DATEL, Inc., Mansfield, MA 02048 (USA) • Tel: (508)339-3000, (800)233-2765 Fax: (508)339-6356 • Email: sales@datel.com • Internet: www.datel.com

Single Output

UNR SM Series

Features

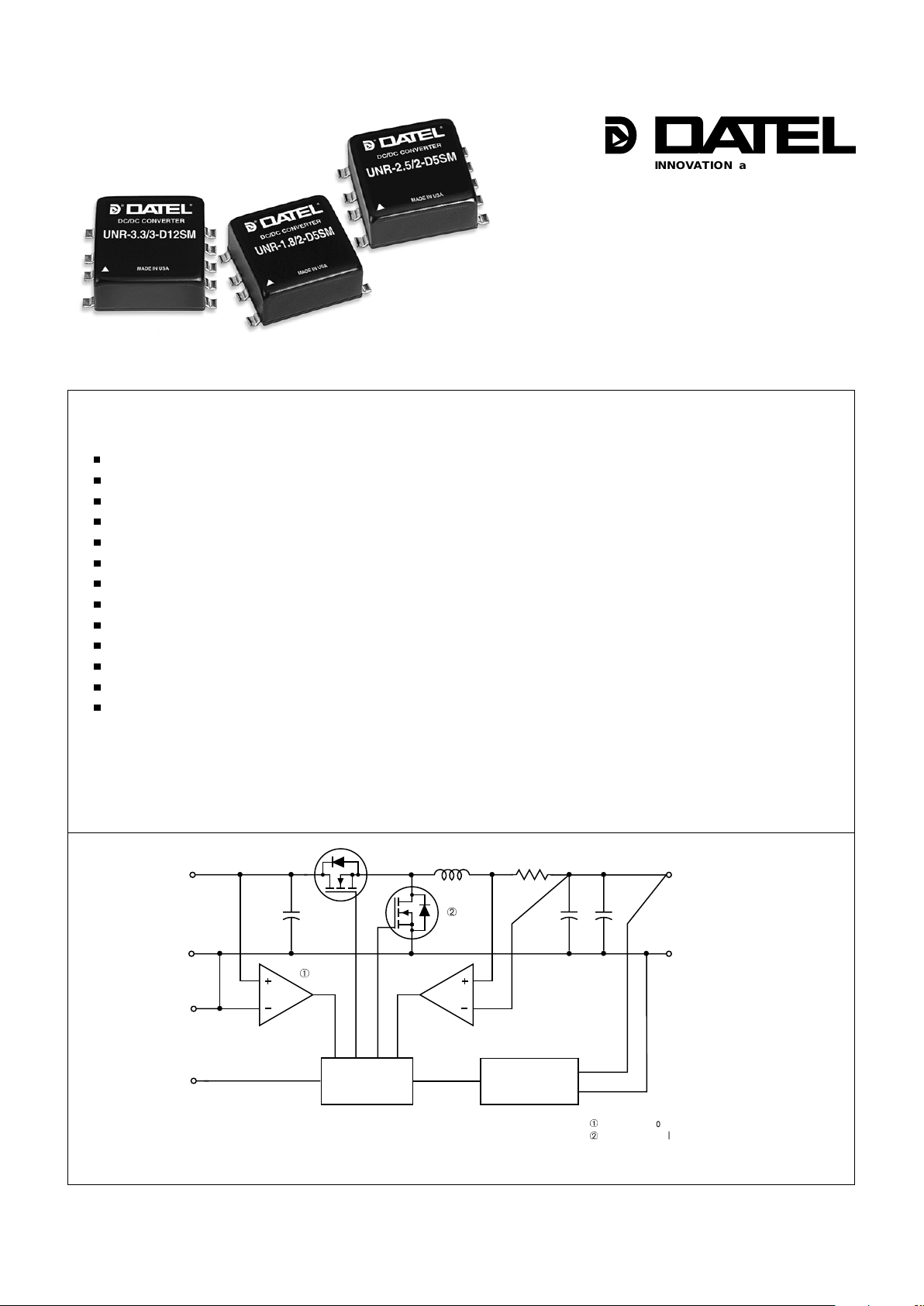

Figure 1. Simplified Schematic

Surface-Mount, Non-Isolated

1.8/2.5/3.3V, 3.6-10W DC/DC Conv e rters

n

n

n

n

n

n

n

n

n

n

n

n

n

INNOVATION and EX C ELL E N C E

®

®

DA TEL's ne w 3.6-10W UNR SM Series consists of non-isolated, 5V -to-1.8V (2A),

5V-to-2.5V (2A), 5V-to-3.3V (3A), and 12V-to-3.3V (3A) DC/DC converters in

miniature, 1" x 1" surface-mount packages. The "gull-wing" packages (with metal

shells and non-conductive plastic baseplates) weigh a mere 17 grams and can

withstand temperatures up to +235°C. They are compatible with virtually all contemporary pick-and-place and solder-reflow processes.

The true benefits of distributed power will ultimately be realized only when every

low-voltage, high-current CPLD , ASIC, DSP, etc. has its own "power plant" right next

to it. With isolated DC/DC converters inevitably residing at the edges of boards in

proximity with backplanes and power buses, the "on-board" proliferation of distributed power will continue with more cost-eff ective, non-isolated de vices. The low-cost,

easy-to-use (no external components required), highly reliable (100% fully automated SMT construction) 3.6-10W UNR SM Series makes this power processing at

the concluding point of use a practical reality today .

These versatile DC/DC's are fully line and load regulated. The y feature useroptional on/off control (for power-sequencing requirements), output current limiting,

and short-circuit protection (foldback technique with auto-recovery). Additionally , the

12V -to-3.3V model offers input undervoltage lockout (at 9.6V). Their impressiv e

guaranteed efficiencies enable all models to deliver their fully rated output power from

–40 to +70°C (ambient) without heat sinking or forced-air cooling.

If you've already considered and rejected the use of inefficient, step-down, linear

regulators, take a look at one of these new s witching buck regulators. Their high

efficiency , ease-of-use, long-term reliability, and over all cost effectiveness will

impress you. Safety agency approvals are currently in progress.

Low cost! High reliability!

1" x 1" x 0.47", SMT package

Gull-wing leads; Standard reflow

Complete; No external components

Outputs: 1.8V/2A, 2.5V/2A, 3.3V/3A

Inputs: 4.75-5.5V , 10.4-13.6V

Guaranteed efficiencies to 87%

Output noise as low as 30mVp-p

T ransient response as quick as 20µsec

–40 to +70°C operation with no derating

On/off control; EMC compliant

IEC950/EN60950/UL1950 pending

Modifications and customs for OEM's

+V

IN

+V

OUT

INPUT

RETURN

ON/OFF

C

ONTROL

OUTPUT

RETURN

CURRENT LIMITING

& S.C. SHUTDOWN

UNDERVOLTAGE

SHUTDOWN

LOGIC

GROUND

REFERENCE &

ERROR AMP

PWM

CONTROLLER

À

À

"D5" models do not have input undervoltage shutdown.

Á

"D5" models employ a more traditional buck-regulator design

in which this FET is replaced with a power Schottky diode.

Á

UNR Series

NON-ISOLATED, 3.6-10W, SURFACE-MOUNT DC/DC CONVERTERS

MECHANICAL SPECIFICATIONS

1.00

(25.40)

0.45

(11.43)

0.055

(1.40)

0.020

(0.51)

0.110

(2.79)

0.015

(0.38)

METAL CASE

INSULATED BASE

4

3

2

1

8

7

6

5

9

0.10

(2.54)

0.110

(2.79)

0.100

(2.54)

0.300

(7.62)

0.500

(12.70)

TOP VIEW

1.00

(25.40)

0.800

(20.32)

4 EQ. SP.@

0.200 (5.08)

Case C17

I/O Connections

Pin Function P24

1N.C.

2 Logic Ground

3 On/Off Control

4N.C.

5 +Output

6N.C.

7 Output Return

8 Intput Return

9 +Input

Output Power (Watts)

Ambient Temperature (˚C)

UNR-3.3/3-D5SM, UNR-3.3/3-D12SM

UNR-2.5/2-D5SM

10

9

8

7

6

5

4

3

2

1

0

–400 404550556065707580859095100

UNR-1.8/2-D5SM

TEMPERATURE DERATING

Performance Specifications and Ordering Guide

IOUT

(Amps)

R/N (mVp-p)

Á

Load

Â

VOUT

(Volts)

Package

(Case,

Pinout)

Efficiency

Regulation (Max.)

Line

VIN Nom.

(Volts)

Range

(Volts)

Model

À

T ypical at TA = +25°C under nominal line voltage and full-load conditions, unless otherwise noted. The UNR-1.8/2-D5SM requires an

external 15k

Ω

pull-up resistor between VIN and On/Off Control for normal operation. See On/Off Control for details.

Á

Ripple/Noise (R/N) measured over a 20MHz bandwidth. The UNR-3.3/3-D12SM is specified with an external

22µF input capacitor. All other models are specified with no external I/O capacitors. Output noise on the "D12" model can be

reduced significantly with the addition of external output capacitors. See I/O Filtering.

Â

"D5" models require a minimum 300mA load current to maintain regulation. The "D12" model has no mimimum load requirement.

Listed specs apply from 300mA to full load for "D5" models and from no load to full load for the "D12" model.

Ã

Nominal line voltage, no-load/full-load conditions.

IIN Ã

(mA)

À

Max.

Typ.

Typ.

Min.

UNR-1.8/2-D5SM 1.8 2 40 75 ±0.35% ±0.35% 5 4.5-5.5 30/90 0 77% 79 % C17, P24

UNR-2.5/2-D5SM 2.5 2 30 50 ±0.25% ±0.5% 5 4.75-5.5 40/1180 83% 85% C17, P24

UNR-3.3/3-D5SM 3.3 3 30 45 ±0.4% ±0.5% 5 4.75-5.5 40/2250 86% 88% C17, P24

UNR-3.3/3-D12SM

Á

3.3 3 100 150 ±0.25% ±0.5% 12 10.4-13.6 40/930 87% 89% C17, P24

Output

Input

PART NUMBER STRUCTURE

Non-Isolated

Output Configuration:

U = Unipolar

Nominal Output Voltage:

1.8, 2.5 or 3.3 Volts

Maximum Output Current

in Amps

Input V oltage Range:

D5 = 4.75-5.5 Volts (5V nominal)

À

D12 = 10.4-13.6 Volts (12V nominal)

U NR 2-

/

D5 SM-2.5

Surface-Mount Packaging

À

4.5-5.5 Volts for UNR-1.8/2-D5SM

2

SM ModelsSM Models

SM ModelsSM Models

SM Models

NON-ISOLATED, 3.6-10W, SURFACE-MOUNT DC/DC CONVERTERS

Performance/Functional Specifications

T ypical @ TA = +25°C under nominal line voltage and full-load conditions with no e xternal filtering,

unless noted.

À

Input

Input V oltage Range:

"D5" Models:

UNR-1.8/2-D5SM 4.5-5.5 V olts (5V nominal)

UNR-2.5/2-D5SM, UNR-3.3/3-D5SM 4.75-5.5 Volts (5V nominal)

"D12" Models 10.4-13.6 Volts (12V nominal)

Overvoltage Shutdown None

Start-Up Threshold:

"D12" Models

Á

10.2V typical, 10.4V maximum

Undervoltage Shutdown:

"D12" Models

Á

9.6V typical, 8.2V minimum

Input Current:

Normal Operating Conditions See Ordering Guide

Standby Mode (Off or undervoltage):

UNR-1.8/2-D5SM 20mA typical, 30mA maximum

UNR-2.5/2-D5SM, UNR-3.3/3-D5SM 10mA typical, 20mA maximum

UNR-3.3/3-D12SM 5mA typical, 10mA maximum

Input Ripple Current:

UNR-1.8/2-D5SM, UNR-3.3/3-D12SM 50mArms

UNR-2.5/2-D5SM, UNR-3.3/3-D5SM 150mArms

Input Filter T ype Capacitive

Reverse-Polarity Protection None

On/Off Control (Pin 3)

Â

TTL high (or open) = on, low = off

1.5V typical logic threshold

Output

VOUT Accuracy (50% load):

UNR-1.8/2-D5SM ±1.5% (±27mV) maximum

UNR-2.5/2-D5SM ±1.5% (±37.5mV) maximum

UNR-3.3/3-D5SM ±1.5% (±50mV) maximum

UNR-3.3/3-D12SM ±1% (±33mV) maximum

Temperature Coefficient ±0.02% per °C

Ripple/Noise (20MHz BW)

Ã

See Ordering Guide

Line/Load Regulation See Ordering Guide

Efficiency See Ordering Guide

Current Limiting

Ä

Auto-recovery

Dynamic Characteristics

Transient Response (50% load step):

UNR-1.8/2-D5SM 20µsec to ±0.5% of final value

UNR-2.5/2-D5SM, UNR-3.3/3-D12SM 30µsec to ±1% of final value

UNR-3.3/3-D5SM 40µsec to ±1% of final value

Start-Up Time:

Å

VIN to VOUT: "D5" Models 100msec typical, 120msec maximum

"D12" Models 13msec typical, 20msec maximum

On/Off to V

OUT: "D5" Models 60msec typical, 120msec maximum

"D12" Models 13msec typical, 20msec maximum

Switching Frequency 200kHz (±30kHz)

Environmental

Operating Temperature (Ambient):

Without Derating –40 to +70°C

With Derating to +100°C (See Derating Curves)

Storage Temperature –40 to +105°C

À

"D5" models require a minimum 300mA load current to maintain specified regulation. "D12"

models have no minimum load requirement. Operating "D5" models under no-load conditions

will not damage these devices, however they may not meet all listed specifications. The

UNR-1.8/2-D5SM requires an external 15

Ω

pull-up resistor between VIN and On/Off Control for

normal operation. See On/Off Control for details. The UNR-3.3/3-D12SM is specifiied with an

external 22µF input capacitor. See I/O Filtering for details.

Á

See Startup Threshold and Undervoltage Shutdown for details.

Â

See On/Off Control for details.

Ã

The 22µF external input capacitor required for the UNR-3.3/3-D12SM should be minimally

rated for 1.5Arms ripple current and 125m

Ω

ESR. Output noise for all models can be further

reduced with the installation of external output capacitors. See See I/O Filtering for details.

Ä

Current limiting initiates at approximately 30% above rated load. Under short-circuit

conditions, output current folds back to approximately 150mA and input current drops to

approximtely 50mA. Both remain at those levels until the short is removed.

Å

See Start-Up Time for details.

Physical

Dimensions 1" x 1" x 0.47" (25 x 25 x 11.9mm)

Shielding None

Case Connection None

Case Material Corrosion-resistant steel with

non-conductive, epoxy-based, black

enamel finish and plastic baseplate

Pin Material Copper, tin plated

Weight 0.6 ounces (17 grams)

Input Voltage:

Continuous:

"D5" Models 7 Volts

"D12" Models 15 Volts

Transient (100msec):

"D5" Models 15 Volts

"D12" Models 24 Volts

Input Reverse-Polarity Protection None

Output Overvoltage Protection None

Output Current Current limited. Devices can

withstand a sustained output

short circuit without damage.

Storage Temperature –40 to +105°C

Lead Temperature (Soldering, 10 sec.) +300°C

These are stress ratings. Exposure of devices to any of these conditions may adversely

affect long-term reliability. Proper operation under conditions other than those listed in the

Performance/Functional Specifications T ab le is not implied.

Absolute Maximum Ratings

3

UNR Series

NON-ISOLATED, 3.6-10W, SURFACE-MOUNT DC/DC CONVERTERS

TECHNICAL NOTES

Return Current Paths

The Input Return (pin 8), Output Return (pin 7) and Logic Ground (pin 2) are all

connected to each other internal to each device. To the extent possible, all load

current should be returned through pin 7 (via low-impedance runs) and all input

current returned through pin 8. Any control signals applied to pin 3 should be

referenced to pin 2. The internal trace leading to pin 2 is not designed to carry

high current. Devices should never be installed in a manner that results in high

current flow through pin 2 (i.e., pins 7 and 8 should never be left open or

attached via high-impedance connections).

Input Fusing

Certain applications and/or safety agencies may require the installation of fuses

at the inputs of power conversion components. Fuses should also be used if the

possibility of sustained, non-current-limited, input-voltage polarity reversals

exists. For D ATEL UNR SM Series 3.6-10 Watt DC/DC Converters, you should

use slow-blow type fuses with values no greater than the following.

Model Number Fuse Va lue

UNR-1.8/2-D5SM 1.5 Amps

UNR-2.5/2-D5SM 2 Amps

UNR-3.3/3-D5SM 3 Amps

UNR-3.3/3-D12SM 1.5 Amps

Start-Up Threshold and Underv oltage Shutdown (UNR-3.3/3-D12SM only)

Under normal start-up conditions, UNR-3.3/3-D12SM devices will not begin to

regulate until the ramping input voltage exceeds the Start-Up Threshold V oltage

(typically 10.2V). Once operating, devices will not turn off until the input voltage

drops below the Undervoltage Shutdown/Lockout limit (typically 9.6V).

Subsequent re-start will not occur until the input is brought back up to the StartUp Threshold. This built-in hysteresis obviously avoids any indeterminate on/off

conditions at a single voltage.

Start-Up Time

For the three "D5" models (that do not have an input turn-on threshold), the V

IN

to VOUT Start-Up Time is the interval between the time a step input is applied to

the device and the fully loaded output voltage enters and remains within its

specified accuracy band.

For the UNR-3.3/3-D12SM, V

IN to VOUT Start-Up Time is the interval between

the time at which a rapidly ramping input voltage crosses the turn-on threshold

point and the fully loaded output voltage enters and remains within its specified

accuracy band. Actual measured times will vary with input source impedance,

external input capacitance, and the slew rate and final value of the input voltage

as it appears to the converter.

The On/Off to V

OUT Start-Up Time assumes the converter is turned off via the

On/Off Control with the nominal input voltage already applied to the converter.

The specification defines the interval between the time at which the converter is

turned on and the fully loaded output voltage enters and remains within its

specified accuracy band.

I/O Filtering and Noise Reduction

All "D5" models of UNR SM Series 3.6-10W DC/DC converters achieve their

rated ripple and noise specifications without the use of external input/output

capacitors. The UNR-3.3/3-D12SM is tested and specified with a single,

external 22µF input capacitor (minimally rated for 1.5Arms ripple current and

120m

Ω

ESR).

In critical applications, input/output ripple/noise may be further reduced by

installing additional external I/O caps. Input capacitors, which function primarily

as energy-storage elements, should be selected for bulk capacitance, low ESR

and high rms-ripple-current ratings. Output capacitors, which function more as

true filter elements, should be selected for bulk capacitance, low ESR, and

appropriate frequency response. All caps should have appropriate voltage

ratings and be mounted as close to the converters as possible. T emperature

variations for all parameters should obviously be taken into consideration.

The most effective combination of external I/O capacitors will be a function of

your line voltage and source impedance, as well as your particular load and

layout conditions. Our Applications Engineers will be happy to recommend

potential solutions and can discuss the possibility of our modifying a given

device’s internal filtering to meet your specific requirements. Contact our

Applications Engineering Group for additional details.

4

SM ModelsSM Models

SM ModelsSM Models

SM Models

NON-ISOLATED, 3.6-10W, SURFACE-MOUNT DC/DC CONVERTERS

260

240

220

200

180

160

140

120

100

80

60

40

20

0

0 30 60 90 120 150 180 210 240 270 300

PRE-HEAT AND TEMPERATURE SOAK

SOLDER

REFLOW

PEAK

TEMP.

235°C

Time (Seconds)

Temperature (°C)

On/Off Control

The On/Off Control pin (pin 3) may be used for remote on/off operation. UNR

SM Series converters are designed so that they are enabled when the control

pin is pulled high or left open (normal mode) and disabled when the control pin is

pulled low (to less than +0.8V relative to Logic Ground, pin 2). As shown in the

figure and table below , each device has an internal pull-up resistor on its On/Off

Control pin whose value and voltage vary with model.

Dynamic control of the on/off function is best accomplished with a mechanical

relay or an open-collector/open-drain drive circuit (optically isolated if appropriate). The drive circuit should obviously be able to sink appropriate current when

activated and withstand appropriate voltage when deactivated.

Applying an external voltage to pin 3 when no input power is applied to the

converter can cause permanent damage to the converter. The on/off control

function, however, is designed such that the converter can be disabled (pin 3

pulled low) while input power is ramping up and then "released" once the

input has stabilized. The time duration between the point at which the converter

is released and its fully loaded output voltage settles to within specified

accuracy can be found in the P erformance/Functional Specifications T able .

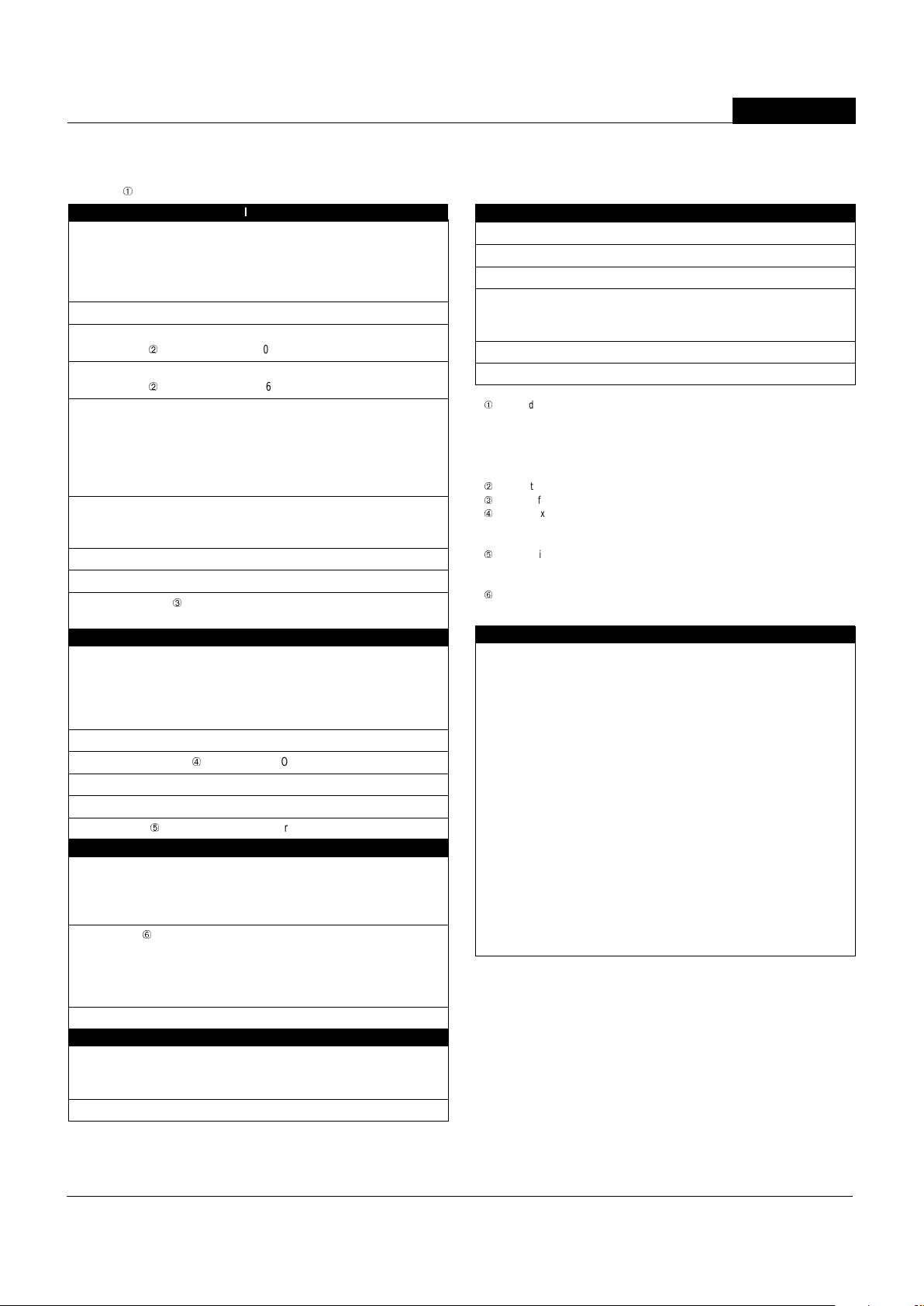

Solder Reflow

For UNR SM Series devices, the packages' gull-wing leads are made of

tin-plated (150 microinches) copper. The gull-wing configuration, as opposed to

"J" leads, was selected to keep the solder joints out from under the package

to minimize both heat conduction away from the leads (into the encapsulated

package) and IR shadowing effects. Through a series of experiments, using

8mil-thick, 63/37/2 (lead/tin/silver) solder paste and single-layer test boards, we

have determined an optimal solder-reflow temperature profile as shown in Figure

2. Obviously , your optimal prof ile will be a function of many factors including

paste thickness, board thickness, number of conductive layers, copper weight,

the density of surrounding components, etc.

The profile in Figure 3 should be used as a starting point for your own

experiments. If you'd like , DATEL can provide you with complimentary "dummy"

units to be used in such tests. Under no circumstances should the peak

temperature exceed +235°C for an extended period of time.

As shown in Figure 4, our tests have determined the optimal landing-pad size

to be 160 mils by 130 mils.

Figure 2. Driving the On/Off Control Pin

Figure 3. Optimal Solder Reflow Profile

+INPUT

LOGIC GROUND

9

2

VIP

RIPREP

3

ON/OFF

CONTROL

Internal External Internal

Pull-Up Pull-Up Pull-Up

Model Resistor (RIP) Resistor (REP) Voltage (VIP )

UNR-1.8/2-D5SM 1k

Ω

15k

Ω

1.8V

UNR-2.5/2-D5SM 1k

Ω

N.A. 2.5V

UNR-3.3/3-D5SM 1k

Ω

N.A. 3.3V

UNR-3.3/3-D12SM 10k

Ω

N.A. VIN

Figure 4. PC Board Land Pattern

0.130*

(3.30)

0.015

(0.38)

0.100**

(2.54)

* PAD DIMENSION

** LEAD DIMENSION

0.160*

(4.06)

0.110**

(2.79)

5

UNR Series

NON-ISOLATED, 3.6-10W, SURFACE-MOUNT DC/DC CONVERTERS

TYPICAL PERFORMANCE CURVES

Efficiency vs. Output Current and Input V oltage

82

81

80

79

78

77

76

75

74

73

UNR-1.8/2-D5SM

(Guaranteed efficiency = 77% at V

IN

= 5V and I

OUT

= 2A)

0.5 0.8 1.1 1.4 1.7 2

+1.8V Output Current (Amps)

V

IN

= 5V

V

IN

= 5.5V

V

IN

= 4.5V

Efficiency (%)

87

86

85

84

83

82

81

80

79

78

UNR-2.5/2-D5SM

(Guaranteed efficiency = 83% at V

IN

= 5V and I

OUT

= 2A)

0.5 0.8 1.1 1.4 1.7 2

+2.5V Output Current (Amps)

V

IN

= 4.75V

V

IN

= 5.5V

V

IN

= 5V

Efficiency (%)

91

90

89

88

87

86

85

84

83

82

UNR-3.3/3-D5SM

(Guaranteed efficiency = 86% at V

IN

= 5V and I

OUT

= 3A)

0.5 1 1.5 2 2.5 3

+3.3V Output Current (Amps)

V

IN

= 4.75V

V

IN

= 5.5V

V

IN

= 5V

Efficiency (%)

92

89

86

83

80

77

74

71

68

65

UNR-3.3/3-D12SM

(Guaranteed efficiency = 87% at V

IN

= 12V and I

OUT

= 3A)

0.5 1 1.5 2 2.5 3

+3.3V Output Current (Amps)

V

IN

= 10.4V

V

IN

= 13.6V

V

IN

= 12V

Efficiency (%)

6

SM ModelsSM Models

SM ModelsSM Models

SM Models

NON-ISOLATED, 3.6-10W, SURFACE-MOUNT DC/DC CONVERTERS

DATEL’s world-class design, development and manuf acturing team stands

ready to work with you to deliver the exact power converter you need for your

demanding, large volume, OEM applications. And ... we’ll do it on time and

within budget!

Our experienced applications and design staffs; quick-turn prototype capability;

highly automated, SMT assembly facilities; and in-line SPC quality-control

techniques combine to give us the unique ability to design and deliver any

quantity of power conv erters to the highest standards of quality and reliability.

We have compiled a large library of DC/DC designs that are currently used in a

variety of telecom, medical, computer, railw ay , aerospace and industrial

applications. We may already have the converter you need.

Contact us. Our goal is to provide you the highest-quality , most cost-eff ective

power converters available.

CUSTOM CAPABILITIES

DATEL makes no representation that the use of its products in the circuits described herein, or the use of other technical information contained herein, will not infringe upon existing or future patent rights. The descriptions

contained herein do not imply the granting of licenses to make, use, or sell equipment constructed in accordance therewith. Specifications are subject to change without notice. The DATEL logo is a registered DATEL,

Inc. trademark.

DATEL (UK) LTD. Tadley, England Tel: (01256)-880444

DATEL S.A.R.L. Montigny Le Bretonneux, France Tel: 01-34-60-01-01

DATEL GmbH München, Germany Tel: 89-544334-0

DATEL KK Tokyo, Japan Tel: 3-3779-1031, Osaka Tel: 6-354-2025

DATEL, Inc. 11 Cabot Boulevard, Mansfield, MA 02048-1151

Tel: (508) 339-3000 (800) 233-2765 Fax: (508) 339-6356

Internet: www.datel.com Email: sales@datel.com

Data Sheet Fax Back:(508) 261-2857

DS-0442 8/99

INNOVATION and EX C ELL E N C

E

®

®

ISO 9001 REGISTERED

7

If you’re designing with EMC in mind, please note that all of DA T EL’s

3.6-10 Watt UNR SM Series DC/DC Converters have been characterized for

radiated and conducted emissions in our new EMI/EMC laboratory . T esting is

conducted in an EMCO 5305 GTEM test cell utilizing EMCO automated EMC

test software. Radiated emissions are tested to the limits of FCC Part 15,

Class B and CISPR 22 (EN 55022), Class B. Correlation to other specifications

can be supplied upon request. Radiated emissions plots to FCC and CISPR 22

for model UNR-3.3/3-D5SM appear below . Published EMC test reports are

available f or each model number . Contact DATEL's Applications Engineering

Department for more details.

EMI Radiated Emissions

80

70

60

50

40

30

20

10

0

–10

–20

100

1000

Frequency (MHz)

100

1000

Frequency (MHz)

Radiated Emissions (dBµV/M)

80

70

60

50

40

30

20

10

0

–10

–20

Radiated Emissions (dBµV/M)

UNR-3.3/3-D5SM Radiated Emissions

FCC Part 15 Class B, 3 Meters

Converter Output = 3.3Vdc @ 2.7 Amps

UNR-3.3/3-D5SM Radiated Emissions

EN 55022 Class B, 10 Meters

Converter Output = 3.3Vdc @ 2.7 Amps

Radiated Emissions

Radiated Emissions

FCC Class B Limit

EN 55022 Class B Limit

Loading...

Loading...