Datasheet VIPER50ASP, VIPER50A, VIPER50, VIPER50SP Datasheet (SGS Thomson Microelectronics)

Page 1

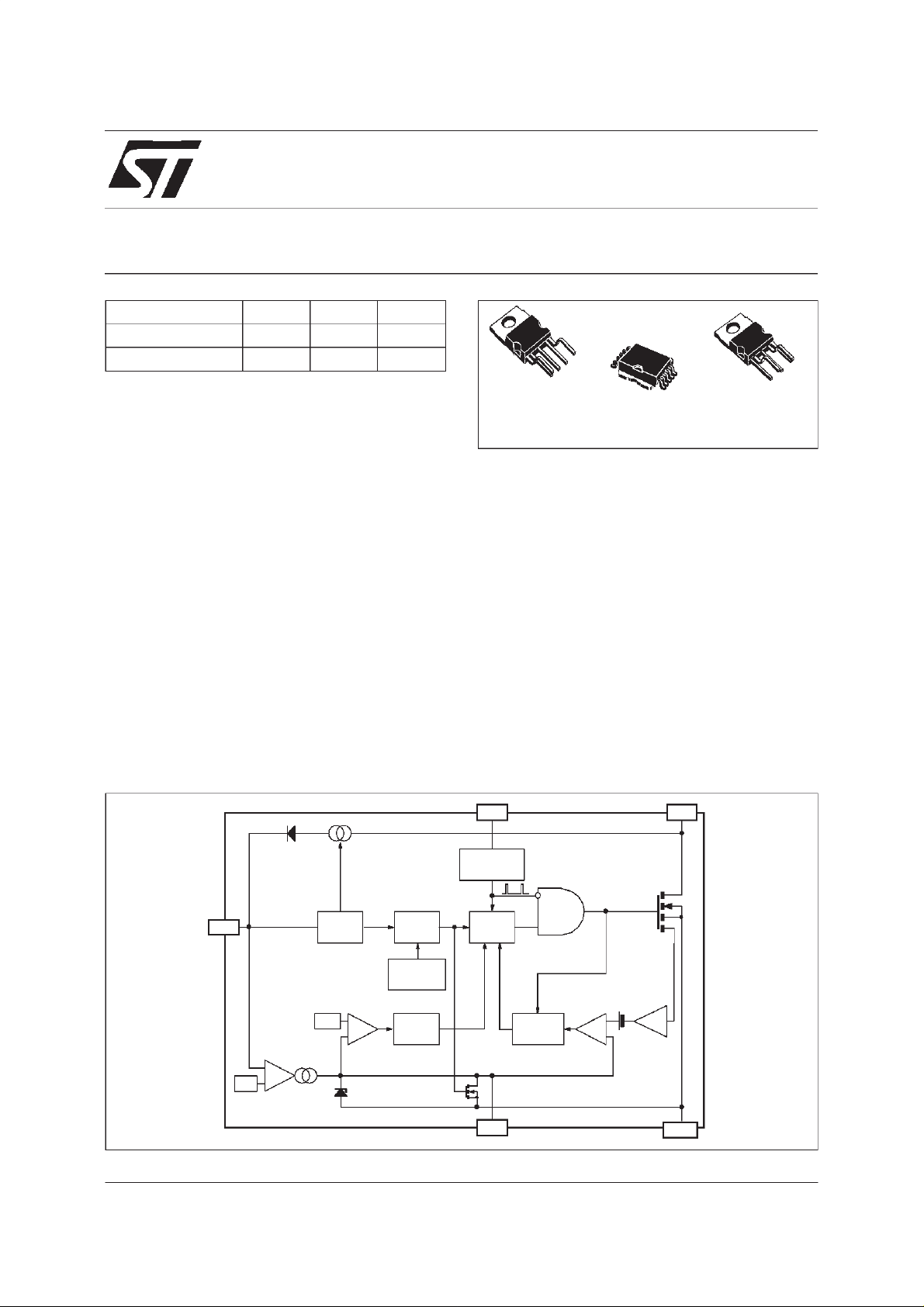

VIPer50/SP

TYPE V

DSS

I

R

n

DS(on)

VI Per 5 0/ SP 620V 1.5 A 5 Ω

VI Per 5 0A /ASP 700V 1.5 A 5.7 Ω

FEATURE

■ ADJUSTABLESWITCHING FREQUENCY UP

TO200KHZ

■ CURRENT MODE CONTROL

■ SOFTSTART ANDSHUT DOWN CONTROL

■ AUTOMATIC BURST MODE OPERATION IN

STAND-BY CONDITION ABLE TO MEET

”BLUE ANGEL” NORM(<1W TOTAL POWER

CONSUMPTION)

■ INTERNALLY TRIMMED ZENER

REFERENCE

■ UNDERVOLTAGE LOCK-OUT WITH

HYSTERESIS

■ INTEGRATED START-UPSUPPLY

■ AVALANCHERUGGED

■ OVERTEMPERATURE PROTECTION

■ LOW STAND-BYCURRENT

■ ADJUSTABLECURRENTLIMITATION

BLOCK DIAGRAM

VIPer50A/ASP

SMPS PRIMARY I.C.

10

PENTAWATTHV PENTAWATT HV

PowerSO-10

DESCRIPTION

VIPer50/50A make using VIPower M0

Technology combines on the same silicon chip a

state-of-the-art PWM circuit together with an

optimized high voltage avalancherugged Vertical

Power MOSFET (620Vor 700V / 1.5A).

Typical applications cover off line power supplies

with a secondary power capabilityof 25W in wide

range condition and 50W in single range or with

doubler configuration. It is compatible from both

primary or secondary regulation loop despite

using around 50% less components when

compared with a discrete solution. Burst mode

operation is an additional feature of this device,

offering the possibility to operate in stand-by

mode withoutextra components.

1

(022Y)

May 1999

_

2 V/A

CURRENT

AMPLIFIER

DRAIN

SOURCE

1

9

2

0

0

C

F

OSC

ON/OFF

SECURITY

LATCH

FF

R/SSQ

OVERTEMP.

DETECTOR

1.7µs

DELAY

ERROR

AMPLIFIER_

LOGIC

0.5 V

UVLO

+

_

4.5 V

VDD

13 V

+

OSCILLATOR

PWM

LATCH

S

R1

FF

R2 R3

COMP

Q

250 ns

BLANKING

0.5V

+

+

_

1/20

Page 2

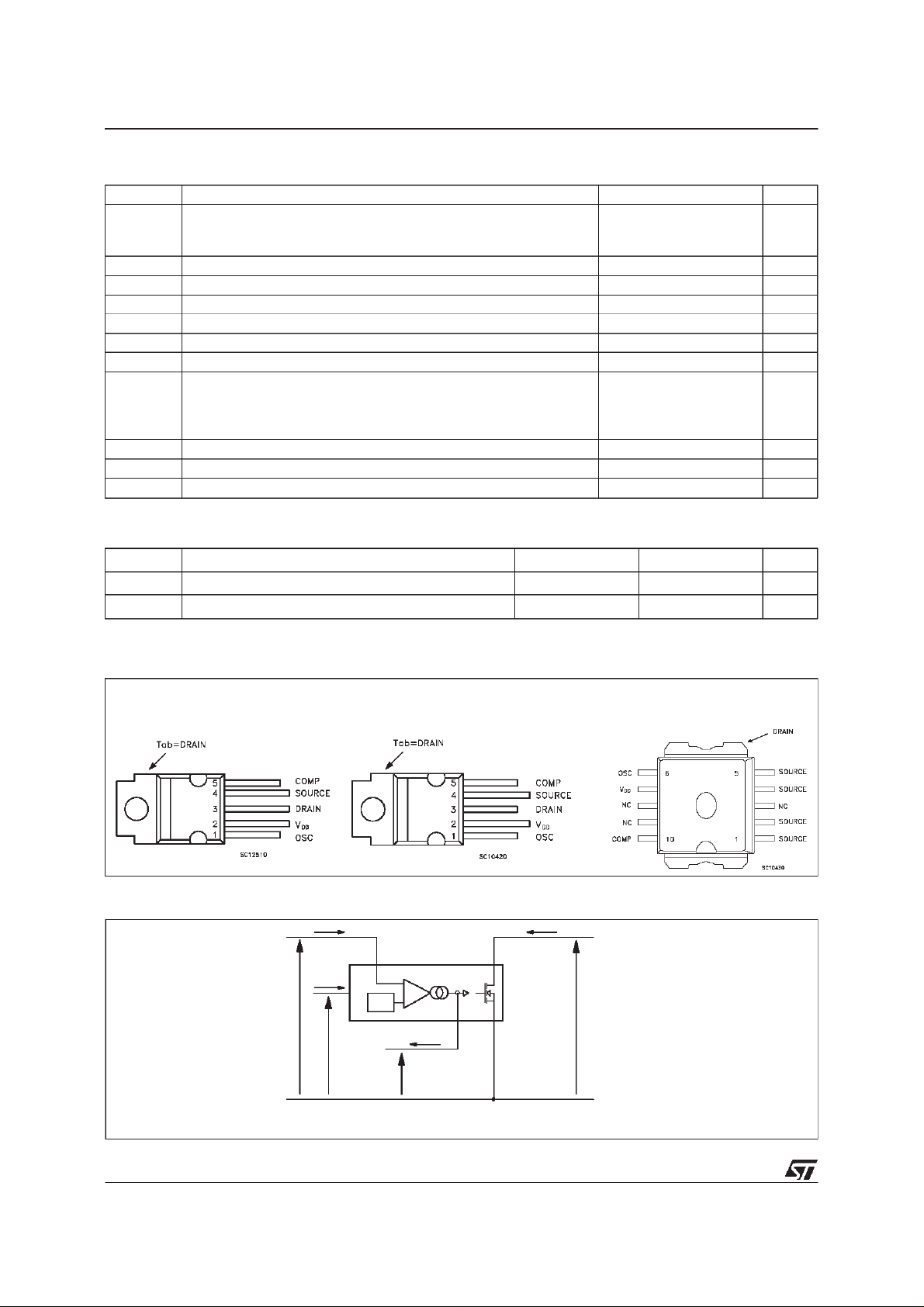

VIPer50/SP - VIPer50A/ASP

ABSOLUTEMAXIMUMRATING

Symb o l Para met er Val u e Uni t

V

I

V

V

OSC

V

COMP

I

COMP

V

I

D(AR)

P

T

T

THERMALDATA

R

thj-case

R

thj-a mb.

(*) When mounted using the minimum recommended pad size on FR-4 board.

Continuous Drain- Sour ce Volta ge (Tj = 25 t o 125oC)

DS

for VIPer50/S P

for VIPer50A/ ASP

Maximum Current Inte rnally Li mited A

D

Supply Volt age 0 to 15 V

DD

Volt age Range Input 0 t o V

-0.3 to 620

-0.3 to 700

DD

Volt age Range Input 0 t o 5 V

Maximum Continuous Cur rent ±2mA

Elect r o st at ic discharge (R = 1.5 KΩ C = 100pF) 4000 V

esd

Avalanche Drain-Source Curre nt , Repetitive or N ot -Repet it ive

(T C = 100

for VIPer50/S P

for VIPer50A/ ASP

Power Dissipation at Tc = 25oC60W

tot

Junction Operatin g Temperature Int ernally Limited

j

St orage T emperature -65 to 150

stg

o

C, Pulse Width Limited by TJmax, δ <1%)

1.5

1

PENTAWATT-HV PowerSO-10(*)

Ther mal Res istan ce Junc ti on-c ase Max 1.9 1.9

Ther mal Res istan ce Ambient-case Max 60 50

o

o

o

C/W

o

C/W

V

V

V

A

A

C

C

CONNECTION DIAGRAMS (Top View)

PENTAWATTHV PENTAWATTHV (022Y) PowerSO-10

CURRENT AND VOLTAGE CONVENTIONS

IDD ID

OSC

I

OSC

DD

V

13V

OSC

V

+

ICOMP

VCOMP

DRAINVDD

COMP SOURCE

VDS

2/20

FC00020

Page 3

ORDERING NUMBERS

PENTAWATT HV PENT AWATT HV (022Y) PowerSO - 10

VIPer50

VIPer50A

VIPer50 ( 022Y)

VI Per50A (022Y)

VIPer50/SP - VIPer50A/ASP

VIP er 50SP

VIPer50ASP

PINSFUNCTIONAL DESCRIPTION

DRAINPIN:

Integrated power MOSFET drain pin. It provides

internal bias current during start-up via an

integrated high voltage current source which is

switched off during normal operation. The device

is able to handle an unclamped current during its

normal operation, assuring self protection against

voltage surges, PCB stray inductance, and

allowing a snubberless operation for low output

power.

SOURCEPIN:

Power MOSFET source pin. Primary side circuit

commonground connection.

VDD PIN :

This pin provides two functions:

- It corresponds to the low voltage supply of the

controlpart of the circuit. If V

the start-up current source is activated and the

output power MOSFET is switched off untilthe

V

voltage reaches 11V. During this phase,

DD

the internal current consumption is reduced,

the V

pin is sourcing a currentof about 2mA

DD

and the COMP pin is shorted to ground. After

that, the current source is shut down, and the

devicetries to start upby switchingagain.

goes below 8V,

DD

- This pin is also connected to the error

amplifier, in order to allow primary as well as

secondary regulation configurations.In case of

primary regulation, an internal 13V trimmed

reference voltage is used to maintain V

13V. For secondary regulation, a voltage

between 8.5V and 12.5V will be puton V

by transformer design, in order to stuck the

output of the transconductanceamplifier to the

high state. The COMP pin behaves as a

DD

DD

at

pin

constant current source, and can easily be

connected to the output of an optocoupler.

Note that any overvoltage due to regulation

loop failure is still detected by the error

amplifier through the V

voltage, which

DD

cannot overpass 13V. The output voltage will

be somewhathigher than the nominalone, but

still undercontrol.

COMP PIN :

This pin providestwo functions :

- It is the output of the error transconductance

amplifier, and allows for the connection of a

compensation network to provide the desired

transfer function of the regulation loop. Its

bandwidth can be easily adjusted to the

needed value with usual componentsvalue. As

stated above, secondary regulation

configurations are also implemented through

the COMPpin.

- When the COMP voltage is going below 0.5V,

the shut-downof thecircuit occurs, with a zero

duty cycle for thepower MOSFET. This feature

can be used to switchoff the converter, and is

automatically activated by the regulation loop

(whatever is the configuration) to provide a

burst mode operation in case of negligible

output power or open load condition.

OSC PIN :

An R

to define the switching frequency. Note that

despite the connection of R

significant frequency change occurs for V

varying from 8V to 15V. It provides also a

synchronisationcapability, when connected to an

external frequency source.

network must be connected on that pin

T-CT

to VDD,no

T

DD

3/20

Page 4

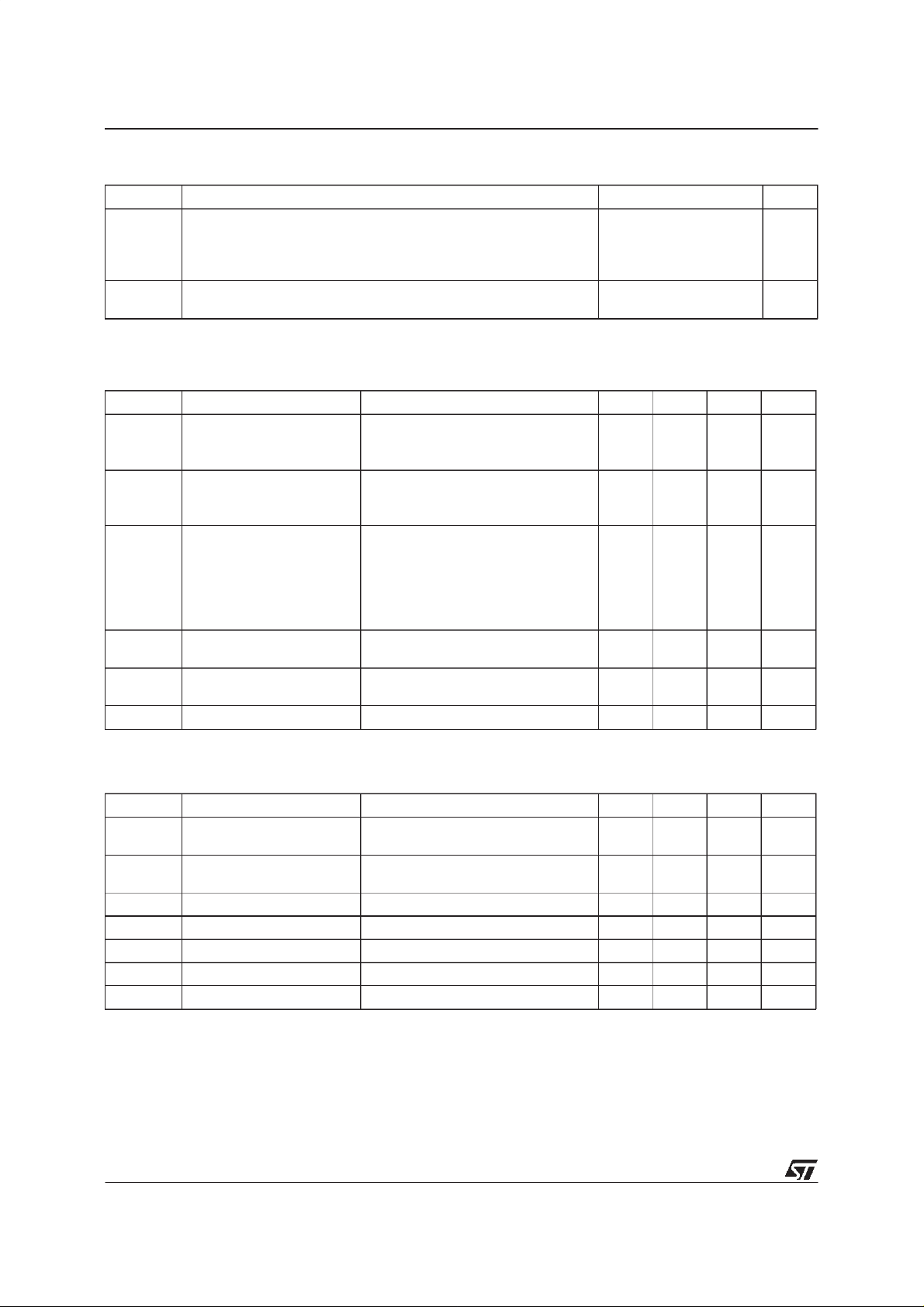

VIPer50/SP - VIPer50A/ASP

AVALANCHE CHARACTERISTICS

Symb o l Para met er Max Valu e Uni t

I

D(ar)

E

ELECTRICAL CHARACTERISTICS (TJ=25oC, VDD=13 V,unless otherwise specified)

POWERSECTION

Symb o l Paramet er Test Con d it i ons Min. Typ . Max. Unit

BV

I

DSS

R

DS(on)

C

OSS

(1) OnInductive Load, Clamped.

Avalanche Current, Repetitive or Not-Repet it ive

(pulse widt h limited by T

for VIPer50/S P

for VIPer50A/ ASP (see f ig. 12)

Single Pulse Avalanche Ener g y

(ar)

(starti ng T

Drain-Source Voltage ID=1mA V

DSS

=25oC, ID=I

j

Of f - State Dra in Curr ent V

St at ic Drain Source on

Resistance

max, δ <1%)

j

) (see fig. 12)

D(ar)

COMP

for VIPer50/SP

for VIPer50A/ASP (see fig. 5)

=0V TJ=125oC

COMP

V

= 620 V for VI P er5 0/ SP

DS

= 700 V for VI P er5 0A/AS P

V

DS

ID=1A

for VIPer50/SP

for VIPer50A/ASP

=1A TJ= 100oC

I

D

1.5

1.0

30 mJ

=0V

620

700

4.0

4.6

for VIPer50/SP

for VIPer50A/ASP

t

Fall Time ID = 0.2 A Vin= 300 V (1)

f

100 ns

(see f ig. 3)

Rise Time ID=1A Vin= 300 V (1)

t

r

50 ns

(see f ig. 3)

Out put Capacitance VDS= 25 V 120 pF

1

1

5.0

5.7

9.0

10.3

A

A

V

V

mA

mA

Ω

Ω

Ω

Ω

SUPPLY SECTION

Symb o l Paramet er Test Con d it i ons Min. Typ . Max. Unit

4/20

I

DDch

I

DD0

I

DD1

I

DD2

V

DDo f f

V

DDo n

V

DDhyst

St art - u p Charging

Current

Oper at i ng Supply Current VDD=12V, FSW=0KHz

VDD=5V VDS=70V

(see fig. 2 and fig . 15)

-2 mA

12 16 mA

(see f ig. 2)

Oper at i ng Supply Current VDD=12V, FSW= 100 KHz 14 mA

Oper at i ng Supply Current VDD=12V, FSW= 200 KHz 16 mA

Undervoltage S hutdown (see fig. 2) 8 V

Undervoltage Reset (see fig. 2) 11 12 V

Hysteresis Start-up (see f ig. 2) 2.4 3 V

Page 5

VIPer50/SP - VIPer50A/ASP

ELECTRICAL CHARACTERISTICS (continued)

OSCILLATORSECTION

Symb o l Paramet er Test Con d it i ons Min. Typ . Max. Unit

F

Os cillator Frequen cy

SW

Total Variation

RT= 8.2 K

= 9 to15 V

V

DD

with R

± 1% CT ± 5%

T

Ω

CT=2.4 nF

(see fig.6 and fig.9)

V

V

OSCih

OSCil

Os cillator Peak Voltage 7.1 V

Os cillator Valley Voltage 3 . 7 V

ERRORAMPLIFIERSECTION

Symbol Parameter Test Condition s Min. Typ. Max. Unit

V

DDreg

∆V

DDreg

G

A

VOL

G

V

COMPLO

V

COMPHI

I

COMPLO

I

COMPHI

VDD Regulat ion Point I

= 0 mA (s e e fig.1) 12.6 13 13.4 V

COMP

Total Variation TJ= 0 to 100oC2%

Unity Gain Bandwidt h F rom Input = VDDto Output = V

BW

COMP

COM P pin i s open (see fig. 10 )

Open Loop Voltage

COM P pin i s open (see fig. 10 ) 45 5 2 dB

Gain

DC Transconductance V

m

Out put Low Level I

Out put High L ev el I

Out put Low Current

= 2.5 V (s ee fig. 1 ) 1.1 1.5 1.9 mA/V

COMP

=-400µAVDD=14V 0.2 V

COMP

= 400 µAVDD=12V 4.5 V

COMP

V

=2.5V VDD= 14 V -600 µA

COMP

Capability

Out put High C ur rent

V

=2.5V VDD= 12 V 600 µA

COMP

Capability

90 100 110 KHz

150 KHz

PWM COMPARATORSECTION

Symbol Parameter Test Condition s Min. Typ. Max. Unit

H

V

COMPoffVCOMP

I

Dpeak

t

∆V

ID

/∆I

COMP

Dpeak

off s et I

V

= 1 to 3 V 1.4 2 2.6 V/A

COMP

=10mA 0.5 V

Dpeak

Peak Current Limitation VDD=12V COMPpinopen 1.5 2 2.7 A

Current Sense Delay

d

ID= 0. 5 A 250 ns

to turn-off

t

t

on(min)

Blanking Time 250 360 ns

b

Minimum on T ime 350 ns

SHUTDOWNAND OVERTEMPERATURESECTION

Symbol Parameter Test Condition s Min. Typ. Max. Unit

V

COMPth

t

DISsu

T

T

hyst

Restart threshold (see fig. 4) 0.5 V

Disable Set Up Time (see fig. 4 ) 1.7 5 µ s

Ther mal Shut down

tsd

(see fig. 8 ) 140 170

Tem perature

Ther mal Shut down

(see fig. 8 ) 40

Hyst eresis

o

o

C

C

5/20

Page 6

VIPer50/SP - VIPer50A/ASP

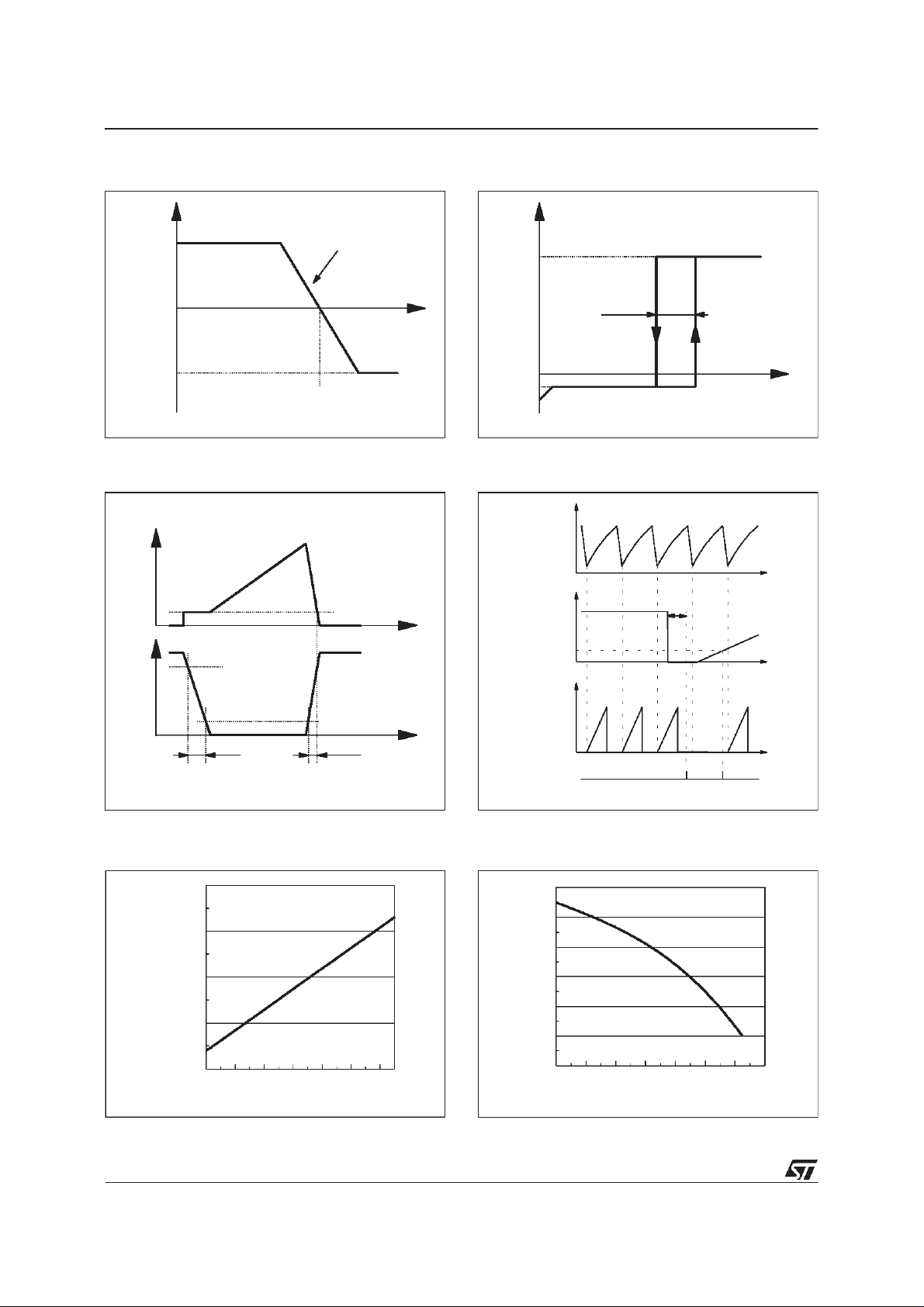

Figure1:VDDRegulationPoint

COMP

I

ICOMPHI

0

ICOMPLO

VDDreg

Figure3: TransitionTime

ID

10%Ipeak

Slope =

Gm in mA/V

FC00150

Figure2: UndervoltageLockout

IDD

IDD0

DD

V

VDDhyst

V

DDoff

IDDch

Figure4: ShutDown Action

VOSC

VCOMP

t

tDISsu

VDS=70V

Fsw = 0

V

DDon

FC00170

VDD

t

VDS

VCOMPth

90%VD

ID

10%V

D

t

tf tr

FC00160

ENABLE

DISABLE

Figure5: Breakdown Voltage vs Temperature Figure6: Typical FrequencyVariation

1.15

BV

DSS

(Normalized)

1.1

1.05

0.95

1

0 20 40 60 80 100 120

Temperature (°C)

FC00180

1

(%)

0

-1

-2

-3

-4

-5

0 20 40 60 80 100 120 140

Temperature (°C)

t

t

ENABLE

FC00060

FC00190

6/20

Page 7

Figure7: Start-upWaveforms

VIPer50/SP - VIPer50A/ASP

Figure8: OvertemperatureProtection

Ttsd

Ttsd-Thyst

Vddon

Vddoff

Tj

t

Vdd

t

Id

t

Vcomp

t

SC10191

7/20

Page 8

VIPer50/SP - VIPer50A/ASP

Figure9: Oscillator

Ct

Rt

OSC

~360Ω

VDD

Dmax

0.9

0.8

0.7

For RT> 1.2 KΩ:

SW

MAX

=

= 1 −

R

2.3

TCT

R

D

MAX

550

− 150

T

MAX

values:

CLK

F

D

RecommendedD

100KHz: > 80%

200KHz: > 70%

FC00050

Maximum duty cycle vs Rt

1

FC00040

Frequency (kHz)

0.6

0.5

1 2 3 5 10 20 30 50

Rt (kΩ)

Oscillatorfrequency vs Rtand Ct

1,000

Ct =1.5 nF

500

Ct = 2.7 nF

300

Ct = 4.7 nF

200

Ct = 10 nF

100

50

30

1 2 3 5 10 20 30 50

Rt (kΩ)

FC00030FC00030

8/20

Page 9

Figure10: ErrorAmplifierFrequency Response

60

RCOMP= +∞

RCOMP= 270k

40

RCOMP= 82k

RCOMP= 27k

VIPer50/SP - VIPer50A/ASP

FC00200

20

VoltageGain (dB)

RCOMP= 12k

0

(20)

0.001 0.01 0.1 1 10 100 1,000

Figure11: ErrorAmplifierPhase Response

200

150

Frequency (kHz)

FC00210

RCOMP= +∞

RCOMP= 270k

RCOMP= 82k

RCOMP= 27k

Phase (°)

100

50

RCOMP= 12k

0

(50)

0.001 0.01 0.1 1 10 100 1,000

Frequency (kHz)

9/20

Page 10

VIPer50/SP - VIPer50A/ASP

Figure12: AvalanceTest Circuit

L1

1mH

BT2

12V

C1

47uF

16V

1

U1

VIPer100

R2

1k

OSC

23

DRAINVDD

-

13V

+

COMP SOURCE

54

R3

100

Q1

2 x STHV102FIin parallel

R1

47

GENERATORINPUT

500us PULSE

FC00195

BT1

0 to 20V

10/20

Page 11

Figure13: OffLine Power SupplyWith Auxliary Supply Feedback

F1

13V

BR1

+

C2

D3

C4

COMP SOURCE

C11

D1

R1

C3

R7

DRAINVDD

VIPer50

C6

R3

AC IN

TR2

C1

R9

R2

OSC

C5

VIPer50/SP - VIPer50A/ASP

TR1

D2

C10

L2

C9C7

FC00301

+Vcc

GND

Figure14: OffLine Power SupplyWith OptocouplerFeedback

F1

13V

BR1

C2

C4

+

C11

D1

R1

D3

R7

DRAINVDD

COMP SOURCE

C6

R3

C3

VIPer50

AC IN

TR2

C1

R9

R2

OSC

C5

TR1

D2

C10

R6

ISO1

U2

C8

L2

C9C7

R4

R5

+Vcc

GND

FC00311

11/20

Page 12

VIPer50/SP - VIPer50A/ASP

OPERATIONDESCRIPTION :

CURRENT MODE TOPOLOGY:

The current mode control method, like the one

integrated in the VIPer50/50A uses two control

loops - an inner current controlloop and an outer

loop for voltage control. When the Power

MOSFET output transistor is on, the inductor

current (primary side of the transformer) is

monitored with a SenseFET technique and

converted into a voltage V

current. When V

reaches V

S

proportional to this

S

(the amplified

COMP

output voltage error) the power switch is switched

off. Thus, the outer voltage control loop defines

the level at which the inner loop regulates peak

current through the powerswitch and the primary

windingof the transformer.

Excellent open loop D.C. and dynamic line

regulation is ensured due to the inherent input

voltage feedforward characteristic of the current

mode control. This results in an improved line

regulation, instantaneous correction to line

changes and better stability for the voltage

regulationloop.

Current mode topology also ensures good

limitation in the caseof short circuit. During a first

phase the output current increases slowly

followingthe dynamic of the regulationloop. Then

it reaches the maximum limitation current

internally set and finally stops because the power

supply on V

is no longer correct. For specific

DD

applications the maximum peak current internally

set can be overridden by externally limiting the

voltage excursion on the COMP pin. An

integrated blanking filter inhibits the PWM

comparator output for a short time after the

integrated Power MOSFET is switched on. This

function prevents anomalous or premature

termination of the switching pulse in the case of

current spikes caused by primary side

capacitance or secondary side rectifier reverse

recovery time.

STAND-BY MODE

Stand-by operation in nearly open load condition

automatically leads to a burst mode operation

allowing voltage regulation on the secondary

side. The transition from normal operation to

burst mode operation happens for a powerP

STBY

given by :

1

2

P

STBY

L

=

PISTBY

2

F

SW

Where:

L

isthe primaryinductance of the transformer.

P

F

is the normal switching frequency.

SW

I

is the minimum controllable current,

STBY

corresponding to the minimum on time that the

deviceis able to provide in normal operation.This

current can be computed as :

I

STBY

b

=

IN

L

P

+ td) V

(t

tb+tdis the sum of the blanking time and of the

propagation time of the internal current sense

and comparator, and represents roughly the

minimum on time of the device. Note that P

STBY

may be affected by the efficiency of the converter

at low load,and must include the power drawn on

the primary auxiliaryvoltage.

As soon as the power goes below this limit, the

auxiliary secondary voltage starts to increase

above the 13V regulation level forcing the output

voltage of the transconductance amplifier to low

state (V

COMP

<V

). This situation leads to

COMPth

the shutdown mode where the power switch is

maintained in the off state, resulting in missing

cycles and zero duty cycle. As soon asV

back to the regulation level and the V

gets

DD

COMPth

threshold is reached, the device operates again.

The above cycle repeats indefinitely, providing a

burst mode of which the effective duty cycle is

much lower than the minimum one when in

normal operation. The equivalent switching

frequency is also lower than the normal one,

leading to a reduced consumption on the input

mains lines. This mode of operation allows the

VIPer50/50A to meet the new German ”Blue

Angel” Norm with less than 1W total power

consumption for the system when working in

stand-by. The output voltage remains regulated

around the normal level, with a low frequency

ripple corresponding to the burst mode. The

amplitude of this ripple is low, because of the

output capacitors and of the low output current

drawn in such conditions.The normal operation

resumes automatically when the power get back

to higher levels than P

STBY

.

HIGH VOLTAGE START-UP CURRENT

SOURCE

An integrated high voltage current source

provides a bias current from the DRAIN pin

during the start-upphase. This current ispartially

absorbed by internal control circuits which are

12/20

Page 13

VIPer50/SP - VIPer50A/ASP

placed into a standby mode with reduced

consumption and also provided to the external

capacitor connected to the V

pin. As soon as

DD

the voltage on this pin reaches the high voltage

threshold V

of the UVLO logic, the device

DDon

turns into active mode and starts switching. The

start up current generatoris switchedoff, and the

converter should normally provide the needed

current on the V

pin through the auxiliary

DD

winding of the transformer, as shown on figure

15.

In case of abnormalcondition where the auxiliary

winding is unable to provide the low voltage

supply current to the V

pin (i.e. short circuit on

DD

the output of the converter), the external

capacitor discharges itself down to the low

threshold voltage V

of the UVLO logic, and

DDoff

the device get back to the inactive state where

the internal circuits are in standbymode and the

start up current source is activated.The converter

enters a endless start up cycle, with a start-up

duty cycle definedby the ratio of charging current

towards discharging when the VIPer50/50A tries

to start. This ratio is fixed by design to 2 to 15,

which gives a 12% start up duty cycle while the

power dissipation at startup is approximately 0.6

W, for a 230 Vrmsinput voltage. Thislow value of

start-up duty cycle prevents the stress of the

output rectifiers and of the transformer when in

short circuit.

The external capacitor C

on the VDDpin must

VDD

be sized according to the time needed by the

converter to start up, when the device starts

switching. This time t

depends on many

SS

parameters, among which transformer design,

output capacitors, soft start feature and

compensation network implemented on the

COMP pin. The followingformula can beused for

definingthe minimumcapacitorneeded:

I

>

DDtSS

V

DDhyst

C

VDD

where:

I

is the consumption current on the VDDpin

DD

when switching. Refer to specified I

DD1

and I

DD2

values.

t

is the start up time of the converter when the

SS

device begins to switch. Worst case is generally

at full load.

V

DDhyst

is the voltage hysteresis of the UVLO

logic. Refer to the minimumspecifiedvalue.

Soft start feature can be implemented on the

COMP pin through a simple capacitor which will

be also used as the compensation network. In

this case, the regulation loop bandwidth is rather

low, because of the large value of this capacitor.

In case a large regulation loop bandwidth is

mandatory, the schematics of figure 16 can be

Figure15: Behaviourof thehigh voltagecurrent source at start-up

VDD

VDDon

VDDoff

t

Auxiliaryprimary

winding

2mA

15 mA

C

VDD

VDD

15 mA1mA

Ref.

UNDERVOLTAGE

LOCK OUT LOGIC

VIPer50

Start up duty cycle ~ 12%

3mA

DRAIN

SOURCE

FC0032 0

13/20

Page 14

VIPer50/SP - VIPer50A/ASP

used. It mixes a high performancecompensation

network together with a separate high value soft

start capacitor. Both soft start time and regulation

loop bandwidthcan be adjustedseparately.

If the device is intentionally shut down by putting

the COMP pin to ground, the device is also

performingstart-up cycles,and theV

oscillatingbetween V

DDon

and V

DDoff

voltage is

DD

. This voltage

can be used for supplying external functions,

provided that their consumption doesn’t exceed

0.5mA. Figure 17 shows a typical application of

this function, with a latchedshut down. Once the

”Shutdown” signal has been activated, the device

remains in the off state until the input voltage is

removed.

TRANSCONDUCTANCE ERROR AMPLIFIER

The VIPer50/50A includes a transconductance

error amplifier. Transconductance Gm is the

change in output current (I

in input voltage(V

I

∂

COMP

=

G

m

∂ V

DD

The output impedance Z

). Thus:

DD

COMP

) versus change

COMP

at the output of this

amplifier (COMP pin) canbe definedas:

Z

COMP

∂V

COMP

=

∂ I

COMP

=

G

∂ V

1

m

COMP

x

∂ V

DD

This last equation shows that the open loop gain

A

canbe relatedto GmandZ

VOL

A

VOL=GmxZCOMP

COMP

:

where Gmvalue for VIPer50/50A is 1.5 mA/V

typically.

G

is well defined by specification, but Z

m

COMP

and therefore A

are subject to large

VOL

tolerances. An impedance Z can be connected

between the COMP pin and ground in order to

define more accurately the transfer function F of

the error amplifier, according to the following

equation,very similar to the one above:

F

=Gm x Z(S)

(S)

The error amplifier frequency response is

reported in figure 10 for different values of a

simple resistance connected on the COMP pin.

The unloaded transconductance error amplifier

shows an internal Z

of about 330 KΩ. More

COMP

complex impedance can be connected on the

COMP pin to achieve different compensation

laws. A capacitor will provide an integrator

function, thus eliminating the DC static error, and

a resistance in series leads to a flat gain at higher

frequency, insuring a correct phase margin. This

configurationis illustratedon figure18.

As shown in figure18 an additional noise filtering

capacitor of 2.2 nF is generally needed to avoid

any highfrequency interference.

It can be also interesting to implement a slope

compensation when working in continuous mode

with duty cycle higher than 50%. Figure 19 shows

such a configuration. Note that R1 and C2 build

the classical compensation network, and Q1 is

injecting the slope compensation with the correct

polarity from the oscillatorsawtooth.

EXTERNALCLOCK SYNCHRONIZATION:

The OSC pin provides a synchronisation

capability, when connected to an external

frequency source. Figure 20 shows one possible

Figure16: MixedSoft Startand Compensation

D2

+

14/20

VIPer50

OSC

C3

-

13V

+

C4

DRAINVDD

COMP SOURCE

R1

C1

D1

C2

+

D3

R3

R2

FC00331

AUXILIARY

WINDING

Figure17: Latched Shut Down

R1

Shutdown

Q2

R4

OSC

R2R3

Q1

VIPer50

-

13V

+

D1

DRAINVDD

COMP SOURCE

FC00340

Page 15

VIPer50/SP - VIPer50A/ASP

schematic to be adapted depending the specific

needs. If the proposed schematic is used, the

pulse durationmust be kept at a lowvalue (500ns

is sufficient) for minimizing consumption. The

optocoupler must be able to provide 20mA

through the optotransistor.

PRIMARY PEAK CURRENT LIMITATION

The primary I

DPEAK

current and, as resulting

effect, the output power can be limited using the

simple circuit shown in figure 21. The circuit

based on Q1, R

and R2clamps the voltage on

1

the COMP pin in order to limit the primary peak

current of thedevice to a value:

I

DPEAK

V

=

COMP

H

− 0.5

ID

Figure18: TypicalCompensation Network

VIPer50

DRAINVDD

COMP SOURCE

R1

C1

OSC

13V

-

+

C2

where:

+ R

R

1

V

COMP

= 0.6x

2

R

2

The suggestedvalue for R1+R2is in the range of

220KΩ.

OVER-TEMPERATUREPROTECTION:

Over-temperature protection is based on chip

temperature sensing. The minimum junction

temperature at which over-temperature cut-out

occurs is 140

o

C while the typical value is 160oC.

The device is automatically restarted when the

junction temperature decreases to the restart

temperaturethreshold that is typically 40

o

C below

the shutdownvalue (seefigure 8).

Figure19: Slope Compensation

R1R2

OSC

Q1

VIPer50

-

13V

+

C2

DRAINVDD

COMP SOURCE

C3

C1 R3

FC00351

FC00361

Figure20:ExternalClock Synchronization Figure21:CurrentLimitation CircuitExample

VIPer50

DRAINVDD

COMP SOURCE

Q1

FC00380

10k

13V

-

+

R1

R2

OSC

VIPer50

-

OSC

13V

+

Ω

DRAINVDD

COMP SOURCE

FC00370

15/20

Page 16

VIPer50/SP - VIPer50A/ASP

Figure22: Recommendedlayout

T1

D1

Tosecondary

D2

C7

filtering and load

From input

diodesbridge

R1

C1

C2

1

OSC

U1

VIPerXX0

2

-

+

13V

ISO1

COMP SOURCE

R2

C3

C4

LAYOUTCONSIDERATIONS

Some simple rules insure a correct running of

switching power supplies. They may be classified

into twocategories:

- To minimise power loops: the waythe switched

power current must be carefully analysed and

the corresponding paths must present the

smallest inner loop area as possible. This

avoids radiated EMC noises, conducted EMC

noises by magnetic coupling, and provides a

better efficiency by eliminating parasitic

inductances,especially on secondaryside.

- Touse different tracks for lowlevel signals and

3

DRAINVDD

C5

5

4

C6

FC00500

power ones. The interferencesdue to a mixing

of signal and power may result in instabilities

and/or anomalous behaviour of the device in

case of violent power surge (Input

overvoltages,output shortcircuits...).

In case of VIPer, these rules apply as shown on

figure 22. The loops C1-T1-U1, C5-D2-T1,

C7-D1-T1 must be minimised. C6 must be as

close as possible from T1. The signal

components C2, ISO1, C3 and C4 are using a

dedicated track to be connected directly to the

sourceof the device.

16/20

Page 17

VIPer50/SP - VIPer50A/ASP

PENTAWATT HV (VERTICAL) MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 4.30 4.80 0.169 0.189

C 1.17 1.37 0.046 0.054

D 2.40 2.80 0.094 0.110

E 0.35 0.55 0.014 0.022

F 0.60 0.80 0.024 0.031

G1 4.90 5.28 0.193 0.208

G2 7.42 7.82 0.292 0.308

H1 9.30 9.70 0.366 0.382

H2 10.40 0.409

H3 10.05 10.40 0.396 0.409

L 16.60 17.30 0.653 0.681

L1 14.60 15.22 0.575 0.599

L2 21.20 21.85 0.835 0.860

L3 22.20 22.82 0.874 0.898

L5 2.60 3.00 0.102 0.118

L6 15.10 15.80 0.594 0.622

L7 6.00 6.60 0.236 0.260

M 2.50 3.10 0.098 0.122

M1 7.56 8.16 0.298 0.321

R 0.50 0.020

V4 90

o

90

Diam. 3.70 3.90 0.146 0.154

G2

G1

M1

M

leads

E

Resin

between

V4

F

L

L1

A

L5

H1

C

H3

H2

Diam

P023H3

R

D

L6

L7

L2

L3

17/20

Page 18

VIPer50/SP - VIPer50A/ASP

PENTAWATT HV 022Y(VERTICAL HIGH PITCH) MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 4.30 4.80 0.169 0.189

C 1.17 1.37 0.046 0.054

D 2.40 2.80 0.094 0.110

E 0.35 0.55 0.014 0.022

F 0.60 0.80 0.024 0.031

G1 4.90 5.28 0.193 0.208

G2 7.42 7.82 0.292 0.308

H1 9.30 9.70 0.366 0.382

H2 10.40 0.409

H3 10.05 10.40 0.396 0.409

L 16.42 17.42 0.646 0.686

L1 14.60 15.22 0.575 0.599

L3 20.52 21.52 0.808 0.847

L5 2.60 3.00 0.102 0.118

L6 15.10 15.80 0.594 0.622

L7 6.00 6.60 0.236 0.260

M 2.50 3.10 0.098 0.122

M1 5.00 5.70 0.197 0.224

R 0.50 0.020

V4 90

o

90

o

Diam. 3.70 3.90 0.146 0.154

G2

M1

G1

M

leads

E

Resin

between

F

L

L1

A

R

V4

D

L6

L7

L3

L5

H1

C

H3

H2

Diam

P023H2

18/20

Page 19

VIPer50/SP - VIPer50A/ASP

PowerSO-10 MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 3.35 3.65 0.132 0.144

A1 0.00 0.10 0.000 0.004

B 0.40 0.60 0.016 0.024

C 0.35 0.55 0.013 0.022

D 9.40 9.60 0.370 0.378

D1 7.40 7.60 0.291 0.300

e 1.27 0.050

E 9.30 9.50 0.366 0.374

E1 7.20 7.40 0.283 0.291

E2 7.20 7.60 0.283 0.300

E3 6.10 6.35 0.240 0.250

E4 5.90 6.10 0.232 0.240

F 1.25 1.35 0.049 0.053

h 0.50 0.002

H 13.80 14.40 0.543 0.567

L 1.20 1.80 0.047 0.071

q 1.70 0.067

α 0

o

o

8

==

==

HE

h

A

F

A1

610

51

eB

M

0.25

D

==

D1

==

E2

==

DETAIL”A”

DETAIL”A”

Q

B

0.10 A

E1E3

==

SEATING

PLANE

A

C

α

B

E4

==

SEATING

PLANE

A1

L

==

0068039-C

19/20

Page 20

VIPer50/SP - VIPer50A/ASP

Information furnished is believed tobeaccurate and reliable. However, STMicroelectronics assumesnoresponsibility fortheconsequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in thispublication are

subject tochange without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a trademark of STMicroelectronics

1999 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroelectronicsGROUP OF COMPANIES

Australia - Brazil -Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta -Mexico - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - UnitedKingdom - U.S.A.

http://www.st.com

.

20/20

Loading...

Loading...