Service line on 1300 367 866 in Australia, or 0800 654 333 in New Zealand, or

send a written letter to Davey at the address listed below. On receipt of your claim, Davey will seek to

resolve your difculties or, if the product is faulty or defective, advise you on how to have your Davey

product repaired, obtain a replacement or a refund.

Your Davey Two Year Guarantee naturally does not cover normal wear or tear, replacement of product

consumables (i.e. mechanical seals, bearings or capacitors), loss or damage resulting from misuse

or negligent handling, improper use for which the product was not designed or advertised, failure to

properly follow the provided installation and operating instructions, failure to carry out maintenance,

corrosive or abrasive water or other liquid, lightning or high voltage spikes, or unauthorized persons

attempting repairs. Where applicable, your Davey product must only be connected to the voltage

shown on the nameplate.

Your Davey Two Year Guarantee does not cover freight or any other costs incurred in making a claim.

Please retain your receipt as proof of purchase; you MUST provide evidence of the date of original

purchase when claiming under the Davey Two Year Guarantee.

Davey shall not be liable for any loss of prots or any consequential, indirect or special loss, damage

or injury of any kind whatsoever arising directly or indirectly from Davey products. This limitation

does not apply to any liability of Davey for failure to comply with a consumer guarantee applicable to

your Davey product under the Australian or New Zealand legislation and does not affect any rights or

remedies that may be available to you under the Australian or New Zealand Consumer Legislation.

In Australia, you are entitled to a replacement or refund for a major failure and for compensation for

any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major

failure.

INSTALLATION AND OPERATING INSTRUCTIONS

DEEP WELL PRESSURE PUMPS & SYSTEMS

MODELS 95D, 125D, 165D

Should your Davey product require repair or service after the guarantee period; contact your nearest

Davey Dealer or phone the Davey Customer Service Centre on the number listed below.

For a complete list of Davey Dealers visit our website (davey.com.au) or call:

AUSTRALIA

Customer Service Centre

6 Lakeview Drive,

Scoresby, Australia 3179

Ph: 1300 367 866

Fax: 1300 369 119

Website: davey.com.au

Davey Water Products Pty Ltd

Member of the GUD Group

ABN 18 066 327 517

® Davey is a registered trade mark of Davey Water Products Pty Ltd.

© Davey Water Products Pty Ltd 2011.

* Installation and operating instructions are included with the product when purchased new.

They may also be found on our website.

NEW ZEALAND

Customer Service Centre

7 Rockridge Avenue,

Penrose, Auckland 1061

Ph: 0800 654 333

Fax: 09 527 7654

Website: daveynz.co.nz

P/N 48532-8 supersedes P/N 48532-7

Read All Instructions First Before Commencing Installation of your New Deep Well Pressure

Pump.

These Instructions have been prepared to acquaint you with the correct method of installing and

operating your Davey Pressure Pump or System. We urge you to study this publication carefully and

follow its recommendations. If you have any installation difculties, or need further advice, you should

contact the Davey Dealer from whom you purchased the system.

Should you be unable to obtain the required advice to resolve any problem through your local Davey

Dealer, please contact the Davey Customer Service Centre.

Please pass these instructions on to the operator of this equipment.

Page 2

Prior to using this pump you must ensure that:

• The pump is installed in a safe and dry environment

• The pump enclosure has adequate drainage in the event of leakage

• Any transport plugs are removed

• The pipe-work is correctly sealed and supported

• The pump is primed correctly

• The power supply is correctly connected

• All steps have been taken for safe operation

Trouble Shooting continued...

6. Pump Not Switching Off or Taking Too Long to Switch Off

May be caused by one or more of the following: a) Voltage supply too low;

b) Blocked jet or venturi;

c) Leak in discharge pipe or tting, taps etc.;

d) Worn or blocked pump components, impeller, casing etc.;

e) Drop in water level in water supply source.

Appropriate details for all of these items are contained in the following Installation

and Operating Instructions. Read these in their entirety before switching on

this pump. If you are uncertain as to any of these Installation and Operating

Instructions please contact your Davey dealer or the appropriate Davey ofce as

listed on the back of this document.

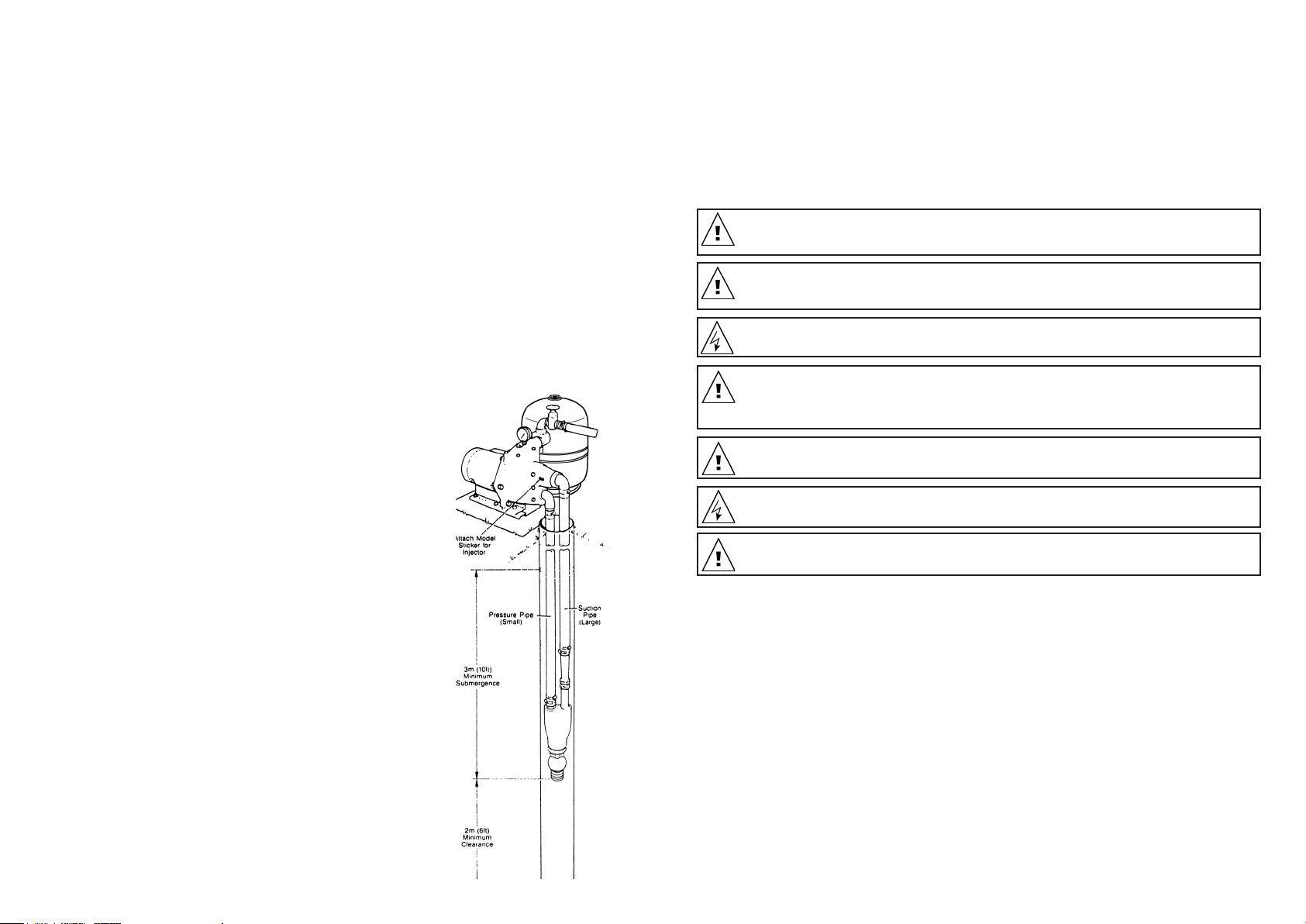

Summary of Installation Procedure

For Automatic Operation as a Pressure System with Supercell Pressure Tank

1. Securely bolt pump to wooden, metal or concrete

base, adjacent to bore, as shown in illustration, to

allow suction pipework to be installed directly down

bore. Alternatively, for offset installations, when

pump is not directly adjacent to bore, pump may be

positioned on a rm base without securing.

2. For base mounted tanks place tank next to pump and

connect tank hose to bottom connection of pressure

regulating valve, after removing cap. If using the

Davey Tank connection kit you need only tighten by

hand (no sealant required). Use of pipe wrench is not

required and should be avoided.

For top mounted tanks a Davey three way tee piece is

required (P/No 48638). This is tted to the priming hole,

and the tank is screwed into the top of the tee.

*NOTE: For protection, the Davey pump motors are tted with an automatic reset

thermal overload, constant tripping of this overload indicates a problem e.g. low

voltage at pump, excessive temperature (above 50°C) in pump enclosure.

WARNING: Automatic reset thermal overloads will allow the pump to restart without

warning. Always disconnect the pump motor from the electrical supply before

maintenance or repairs.

WARNING: When servicing or attending pump, always ensure power is switched off and

lead unplugged. Electrical connections should be serviced only by qualied persons.

Care should also be taken when servicing or disassembling pump to avoid possible

injury from hot pressurised water. Unplug pump, relieve pressure by opening a tap on

the discharge side of the pump and allow any hot water in the pump to cool before

attempting to dismantle.

IMPORTANT: DO NOT USE petroleum based uids or solvents (e.g. Oils, Kerosene,

Turpentine, Thinners, etc) on the plastic pump components or seal components.

WARNING: Do not use hydrocarbon based or hydrocarbon propelled sprays around the

electrical components of this pump.

In accordance with AS 3350.2.41 we are obliged to inform you that this pump is not to

be used by children or inrm persons and must not be used as a toy by children.

3. Fit a gate valve to the 11/4” BSP outlet at the pressure

regulating valve.

4. Prepare injector, connecting lengths of polythene

pipe of the correct size to the venturi tube and

injector body.

- 2 - - 11 -

Page 3

Trouble Shooting

1. Pump not Delivering Water or not Building Up Pressure

May be caused by one or more of the following: a) Pump not properly primed;

b) Foot valve leaking;

c) Deep Well injector not installed below water level;

d) Suction lift too high;

e) Suction piping not correctly sealed or holed allowing air to enter pump

suction;

f) Blocked jet or venturi;

g) Piping connected in reverse, ie suction and pressure pipes transposed;

h) Motor thermal overload tripping - refer No 4;

i) Insufcient water supply at source;

j) Pressure system not switching on due to static delivery head causing higher

pressure on the pump than the pressure switch cut-in setting.

2. Pump not Operating at Minimum Operating Pressure for Deep Well injector

May be caused by air leaks in suction pipe or

ADR control not correctly set.

3. Motor not running

May be caused by one or more of the following: a) Power failure;

b) Blown fuse;

c) Motor overload tripping;

d) Motor windings faulty.

4. Motor Thermal Overload Tripping

May be caused by one or more of the following:-

a) Low voltage supply;

b) Motor or pump seized;

c) Motor windings faulty.

5. Remove suction cover from pump and screw elbows supplied with Deep Well

Injector into cover, ensuring that an air tight seal is achieved. Use ample thread

seal tape. Fit polythene pipes onto elbows, again ensuring that no air leaks

exist. “Silastic” used in joints between pipes and connectors will assist in

sealing.

6. Lower injector into bore and re-attach suction cover to pump with rubber

gasket, evenly tightening cover retaining nuts.

7. Attach injector model label (supplied with Injector Kit) to pump suction cover as

shown.

8. Connect outlet piping at gate valve.

9. Fit pressure gauge (supplied with pump) at top of pump as indicated on

illustration.

For Manual Operation (i.e. without pressure tank)

Follow procedure as above, except no pressure tank tted as described under (2).

Remove pressure switch tube from regulating valve and plug connection hole with

tting supplied.

Housing your Pump

As the pump is an electrical apparatus, it must be protected from the weather, at

the same time adequate ventilation must be provided for the motor.

Do not enclose the pump in such a manner that a “Hotbox” condition is created.

Ventilation should be provided near the top of any enclosure to prevent a buildup of

condensation.

Your pump should be securely bolted to a rm base, high enough to prevent

any surface water that may accumulate from coming into contact with the unit.

Positioning of the unit should allow the nameplate to be easily read, and provide

adequate access for service purposes.

The power outlet may need to be provided by an electrician in a safe, dry place

(possibly within the weather proof enclosure).

5. Pump Switching On and Off Frequently or When No Taps Turned On

May be caused by one or more of the following: a) Foot valve not retaining pressure or water;

b) Water leaking from suction or delivery piping;

c) Faulty ball valve in toilet cistern, hot water system, or stock troughs allowing

unit to over-ow;

d) Pressure tank not retaining air pressure or air charge too high;

e) Motor thermal overload tripping.

- 10 - - 3 -

WARNING: Some insects, such as small ants, nd electrical devices attractive for

various reasons. If your pump enclosure is susceptible to insect infestation you

should implement a suitable pest control plan.

Water Quality

Your Davey pump is made from food safe materials, and tested using sanitised

water. Davey has no control over your pump once it leaves our warehouse.

For potable (drinking) water applications we recommend that you ush the pump

with clean water prior to use.

Page 4

Installation Procedure

The Deep Well Injector Kit comprises a bronze injector and foot valve

assembly which is attached to the end of polythene piping and lowered

into the water. Deep well injector kits include all appropriate ttings for

connection of pipes to pump.

With the adjustment screw on the ADR valve adjusted fully out, run the pump

until the bore is pumped down to its ‘draw down’ level, whilst the pump outlet is

allowing water to discharge unimpeded.

Maintain the pump pressure at this level using gate valve.

Suction Piping for use on Deep Well Injectors

All Deep Well Injectors require two pipes to be connected between the pump and

the injector, the larger being the suction pipe and the smaller the pressure pipe.

Pipe sizes are according to the table below (except where special sizes may

be specied for a particular installation - consult your Davey Dealer or Davey

Customer Service Centre).

Deep Well Injector Kit No. Suction and Pressure Pipe Sizes

22469, 22470, 22471, 22472.

22473, 22474, 22475 11/2”and 11/4”

22570, 22571, 22572, 22573 2” and 11/2”

Polythene piping is recommended. Select the grade of pipe which has a pressure

rating equal to the pump max. pressure and the depth to water. Normally rural

class B polypipe is ample. If higher rating pipe is required, consult your Davey

dealer.

Plumbing of Deep Well Injectors

A minimum submergence of 3m (10 ft.) is required for the injector and foot valve

assembly for correct operation.

When water is pumped out from a borehole it is common for the water level in

the bore to drop. However, there is usually a point at which the bore water level

remains static or constant for a given maximum ow from the bore. This new level

is known as the ‘draw down level’ of the bore. It is necessary to establish this

draw down level and the output capacity of the bore at this level before installing a

pump on the bore.

Once the pump has been installed on the bore, it is necessary to regulate the

ow from the pump to ensure it does not exceed the maximum capacity of the

bore at the draw down level. Refer Automatic Demand Response (ADR) Set Up

Instructions.

The minimum submergence of the injector and foot valve assembly of 3m (10 ft) means

the length of piping required from the top of the bore to injector assembly is equal

to the draw down level plus 3m (10 ft). Furthermore, ensure that at least a 2m (6 ft)

clearance exists between the injector assembly and the bottom of the bore.

- 4 - - 9 -

Screw regulating valve adjustment screw in until pressure starts to rise. Open

gate valve a little further, then readjust regulating valve to maintain required

minimum pressure on gauge When gate valve is fully open and regulating valve

is maintaining operating pressure, adjustment is complete. Your pump will now

resist operating in a loss of prime condition, but also optimise it’s performance at

higher pressures. If pump is allowed to operate below the minimum on the table

below, cavitation will occur which causes excessive pump wear, or prime may be

lost.

Deep Well Minimum Operating Max Shut-off

Injector Pressure Pressure

Model kPa psi kPa psi

22469 200 29 550 80

22470 195 28 645 93

22471 220 32 575 83

22472 235 34 660 96

22473 160 23 620 90

22474 240 35 635 92

22475 240 35 750 109

22570 230 33 650 94

22571 170 25 590 86

22572 230 33 630 91

22573 240 35 540 78

Once set there should be no need to alter the setting of the ADR valve, unless

there is a major change with the installation.

Always operate the pump at or above the minimum operating pressure. Failure to do

so will result in pump damage not covered by guarantee.

To Check for Correct Automatic Pressure System

Operation

1. Close gate valve at pump outlet, allowing pump to run and build up pressure

until it switches off at cut-out setting of pressure switch (factory setting of

350kPa).

2. Open gate valve at pump outlet to allow water to discharge to an outlet point.

Pump will automatically switch on at cut-in setting of pressure switch (factory

setting of 210kPa).

Page 5

Power connections and wiring must be carried out by an Authorised Electrician.

Having established the length of the piping required for attachment to the injector,

connect the injector assembly making sure that the larger pipe is tted to the long

venturi tube of the injector.

Pressure Switch Setting

All Deep Well Models have a factory-set pressure switch cut-in of 210 kPa, and

350 kPa, cut-out. The switch settings may require adjustment to provide the best

constant performance, reducing pump cycling to a minimum. This work may

require the assistance of an experienced pump installer.

Pressure Tank Pre-Charge

The Davey Supercell Pressure Tank requires the correct pre-charge of air for

satisfactory operation. This pre-charge of air is determined by the cut-in pressure

switch setting required for the particular system purchased. This pressure must

be adjusted prior to operation of the system to 195kPa (28 psi) which is the correct

pre-charge for Deep Well pressure switch setting of 210 — 350 kPa. If higher

operating pressures are required, the tank pressure must be set to 15kPa (2psi)

below the cut-in switch. Adjust this pre-charge before operating the pressure

system. This pre-charge pressure may be checked using a standard automotive

type tyre pressure gauge.

Operating the Pump

1. Close gate valve (in outlet piping).

2. Remove priming plug and ll pump body and suction pipes with water by

pouring water into the priming port on top of the pump until suction pipes

and pump are completely full. Allow air bubbles to come to top of casing.

Continue topping-up as air bubbles come out. For long ‘offset’ installations, it

is recommended that an engine powered pump be used to ll suction pipes.

Riser pipes installed at high points in both suction pipes may be necessary to

‘bleed’ out air fully. Ensure all tting and caps are air tight.

3. Replace priming plug and switch on pump.

4. Crack gate valve at pump outlet to expel trapped air. When pump primes,

pressure gauge reading will climb to over 350kPa. It may be necessary to

switch off and top up pump and pipes with water several times to expel all air in

the system and gain prime.

5. Once prime is established, open gate valve slowly. A strong ow of water

should be evident at an outlet tap indicating pump is functioning.

Automatic Demand Response

(ADR) - setting up instructions

Deep Well Installations require a certain

minimum pump pressure to operate

satisfactorily (See Table).

- 8 - - 5 -

Use 2 hose clips on each pipe connection with worm drives facing but on opposite

sides of pipe, and tighten securely. It may be necessary to heat the polythene

piping slightly before pushing it on to the hose tails. At the other end of the suction

pipes (top of bore end), remove the suction cover from the pump and t it to the

piping using the elbow connectors provided with the injector housing kit.

Ensure joints are air tight, thread seal tape or pipe joining compound is essential.

Securely tighten 2 hose clips on each connector. It is essential that there be no air

leaks at this connection, particularly because air leaks are the biggest cause of suction

priming difculties. Air being sucked in is almost impossible to detect. Ensure that

both pipes are an even length, and will lie straight side by side before installing in the

bore hole.

Lower injector assembly into bore hole and attach suction cover to pump with

rubber gasket in place. Tighten the nuts sufciently to prevent air leaks around the

gasket, but do not overtighten. Attach Deep Well Injector model label (supplied

with injector kit) to pump suction cover adjacent to inlet thread.

Delivery Piping

Polythene piping, imperial or metric, is recommended. Select the grade of pipe

which has a pressure rating suitable for your application. Galvanised or PVC

piping may also be used, provided the pressure rating is adequate.

For more detailed advice and information regarding pipe sizes for longer suction

situations or greater suction lifts, please contact your Davey Dealer or the Davey

Customer Service Centre.

Outlet Plumbing Connections

A gate valve must be tted to the 11/4” pump outlet at the pressure regulating

valve before the connection of outlet piping.

Pumps to be Operated as Automatic Pressure Systems

BASE MOUNTED TANKS USED.

1. Remove cap from ADR regulator valve and connect hose from it to Davey

Supercell Pressure Tank. If using Davey Tank Hose rm hand tight should be

sufcient. Ensure tank connection hose is not kinked.

2. Fit gate valve on the 1

using thread seal tape.

3. Connect delivery piping at gate valve.

4. Fit pressure gauge/priming plug on top of Pump.

1

¦

4” outlet connection of the pressure regulating valve

Page 6

TOP MOUNT TANKS

1. Fit a Davey three way tee piece (P/No 48638) into the priming hole on top of

the pump. Ensure adequate thread tape is used.

2. Screw the tank into the top of the three way tee using thread tape.

3. Perform steps (2) through to (3) above.

4. Fit the pressure gauge/priming plug to the horizontal outlet on the three way

tee.

Pumps to be Operated Manually at Power Point

As for automatic operation except that no pressure tank tted, and pressure

switch tube to be removed from regulating valve, and valve connection plugged

with plug supplied.

Power Connection - Single Phase

A power connection point should be provided by a qualied electrician within the

pump housing.

Power connections and wiring must be carried out by an authorised electrician,

in compliance with applicable local standards.

Single phase Models are rated for 220/250 volts, 50Hz operation, and may be

connected to a standard 10 amp power outlet.

All single phase Models have automatic reset thermal overload protection built

in, i.e. should overload on motor cause thermal to open circuit and switch motor

off, it will automatically re-set and switch motor on when motor has cooled down

sufciently, usually within a few minutes.

WARNING: Automatic reset thermal overloads will allow the pump to restart without

warning.

ALWAYS disconnect the pump motor from the electrical supply before maintenance

or repairs.

1. Long extension leads should be avoided as they often have insufcient current

carrying capacity to run electric motors, hence they can cause substantial voltage

drop and operating problems.

2. Minimum voltage at the electric motor must not fall below 216 volts for single

phase, otherwise motor damage may result which is not claimable under

Guarantee.

3. If the electrical ttings in your country make it necessary to remove the plug

from the lead tted to the motor, care should be taken to ensure that the earth

conductor green/yellow in the lead is properly connected to a good earth. This

work must only be undertaken by an authorised electrician.

Davey recommend the use of overloads which also have the ability to detect

“single phasing” or “dropped phase” conditions in the power supply.

NOTE: Minimum three phase voltage supply at the motor must not fall below 374

volts, otherwise motor damage may result which is not claimable under Guarantee.

Three phase 165D Pressure Pump models have

been designed to allow for connection either side

of the Capacitor Cover (marked “A” in gure one)

on the motor. (NOTE: Three phase motors do

not have capacitors tted in the Capacitor Cover).

This is achieved by way of either of the two 19mm

access holes (marked “B” in gure one).

The access holes are designed to accept most

standard cable grommets. The unused hole can be sealed by inserting the plug

enclosed with the pump. To connect a three phase Pressure Pump start by

removing the Terminal Cover (“C”).

A short four core ex (“D”) is tted from the motor

terminals (“E”). This lead is inserted through the

Blanking Grommet (“F”). Pressure switch or other

control leads (“G”) can be tted as well. Incoming

power (“H”) can be tted through the preferred

access hole, and terminated as shown in Figure

Three. A termination kit is available if required.

Insert the Blanking Grommet (“F”) into the Capacitor

Cover (“A”). Fix the short lead (“D”) into the path

provided in the non-drive end-shield and replace the

Terminal Cover (“C”).

IMPORTANT NOTE: – THREE PHASE MODELS ONLY

Before nalising wiring connections, check that motor rotates in direction of arrow

(clockwise when shaft is viewed from wiring connection end). To alter rotation,

change any two power leads at motor terminals.

Power Connection - Three Phase

Model 165D only is also available for connection to a 3 phase 50Hz, nominal

415 volt power supply. A recommended wiring diagram can be found inside the

capacitor cover (see gure one below). Three phase units must be wired in by an

authorised electrician in conjunction with a contactor which has quicktrip or M10

rated overloads set at nameplate current.

- 6 - - 7 -

When the unit is connected and operating the phase balance should be checked.

This should be within 5% variation. “Rolling” the leads may help to improve a

small unbalance, but major phase unbalance will usually be attributable to an

input power unbalance. This must be addressed before the pump is used.

Loading...

Loading...