Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD78P4908

16-BIT SINGLE-CHIP MICROCONTROLLER

DESCRIPTION

The µPD78P4908, 78K/IV series' product, is a one-time PROM version of the µPD784907 and µPD784908 with

internal mask ROM.

Since user programs can be written to PROM, this microcomputer is best suited for evaluation in system

development, manufacture of small quantities of multiple products, and fast start-up of applications.

For specific functions and other detailed information, consult the following user's manuals.

These manuals are required reading for design work.

µ

PD784908 Subseries User's Manual - Hardware : U11787E

78K/IV Series User's Manual - Instruction : U10905E

FEATURES

• 78K/IV series

• Internal PROM: 128 Kbytes

• Internal RAM: 4,352 bytes

• Supply voltage: VDD = 4.5 to 5.5 V

(At main clock: f

V

DD = 4.0 to 5.5 V

(Other than above: f

ORDERING INFORMATION

Part number Package Internal ROM

µ

PD78P4908GF-3BA 100-pin plastic QFP (14 × 20 mm) One-time PROM

XX = 12.58 MHz, internal system clock = fXX: fCYK = 79 ns)

CYK = 159 ns)

The information in this document is subject to change without notice.

Document No. U11681EJ2V0DS00 (2nd edition)

Date Published February 1999 N CP(K)

Printed in Japan

The mark shows major revised points.

©

1996

Page 2

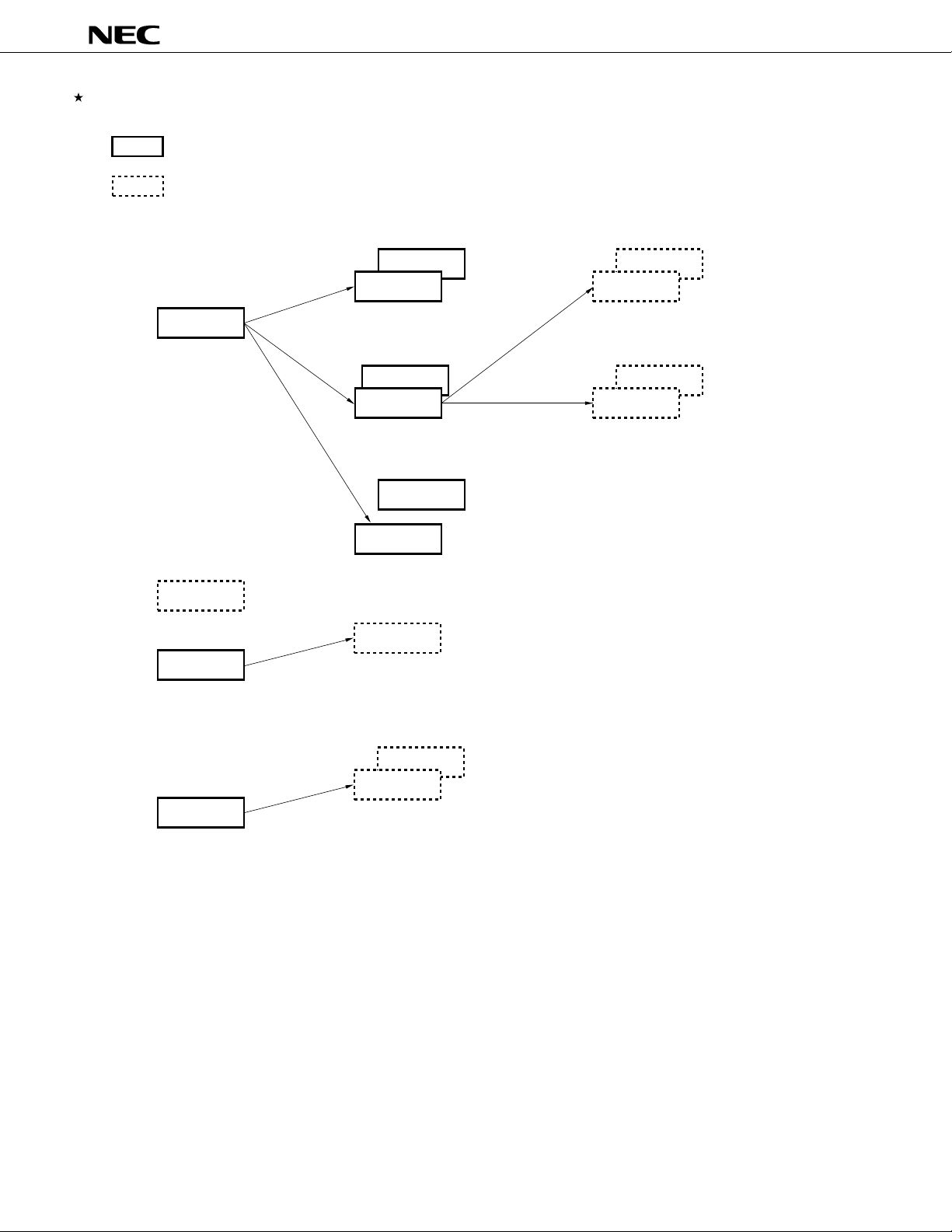

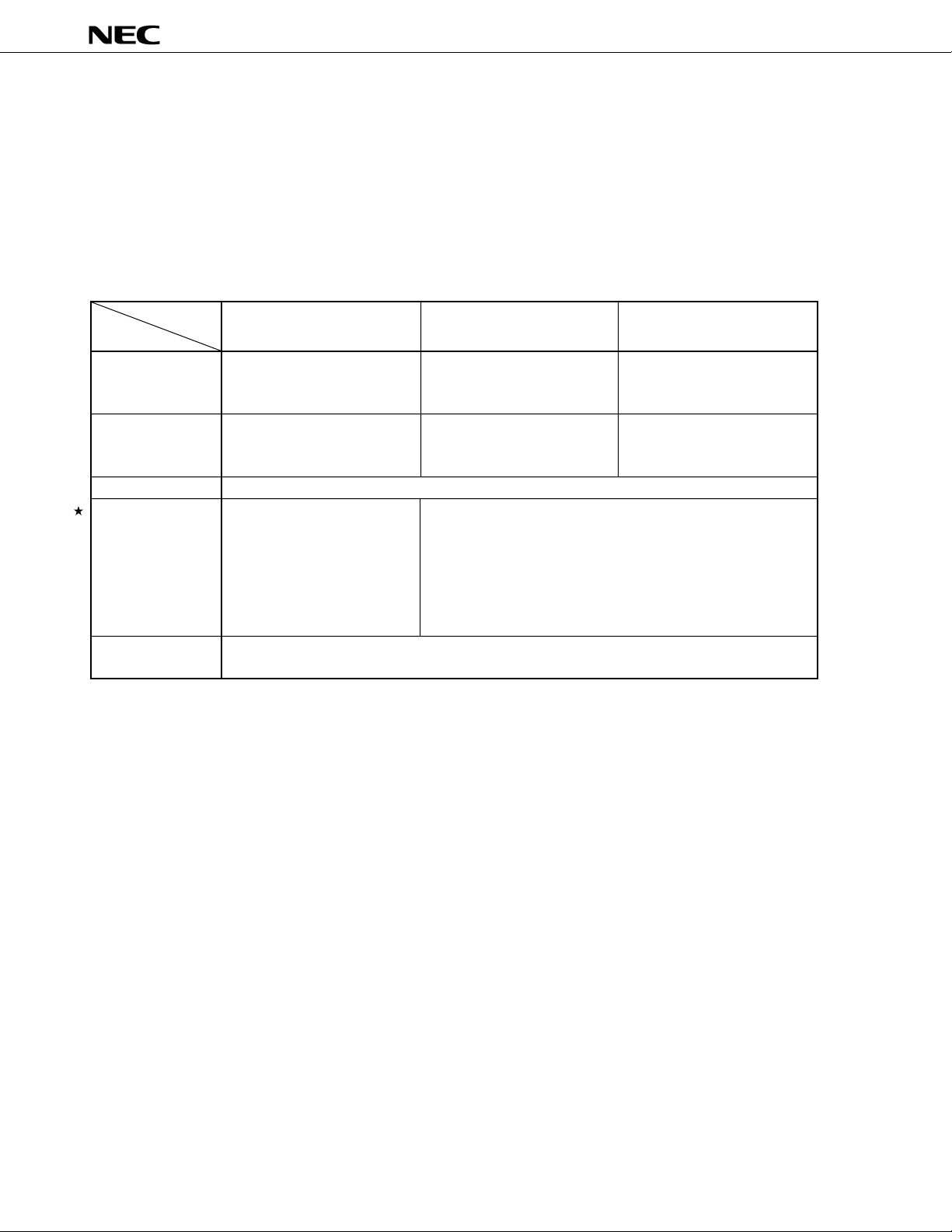

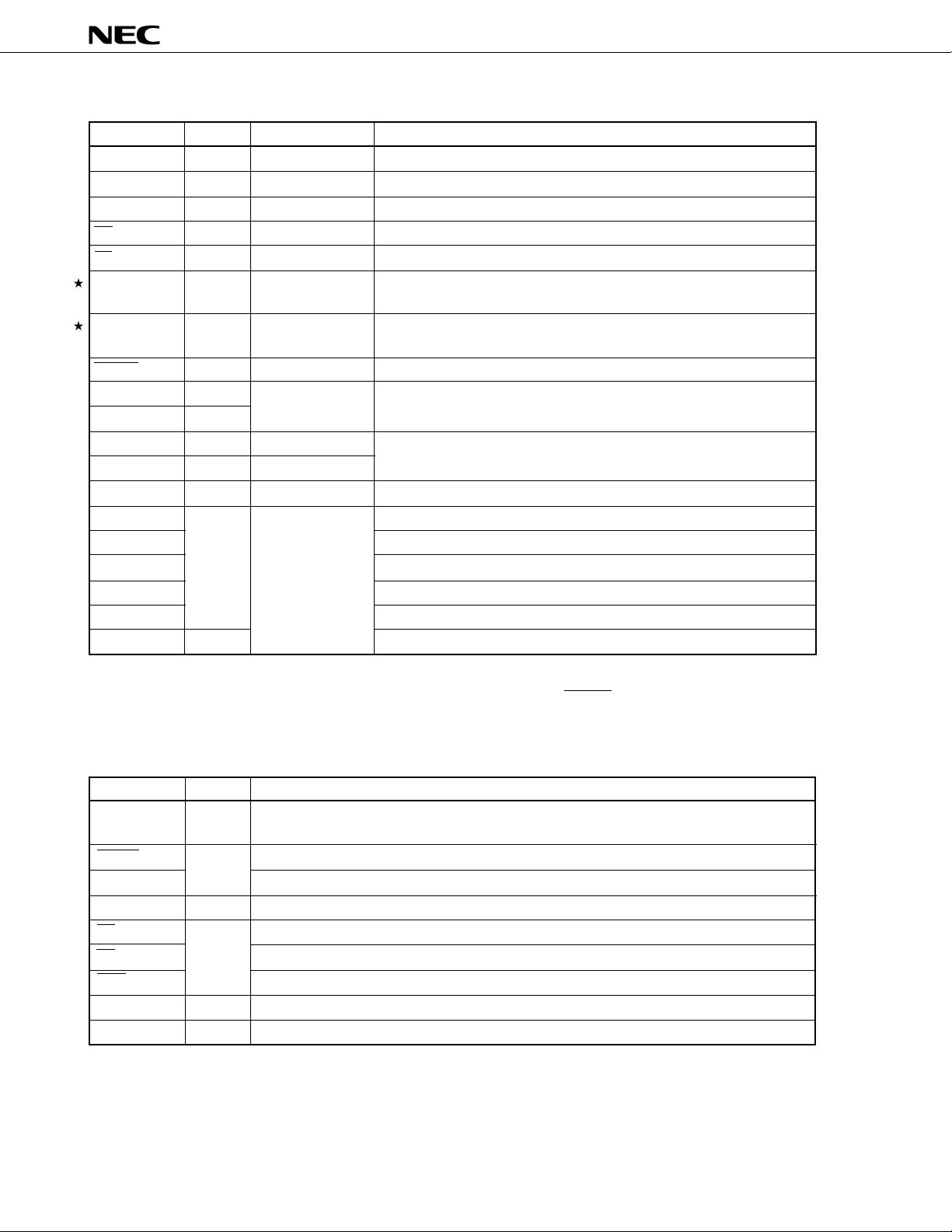

78K/IV SERIES PRODUCT DEVELOPMENT DIAGRAM

: Under mass production

: Under development

µ

PD78P4908

Standard models

PD784026

µ

Enhanced A/D,

16-bit timer,

and power

management

ASSP models

PD784955

µ

For DC inverter control

PD784908

µ

Equipped with IEBus

controller

I2C bus supported

PD784038Y

µ

PD784038

µ

Enhanced internal memory capacity,

pin compatible with the PD784026

µ

PD784216Y

µ

PD784216

100 pins,

enhanced I/O and

internal memory capacity

µ

PD784054

µ

PD784046

Equipped with 10-bit A/D

PD784938

µ

Enhanced function of the PD784908,

TM

enhanced internal memory capacity,

added ROM correction

µ

µ

Multimaster I2C bus supported

PD784225Y

µ

PD784225

µ

80 pins,

added ROM correction

Multimaster I2C bus supportedMultimaster I2C bus supported

PD784218Y

µ

PD784218

µ

Enhanced internal memory capacity,

added ROM correction

µ

PD784915

For software servo control,

equipped with analog circuit

for VCR,

enhanced timer

Multimaster I2C bus supported

PD784928Y

µ

PD784928

µ

Enhanced function of the PD784915

µ

2

Data Sheet U11681EJ2V0DS00

Page 3

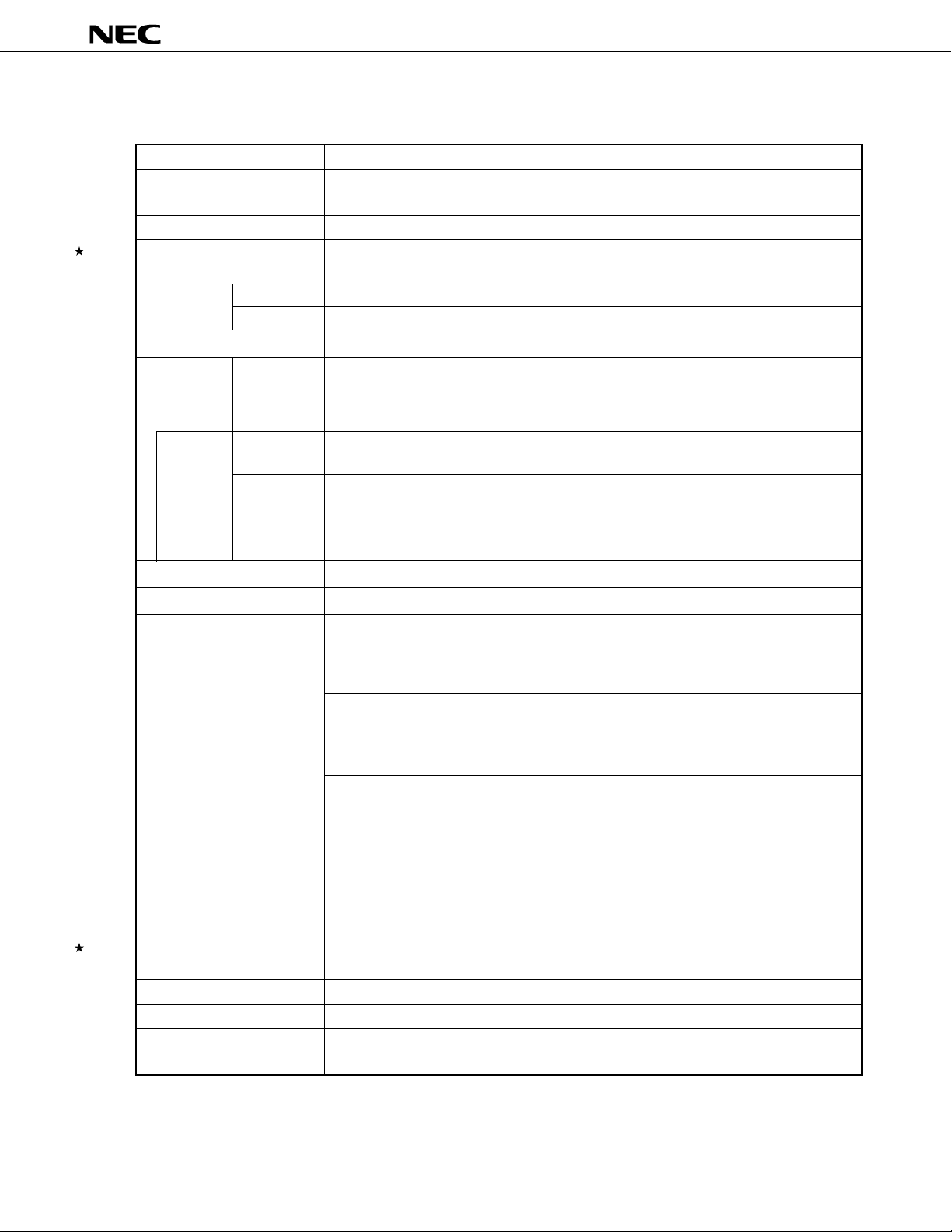

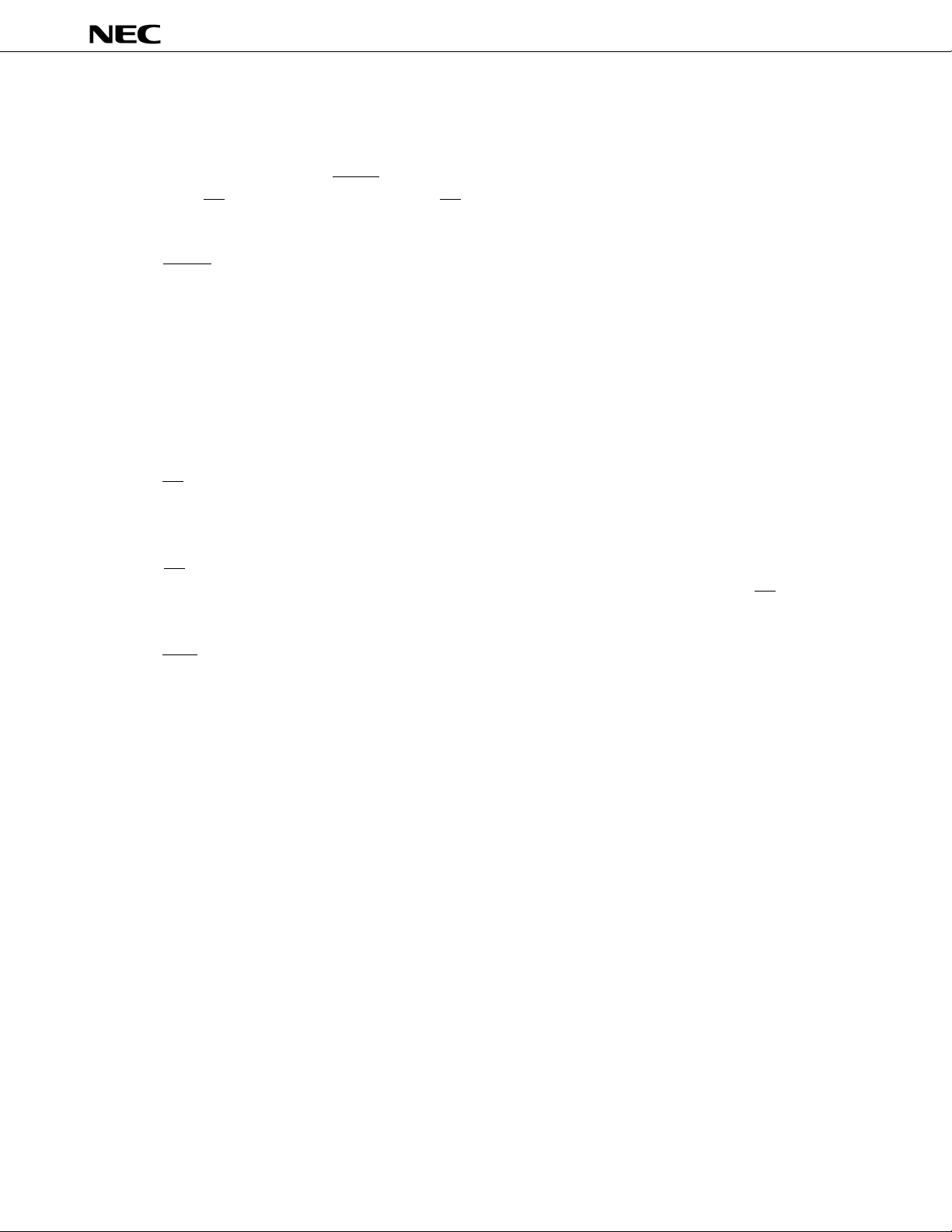

FUNCTIONS

µ

PD78P4908

(1/2)

Item

Number of basic instructions

(mnemonics)

General-purpose register

Minimum instruction execution

time

Internal

memory

Memory space

I/O ports

Additional

function

Note

pins

Real-time output ports

IEBus controller

Timer/counter

Clock timer

Clock output

PWM outputs

Serial interface

ROM

RAM

Total

Input

Input/output

LED direct

drive outputs

Transistor

direct drive

N-ch open

drain

Function

113

8 bits × 16 registers × 8 banks, or 16 bits × 8 registers × 8 banks (memory mapping)

• 320 ns/636 ns/1.27

• 160 ns/320 ns/636 ns/1.27

128 Kbytes

4,352 bytes

Program and data: 1 Mbyte

80

8

72

24

8

4

4 bits × 2, or 8 bits × 1

Incorporated (simple version)

Timer/counter 0: Timer register × 1 Pulse output capability

(16 bits) Capture register × 1 • Toggle output

Timer/counter 1: Timer register × 1 Real-time output port

(16 bits) Capture register × 1

Timer/counter 2: Timer register × 1 Pulse output capability

(16 bits) Capture register × 1 • Toggle output

Timer 3: Timer register × 1

(16 bits) Compare register × 1

Interrupt requests are generated at 0.5-second intervals. (A clock timer oscillator is

incorporated.)

Either the main clock (6.29 MHz/12.58 MHz) or real-time clock (32.768 kHz) can be

selected as the input clock.

Selected from fCLK, fCLK/2, fCLK/4, fCLK/8, or fCLK/16 (can be used as a 1-bit output port)

12-bit resolution × 2 channels

UART/IOE (3-wire serial I/O) : 2 channels (incorporating baud rate generator)

CSI (3-wire serial I/O) : 2 channels

µ

s/2.54 µs (at 6.29 MHz)

µ

s (at 12.58 MHz)

Compare register × 2 • PWM/PPG output

• One-shot pulse output

Capture/compare register × 1

Compare register × 1

Capture/compare register × 1 • PWM/PPG output

Compare register × 1

Note Additional function pins are included in the I/O pins.

Data Sheet U11681EJ2V0DS00

3

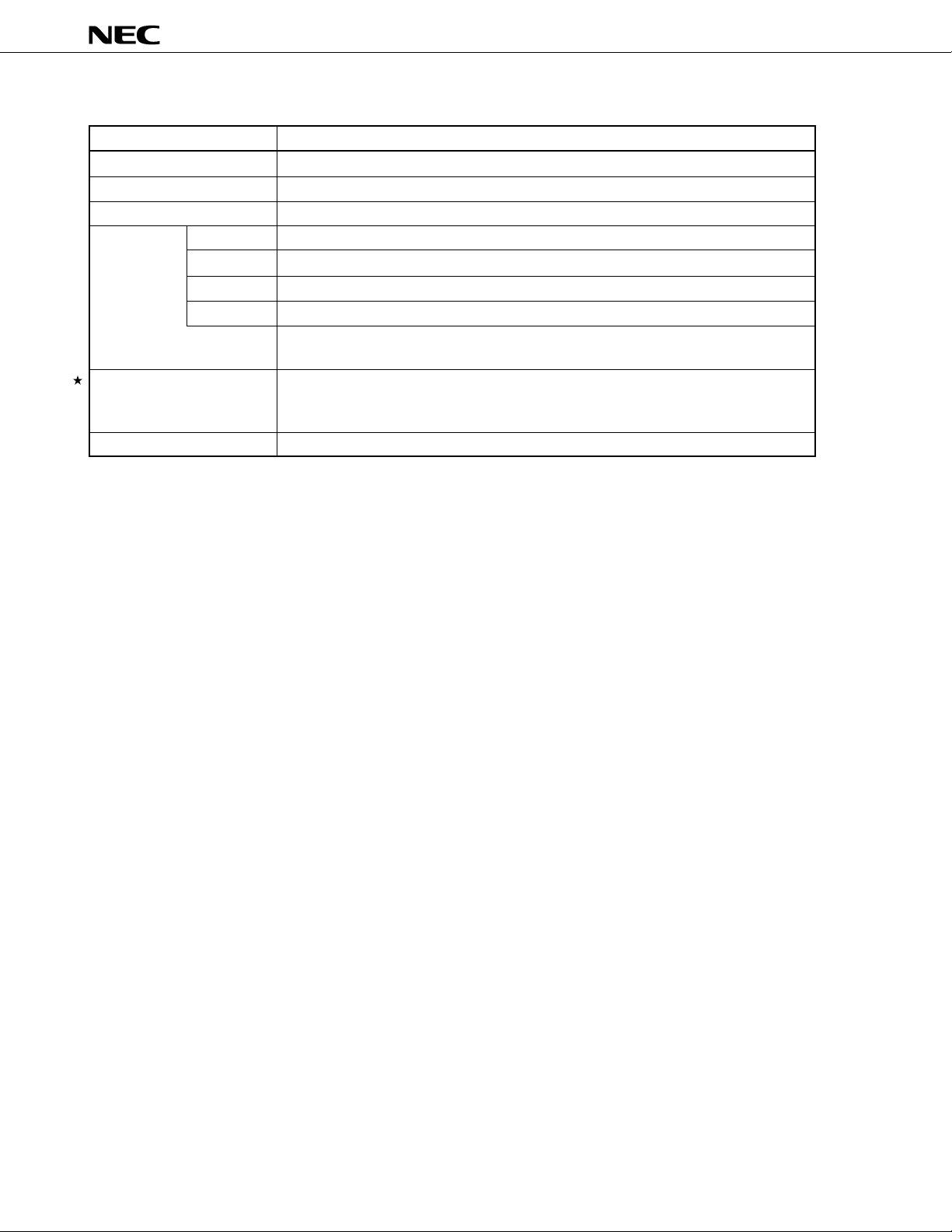

Page 4

µ

PD78P4908

(2/2)

Item

A/D converter

Watchdog timer

Standby

Interrupt

Power supply voltage

Package

Hardware source

Software source

Nonmaskable

Maskable

Function

8-bit resolution × 8 channels

1 channel

HALT/STOP/IDLE mode

27 (20 internal, 7 external (sampling clock variable input: 1))

BRK or BRKCS instruction, operand error

1 internal, 1 external

19 internal, 6 external

• 4-level programmable priority

• 3 operation statuses: vectored interrupt, macro service, context switching

• VDD = 4.5 to 5.5 V (At main clock: fXX = 12.58 MHz, internal system clock = fXX: fCYK =

79 ns)

• VDD = 4.0 to 5.5 V (Other than above: fCYK = 159 ns)

100-pin plastic QFP (14 × 20 mm)

4

Data Sheet U11681EJ2V0DS00

Page 5

µ

PD78P4908

CONTENTS

1. DIFFERENCES BETWEEN µPD78P4908 AND MASK ROM PRODUCTS ............................ 6

2. PIN CONFIGURATION (TOP VIEW) ......................................................................................... 7

3. BLOCK DIAGRAM ..................................................................................................................... 1 0

4. PIN FUNCTIONS ........................................................................................................................ 1 1

4.1 PINS FOR NORMAL OPERATING MODE.................................................................................... 11

4.2 PINS FOR PROM PROGRAMMING MODE (V

4.2.1 Pin Functions ................................................................................................................. 14

4.2.2 Pin Functions ................................................................................................................. 15

4.3 I/O CIRCUITS FOR PINS AND HANDLING OF UNUSED PINS ................................................. 16

PP ≥ +5 V or +12.5 V, RESET = L) .................... 14

5. INTERNAL MEMORY SIZE SELECT REGISTER (IMS).......................................................... 19

6. PROM PROGRAMMING ............................................................................................................ 20

6.1 OPERATION MODE........................................................................................................................ 20

6.2 PROM WRITE SEQUENCE ............................................................................................................ 2 2

6.3 PROM READ SEQUENCE ............................................................................................................. 26

7. SCREENING ONE-TIME PROM PRODUCTS .......................................................................... 26

8. ELECTRICAL CHARACTERISTICS ......................................................................................... 27

9. PACKAGE DRAWING ................................................................................................................ 51

10. RECOMMENDED SOLDERING CONDITIONS ........................................................................ 52

APPENDIX A DEVELOPMENT TOOLS .......................................................................................... 53

APPENDIX B CONVERSION SOCKET (EV-9200GF-100) PACKAGE DRAWING ..................... 56

APPENDIX C RELATED DOCUMENTS ......................................................................................... 58

Data Sheet U11681EJ2V0DS00

5

Page 6

µ

PD78P4908

1. DIFFERENCES BETWEEN µPD78P4908 AND MASK ROM PRODUCTS

The µPD78P4908 is produced by replacing the mask ROM in the µPD784907 or µPD784908 with PROM to which

µ

data can be written. The functions of the

for the PROM specification such as writing and verification, except that the PROM size can be changed to 96 or 128

Kbytes, and except that the internal RAM size can be changed to 3,584 or 4,352 bytes.

Table 1-1 shows the differences between these products.

Table 1-1. Differences Between the

PD78P4908 are the same as those of the µPD784907 or µPD784908 except

µ

PD78P4908 and Mask ROM Products

Product name

Item

Internal program

memory

Internal RAM

Pin connection

Power supply voltage

Electrical

characteristics

µ

µ

PD78P4908

• 128-Kbyte PROM

• 96-Kbyte mask ROM

PD784907

µ

PD784908

• 128-Kbyte mask ROM

• Can be changed to 96

Kbytes by IMS

• 4,352-byte internal RAM

• 3,584-byte internal RAM

• 4,352-byte internal RAM

• Can be changed to 3,584

bytes by IMS

Pin functions related to writing or reading of PROM have been added to the µPD78P4908.

• VDD = 4.5 to 5.5 V • VDD = 4.0 to 5.5 V

(At main clock: fXX = 12.58 (At main clock: fXX = 12.58 MHz, internal system clock = fXX:

MHz, internal system clock = fCYK = 79 ns)

fXX: fCYK = 79 ns • VDD = 3.5 to 5.5 V

• VDD = 4.0 to 5.5 V (Other than above: fCYK = 159 ns)

(Other than above: fCYK =

159 ns)

Partially differs between these products.

6

Data Sheet U11681EJ2V0DS00

Page 7

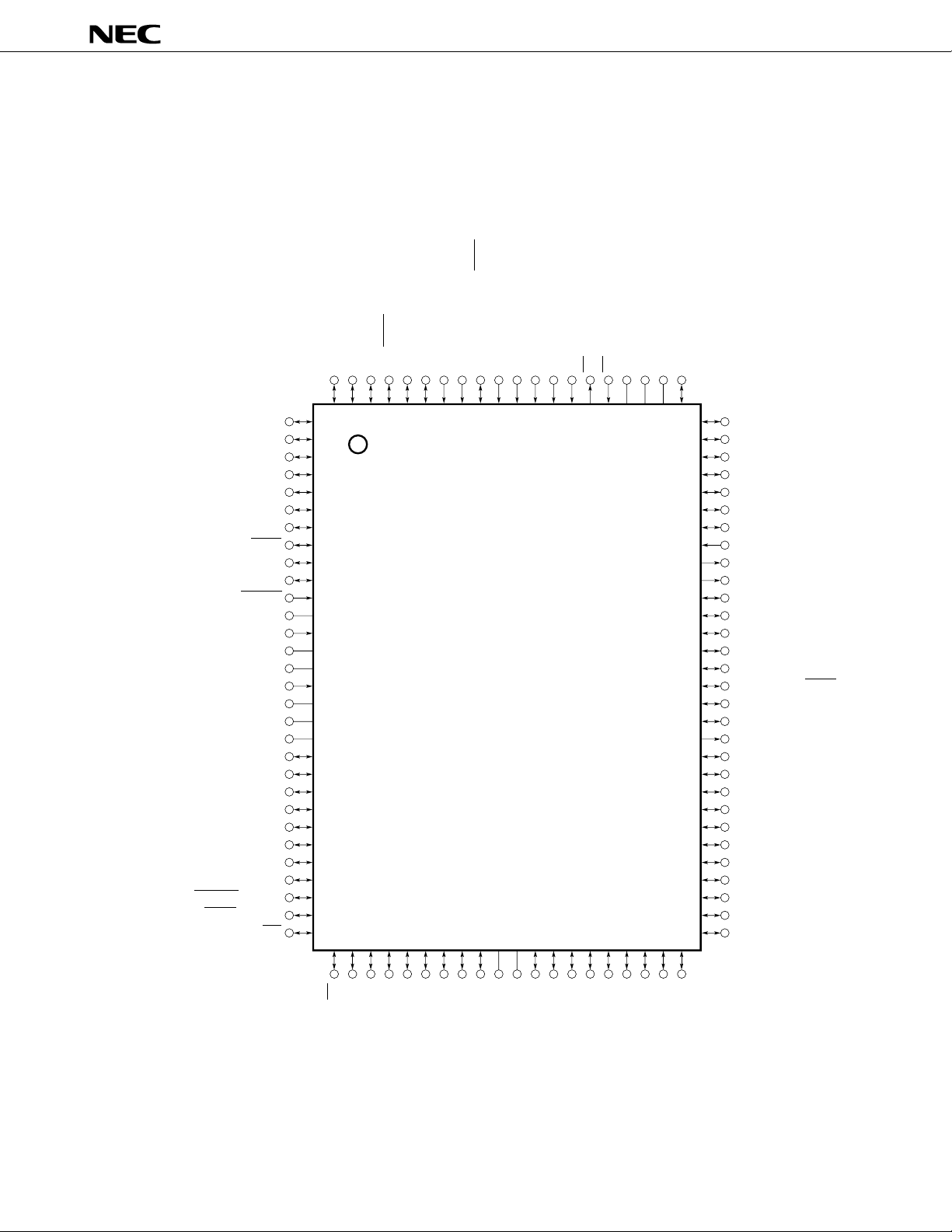

2. PIN CONFIGURATION (TOP VIEW)

(1) Normal operation mode

• 100-pin plastic QFP (14 × 20 mm)

µ

PD78P4908GF-3BA

P35/TO1

P34/TO0

P33/SO0

P32/SCK0

100

99

98

97

96

P37/TO3

P100

Note 2

Note 3

2

3

4P101

5P102

6P103

7P104

8P105/SCK3

9P106/SI3

10P107/SO3

11RESET

12XT2

13XT1

14V

SS

15X2

16X1

17REGOFF

18REGC

19VDD

20P00

21P01

22P02

23P03

24P04

25P05

26P06

27P07

28P67/REFRQ/HLDAK

29P66/WAIT/HLDRQ

30P65/WR

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

P31/TxD/SO1

P30/RxD/SI1

P27/SI094P26/INTP5

95

93

92

P25/INTP4/ASCK/SCK1

P24/INTP3

P23/INTP2/CI

P22/INTP1

P21/INTP0

P20/NMI87TX86RX85AVSS84AVREF183AVDD82P77/ANI7

91

90

89

88

µ

PD78P4908

81

80 P76/ANI61P36/TO2

79 P75/ANI5

78 P74/ANI4

77 P73/ANI3

76 P72/ANI2

75 P71/ANI1

74 P70/ANI0

73 TEST

72 PWM1

71 PWM0

70 P17

69 P16

68 P15

67 P14/TxD2/SO2

66 P13/RxD2/SI2

65 P12/ASCK2/SCK2

64 P11

63 P10

62 ASTB/CLKOUT

61 P90

60 P91

59 P92

58 P93

57 P94

56 P95

55 P96

54 P97

53 P40/AD0

52 P41/AD1

51 P42/AD2

Note 1

P64/RD

P63/A19

P62/A18

Notes 1. Connect the TEST pin to V

2. Connect the REGOFF pin to V

3. Connect the REGC pin to V

SS

V

VDD

P61/A17

P60/A16

P57/A15

P56/A14

P55/A13

P54/A12

SS directly.

SS directly (select regulator operation)

SS through a 1-

Data Sheet U11681EJ2V0DS00

µ

F capacitor.

P53/A11

P52/A10

P51/A9

P50/A8

P47/AD7

P46/AD6

P45/AD5

P44/AD4

P43/AD3

7

Page 8

µ

PD78P4908

A8-A19 : Address bus

AD0-AD7 : Address/data bus

ANI0-ANI7 : Analog input

ASCK, ASCK2 : Asynchronous serial clock

ASTB : Address strobe

DD : Analog power supply

AV

REF1 : Reference voltage

AV

SS : Analog ground

AV

CI : Clock input

CLKOUT : Clock output

HLDAK : Hold acknowledge

HLDRQ : Hold request

INTP0-INTP5 : Interrupt from peripherals

NMI : Non-maskable interrupt

P00-P07 : Port 0

P10-P17 : Port 1

P20-P27 : Port 2

P30-P37 : Port 3

P40-P47 : Port 4

P50-P57 : Port 5

P60-P67 : Port 6

P70-P77 : Port 7

P90-P97 : Port 9

P100-P107 : Port 10

PWM0, PWM1 : Pulse width modulation output

RD : Read strobe

REFRQ : Refresh request

REGC : Regulator capacitance

REGOFF : Regulator off

RESET : Reset

RX : IEBus receive data

RxD, RxD2 : Receive data

SCK0-SCK3 : Serial clock

SI0-SI3 : Serial input

SO0-SO3 : Serial output

TEST : Test

TO0-TO3 : Timer output

TX : IEBus transmit data

TxD, TxD2 : Transmit data

DD : Power supply

V

SS : Ground

V

WAIT : Wait

WR : Write strobe

X1, X2 : Crystal (main system clock)

XT1, XT2 : Crystal (watch)

8

Data Sheet U11681EJ2V0DS00

Page 9

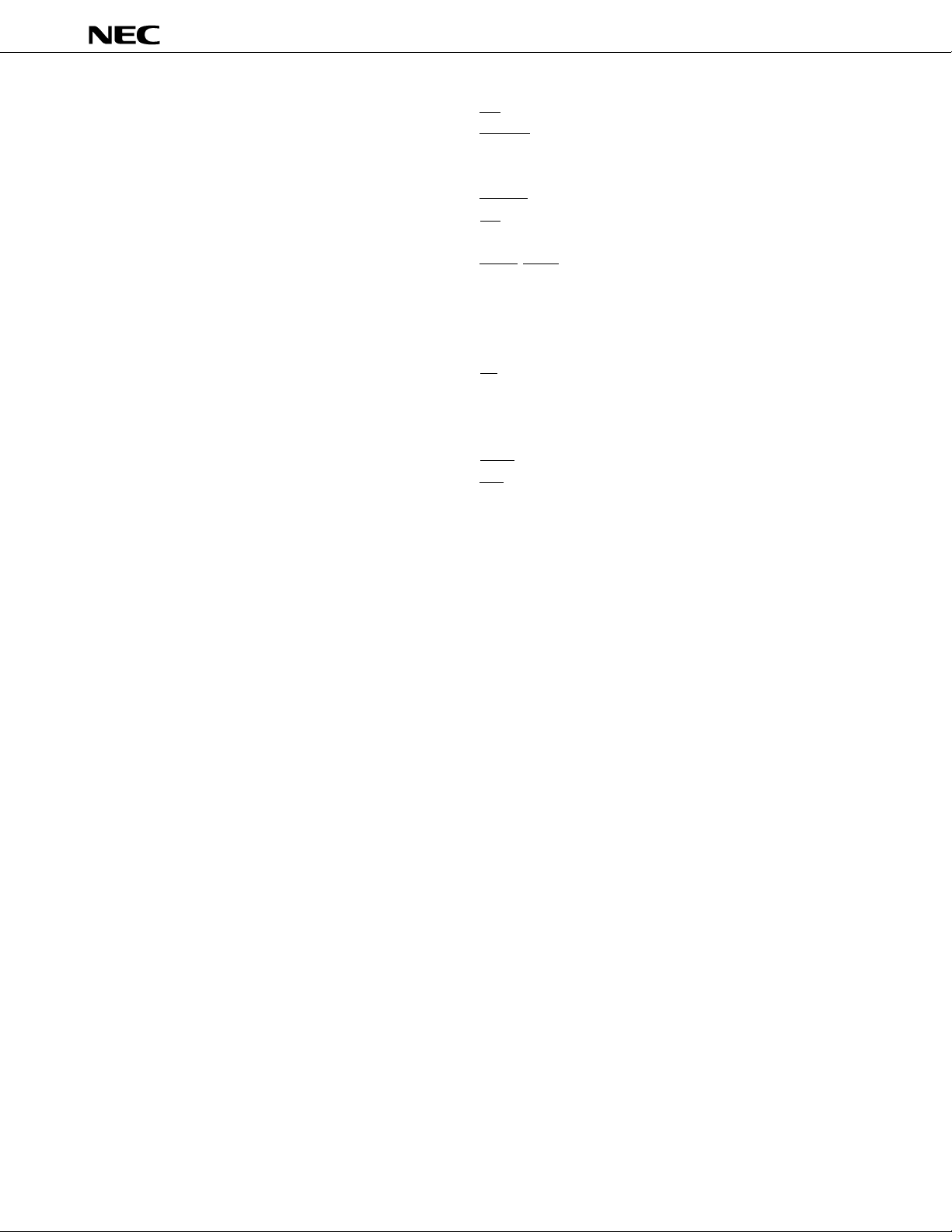

(2) PROM programming mode

• 100-pin plastic QFP (14 × 20 mm)

µ

PD78P4908GF-3BA

µ

PD78P4908

OPEN

RESET

OPEN

OPEN

V

PGM

OPEN

SS

V

(L)A9V

SS

OPEN

OPEN

VSSVSS

VDD

OPEN

81828384858687888990919293949596979899100

1

2

3

4

5

6

7

8

9

10

11

12

13

SS

V

VSS

14

15

V

16

SS

17

DD

18

19

D0

D1

D2

D3

D4

D5

D6

D7

(L)

20

21

22

23

24

25

26

27

28

29

CE

30

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

OPEN

PP

V

OPEN

A0

A1

A2

OE

(L)

A15

A14

A13

A12

SS

V

VDD

A11

A8A7A6A5A4

A10

A16

A3

Caution L : Connect these pins separately to the VSS pins through 10-kΩ pull-down resistors.

SS : To be connected to the ground.

V

Open : Nothing should be connected on these pins.

RESET: Set a low-level input.

A0-A16 : Address bus RESET : Reset

CE : Chip enable V

D0-D7 : Data bus V

OE : Output enable V

DD : Power supply

PP : Programming power supply

SS : Ground

PGM : Program

Data Sheet U11681EJ2V0DS00

9

Page 10

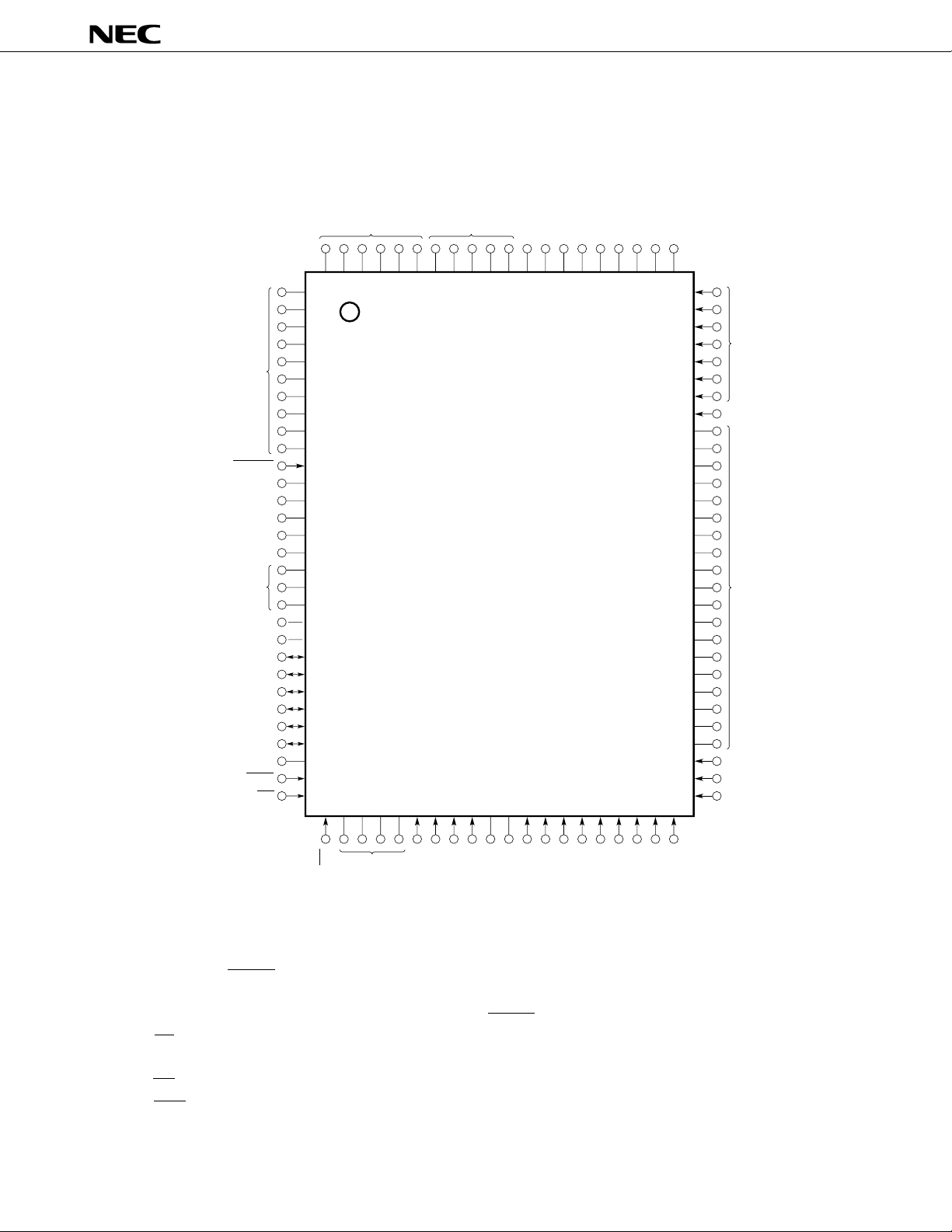

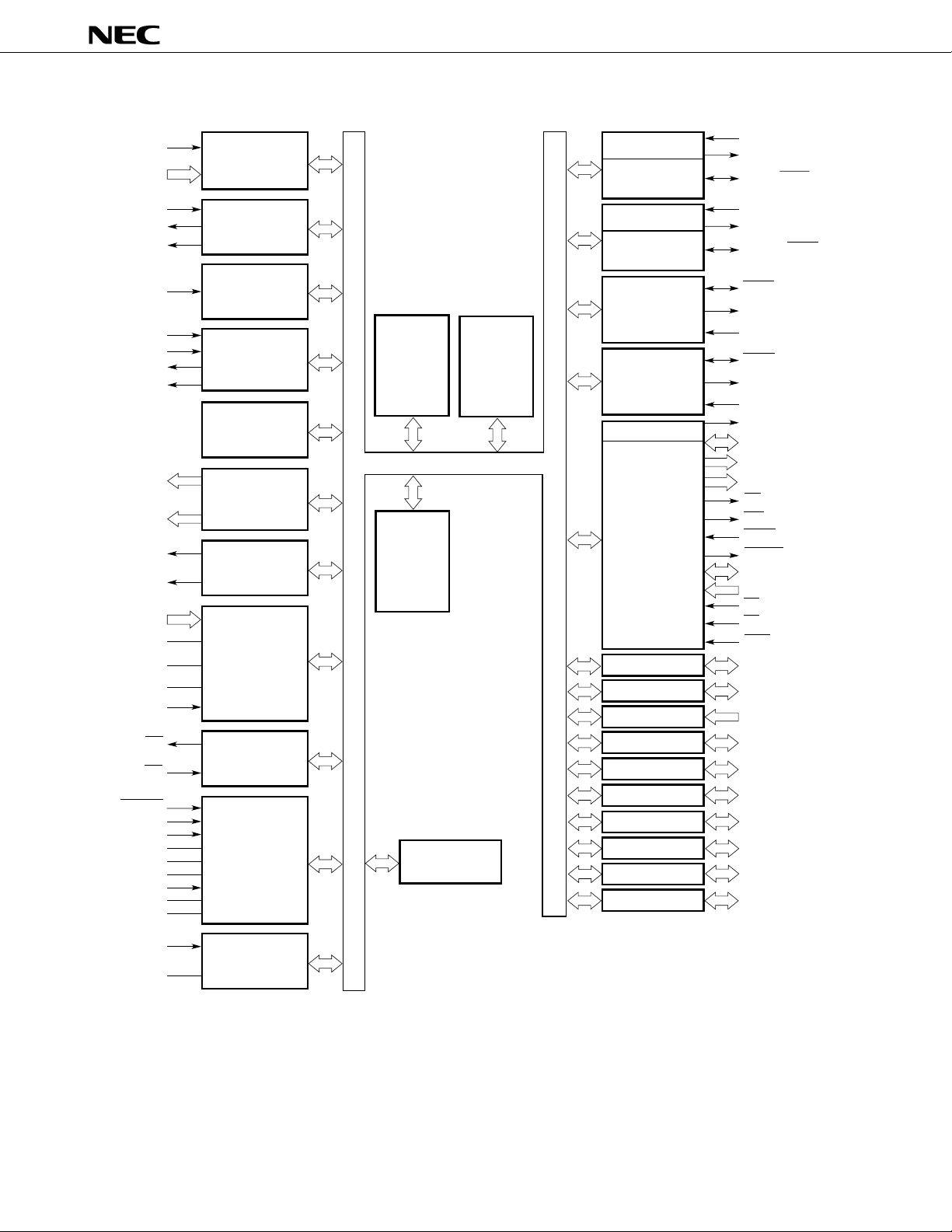

3. BLOCK DIAGRAM

µ

PD78P4908

NMI

INTP0-INTP5

INTP3

TO0

TO1

INTP0

INTP1

INTP2/CI

TO2

TO3

P00-P03

P04-P07

PWM0

PWM1

ANI0-ANI7

AVDD

AVREF1

AVSS

INTP5

TX

RX

RESET

TEST

X1

X2

REGC

REGOFF

Note

VPP

VDD

VSS

Programmable

interrupt controller

Timer/counter 0

(16 bits)

Timer/counter 1

(16 bits)

Timer/counter 2

(16 bits)

Timer 3

(16 bits)

Real-time output

port

PWM

A/D converter

IEBus controller

System control

(regulator)

78K/IV

CPU core

(RAM 512 bytes)

RAM

(3,840 bytes)

Watchdog timer

ROM

(128 Kbytes)

UART/IOE2

Baud-rate

generator

UART/IOE1

Baud-rate

generator

Clocked serial

interface

Clocked serial

interface 3

Clock output

Bus interface

Port 0

Port 1

Port 2

Port 3

Port 4

Port 5

Port 6

Port 7

Port 9

Port 10

RxD/SI1

TxD/SO1

ASCK/SCK1

RxD2/SI2

TxD2/SO2

ASCK2/SCK2

SCK0

SO0

SI0

SCK3

SO3

SI3

ASTB/CLKOUT

AD0-AD7

A8-A15

A16-A19

RD

WR

WAIT/HLDRQ

REFRQ/HLDAK

Note

D0-D7

Note

A0-A16

Note

CE

Note

OE

Note

PGM

P00-P07

P10-P17

P20-P27

P30-P37

P40-P47

P50-P57

P60-P67

P70-P77

P90-P97

P100-P107

XT1

Watch timer

XT2

Note In the PROM programming mode.

10

Data Sheet U11681EJ2V0DS00

Page 11

4. PIN FUNCTIONS

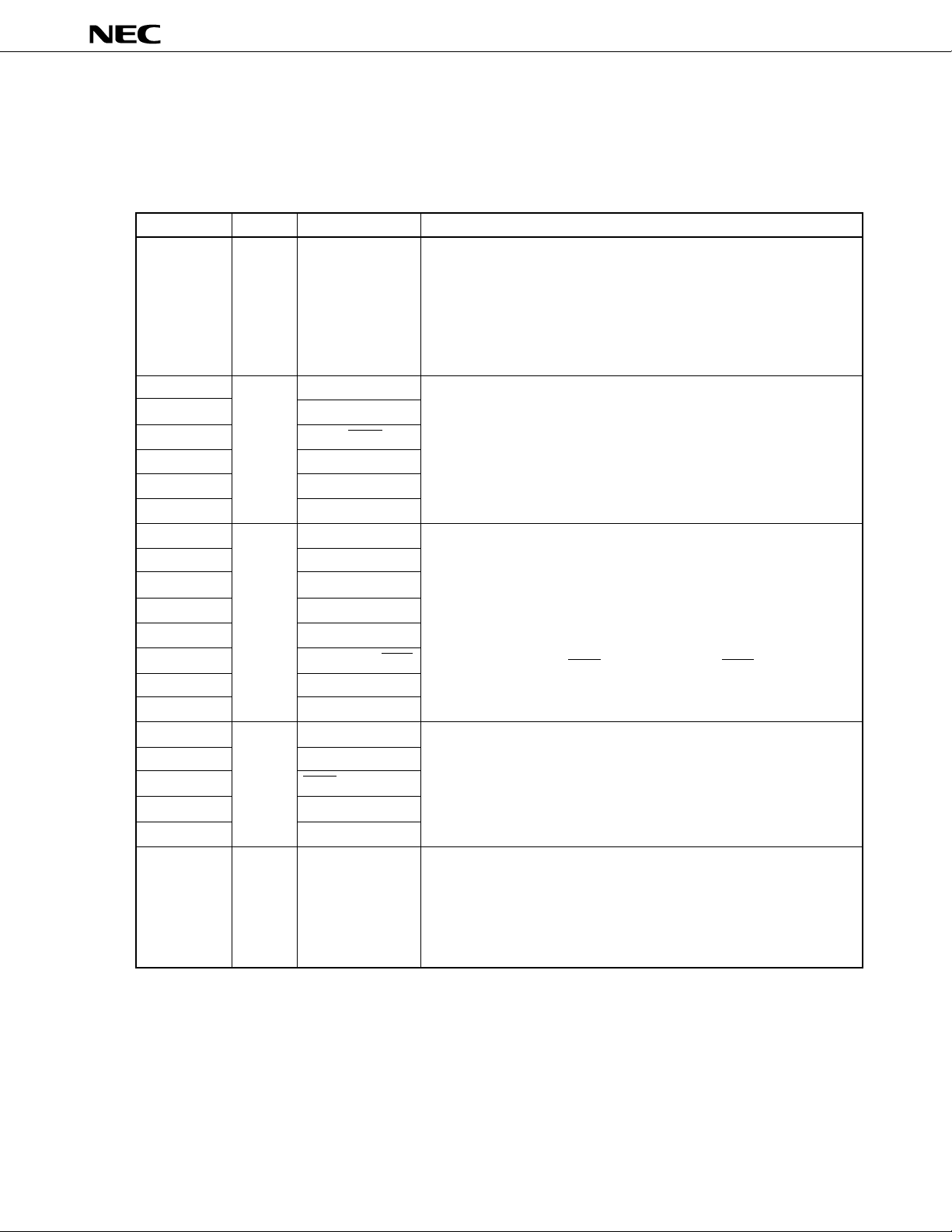

4.1 PINS FOR NORMAL OPERATING MODE

(1) Port pins (1/2)

µ

PD78P4908

Pin

P00-P07

P10

P11

P12

P13

P14

P15-P17

P20

P21

P22

P23

P24

P25

P26

P27

P30

P31

P32

P33

P34-P37

P40-P47

I/O

I/O

Input

I/O

I/O

I/O

Also used as

—

—

—

ASCK2/SCK2

RxD2/SI2

TxD2/SO2

—

NMI

INTP0

INTP1

INTP2/CI

INTP3

INTP4/ASCK/SCK1

INTP5

SI0

RxD/SI1

TxD/SO1

SCK0

SO0

TO0-TO3

AD0-AD7

Function

Port 0 (P0):

• 8-bit I/O port.

• Functions as a real-time output port (4 bits × 2).

• Inputs and outputs can be specified bit by bit.

• The use of built-in pull-up resistors can be simultaneously specified by

software for all pins in input mode.

• Can drive a transistor.

Port 1 (P1):

• 8-bit I/O port.

• Inputs and outputs can be specified bit by bit.

• The use of built-in pull-up resistors can be simultaneously specified by

software for all pins in input mode.

• Can drive LED.

Port 2 (P2):

• 8-bit input-only port.

• P20 does not function as a general-purpose port (nonmaskable

interrupt). However, the input level can be checked by an interrupt

service routine.

• The use of built-in pull-up resistors can be specified by software for pins

P22 to P27 (in units of 6 bits).

• The P25/INTP4/ASCK/SCK1 pin functions as the SCK1 input/output pin

by CSIM1.

Port 3 (P3):

• 8-bit I/O port.

• Inputs and outputs can be specified bit by bit.

• The use of built-in pull-up resistors can be simultaneously specified by

software for all pins in input mode.

• P32 and P33 can be set as the N-ch open-drain pin.

Port 4 (P4):

• 8-bit I/O port.

• Inputs and outputs can be specified bit by bit.

• The use of built-in pull-up resistors can be simultaneously specified by

software for all pins in input mode.

• Can drive LED.

Data Sheet U11681EJ2V0DS00

11

Page 12

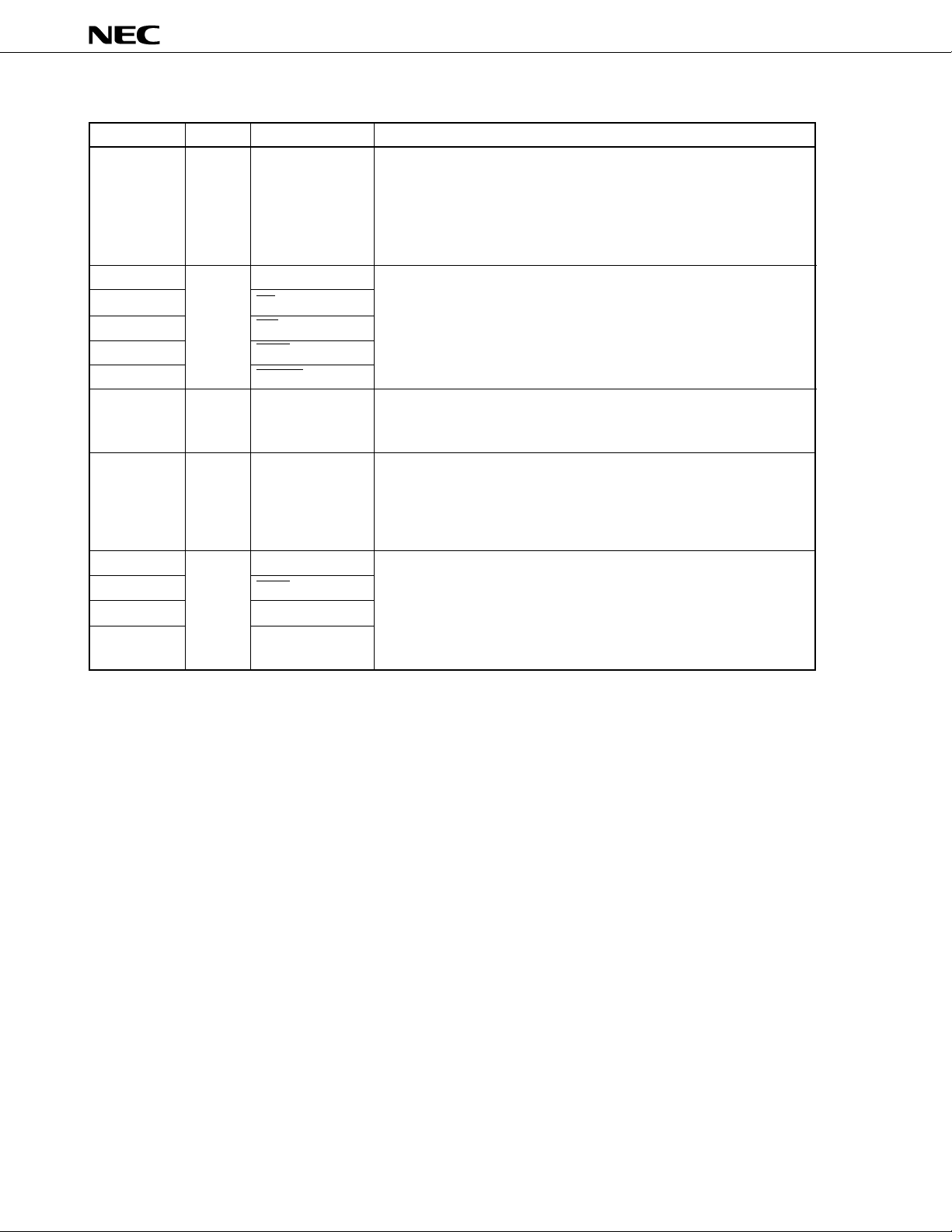

(1) Port pins (2/2)

µ

PD78P4908

Pin

P50-P57

P60-P63

P64

P65

P66

P67

P70-P77

P90-P97

P100-P104

P105

P106

P107

I/O

I/O

I/O

I/O

I/O

I/O

Also used as

A8-A15

A16-A19

RD

WR

WAIT/HLDRQ

REFRQ/HLDAK

ANI0-ANI7

—

—

SCK3

SI3

SO3

Function

Port 5 (P5):

• 8-bit I/O port.

• Inputs and outputs can be specified bit by bit.

• The use of built-in pull-up resistors can be simultaneously specified by

software for all pins in input mode.

• Can drive LED.

Port 6 (P6):

• 8-bit I/O port.

• Inputs and outputs can be specified bit by bit.

• The use of built-in pull-up resistors can be simultaneously specified by

software for all pins in input mode.

Port 7 (P7):

• 8-bit I/O port.

• Inputs and outputs can be specified bit by bit.

Port 9 (P9):

• 8-bit I/O port.

• Inputs and outputs can be specified bit by bit.

• The use of built-in pull-up resistors can be simultaneously specified by

software for all pins in input mode.

Port 10 (P10):

• 8-bit I/O port.

• Inputs and outputs can be specified bit by bit.

• The use of built-in pull-up resistors can be simultaneously specified by

software for all pins in input mode.

• P105 and P107 can be set as the N-ch open-drain pin.

12

Data Sheet U11681EJ2V0DS00

Page 13

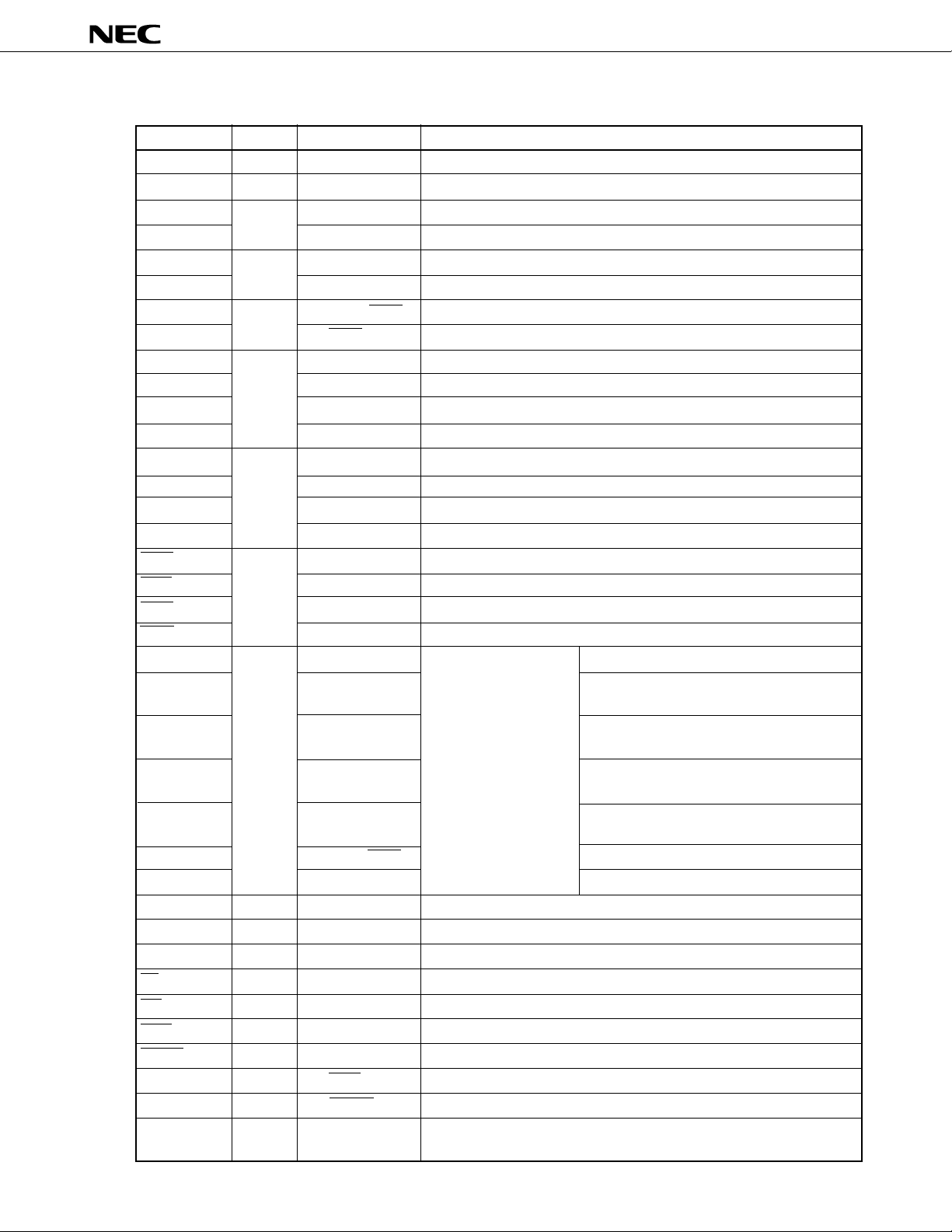

(2) Non-port pins (1/2)

µ

PD78P4908

Pin

TO0-TO3

CI

RxD

RxD2

TxD

TxD2

ASCK

ASCK2

SI0

SI1

SI2

SI3

SO0

SO1

SO2

SO3

SCK0

SCK1

SCK2

SCK3

NMI

INTP0

INTP1

INTP2

INTP3

INTP4

INTP5

AD0-AD7

A8-A15

A16-A19

RD

WR

WAIT

REFRQ

HLDRQ

HLDAK

ASTB

I/O

Output

Input

Input

Output

Input

Input

Output

I/O

Input

I/O

Output

Output

Output

Output

Input

Output

Input

Output

Output

Also used as

P34-P37

P23/INTP2

P30/SI1

P13/SI2

P31/SO1

P14/SO2

P25/INTP4/SCK1

P12/SCK2

P27

P30/RxD

P13/RxD2

P106

P33

P31/TxD

P14/TxD2

P107

P32

P25/INTP4/ASCK

P12/ASCK2

P105

P20

P21

P22

P23/CI

P24

P25/ASCK/SCK1

P26

P40-P47

P50-P57

P60-P63

P64

P65

P66/HLDRQ

P67/HLDAK

P66/WAIT

P67/REFRQ

CLKOUT

Function

Timer output

Input of a count clock for timer/counter 2

Serial data input (UART0)

Serial data input (UART2)

Serial data output (UART0)

Serial data output (UART2)

Baud rate clock input (UART0)

Baud rate clock input (UART2)

Serial data input (3-wire serial I/O 0)

Serial data input (3-wire serial I/O 1)

Serial data input (3-wire serial I/O 2)

Serial data input (3-wire serial I/O 3)

Serial data output (3-wire serial I/O 0)

Serial data output (3-wire serial I/O 1)

Serial data output (3-wire serial I/O 2)

Serial data output (3-wire serial I/O 3)

Serial clock I/O (3-wire serial I/O 0)

Serial clock I/O (3-wire serial I/O 1)

Serial clock I/O (3-wire serial I/O 2)

Serial clock I/O (3-wire serial I/O 3)

External interrupt request —

• Input of a count clock for timer/counter 1

• Capture/trigger signal for CR11 or CR12

• Input of a count clock for timer/counter 2

• Capture/trigger signal for CR22

• Input of a count clock for timer/counter 2

• Capture/trigger signal for CR21

• Input of a count clock for timer/counter 0

• Capture/trigger signal for CR02

—

Input of a conversion start trigger for A/D converter

Time multiplexing address/data bus (for connecting external memory)

High-order address bus (for connecting external memory)

High-order address during address expansion (for connecting external memory)

Strobe signal output for reading the contents of external memory

Strobe signal output for writing on external memory

Wait signal insertion

Refresh pulse output to external pseudo static memory

Input of bus hold request

Output of bus hold response

Latch timing output of time multiplexing address (A0-A7) (for connecting

external memory)

Data Sheet U11681EJ2V0DS00

13

Page 14

(2) Non-port pins (2/2)

µ

PD78P4908

Pin

CLKOUT

PWM0

PWM1

RX

TX

REGC

REGOFF

RESET

X1

X2

XT1

XT2

ANI0-ANI7

AV

REF1

AVDD

AVSS

VDD

VSS

TEST

I/O

Output

Output

Output

Input

Output

—

—

Input

Input

—

Input

—

Input

—

Input

Also used as

ASTB

P70-P77

—

—

—

—

—

—

—

—

—

—

—

Function

Clock output

PWM output 0

PWM output 1

Data input (IEBus)

Data output (IEBus)

Capacitor connection for stabilizing the regulator output/Power supply

when the regulator is stopped. Connect to V

Signal for specifying regulator operation. Directly connect to VSS (regulator

selected).

Chip reset

Crystal input for system clock oscillation (A clock pulse can also be input

to the X1 pin.)

Real-time clock connection

Analog voltage inputs for the A/D converter

Application of A/D converter reference voltage

Positive power supply for the A/D converter

Ground for the A/D converter

Positive power supply

Ground

Directly connect to V

SS. (The TEST pin is for the IC test.)

SS via a 1-

µ

F capacitor.

4.2 PINS FOR PROM PROGRAMMING MODE (VPP ≥ +5 V or +12.5 V, RESET = L)

4.2.1 Pin Functions

Pin name

V

PP

RESET

A0-A16

D0-D7

CE

OE

PGM

V

DD

VSS

Input

I/O

Input

I/O

—

—

—

PROM programming mode selection

High voltage input during program write or verification

PROM programming mode selection

Address bus

Data bus

PROM enable input/program pulse input

Read strobe input to PROM

Program/program inhibit input during PROM programming mode

Positive power supply

GND

Function

14

Data Sheet U11681EJ2V0DS00

Page 15

4.2.2 Pin Functions

(1) V

PP (Programming power supply): Input

µ

Input pin for setting the

+6.5 V or more and when RESET input goes low, the

When CE is made low for V

PD78P4908 to the PROM programming mode. When the input voltage on this pin is

µ

PD78P4908 enters the PROM programming mode.

PP = +12.5 V and OE = high, program data on D0 to D7 can be written into the internal

PROM cell selected by A0 to A16.

(2) RESET (Reset): Input

µ

Input pin for setting the

the input voltage on the V

PD78P4908 to the PROM programming mode. When input on this pin is low, and when

PP pin goes +5 V or more, the

µ

PD78P4908 enters the PROM programming mode.

(3) A0 to A16 (Address bus): Input

Address bus that selects an internal PROM address (0000H to 1FFFFH)

(4) D0 to D7 (Data bus): I/O

Data bus through which a program is written on or read from internal PROM

µ

PD78P4908

(5) CE (Chip enable): Input

This pin inputs the enable signal from internal PROM. When this signal is active, a program can be written or

read.

(6) OE (Output enable): Input

This pin inputs the read strobe signal to internal PROM. When this signal is made active for CE = low, a onebyte program in the internal PROM cell selected by A0 to A16 can be read onto D0 to D7.

(7) PGM (Program): Input

The input pin for the operation mode control signal of the internal PROM.

Upon activation, writing to the internal PROM is enabled.

Upon inactivation, reading from the internal PROM is enabled.

DD

(8) V

Positive power supply pin

(9) V

SS

Ground potential pin

Data Sheet U11681EJ2V0DS00

15

Page 16

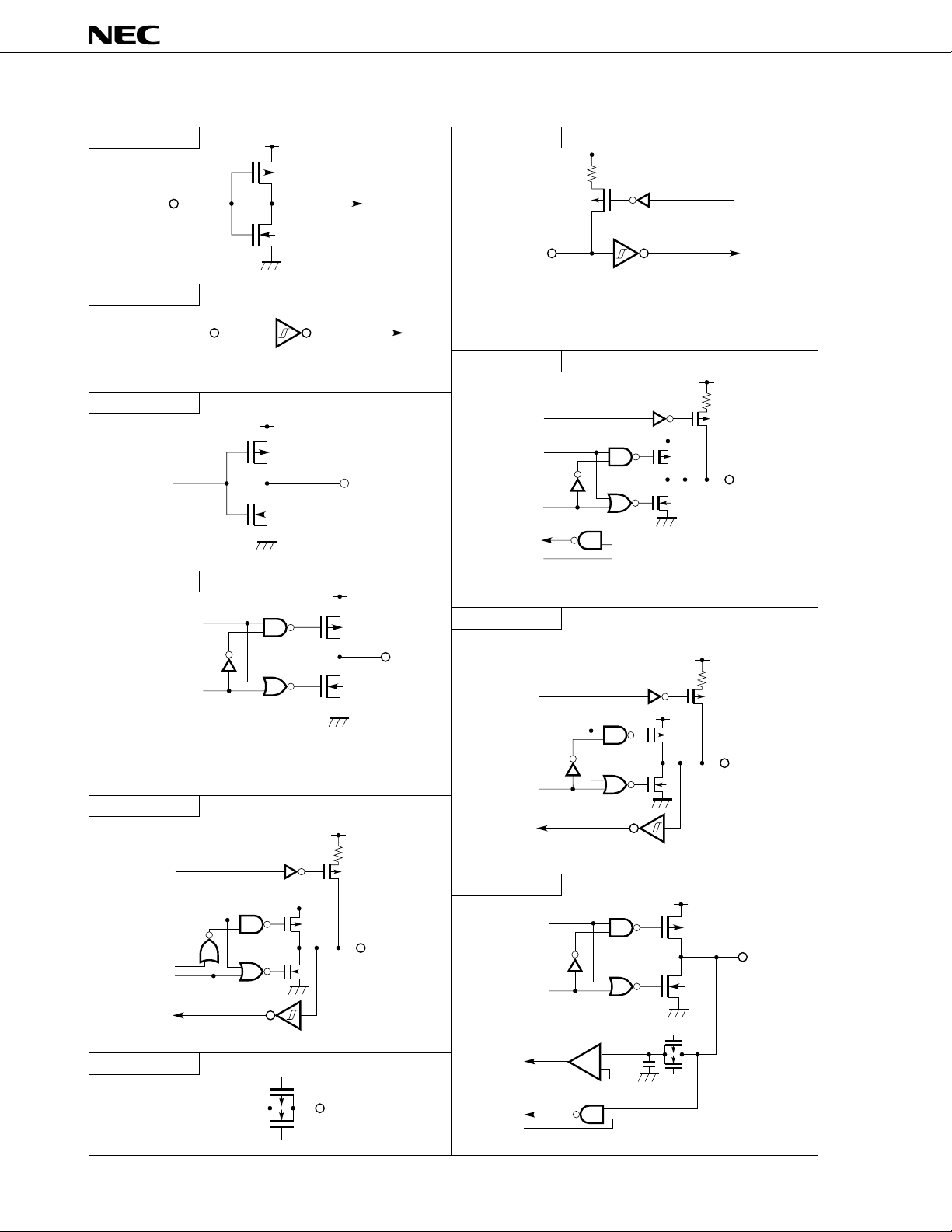

4.3 I/O CIRCUITS FOR PINS AND HANDLING OF UNUSED PINS

Table 4-1 describes the types of I/O circuits for pins and the handling of unused pins.

Figure 4-1 shows the configuration of these various types of I/O circuits.

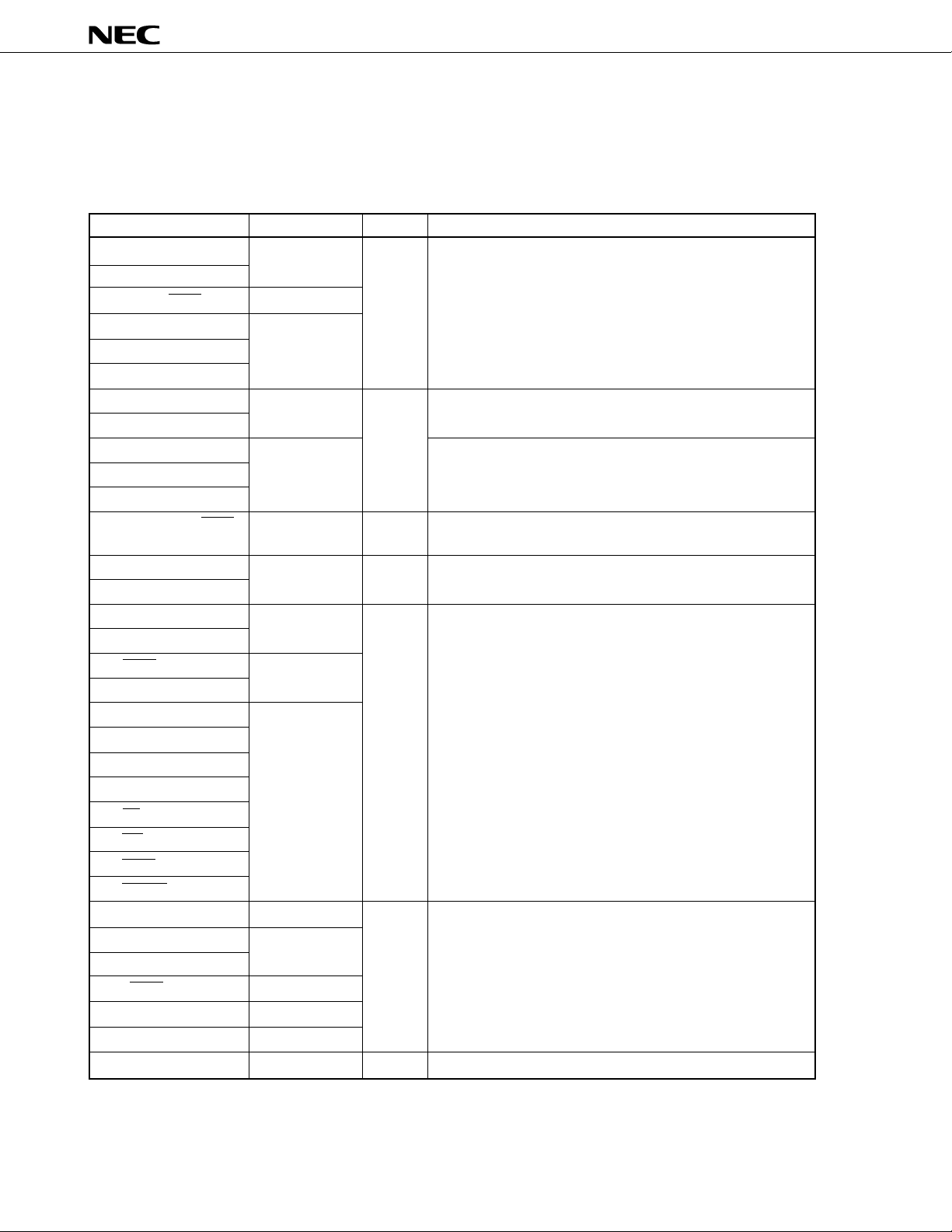

Table 4-1. Types of I/O Circuits for Pins and Handling of Unused Pins (1/2)

µ

PD78P4908

Pin

P00-P07

P10, P11

P12/ASCK2/SCK2

P13/RXD2/SI2

P14/TXD2/SO2

P15-P17

P20/NMI

P21/INTP0

P22/INTP1

P23/INTP2/CI

P24/INTP3

P25/INTP4/ASCK/SCK1

P26/INTP5

P27/SI0

P30/R

XD/SI1

P31/TXD/SO1

P32/SCK0

P33/SO0

P34/TO0-P37/TO3

P40/AD0-P47/AD7

P50/A8-P57/A15

P60/A16-P63/A19

P64/RD

P65/WR

P66/WAIT/HLDRQ

P67/REFRQ/HLDAK

P70/ANI0-P77/ANI7

P90-P97

P100-P104

P105/SCK3

P106/SI3

P107/SO3

ASTB/CLKOUT

I/O circuit type

5-A

8-A

5-A

2

2-A

8-A

2-A

5-A

10-A

5-A

20

5-A

10-A

8-A

10-A

4

I/O

I/O

Input

I/O

Input

I/O

I/O

Output

Recommended connection method for unused pins

Input state: To be connected to VDD

Output state: To be left open

To be connected to VDD or VSS

To be connected to VDD

Input state: To be connected to VDD

Output state: To be left open

To be connected to VDD

Input state: To be connected to VDD

Output state: To be left open

Input state: To be connected to V

Output state : To be left open

To be left open

DD or VSS

16

Data Sheet U11681EJ2V0DS00

Page 17

µ

PD78P4908

Table 4-1. Types of I/O Circuits for Pins and Handling of Unused Pins (2/2)

Pin

RESET

TEST

XT2

XT1

PWM0, PWM1

RX

TX

AV

REF1

AVSS

AVDD

I/O circuit type

2

1

—

3

1

3

—

I/O

Input

—

Input

Output

Input

Output

—

Caution When the I/O mode of an I/O dual-function pin is unpredictable, connect the pin to V

Recommended connection method for unused pins

—

To be connected to V

To be left open

To be connected to VSS

To be left open

To be connected to VDD or VSS

To be left open

To be connected to VSS

To be connected to VDD

SS directly

DD through

a resistor of 10 to 100 kΩ (particularly when the voltage of the reset input pin becomes higher

than that of the low level input at power-on or when I/O is switched by software).

Remark Since type numbers are consistent in the 78K series, those numbers are not always serial in each product.

(Some circuits are not included.)

Data Sheet U11681EJ2V0DS00

17

Page 18

Figure 4-1. I/O Circuits for Pins

Data

V

DD

P

N

IN/OUT

Output

disable

VDD

P

Pull-up

enable

Input

enable

Data

V

DD

P

N

IN/OUT

Output

disable

VDD

P

Pull-up

enable

µ

PD78P4908

Type 1

VDD

P

IN

N

Type 2

IN

Schmitt trigger input with hysteresis characteristics

Type 3

V

DD

P-ch

Data OUT

N-ch

Type 4

VDD

Data

P

Type 2-A

VDD

P

Pull-up

enable

IN

Schmitt trigger input with hysteresis characteristics

Type 5-A

Type 8-A

Output

disable

Push-pull output which can output high impedance

(both the positive and negative channels are off.)

Type 10-A

Pull-up

enable

Data

P

Open

drain

Output

N

disable

Type 12

Analog output

voltage

P

N

18

OUT

N

VDD

P

Type 20

V

V

DD

Data

IN/OUT

Output

disable

DD

P

IN/OUT

N

Comparator

P

N

OUT

+

–

(Threshold voltage)

VREF

Input

enable

Data Sheet U11681EJ2V0DS00

Page 19

µ

PD78P4908

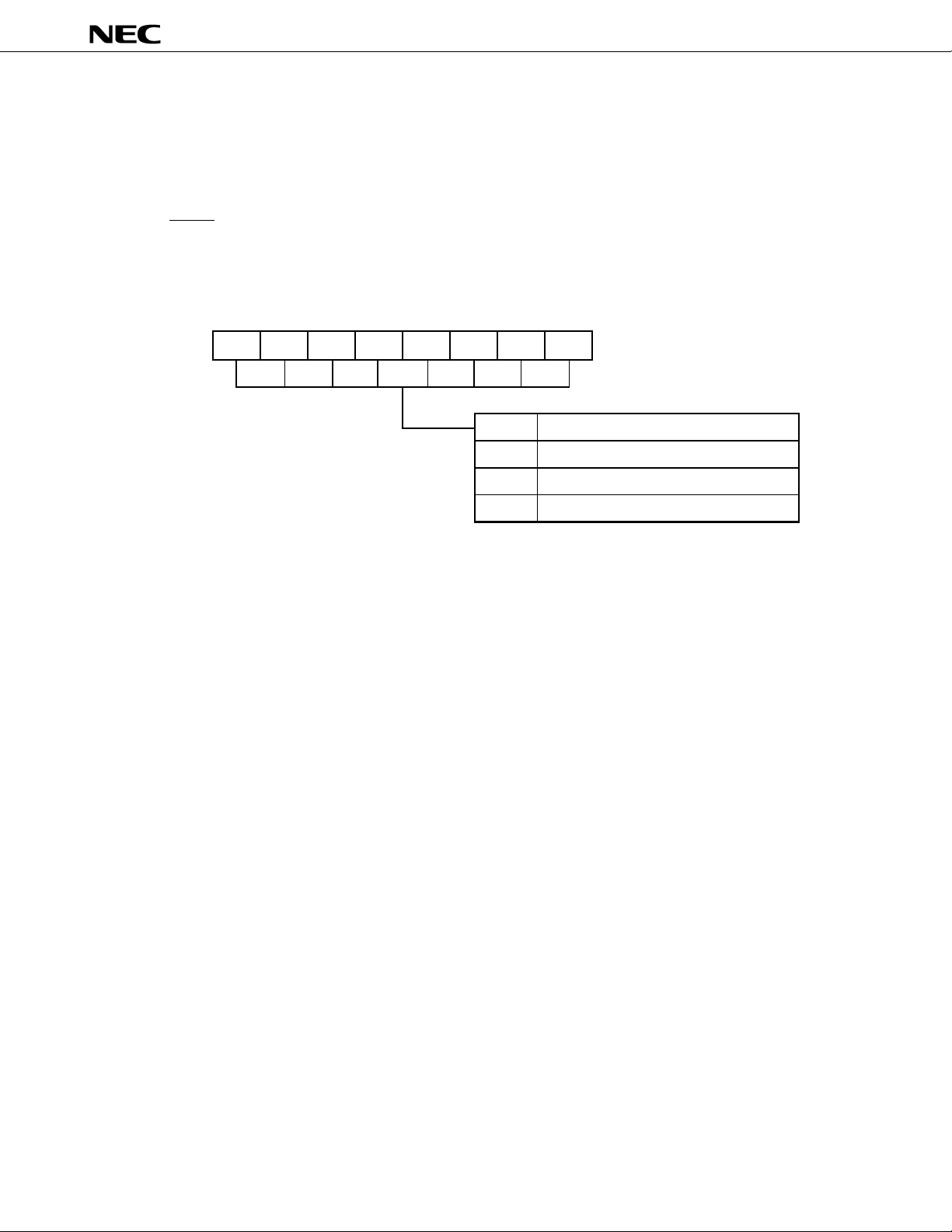

5. INTERNAL MEMORY SIZE SELECT REGISTER (IMS)

This register enables the software to avoid using part of the internal memory. The IMS can be set to establish

the same memory mapping as used in mask ROM products that have different internal memory (ROM and RAM)

configurations.

The IMS is set using 8-bit memory operation instructions.

A RESET input sets the IMS to FFH.

Figure 5-1. Internal Memory Size Select Register (IMS)

76543210

IMS IMS7 IMS6

The IMS is not contained in a mask ROM product (

IMS5

IMS4 IMS3 IMS2 IMS1 IMS0

IMS0-7

FFH

EEH

Other than

the above

µ

PD784907 or µPD784908). But the action is not affected if

Same as the PD784908

Same as the PD784907

Not to be set

the write command to the IMS is executed to the mask ROM product.

Address

0FFFCH

Memory size

µ

µ

Reset valueWR/W

FFH

Data Sheet U11681EJ2V0DS00

19

Page 20

µ

PD78P4908

6. PROM PROGRAMMING

The µPD78P4908 has an on-chip 128-KB PROM device for use as program memory. When programming, set

PP and RESET pins for PROM programming mode. See 2. PIN CONFIGURATION (TOP VIEW) (2) PROM

the V

programming mode with regard to handling of other, unused pins.

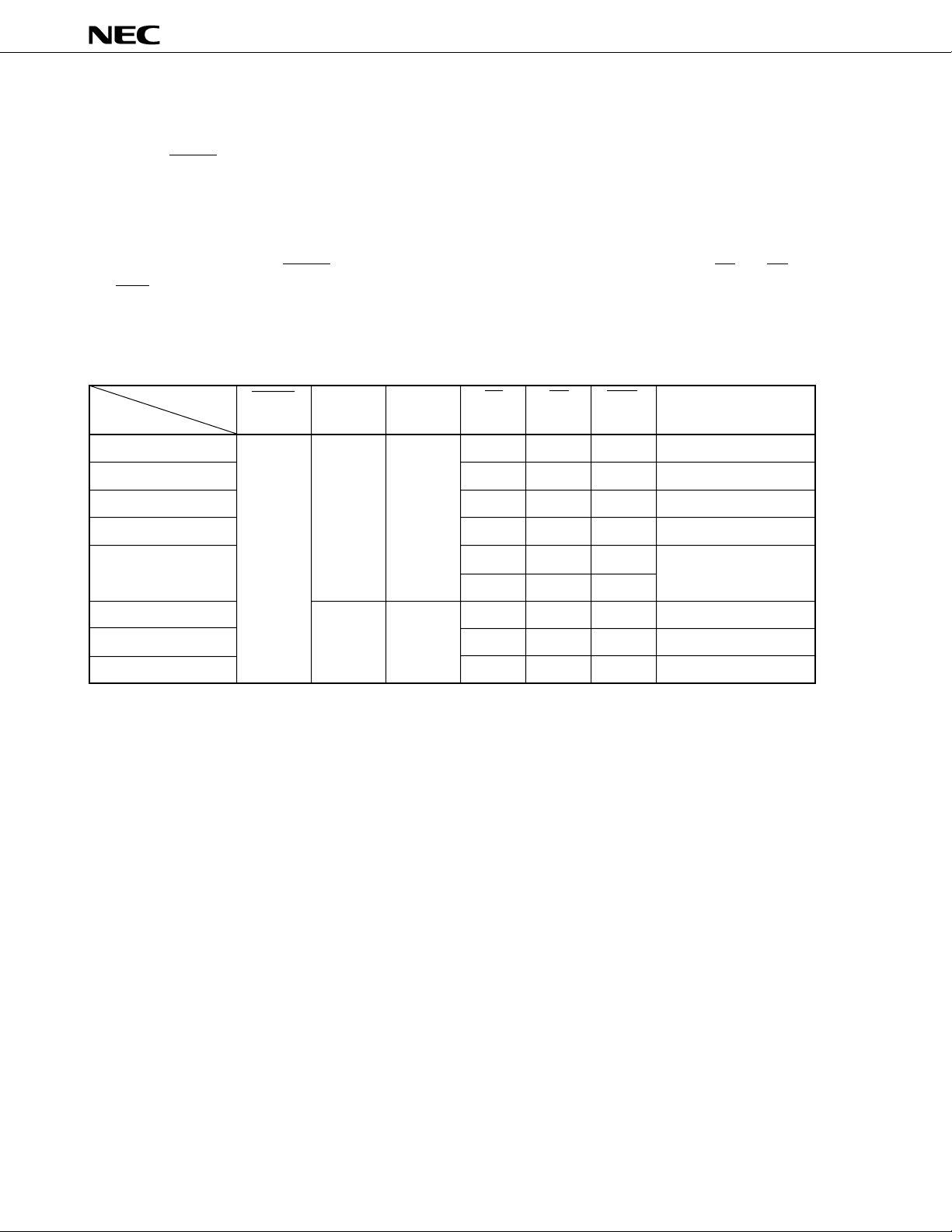

6.1 OPERATION MODE

PROM programming mode is selected when +6.5 V is added to the V

low-level input is added to the RESET pin. This mode can be set to operation mode by setting the CE pin, OE pin,

and PGM pin as shown in Table 6-1 below.

In addition, the PROM contents can be read by setting read mode.

Table 6-1. PROM Programming Operation Mode

Pin RESET VPP VDD CE OE PGM D0-D7

Operation mode

Page data latch L +12.5 V +6.5 V H L H Data input

Page write H H L High impedance

DD pin, +12.5 V is added to the VPP pin, or

Byte write L H L Data input

Program verify L L H Data output

Program inhibit × H H High impedance

× LL

Read +5 V +5 V L L H Data output

Output disable L H × High impedance

Standby H ×× High impedance

Remark × = L or H

20

Data Sheet U11681EJ2V0DS00

Page 21

µ

PD78P4908

(1) Read mode

Set CE to L and OE to L to set read mode.

(2) Output disable mode

Set OE to H to set high impedance for data output and output disable mode.

µ

Consequently, if several

select data output from any of the devices.

(3) Standby mode

Set CE to H to set standby mode.

In this mode, data output is set to high impedance regardless of the OE setting.

(4) Page data latch mode

At the beginning of page write mode, set CE to H, PGM to H, and OE to L to set page data latch mode.

In this mode, 1 page (4 bytes) of data are latched to the internal address/data latch circuit.

(5) Page write mode

After latching the address and data for one page (4 bytes) using page data latch mode, adding a 0.1 ms program

pulse (active, low) to the PGM pin with both CE and OE set to H causes page write to be executed. Later, setting

both CE and OE to L causes program verification to be executed.

If programming is not completed after one program pulse, the write and verify operations may be repeated X times

(where X ≤ 10).

PD78P4908 devices are connected to a data bus, the OE pins can be controlled to

(6) Byte write mode

Adding a 0.1 ms program pulse (active, low) to the PGM pin with setting CE to L and OE to H causes byte write

to be executed. Later, setting OE to L causes program verification to be executed.

If programming is not completed after one program pulse, the write and verify operations may be repeated X times

(where X ≤ 10).

(7) Program verify mode

Set CE to L, PGM to H, and OE to L to set program verify mode. Use verify mode for verification following each

write operation.

(8) Program inhibit mode

µ

Program inhibit mode is used to write to a single device when several

parallel to OE , V

Use the page write mode or byte write mode described above for each write operation. Write operations cannot

be done for devices in which the PGM pin has been set to H.

PP, and D0 to D7 pins.

PD78P4908 devices are connected in

Data Sheet U11681EJ2V0DS00

21

Page 22

6.2 PROM WRITE SEQUENCE

Figure 6-1. Page Program Mode Flowchart

Start

Address = G

DD = +6.5 V, VPP = +12.5 V

V

X = 0

Latch

Address = Address + 1

Latch

Address = Address + 1

µ

PD78P4908

Address = Address + 1

Latch

Address = Address + 1

Latch

X = X + 1

0.1 ms program pulse

Verify 4 bytes

No

Pass

Address = N ?

DD = 4.0 to 5.5 V, VPP = VDD

V

Verify all bytes

Pass

Yes

All pass

Fail

Fail

No

X = 10 ?

Yes

Remark G = Start address

N = Program end address

22

Write end

Data Sheet U11681EJ2V0DS00

Defective

Page 23

Figure 6-2. Page Program Mode Timing

µ

PD78P4908

A2-A16

A0, A1

D0-D7

VPP

VDD

CE

Page data latch

Hi-Z Hi-Z

Data input Data output

PP

V

VDD

VDD + 1.5

DD

V

VIH

VIL

Page program Program verify

PGM

OE

VIH

VIL

VIH

VIL

Data Sheet U11681EJ2V0DS00

23

Page 24

Figure 6-3. Byte Program Mode Flowchart

Start

Address = G

DD = +6.5 V, VPP = +12.5 V

V

= 0

X

µ

PD78P4908

Address = Address + 1

Remark G = Start address

N = Program end address

= X + 1

X

0.1 ms program pulse

Verify

No

Pass

Address = N ?

V

DD = 4.0 to 5.5 V, VPP = VDD

Verify all bytes

Write end Defective

Pass

Yes

All pass

Fail

Fail

X

= 10 ?

No

Yes

24

Data Sheet U11681EJ2V0DS00

Page 25

Figure 6-4. Byte Program Mode Timing

µ

PD78P4908

A0-A16

D0-D7

VPP

VDD

CE

Program

Hi-Z Hi-Z Hi-Z

V

PP

VDD

VDD + 1.5

V

DD

VIH

VIL

Data input Data output

Program verify

VIH

PGM

VIL

VIH

OE

VIL

Cautions 1. Add V

2. Do not allow V

3. Reliability problems may result if the device is inserted or pulled out while 12.5 V is applied

PP.

at V

DD before VPP, and turn off the VDD after VPP.

PP to exceed 13.5 V including overshoot.

Data Sheet U11681EJ2V0DS00

25

Page 26

6.3 PROM READ SEQUENCE

Follow this sequence to read the PROM contents to an external data bus (D0 to D7).

µ

PD78P4908

(1) Set the RESET pin to low level and add 5 V to the V

PP pin. See 2. PIN CONFIGURATION (TOP VIEW) (2) PROM

programming mode with regard to handling of other, unused pins.

(2) Add 5 V to the V

DD and VPP pins.

(3) Input the data address to be read to pins A0 to A16.

(4) Set read mode.

(5) Output the data to pins D0 to D7.

Figure 6-5 shows the timing of steps (2) to (5) above.

Figure 6-5. PROM Read Timing

A0-A16

CE (input)

OE (input)

Address input

D0-D7

Hi-Z Hi-Z

Data output

7. SCREENING ONE-TIME PROM PRODUCTS

NEC cannot execute a complete test of one-time PROM products (µPD78P4908GF-3BA) due to their structure

before shipment. It is recommended that you screen (verify) PROM products after writing necessary data into them

and storing them at 125°C for 24 hours.

26

Data Sheet U11681EJ2V0DS00

Page 27

µ

PD78P4908

8. ELECTRICAL CHARACTERISTICS

ABSOLUTE MAXIMUM RATINGS (TA = 25 °C)

Parameter Symbol Conditions Rating Unit

Supply voltage VDD –0.3 to +7.0 V

AVDD –0.3 to VDD + 0.3 V

AVSS –0.3 to +0.3 V

Input voltage VI1 For pins other than VPP, A9 –0.3 to VDD + 0.3 V

VI2 VPP, A9 –0.3 to +13.5 V

Analog input voltage VAN AVSS – 0.3 to AVREF1 + 0.3 V

Output voltage VO –0.3 to VDD + 0.3 V

Output low current I OL One pin 10 mA

Total for the P00-P07, P30- 50 mA

P37, P54-P57, P60-P67, and

P100-P107 pins

Total for the P10-P17, P40- 50 mA

P47, P50-P53, P70-P77,

P90-P97, PWM0, PWM1,

and TX pins

Output high current IOH One pin –6 mA

Total for the P00-P07, P30- –30 mA

P37, P54-P57, P60-P67, and

P100-P107 pins

Total for the P10-P17, P40- –30 mA

P47, P50-P53, P70-P77,

P90-P97, PWM0, PWM1,

and TX pins

A/D converter reference input AVREF1 –0.3 to VDD + 0.3 V

voltage

Operating ambient temperature TA –40 to +85 °C

Storage temperature Tstg –65 to +150 °C

Caution Absolute maximum ratings are rated values beyond which physical damage will be caused to

the product; if the rated value of any of the parameters in the above table is exceeded, even

momentarily, the quality of the product may deteriorate. Always use the product within its rated

values.

Remark Unless otherwise stated, the characteristics of a dual-function pin are the same as those of a port pin.

Data Sheet U11681EJ2V0DS00

27

Page 28

OPERATING CONDITIONS

• Operating ambient temperature (T

A): –40 °C to +85 °C

• Power supply voltage and clock cycle time: See Figure 8-1.

• Internal regulator operation selected (REGOFF pin: low level)

Figure 8-1. Power Supply Voltage and Clock Cycle Time

10,000

4,000

µ

PD78P4908

CAPACITANCE (T

Parameter

Input capacitance

Output capacitance

I/O capacitance

1,000

159

100

79

Clock cycle time tCYK [ns]

10

01234567

A = 25 °C, VDD = VSS = 0 V)

Symbol

C

I

CO

CIO

f = 1 MHz

0 V on pins other than measured pins

Guaranteed

operating

range

Power supply voltage [V]

Conditions

MIN. TYP. MAX.

15

15

15

Unit

pF

pF

pF

28

Data Sheet U11681EJ2V0DS00

Page 29

µ

PD78P4908

MAIN OSCILLATOR CHARACTERISTICS (TA = –40 °C to +85 °C, VDD = 4.0 to 5.5 V, VSS = 0 V)

Parameter

Oscillator frequency

fXX

Symbol

Conditions

Ceramic or crystal resonator

MIN.

2

MAX.

12.58

Caution When using the clock generator, run wires according to the following rules to avoid effects such

as stray capacitance:

• Minimize the wiring length.

• Never cause the wires to cross other signal lines.

• Never cause the wires to run near a line carrying a large varying current.

• The grounding point of the capacitor of the oscillator circuit must always be the same potential

SS1. Never connect the capacitor to a ground pattern carrying a large current.

as V

• Never extract a signal from the oscillator.

Remark Connect a 12.582912 or 6.291456 MHz oscillator to operate the internal clock timer with the main clock.

CLOCK OSCILLATOR CHARACTERISTICS (T

Parameter

Oscillator frequency

Oscillation settling time

Oscillation hold voltage

Watch timer operating

voltage

Symbol

fXT

tSXT

VDDXT

VDDW

Ceramic or crystal resonator

VDD = 4.5 to 5.5 V

A = –40 °C to +85 °C, VDD = 4.0 to 5.5 V, VSS = 0 V)

Conditions

MIN.

32

4.0

4.0

TYP.

32.768

1.2

MAX.

35

2

10

5.5

5.5

Unit

MHz

Unit

kHz

s

s

V

V

Data Sheet U11681EJ2V0DS00

29

Page 30

µ

DC CHARACTERISTICS (TA = –40 °C to +85 °C, VDD = AVDD = 4.0 to 5.5 V, VSS = AVSS = 0 V) (1/2)

PD78P4908

Parameter

Input low voltage

Input high voltage

Output low voltage

Output high voltage

Note 5

Symbol

VIL1

VIL2

VIL3

VIH1

VIH2

VIH3

VOL1

VOL2

VOH1

VOH2

Conditions

For pins other than those described in

Notes 1 and 2

For pins described in Note 1

VDD = 4.5 to 5.5 V

For pins described in Note 2

For pins other than those described in

Notes 1 and 2

For pins described in Note 1

V

DD = 4.5 to 5.5 V

For pins described in Note 2

IOL = 20 µA

IOL = 100 µA

IOL = 2 mA

IOL = 8 mA

For pins described in Note 4

VDD = 4.5 to 5.5 V

IOH = -20 µA

IOH = -100 µA

IOH = -2 mA

VDD = 4.5 to 5.5 V

IOH = -5 mA

For pins described in Note 3

MIN.

–0.3

–0.3

–0.3

DD

0.7 V

0.8 VDD

2.2

VDD – 0.1

VDD – 0.2

VDD – 1.0

VDD – 2.4

TYP. MAX.

0.3 V

0.2 VDD

+0.8

VDD + 0.3

DD + 0.3

V

VDD + 0.3

0.1

0.2

0.4

1.0

Unit

DD

V

V

V

V

V

V

V

V

V

V

V

V

V

V

Notes 1. X1, X2, RESET, P12/ASCK2/SCK2, P20/NMI, P21/INTP0, P22/INTP1, P23/INTP2/CI, P24/INTP3,

P25/INTP4/ASCK/SCK1, P26/INTP5, P27/SI0, P32/SCK0, P33/SO0, P105/SCK3, P106/SI3,

P107/SO3, XT1, XT2

2. P40/AD0-P47/AD7, P50/A8-P57/A15, P60/A16-P67/REFRQ/HLDAK, P00-P07

3. P00-P07

4. P10-P17, P40/AD0-P47/AD7, P50/A8-P57/A15

5. Other than pull-up resistors

30

Data Sheet U11681EJ2V0DS00

Page 31

µ

PD78P4908

DC CHARACTERISTICS (TA = –40 °C to +85 °C, VDD = AVDD = 4.0 to 5.5 V, VSS = AVSS = 0 V) (2/2)

Parameter

Input leakage current

Output leakage current

V

DD supply current

Pull-up resistor

Note

Symbol

LI1

I

ILI2

ILO

IDD1

IDD2

IDD3

RL

Conditions

0 V ≤ VI ≤ VDD For pins other than

X1 and XT1

X1, XT1

0 V ≤ V

O ≤ VDD

Operation mode fXX = 12.58 MHz

VDD = 4.5 to 5.5 V

fXX = 6.29 MHz

VDD = 4.0 to 5.5 V

HALT mode fXX = 12.58 MHz

VDD = 4.5 to 5.5 V

fCLK = fXX/8

(STBC = B1H)

Peripheral operation

stops.

fXX = 6.29 MHz

VDD = 4.0 to 5.5 V

fCLK = fXX/8

(STBC = 31H)

Peripheral operation

stops.

IDLE mode fXX = 12.58 MHz

VDD = 4.5 to 5.5 V

fXX = 6.29 MHz

VDD = 4.0 to 5.5 V

VI = 0 V

MIN.

15

TYP.

20

10

5.2

2.6

2.4

1.8

MAX.

±10

±20

±10

40

20

10.4

5.2

4.8

3.6

80

Unit

µ

µ

µ

mA

mA

mA

mA

mA

mA

kΩ

A

A

A

Note These values are valid when the internal regulator is ON (REGOFF pin = low level). They do not include

DD and AVREF1 currents.

the AV

Data Sheet U11681EJ2V0DS00

31

Page 32

AC CHARACTERISTICS (TA = –40°C to +85°C, VDD = AVDD = 4.0 to 5.5 V, AVSS = VSS = 0 V)

(1) Read/write operation

µ

PD78P4908

Parameter

Address setup time

(to ASTB↓)

ASTB high-level width

Address hold time (to ASTB↓)

Address hold time (to RD↑)

Delay from address to RD↓

Address float time (to RD↓)

Delay from address to data

input

Delay from ASTB↓ to data input

Delay from RD↓ to data input

Delay from ASTB↓ to RD↓

Data hold time (to RD↑)

Delay from RD↑ to address

active

Delay from RD↑ to ASTB↑

RD low-level width

Delay from address↓ to WR↓

Address hold time (to WR↑)

Delay from ASTB↓ to data

output

Delay from WR↓ to data output

Delay from ASTB↓ to WR↓

Data setup time (to WR↑)

Data hold time (to WR↑)

Delay from WR↑ to ASTB↑

WR low-level width

Symbol

tSAST

tWSTH

tHSTLA

tHRA

tDAR

tFRA

tDAID

tDSTID

tDRID

tDSTR

tHRID

tDRA

tDRST

tWRL

tDAW

tHWA

tDSTOD

tDWOD

tDSTW

tSODWR

tHWOD

tDWST

tWWL

Conditions

VDD = 5.0 V (0.5 + a)T – 11

VDD = 5.0 V (0.5 + a)T – 17

VDD = 5.0 V 0.5T – 19

VDD = 5.0 V 0.5T – 14

VDD = 5.0 V (1 + a)T – 5

VDD = 5.0 V (2.5 + a + n)T – 37

DD = 5.0 V (2 + n)T – 35

V

VDD = 5.0 V (1.5 + n)T – 40

VDD = 5.0 V 0.5T – 9

VDD = 5.0 V 0.5T – 2

VDD = 5.0 V 0.5T – 9

VDD = 5.0 V (1.5 + n)T – 25

VDD = 5.0 V (1 + a)T – 5

VDD = 5.0 V 0.5T – 14

VDD = 5.0 V 0.5T + 15

V

DD = 5.0 V 0.5T – 9

VDD = 5.0 V (1.5 + n)T – 20

VDD = 5.0 V 0.5T – 14

VDD = 5.0 V 0.5T – 9

VDD = 5.0 V (1.5 + n)T – 25

MIN.

29

23

21

26

74

0

31

0

38

31

94

74

26

31

99

26

31

94

MAX.

400

283

238

55

15

Unit

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Remark T: tCYK (system clock cycle time) VDD = 5.0 V T = 79 ns (MIN.)

a: 1 during address wait, otherwise, 0

n: Number of wait states (n ≥ 0)

32

Data Sheet U11681EJ2V0DS00

Page 33

(2) External wait timing

µ

PD78P4908

Parameter

Delay from address to WAIT↓

input

Delay from ASTB↓ to WAIT↓

input

Hold time from ASTB↓ to WAIT

Delay from ASTB↓ to WAIT↑

Delay from RD↓ to WAIT↓

input

Hold time from RD↓ to WAIT

Delay from RD↓ to WAIT↑

Delay from WAIT↑ to data

input

Delay from WAIT↑ to RD↑

Delay from WAIT↑ to WR↑

Delay from WR↓ to WAIT↓

input

Hold time from WR↓ to WAIT

Delay from WR↓ to WAIT↑

Symbol

tDAWT

tDSTWT

tHSTWT

tDSTWTH

tDRWTL

tHRWT

tDRWTH

tDWTID

tDWTR

tDWTW

tDWWTL

tHWWT

tDWWTH

Conditions

VDD = 5.0 V (2 + a)T – 40

VDD = 5.0 V 1.5T – 40

VDD = 5.0 V (0.5 + n)T + 5

VDD = 5.0 V (1.5 + n)T – 40

VDD = 5.0 V T – 40

VDD = 5.0 V nT + 5

VDD = 5.0 V (1 + n)T – 40

V

DD = 5.0 V 0.5T – 5

VDD = 5.0 V 0.5T

VDD = 5.0 V 0.5T

VDD = 5.0 V T – 40

VDD = 5.0 V nT + 5

VDD = 5.0 V (1 + n)T – 40

MIN.

124

84

40

40

84

MAX.

198

79

238

39

198

35

39

198

Unit

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Remark T: t

a: 1 during address wait, otherwise, 0

n: Number of wait states (n ≥ 0)

CYK (system clock cycle time) VDD = 5.0 V T = 79 ns (MIN.)

Data Sheet U11681EJ2V0DS00

33

Page 34

(3) Bus hold timing

µ

PD78P4908

Parameter

Delay from HLDRQ↑ to float

Delay from HLDRQ↑ to HLDAK↑

Delay from float to HLDAK↑

Delay from HLDRQ↓ to HLDAK↓

Delay from HLDRQ↓ to active

Remark T: t

CYK (system clock cycle time) VDD = 5.0 V T = 79 ns (MIN.)

a: 1 during address wait, otherwise, 0

n: Number of wait states (n ≥ 0)

(4) Refresh timing

Parameter

Random read/write cycle time

REFRQ low-level pulse width

Delay from ASTB↓ to REFRQ

Delay from RD↑ to REFRQ

Delay from WR↑ to REFRQ

Delay from REFRQ↑ to ASTB

REFRQ high-level pulse width

Symbol

tFHQC

tDHQHHAH

tDCFHA

tDHQLHAL

tDHAC

Symbol

tRC

tWRFQL

tDSTRFQ

tDRRFQ

tDWRFQ

tDRFQST

tWRFQH

Conditions

VDD = 5.0 V (2 + 4 + a + n)T + 50

VDD = 5.0 V (3 + 4 + a + n)T + 30

V

DD = 5.0 V T + 30

VDD = 5.0 V 2T + 40

VDD = 5.0 V T – 20

Conditions

VDD = 5.0 V 3T

VDD = 5.0 V 1.5T – 25

VDD = 5.0 V 0.5T – 9

VDD = 5.0 V 1.5T – 9

V

DD = 5.0 V 1.5T – 9

VDD = 5.0 V 0.5T – 9

VDD = 5.0 V 1.5T – 25

MIN.

59

MIN.

238

94

31

110

110

31

94

MAX.

765

825

109

199

MAX.

Unit

ns

ns

ns

ns

ns

Unit

ns

ns

ns

ns

ns

ns

ns

Remark T: t

CYK (system clock cycle time) VDD = 5.0 V T = 79 ns (MIN.)

34

Data Sheet U11681EJ2V0DS00

Page 35

SERIAL OPERATION (TA = –40 °C to +85 °C, VDD = 4.0 to 5.5 V, AVSS = VSS = 0 V)

(1) CSI, CSI3

µ

PD78P4908

Parameter

Serial clock cycle time

(SCK0, SCK3)

Serial clock low-level width

(SCK0, SCK3)

Serial clock high-level width

(SCK0, SCK3)

Setup time for SI0, SI3

(to SCK0, SCK3↑)

Hold time for SI0, SI3

(to SCK0, SCK3↑)

Output delay time for SO0,

SO3 (to SCK0, SCK3↓)

Output hold time for SO0,

SO3 (to SCK0, SCK3↑)

Symbol

tCYSK0

tWSKL0

tWSKH0

tSSSK0

tHSSK0

tDSBSK1

tDSBSK2

tHSBSK

Conditions

Input fCLK = fXX

Other than fCLK = fXX

Output Other than f CLK = fXX/8

fCLK = fXX/8

Input fCLK = fXX

Other than fCLK = fXX

Output Other than f CLK = fXX/8

fCLK = fXX/8

Input fCLK = fXX

Other than fCLK = fXX

Output Other than f CLK = fXX/8

f

CLK = fXX/8

External clock

Internal clock

CMOS push-pull output External clock

Internal clock

Open-drain output External clock

RL = 1 kΩ

When data is transferred

Internal clock

MIN.

8/fXX

4/fCLK

8/fXX

16/fXX

4/fXX – 40

2/fCLK – 40

4/fXX – 40

8/fXX – 40

4/fXX – 40

2/fCLK – 40

4/f

XX – 40

8/fXX – 40

80

1/fCLK + 80

80

0

0

0

0

0.5tCYSK0 – 40

MAX.

1/fCLK + 150

150

1/fCLK + 400

400

Unit

ns

ns

ns

ns

ns

µ

ns

µ

ns

ns

ns

ns

ns

ns

ns

s

s

Remarks 1. The values in this table are those when f

CLK: System clock frequency (selectable from fXX, fXX/2, fXX/4, and fXX/8 by the standby control

2. f

register (STBC))

XX : Oscillation frequency (fXX = 12.58 MHz or fXX = 6.29 MHz)

3. f

Data Sheet U11681EJ2V0DS00

XX = 12.58 MHz, CL is 100 pF.

35

Page 36

(2) IOE1, IOE2 (TA = –40 °C to +85 °C, V DD = AVDD = 4.0 to 5.5 V, AVSS = VSS = 0 V)

µ

PD78P4908

Parameter

Serial clock cycle time

(SCK1, SCK2)

Serial clock low-level width

(SCK1, SCK2)

Serial clock high-level width

(SCK1, SCK2)

Setup time for SI1 and SI2

(to SCK1, SCK2↑)

Hold time for SI1 and SI2

(to SCK1, SCK2↑)

Output delay time for SO1 and

SO2 (to SCK1, SCK2↓)

Output hold time for SO1 and

SO2 (to SCK1, SCK2↑)

Symbol

tCYSK1

tWSKL1

tWSKH1

tSSSK1

tHSSK1

tDSOSK

tHSOSK

Conditions

Input VDD = 4.5 to 5.5 V

Output Internal, divided by 8

Input V

Output Internal, divided by 8

Input VDD = 4.5 to 5.5 V

Output Internal, divided by 8

When data is transferred

DD = 4.5 to 5.5 V

Remarks 1. The values in this table are those when C

2. T: Serial clock cycle set by software. The minimum value is 8/f

L is 100 pF.

MIN.

640

1,280

280

600

0.5T – 40

280

600

0.5T – 40

40

40

0.5t

CYSK1 – 40

XX.

MAX.

T

0

50

Unit

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

(3) UART, UART2 (T

Parameter

ASCK clock input cycle time

ASCK clock low-level width

ASCK clock high-level width

A = –40 °C to +85 °C, VDD = AVDD = 4.0 to 5.5 V, AVSS = VSS = 0 V)

Symbol

tCYASK

tWASKL

tWASKH

Conditions

VDD = 4.5 to 5.5 V

VDD = 4.5 to 5.5 V

DD = 4.5 to 5.5 V

V

MIN.

160

320

65

120

65

120

MAX.

Unit

ns

ns

ns

ns

ns

ns

36

Data Sheet U11681EJ2V0DS00

Page 37

µ

PD78P4908

CLOCK OUTPUT OPERATION (TA = –40°C to +85°C, VDD = AVDD = 4.0 to 5.5 V, AVSS = VSS = 0 V)

Parameter

CLKOUT cycle time

CLKOUT low-level width

CLKOUT high-level width

CLKOUT rise time

CLKOUT fall time

Symbol

tCYCL

tCLL

tCLH

tCLR

tCLF

Conditions

nT

VDD = 4.5 to 5.5 V, 0.5T – 10

0.5T – 20

VDD = 4.5 to 5.5 V, 0.5T – 10

0.5T – 20

4.5 V ≤ VDD < 5.5 V

4.0 V ≤ VDD < 4.5 V

4.5 V ≤ VDD < 5.5 V

4.0 V ≤ VDD < 4.5 V

Remark n: Dividing ratio set by software in the CPU (n = 1, 2, 4, 8, and 16)

CYK (system clock cycle time)

T: t

OTHER OPERATIONS (T

Parameter

NMI low-level width

NMI high-level width

INTP0 low-level width

INTP0 high-level width

Low-level width for INTP1-

INTP3 and CI

High-level width for INTP1-

INTP3 and CI

Low-level width for INTP4 and

INTP5

High-level width for INTP4 and

INTP5

RESET low-level width

RESET high-level width

A = –40 °C to +85 °C, VDD = AVDD = 4.0 to 5.5 V, AV SS = VSS = 0 V)

Note

Symbol

tWNIL

tWNIH

tWIT0L

tWIT0H

tWIT1L

tWIT1H

tWIT2L

tWIT2H

tWRSL

tWRSH

Conditions

MIN.

79

30

20

30

20

MIN.

10

10

4 tCYSMP

4 tCYSMP

4 tCYCPU

4 tCYCPU

10

10

10

10

MAX.

32,000

10

20

10

20

MAX.

Unit

ns

ns

ns

ns

ns

ns

ns

ns

ns

Unit

µ

µ

ns

ns

ns

ns

µ

µ

µ

µ

s

s

s

s

s

s

Note Use the RESET low-level width to ensure the lapse of the oscillation settling time when the power is applied.

Remark t

CYSMP: Sampling clock set by software

CYCPU: CPU operation clock set by software in the CPU

t

Data Sheet U11681EJ2V0DS00

37

Page 38

µ

PD78P4908

A/D CONVERTER CHARACTERISTICS (TA = –40 °C to +85 °C, VDD = AVDD = AVREF1 = 4.0 to 5.5 V, AVSS = VSS = 0 V)

Parameter

Resolution

Total error

Quantization error

Conversion time

Sampling time

Analog input impedance

AV

AVDD power supply

voltage

Note

REF1 impedance

Symbol

tCONV

tSAMP

RAN

RREF1

AIDD1

AIDD2

IEAD = 00H FR = 0

IEAD = 01H VDD = 4.5 to 5.5 V

FR = 1 120/fCLK

FR = 0 240/fCLK

FR = 1 18/fCLK

FR = 0 36/fCLK

CS = 1

CS = 0, STOP mode

Conditions

FR = 1

MIN.

8

9.5

19.1

1.4

2.9

3

TYP.

1

1,000

10

2.0

1.0

MAX.

0.6

1.5

2.2

±1/2

480

960

72

144

5.0

20

Unit

bit

%

%

%

LSB

µ

s

µ

s

µ

s

µ

s

MΩ

kΩ

mA

µ

A

Note Quantization error is not included. This parameter is indicated as the ratio to the full-scale value.

Caution To execute the conversion by the A/D converter set port 7, multiplexed with the A/D input lines,

to output mode to prevent data from being inverted.

Remark f

CLK: System clock frequency (selectable from fXX, fXX/2, fXX/4, and fXX/8 by the standby control register

(STBC))

IEBus CONTROLLER CHARACTERISTICS (TA = –40°C to +85°C, VDD = AVDD = AVREF1 = 4.5 to 5.5 V, AVSS = VSS = 0 V)

Parameter

IEBus standard

frequency

Driver delay time (delay from

TX output to bus line)

Receiver delay time

(delay from bus line to

RX output)

Transmission delay on

bus

Note 1

Note 2

Note 2

Note 2

Symbol

fS

tDTX

tDRX

tDBUS

Conditions

Transfer speed: mode 1

C

L = 50 pF

Note 3

MIN.

6.20

TYP.

6.29

MAX.

6.39

1.5

0.7

0.85

Unit

MHz

µ

s

µ

s

µ

s

Notes 1. The value conforms to the IEBus standard. The IEBus controller is operable within the range of the

oscillator frequency of oscillator characteristics.

2. The value is measured when IEBus system clock: f

L is the load capacitance of TX output line.

3. C

X = 6.29 MHz.

38

Data Sheet U11681EJ2V0DS00

Page 39

DATA RETENTION CHARACTERISTICS (TA = –40 °C to +85 °C)

µ

PD78P4908

Parameter

Data retention voltage

Data retention current

VDD rise time

VDD fall time

VDD hold time

(to STOP mode setting)

STOP clear signal input time

Oscillation settling time

Input low voltage

Input high voltage

Symbol

VDDDR

IDDDR

tRVD

tFVD

tHVD

tDREL

tWAIT

VIL

VIH

Conditions

STOP mode

STOP mode V

Crystal resonator

Ceramic resonator

Specific pins

DDDR = 2.5 V, AVREF =

0 V

VDDDR = 4.0 to 5.5 V,

AVREF1 = 0 V

Note 2

Note 1

Note 1

Notes 1. Valid when input voltages to the pins described in Note 2 satisfy V

2. RESET, P12/ASCK2/SCK2, P20/NMI, P21/INTP0, P22/INTP1, P23/INTP2/CI, P24/INTP3,

P25/INTP4/ASCK/SCK1, P26/INTP5, P27/SI0, P32/SCK0, P33/SO0, P105/SCK3, P106/SI3, and

P107/SO3 pins

MIN.

2.5

200

200

0.9 V

0

0

30

5

0

DDDR

TYP.

2

10

IL or VIH in the above table.

MAX.

5.5

0.1 V

VDDDR

10

50

DDDR

Unit

V

µ

µ

µ

µ

ms

ms

ms

ms

V

V

A

A

s

s

AC TIMING TEST POINTS

V

DD – 1 V

0.45 V

0.8 VDD or 2.2 V

0.8 V

0.8 VDD or 2.2 V

Test points

0.8 V

Data Sheet U11681EJ2V0DS00

39

Page 40

TIMING WAVEFORM

(1) Read operation

ASTB

tWSTH

µ

PD78P4908

A8-A19

AD0-AD7

RD

(2) Write operation

ASTB

tSAST

tWSTH

tSAST

tDAR

tDSTID

tHSTLA

tDAID tHRA

tDSTR

tHSTLA

tFRA

tDRID

tWRL

tDSTOD

tDRST

tHRID

tDRA

tDWST

A8-A19

AD0-AD7

WR

tDSTW tHWOD

tDAW

tDWOD

tSODWR

tWWL

tHWA

40

Data Sheet U11681EJ2V0DS00

Page 41

HOLD TIMING

ASTB

A8-A19

AD0-AD7

WR

WAIT

tDSTWT

tHSTWTH

tDSTWTH

tDAWT

tDWTW

tDWWTL

tHWWT

tDWWTH

ASTB, A8-A19,

AD0-AD7, RD, WR

HLDRQ

tFHQC

tDCFHA

tDHAC

µ

PD78P4908

tDHQHHAH

HLDAK

EXTERNAL WAIT SIGNAL INPUT TIMING

(1) Read operation

ASTB

tDSTWT

A8-A19

AD0-AD7

tDAWT tDWTID

RD

WAIT

tDSTWTH

tHSTWTH

tDRWTL

tDHQLHAL

tDWTR

(2) Write operation

tHRWT

tDRWTH

Data Sheet U11681EJ2V0DS00

41

Page 42

REFRESH TIMING WAVEFORM

(1) Random read/write cycle

tRC

ASTB

WR

RD

(2) When refresh memory is accessed for a read and write at the same time

ASTB

RD, WR

µ

PD78P4908

tRCtRC tRC tRC

REFRQ

(3) Refresh after a read

ASTB

RD

REFRQ

(4) Refresh after a write

ASTB

tDSTRFQ tDRFQST

tWRFQL

tWRFQH

tDRRFQ

tDRFQST

tWRFQL

42

tDRFQST

WR

tDWRFQ

REFRQ

tWRFQL

Data Sheet U11681EJ2V0DS00

Page 43

SERIAL OPERATION (CSI, CSI3)

SCK0, SCK3

SI0, SI3

SO0, SO3

Output data

Input data

t

SSSK0tHSSK0

t

DSBSK1

t

WSKL0

t

WSKH0

t

HSBSK1

t

CYSK0

SERIAL OPERATION (IOE1, IOE2)

SCK1, SCK2

t

WSKL1

t

CYSK1

t

WSKH1

SSSK1tHSSK1

t

µ

PD78P4908

SI1, SI2

SO1, SO2

SERIAL OPERATION (UART, UART2)

ASCK,

ASCK2

CLOCK OUTPUT TIMING

CLKOUT

t

DSOSK

Output data

tWASKH tWASKL

tCYASK

tCLH tCLL

tCLFtCLR

tCYCL

t

HSOSK

Input data

Data Sheet U11681EJ2V0DS00

43

Page 44

INTERRUPT REQUEST INPUT TIMING

NMI

INTP0

tWNIH tWNIL

tWIT0H tWIT0L

tWIT1H tWIT1L

µ

PD78P4908

INTP1-INTP3

CI,

INTP4, INTP5

RESET INPUT TIMING

RESET

tWIT2H tWIT2L

tWRSH tWRSL

44

Data Sheet U11681EJ2V0DS00

Page 45

EXTERNAL CLOCK TIMING

tWXH tWXL

X1

DATA RETENTION CHARACTERISTICS

STOP mode setting

tCYX

µ

PD78P4908

tXFtXR

VDD

tHVD tFVD tRVD

RESET

NMI

(Clearing by falling edge)

NMI

(Clearing by rising edge)

VDDDR

tDREL

tWAIT

Data Sheet U11681EJ2V0DS00

45

Page 46

DC PROGRAMMING CHARACTERISTICS (TA = 25°C ±5°C, VSS = 0 V)

µ

PD78P4908

Parameter

High-level input

voltage

Low-level input

voltage

Input leakage current

High-level output

voltage

Low-level output

voltage

Output leakage

current

VDDP supply voltage

VPP supply voltage

VDDP supply current

VPP supply current

Symbol

VIH

VIL

ILIP

VOH

VOL

ILO

VDDP

VPP

IDD

IPP

Symbol

VIH

VIL

ILI

VOH

VOL

–

VCC

VPP

IDD

IPP

Note 1

Conditions

0 ≤ VI ≤ VDDP

IOH = –400 µA

IOL = 2.1 mA

0 ≤ VO ≤ VDDP, OE = VIH

Program memory write mode

Program memory read mode

Program memory write mode

Program memory read mode

Program memory write mode

Program memory read mode

Program memory write mode

Program memory read mode

Note 2

MIN.

2.2

–0.3

2.4

6.25

4.5

12.2

TYP.

6.5

5.0

12.5

VPP = VDDP

10

10

5

1.0

MAX.

VDDP + 0.3

+0.8

±10

0.45

±10

6.75

5.5

12.8

40

40

50

100

Unit

V

V

µ

V

V

µ

V

V

V

V

mA

mA

mA

µ

A

A

A

Notes 1. Symbols for the corresponding

2. The V

DDP represents the VDD pin as viewed in the programming mode.

µ

PD27C1001A

46

Data Sheet U11681EJ2V0DS00

Page 47

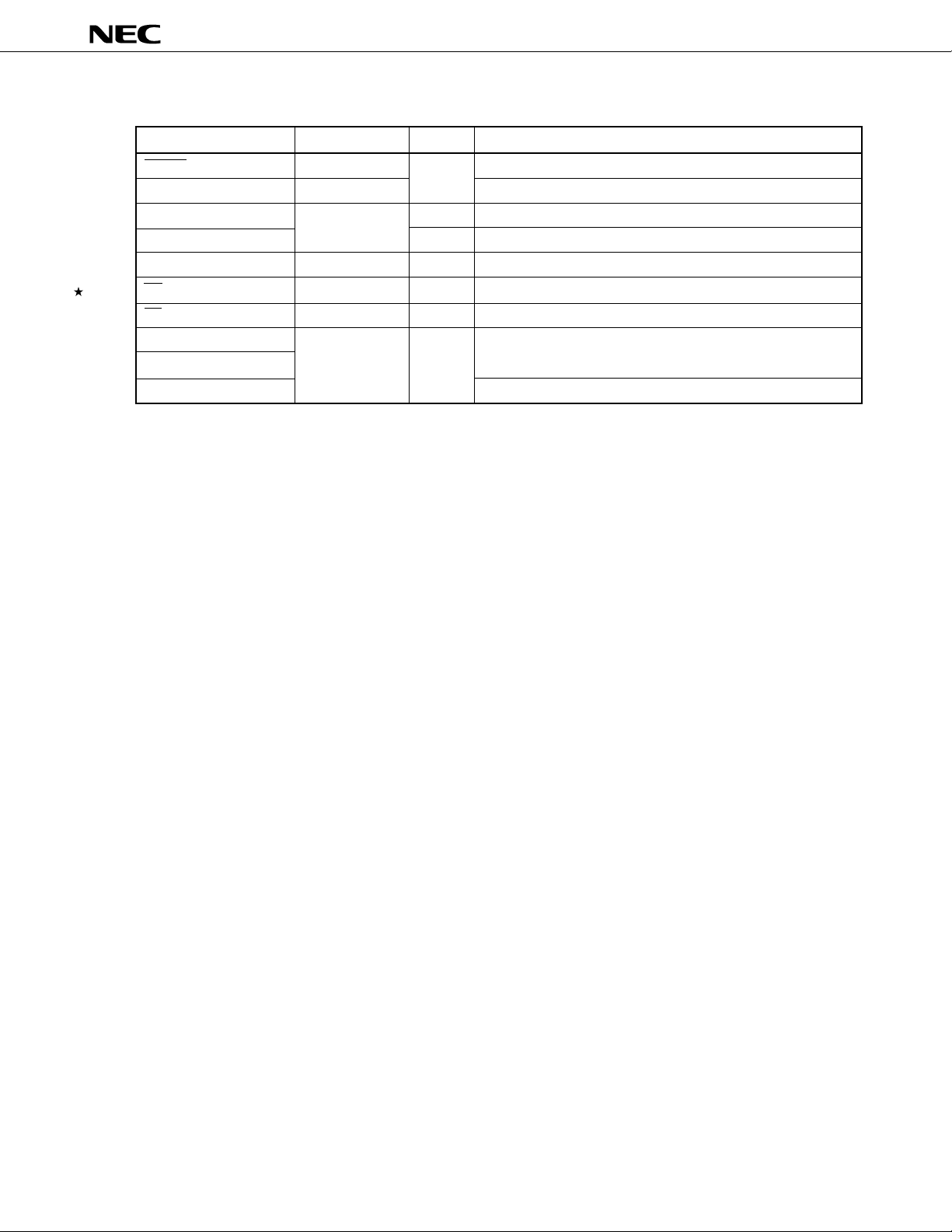

AC PROGRAMMING CHARACTERISTICS (TA = 25°C ±5°C, VSS = 0 V)

PROM Write Mode (Page Program Mode)

µ

PD78P4908

Parameter

Address setup time

CE set time

Input data setup time

Address hold time

Input data hold time

Output data hold time

VPP setup time

VDDP setup time

Initial program pulse width

OE set time

Valid data delay time from OE

OE pulse width in the data latch

PGM setup time

CE hold time

OE hold time

Symbol

tVDS

tPGMS

Note 1

tAS

tCES

tDS

tAH

tAHL

tAHV

tDH

tDF

tVPS

Note 2

tPW

tOES

tOE

tLW

tCEH

tOEH

Conditions Unit

MIN.

2

2

2

2

2

0

2

0

2

2

0.095

2

1

2

2

2

TYP.

0.1

1

MAX.

130

0.105

2

µ

µ

µ

µ

µ

µ

µ

ns

µ

µ

ms

µ

ns

µ

µ

µ

µ

s

s

s

s

s

s

s

s

s

s

s

s

s

s

Notes 1. These symbols (except t

µ

2. For

PD27C1001A, read tVDS as tVCS.

VDS) correspond to those of the corresponding

µ

PD27C1001A.

Data Sheet U11681EJ2V0DS00

47

Page 48

PROM Write Mode (Byte Program Mode)

µ

PD78P4908

Parameter

Address setup time

CE set time

Input data setup time

Address hold time

Input data hold time

Output data hold time

VPP setup time

VDDP setup time

Initial program pulse width

OE set time

Valid data delay time from OE

Notes 1. These symbols (except t

µ

2. For

PD27C1001A, read tVDS as tVCS.

PROM Read Mode

Parameter

Data output time from address

Delay from CE ↓ to data output

Delay from OE ↓ to data output

Data hold time to OE↑ or CE↑

Data hold time to address

Note 2

Note 1

Symbol

tAS

tCES

tDS

tAH

tDH

tDF

tVPS

Note 2

tVDS

tPW

tOES

tOE

VDS) correspond to those of the corresponding

Note 1

Symbol

tACC

tCE

tOE

tDF

tOH

Conditions MAX.

Conditions

CE = OE = VIL

OE = VIL

CE = VIL

CE = VIL or OE = VIL

CE = OE = VIL

MIN.

2

2

2

2

2

0

2

2

0.095

2

MIN.

0

0

TYP.

0.1

1

µ

PD27C1001A.

TYP.

1

1

130

0.105

2

MAX.

200

2

2

60

Unit

µ

µ

µ

µ

µ

ns

µ

µ

ms

µ

ns

Unit

ns

µ

µ

ns

ns

s

s

s

s

s

s

s

s

s

s

Notes 1. These symbols correspond to those of the corresponding

DF is the time measured from when either OE or CE reaches VIH, whichever is faster.

2. t

µ

PD27C1001A.

48

Data Sheet U11681EJ2V0DS00

Page 49

PROM Write Mode Timing (Page Program Mode)

Page data latch Page program Program verify

A2-A16

µ

PD78P4908

VPP

VDDP

CE

PGM

OE

A0, A1

D0-D7

V

VDDP

VDDP + 1.5

VDDP

VIH

VIL

VIH

VIL

VIH

VIL

tAS tAHL

tDS tDH

Hi-Z Hi-ZHi-Z

tVPS Data input

PP

tVDS

tLW

tPGMS

tPW

tCEH

tCES

tOE

tAHV

tDF

Data

output

tAH

tOEH

tOES

Data Sheet U11681EJ2V0DS00

49

Page 50

PROM Write Mode Timing (Byte Program Mode)

Program Program verify

A0-A16

µ

PD78P4908

D0-D7

V

VPP

VDDP

VDDP + 1.5

VDDP

VDDP

CE

PGM

OE

Cautions 1. V

2. V

3. Plugging in or out the board with the V

reliability.

tAS

Hi-Z Hi-ZHi-Z

tDS

PP

Data input

tDS

tVPS

tVDS

VIH

VIL

tCES

tPW

VIH

VIL

tOES tOE

VIH

VIL

DDP must be applied before VPP, and must be cut after VPP.

PP including overshoot must not exceed 13.5 V.

PP pin supplied with 12.5 V may adversely affect its

tDF

Data output

tAHtDH

PROM Read Mode Timing

A0-A16

CE

OE

D0-D7

Notes 1. For reading within t

DF is the time measured from when either OE or CE reaches VIH, whichever is faster.

2. t

50

Valid address

tCE

Note 2

Note 1

tACC

Hi-Z Hi-Z

ACC, the delay of the OE input from falling edge of CE must be within tACC-tOE.

Note 1

tOE

Data output

Data Sheet U11681EJ2V0DS00

tOH

tDF

Page 51

9. PACKAGE DRAWING

100PIN PLASTIC QFP (14x20)

µ

PD78P4908

A

B

80

81

100

1

51

30

50

31

F

G

H

M

I

J

P

N

NOTE

Each lead centerline is located within 0.15 mm (0.006 inch) of

its true position (T.P.) at maximum material condition.

Remark The shape and material of the ES version are the same

as those of the corresponding mass-produced product.

CD

K

M

L

detail of lead end

S

Q

ITEM MILLIMETERS INCHES

A 23.6±0.4 0.929±0.016

B 20.0±0.2 0.795

C 14.0±0.2 0.551

D 17.6±0.4 0.693±0.016

F 0.8 0.031

G 0.6 0.024

H 0.30±0.10 0.012

I 0.15 0.006

J 0.65 (T.P.) 0.026 (T.P.)

K 1.8±0.2 0.071

L 0.8±0.2 0.031

M 0.15 0.006

N 0.10 0.004

P 2.7±0.1 0.106

Q 0.1±0.1 0.004±0.004

R5°±5° 5°±5°

S 3.0 MAX. 0.119 MAX.

R

+0.10

–0.05

P100GF-65-3BA1-3

+0.009

–0.008

+0.009

–0.008

+0.004

–0.005

+0.008

–0.009

+0.009

–0.008

+0.004

–0.003

+0.005

–0.004

Data Sheet U11681EJ2V0DS00

51

Page 52

µ

PD78P4908

10. RECOMMENDED SOLDERING CONDITIONS

The conditions listed below shall be met when soldering the µPD78P4908.

For details of the recommended soldering conditions, refer to our document Semiconductor Device Mounting

Technology Manual (C10535E).

Please consult with our sales offices in case any other soldering process is used, or in case soldering is done under

different conditions.

Table 10-1. Soldering Conditions for Surface-Mount Devices

µ

PD78P4908GF-3BA: 100-pin plastic QFP (14 × 20 mm)

Soldering process

Infrared ray reflow

VPS

Wave soldering

Partial heating method

Soldering conditions

Peak package's surface temperature: 235°C

Reflow time: 30 seconds or less (210°C or more)

Maximum allowable number of reflow processes: 2

Exposure limit: 7 days

afterward)

Peak package's surface temperature: 215°C

Reflow time: 40 seconds or less (200°C or more)