Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD98402A

LOCAL ATM SONET FRAMER

The µPD98402A is one of the ATM-LAN LSIs and incorporates the TC sublayer function in the SONET/SDH-

µ

based physical layer of the ATM protocol. The main functions of the

mapping ATM cells received from the ATM layer onto the payload block of the SONET STS-3c/SDH STM-1 frame

and sending them to PMD (Physical Media Dependent) in the physical layer, and a receive function for separating

the overhead block and ATM cells from the data string received from the PMD sublayer and sending the ATM cells

to the ATM layer.

µ

Futhermore, the

PD98402A is compliant with the ATM Forum UNI Recommendations.

PD98402A include a transmit function for

FEATURES

• Provision of TC sublayer function of ATM protocol physical layer

• Support of SONET STS-3c frame/SDH STM-1 frame format

• Provision of stop mode for cell scramble/descramble and frame scramble/descramble

• Disposal/transitory selection of unassigned cells is possible.

• Compliant with UTOPIA interface

• Incorporation of internal loopback function at PMD and ATM layer turns

• PMD interface

155.52 Mbps serial interface

19.44 MHz parallel interface

• Provided with registers for writing/reading overhead information

SOH (section overhead): C1 (1st to 3rd) bytes, F1 byte

LOH (line overhead): K2 byte

POH (pass overhead): F2 byte, C2 byte

• CMOS process

• +5 V single power supply

Document No. S10835EJ1V0DS00 (1st edition)

Date Published December 1995 P

Printed in Japan

The information in this document is subject to change without notice.

©

1995

Page 2

• Incorporation of OAM (Operation And Maintenance) function

µ

PD98402A

Transmitting side

Transmission of various alarms

• Transmission by generation of sources

Line RDI (FERF), Path RDI (FERF)

Line FEBE, Path FEBE

• Transmission by command instruction

Line AIS, Path AIS

Line FEBE, Path FEBE

Receiving side

• Detection of alarms and error signals

LOS (Loss Of Signal)

OOF (Out Of Frame)

LOF (Loss Of Frame)

LOP (Loss Of Pointer)

LOC (Loss Of Cell delineation)

Line RDI (FERF), Path RDI (FERF)

Line AIS, Path AIS

• Detection and display of quality deterioration sources

B1 error, B2 error, B3 error, Line FEBE,

Path FEBE

• Incorporation of counter for counting number of performance

monitoring errors

B1 byte error counter

B2 byte error counter

B3 byte error counter

Line FEBE error counter

Path FEBE error counter

2

Page 3

µ

PD98402A

ORDERING INFORMATION

Part Number Package

µ

PD98402AGM-KED160-pin plastic QFP (FINE PITCH) (24 × 24 mm)

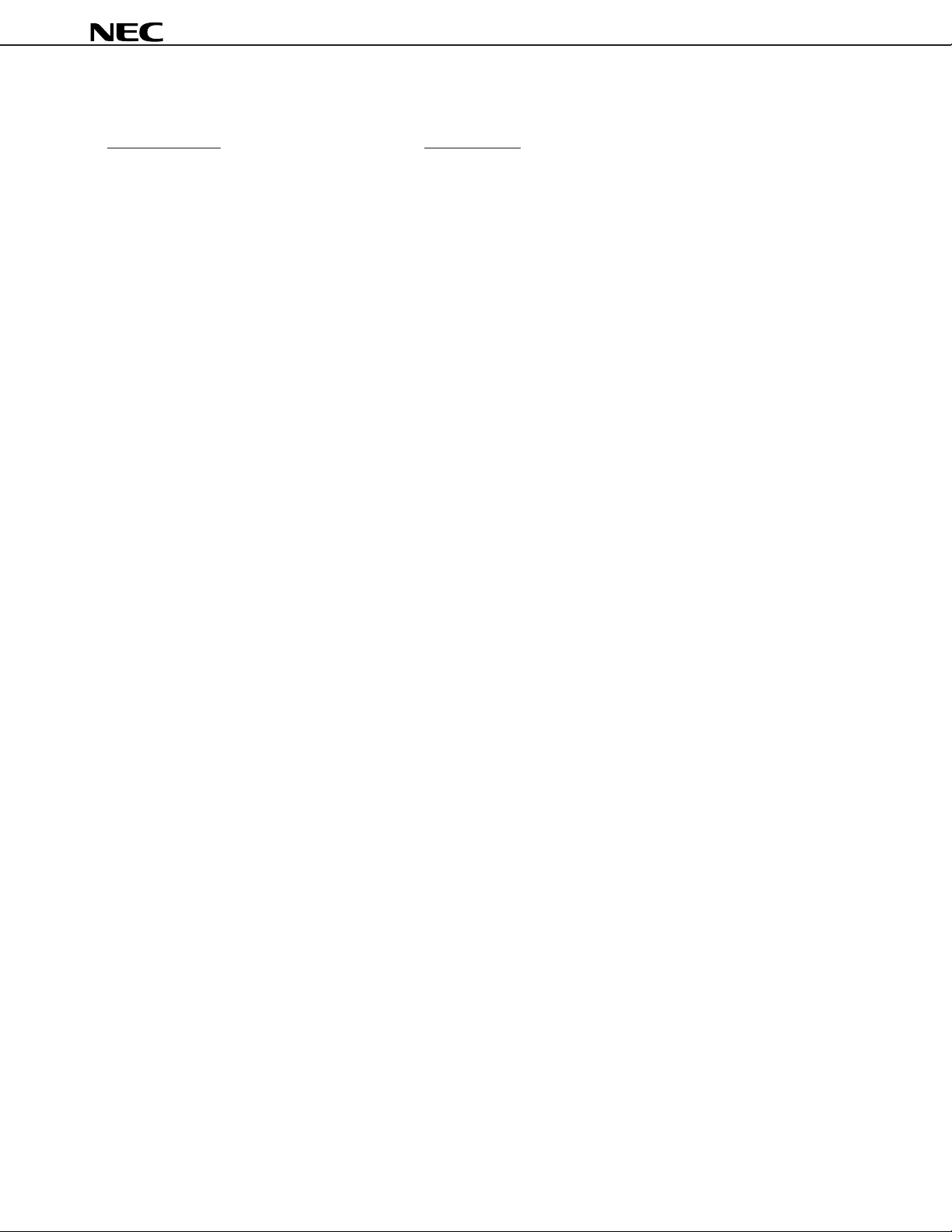

APPLICATION EXAMPLES

The followings are examples of the terminal equipment and the ATM Hub application using the µPD98402A.

NIC APPLICATION

DATA I/F (UTOPIA)

CONTROL

MEMORY

PD98401A

m

SAR CHIP

CNT I/F

PD98402A

m

PHY CHIP

155.52MHz

CLOCK

RECOVERY

CHIP

Rx PMD

TO HUB

Tx PMD

HOST BUS I/F

SWITCH

SYSTEM

SYNTHESIZER

HOST BUS

HUB APPLICATION (NIC SIDE)

DATA I/F

(UTOPIA)

CNT I/F

PD98402A

m

PHY CHIP

SYNTHESIZER

155.52MHz

CLOCK

RECOVERY

CHIP

Rx PMD

TO NIC

Tx PMD

CONTROLLER BUSCONTROLLER

3

Page 4

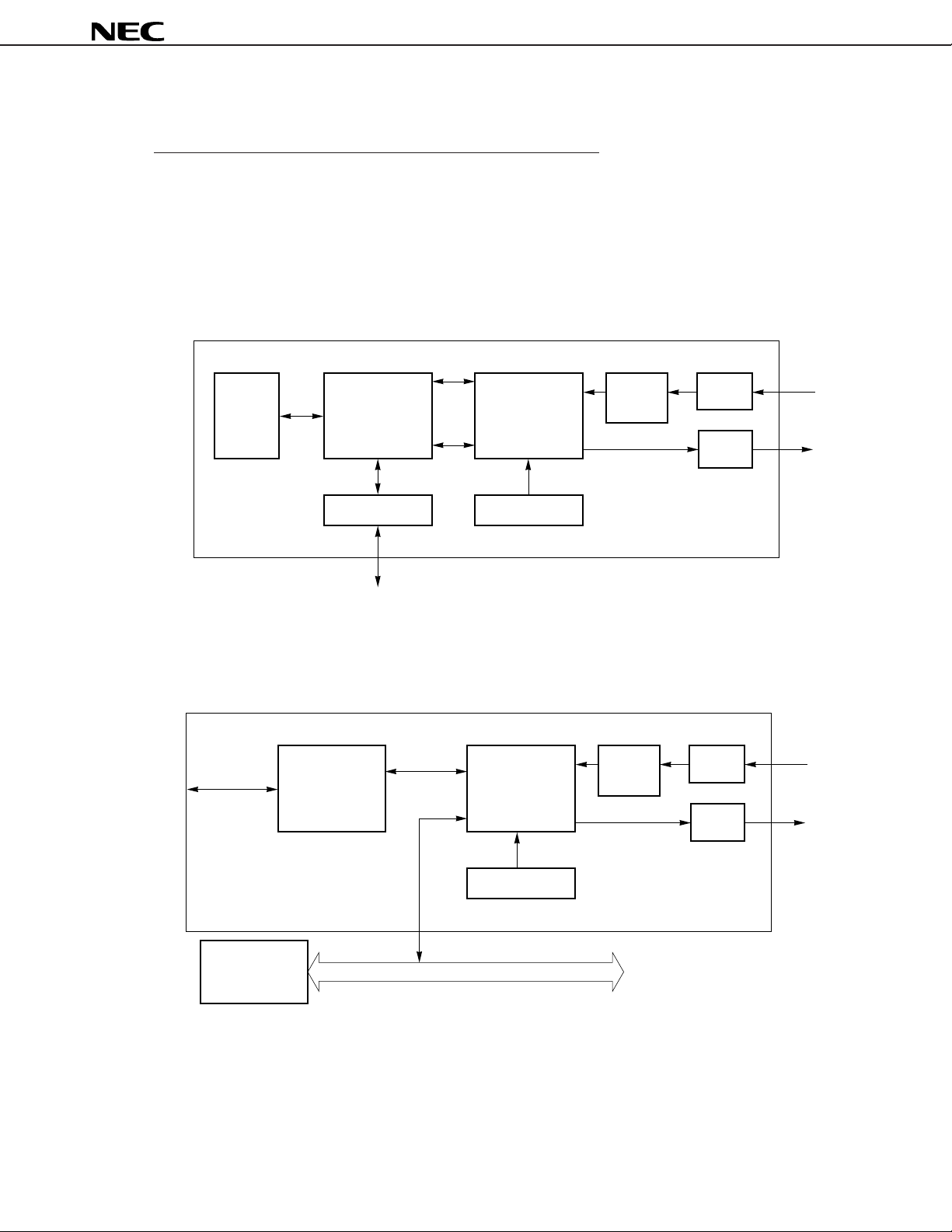

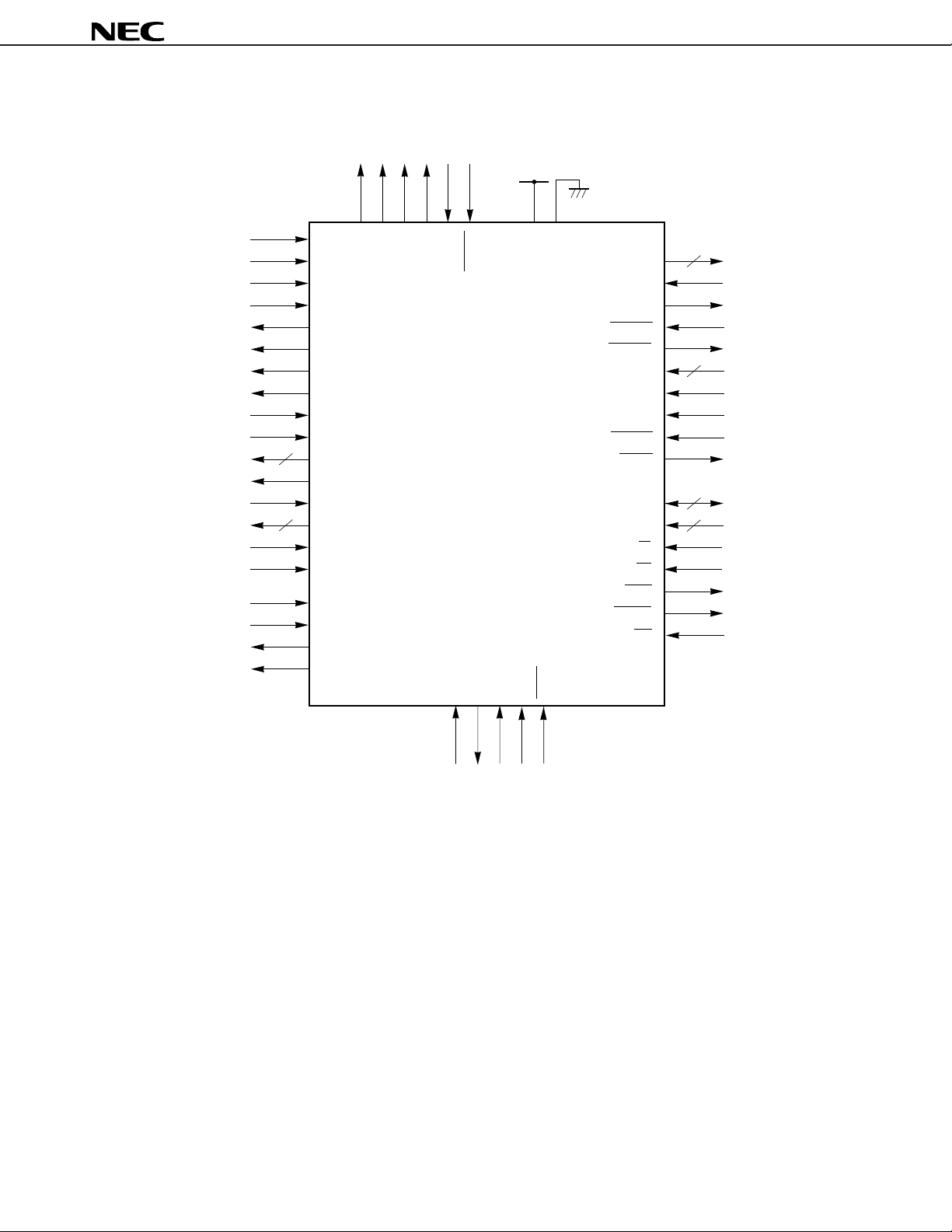

BLOCK DIAGRAM

RDO0—RDO7

RENBL

EMPTY

RSOC

RCLK

TDI0—TDI7

TENBL

FULL

TSOC

TCLK

D0—D7

A0—A5

R/W

ACK

CEOEPHINT

µ

PD98402A

ATM Layer Interface

Rx FIFO

4 Cell

Idle Cell

Drop

Loop Back

Cell

Descrambler

Cell Delineation

HEC Verification

HEC Correction

Generator

Rx Timing

Tx FIFO

4 Cell

HEC

Generator

Cell

Scrambler

+

Idle Cell

Insert

Management Interface

F2

C2

F1

Tx Overhead Registers

K2

C1(#1~#3)

Rx Overhead

Controller

F2

C2

F1

Rx Overhead Registers

K2

C1(#1~#3)

INT Cause

Registers

OAM Sequencer

Performance

Registers

RAL

TAL

LOS

Mode

Register

TFSS

TCL

TxFP

RxFP

OOF

RCL

Descrambler

A1, A2

SONET

Framing

Parallel

Serialfi

Scrambler

+

Parallel

fiSerial

Tx Overhead

Controller

Tx Timing Generator

Loop Back

BIP

Generator

PSEL

PMD Interface

RDIC, RDIT

TFKC, TFKT

TCOC, TCOT

TDOC, TDOT

TPC

TPD0-TPD7

RCIC, RCIT

TFC

RPC

RPD0-RPD7

(Tx)

BIP

Generator

(Rx)

TDO

Test

TJI

Block

TCK

TMS

TRST

DD

V

RESET

GND

4

Page 5

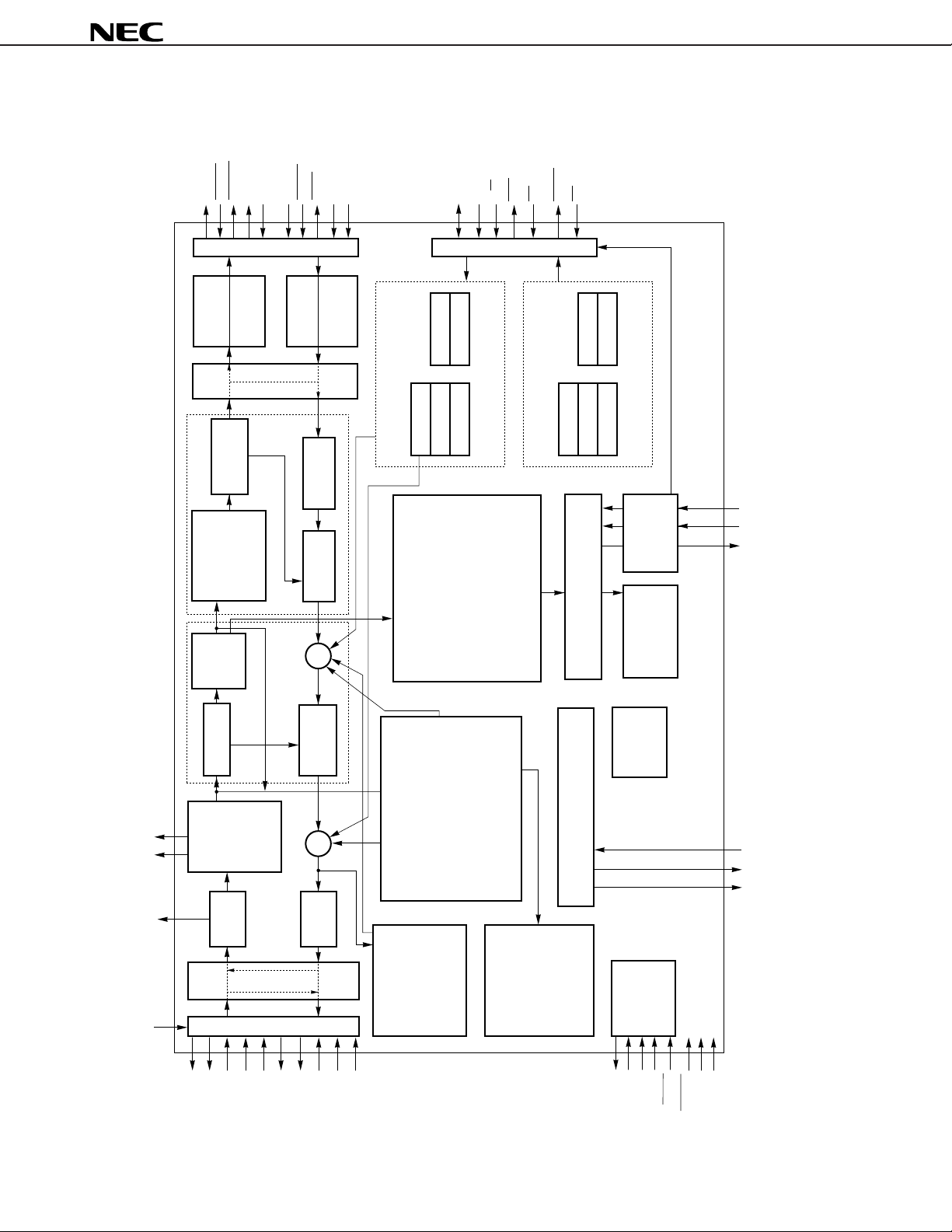

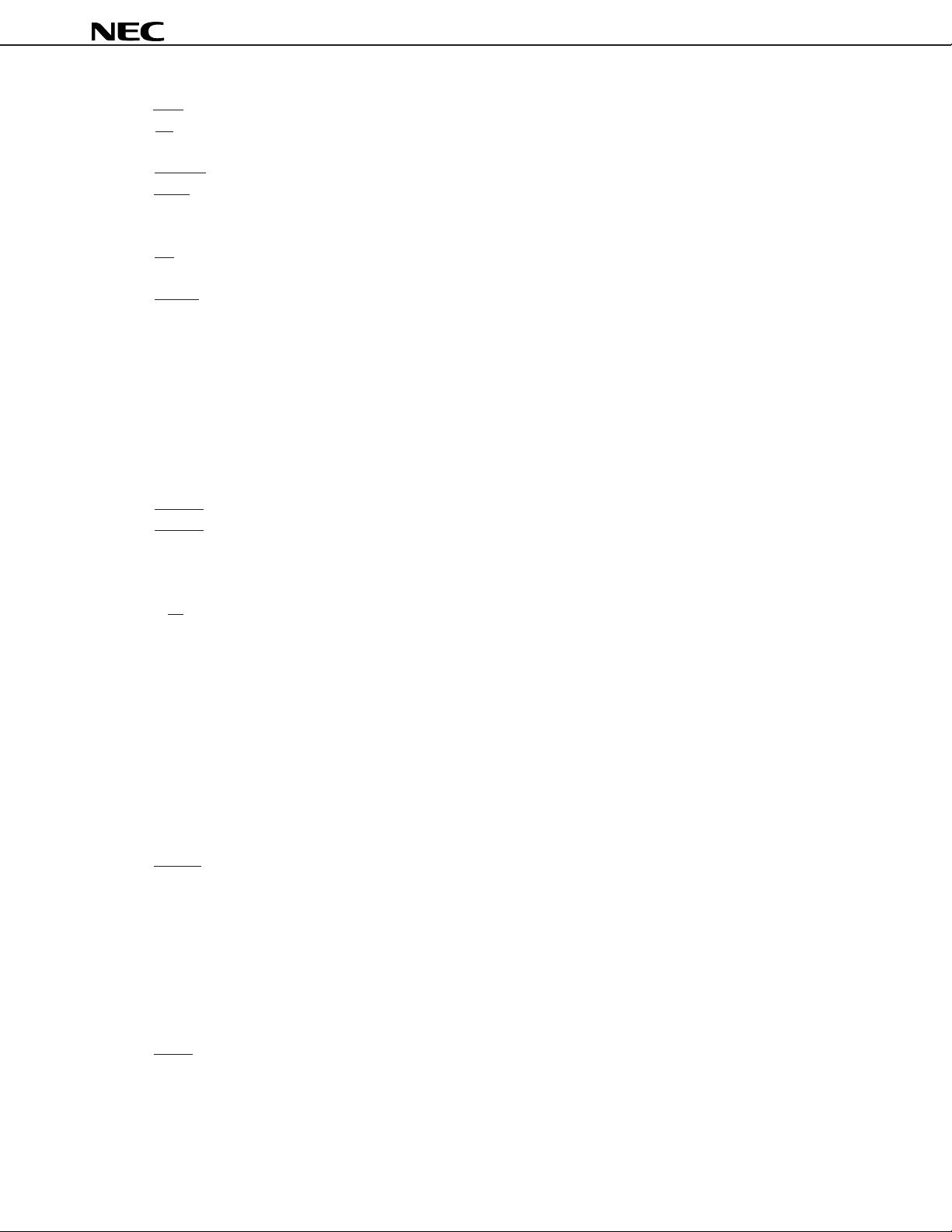

FUNCTIONAL PIN GROUPS

Control

µ

PD98402A

PMD

Interface

OAM

Interface

8

8

RDIC

RDIT

RCIC

RCIT

TDOC

TDOT

TCOC

TCOT

TFKC

TFKT

TPD0-TPD7

TPC

TFC

RPD0-RPD7

RPC

PSEL

RAL

TAL

LOS

OOF

RCL

TCL

TxFP

RxFP

TFSS

TJI

RESET

TDO

TCK

TMS

DD

V

TRST

GND

RDO0-RDO7

TDI0-TDI7

RCLK

RSOC

RENBL

EMPTY

TCLK

TSOC

TENBL

FULL

D0-D7

A0-A5

R/W

CE

ACK

PHINT

OE

8

ATM Layer

8

8

6

Interface

Management

Interface

Note

JTAG boundary scan

pin

Note This function can be supported at the customer’s request.

5

Page 6

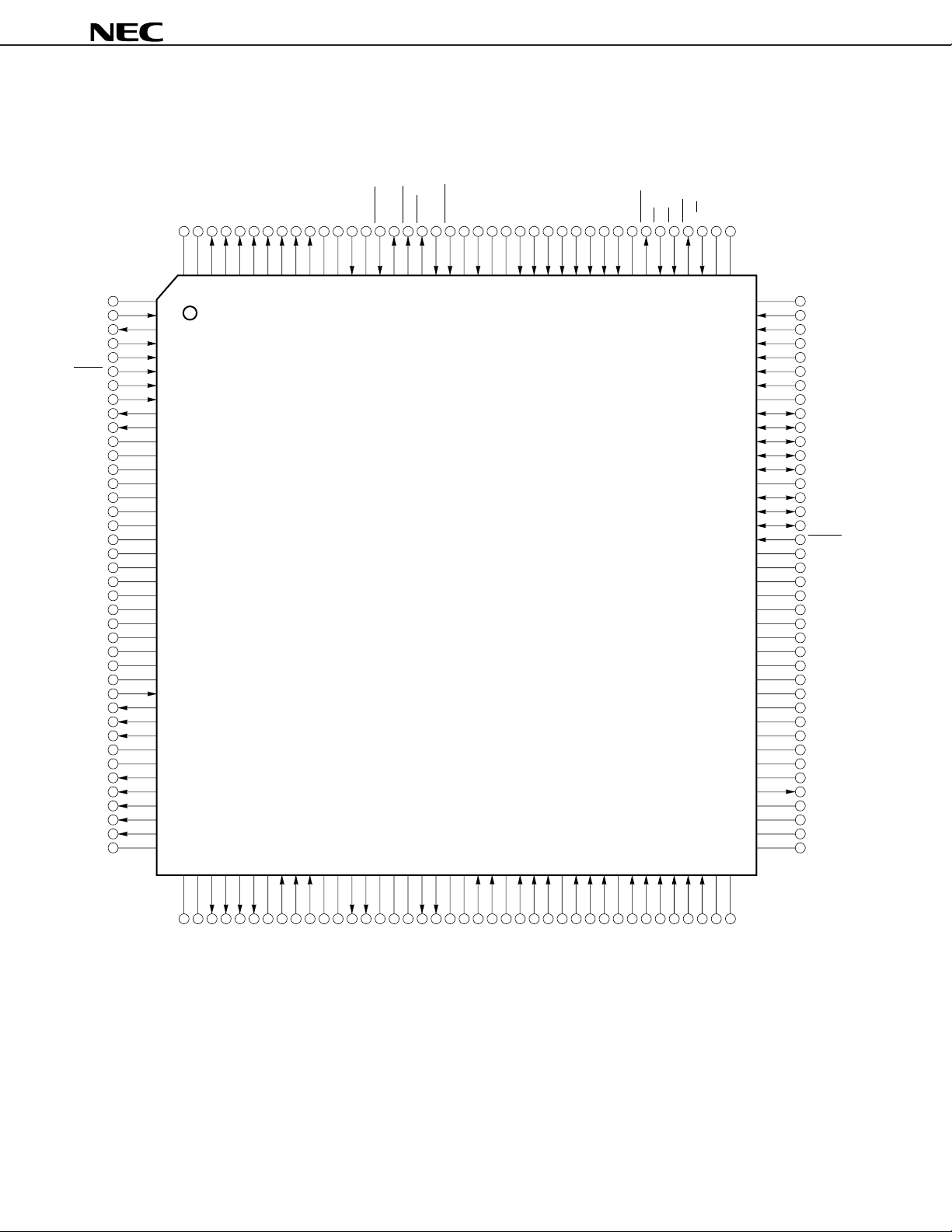

PIN CONFIGURATION

160-pin plastic QFP (FINE PITCH) (24 × 24 mm) (Top View)

µ

PD98402A

V

TCK

TDO

TJI

TMS

TRST

RAL

TAL

LOS

OOF

IC

IC

IC

IC

IC

IC

IC

IC

IC

V

GND

IC

IC

IC

IC

IC

IC

IC

TFSS

RxFP

TxFP

TCL

V

GND

TPD0

TPD1

TPD2

TPD3

TPD4

V

GND

GND

RDO7

RDO6

RDO5

RDO4

RDO3

RDO2

RDO1

DD

RDO0

V

GND

RCLK

GND

RENBL

RSOC

EMPTY

FULL

TSOC

TEMBL

GND

TCLK

GND

VDDTDI7

TDI6

TDI5

TDI4

TDI3

TDI2

TDI1

TDI0

GND

PHINTCEOE

ACK

R/W

GND

GND

121122123124125126127128129130131132133134135136137138139140141142143144145146147148149150151152153154155156157158159160

V

DD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

µ

PD98402AGM-KED

17

18

19

DD

20

21

22

23

24

25

26

27

28

29

30

31

32

DD

33

34

35

36

37

38

39

DD

40

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

DD

A5

A4

A3

A2

A1

A0

GND

D7

D6

D5

D4

D3

GND

D2

D1

D0

RESET

CG

GND

DD

V

IC

IC

IC

IC

IC

GND

IC

IC

IC

IC

IC

IC

IC

IC

RCL

IC

IC

IC

DD

V

807978777675747372717069686766656462616059585756555453525150494847464544434241 63

GND

GND

TPD5

TPD6

TPC

TPD7

GND

TFC

TFKT

TFKC

GND

V

TCOT

TCOC

GND

V

DD

DD

DD

V

Remarks 1. IC : Internally Connected. Leave open.

2. CG : Connect to GND.

6

TDOT

TDOC

DD

V

GND

RCIT

RCIC

GND

RDIT

RPC

RDIC

GND

RPD7

RPD6

GND

RPD5

RPD4

RPD3

RPD2

RPD1

PSEL

RPD0

GND

GND

Page 7

A0-A5 : Address Bus

ACK : Read/write Cycle Receive Acknowledge

CE : Chip Enable

D0–D7 : Data Bus

EMPTY : Output Buffer Empty

FULL : Buffer Full

GND : Ground

LOS : Loss of Signal

OE : Output Enable

OOF : Out of Frame

PHINT : Physical Interrupt

PSEL : PMD I/F Select

RAL : Receive Alarm

RCIC : Receive Clock Input Complement

RCIT : Receive Clock Input True

RCL : Internal Receive System Clock

RCLK : Receive Data Transferring Clock from the ATM Layer Device

RDIC : Receive Data Input Complement

RDIT : Receive Data Input True

RDO0-RDO7 : Receive Data Output

RENBL : Receive Data Enable

RESET : System Reset

RPC : Receive Parallel Data Clock

RPD0-RPD7 : Receive Parallel Data

RSOC : Receive Start Address of ATM Cell

R/W : Read/write Control

RxFP : Receive Frame Pulse

TAL : Transmit Alarm

TCK : Test Clock

TCL : Internal Transmit System Clock

TCLK : Transmit Data Transferring Clock from the ATM Layer Device

TCOC : Transmit Clock Output Complement

TCOT : Transmit Clock Output True

TDI0-TDI7 : Transmit Data Input from the ATM Layer

TDO : Test Data Output

TDOC : Transmit Data Output Complement

TDOT : Transmit Data Output True

TENBL : Transmit Data Enable

TFC : Transmit Reference Clock

TFKC : Transmit Reference Clock Complement

TFKT : Transmit Reference Clock True

TFSS : Transmit Frame Set Signal

TJI : Test JTAG Data Input

TPC : Transmit Parallel Data Clock

TPD0-TPD7 : Transmit Parallel Data

TMS : Test Mode Select

TRST : Test Reset

TSOC : Transmit Start Address of ATM Cell

TxFP : Transmit Frame Pulse

DD : Supply Voltage

V

µ

PD98402A

7

Page 8

µ

PD98402A

1. PIN FUNCTIONS

• PMD Interface

Symbol Pin No. I/O I/O Level Function

RDIC 66 I Pseudo ECL These pins are used to input receive serial data when serial

Complement (–) interface mode is used (PSEL pin input = low level). Ground

RDIT 65 I Pseudo ECL

True (+)

RCIC 63 I Pseudo ECL These pins are used to input the receive system clock when

Complement (–) serial interface mode is used (PSEL pin input = low level).

RCIT 62 I Pseudo ECL

True (+)

TDOC 59 O Pseudo ECL These pins are used to output transmit serial data when serial

Complement (–) interface mode is used (PSEL pin input = low level). They are

TDOT 58 O Pseudo ECL

True (+)

TCOC 54 O Pseudo ECL These pins are used to output transmit clocks when serial

Complement (–) interface mode is used (PSEL pin input = low level). Transmit

TCOT 53 O Pseudo ECL

True (+)

TFKC 50 I Pseudo ECL These pins are used to input transmit system clocks when

Complement (–) serial interface mode is used (PSEL pin input = low level).

TFKT 49 I Pseudo ECL

True (+)

them when Parallel interface mode is used.

Clocks are input in synchronization with receive data. Ground

them when parallel interface mode is used.

open-drain pins. Terminate them with VDD –2 V via a 50 Ω

resistor. To be undefined after reset.

clocks to be input to the TFKC/TFKT pins are output passing

through internal gates. They are open-drain pins. Terminate

them with VDD –2 via a 50 Ω resistor. To be undefined after

reset.

Transmit data output from the TDOC/TDOT pins is output in

synchronization with clocks that are input to these pins.

Ground them when parallel interface mode is used.

RPD0-RPD7 77-73, 71-69 I TTL These pins are used to input receive parallel data when

parallel interface mode is used (PSEL pin input = high level).

Leave them open when serial interface mode is used.

RPC 67 I TTL This pin is used to input the receive system clock when

parallel interface mode is used (PSEL pin input = high level).

Input clocks synchronous with the receive data. Leave it open

when serial interface mode is used.

TPD0-TPD7 35-39, 43-45 O CMOS These pins are used to output transmit parallel data when

parallel interface mode is used (PSEL pin input = high level).

Leave them open when serial interface mode is used.

TPC 46 O CMOS This pin is used to output transmit clocks when parallel

interface mode is used (PSEL pin input = high level). Transmit

clocks to be input to the TFC pin are output passing through

internal gates. Leave it open when serial interface mode is

used.

TFC 48 I TTL This pins is used to input transmit system clocks when parallel

interface mode is used (PSEL pin input = high level). Transmit

data output from pins TPD0 to TPD7 are output in

synchronization with the clocks input to this pin. Leave it open

when serial interface mode is used.

PSEL 78 I CMOS This pin is used to select the mode for PMD interface serial/

parallel interface.

Low level: Serial interface mode

High level: Parallel interface mode

8

Page 9

µ

PD98402A

• Power supply

Symbol Pin No. I/O Function

VDD 1, 20, 33, 40, – Supply voltage, 5 V ±5 %

52, 55, 57, 60,

81, 100, 120,

137, 150

GND 21, 34, 41, 42, – Ground

47, 51, 56, 61,

64, 68, 72, 79,

80, 94, 101,

107, 113, 121,

122, 128, 138,

140, 147, 149,

159, 160

• ATM Layer Interface

Symbol Pin No. I/O I/O Level Function

RDO0-RDO7 151-158 O CMOS Connected to 8-bit data bus to output the receive data to the

ATM Layer device. Output is synchronized with the RCLK

rising up. To be undefined after reset.

RCLK 148 I TTL Input pin of the receive data transferring clock from the ATM

Layer device.

RSOC 145 O CMOS Receive cell start address signal. To the ATM Layer device,

this signal indicates the start address byte of the receive ATM

cell. To be undefined after reset.

RENBL 146 I TTL Receive enable signal. Input pin of the signal indicating that

the ATM layer device can receive data.

EMPTY 144 O CMOS Output buffer empty signal. This signal indicates that there is

no data to be transferred to the receive FIFO of the

µ

PD98402A. To be inactive after reset.

TDI0-TDI7 129-136 I TTL 8-bit data bus to input the transmit data from the ATM Layer

device. Reading a data on the bus is synchronized with the

TCLK rising-up.

TCLK 139 I TTL Input pin of the transmit data transferring clock from the ATM

layer device.

TSOC 142 I TTL Transmit cell start address signal. Input pin of the signal

indicating the start byte of the transmit ATM cell input from the

ATM Layer device to the µPD98402A.

TENBL 141 I TTL Transmit enable signal. This signal indicates that the ATM

Layer device is transmitting the valid data to the TDI0-TDI7.

FULL 143 O CMOS Input buffer full signal. When 4 bytes remain as the

acceptable bytes of transmit FIFO at last, this signal changes

to active. To be inactive after reset.

9

Page 10

µ

PD98402A

• Management Interface

Symbol Pin No. I/O I/O Level Function

D0-D7 104-106 I/O CMOS 8-bit data bus for data transfer between the control processor

108-112 and the internal register of the µPD98402A.

A0-A5 114-119 I TTL Address bus. Used for setting the internal register address of

the µPD98402A.

R/W 123 I TTL Read/write control signal.

Low level: Write cycle

High level: Read cycle

CE 126 I TTL Chip enable signal.

At low level, internal register access is to be enable.

ACK 124 O CMOS Read/write cycle receive acknowledge or ready signal.

After reset, this signal indicates inactive level.

PHINT 127 O CMOS Signal which indicates the interrupt cause occurrence to the

processor.

After reset, this signal indicates inactive level.

OE 125 I TTL Output enable. When this signal is set to low level, the

µ

PD98402A outputs data to the control bus. Even if the CE

signal is inactive, when this signal is at low level, the

µ

PD98402A drives the control bus.

• OAM Interface

Symbol Pin No. I/O I/O Level Function

LOS 9 O CMOS Loss of signal detection. Output high level when receive serial

data input is "0" for 50 µs continuously or optical input stop

signal (RAL) is input. When 2 consecutive frames of valid

synchronous pattern is detected, or when input of the optical

input stop signal is released, low level is output. To be

inactive after reset.

OOF 10 O CMOS Out of frame detection. When 4 consecutive frames of wrong

synchronous pattern are detected, high level is output. When

2 consecutive frames of normal synchronous pattern are

detected, low level is output. To be inactive after reset.

RAL 7 I TTL Receive alarm. Inputs receiver-side optical input stop signal

by the optical module.

Low level: Normal

High level: Optical input stopped.

TAL 8 I TTL Transmit alarm. Inputs transmit-side optical output stop signal

output by the optical module.

Low level: Normal

High level: Optical output stopped.

10

Page 11

µ

PD98402A

• Control

Symbol Pin No. I/O I/O Level Function

TFSS 29 I TTL This is the transmit frame setting signal input pin.

It allows synchronization timing of transmit frame output to be

set. The µPD98402A samples this input signal by the internal

transmit system clock (TCL).

Initial output of the transmit frame is restarted 9 clocks into

TCL clock cycle after a high level is latched at TCL rise.

RESET 103 I TTL This is the system reset signal input pin.

It initializes the µPD98402A. It is necessary to input a reset

signal with a pulse width of 2 cycles or more of the clock that

has the longest cycle among the following clocks input to the

µ

PD98402A.

ATM layer : TCLK, RCLK clock cycles

PMD layer : 1/8 cycle of TFKT/TFKC, RCIC/RCIT clocks,

TFC, RPC clock cycles

Immediately after a reset, no read/write is possible to registers

during 5 clocks of the TCL clock (19.44 MHz).

TCL 32 O CMOS This pin is used to output an internal transmit system clock.

The µPD98402A outputs as the internal transmit system clock,

the TFKT/TFKC input clock (155.52 MHz) scaled by 8 in serial

interface mode, and the TFC input clock (19.44 MHz) in

parallel interface mode.

RCL 85 O CMOS This pin is used to output an internal receive system clock.

The µPD98402A outputs as the internal receive system clock,

the RCIC/RCIT input clock (155.52 MHz) scaled by 8 in serial

interface mode, and the RFC input clock (19.44 MHz) in

parallel interface mode.

TxFP 31 O CMOS This is a frame pulse signal on the transmitting side. It

outputs pulses synchronous with the transmit frame start. To

be inactive after reset.

RxFP 30 O CMOS This is a frame pulse signal on the receiving side. It outputs

pulses synchronous with the receive frame start. To be

inactive after reset.

• JTAG boundary scan pins (This function can be supported at the customer’s request.)

Symbol Pin No. I/O I/O Level Function

TJI 4 I TTL This is a pin for JTAG boundary scan.

Pull it up or ground it in normal operation.

TDO 3 O CMOS This is a pin for JTAG boundary scan.

Leave it open in normal operation.

TCK 2 I TTL This is a pin for JTAG boundary scan.

Pull it up or ground it in normal operation.

TMS 5 I TTL This is a pin for JTAG boundary scan.

Pull it up or ground it in normal operation.

TRST 6 I TTL This is a pin for JTAG boundary scan.

Ground it in normal operation.

11

Page 12

• Recommended Connection for Unused Pins

Pin Recommended connection

TDOC, TDOT, TCOC, TCOT, ACK, LOS,

OOF, TCL, TxFP, RxFP

RAL, TAL, TFSS connect to GND

leave open

µ

PD98402A

12

Page 13

µ

PD98402A

2. ELECTRICAL SPECIFICATION

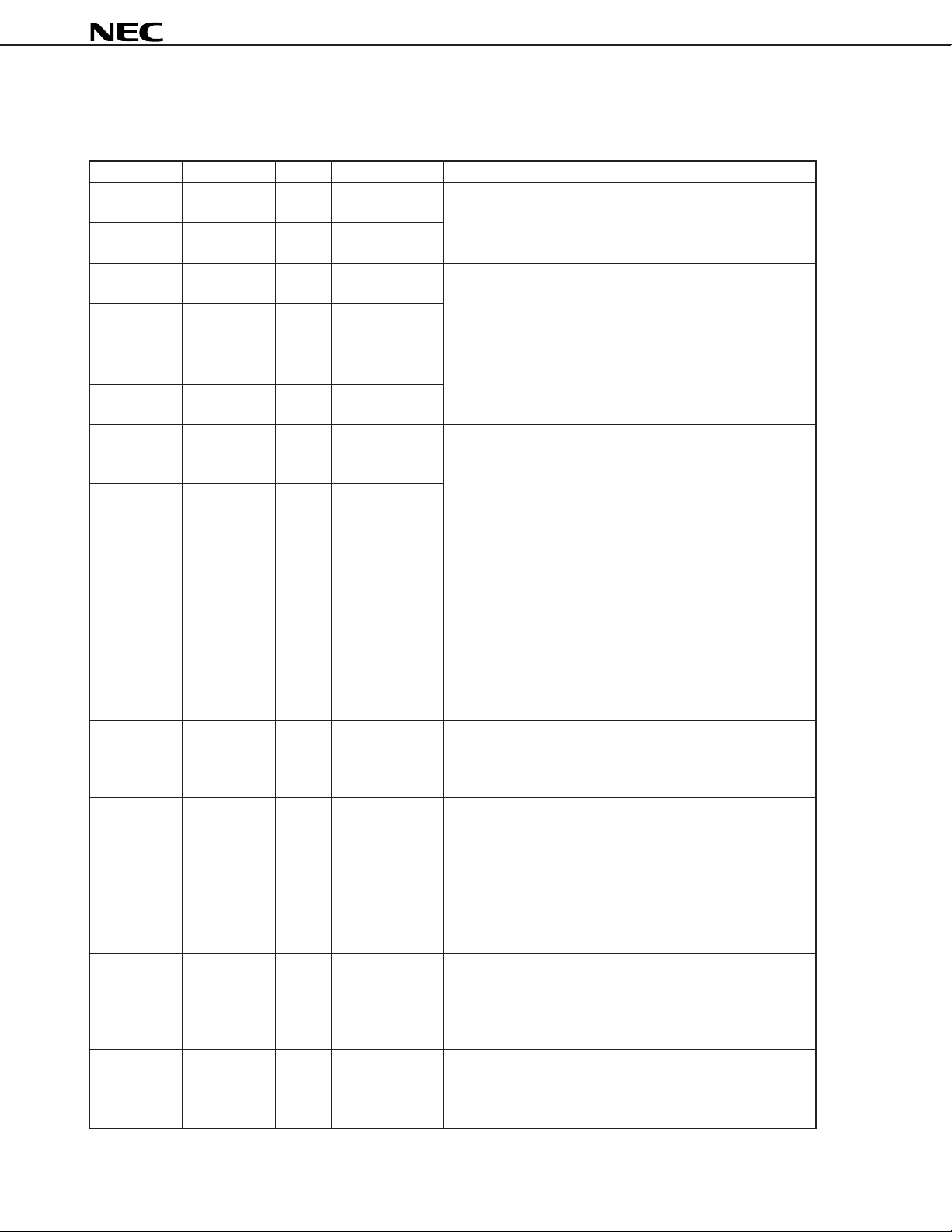

Absolute maximum ratings

Parameters Symbol Conditions Ratings Unit

Supply voltage VDD –0.5 to +6.5 V

Input/output voltage VI/VO –0.5 to VDD +0.5 V

Operating ambient temperature TA 0 to +70 °C

Storage temperature Tstg –65 to +150 °C

Caution Exposure to absolute maximum ratings for extended periods may affect device reliability;

exceeding the ratings could cause permanent damage. The parameters apply independently.

The device should be operated within the limits specified under DC and AC characteristics.

Capacitance

Parameters Symbol Conditions MIN. TYP. MAX. Unit

Input capacitance CI 10 20 pF

Output capacitance CO f = 1 MHz 10 20 pF

Input/output capacitance CIO 10 20 pF

Recommended operating conditions

Parameters Symbol Conditions MIN. TYP. MAX. Unit

Supply voltage VDD 4.75 5.25 V

Operating ambient temperature TA 0 +70 °C

VIL1 Note1 0 +0.8

Low level input voltage VIL2 Note2 VDD–2 VDD–1.5 V

VIL3 Note3 0 0.3 VDD

VIH1 Note1 2.2 VDD

High level input voltage VIH2 Note2 VDD–1.1 VDD V

VIH3 Note3 0.7 VDD VDD

Notes 1. TTL input pin

2. Pseudo ECL input pin

3. CMOS input pin

13

Page 14

µ

PD98402A

DC Characteristics (VDD = 5 V ±0.25 V, TA = 0 to +70 °C)

Parameters Symbol Conditions MIN. TYP. MAX. Unit

Note4

Note4

Note1

Note2

—10

—10

0.7 VDD —

— 0.4

Off-state output current IOZ VI = VDD or GND

ILI1 VI = VDD or GND

Input leak current

ILI2 Note 3 —10

VOH1 IOH = –0.5 mA

High level output voltage V

VOH2 Note 5 VDD–0.9 VDD–0.4

VOL1 IOL = 6.0 mA

Low level output voltage V

VOL2 Note 5 VDD–2.0 VDD–1.7

Supply current IDD Normal operation — 300 mA

Notes 1. 3-state data bus

2. TTL input pin

3. Pseudo ECL input pin

4. CMOS output pin

5. Pseudo ECL output pin

µ

A

µ

A

14

Page 15

µ

PD98402A

AC Characteristics

(1) Management Interface

Internal Register Read/Write

Parameters Symbol Conditions MIN. TYP. MAX. Unit

A0-A5 setup time (to CE↓)tSCC1 5

R/W setup time (to CE↓)tSCC2 5

A0-A5 hold time (to CE↓)tHCC1 3

R/W hold time (to CE↓)tHCC2 3

CE↓→ACK↓ delay time (read) tDCNAR Load capacitor 15 pF 3 × 4.5 ×

At parallel data input tCYPPR tCYPPR

Load capacitor 15 pF 3 × 4.5 ×

At serial data input (tCYPSR × 8) (tCYPSR × 8)

CE↓→ACK↓ delay time (write) tDCNAW Load capacitor 15 pF 2 × 3.5 ×

At parallel data input tCYPPR tCYPPR

Load capacitor 15 pF 2 × 3.5 ×

At serial data input (tCYPSR × 8) (tCYPSR × 8)

CE↑→ACK↑ delay time tDCPA Load capacitor 15 pF 1 × 2.5 ×

At parallel data input tCYPPR tCYPPR

Load capacitor 15 pF 1 × 2.5 ×

At serial data input (tCYPSR × 8) (tCYPSR × 8)

CE↓→ data output delay time tDCD Load capacitor 15 pF 2 × 3.5 ×

At parallel data input tCYPPR tCYPPR

Load capacitor 15 pF 2 × 3.5 ×

At serial data input (tCYPSR × 8) (tCYPSR × 8)

OE↓→ data output delay time tDOD Load capacitor 15 pF — 9.4 ns

OE↑→ data floating output delay time tFOD Load capacitor 15 pF — 10 ns

D0-D7 setup time (to CE↓)tSDC 5—ns

D0-D7 hold time (to CE↓)tHCD 3—ns

CE low-level width tCEBW At parallel data input 3.5 × —

tCYPPR

At serial data input 3.5 × —

(tCYPSR × 8)

OE low-level width tOEBW At parallel data input 2.5 × —

tCYPPR

At serial data input 2.5 × —

(tCYPSR × 8)

ns

ns

ns

ns

ns

ns

ns

ns

Remarks 1. For tCYPPR, refer to (6) PMD parallel interface timing.

2. For t

CYPSR, refer to (7) PMD serial interface timing.

15

Page 16

Management Interface

Internal Register Read

(a) Case 1 When the host uses ACK signal

t

SCC1

A0-A5

t

HCC1

µ

PD98402A

R/W

SCC2

t

t

CEBW

t

HCC2

CE

t

OEBW

OE

t

DCNAR

ACK

D0-D7

t

DOD

t

Valid

DCD

(b) Case 2 When the host does not use ACK signal

t

A0-A5

R/W

CE

SCC1

t

SCC2

t

HCC1

t

HCC2

t

t

CEBW

DCPA

t

FOD

16

OE

D0-D7

t

DOD

t

OEBW

Valid

t

FOD

Page 17

Internal Register Write

A0-A5

R/W

CE

t

t

SCC1

SCC2

t

HCC1

t

HCC2

t

DCPA

µ

PD98402A

ACK

D0-D7

OE

t

SDC

t

DCNAW

Valid

t

HCD

“ H ”

(2) OAM Interface

Parameters Symbol Conditions MIN. TYP. MAX. Unit

TCL↑→LOS delay time tDCLS load capacitor = 15 pF 5 30 ns

RCL↑→OOF delay time tDCOF load capacitor = 15 pF –5 +7 ns

OAM Interface

TCL

RCL

t

DCLS

LOS

OOF

DCOF

t

17

Page 18

µ

PD98402A

(3) Control Signal Interface

Parameters Symbol Conditions MIN. TYP. MAX. Unit

TCL↑→TPC delay time tDTCP load capacitor = 15 pF 0 +5 ns

TFSS setup time (to TCL↑)tSFSC 10 — ns

TFSS hold time (to TCL↑)tHCFS 5—ns

TCL↑→TxFP delay time tDCFP load capacitor = 15 pF 0 +20 ns

RCL↑→RxFP delay time t DCRP load capacitor = 15 pF –5 +20 ns

Control Signal Interface

TPC

t

DTCP

TCL

t

TFSS

DCFP

t

DCFP

TxFP

RCL

RxFP

t

SFSC

t

HCFS

t

DCRP

t

DCRP

18

Page 19

µ

PD98402A

(4) SAR Interface (Transmitter Side)

Parameters Symbol Conditions MIN. TYP. MAX. Unit

TCLK cycle time tCYST 30 125 ns

TCLK high level width tSTH 12 110 ns

TCLK low level width tSTL 12 110 ns

TCLK↑→FULL↓ delay time tFD load capacitor = 15 pF 5 17 ns

TDI0-TDI7 setup time (to TCLK↑)tSTDK1 5—ns

TSOC setup time (to TCLK↑)tSTDK2 12 — ns

TENBL setup time (to TCLK↑)tSTDK3 5—ns

TDI0-TDI7 hold time (to TCLK↑)tHKTD1 3—ns

TSOC hold time (to TCLK↑)tHKTD2 3—ns

TENBL hold time (to TCLK↑)tHKTD2 3—ns

SAR Interface (Transmitter Side)

TCLK

FULL

TENBL

TSOC

TDI0-TDI7

CYST

t

t

STHtSTL

t

t

t

FD

t

STDK2

HKTD3

t

HKTD2

STDK3

t

STDK1

P48 H1 Invalid H2 H3

t

HKTD1

19

Page 20

µ

PD98402A

(5) SAR Interface (Receiver Side)

Parameters Symbol Conditions MIN. TYP. MAX. Unit

RCLK cycle time tSYCR 30 125 ns

RCLK high level width tSRH 12 110 ns

RCLK low level width tSRL 12 110 ns

RCLK↑→EMPTY↑↓delay time tED load capacitor = 15 pF 5 17 ns

RENBL setup time (to RCLK↑)tSREK 12 — ns

RENBL hold time (to RCLK↑)tHKRE 3—ns

RCLK↑→RSOC↑↓ delay time tRSD load capacitor = 15 pF 0 17 ns

RCLK↑→RDO0-RDO7 delay time tRDD load capacitor = 15 pF 0 17 ns

SAR Interface (Receiver Side)

t

SYCR

RCLK

EMPTY

RENBL

RSOC

RDO0-RDO7

t

SRHtSRL

t

SREK

t

t

RSD

RDD

t

ED

t

ED

t

RSD

t

RDD

P48 H1 H2 H3

t

HKRE

20

Page 21

µ

PD98402A

(6) PMD Parallel Interface

Parameters Symbol Conditions MIN. TYP. MAX. Unit

RPC cycle time tCYPPR 50 — ns

RPC high level width tPPRH 20 — ns

RPC low level width tPPRL 20 — ns

TFC cycle time tCYPPT 50 — ns

TFC high level width tPPTH 20 — ns

TFC low level width tPPTL 20 — ns

RPD0-RPD7 setup time (to RPC↑)tSPDC 5—ns

RPD0-RPD7 hold time (to RPC↑)tHPCD 3—ns

TFC↑→TPC↑ delay time tDFPCP load capacitor = 15 pF 3 25 ns

TFC↓→TPC↓ delay time tDFPCN load capacitor = 15 pF 3 25 ns

TPC↑→TPD0-TPD7 delay time tDPCD load capacitor = 15 pF –3.0 +1.0 ns

PMD Parallel Interface

Receive Side

RPD0-RPD7

Transmit Side

TPD0-TPD7

RPC

TFC

TPC

t

PPRH

t

DFPCPtDFPCN

t

CYPPR

t

PPRL

SPDC

t

t

PPTH

t

HPCD

t

CYPPT

t

PPTL

DPCD

t

21

Page 22

µ

PD98402A

(7) PMD Serial Interface

Parameters Symbol Conditions MIN. TYP. MAX. Unit

RCIT (RCIC) cycle time tCYPSR 6.4 — ns

TFKT (TFKC) cycle time tCYPST 6.4 — ns

Serial data setup time tSSDC 1.0 — ns

Serial data hold time tHSCD 1.0 — ns

Serial clock delay time (rising) tDFSCP Load capacitor 15 pF — 8 ns

Serial clock delay time (falling) tDFSCN Load capacitor 15 pF — 8 ns

Transmit serial data delay time tDSCD Load capacitor 15 pF — 3 ns

PMD Serial Interface

Receive Side

t

CYPSR

Transmit Side

RCIC, RCIT

RDIC, RDIT

TFKC, TFKT

TCOC, TCOT

TDOC, TDOT

t

DFSCPtDFSCN

t

DSCD

t

SSDC

t

HSCD

t

CYPST

22

Page 23

3. PACKAGE DRAWING

160 PIN PLASTIC QFP (FINE PITCH) ( 24)

A

B

120 81

121

80

µ

PD98402A

detail of lead end

160

1

41

40

F

G H IJ

M

P

N

NOTE

Each lead centerline is located within 0.10 mm (0.004 inch) of

its true position (T.P.) at maximum material condition.

C D

S

Q

K

M

L

ITEM MILLIMETERS INCHES

A 26.0±0.2 1.024

B

24.0±0.2

C 24.0±0.2

D 26.0±0.2 1.024

F

2.25

G 2.25

H 0.22 0.009±0.002

I 0.10 0.004

J 0.5 (T.P.) 0.020 (T.P.)

K 1.0±0.2 0.039

L 0.5±0.2 0.020

M 0.17 0.007

N 0.10 0.004

P 2.7 0.106

Q 0.125±0.075

R 5°±5° 5°±5°

S 3.0 MAX. 0.119 MAX.

R

+0.008

–0.009

0.945±0.008

0.945±0.008

+0.008

–0.009

0.089

0.089

+0.05

–0.04

+0.009

–0.008

+0.008

–0.009

+0.03

–0.07

S160GM-50-3ED, JED, KED-2

+0.001

–0.003

0.005±0.003

23

Page 24

µ

PD98402A

4. RECOMMENDED SOLDERING CONDITIONS

For the µPD98402A, soldering must be performed under the following conditions.

For details of recommended conditions for surface mounting, refer to information document “Semiconductor

Device Mounting Technology Manual” (IEI-1207).

For other soldering methods, please consult with NEC sales personnel.

µ

PD98402AGM-KED: 160-pin plastic QFP (FINE PITCH) (24 × 24 mm)

•

Soldering Method Soldering Conditions Symbol

Package peak temperature: 235 °C, time: 30 sec. max. (over 210 °C), count:

twice or less, restriction days: 3

is necessary)

Infrared reflow Precautions: IR35-203-2

(1) Reflow a second time should be started when the device temperature has

returned to its normal state after the first reflow.

(2) Avoid flux cleaning with water after the first reflow.

Pin partial heating Pin temperature: 300 °C max., time: 3 seconds max. (per side) —

Note This means the number of days after unpacking the dry pack. Storage conditions are 25 °C and 65 % RM

max.

Note

(after that, 125 °C pre-baking for 20 hours

24

Page 25

[MEMO]

µ

PD98402A

25

Page 26

µ

PD98402A

[MEMO]

The export of this product from Japan is prohibited without governmental license. To export or re-export this product from

a country other than Japan may also be prohibited without a license from that country. Please call an NEC sales

representative.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customer must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

“Standard“, “Special“, and “Specific“. The Specific quality grade applies only to devices developed based on

a customer designated “quality assurance program“ for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard:Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices in “Standard“ unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact NEC Sales Representative in advance.

Anti-radioactive design is not implemented in this product.

26

M4 94.11

Loading...

Loading...