Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD784031Y

16-/8-BIT SINGLE-CHIP MICROCONTROLLERS

The µPD784031Y is based on the µPD784031 with an I2C bus control function appended, and is ideal for

applications in audio-visual systems.

µ

PD784031Y is a ROM-less version of µPD784035Y and 784036Y.

The

The functions are explained in detail in the following User’s Manual. Be sure to read this manual when

designing your system.

µ

PD784038, 784038Y Subseries User’s Manual - Hardware : U11316E

78K/IV Series User’s Manual - Instruction : U10905E

FEATURES

78K/IV Series

Pin-compatible with µPD78234 Subseries,

µ

PD784026 Subseries, and µPD784038

Subseries

Minimum instruction execution time: 125 ns

(@ 32-MHz operation)

I/O ports: 46

Serial interface: 3 channels

UART/IOE (3-wire serial I/O): 2 channels

2

CSI (3-wire serial I/O, 2-wire serial I/O, I

1 channel

PWM output: 2 outputs

C bus):

Timer/counter

16-bit Timer/counter x 3 units

16-bit Timer x 1 unit

Standby function

HALT/STOP/IDLE mode

Clock division function

Watchdog timer: 1 channel

A/D converter: 8-bit resolution x 8 channels

D/A converter: 8-bit resolution x 2 channels

Supply voltage: VDD = 2.7 to 5.5 V

APPLICATION FIELDS

Cellular phones, cordless phones, audio-visual systems, etc.

ORDERING INFORMATION

Part Number Package

µ

PD784031YGC-3B9

µ

PD784031YGC-8BT

µ

PD784031YGK-BE9 80-pin plastic TQFP (fine pitch) (12 x 12 mm) None 2048

80-pin plastic QFP (14 x 14 mm, thickness 2.7 mm)

80-pin plastic QFP (14 x 14 mm, thickness 1.4 mm)

Internal ROM (Bytes) Internal RAM (Bytes)

None 2048

None 2048

Document No. U11504EJ1V0DS00 (1st edition)

Date Published July 1997 N

Printed in Japan

The information in this document is subject to change without notice.

The mark

shows major revised points.

©

1996

Page 2

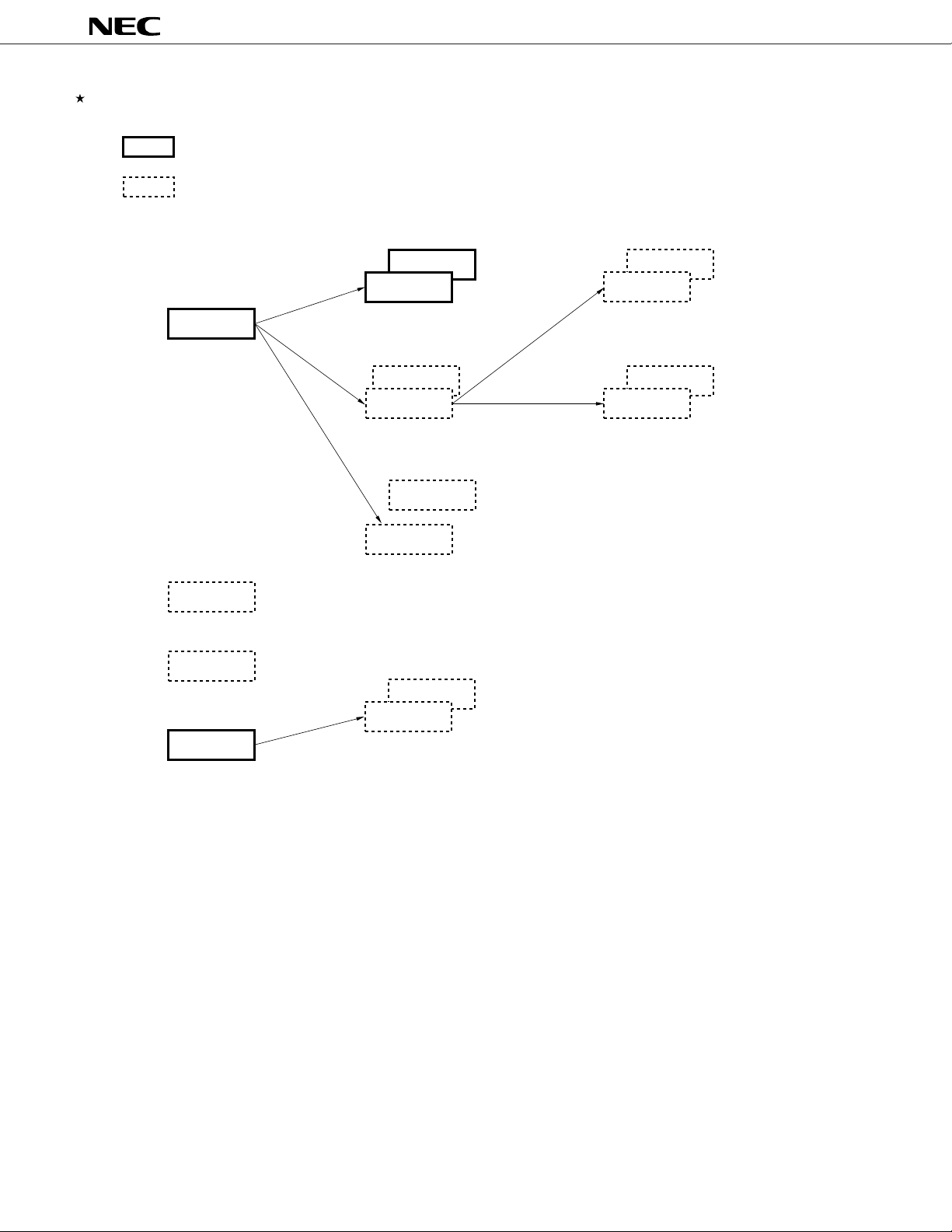

78K/IV SERIES PRODUCT DEVELOPMENT

: Under mass production

: Under development

µ

PD784031Y

Standard models

µPD784026

Enhanced A/D,

16-bit timer,

and power

management

ASSP models

µPD784908

Equipped with IEBus

controller

µPD78F4943

For CD-ROM,

56-Kbyte flash memory

µPD784915

Equipped with analog circuit for

software servo control VCR,

enhanced timer

TM

2

C bus supported

I

µPD784038Y

µPD784038

Enhanced internal memory capacity,

pin compatible with the µPD784026

µPD784216Y

µPD784216

100 pins,

enhanced I/O and

internal memory capacity

µPD784054

µPD784046

Equipped with 10-bit A/D

2

Multimaster I

µPD784928

Enhanced function of the µPD784915

C bus supported

µPD784928Y

2

Multimaster I

µPD784225

80 pins,

added ROM correction

Multimaster I

µPD784218

Enhanced internal memory capacity,

added ROM correction

C bus supported

µPD784225Y

2

C bus supportedMultimaster I2C bus supported

µPD784218Y

2

Page 3

µ

PD784031Y

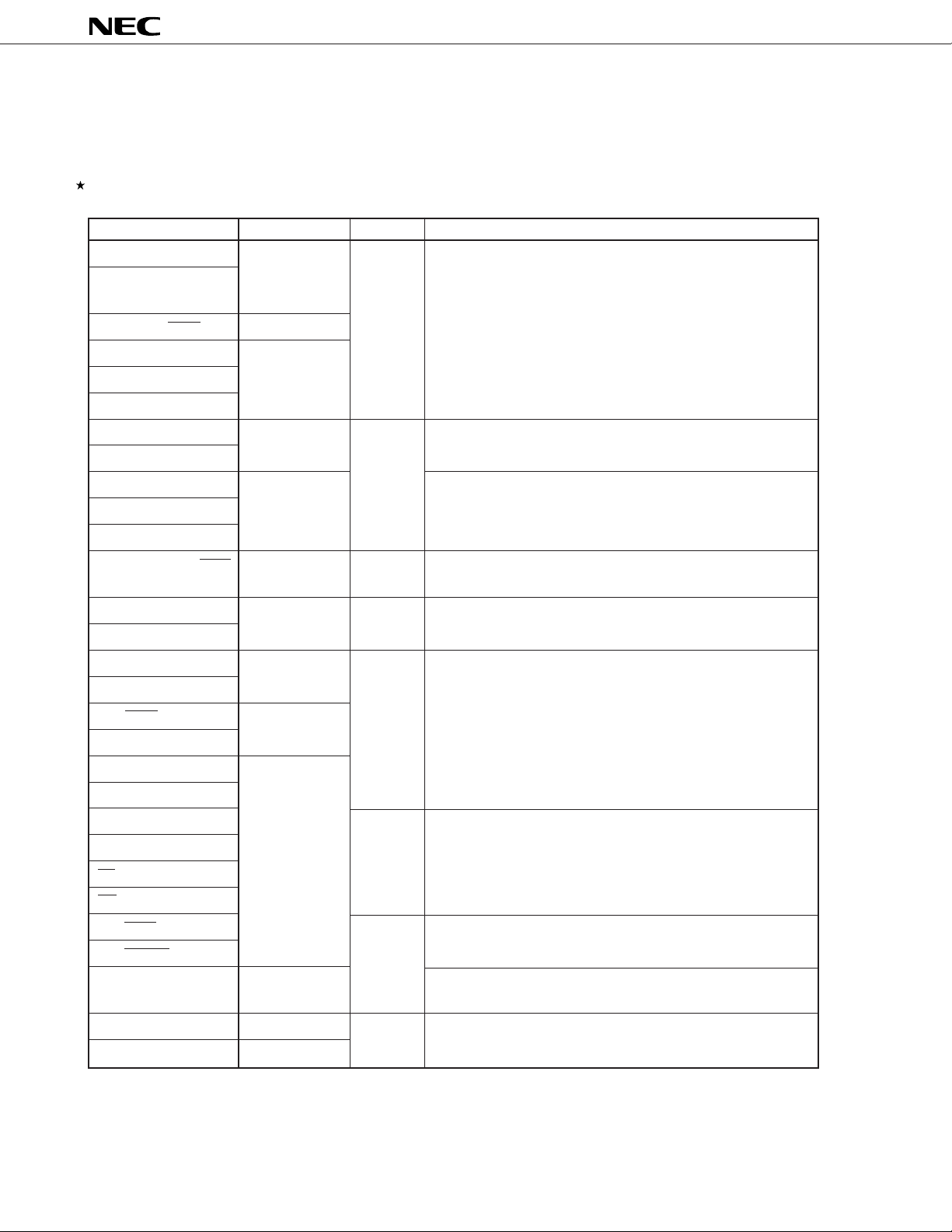

FUNCTIONS

Item Function

Number of basic instructions 113

(mnemonics)

General-purpose register 8 bits x 16 registers x 8 banks, or 16 bits x 8 registers x 8 banks (memory mapping)

Minimum instruction execution 125 ns/250 ns/500 ns/1000 ns (at 32 MHz)

time

Internal memory ROM None

RAM 2048 bytes

Memory space 1 Mbytes with program and data spaces combined

I/O port Total 46

Input 8

I/O 34

Output 4

Pins with

ancillary

Note

function

Real-time output port 4 bits x 2, or 8 bits x 1

Timer/counter Timer/counter 0: Timer register x 1 Pulse output

PWM output 12-bit resolution x 2 channels

Serial interface UART/IOE (3-wire serial I/O) : 2 channels (on-chip baud rate generator)

A/D converter 8-bit resolution x 8 channels

D/A converter 8-bit resolution x 2 channels

Watchdog timer 1 channel

Standby HALT/STOP/IDLE mode

Interrupt

Supply voltage VDD = 2.7 to 5.5 V

Package 80-pin plastic QFP (14 x 14 mm, thickness 2.7 mm)

Pins with pull- 32

up resistor

LEDs direct 8

drive output

Transistor 8

direct drive

Capture register x 1 • Toggle output

Compare register x 2 • PWM/PPG output

(16 bits) • One-shot pulse output

Timer/counter 1: Timer register x 1 Pulse output

Capture register x 1 • Real-time output (4 bits x 2)

(8/16 bits) Capture/compare register x 1

Compare register x 1

Timer/counter 2: Timer register x 1 Pulse output

Capture register x 1 • Toggle output

(8/16 bits) Capture/compare register x 1 • PWM/PPG output

Compare register x 1

Timer 3: Timer register x 1

(8/16 bits) Compare register x 1

CSI (3-wire serial I/O, 2-wire serial I/O, I2C bus) : 1 channel

Hardware source

Software source

Non-maskable

Maskable Internal: 16, external: 6

24 (internal: 17, external: 7 (variable sampling clock input: 1))

BRK instruction, BRKCS instruction, operand error

Internal: 1, external: 1

• 4 programmable priority levels

• 3 processing styles: vectored interrupt/macro service/context switching

80-pin plastic QFP (14 x 14 mm, thickness 1.4 mm)

80-pin plastic TQFP (fine pitch) (12 x 12 mm)

Note The pins with ancillary function are included in the I/O pins.

3

Page 4

µ

PD784031Y

CONTENTS

1. DIFFERENCES AMONG MODELS IN µPD784038Y SUBSERIES.................................................. 6

2. MAJOR DIFFERENCES FROM µPD784026 SUBSERIES AND µPD78234 SUBSERIES.............. 7

3. PIN CONFIGURATION (Top View)................................................................................................... 8

4. BLOCK DIAGRAM ............................................................................................................................ 10

5. PIN FUNCTION ............................................................................................................................... 11

5.1 Port Pins ................................................................................................................................................ 11

5.2 Non-port Pins ........................................................................................................................................ 12

5.3 Types of Pin I/O Circuits and Connections for Unused Pins............................................................ 14

6. CPU ARCHITECTURE .................................................................................................................... 17

6.1 Memory Space....................................................................................................................................... 17

6.2 CPU Registers ....................................................................................................................................... 19

6.2.1 General-purpose registers .......................................................................................................... 19

6.2.2 Control registers.......................................................................................................................... 20

6.2.3 Special function registers (SFRs) ............................................................................................... 21

7. PERIPHERAL HARDWARE FUNCTIONS ..................................................................................... 26

7.1 Ports....................................................................................................................................................... 26

7.2 Clock Generation Circuit...................................................................................................................... 27

7.3 Real-time Output Port ........................................................................................................................... 29

7.4 Timer/Counter........................................................................................................................................ 30

7.5 PWM Output (PWM0, PWM1)................................................................................................................ 32

7.6 A/D Converter........................................................................................................................................ 33

7.7 D/A Converter........................................................................................................................................ 34

7.8 Serial Interface ...................................................................................................................................... 35

7.8.1 Asynchronous serial interface/3-wire serial I/O (UART/IOE) ...................................................... 36

7.8.2 Clocked serial interface (CSI) ..................................................................................................... 38

7.9 Edge Detection Function...................................................................................................................... 39

7.10 Watchdog Timer .................................................................................................................................... 40

8. INTERRUPT FUNCTION ................................................................................................................. 41

8.1 Interrupt Sources .................................................................................................................................. 41

8.2 Vectored Interrupt................................................................................................................................. 43

8.3 Context Switching................................................................................................................................. 44

8.4 Macro Service........................................................................................................................................ 44

8.5 Application Example of Macro Service............................................................................................... 45

4

Page 5

µ

PD784031Y

9. LOCAL BUS INTERFACE .............................................................................................................. 47

9.1 Memory Expansion ............................................................................................................................... 47

9.2 Memory Space....................................................................................................................................... 48

9.3 Programmable Wait .............................................................................................................................. 49

9.4 Pseudo Static RAM Refresh Function................................................................................................. 49

9.5 Bus Hold Function ................................................................................................................................ 49

10. STANDBY FUNCTION .................................................................................................................... 50

11. RESET FUNCTION ......................................................................................................................... 51

12. INSTRUCTION SET ........................................................................................................................ 52

13. ELECTRICAL SPECIFICATIONS ................................................................................................... 57

14. PACKAGE DRAWINGS .................................................................................................................. 77

15. RECOMMENDED SOLDERING CONDITIONS .............................................................................. 80

APPENDIX A. DEVELOPMENT TOOLS ............................................................................................... 82

APPENDIX B. RELATED DOCUMENTS ............................................................................................... 84

5

Page 6

µ

PD784031Y

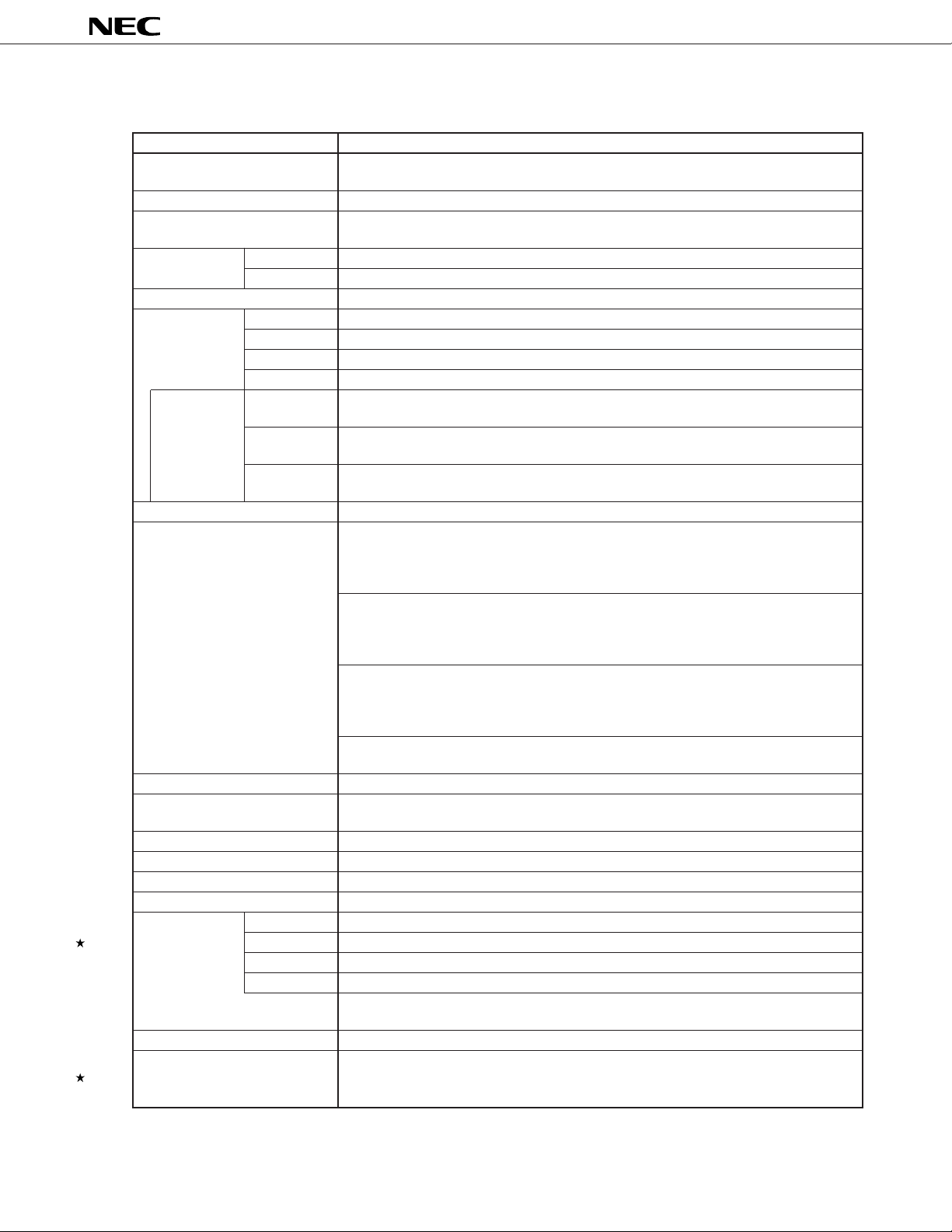

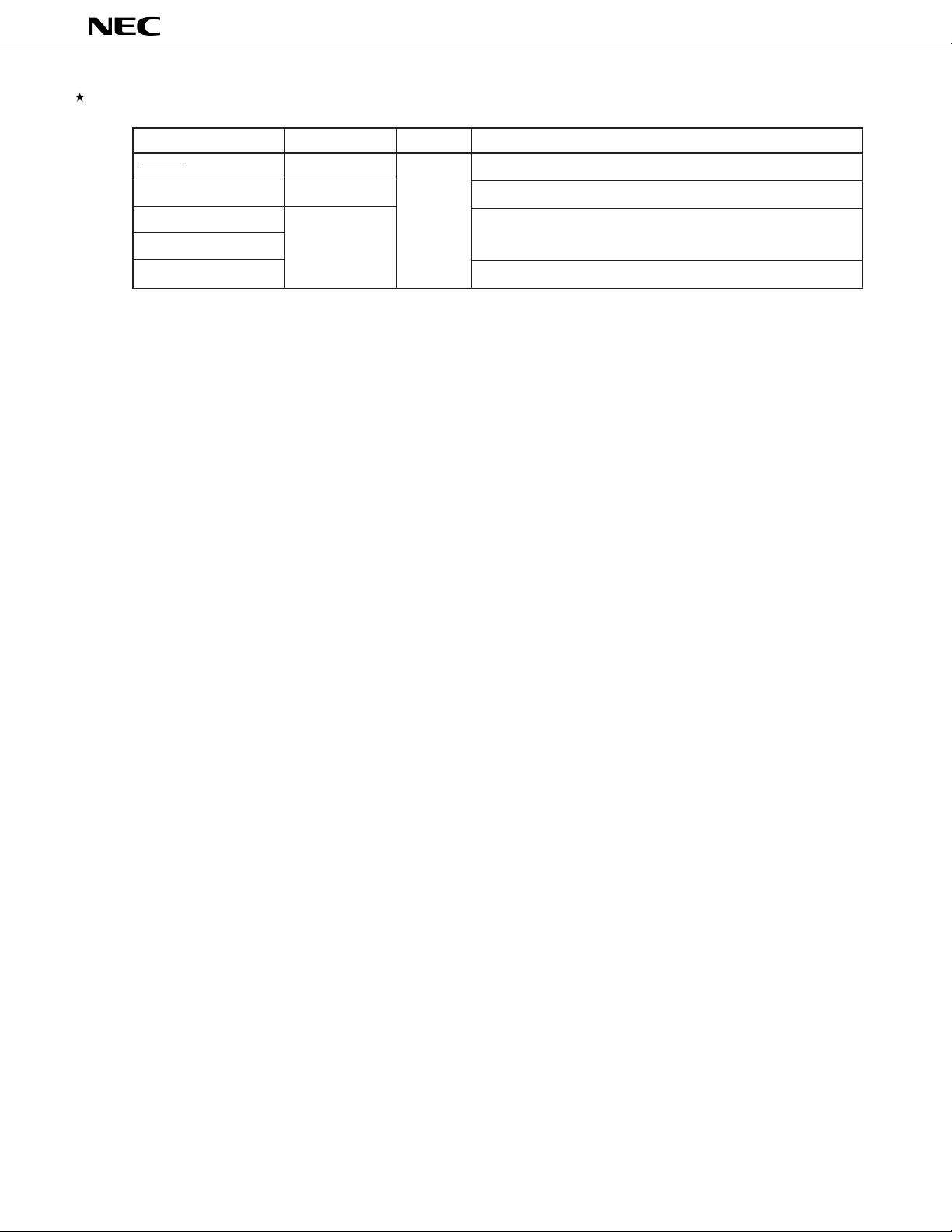

1. DIFFERENCES AMONG MODELS IN µPD784038Y SUBSERIES

The only difference among the µPD784031Y, 784035Y, 784036Y, 784037Y, and 784038Y lies in the internal memory

capacity.

The µPD78P4038Y is provided with a 128-Kbyte one-time PROM or EPROM instead of the mask ROM of the

µ

PD784035Y, 784036Y, 784037Y, and 784038Y. These differences are summarized in Table 1-1.

Table 1-1. Differences among Models in µPD784038Y Subseries

Part NumberµPD784031Y

Item

Internal ROM None 48 Kbytes 64 Kbytes 96 Kbytes 128 Kbytes 128 Kbytes

Internal RAM 2048 bytes 3584 bytes 4352 bytes

Package 80-pin plastic QFP (14 x 14 mm, thickness 2.7 mm)

80-pin plastic QFP (14 x 14 mm, thickness 1.4 mm)

80-pin plastic TQFP (fine pitch) (12 x 12 mm)

µ

PD784035YµPD784036YµPD784037YµPD784038YµPD78P4038Y

(mask ROM) (mask ROM) (mask ROM) (mask ROM)

(one-time PROM

or EPROM)

80-pin ceramic

WQFN

(14 x 14 mm)

6

Page 7

µ

PD784031Y

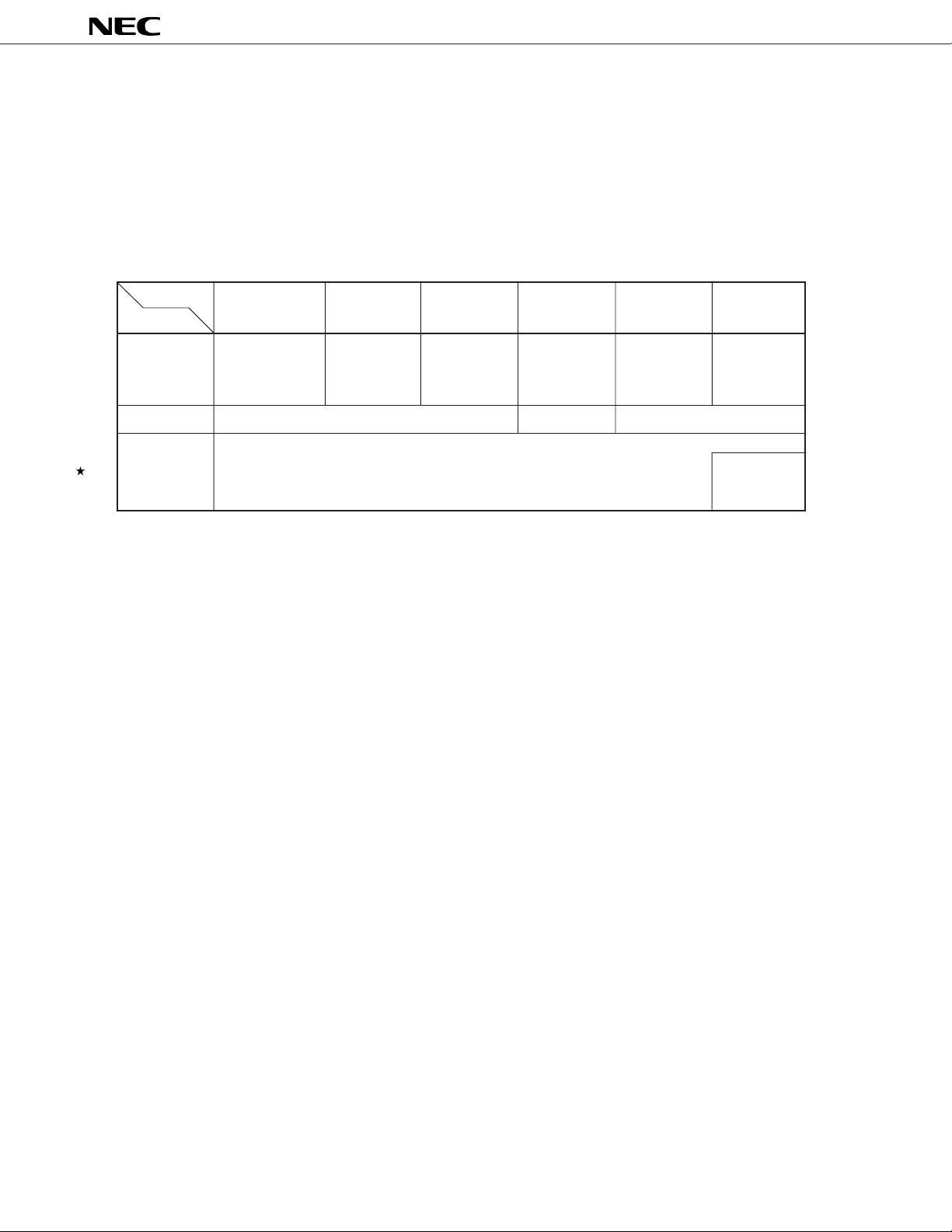

2. MAJOR DIFFERENCES FROM µPD784026 SUBSERIES AND µPD78234 SUBSERIES

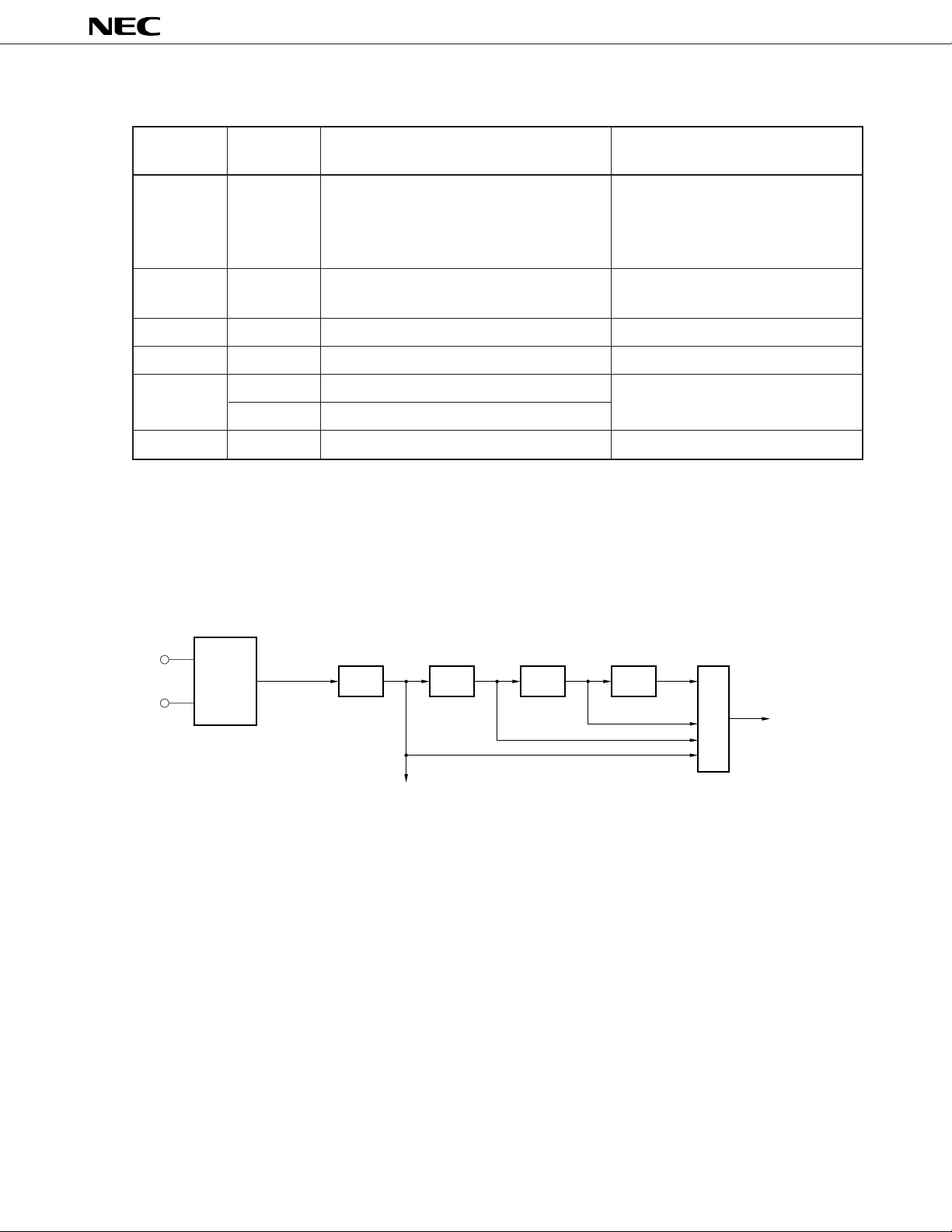

Series Name

Item

Number of basic instructions 113 65

(mnemonics)

Minimum instruction execution time 125 ns 160 ns 333 ns

Memory space (program/data) 1 Mbytes combined 64 Kbytes/1 Mbytes

Timer/counter 16-bit timer/counter x 1 16-bit timer/counter x 1

Clock output function Provided None

Watchdog timer Provided None

Serial interface

Interrupt Context Provided None

switching

µ

PD784038Y Subseries

µ

PD784038 Subseries

(@ 32-MHz operation) (@ 25-MHz operation) (@ 12-MHz operation)

8-/16-bit timer/counter x 2 8-bit timer/counter x 2

8-/16-bit timer x 1 8-bit timer x 1

UART/IOE (3-wire serial

I/O) x 2 channels

CSI (3-wire serial I/O,

2-wire serial I/O, I2C

Note

bus

) x 1 channel

µ

PD784026 Subseries

UART/IOE (3-wire serial

I/O) x 2 channels

CSI (3-wire serial I/O, SBI)

x 1 channel

µ

PD78234 Subseries

UART x 1 channel

CSI (3-wire serial I/O, SBI)

x 1 channel

Priority 4 levels 2 levels

Standby function HALT/STOP/IDLE mode HALT/STOP mode

Operating clock Selectable from fXX/2, fXX/4, fXX/8, and fXX/16 Fixed to fXX/2

Pin function MODE pin None Specifies ROM-less mode

(always high level with

µ

PD78233 and 78237)

TEST pin Device test pin None

Usually, low level

Package

80-pin plastic QFP

(14 x 14 mm, thickness 2.7 mm)

80-pin plastic QFP

(14 x 14 mm, thickness 1.4 mm)

80-pin plastic TQFP

(fine pitch) (12 x 12 mm)

80-pin ceramic WQFN

(14 x 14 mm):

µ

PD78P4038Y and

78P4038 only

80-pin plastic QFP

(14 x 14 mm, thickness 2.7 mm)

80-pin plastic TQFP

(fine pitch) (12 x 12 mm):

µ

PD784021 only

80-pin ceramic WQFN

(14 x 14 mm):

µ

PD78P4026 only

80-pin plastic QFP

(14 x 14 mm, thickness 2.7 mm)

94-pin plastic QFP

(20 x 20 mm)

84-pin plastic QFJ

(1150 x 1150 mil)

94-pin ceramic WQFN

(20 x 20 mm):

µ

PD78P238 only

NoteµPD784038Y Subseries only

7

Page 8

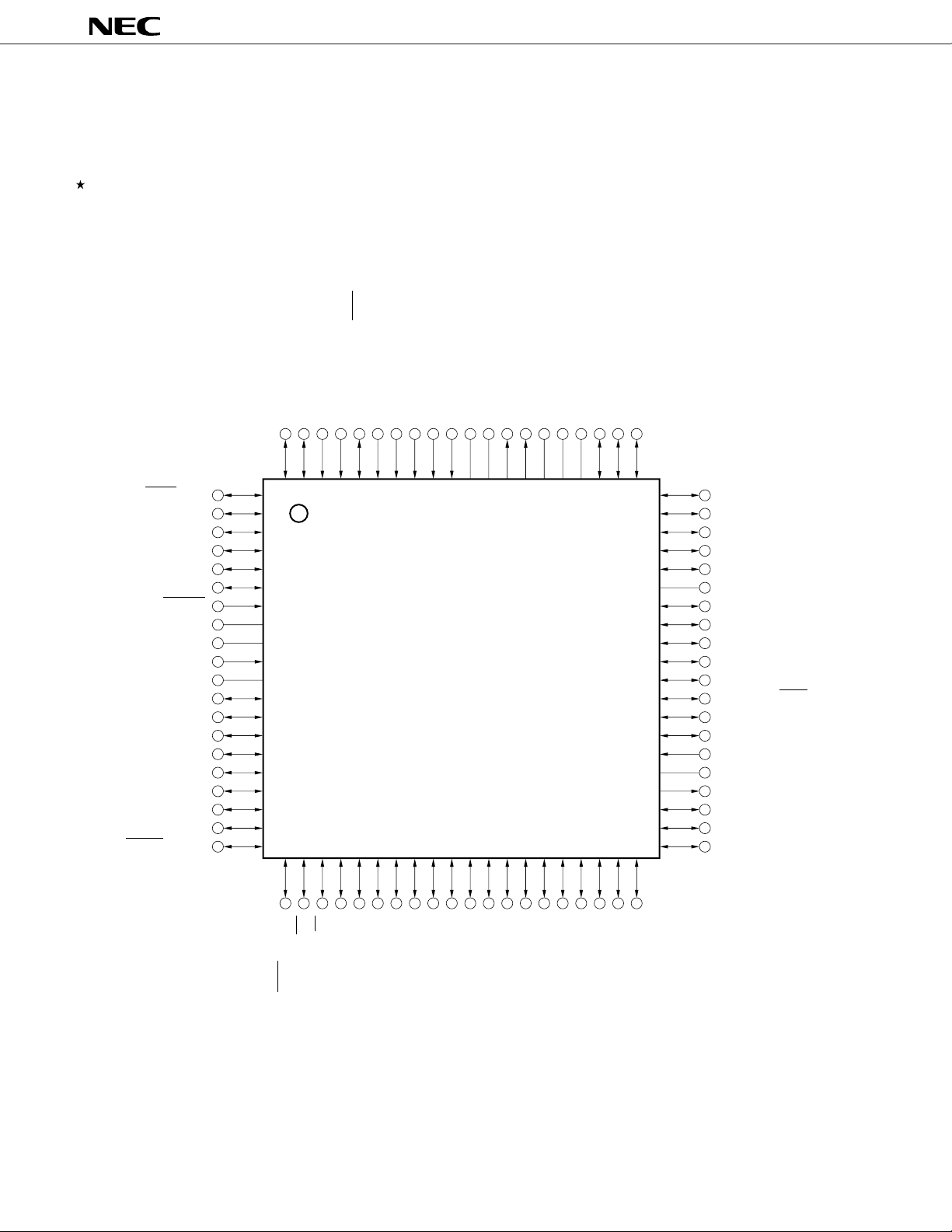

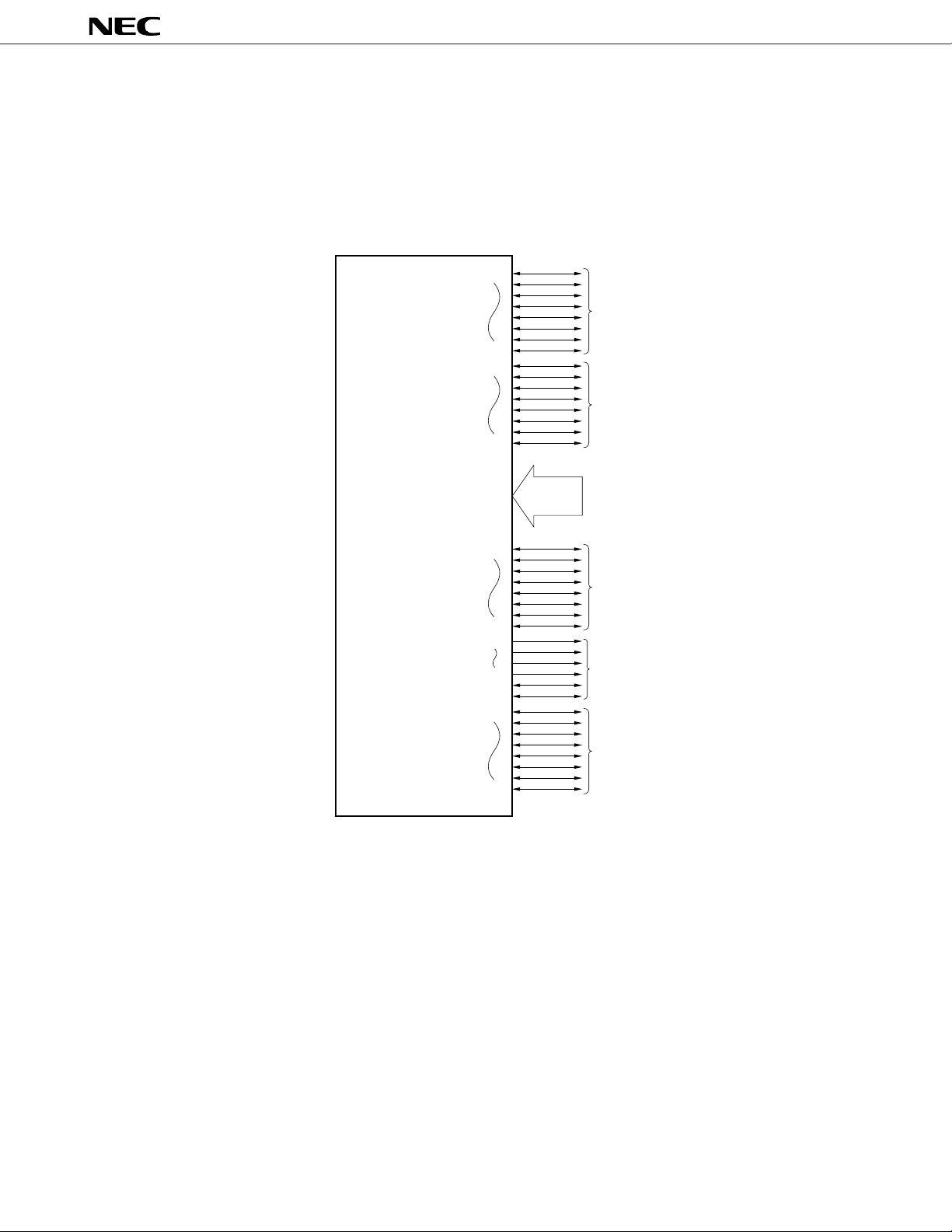

3. PIN CONFIGURATION (Top View)

• 80-pin plastic QFP (14 x 14 mm, thickness 2.7 mm)

µ

PD784031YGC-3B9

• 80-pin plastic QFP (14 x 14 mm, thickness 1.4 mm)

µ

PD784031YGC-8BT

• 80-pin plastic TQFP (fine pitch) (12 x 12 mm)

µ

PD784031YGK-BE9

µ

PD784031Y

P32/SCK0/SCL

P33/SO0/SDA

P34/TO0

P35/TO1

P36/TO2

P37/TO3

RESET

V

DD1

X2

X1

V

SS1

P00

P01

P02

P03

P04

P05

P06

P07

P67/REFRQ/HLDAK

REF3AVREF2

P31/TxD/SO1

P30/RxD/SI1

P27/SI0

P26/INTP5

P25/INTP4/ASCK/SCK1

P24/INTP3

P23/INTP2/CI

P22/INTP1

P21/INTP0

P20/NMI

AV

ANO1

80 6179 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21 4022 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

ANO0

AVSSAV

REF1AVDD

P77/ANI7

P76/ANI6

P75/ANI5

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

P74/ANI4

P73/ANI3

P72/ANI2

P71/ANI1

P70/ANI0

V

DD0

P17

P16

P15

P14/TxD2/SO2

P13/TxD2/SI2

P12/ASCK2/SCK2

P11/PWM1

P10/PWM0

Note

TEST

V

SS0

ASTB

AD0

AD1

AD2

RD

WR

P66/WAIT/HLDRQ

Note Directly connect the TEST pin to V

8

P63/A19

P62/A18

SS0.

P61/A17

P60/A16

A15

A14

A13

A12

A11

A10

A9

A8

AD7

AD6

AD5

AD4

AD3

Page 9

µ

PD784031Y

A8 to A19 : Address Bus

AD0 to AD7 : Address/Data Bus

ANI0 to ANI7 : Analog Input

ANO0, ANO1 : Analog Output

ASCK, ASCK2 : Asynchronous Serial Clock

ASTB : Address Strobe

DD : Analog Power Supply

AV

AVREF1 to AVREF3 : Reference Voltage

SS : Analog Ground

AV

CI : Clock Input

HLDAK : Hold Acknowledge

HLDRQ : Hold Request

INTP0 to INTP5 : Interrupt from Peripherals

NMI : Non-maskable Interrupt

P00 to P07 : Port0

P10 to P17 : Port1

P20 to P27 : Port2

P30 to P37 : Port3

P60 to P63, P66, P67

: Port6

P70 to P77 : Port7

PWM0, PWM1 : Pulse Width Modulation Output

RD : Read Strobe

REFRQ : Refresh Request

RESET : Reset

RxD, RxD2 : Receive Data

SCK0 to SCK2 : Serial Clock

SCL : Serial Clock

SDA : Serial Data

SI0 to SI2 : Serial Input

SO0 to SO2 : Serial Output

TEST : Test

TO0 to TO3 : Timer Output

TxD, TxD2 : Transmit Data

DD0, VDD1 : Power Supply

V

VSS0, VSS1 : Ground

WAIT : Wait

WR : Write Strobe

X1, X2 : Crystal

9

Page 10

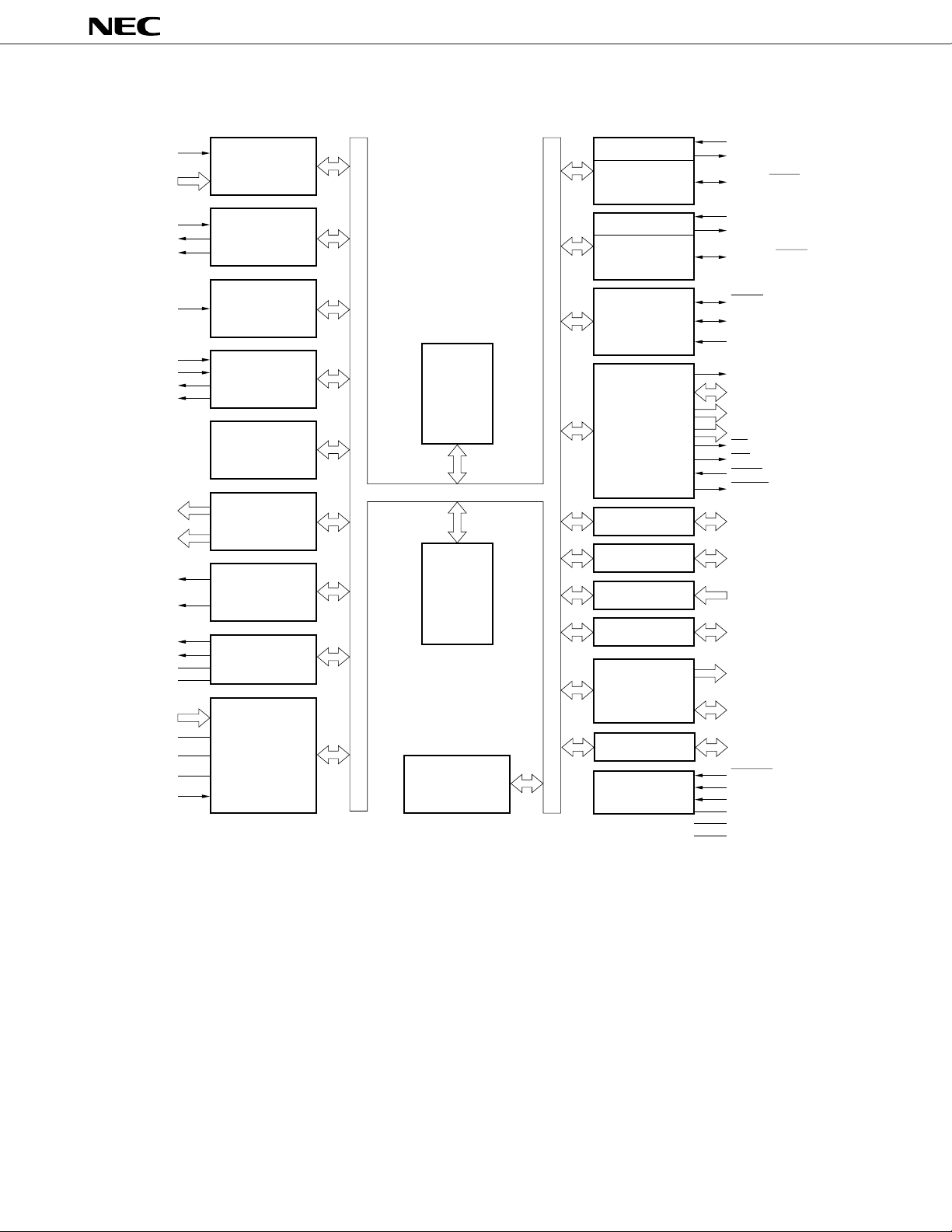

4. BLOCK DIAGRAM

µ

PD784031Y

NMI

INTP0 to INTP5

INTP3

TO0

TO1

INTP0

INTP1

INTP2/CI

TO2

TO3

P00

to

P03

P04

to

P07

PWM0

PWM1

ANO0

ANO1

REF2

AV

AV

REF3

ANI0 to ANI7

DD

AV

AV

REF1

AV

SS

INTP5

PROGRAMMABLE

INTERRUPT

CONTROLLER

TIMER/COUNTER0

(16 BITS)

TIMER/COUNTER1

(16 BITS)

TIMER/COUNTER2

(16 BITS)

TIMER3

(16 BITS)

REAL-TIME

OUTPUT PORT

PWM

D/A

CONVERTER

A/D

CONVERTER

78K/IV

CPU CORE

RAM

WATCHDOG

TIMER

UART/IOE2

BAUD-RATE

GENERATOR

UART/IOE1

BAUD-RATE

GENERATOR

CLOCKED

SERIAL

INTERFACE

BUS I/F

PORT0

PORT1

PORT2

PORT3

PORT6

PORT7

SYSTEM

CONTROL

RxD/SI1

TxD/SO1

ASCK/SCK1

RxD2/SI2

TxD2/SO2

ASCK2/SCK2

SCK0/SCL

SO0/SDA

SI0

ASTB

AD0

to

AD7

A8

to

A15

A16

to

A19

RD

WR

WAIT/HLDRQ

REFRQ/HLDAK

P00

to

P07

P10

to

P17

to

P27

P20

to

P37

P30

to

P63

P60

to

P67

P66

P70

to

P77

RESET

TEST

X1

X2

DD0,VDD1

V

V

SS0,VSS1

10

Page 11

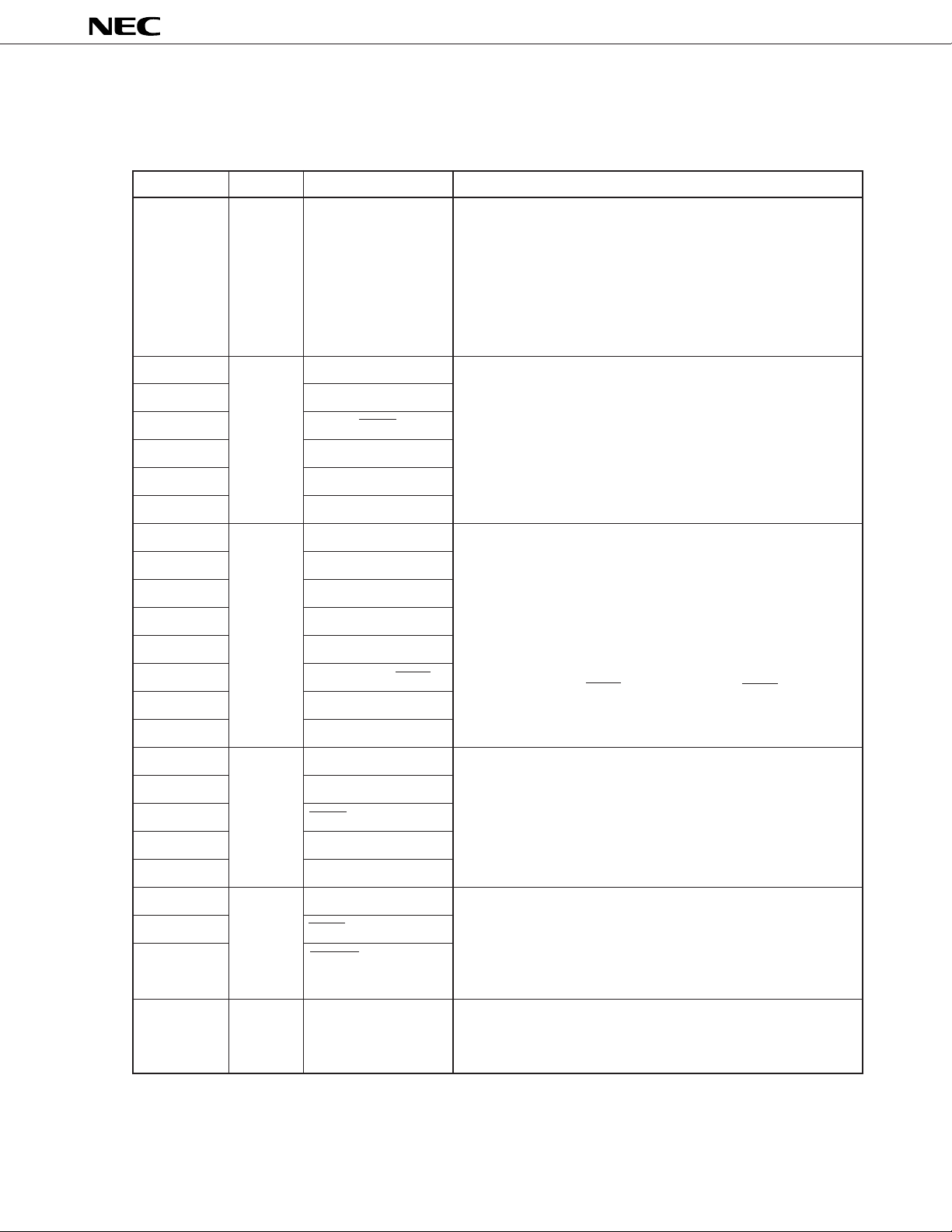

5. PIN FUNCTION

5.1 Port Pins

Pin Name I/O Alternate Function Function

µ

PD784031Y

P00 to P07 I/O –

P10 I/O PWM0

P11 PWM1

P12 ASCK2/SCK2

P13 RxD2/SI2

P14 TxD2/SO2

P15 to P17 –

P20 Input NMI

P21 INTP0

P22 INTP1

P23 INTP2/CI

P24 INTP3

P25 INTP4/ASCK/SCK1

P26 INTP5

P27 SI0

Port 0 (P0):

• 8-bit I/O port

• Can be used as real-time output port (4 bits x 2).

• Can be set in input or output mode bitwise.

• Pins set in input mode can be connected to internal pull-up

resistors by software.

• Can drive transistor.

Port 1 (P1):

• 8-bit I/O port

• Can be set in input or output mode bitwise.

• Pins set in input mode can be connected to internal pull-up

resistors by software.

• Can drive LEDs.

Port 2 (P2):

• 8-bit input port

• P20 cannot be used as general-purpose port pin (non-maskable

interrupt). However, its input level can be checked by interrupt

routine.

• P22 through P27 can be connected to internal pull-up resistors

by software in 6-bit units.

• P25/INTP4/ASCK/SCK1 pin can operate as SCK1 output pin if

so specified by CSIM1.

P30 I/O RxD/S1

P31 TxD/SO1

P32 SCK0/SCL

P33 SO0/SDA

P34 to P37 TO0 to TO3

P60 to P63 I/O A16 to A19

P66 WAIT/HLDRQ

P67 REFRQ/HLDAK

P70 to P77 I/O AN10 to AN17

Port 3 (P3):

• 8-bit I/O port

• Can be set in input or output mode bitwise.

• Pins set in input mode can be connected to internal pull-up

resistors by software.

Port 6 (P6):

• P60 through P63 is dedicated ports for output.

• P66 and P67 can be set in input or output mode bitwise.

• Pins set in input mode can be connected to internal pull-up

resistors by software.

Port 7 (P7):

• 8-bit I/O port

• Can be set in input or output mode bitwise.

11

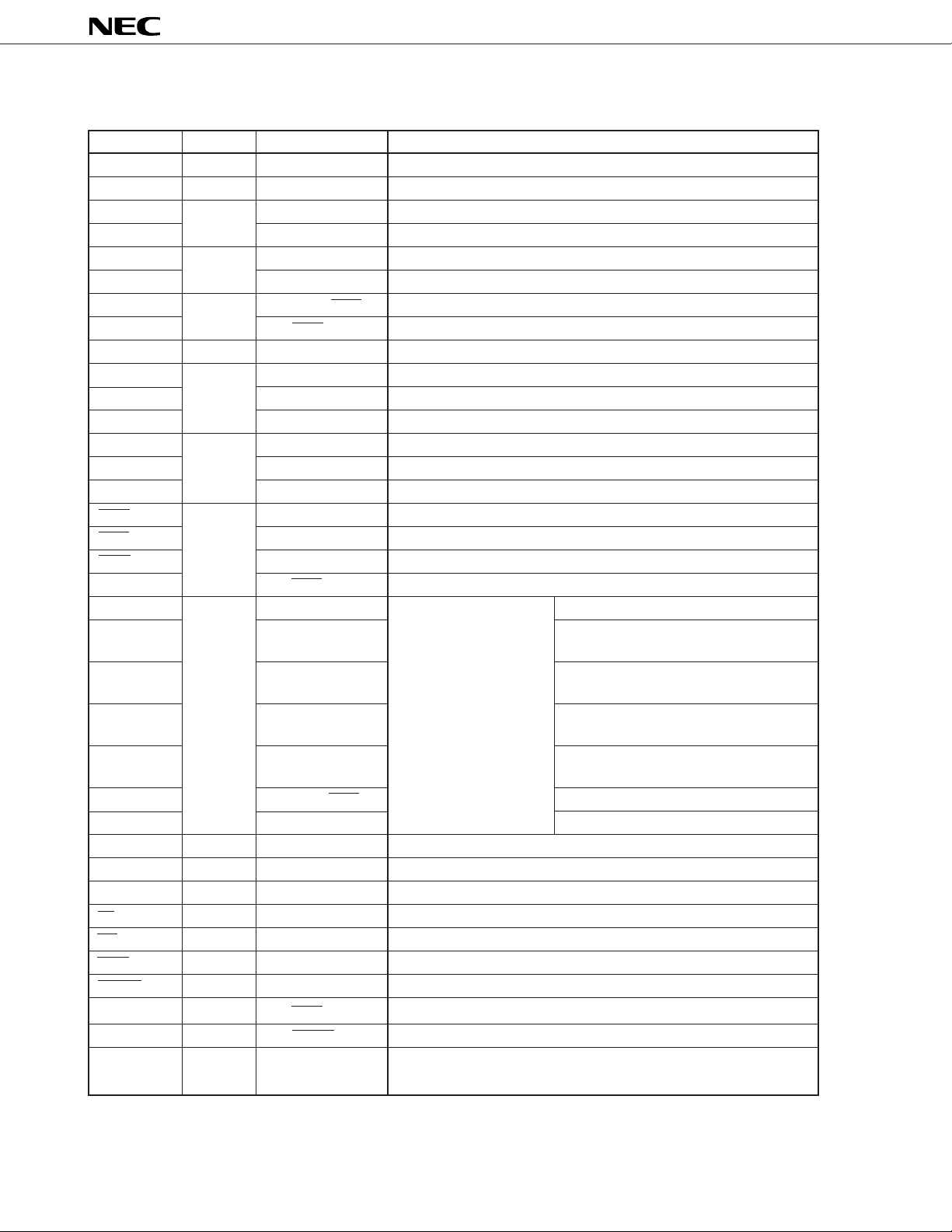

Page 12

µ

PD784031Y

5.2 Non-port Pins

Pin Name I/O Alternate Function Function

TO0 to TO3 Output P34 to P37 Timer output

CI Input P23/INTP2 Count clock input to timer/counter 2

RxD Input P30/SI1 Serial data input (UART0)

RxD2 P13/SI2 Serial data input (UART2)

TxD Output P31/SO1 Serial data output (UART0)

TxD2 P14/SO2 Serial data output (UART2)

ASCK Input P25/INTP4/SCK1 Baud rate clock input (UART0)

ASCK2 P12/SCK2 Baud rate clock input (UART2)

SDA I/O P33/SO0 Serial data input/output (2-wire serial I/O, I2C bus)

SI0 Input P27 Serial data input (3-wire serial I/O0)

SI1 P30/RxD Serial data input (3-wire serial I/O1)

SI2 P13/RxD2 Serial data input (3-wire serial I/O2)

SO0 Output P33/SDA Serial data output (3-wire serial I/O0)

SO1 P31/TxD Serial data output (3-wire serial I/O1)

SO2 P14/TxD2 Serial data output (3-wire serial I/O2)

SCK0 I/O P32/SCL Serial clock input/output (3-wire serial I/O0)

SCK1 P25/INTP4/ASCK Serial clock input/output (3-wire serial I/O1)

SCK2 P12/ASCK2 Serial clock input/output (3-wire serial I/O2)

SCL P32/SCK0 Serial clock input/output (2-wire serial I/O, I2C bus)

NMI Input P20 External interrupt requests –

INTP0 P21 • Count clock input to timer/counter 1

• Capture trigger signal of CR11 or CR12

INTP1 P22 • Count clock input to timer/counter 2

• Capture trigger signal of CR22

INTP2 P23/CI • Count clock input to timer/counter 2

• Capture trigger signal of CR21

INTP3 P24 • Count clock input to timer/counter 0

• Capture trigger signal of CR02

INTP4 P25/ASCK/SCK1 –

INTP5 P26 Conversion start trigger input to A/D converter

AD0 to AD7 I/O – Time-division address/data bus (for external memory connection)

A8 to A15 Output – Higher address bus (for external memory connection)

A16 to A19 Output P60 to P63 Higher address when address is extended (for external memory connection)

RD Output – Read strobe to external memory

WR Output – Write strobe to external memory

WAIT Input P66/HLDRQ Wait insertion

REFRQ Output P67/HLDAK Refresh pulse output to external pseudo static memory

HLDRQ Input P66/WAIT Bus hold request input

HLDAK Output P67/REFRQ Bus hold acknowledge output

ASTB Output – Latch timing output of time-division address (A0 through A7)

(when accessing external memory)

12

Page 13

Pin Name I/O Alternate Function Function

RESET Input – Chip reset

X1 Input – Crystal connection for system clock oscillation

X2 – (Clock can also be input to X1.)

ANI0 to ANI7 Input P70 to P77 Analog voltage input to A/D converter

ANO0, ANO1 Output – Analog voltage output from D/A converter

AVREF1 – – Reference voltage to A/D converter

AVREF2, AVREF3

AVDD A/D converter power supply

AVSS A/D converter GND

Note 1

VDD0

Note 1

VDD1

Note 2

VSS0

Note 2

VSS1

TEST Directly connect to VSS0 (IC test pin).

Reference voltage to D/A converter

Power supply of port

Power supply except for port

GND of port

GND except for port

Notes 1. Provide the same potential to VDD0 and VDD1.

2. Provide the same potential to V

SS0 and VSS1.

µ

PD784031Y

13

Page 14

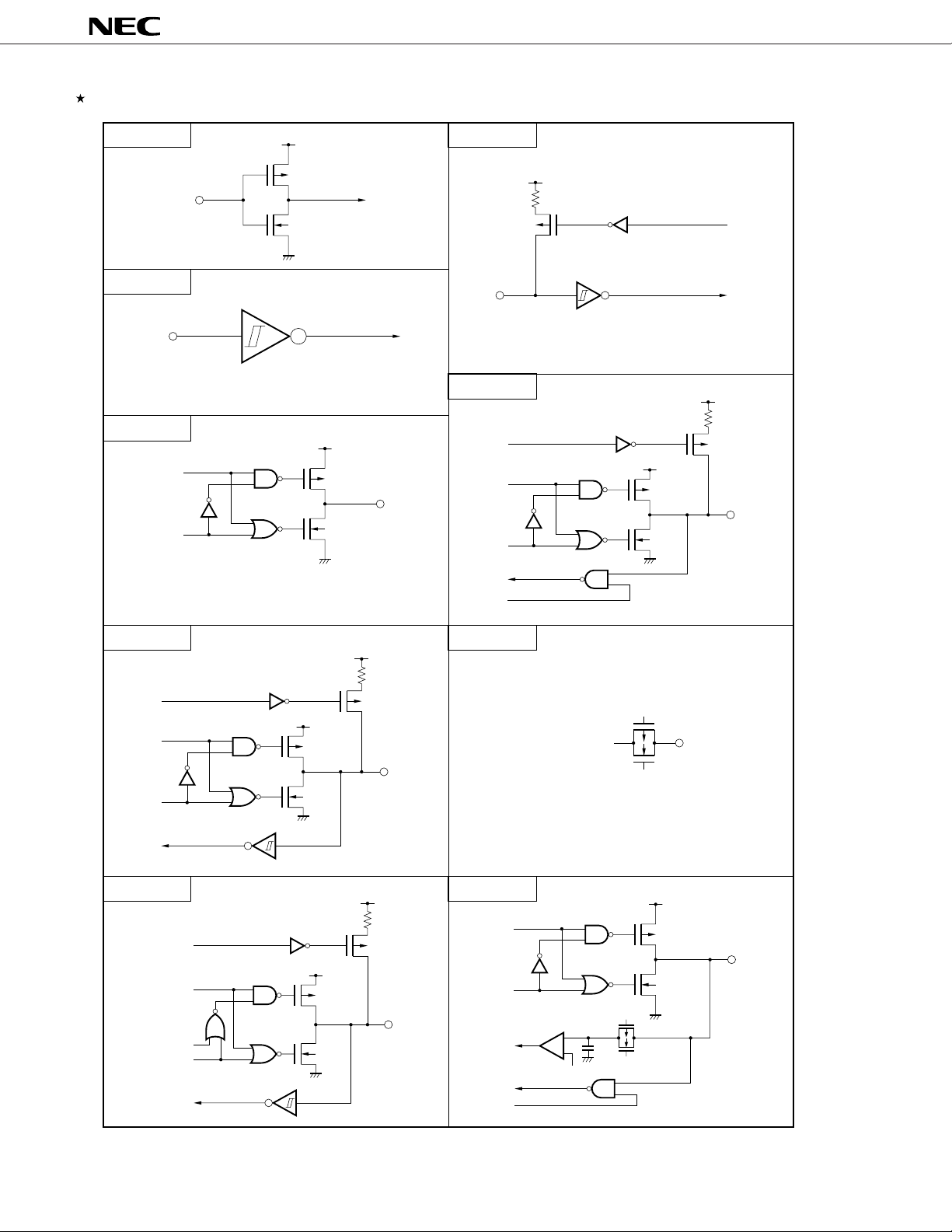

5.3 Types of Pin I/O Circuits and Connections for Unused Pins

Table 5-1 shows types of pin I/O circuits and the connections for unused pins.

For the input/output circuit of each type, refer to Figure 5-1.

Table 5-1. Types of Pin I/O Circuits and Connections for Unused Pins (1/2)

Pin Name I/O Circuit Type I/O Recommended Connection for Unused Pins

P00 to P07 5-H I/O Input: Connect to VDD0.

P10/PWM0 Output: Open

P11/PWM1

P12/ASCK2/SCK2 8-C

P13/RxD2/SI2 5-H

P14/TxD2/SO2

P15 to P17

P20/NMI 2 Input Connect to VDD0 or VSS0.

P21/INTP0

P22/INTP1 2-C Connect to VDD0.

µ

PD784031Y

P23/INTP2/CI

P24/INTP3

P25/INTP4/ASCK/SCK1 8-C I/O Input: Connect to VDD0.

Output: Open

P26/INTP5 2-C Input Connect to VDD0.

P27/SI0

P30/RxD/SI1 5-H I/O Input: Connect to VDD0.

P31/TxD/SO1 Output: Open

P32/SCK0/SCL 10-B

P33/SO0/SDA

P34/TO0 to P37/TO3 5-H

AD0 to AD7

A8 to A15 Output

P60/A16 to P63/A19

RD

WR

P66/WAIT/HLDRQ I/O Input: Connect to VDD0.

P67/REFRQ/HLDAK Output: Open

P70/ANI0 to P77/ANI7 20-A Input: Connect to VDD0 or VSS0.

ANO0, ANO1 12 Output Open

Note

Open

Output: Open

ASTB 4-B

Note I/O circuit type of these pins is 5-H. However these pins perform only as output by an internal circuit.

14

Page 15

Table 5-1. Types of Pin I/O Circuits and Connections for Unused Pins (2/2)

Pin Name I/O Circuit Type I/O Recommended Connection for Unused Pins

RESET 2 Input –

TEST 1-A Directly connect to VSS0.

AVREF1 to AVREF3 – Connect to VSS0.

AVSS

AVDD Connect to VDD0.

µ

PD784031Y

Caution Connect an I/O pin whose input/output mode is unstable to V

DD0 via a resistor of several 10 kΩ

(especially if the voltage on the reset input pin rises higher than the low-level input level on power

application or when the mode is switched between input and output by software).

Remark Because the circuit type numbers shown in the above table are commonly used with all the models in the 78K

Series, these numbers of some models are not serial (because some circuits are not provided to some models).

15

Page 16

Figure 5-1. Types of Pin I/O Circuits

µ

PD784031Y

Type 1-A

DD0

V

P

IN

N

V

SS0

Type 2

IN

Schmitt trigger input with hysteresis characteristics

Type 4-B

data

output

disable

DD0

V

P

N

V

SS0

OUT

Type 2-C

V

DD0

P

IN

Schmitt trigger input with hysteresis characteristics

Type 5-H

pullup

enable

data

output

disable

DD0

V

P

N

V

SS0

pullup

enable

V

DD0

P

IN/OUT

Push-pull output that can go into a high-impedance

state (with both P-ch and N-ch off)

Type 8-C

pullup

enable

data

output

disable

DD0

V

P

N

V

SS0

Type 10-B

pullup

enable

DD0

V

data

open drain

output disable

P

N

V

SS0

input

enable

Type 12

V

DD0

P

P

Analog output voltage

IN/OUT

V

DD0

Type 20-A

N

data

P

OUT

DD0

V

P

IN/OUT

IN/OUT

output

disable

Comparator

+

–

AV

AV

REF

(threshold voltage)

N

V

SS0

P

N

SS

input

enable

16

Page 17

µ

PD784031Y

6. CPU ARCHITECTURE

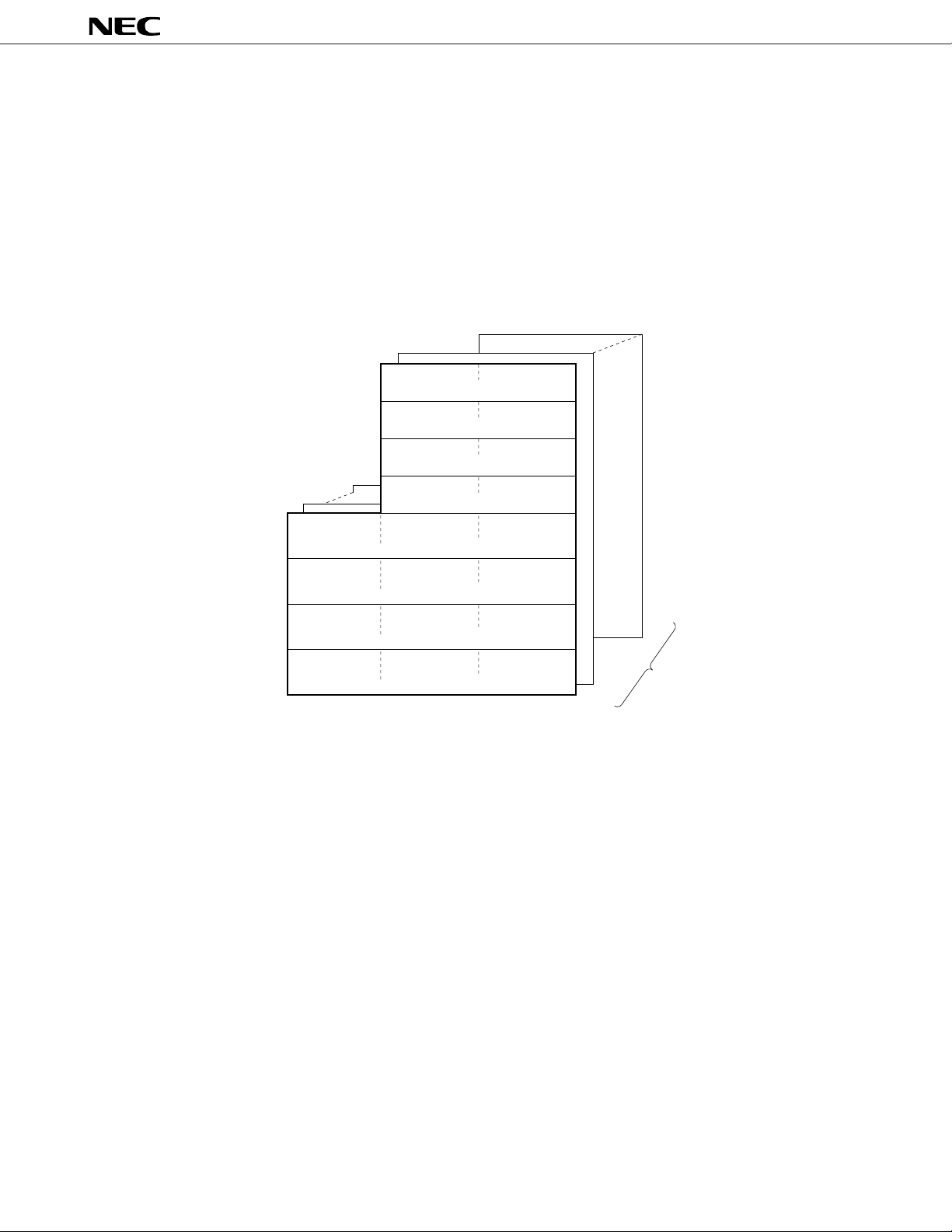

6.1 Memory Space

A memory space of 1 Mbytes can be accessed. Mapping of the internal data area (special function registers and internal

RAM) can be specified the LOCATION instruction. The LOCATION instruction must be always executed after reset

cancellation, and must not be used more than once.

(1) When LOCATION 0 instruction is executed

The internal data area is mapped in 0F700H to 0FFFFH.

(2) When LOCATION 0FH instruction is executed

The internal data area is mapped in FF700H to FFFFFH.

17

Page 18

18

Figure 6-1. Memory Map of

µ

PD784031Y

On execution of

LOCATION 0 instruction

HFFFFF

External memory

(960 Kbytes)

H00001

HFFFF0

Special function registers (SFR)

HFDFF0

H0DFF0

H00FF0

HFFEF0

H00DF0

HFFCF0

(256 bytes)

Internal RAM

(2 Kbytes)

H007F0

HFF6F0

External memory

(63232 bytes)

H00000

Note

HFFEF0

General-purpose

registers (128 bytes)

H08EF0

HF7EF0

H13EF0

Macro service control word

area (44 bytes)

H60EF0

Data area (512 bytes)

H00DF0

HFFCF0

Program/data area

(1536 bytes)

H007F0

H00010

HFFF00

CALLF entry area

(2 Kbytes)

H00800

HFF700

H08000

HF7000

CALLT table area

(64 bytes)

H04000

HF3000

Vector table area

(64 bytes)

H00000

On execution of

LOCATION 0FH instruction

HFFFFF

Special function registers (SFR)

HFDFFF

H0DFFF

HFFEFF

H00FFF

HFFEFF

(256 bytes)

Internal RAM

(2 Kbytes)

H08EFF

HF7EFF

13

HEFF

H60EFF

H00DFF

HFFCFF

H007FF

HFF6FF

External memory

(1046272 bytes)

H007FF

HFFF00

H00800

HFF700

H08000

HF7000

H00001

HFFFF0

Note

H00000

µ

PD784031Y

Note Base area and entry area for reset or interrupt. However, the internal RAM area is not used as a reset entry area.

Page 19

µ

(

PD784031Y

6.2 CPU Registers

6.2.1 General-purpose registers

Sixteen 8-bit general-purpose registers are available. Two 8-bit registers can be also used in pairs as a 16-bit register.

Of the 16-bit registers, four can be used in combination with an 8-bit register for address expansion as 24-bit address

specification registers.

Eight banks of these registers are available which can be selected by using software or the context switching function.

The general-purpose registers except V, U, T, and W registers for address expansion are mapped to the internal RAM.

Figure 6-2. General-purpose Register Format

V

VVP (RG4)

U

UUP (RG5)

T

TDE (RG6)

W

WHL (RG7)

Parentheses

A (R1)

AX (RP0)

B (R3)

BC (RP1)

R5

R7

R9

VP (RP4)

R11

UP (RP5)

D (R13)

DE (RP6)

H (R15)

HL (RP7)

) indicate an absolute name.

X (R0)

C (R2)

R4

RP2

R6

RP3

R8

R10

E (R12)

L (R14)

8 banks

Caution Registers R4, R5, R6, R7, RP2, and RP3 can be used as X, A, C, B, AX, and BC registers, respectively,

by setting the RSS bit of the PSW to 1. However, use this function only for recycling the program of

the 78K/III Series.

19

Page 20

6.2.2 Control registers

(1) Program counter (PC)

The program counter is a 20-bit register whose contents are automatically updated when the program is executed.

Figure 6-3. Program Counter (PC) Format

19 0

PC

(2) Program status word (PSW)

This register holds the statuses of the CPU. Its contents are automatically updated when the program is executed.

Figure 6-4. Program Status Word (PSW) Format

15 14 13 12 11 10 9 8

UF RBS2 RBS1 RBS0 – – – –PSWH

µ

PD784031Y

PSW

76543210

S Z RSS

Note

AC IE P/V 0 CYPSWL

Note This flag is provided to maintain compatibility with the 78K/III Series. Be sure to clear this flag to 0, except when

the software for the 78K/III Series is used.

(3) Stack pointer (SP)

This is a 24-bit pointer that holds the first address of the stack.

Be sure to write 0 to the higher 4 bits of this pointer.

Figure 6-5. Stack Pointer (SP) Format

23 0

SP

20

0000

20

Page 21

µ

PD784031Y

6.2.3 Special function registers (SFRs)

The special function registers, such as the mode registers and control registers of the internal peripheral hardware, are

registers to which special functions are allocated. These registers are mapped to a 256-byte space of addresses 0FF00H

Note

through 0FFFFH

Note On execution of the LOCATION 0 instruction. FFF00H through FFFFFH on execution of the LOCATION 0FH

instruction.

Caution Do not access an address in this area to which no SFR is allocated. If such an address is accessed by

mistake, the

inputting the reset signal.

Table 6-1 lists the special function registers (SFRs). The meanings of the symbols in this table are as follows:

• Symbol................................ Symbol indicating an SFR. This symbol is reserved for NEC’s assembler (RA78K4).

.

µ

PD784031Y may be in the deadlock status. This deadlock status can be cleared only by

It can be used as an sfr variable by the #pragma sfr command with the C compiler

(CC78K4).

• R/W..................................... Indicates whether the SFR is read-only, write-only, or read/write.

R/W : Read/write

R : Read-only

W : Write-only

• Bit units for manipulation .... Bit units in which the value of the SFR can be manipulated.

SFRs that can be manipulated in 16-bit units can be described as the operand

sfrp of an instruction. To specify the address of this SFR, describe an even

address.

SFRs that can be manipulated in 1-bit units can be described as the operand of a

bit manipulation instruction.

• After reset........................... Indicates the status of the register when the RESET signal has been input.

21

Page 22

µ

PD784031Y

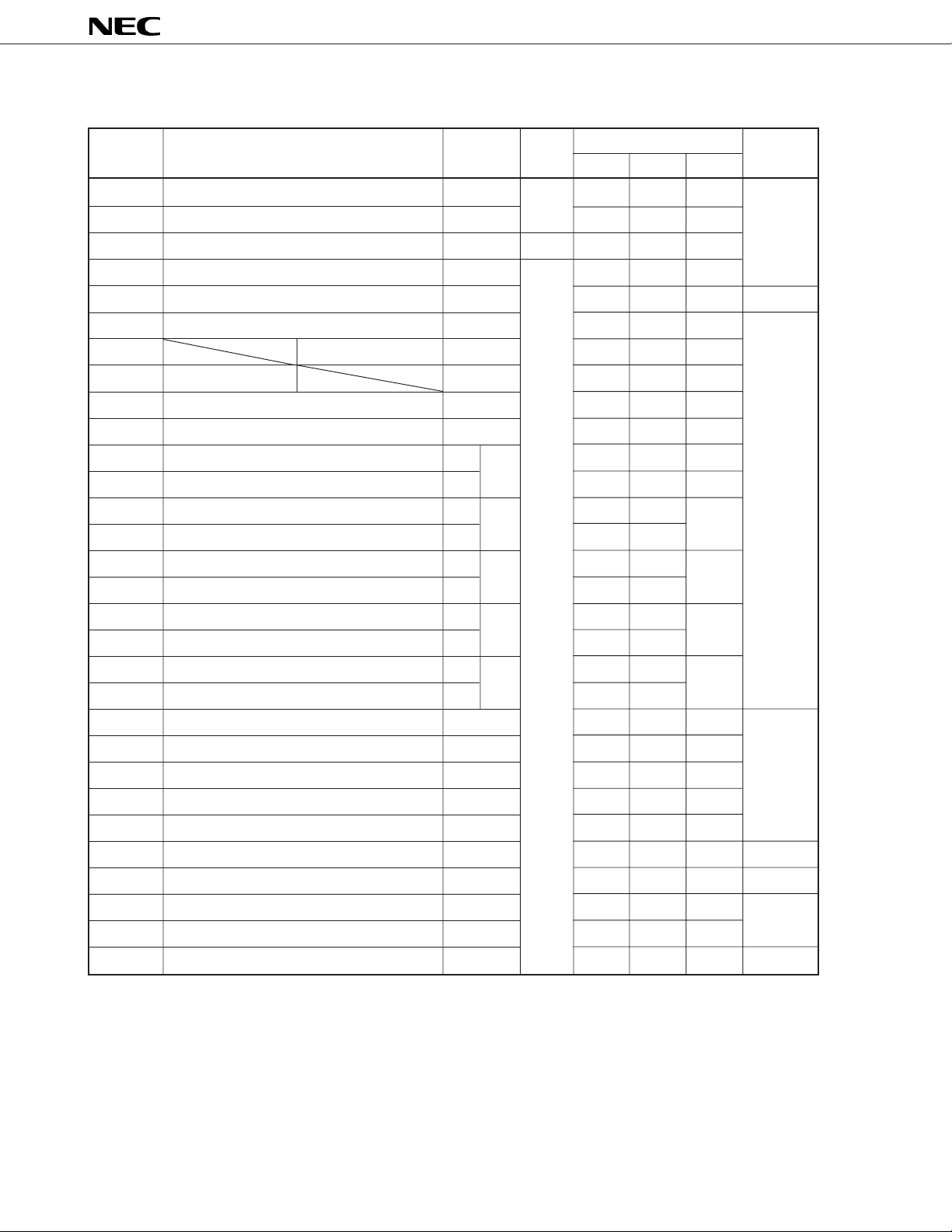

Table 6-1. Special Function Registers (SFRs) (1/4)

Note

Address

0FF00H Port 0 P0 R/W √√– Undefined

0FF01H Port 1 P1 √√–

0FF02H Port 2 P2 R √√–

0FF03H Port 3 P3 R/W √√–

0FF06H Port 6 P6 √√– 00H

0FF07H Port 7 P7 √√– Undefined

0FF0EH Port 0 buffer register L P0L √√–

Special Function Register (SFR) Name Symbol R/W Bit Units for Manipulation After Reset

1 bit 8 bits 16 bits

0FF0FH

0FF10H Compare register (timer/counter 0) CR00 – – √

0FF12H Capture/compare register (timer/counter 0) CR01 – – √

0FF14H Compare register L (timer/counter 1)

0FF15H Compare register H (timer/counter 1) – – –

0FF16H Capture/compare register L (timer/counter 1)

0FF17H Capture/compare register H (timer/counter 1) – – –

0FF18H Compare register L (timer/counter 2)

0FF19H Compare register H (timer/counter 2) – – –

0FF1AH Capture/compare register L (timer/counter 2)

0FF1BH Capture/compare register H (timer/counter 2) – – –

0FF1CH Compare register L (timer 3)

0FF1DH Compare register H (timer 3) – – –

0FF20H Port 0 mode register PM0 √√– FFH

0FF21H Port 1 mode register PM1 √√–

0FF23H Port 3 mode register PM3 √√–

0FF26H Port 6 mode register PM6 √√–

0FF27H Port 7 mode register PM7 √√–

Port 0 buffer register H

P0H √√–

CR10

CR11

CR20

CR21

CR30

CR10W

CR11W

CR20W

CR21W

CR30W

– √√

– √√

– √√

– √√

– √√

0FF2EH Real-time output port control register RTPC √√– 00H

0FF30H Capture/compare control register 0 CRC0 – √ – 10H

0FF31H Timer output control register TOC √√– 00H

0FF32H Capture/compare control register 1 CRC1 – √ –

0FF33H Capture/compare control register 2 CRC2 – √ – 10H

Note When the LOCATION 0 instruction is executed. When the LOCATION 0FH instruction is executed, “F0000H” is

added to this value.

22

Page 23

µ

PD784031Y

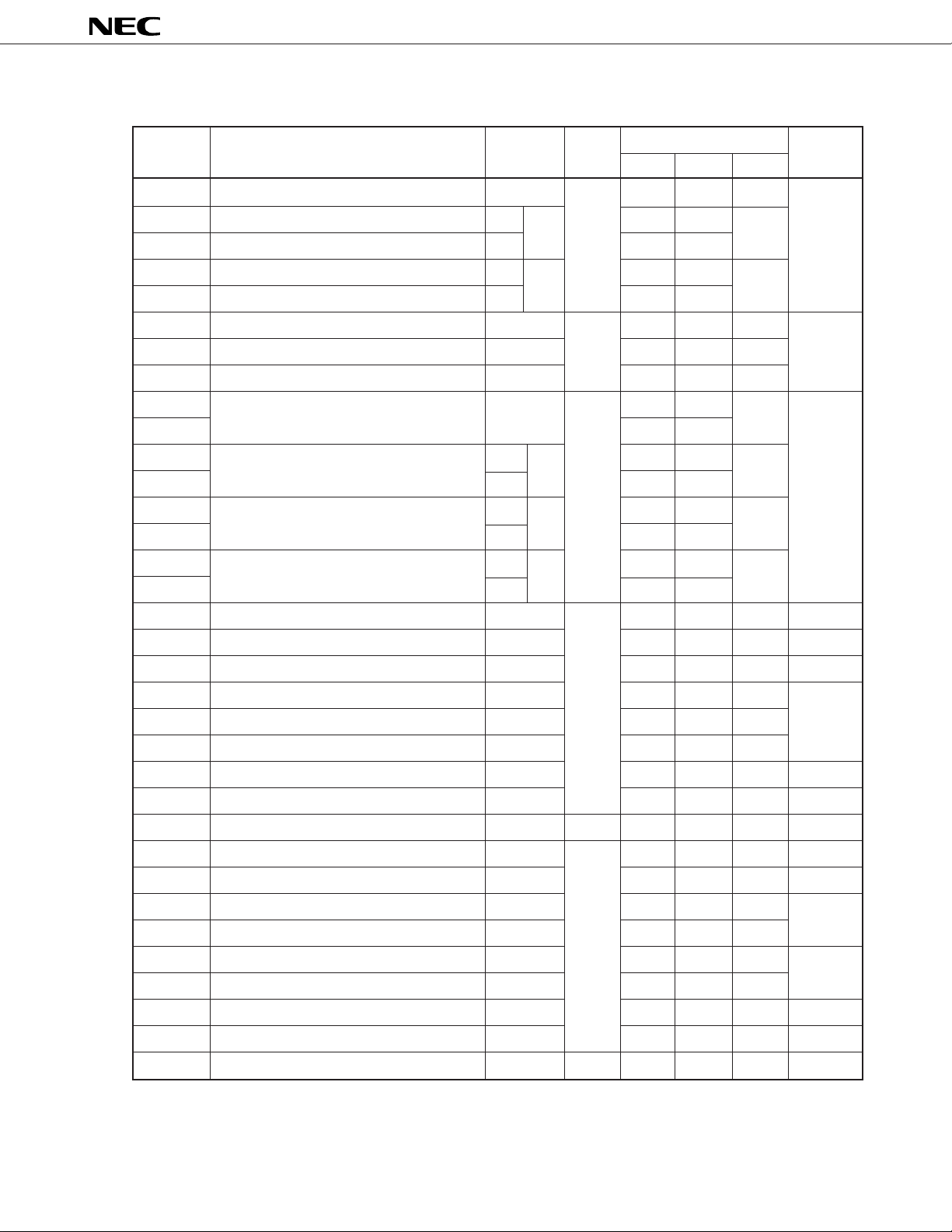

Table 6-1. Special Function Registers (SFRs) (2/4)

Note 1

Address

0FF36H Capture register (timer/counter 0) CR02 R – – √ 0000H

0FF38H Capture register L (timer/counter 1)

0FF39H Capture register H (timer/counter 1) – – –

Special Function Register (SFR) Name Symbol R/W Bit Units for Manipulation After Reset

1 bit 8 bits 16 bits

CR12

CR12W

– √√

0FF3AH Capture register L (timer/counter 2)

0FF3BH Capture register H (timer/counter 2) – – –

0FF41H Port 1 mode control register PMC1 R/W √√– 00H

0FF43H Port 3 mode control register PMC3 √√–

0FF4EH Pull-up resistor option register PUO √√–

0FF50H Timer register 0 TM0 R – – √ 0000H

0FF51H ––

0FF52H Timer register 1 TM1

0FF53H – – –

0FF54H Timer register 2 TM2

0FF55H – – –

0FF56H Timer register 3 TM3

0FF57H – – –

0FF5CH Prescaler mode register 0 PRM0 R/W – √ – 11H

0FF5DH Timer control register 0 TMC0 √√ – 00H

0FF5EH Prescaler mode register 1 PRM1 – √ – 11H

0FF5FH Timer control register 1 TMC1 √√– 00H

0FF60H D/A conversion value setting register 0 DACS0 – √ –

CR22

CR22W

TM1W

TM2W

TM3W

– √√

– √√

– √√

– √√

0FF61H D/A conversion value setting register 1 DACS1 – √ –

0FF62H D/A converter mode register DAM √√– 03H

0FF68H A/D converter mode register ADM √√– 00H

0FF6AH A/D conversion result register ADCR R – √ – Undefined

0FF70H PWM control register PWMC R/W √√– 05H

0FF71H PWM prescaler register PWPR – √ – 00H

0FF72H PWM modulo register 0 PWM0 – – √ Undefined

0FF74H PWM modulo register 1 PWM1 – – √

0FF7DH One-shot pulse output control register OSPC √√ – 00H

0FF80H I2C bus control register IICC √√–

0FF81H Prescaler mode register for serial clock SPRM – √ – 04H

0FF82H Clocked serial interface mode register CSIM √√– 00H

0FF83H Slave address register SVA

Note 2√Note 3

R/W

√ – 01H

Notes 1. When the LOCATION 0 instruction is executed. When the LOCATION 0FH instruction is executed, “F0000H”

is added to this value.

2. Bit 0 is read-only.

3. Only bit 0 can be manipulated in bit units.

23

Page 24

µ

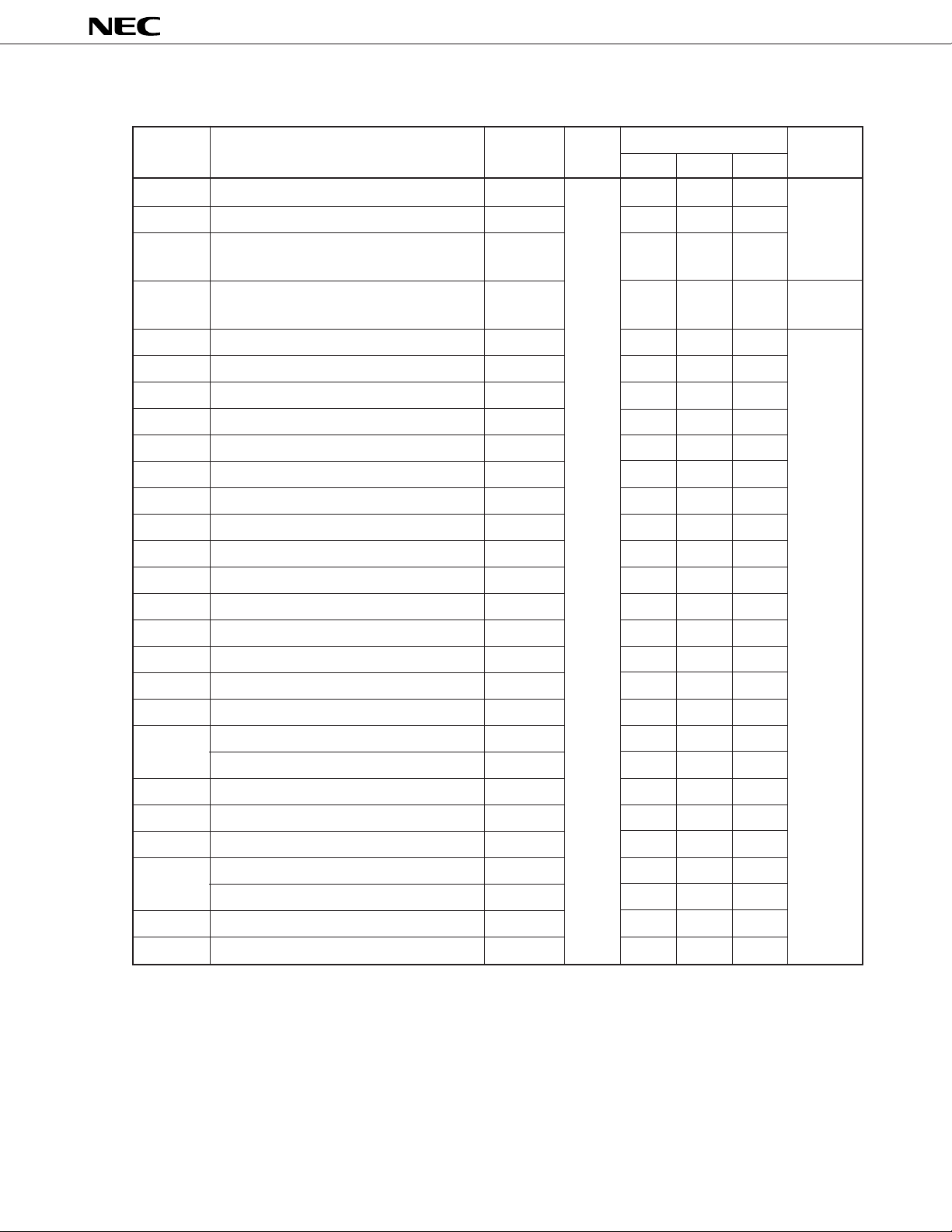

Table 6-1. Special Function Registers (SFRs) (3/4)

Note 1

Address

0FF84H Clocked serial interface mode register 1 CSIM1 R/W √√– 00H

0FF85H Clocked serial interface mode register 2 CSIM2 √√–

0FF86H Serial shift register SIO – √ –

0FF88H Asynchronous serial interface mode register ASIM √√–

0FF89H Asynchronous serial interface mode register 2 ASIM2 √√–

0FF8AH Asynchronous serial interface status register ASIS R √√–

Special Function Register (SFR) Name Symbol R/W Bit Units for Manipulation After Reset

1 bit 8 bits 16 bits

PD784031Y

0FF8BH

0FF8CH Serial receive buffer: UART0 RXB – √ – Undefined

0FF8DH Serial receive buffer: UART2 RXB2 R – √ –

0FF90H Baud rate generator control register BRGC – √ – 00H

0FF91H Baud rate generator control register 2 BRGC2 – √ –

0FFA0H External interrupt mode register 0 INTM0 √√–

0FFA1H External interrupt mode register 1 INTM1 √√–

0FFA4H Sampling clock select register SCS0 – √ –

0FFA8H In-service priority register ISPR R √√–

0FFAAH Interrupt mode control register IMC R/W √√– 80H

0FFACH Interrupt mask register 0L MK0L MK0 √√√FFFFH

0FFADH Interrupt mask register 0H

0FFAEH Interrupt mask register 1L MK1L √√– FFH

0FFC0H Standby control register STBC – √

0FFC2H Watchdog timer mode register WDM – √

Asynchronous serial interface status register 2

Serial transmit shift register: UART0 TXS W – √ –

Serial shift register: IOE1 SIO1 R/W – √ –

Serial transmit shift register: UART2 TXS2 W – √ –

Serial shift register: IOE2 SIO2 R/W – √ –

ASIS2 √√–

MK0H

√√

Note 2

Note 2

– 30H

– 00H

0FFC4H Memory expansion mode register MM √√– 20H

0FFC5H Hold mode register HLDM √√– 00H

0FFC6H Clock output mode register CLOM √√–

0FFC7H Programmable wait control register 1 PWC1 – √ – AAH

0FFC8H Programmable wait control register 2 PWC2 – – √ AAAAH

Notes 1. When the LOCATION 0 instruction is executed. When the LOCATION 0FH instruction is executed, “F0000H”

is added to this value.

2. Data can be written by using only dedicated instructions such as MOV STBC, #byte and MOV WDM, #byte,

and cannot be written with any other instructions.

24

Page 25

µ

PD784031Y

Table 6-1. Special Function Registers (SFRs) (4/4)

Note

Address

0FFCCH Refresh mode register RFM R/W √√– 00H

0FFCDH Refresh area specification register RFA √√–

0FFCFH Oscillation stabilization time specification OSTS – √ –

0FFD0H to External SFR area – √√––

0FFDFH

0FFE0H Interrupt control register (INTP0) PIC0 √√– 43H

0FFE1H Interrupt control register (INTP1) PIC1 √√–

0FFE2H Interrupt control register (INTP2) PIC2 √√–

0FFE3H Interrupt control register (INTP3) PIC3 √√–

0FFE4H Interrupt control register (INTC00) CIC00 √√ –

0FFE5H Interrupt control register (INTC01) CIC01 √√ –

Special Function Register (SFR) Name Symbol R/W Bit Units for Manipulation After Reset

1 bit 8 bits 16 bits

register

0FFE6H Interrupt control register (INTC10) CIC10 √√ –

0FFE7H Interrupt control register (INTC11) CIC11 √√ –

0FFE8H Interrupt control register (INTC20) CIC20 √√ –

0FFE9H Interrupt control register (INTC21) CIC21 √√ –

0FFEAH Interrupt control register (INTC30) CIC30 √√ –

0FFEBH Interrupt control register (INTP4) PIC4 √√–

0FFECH Interrupt control register (INTP5) PIC5 √√–

0FFEDH Interrupt control register (INTAD) ADIC √√–

0FFEEH Interrupt control register (INTSER) SERIC √√–

0FFEFH Interrupt control register (INTSR) SRIC √√–

Interrupt control register (INTCSI1) CSIIC1 √√–

0FFF0H Interrupt control register (INTST) STIC √√–

0FFF1H Interrupt control register (INTCSI) CSIIC √√–

0FFF2H Interrupt control register (INTSER2) SERIC2 √√–

0FFF3H Interrupt control register (INTSR2) SRIC2 √√–

Interrupt control register (INTCSI2) CSIIC2 √√–

0FFF4H Interrupt control register (INTST2) STIC2 √√–

0FFF5H Interrupt control register (INTSPC) SPCIC √√–

Note When the LOCATION 0 instruction is executed. When the LOCATION 0FH instruction is executed, “F0000H” is

added to this value.

25

Page 26

µ

PD784031Y

7. PERIPHERAL HARDWARE FUNCTIONS

7.1 Ports

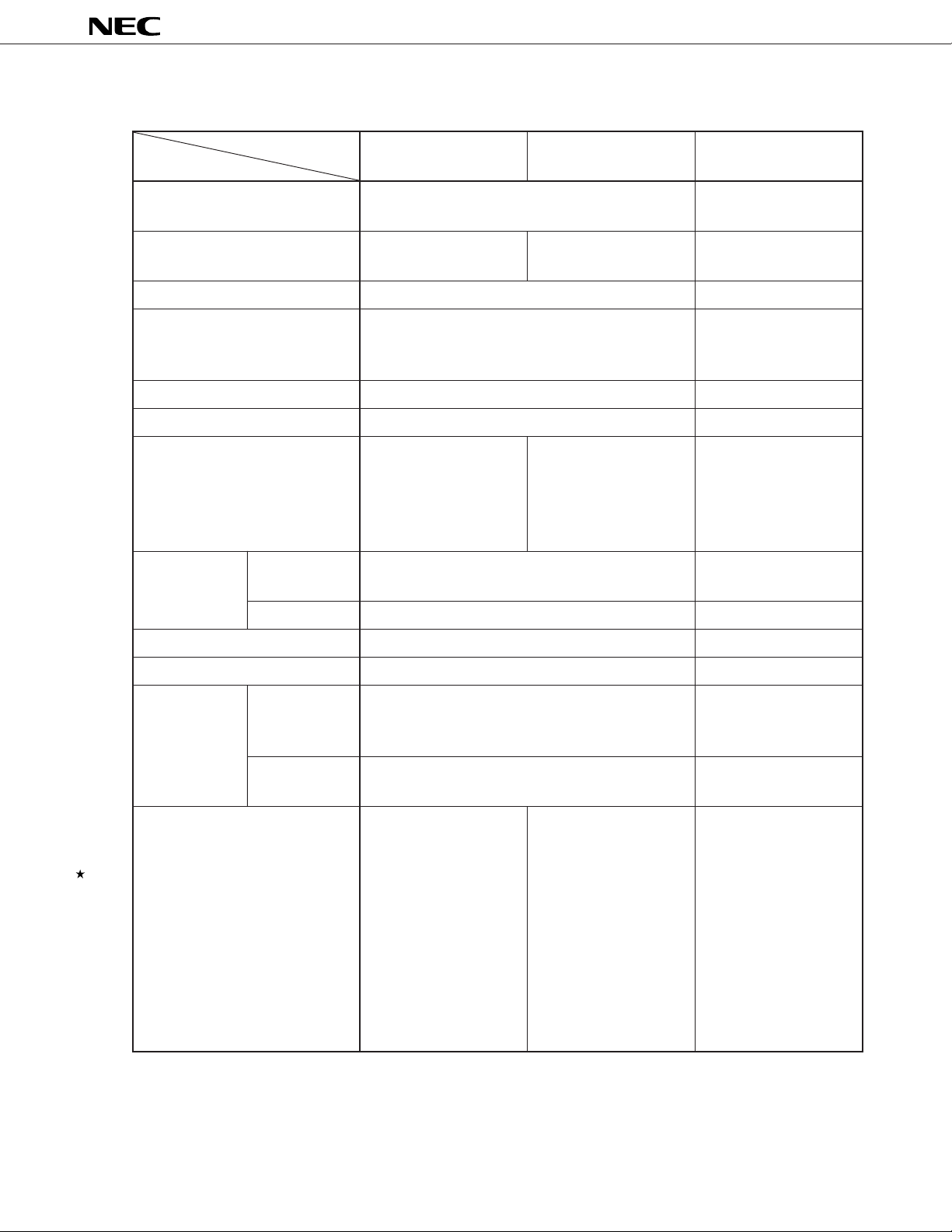

The ports shown in Figure 7-1 are provided to make various control operations possible. Table 7-1 shows the function

of each port. Ports 0 through 6 can be connected to internal pull-up resistors by software when inputting.

Figure 7-1. Port Configuration

P00

Port 0

P07

P10

Port 1

P17

P20 to P27

P30

P37

P60

P63

P66

P67

P70

P77

Port 2

8

Port 3

Port 6

Port 7

26

Page 27

µ

PD784031Y

Table 7-1. Port Functions

Port Name Pin Name Function Specification of Pull-up Resistor

Connection by Software

Port 0 P00 to P07 • Can be set in input or output mode in 1-bit units. All port pins in input mode

• Can operate as 4-bit real-time output port

(P00 through P03 and P04 through P07).

• Can drive transistor.

Port 1 P10 to P17 • Can be set in input or output mode in 1-bit units. All port pins in input mode

• Can drive LEDs.

Port 2 P20 to P27 • Input port In 6-bit units (P22 through P27)

Port 3 P30 to P37 • Can be set in input or output mode in 1-bit units. All port pins in input mode

Port 6 P60 to P63 • Output only All port pins in input mode

P66, P67 • Can be set in input or output mode in 1-bit units.

Port 7 P70 to P77 • Can be set in input or output mode in 1-bit units. –

7.2 Clock Generation Circuit

An on-chip clock generation circuit necessary for operation is provided. This clock generation circuit has a divider circuit.

If high-speed operation is not necessary, the internal operating frequency can be lowered by the divider circuit to reduce

the current consumption.

Figure 7-2. Block Diagram of Clock Generation Circuit

X1

Oscillation

circuit

X2

Remark fXX : oscillation frequency or external clock input

fCLK: internal operating frequency

f

XX

1/2 1/2 1/2 1/2

f

XX

/2

UART/IOE

INTP0 noise reduction circuit

Oscillation stabilization timer

Selector

CLK

f

CPU

Peripheral circuit

27

Page 28

Figure 7-3. Example of Using Oscillation Circuit

(1) Crystal/ceramic oscillation

PD784031Y

µ

V

SS1

X1

X2

(2) External clock

• EXTC bit of OSTS = 1 • EXTC bit of OSTS = 0

µ

PD784031Y

µ

PD74HC04, etc.

PD784031Y

µ

X1

X2

PD784031Y

µ

X1

X2Open

Caution When using the clock oscillation circuit, wire the dotted portion in the above figure as follows to avoid

adverse influences of wiring capacitance.

• Keep the wiring length as short as possible.

• Do not cross the wiring with other signal lines.

• Do not route the wiring in the vicinity of lines through which a high alternating current flows.

• Always keep the potential at the ground point of the capacitor in the oscillation circuit the same

SS1. Do not ground to a ground pattern through which a high current flows.

as V

• Do not extract signals from the oscillation circuit.

28

Page 29

µ

PD784031Y

7.3 Real-time Output Port

The real-time output port outputs data stored in a buffer in synchronization with the coincidence interrupt generated by

timer/counter 1 or with an external interrupt. As a result, pulses without jitter can be output.

The real-time output port is therefore ideal for applications where arbitrary patterns must be output at specific intervals

(such as open loop control of a stepping motor).

The real-time output port mainly consists of port 0 and port 0 buffer registers (P0H and P0L) as shown in Figure 7-4.

Figure 7-4. Block Diagram of Real-time Output Port

Internal bus

844

INTP0 (from external source)

INTC10 (from timer/counter 1)

INTC11 (from timer/counter 1)

Real-time output port

control register (RTPC)

Output trigger

control circuit

Buffer register

8

P0H P0L

44

Output latch (P0)

P07 P00

29

Page 30

µ

PD784031Y

7.4 Timer/Counter

Three units of timers/counters and one unit of timer are provided.

Because a total of seven interrupt requests are supported, these timers/counters and timer can be used as seven units

of timers/counters.

Table 7-2. Operations of Timers/Counters

Name Timer/Counter 0 Timer/Counter 1 Timer/Counter 2 Timer 3

Item

Count width 8 bits – √√√

16 bits √√√√

Operation

mode

Function Timer output 2ch – 2ch –

Interval timer 2ch 2ch 2ch 1ch

External event counter √√√–

One-shot timer – – √ –

Toggle output √ – √ –

PWM/PPG output √ – √ –

One-shot pulse output

Real-time output – √ ––

Pulse width measurement 1 input 1 input 2 inputs –

Number of interrupt requests 2221

Note

√ –––

Note The one-shot pulse output function makes a pulse output level active by software and inactive by hardware (interrupt

request signal).

This function is different in nature from the one-shot timer function of timer/counter 2.

30

Page 31

Timer/counter 0

Figure 7-5. Block Diagram of Timers/Counters

Clear control

Software trigger

µ

PD784031Y

INTP3

Timer/counter 1

INTP0

f

XX/8

Edge detection

XX/8

f

Edge detection

Prescaler

Prescaler

Event input

INTP3

INTP0

Selector

Selector

Capture/Compare register

Timer register 0

(TM0)

Compare register

(CR00)

Compare register

(CR01)

Capture register

(CR02)

Clear control

Timer register 1

(TM1/TM1W)

Compare register

(CR10/CR10W)

(CR11/CR11W)

Capture register

(CR12/CR12W)

Match

Match

Match

Match

OVF

TO0

TO1

Pulse output control

INTC00

INTC01

OVF

INTC10

To real-time output port

INTC11

Timer/counter 2

f

XX/8

INTP1

Edge detection

Edge detection

INTP2/CI

Timer 3

XX/8

f

Remark OVF: overflow flag

Prescaler

INTP2

Prescaler

INTP1

Selector

Capture/Compare register

Clear control

Timer register 2

(TM2/TM2W)

Compare register

(CR20/CR20W)

(CR21/CR21W)

Capture register

(CR22/CR22W)

Timer register 3

(TM3/TM3W)

Compare register

(CR30/CR30W)

Match

Match

Clear

Match

OVF

TO2

TO3

Pulse output control

INTC20

INTC21

CSI

INTC30

31

Page 32

µ

PD784031Y

7.5 PWM Output (PWM0, PWM1)

Two channels of PWM (pulse width modulation) output circuits with a resolution of 12 bits and a repeat frequency of

62.5 kHz (f

These outputs are ideal for controlling the speed of a DC motor.

CLK = 16 MHz) are provided. Both these PWM output channels can select a high or low level as the active level.

Figure 7-6. Block Diagram of PWM Output Unit

Internal bus

f

CLK

Prescaler

Remark n = 0 or 1

PWM modulo register

PWMn

8-bit down counter

1/256

16

0347815

8

4

Pulse control circuit

4-bit counter

8

PWM control

register (PWMC)

Reload

control

Output

control

PWMn (output pin)

32

Page 33

µ

Internal bus

ANI0

ANI1

ANI2

ANI3

ANI4

ANI5

ANI6

ANI7

INTP5

Input selector

Edge

detection

circuit

Conversion trigger

Sample & hold circuit

Voltage comparator

Successive approximation

register (SAR)

Control

Circuit

INTAD

8

Series resistor string

R/2

Tap selector

R

R/2

AV

REF1

AV

SS

8

Trigger enable

A/D converter mode

register (ADM)

8

A/D conversion result

register (ADCR)

PD784031Y

7.6 A/D Converter

An analog-to-digital (A/D) converter with eight multiplexed inputs (ANI0 through ANI7) is provided.

This A/D converter is of successive approximation type. The result of conversion is retained by an 8-bit A/D conversion

result register (ADCR). Therefore, high-speed, high-accuracy conversion can be performed (conversion time: approx. 7.5

µ

s at fCLK = 16 MHz).

A/D conversion can be started in either of the following two modes:

• Hardware start: Conversion is started by trigger input (INTP5).

• Software start: Conversion is started by setting a bit of the A/D converter mode register (ADM).

After started, the A/D converter operates in the following modes:

• Scan mode: Two or more analog inputs are sequentially selected, and data to be converted are obtained from all the

input pins.

• Select mode: Only one analog input pin is used to continuously obtain converted values.

These operation modes and whether starting or stopping the A/D converter are specified by the ADM.

When the result of conversion is transferred to the ADCR, interrupt request INTAD is generated. By using this request

and macro service, the converted values can be successively transferred to the memory.

Figure 7-7. Block Diagram of A/D Converter

33

Page 34

µ

PD784031Y

7.7 D/A Converter

Two circuits of digital-to-analog (D/A) converters are provided. These D/A converters are of voltage output type and

have a resolution of 8 bits.

The conversion method is of R-2R resistor ladder type. By writing a value to be output to an 8-bit D/A conversion value

setting register (DACSn: n = 0 or 1), an analog value is output to the ANOn (n = 0 or 1) pin. The output voltage range is

determined by the voltage applied across the AV

Because the output impedance is high, no current can be extracted from the output. If the impedance of the load is low,

insert a buffer amplifier between the load and output pin.

The ANOn pin goes into a high-impedance state while the RESET signal is low. After releasing reset, DACSn is cleared

to 0.

Figure 7-8. Block Diagram of D/A Converter

AV

REF2

REF2 and AVREF3 pins.

ANOn

2R

R

AV

REF3

2R

Selector

R

2R

R

2R

DACSn DACEn

Remark n = 0 or 1

34

Internal bus

Page 35

µ

PD784031Y

7.8 Serial Interface

Three independent serial interface channels are provided.

Asynchronous serial interface (UART)/3-wire serial I/O (IOE) x 2

Clocked serial interface (CSI) x 1

• 3-wire serial I/O (IOE)

• 2-wire serial I/O (IOE)

2

C bus interface (I2C)

• I

Therefore, communication with an external system and local communication within the system can be simultaneously

executed (refer to Figure 7-9).

Figure 7-9. Example of Serial Interface

2

C

V

DD

V

DD

PD6272 (EEPROM

µ

SDA

SCL

PD78062Y (slave)

µ

TM

)

PD4711A

µ

RS-232-C

driver/receiver

PD784031Y (master)

µ

[UART]

RxD

TxD

Port

(a) UART + I

2

C]

[I

SDA

SCL

PD4711A

µ

RS-232-C

driver/receiver

PD4711A

µ

RS-232-C

driver/receiver

[UART]

RxD2

TxD2

Port

(b) UART + 3-wire serial I/O + 2-wire serial I/O

PD784031Y (master)

µ

[3-wire serial I/O]

SI1

Note

Port

V

SCL

Note

Port

[2-wire serial I/O]

[UART]

RxD

TxD

Port

SO1

SCK1

INTPm

SDA

INTPn

SDA

SCL

PD75108 (slave)

µ

SI

SO

SCK

Port

INT

V

DD

DD

PD78014 (slave)

µ

SB0

SCK0

Port

INT

LCD

Note Handshake line

35

Page 36

µ

PD784031Y

7.8.1 Asynchronous serial interface/3-wire serial I/O (UART/IOE)

Two channels of serial interfaces that can select an asynchronous serial interface mode and 3-wire serial I/O mode are

provided.

(1) Asynchronous serial interface mode

In this mode, data of 1 byte following the start bit is transferred or received.

Because an on-chip baud rate generator is provided, a wide range of baud rates can be set.

Moreover, the clock input to the ASCK pin can be divided to define a baud rate.

When the baud rate generator is used, a baud rate conforming to the MIDI standard (31.25 kbps) can be also

obtained.

Figure 7-10. Block Diagram in Asynchronous Serial Interface Mode

Internal bus

Receive buffer RXB, RXB2

R

X

D, RXD2

T

X

D, TXD2

Baud rate generator

f

XX

/2

ASCK, ASCK2

Remark f

XX: oscillation frequency or external clock input

n = 0 through 11

m = 16 through 30

Selector

1/2

n + 1

Receive shift

register

Receive control

parity check

1/2m

1/2m

INTSR,

INTSR2

INTSER,

INTSER2

Transmit shift

register

Transmit control

parity append

TXS, TXS2

INTST, INTST2

36

Page 37

µ

PD784031Y

(2) 3-wire serial I/O mode

In this mode, the master device starts transfer by making the serial clock active and transfers 1-byte data in

synchronization with this clock.

This mode is used to communicate with a device having the conventional clocked serial interface. Basically,

communication is established by using three lines: one serial clock (SCK) and two serial data (SI and SO) lines.

Generally, to check the communication status, a handshake line is necessary.

Figure 7-11. Block Diagram in 3-wire Serial I/O Mode

Internal bus

Direction control circuit

SIO1, SIO2

SI1, SI2

Shift register Output latch

SO1, SO2

SCK1, SCK2

Remark f

Serial clock counter

Serial clock

control circuit

XX: oscillation frequency or external clock input

n = 0 through 11

m = 1 or 16 through 30

Interrupt signal

generation circuit

1/m 1/2

Selector

INTCSI1,

INTCSI2

n + 1

fXX/2

37

Page 38

µ

PD784031Y

7.8.2 Clocked serial interface (CSI)

In this mode, the master device starts transfer by making the serial clock active and communicates 1-byte data in

synchronization with this clock.

Figure 7-12. Block Diagram of Clocked Serial Interface

Internal bus

SI0

SO0/SDA

(in 2-wire or I

SCK0/SCL

N-ch open drain output

2

C bus mode)

Selector

Direction

control

register

Shift register

Start condition

detection circuit

detection circuit

Stop condition

detection circuit

Serial clock

Slave address

register

Acknowledge

counter

Match signal

Set Reset

Output latch

Interrupt signal

generation

circuit

Acknowledge

detection

control

Wake-up

control circuit

INTSPC

INTCSI

Remark f

38

Serial clock

control circuit

N-ch open drain output

(in 2-wire or I

XX: oscillation frequency or external clock input

2

C bus mode)

CLS0

CLS1

Selector

Timer 3 output

XX

/16

f

Selector

Prescaler

XX

/2

f

Page 39

µ

PD784031Y

(1) 3-wire serial I/O mode

This mode is to communicate with devices having the conventional clocked serial interface.

Basically, communication is established in this mode with three lines: one serial clock (SCK0) and two serial data

(SI0 and SO0) lines.

Generally, a handshake line is necessary to check the communication status.

(2) 2-wire serial I/O mode

This mode is to transfer 8-bit data by using two lines: serial clock (SCL) and serial data bus (SDA).

Generally, a handshake line is necessary to check the communication status.

2

C (Inter IC) bus mode

(3) I

2

This mode is to communicate with devices conforming to the I

This mode is to transfer 8-bit data with two or more devices by using two lines: serial clock (SCL) and serial data

bus (SDA).

During transfer, a “start condition”, “data”, and “stop condition” can be output onto the serial data bus. During

reception, these data can be automatically detected by hardware.

C bus format.

7.9 Edge Detection Function

The interrupt input pins (NMI and INTP0 through INTP5) are used not only to input interrupt requests but also to input

trigger signals to the internal hardware units. Because these pins operate at an edge of the input signal, they have a function

to detect an edge. Moreover, a noise reduction circuit is also provided to prevent erroneous detection due to noise.

Pin Name Detectable Edge Noise Reduction

NMI Either of rising or falling edge By analog delay

INTP0 to INTP3 Either or both of rising and falling edges By clock sampling

INTP4, INTP5 By analog delay

Note INTP0 can select a sampling clock.

Note

39

Page 40

µ

PD784031Y

7.10 Watchdog Timer

A watchdog timer is provided to detect a hang up of the CPU. This watchdog timer generates a non-maskable interrupt

unless it is cleared by software within a specified interval time. Once enabled to operate, the watchdog timer cannot be

stopped by software. Whether the interrupt by the watchdog timer or the interrupt input from the NMI pin takes precedence

can be specified.

Figure 7-13. Block Diagram of Watchdog Timer

f

CLK

Clear signal

Timer

21

f

CLK

/2

20

f

CLK

/2

19

f

CLK

/2

17

f

CLK

/2

Selector

INTWDT

40

Page 41

µ

PD784031Y

8. INTERRUPT FUNCTION

As the servicing in response to an interrupt request, the three types shown in Table 8-1 can be selected by program.

Table 8-1. Servicing of Interrupt Request

Servicing Mode Entity of Servicing Servicing Contents of PC and PSW

Vector interrupt Software Branches and executes servicing routine Saves to and restores

(servicing is arbitrary). from stack.

Context switching Automatically switches register bank, Saves to or restores from

branches and executes servicing routine fixed area in register bank.

(servicing is arbitrary).

Macro service Firmware Executes data transfer between memory Retained

and I/O (servicing is fixed).

8.1 Interrupt Sources

Table 8-2 shows the interrupt sources available. As shown, interrupts are generated by 24 types of sources, execution

of the BRK instruction or BRKCS instruction, or an operand error.

The priority of interrupt servicing can be set to four levels, so that nesting can be controlled during interrupt servicing

and that which of the two or more interrupts that simultaneously occur should be serviced first. When the macro service

function is used, however, nesting always proceeds.

The default priority is the priority (fixed) of the service that is performed if two or more interrupt requests, having the same

request, simultaneously generate (refer to Table 8-2).

41

Page 42

Table 8-2. Interrupt Sources

µ

PD784031Y

Type Default Source Internal/

Priority Name Trigger External

Software – BRK instruction Instruction execution – –

BRKCS instruction

Operand error If result of exclusive OR between byte of operand and

byte is not FFH when MOV STBC, #byte, MOV WDM,

#byte, or LOCATION instruction is executed

Non-maskable

Maskable 0 (highest) INTP0 Detection of pin input edge External √

– NMI Detection of pin input edge External –

WDT Overflow of watchdog timer Internal

(TM1/TM1W capture trigger, TM1/TM1W event counter input)

1 INTP1 Detection of pin input edge

(TM2/TM2W capture trigger, TM2/TM2W event counter input)

2 INTP2 Detection of pin input edge

(TM2/TM2W capture trigger, TM2/TM2W event counter input)

3 INTP3 Detection of pin input edge

(TM0 capture trigger, TM0 event counter input)

4 INTC00 Generation of TM0-CR00 match signal Internal √

5 INTC01 Generation of TM0-CR01 match signal

6 INTC10 Generation of TM1-CR10 match signal

(in 8-bit operation mode)

Generation of TM1W-CR10W match signal

(in 16-bit operation mode)

7 INTC11 Generation of TM1-CR11 match signal

(in 8-bit operation mode)

Generation of TM1W-CR11W match signal

(in 16-bit operation mode)

8 INTC20 Generation of TM2-CR20 match signal

(in 8-bit operation mode)

Generation of TM2W-CR20W match signal

(in 16-bit operation mode)

9 INTC21 Generation of TM2-CR21 match signal

(in 8-bit operation mode)

Generation of TM2W-CR21W match signal

(in 16-bit operation mode)

10 INTC30 Generation of TM3-CR30 match signal

(in 8-bit operation mode)

Generation of TM3W-CR30W match signal

(in 16-bit operation mode)

11 INTP4 Detection of pin input edge External √

12 INTP5 Detection of pin input edge

13 INTAD End of A/D conversion (transfer of ADCR) Internal √

14 INTSER Occurrence of ASI0 reception error –

15 INTSR End of ASI0 reception or CSI1 transfer √

INTCSI1

16 INTST End of ASI0 transfer

17 INTCSI End of CSI1 transfer

18 INTSER2 Occurrence of ASI2 reception error –

19 INTSR2 End of ASI2 reception or CSI2 transfer √

INTCSI2

20 INTST2 End of ASI2 transfer

21 (lowest) INTSPC I2C bus stop condition interrupt

Macro Service

Remark ASI: asynchronous serial interface

CSI: clocked serial interface

42

Page 43

µ

PD784031Y

8.2 Vectored Interrupt

Execution branches to a servicing routing by using the memory contents of a vector table address corresponding to

the interrupt source as the address of the branch destination.

So that the CPU performs interrupt servicing, the following operations are performed:

• On branching : Saves the status of the CPU (contents of PC and PSW) to stack

• On returning : Restores the status of the CPU (contents of PC and PSW) from stack

To return to the main routine from an interrupt service routine, the RETI instruction is used.

The branch destination address is in a range of 0 to FFFFH.

Table 8-3. Vector Table Address

Interrupt Source Vector Table Address

BRK instruction 003EH

Operand error 003CH

NMI 0002H

WDT 0004H

INTP0 0006H

INTP1 0008H

INTP2 000AH

INTP3 000CH

INTC00 000EH

INTC01 0010H

INTC10 0012H

INTC11 0014H

INTC20 0016H

INTC21 0018H

INTC30 001AH

INTP4 001CH

INTP5 001EH

INTAD 0020H

INTSER 0022H

INTSR 0024H

INTCSI1

INTST 0026H

INTCSI 0028H

INTSER2 002AH

INTSR2 002CH

INTCSI2

INTST2 002EH

INTSPC 0030H

43

Page 44

µ

PD784031Y

8.3 Context Switching

When an interrupt request is generated or when the BRKCS instruction is executed, a predetermined register bank is

selected by hardware. Context switching is a function that branches execution to a vector address stored in advance in

the register bank, and to stack the current contents of the program counter (PC) and program status word (PSW) to the

register bank.

The branch address is in a range of 0 to FFFFH.

Figure 8-1. Context Switching Operation when Interrupt Request is Generated

0000B

<7> Transfer

PC19 to 16

<2> Save

(bits 8 through 11

of temporary register)

Temporary register

<1> Save

PSW

PC15 to 0

<6> Exchange

<5> Save

Register bank n (n = 0 to 7)

A

B

R5

R7

V

U

T

W

VP

UP

D

H

X

C

R4

R6

<3> Switching of register bank

E

L

(RBS0 to RBS2 ← n)

<4> RSS ← 0

IE ←0

Register bank n

(0 to 7)

8.4 Macro Service

This function is to transfer data between memory and a special function register (SFR) without intervention by the CPU.

A macro service controller accesses the memory and SFR in the same transfer cycle and directly transfers data without

loading it.

Because this function does not save or restore the status of the CPU, or load data, data can be transferred at high

speeds.

44

CPU

Internal bus

Figure 8-2. Macro Service

Read

Memory SFR

Write

Macro service

controller

Write

Read

Page 45

8.5 Application Example of Macro Service

(1) Transfer of serial interface

Transfer data storage buffer (memory)

Data n

Data n – 1

Data 2

Data 1

Internal bus

µ

PD784031Y

TxD

Transfer shift register

Transfer control INTST

TXS (SFR)

Each time macro service request INTST is generated, the next transfer data is transferred from memory to TXS. When

data n (last byte) has been transferred to TXS (when the transfer data storage buffer has become empty), vectored interrupt

request INTST is generated.

(2) Reception of serial interface

Receive data storage buffer (memory)

Data n

Data n – 1

Data 2

Data 1

Internal bus

RXB (SFR)

INTSR

RxD

Receive buffer

Receive shift register

Reception control

Each time macro service request INTSR is generated, the receive data is transferred from RXB to memory. When data

n (last byte) has been transferred to memory (when the receive data storage buffer has become full), vectored interrupt

request INTSR is generated.

45

Page 46

µ

(3) Real-time output port

INTC10 and INTC11 serve as the output triggers of the real-time output port. The macro services for these can

set the following output pattern and intervals simultaneously. Therefore, INTC10 and INTC11 can control two

stepping motors independently of each other. They can also be used for PWM output or to control DC motors.

PD784031Y

Output timing profile (memory)

Internal bus

Match

CR10

INTC10

T

Tn– 1

T2

T1

TM1

n

(SFR)

P00 to P03

Output pattern profile (memory)

n

P

Pn– 1

P2

P1

Internal bus

(SFR)

P0L

Output latch

Each time macro service request INTC10 is generated, the pattern and timing are transferred to the buffer register (P0L)

and compare register (CR10), respectively. When the contents of the timer register 1 (TM1) coincide with those of CR10,

INTC10 is generated again, and the contents of P0L are transferred to the output latch. When Tn (last byte) has transferred

to CR10, vectored interrupt request INTC10 is generated.

The same applies to INTC11.

46

Page 47

µ

PD784031Y

9. LOCAL BUS INTERFACE

The local bus interface can connect an external memory or I/O (memory mapped I/O) and support a memory space

of 1 Mbytes (refer to Figure 9-1).

Figure 9-1. Example of Local Bus Interface

PD784031Y

µ

A16 to A19

Decoder

RD

WR

REFRQ

AD0 to AD7

ASTB

A8 to A15

Latch

Pseudo SRAM

PD27C1001A

µ

Data bus

Address bus

Gate array

I/O expansion

Centronics I/F, etc.

PROM

Character

generator

µ

PD24C1000

9.1 Memory Expansion

The memory capacity can be expanded in seven steps, from 256 bytes to 1 Mbytes, by connecting an external program

memory and data memory.

47

Page 48

µ

PD784031Y

9.2 Memory Space

The 1-Mbyte memory space is divided into eight spaces of logical addresses. Each space can be controlled by using

the programmable wait function and pseudo static RAM refresh function.

Figure 9-2. Memory Space

HFFFFF

512 Kbytes

H00008

HFFFF7

256 Kbytes

H00004

HFFFF3

128 Kbytes

H00002

HFFFF1

64 Kbytes

H00001

HFFFF0

16 Kbytes

H000C0

HFFFB0

16 Kbytes

H00080

HFFF70

16 Kbytes

H00040

HFFF30

16 Kbytes

H00000

48

Page 49

µ

PD784031Y

9.3 Programmable Wait

The memory space can be divided into eight spaces and wait states can be independently inserted in each of these

spaces while the RD and WR signals are active. Even when a memory with a different access time is connected, therefore,

the efficiency of the entire system does not drop.

In addition, an address wait function that extends the active period of the ASTB signal is also provided so as to have

a sufficient address decode time (this function can be set to the entire space).

9.4 Pseudo Static RAM Refresh Function

The following refresh operations can be performed:

• Pulse refresh : A bus cycle that outputs a refresh pulse to the REFRQ pin at a fixed cycle is inserted. The

memory spaces is divided into eight spaces, and a refresh pulse can be output from the

REFRQ pin while a specified memory space is accessed. Therefore, the normal memory

access is not kept to wait by the refresh cycle.

• Power-down self-refresh : The low level is output to the REFRQ pin in the standby mode to retain the contents of the

pseudo static RAM.

9.5 Bus Hold Function

A bus hold function is provided to facilitate connection of a DMA controller. When a bus hold request signal (HLDRQ)

is received from an external bus master, the address bus, address/data bus, and ASTB, RD, and WR pins go into a highimpedance state when the current bus cycle has been completed. This makes the bus hold acknowledge (HLDAK) signal

active, and releases the bus to the external bus master.

Note that, while the bus hold function is used, the external wait function and pseudo static RAM refresh function cannot

be used.

49

Page 50

µ

PD784031Y

10. STANDBY FUNCTION

This function is to reduce the power dissipation of the chip, and can be used in the following modes:

• HALT mode : Stops supply of the operating clock to the CPU. This mode is used in combination with the normal

operation mode for intermittent operation to reduce the average power dissipation.

• IDLE mode : Stops the entire system with the oscillation circuit continuing operation. The power dissipation in this

mode is close to that in the STOP mode. However, the time required to restore the normal program

operation from this mode is almost the same as that from the HALT mode.

• STOP mode: Stops the oscillator and thereby to stop all the internal operations of the chip. Consequently, the power

dissipation is minimized with only leakage current flowing.

These modes are programmable.

The macro service can be started from the HALT mode.

Figure 10-1. Transition of Standby Status

Macro service request

End of one processing

End of macro service

Interrupt request

RESET input

Sets HALT mode

Note 2

HALT