DATA SHEET

DATA SHEET

CMOS DIGITAL INTEGRATED CIRCUITS

PPPP

PD2845GR

1 V, 1.3 mA, 94MHz PLL SYNTHESIZER LSI

FOR PAGER SYSTEM

DESCRIPTION

PD2845GR is a PLL synthesizer LSI for pager system. This LSI is manufactured using low voltage CMOS

P

process and therefore realized the low power consumption PLL operated on 1 V, 1.3 mA. This LSI is packaged in 16

pin plastic SSOP suitable for high-density surface mounting. So, this product contributes to produce a long-lifebattery and physically-small pager system.

FEATURES

• Operating frequency : · Input frequency : fin = 10 MHz to 94 MHz

· Reference oscillating frequency : f

• Low Supply voltage : · PLL block : V

· Charge pump block: V

• Low power consumption • I

• Equipped with power-save function • Serial data can be received in power-save mode.

• Packaged in 16 pin plastic SSOP suitable for high-density surface mounting.

DD

= 1.3 mA TYP. @ fin = 70 MHz, f

DD1

= 1.00 V to 1.15 V @ fin = 10 MHz to 70 MHz

DD1

V

= 1.05 V to 1.15 V @ fin = 10 MHz to 94 MHz

DD2

= 3.0 V ± 300 mV

x’tal

= 12.8 MHz

x’tal

= 12.8 MHz

ORDERING INFORMATION

PART NUMBER PACKAGE SUPPLYING FORM

P

PD2845GR-E1 16 pin plastic SSOP

(225 mil)

P

PD2845GR-E2 16 pin plastic SSOP

(225 mil)

* To order evaluation samples, please contact your local NEC sales office (Order number : PPD2845GR).

Embossed tape 12 mm wide. QTY 2.5 k/reel

Pin 1 is in tape pull-out direction.

Embossed tape 12 mm wide. QTY 2.5 k/reel

Pin 1 is in tape roll-in direction.

PIN ASSIGNMENT

(Top View)

V

DD1

F

GND

FR

RESET

EO

IN

XI

XO

LE

CLK

DATA

PS

EOP

EON

Document No. P12150EJ2V0DS00 (2nd edition)

(Previous No. IC-3291)

Date Published February 1997 N

NC

V

DD2

Caution Electro-static sensitive devices

1994©

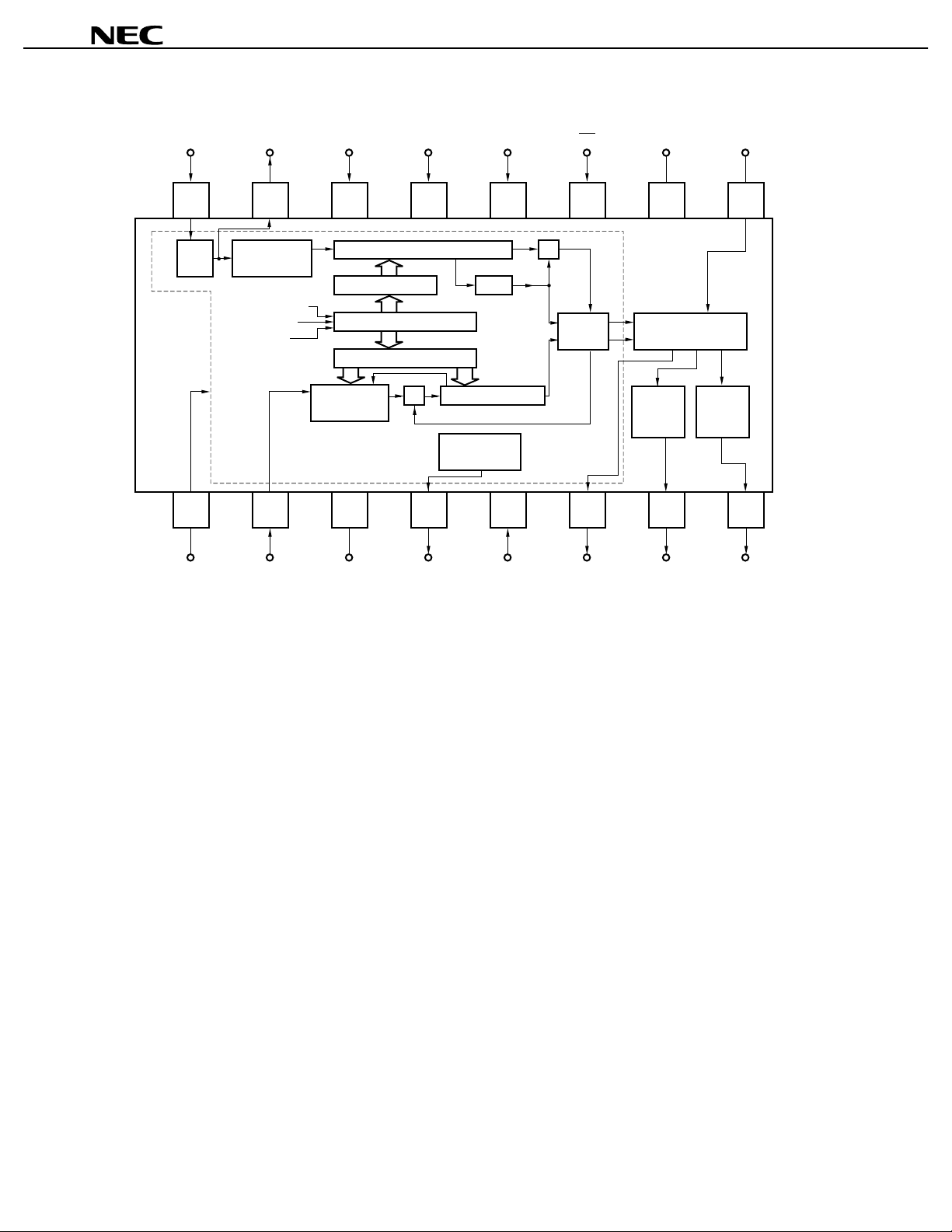

INTERNAL BLOCK DIAGRAM

PPPP

PD2845GR

XI XO LE

16 15 14 13 12 11 10 9

IN

AMP

1 2 3 4 5 6 7 8

V

DD1

1/2

PRESCALER

DATA

CLK

LE

F

IN

5 BIT

reference divider 13 BIT

latch 13 BIT

Shift register 23 BIT

32/33

PRESCALER

GND FR RESET EO EOP EON

CLK

latch 18 BIT

gate

DATA

gate

timer

divider 13 BIT

TEST CIRCUIT

FV

PS NC V

FR

Phase

comparator

Phase detector

error out

Pch

open

drain

Nch

open

drain

DD2

2

PPPP

PD2845GR

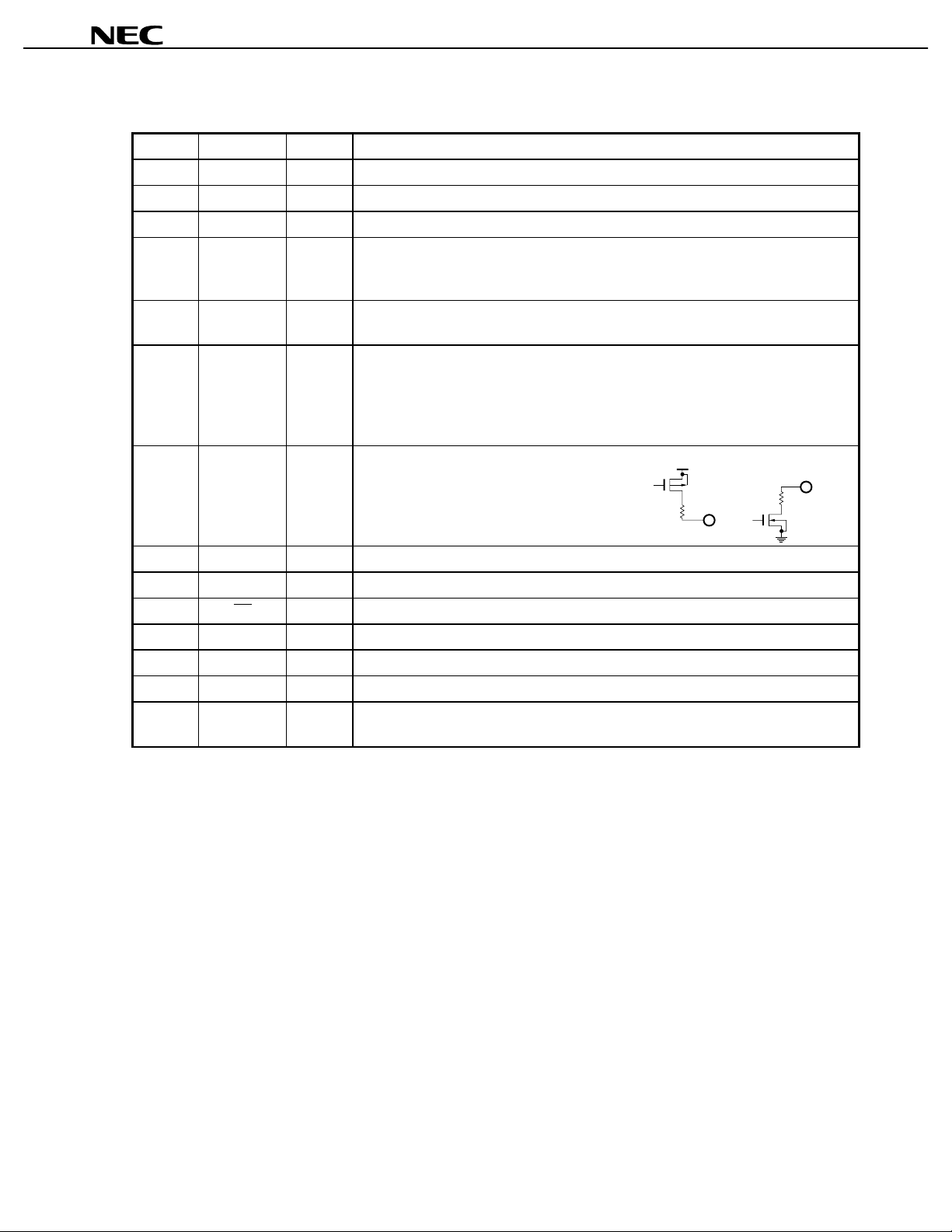

PIN EXPLANATION

PIN No. PIN NAME I/O EXPLANATION FOR FUNCTION

1V

2FINI Frequency Input

3 GND

4 FR O Test pin for monitor.

5 RESET I Test pin for monitor reset. (Refer to RESET on 12 page)

6 EO O Internal charge pump output. In the case of passive filter, this output should be used.

7

8

DD1

EOP

EON

•

•

O

O

Supply voltage to PLL block

Ground

Normally used as PLL, output L should be selected by test bit and this pin should be

opened. (Refer to setting for reference counter on 11 page)

Normally used as PLL, this pin should be grounded.

p

Input signal phase f

fp > fr : Low output

p

< fr : High output

f

p

= fr : High-impedance

f

Outputs for external charge pump. In the case of active filter, this outputs should be used.

EOP : PCH open drain

EON : NCH open drain

vs. reference signal f

r

EON

EOP

9V

10 NC

11 PS I Control bias input for power-save (Refer to Power-save on 12 page).

12 DATA I Data input for divided ratio.

13 CLK I Clock input for shift register.

14 LE I Latch enable input.

15

16

DD2

XO

XI

•

•

O

Supply voltage to charge pump.

Non Connection.

X’tal oscillator connection pin.

I

3

PPPP

PD2845GR

ABSOLUTE MAXIMUM RATINGS (UNLESS OTHERWISE SPECIFIED, TA = +25 °C

Supply Voltage V

Input Voltage V

Output Voltage V

Output Current I

Operating Ambient Temperature T

Storage Temperature T

DD1

DD2

V

I1

I2

V

O1

O2

V

O

A

stg

0.3 to 2.0 V

ð

0.3 to 6.0 V

ð

0.3 to V

ð

0.3 to 6.0 (DATA, CLK, LE, PS) V

ð

0.3 to V

ð

0.3 to V

ð

DD1

+0.3 (Except for DATA, CLK, LE, PS pin) V

DD1

+0.3 (XO, FR) V

DD2

+0.3 (EO, EOP, EON) V

10 mA

10 to +50 °C

ð

55 to +125 °C

ð

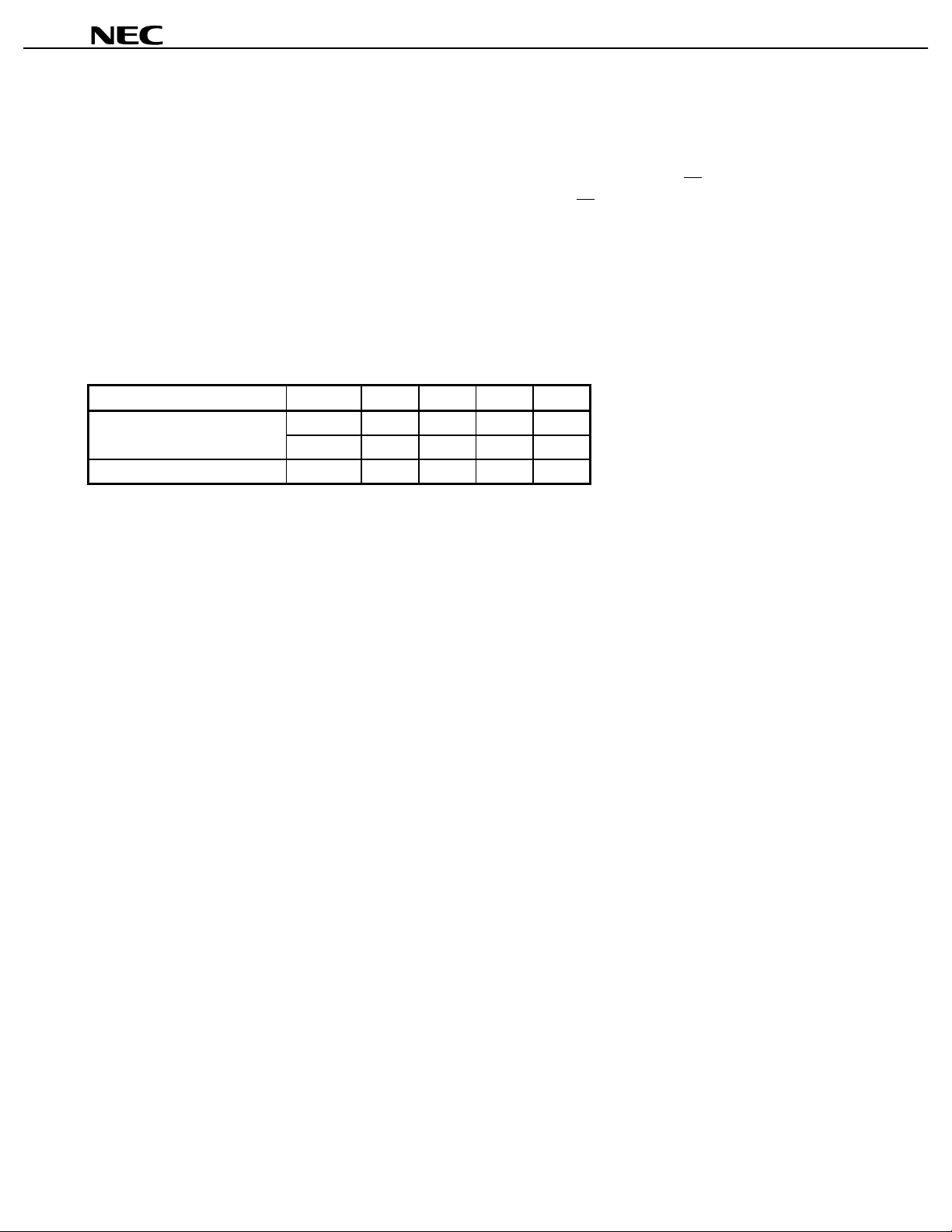

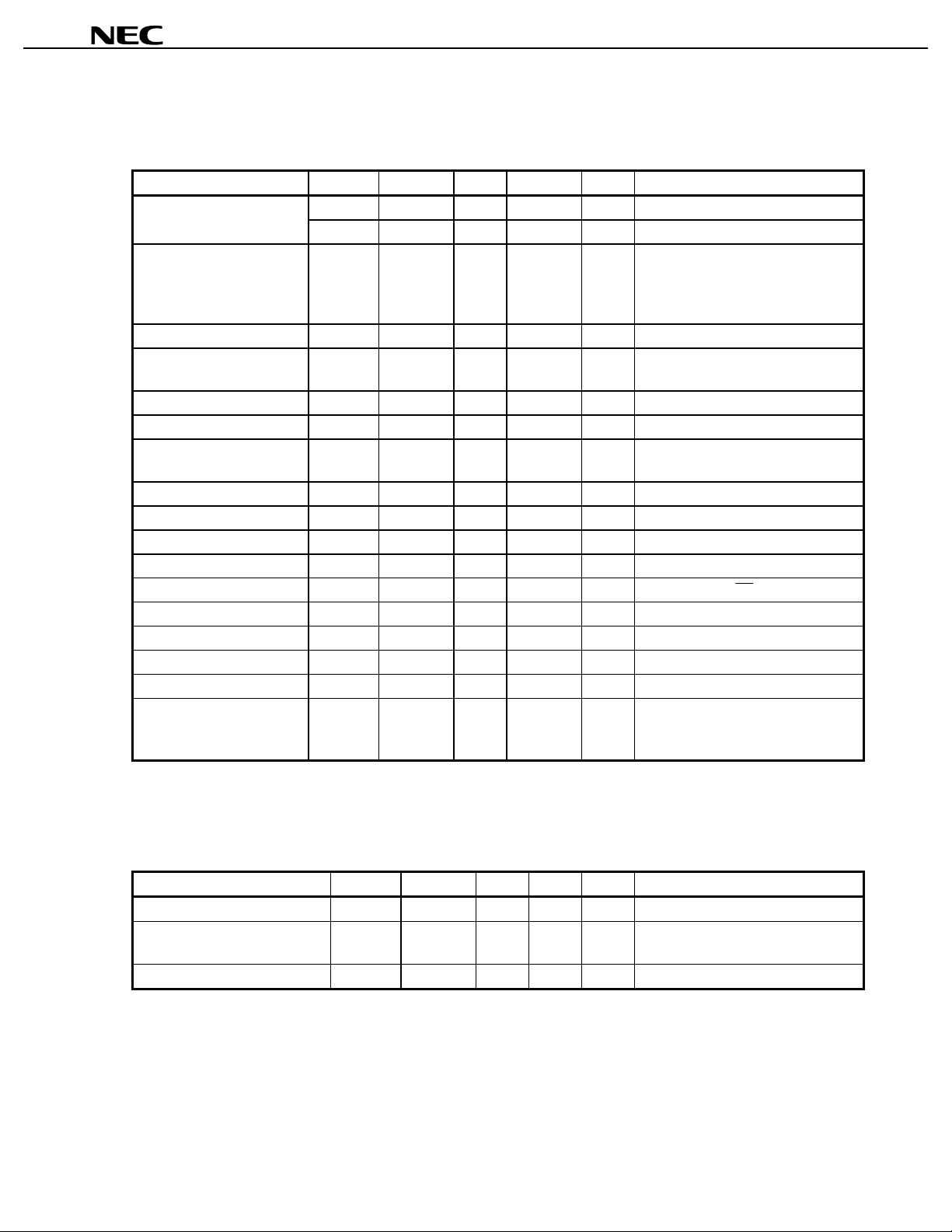

RECOMMENDED OPERATING RANGE

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

DD1

Supply Voltage

Operating Ambient Temperature T

V

V

DD2

A

1.0 1.05 1.1 V

2.85 3.0 3.15 V

10 +25 +50 °C

ð

)

4

ELECTRICAL CHARACTERISTICS

PPPP

PD2845GR

DC PERFORMANCE (Unless otherwise specified, V

PARAMETER SYMBOL MIN. TYP. MAX. UNIT CONDITIONS

Supply Voltage V

Circuit Current I

Data Retain Current I

High Level Output Current1

High Level Output Current2

High Level Output Current3

Low Level Output Current1

Low Level Output Current2

Low Level Output Current3

High Level Input Current1

Low Level Input Current1

High Level Input Current2

*1

*1

*1

*2

*2

*2

*2

*1

*2

High Level Input Voltage1 V

Low Level Input Voltage1 V

High Level Input Voltage2 V

Low Level Input Voltage2 V

Output Leak Current I

DD1

DD2

V

DD1

DR

OH1

I

OH2

I

OH3

I

OL1

I

OL2

I

OL3

I

IH1

I

IL1

I

IH2

I

IH1

IL1

IH2

IL2

L

1.00 1.05 1.15 V PLL Operation

2.70 3.0 3.30 V P/D Charge pump block

1.0 mA EO, EOP pin. V

ð

0.5 mA XO pin. V

ð

0.1 mA FR pin. V

ð

1.0 mA EO, EON pin. V

0.4 mA XO pin. VOL = 0.5 V

0.4 mA FR pin. VOL = 0.5 V

0.4

0.4

ð

DD1

0.8 u V

0 0.2 u V

DD1

0.8 u V

0 0.2 u V

DD1

= 1.00 V to 1.15 V, V

DD2

= 2.70 to 3.30 V, TA =

1.3 2.2 mA fin = 70 MHz, 0.2 V

fx’tal = 12.8 MHz X’tal OSC IN.

DD1

= 1.0 V to 1.1 V

V

DD2

= 2.85 V to 3.15 V

V

1.0 10

1.0

A No Input Signal, V

P

OH

DD2

= V

= 0.5 V

ð0.5 V

OH

= V

OH

= V

V

OL

V

AFIN, XI pin. VIH = V

P

AFIN, XI pin. VIL = 0 V, V

P

A DATA, CLK, LE, PS pin. V

P

4.0 V DATA, CLK, LE, PS pin.

10

DD1

DD1

V

DD1

4

ð

1.0

r

V DATA, CLK, LE, PS pin.

V RESET pin.

V RESET pin.

A EO, EOP, EON pin.

P

DD1

= 1.0 V to 1.1 V

V

DD2

= 2.85 V to 3.15 V

V

DD2

DD1

DD1

DD2

P-P

DD1

ð0.5 V

ð0.5 V

DD1

10 to +50 °C)

ðððð

.

= 1.1 V

= 2.85 V

= 2.85 V

1.0 V

DD1

1.0 V

IH1

= 3.85 V

Current from IC

*1

Current into IC

*2

AC PERFORMANCE (Unless otherwise specified, V

PARAMETER SYMBOL MIN. TYP. MAX. UNIT CONDITIONS

Input frequency 1 f

Input frequency 2 f

Reference Oscillating Frequency f

in1

in2

x’tal

10 70 MHz FIN pin, Vin = 0.2 V

10 94 MHz FIN pin, Vin = 0.2 V

DD1

= 1.00 V to 1.15 V, V

DD2

= 2.70 to 3.30 V, TA =

12.8 MHz XI, XO pin

DD1

= 1.05 V to 1.15 V

V

P-P

P-P

,

10 to +50

ðððð

C)

qqqq

5

TEST CIRCUIT

DC measurement

BS2

2

GND

4

5

6

7

8

V

DD1

F

IN

GND

FR

RESET

EO

EOP

EON

PD2845GR

µ

XO

LE

CLK

DATA

PS

NC

V

DD2

PPPP

PD2845GR

relay RL1

C1

X’tal

XI

C2

D1

BS3 GND

16

15

14

13

12

11

10

BS1

AC measurement

V

DD1

V

DD2

1 F

µ

1 F

BNC1

BNC2

relay RL1

Diode D1

Capacitor C1,C2

X’tal

1 000 pF

SW 1

V

DD1

F

IN

GND

FR

RESET

EO

EOP

10 pF

XI

X’tal

XO

10 pF

LE

CLK

DATA

PS

NC

µ

100 pF

50 Ω

SW3

: SRR-204

: 1S945

: 18 pF

: 12.8 MHz

12.8 MHz

SW2

BNC1

: Frequency input

BNC2

: Frequency output

SW1

: switch for voltage on/off

SW2

: Desired for PS mode : Low

SW3

: Desired for reset mode : High

EON

PD2845GR

µ

V

DD2

100 pF

6

APPLICATION CIRCUIT EXAMPLES

Passive filter application example (using internal charge pump)

V

DD1

1 F

µ

V

DD2

100 pF

1 000 pF

V

DD1

F

IN

GND

1 F

µ

VCO out

VCO

XO

LE

PPPP

PD2845GR

10 pF

XI

X’tal

12.8 MHz

10 pF

controller

FR

RESET

EO

passive filter

EOP

EON

PD2845GR

µ

Active filter application example (using external charge pump)

IN

(2 pin)

F

VCO

LPF

PMOS

NMOS

CLK

DATA

PS

NC

V

DD2

EO

EOP

EON

100 pF

V

DD1

V

DD2

X’tal

: 1.0 to 1.1 V

: 2.85 to 3.15 V

: 12.8 MHz

7

INPUT TIMING OF SERIAL DATA

DATA

latch

PPPP

PD2845GR

CLK

LE

This logic circuit is controlled by a 3-wire serial bus interface with DATA (12 pin), CLK (13 pin) and LE (14 pin).

On the control setting, Binary-coded serial data is input to DATA pin. This data is read into the shift register at the

rising edge of the CLK signal input to the CLK pin. When the LE signal is at the low level, DATA CLK are received

into the LSI to be latched at the rising edge of the LE signal.

While the LE signal is at the high level, neither DATA nor CLK signals can be received.

CAUTION At the initial V

the non-data input stage. [Refer to ‘Power-save (pin 11)’ on 12 page]

read

CC

supplied time, serial data must be input, because the IC output is unstable on

8

PPPP

PD2845GR

INPUT SIGNAL DIVIDER

INPUT SIGNAL DIVIDER obtain the frequency: fp input to phase comparator. This circuit divides input frequency:

fin to obtain fp. This block consists of prescaler, 5 bit swallow counter, 13 bit main counter and divide-ratio control

circuit.

Setting numbers

• Main counter M = 32 to 8 191

• Swallow counter S = 0 to 31

• Prescaler P = 32, P+1 = 33

Total divide ratio

NT = S(P+1) + P(MðS) = PM+S = 32 M+S (M t S)

NT = 1 024 to 262 143

?

p

in

Relation between f

fp = fin/(32 M+S)

(ex)

At fp = 5 kHz fin = 70 MHz

NT = 70 M/5 k = 14 000

Therefore 14 000 32 = 437 • • • 16

and f

nn

MS

Reference Counter

Reference Counter obtain the frequency: fr input to phase comparater. This circuit divides the reference

oscillating frequency: f

X’tal

of X’tal or TCXO to obtain fr. This block consists of 13 bit programmable reference counter

and prescaler of divide-by-2.

Setting number

• 13 bit programmable reference counter R = 2 to 8 191

Total reference counter block divide ratio

RT = 2 u R

RT = 4 to 16 382

?

r

X’tal

Relation between f

X’tal

fr = (f

/2)/R

and f

(ex)

fr = 5 kHz f

X’tal

= 12.8 MHz

R = (12.8 MHz/2)/5 kHz = 1 280

9

Data format of shift register

Foundaly constraction of shift register

PPPP

PD2845GR

LE

LSB

DATA

CLK

A D22D21D20D19D18D17D16D15D14D13D12D11D10 D9 D8 D7 D6 D5 D4 D3 D2 D1

last bit

(1) Setting for data selection bit

Data selection bit: last A bit can govern the latch selection.

Data selection bit’s construction and function

A Function

1 Setting for swallow and main counter’s divide ratio.

Setting for charge pump output selection.

0 Setting for reference counter’s divide ratio.

“0” = Low, “1” = High

(2) Setting for swallow/main counter’s data and charge pump output selection

Bit constraction of setting for swallow/main counter and charge pump output selection

MSB

first bit

D22A D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1

A

A = 1 charge

pump

output

selection

no

assigned

02122232420212223242526272829210211212

2

swallow counter : S

(5 bits 0 to 31)

main counter : M

(13 bits 32 to 8 191)

CAUTION D19, D20 are not assigned for setting but CLK signals must be input because of the bit

construction.

• SWALLOW COUNTER DATA

S = (D14 u 2

4

) + (D15 u 23) + (D16 u 22) + (D17 u 21) + (D18 u 20)

• MAIN COUNTER DATA

M = (D1 u 212) + (D2 u 211) + (D3 u 210) + (D4 u 29) + (D5 u 28) + (D6 u 27) + (D7 u 26) + (D8 u 25) + (D9 u 24) +

(D10 u 23) + (D11 u 22) + (D12 u 21) + (D13 u 20)

10

PPPP

PD2845GR

NT = 32M + S

= 32 u {(D1 u 212) + (D2 u 211) + (D3 u 210) + (D4 u 29) + (D5 u 28) + (D6 u 27) + (D7 u 26) + (D8 u 25) + (D9 u 24) +

(D10 u 23) + (D11 u 22) + (D12 u 21) + (D13 u 20)} + {(D14 u 24) + (D15 u 23) + (D16 u 22) + (D17 u 21) + (D18

20)}

NT = (D1 u 217) + (D2 u 216) + (D3 u 215) + (D4 u 214) + (D5 u 213) + (D6 u 212) + (D7 u 211) + (D8 u 210) + (D9 u 29) +

?

(D10 u 28) + (D11 u 27) + (D12 u 26) + (D13 u 25) + (D14 u 24) + (D15 u 23) + (D16 u 22) + (D17 u 21) + (D18 u 20)

Thus, total divide ratio of input signal divider ‘NT’ can be transferred to binary-code in order to setting data ‘D1 to

D18’ input. (D1 should be top digit and D18 should be bottom digit.)

• Charge pump output selection data

u

D22 D21 EO Pin

(To use internal

charge pump)

0 0 Hi- Impedance OFF

0 1 Hi-Impedance OUTPUT

1 0 OUTPUT OFF

1 1 OUTPUT OUTPUT

EOP, EO Pin

(To use external

charge pump)

“0” = Low, “1” = High

(3) Setting for reference counter

D22A D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1

0212223242526272829210211212

2

A

A = 0

(13 bits 2 to 8 191)

01

TEST BIT

(FR pin)

no assignedreference counter : R

CAUTION D1 to D7 are not assigned for setting but CLK signals must be input because of the bit

construction.

RT = 2 u R

RT = 2 u {(D10 u 2

?

12

) + (D11 u 211) + (D12 u 210) + (D13 u 29) + (D14 u 28) + (D15 u 27) + (D16 u 26) + (D17 u 25) +

(D18 u 24) + (D19 u 23) + (D20 u 22) + (D21 u 21) + (D22 u 20)}

*TEST BIT:

for IC tester (FR pin) use or not use (PLL operation).

for normally PLL operation, input D9 = 0, D8 = 1 (FR pin = output L).

11

PPPP

PD2845GR

Power-save and RESET

Power-save (PIN 11)

Power-save-mode can be selected by input data to PS pin.

H; operation mode

L; power-save-mode

On the power-save-mode, reference oscillator and prescaler turn off and error-outs (EO, EOP, EON) output Hi-

impedance but shift register data is remained. Serial data can be received in power-save-mode.

Power-save usage for initial VCC supplying

Note:

To prevent unstable mode at initial VCC supplying, Power-save-mode must be selected. After counter data

setting, normal operation mode can be selected.

RESET (PIN 5)

Reset-mode can be selected by input data to RESET pin.

H; reset-mode L(GND or Open); Normal operation.

On the reset-mode, reference oscillator/prescalers turn off and error-outs (EO, EOP, EON) output Hi-impedance.

Shift-register data is initialized.

This reset-mode should be used at LSI testing, normally use as PLL, RESET pin should be opened or grounded.

Supplementary explanation:

When RESET pin bias is switched from H to L, initial divide ratios can be set automatically as follows

• Input signal divider: NT = 10372

• 13 bit programmable reference counter: R = 1 280 (RT = 2 560)

These divide ratios make PLL loop without controller on condition as follows

fin = 51.86 MHz

x’tal

f

= 12.8 MHz

fp = fr = 5.0 kHz

12

PHASE COMPARATOR

PHASE COMPARATOR compares the phase between divided input frequency (f

This circuit make the change pump output signals according to following detection.

To use internal charge pump

detection

p

fr > f

p

fr = f

p

fr < f

*3

EO

H H OFF

Hi-Impedance OFF OFF

L OFF L

EOP

*4

EON

*4

*3

(passive filter type)

To use external charge pump

*4

(active filter type)

VCO should be used as type of ‘higher voltagehigher frequency’.

EO

EOP

PPPP

PD2845GR

p

) and reference frequency (fr).

EON

EOP is Pch open drain, EON is Nch open drain. EO is output pin of internal charge pump.

SYSTEM APPLICATION EXAMPLE

Pager block diagram of direct conversion type

π/2

×5

LPF

PLL

µ

PD2845GR

LPF

∫

DET

DECODER

CLOCK

∫

DRIVER

DRIVER

BZ

LCD

13

PACKAGE DIMENSIONS

16 PIN PLASTIC SHRINK SOP (225 mil)

16 9

detail of lead end

P

PPPP

PD2845GR

18

A

G

F

K

E

C

B

N

DM

NOTE

Each lead centerline is located within 0.10 mm (0.004 inch) of

its true position (T.P.) at maximum material condition.

M

L

H

I

ITEM MILLIMETERS INCHES

A

5.50 MAX.

B

0.475 MAX.

C

0.65 (T.P.)

D 0.20±0.10 0.008±0.004

E

0.125±0.075

F

1.8 MAX.

G

1.44

H

6.2±0.3

I

4.4±0.2

J

0.9±0.2

K 0.15

L 0.5±0.2 0.020

M

N

P5°±5°

+0.10

–0.05

0.10

0.10 0.004

J

0.217 MAX.

0.019 MAX.

0.026 (T.P.)

0.005±0.003

0.071 MAX.

0.057

0.244±0.012

+0.009

0.173

–0.008

+0.009

0.035

–0.008

+0.004

0.006

–0.002

+0.008

–0.009

0.004

5°±5°

P16GM-65-225B-2

14

PPPP

PD2845GR

NOTE ON CORRECT USE

(1) Observe precautions for handling because of electrostatic sensitive devides.

(2) Form a ground pattern as wide as possible to minimize ground impedance.

(3) Connect a bypass capacitor (e. g. 1 000 pF) to the V

(4) The DC cut capacitor must be each attached to FIN, XI and XO pin.

(5) External R, C values of loop filter should be determined according to the VCO specification.

(6) While VCO signal is not input to FIN pin, power-save-mode must be set.

(7) After initially VCC, VDD are supplied, serial data should be input immediately. (Before serial data input, LSI

operation is unstable or undesired.)

DD

pin.

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered in the following recommended conditions. Other soldering method and conditions

than the recommended conditions are to be consulted with our sales representatives.

PD2845GR

PPPP

Soldering process Soldering conditions Symbol

Infrared ray reflow Peak package’s surface temperature: 235 °C or below,

Reflow time: 30 seconds or below (210 °C or higher),

Number of reflow process: 2, Exposure limit*: None

VPS Peak package’s surface temperature: 215 °C or below,

Reflow time: 40 seconds or below (200 °C or higher),

Number of reflow process: 2, Exposure limit*: None

Partial heating method Terminal temperature: 300 °C or below,

Flow time: 3 seconds or below, Exposure limit*: None

*: Exposure limit before soldering after dry-package is opened.

Storage conditions: 25 °C and relative humidity at 65 % or less.

Apply only a single process at once, except for “Partial heating method”.

Note

For details of recommended soldering conditions for surface mounting, refer to information document

SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL (C10535E).

IR35-00-2

VP15-00-2

15

PPPP

PD2845GR

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96. 5

Loading...

Loading...