Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD17P709

4-BIT SINGLE-CHIP MICROCONTROLLER WITH

BUILT-IN HARDWARE DEDICATED TO DIGITAL TUNING SYSTEMS

The µPD17P709 is produced by replacing the built-in masked ROM of the µPD17704

µ

PD17707, µPD17708, and µPD17709 with a one-time PROM.

The µPD17P709 allows programs to be written once, so that the µPD17P709 is suitable for preproduction in

µ

PD17704, µPD17705, µPD17707, µPD17708, or µPD17709 system development or low-volume production.

µ

When reading this document, also refer to the publications on the

µ

PD17708, or µPD17709.

Note Under development

The electrical characteristics (including power supply currents) and PLL analog characteristics of

the µPD17P709 differ from those of the µPD17704, µPD17705, µPD17707, µPD17708, and µPD17709. In

high-volume application set production, carefully check those differences.

FEATURES

• Compatible with the µPD17704, µPD17705, µPD17707, µPD17708, and µPD17709

• Built-in one-time PROM : 32K bytes (16384 × 16 bits)

• Supply voltage : VDD = 5 V ±10%

ORDERING INFORMATION

PD17704, µPD17705, µPD17707,

Note

, µPD17705

Note

,

Part number Package

µ

PD17P709GC-3B9 80-pin plastic QFP (14 × 14 mm, 0.65-mm pitch)

The information in this document is subject to change without notice.

Document No. U10142EJ2V0DS00 (2nd edition)

Date Published November 1996 P

Printed in Japan

The mark shows major revised points.

©

1995

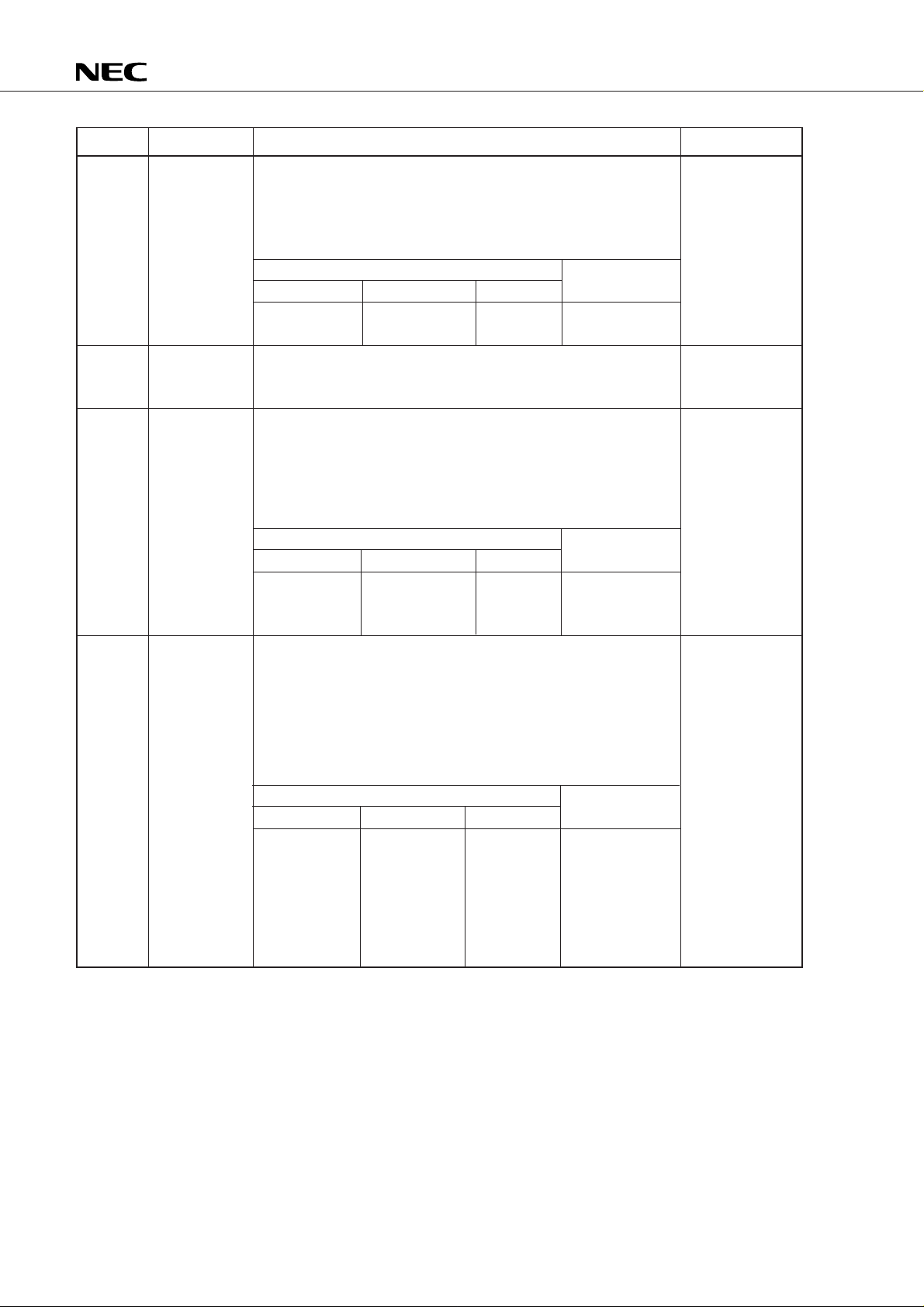

Page 2

µ

PD17P709

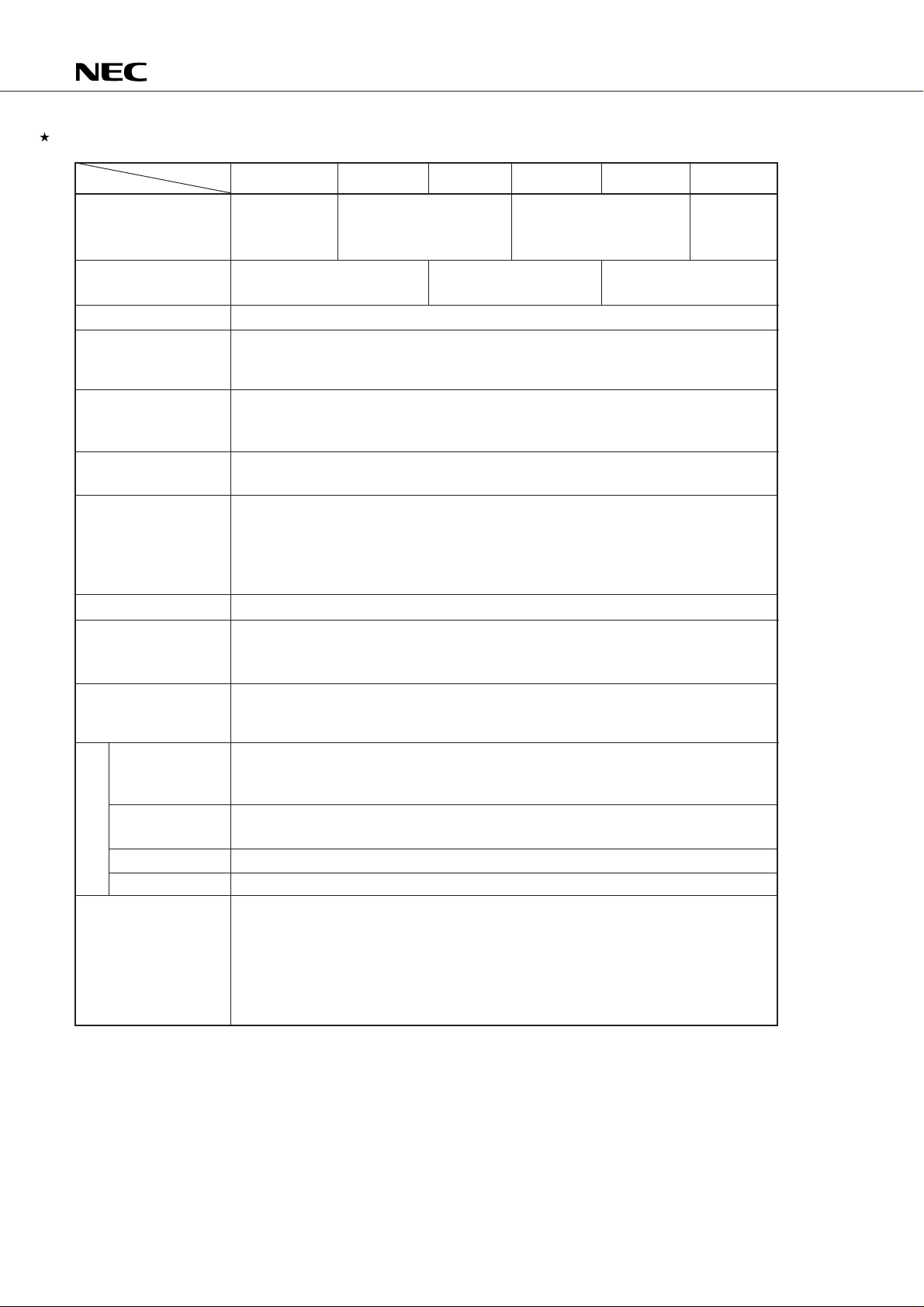

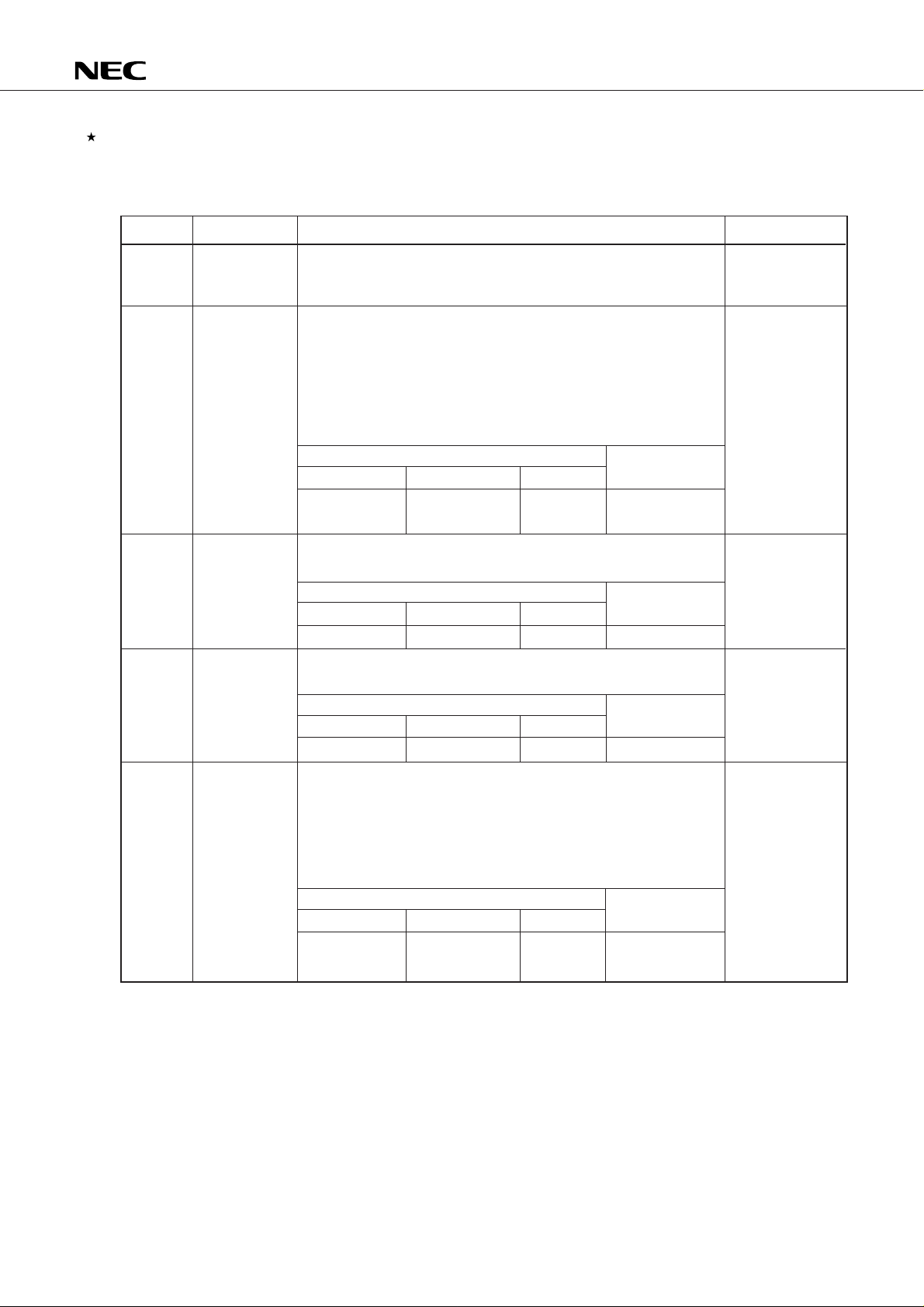

FUNCTION OVERVIEW

Item

Program memory (ROM)

General-purpose data

memory (RAM)

Instruction execution time

General-purpose ports

Stack level

Interrupt

Timers

A/D converter

D/A converter

(PWM)

Serial interface

Frequency

PLL

division

system

Reference

frequency

Charge pump

Phase comparator

Intermediate frequency

counter

Product

Note

µ

µ

PD17704

8192 × 16 bits 12288 × 16 bits

(masked ROM) (masked ROM)

672 × 4 bits 1120 × 4 bits

1.78 µs (with 4.5-MHz crystal)

• I/O ports : 46

• Input ports : 12

• Output ports : 4

• Address stack : 15 levels

• Interrupt stack: 4 levels

• DBF stack : 4 levels (operated by software)

• External : 6 (CE rising edge and INT0 to INT4)

• Internal : 6 (timers 0 to 3, serial interfaces 0 and 1)

5 channels

• Basic timer (clock: 10, 20, 50, 100 Hz) : 1 channel

• 8-bit timer with gate counter (clock: 1 k, 2 k, 10 k, 100 kHz) : 1 channel

• 8-bit timer (clock: 1 k, 2 k, 10 k, 100 kHz) : 2 channels

• 8-bit timer, also used for PWM (clock: 440 Hz, 4.4 kHz) : 1 channel

8 bits × 6 channels (Hardware or software mode can be selected.)

3 channels (8-bit or 9-bit resolution, selected by software.)

Output frequency : 4.4 kHz, 440 Hz (8-bit PWM)

2 systems (3 channels)

• 3-wire serial I/O : 2 channels

• 2-wire serial I/O/I2C bus : 1 channel

• Direct frequency division system (VCOL pin (MF mode) : 0.5 to 3 MHz)

• Pulse swallow system (VCOL pin (HF mode) : 10 to 40 MHz)

Can be set to one of 13 frequencies

(1, 1.25, 2.5, 3, 5, 6.25, 9, 10, 12.5, 18, 20, 25, or 50 kHz).

2 error output pins (EO0 and EO1)

Unlock detection is enabled by software.

• Intermediate frequency measurement

P1C0/FMIFC pin : 10 to 11 MHz in FMIF mode

P1C1/AMIFC pin : 0.4 to 0.5 MHz in AMIF mode

• External gate width measurement

P2A1/FCG1 and P2A0/FCG0 pins

PD17705

2.2 kHz, 220 Hz (9-bit PWM)

Note

µ

PD17707

(VCOH pin (VHF mode): 60 to 130 MHz)

0.4 to 0.5 MHz in AMIF mode

µ

16384 × 16 bits

(masked ROM)

PD17708

µ

PD17709

1776 × 4 bits

(1/2)

µ

PD17P709

16384 × 16 bits

(one-time

PROM)

Note Under development

2

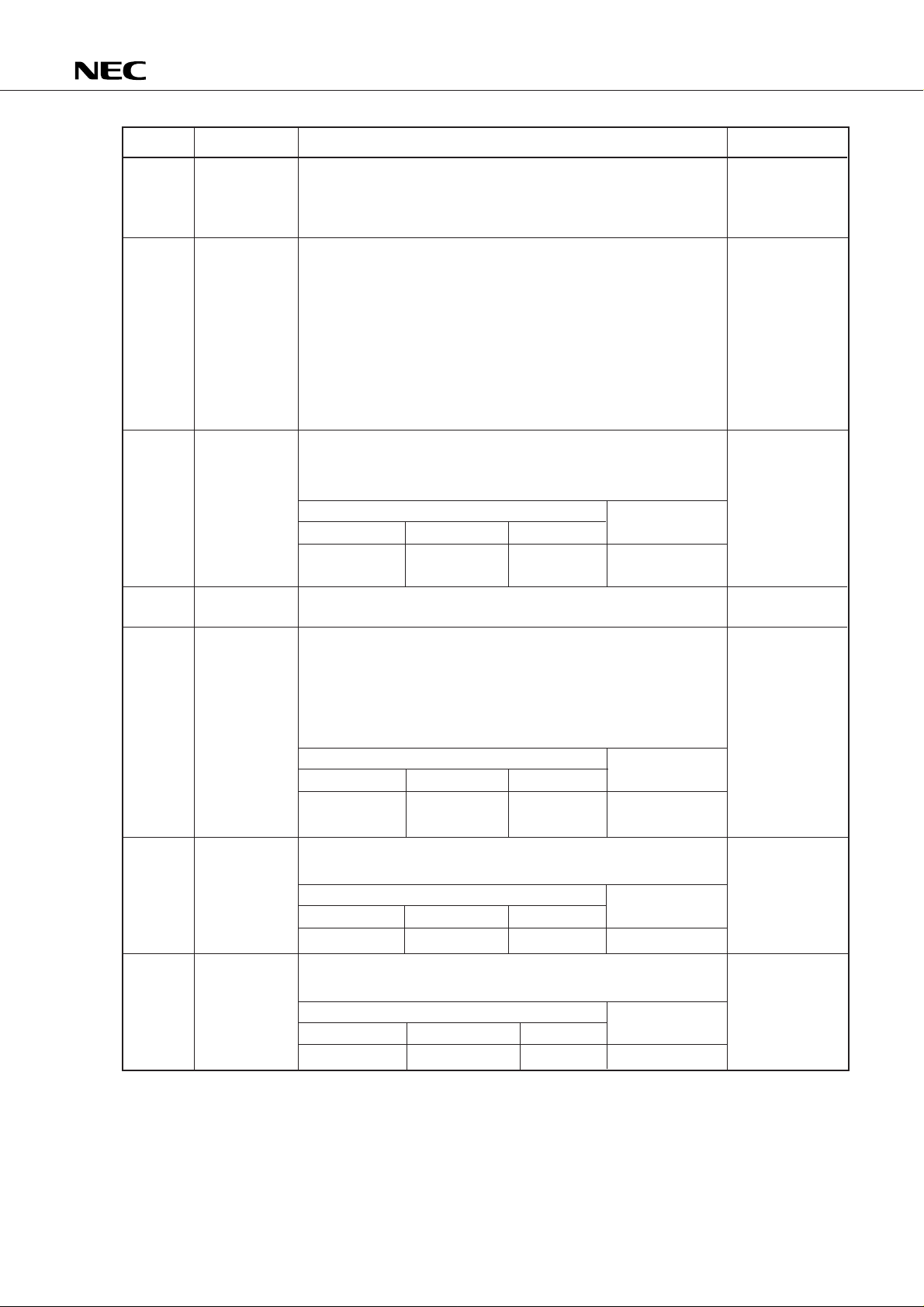

Page 3

µ

PD17P709

(2/2)

Item

BEEP output

Reset

Standby

Supply voltage

Package

Product

Note Under development

Note

µ

µ

PD17704

2

Output frequency : 1 kHz, 3 kHz, 4 kHz, 6.7 kHz (BEEP0 pin)

• Power-on reset (when the power is turned on)

• Reset using the RESET pin

• Watchdog timer reset

Can be set only once at power-on: 65,536 instructions, 131,072 instructions, or non-use

can be selected.

• Stack pointer overflow/underflow reset

Can be set only once at power-on: the interrupt stack or address stack can be selected.

• CE reset (CE pin: low → high)

A CE reset delay timing can be set.

• Power-failure detection function

• Clock stop mode (STOP)

• Halt mode (HALT)

• PLL operation : VDD = 4.5 to 5.5 V

• CPU operation: VDD = 3.5 to 5.5 V

80-pin plastic QFP (14 × 14 mm, 0.65-mm pitch)

PD17705

67 Hz, 200 Hz, 3 kHz, 4 kHz (BEEP1 pin)

Note

µ

PD17707

µ

PD17708

µ

PD17709

µ

PD17P709

3

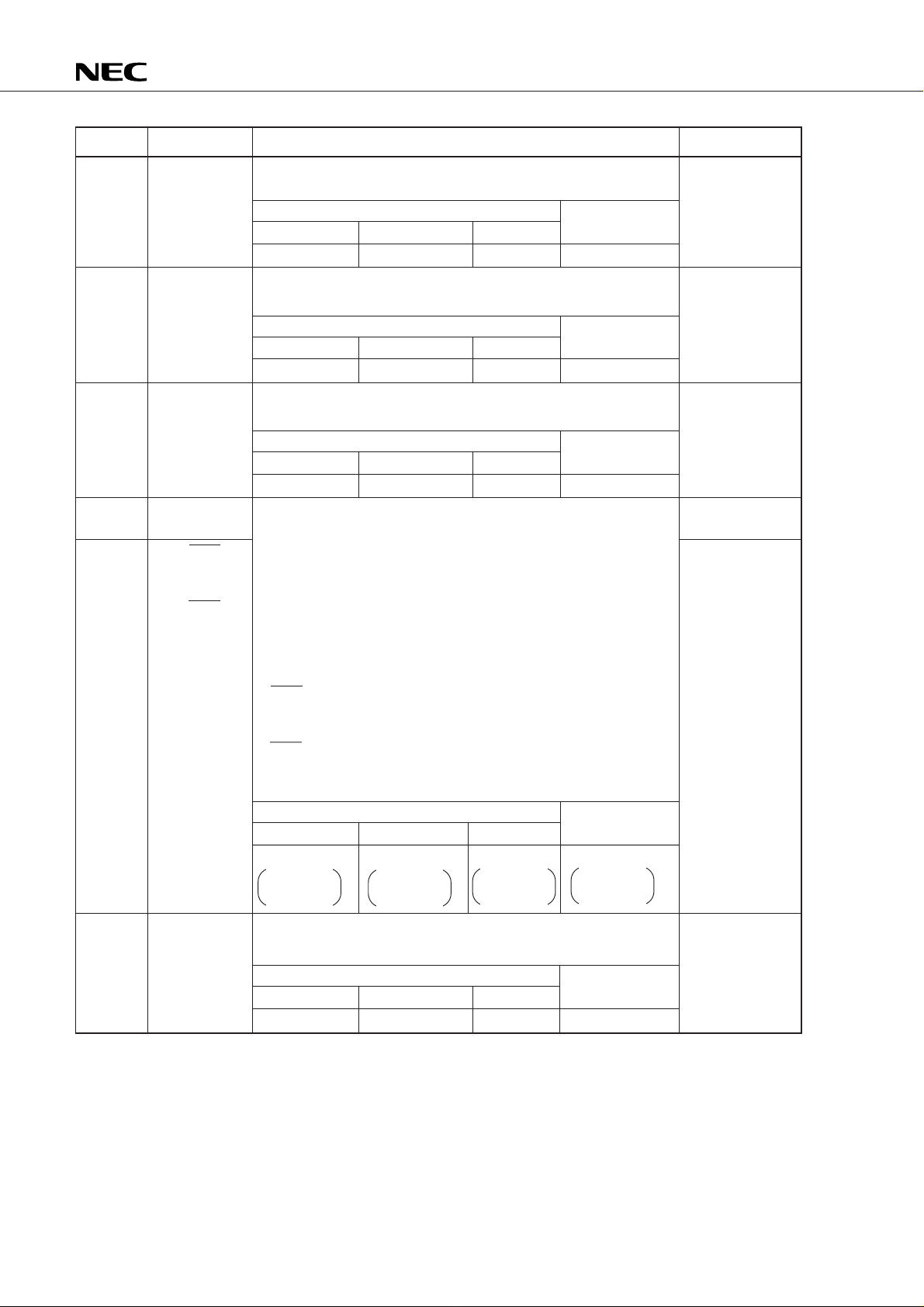

Page 4

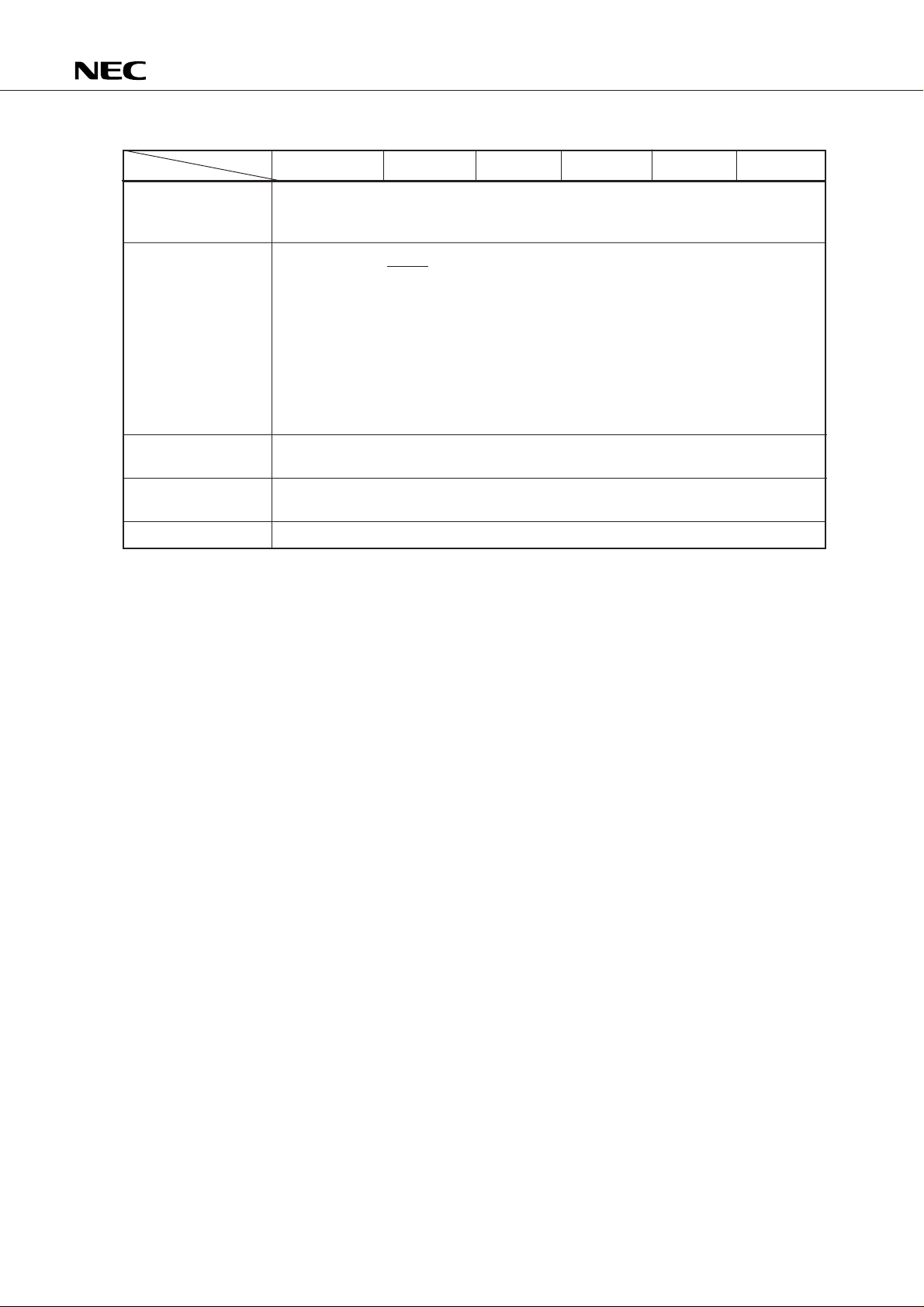

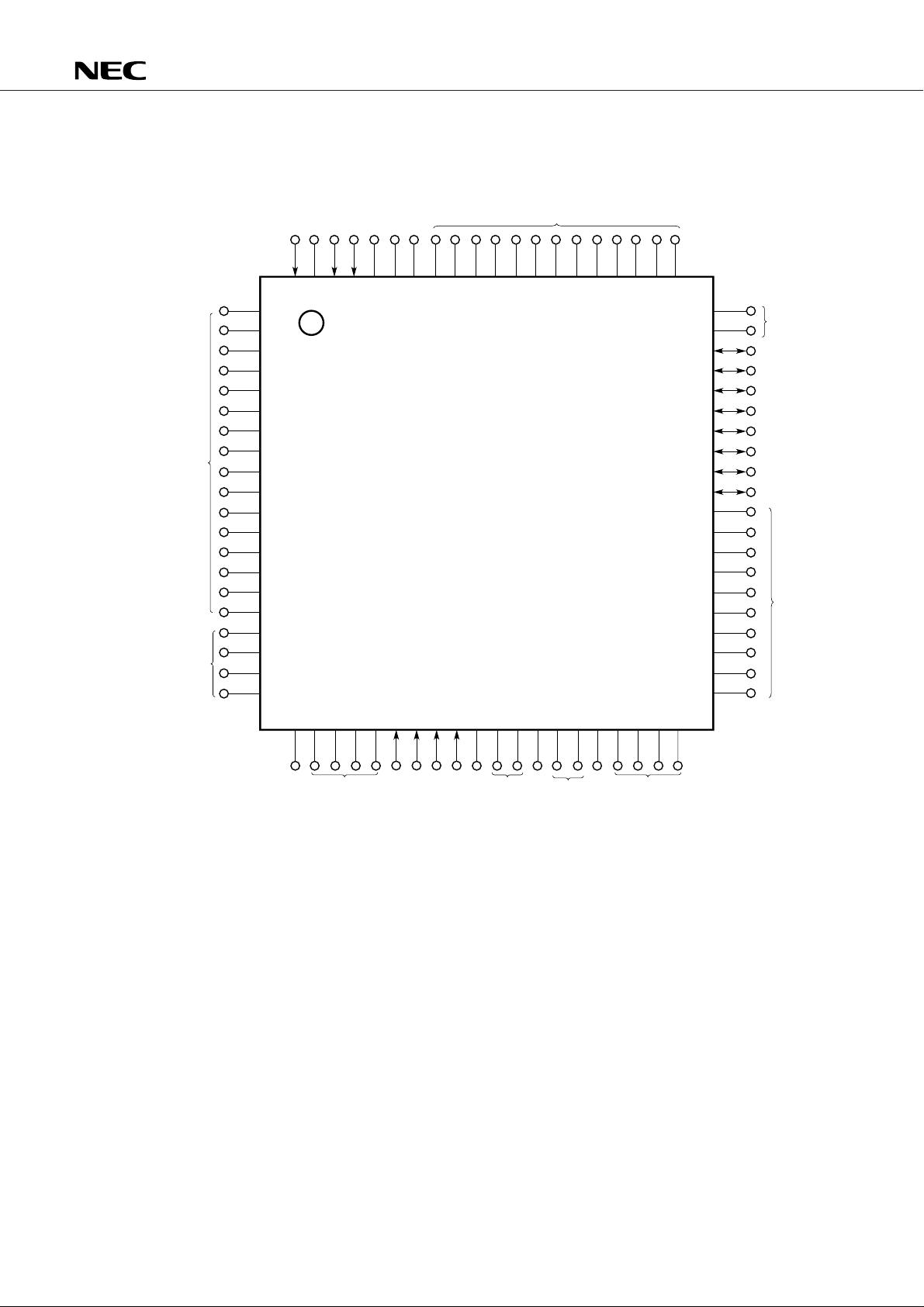

PIN CONFIGURATION (TOP VIEW)

80-pin plastic QFP (14 × 14 mm, 0.65-mm pitch)

µ

PD17P709GC-3B9

(1) Normal operation mode

0

DD

INXOUT

GND0

X

INT2

P1A3/INT4

P1A2/INT3

P1A1

P1A0/TM0G

P3A3

P3A2

P3A1

P3A0

P3B3

P3B2

P3B1

P3B0

P2A2

P2A1/FCG1

P2A0/FCG0

P1B3

P1B2/PWM2

P1B1/PWM1

P1B0/PWM0

CE

RESET

V

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

REG

P2D0

P2D1

P2D2

P0B0/SI1

P0B1/SO1

P0B2/SCK1

P0B3/SI0

P0A0/SO0

P0A1/SCK0

P0A2/SCL

P0A3/SDA

P0C0

P0C1

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

µ

PD17P709

P0C2

P0C3

P2C0

P2C1

P2C2

P2C3

P3D0

P3D1

P3D2

P3D3

P3C0

P3C1

P3C2

P3C3

P2B0

P2B1

P2B2

P2B3

INT0

INT1

22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

21

1

GND2

P0D3/AD3

P0D2/AD2

P0D1/AD1

P0D0/AD0

P1C3/AD5

P1C2/AD4

P1C1/AMIFC

DD

V

VCOH

P1C0/FMIFC

VCOL

GND1

EO0

EO1

TEST

P1D3

P1D2

P1D1/BEEP1

P1D0/BEEP0

4

Page 5

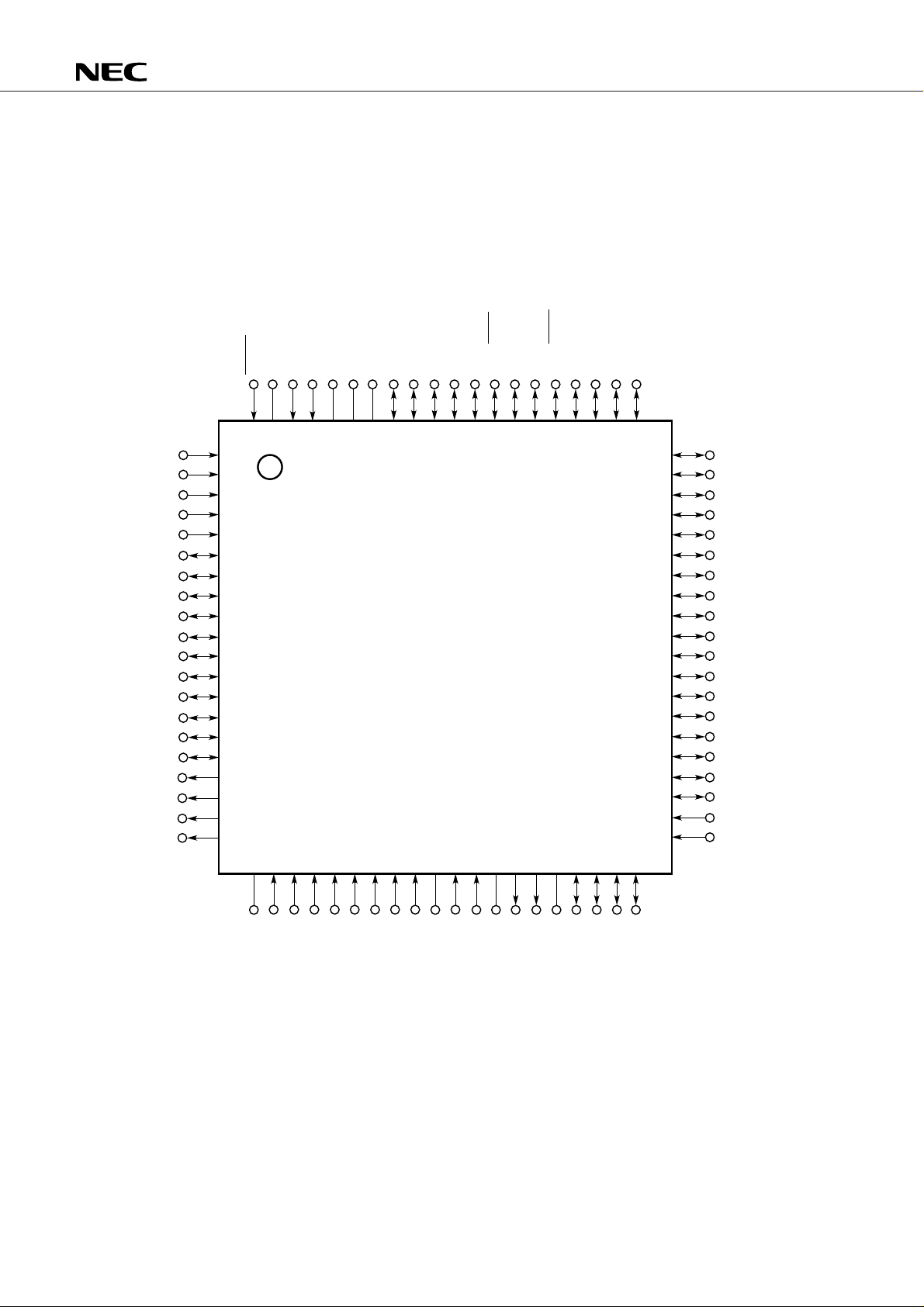

(2) PROM programming mode

µ

PD17P709

(L)

(OPEN)

(OPEN)

GND0

Note

REG

(L)

0

DD

(H)

V

(L)

CLK

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

(L)

D0

D1

D2

D3

D4

D5

D6

D7

(L)

22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

21

(L)

GND2

MD3

Note Connect to the same potential as V

MD2

DD.

MD1

MD0

1

(L)

DD

V

GND1

PP

V

(OPEN)

(L)

Caution The parentheses above indicate the handling of the pins not used in PROM programming mode.

L : Connect each pin to GND through a resistor (470 ohms).

H : Connect each pin to V

DD through a resistor (470 ohms).

OPEN : Leave each pin open.

5

Page 6

PIN NAMES

µ

PD17P709

AD0-AD5 : A/D converter inputs

AMIFC : AM frequency counter input

BEEP0, BEEP1 : Beep outputs

CE : Chip enable

CLK : Address update clock input

D0-D7 : Data I/O

EO0, EO1 : Error outputs

FCG0, FCG1 : Frequency counter gate inputs

FMIFC : FM frequency counter input

GND0-GND2 : Ground 0 to 2

INT0-INT4 : External interrupt inputs

MD0-MD3 : Operating mode selection

PWM0-PWM2 : D/A converter outputs

P0A0-P0A3 : Port 0A

P0B0-P0B3 : Port 0B

P0C0-P0C3 : Port 0C

P0D0-P0D3 : Port 0D

P1A0-P1A3 : Port 1A

P1B0-P1B3 : Port 1B

P1C0-P1C3 : Port 1C

P1D0-P1D3 : Port 1D

P2A0-P2A2 : Port 2A

P2B0-P2B3 : Port 2B

P2C0-P2C3 : Port 2C

P2D0-P2D2 : Port 2D

P3A0-P3A3 : Port 3A

P3B0-P3B3 : Port 3B

P3C0-P3C3 : Port 3C

P3D0-P3D3 : Port 3D

REG : CPU regulator

RESET : Reset input

SCK0, SCK1 : 3-wire serial clock I/O

SCL : 2-wire serial clock I/O

SDA : 2-wire serial data I/O

SI0, SI1 : 3-wire serial data input

SO0, SO1 : 3-wire serial data output

TEST : Test input

TM0G : Timer 0 gate input

VCOH : Local oscillation high input

VCOL : Local oscillation low input

DD0, VDD1 : Power supply

V

VPP : Program voltage application

XIN, XOUT : Main clock oscillation

6

Page 7

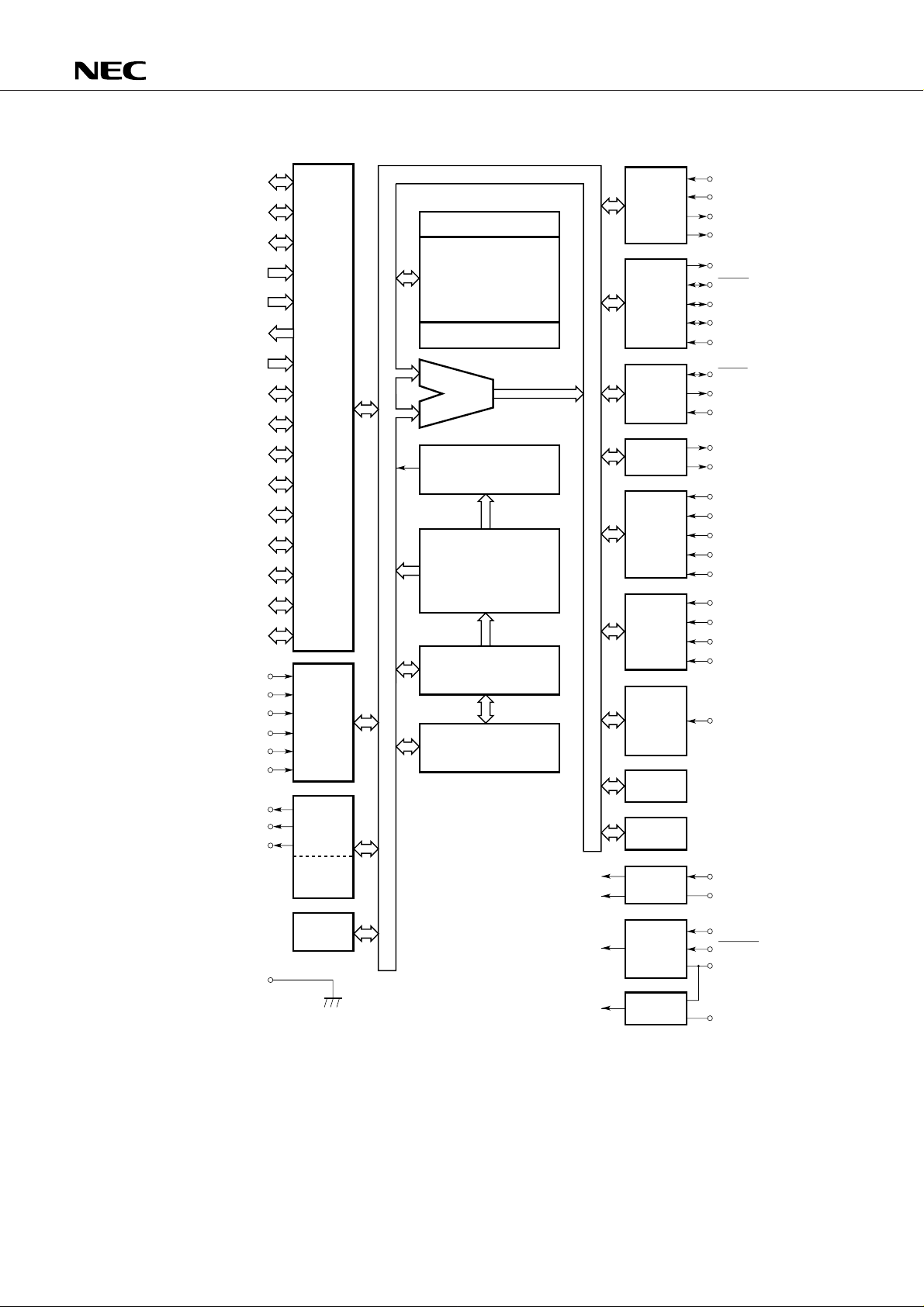

BLOCK DIAGRAM

µ

PD17P709

P0A0-P0A3

P0B0-P0B3

P0C0-P0C3

P0D0-P0D3

P1A0-P1A3

P1B0-P1B3

P1C0(MD0)-

P1C3(MD3)

P1D0-P1D3

P2A0-P2A2

P2B0-P2B3

P2C0(D0)-P2C3(D3)

P2D0-P2D2

P3A0-P3A3

P3B0-P3B3

P3C0-P3C3

P3D0(D4)-P3D3(D7)

AD0/P0D0

AD1/P0D1

AD2/P0D2

AD3/P0D3

AD4/P1C2

AD5/P1C3

PWM0/P1B0

PWM1/P1B1

PWM2/P1B2

4

4

4

4

4

4

4

4

3

4

4

3

4

4

4

4

Ports

A/D

converter

D/A

converter

8-bit

timer 3

RF

RAM

1776 × 4 bits

SYSREG

ALU

Instruction

decoder

One-time PROM

16384 × 16 bits

Program counter

Stack

CPU

Peripheral

PLL

Serial

interface 0

Serial

interface 1

BEEP

Interrupt

control

Frequency

counter

8-bit

timer 0

Gate

counter

8-bit

timer 1

8-bit

timer 2

OSC

VCOH

VCOL

EO0

EO1

SO0/P0A0

SCK0/P0A1

SCL/P0A2

SDA/P0A3

SI0/P0B3

SCK1/P0B2

SO1/P0B1

SI1/P0B0

BEEP0/P1D0

BEEP1/P1D1

INT0

INT1

INT2

INT3/P1A2

INT4/P1A3

FCG0/P2A0

FCG1/P2A1

FMIFC/P1C0

AMIFC/P1C1

TM0G/P1A0

X

IN

(CLK)

X

OUT

Basic

timer

GND0-GND2

CPU

V

Regurator

Remark Pins enclosed in parentheses are used in PROM programming mode.

Reset

CE

RESET

VDD0,VDD1

REG

7

Page 8

µ

PD17P709

CONTENTS

1. PIN FUNCTIONS......................................................................................................................... 9

1.1 NORMAL OPERATION MODE ....................................................................................................... 9

1.2 PROM PROGRAMMING MODE..................................................................................................... 13

1.3 EQUIVALENT CIRCUIT OF PINS .................................................................................................. 14

1.4 HANDLING UNUSED PINS ............................................................................................................ 19

1.5 NOTES ON USE OF THE CE, INT0-INT4, AND RESET PINS (ONLY IN NORMAL

OPERATION MODE) ....................................................................................................................... 21

1.6 NOTES ON USE OF THE TEST PIN (ONLY IN NORMAL OPERATION MODE) ...................... 21

2. ONE-TIME PROM (PROGRAM MEMORY) WRITE, READ, AND VERIFICATION ................ 22

2.1 OPERATING MODES FOR PROGRAM MEMORY WRITE, READ, AND VERIFICATION ........ 23

2.2 PROGRAM MEMORY WRITE PROCEDURE ............................................................................... 24

2.3 PROGRAM MEMORY READ PROCEDURE................................................................................. 2 5

3. ELECTRICAL CHARACTERISTICS .......................................................................................... 26

4. PACKAGE DRAWING ................................................................................................................ 31

5. RECOMMENDED SOLDERING CONDITIONS....................................................................... 32

APPENDIX DEVELOPMENT TOOLS.............................................................................................. 33

8

Page 9

1. PIN FUNCTIONS

1.1 NORMAL OPERATION MODE

µ

PD17P709

Pin No.

1

41

42

2

3

4

5

6

to

9

10

to

13

14

15

16

Symbol

INT2

INT1

INT0

P1A3/INT4

P1A2/INT3

P1A1

P1A0/TM0G

P3A3

to

P3A0

P3B3

to

P3B0

P2A2

P2A1/FCG1

P2A0/FCG0

Input for edge-detected vectored. Either a rising edge or falling edge

can be selected.

Input for port 1A, external interrupt request signal, and event signal

• P1A3-P1A0

• 4-bit input port

• INT4, INT3

• Edge-detected vectored interrupt

• TM0G

• Gate input for 8-bit timer 0

When reset

Power-on reset WDT&SP reset

Input

(P1A3-P1A0)

4-bit I/O port.

Input/output can be specified in 4-bit units.

Power-on reset WDT&SP reset

Input

4-bit I/O port.

Input/output can be specified in 4-bit units.

Power-on reset WDT&SP reset

Input

Input for port 2A and external gate counter

Input

(P1A3-P1A0)

When reset

Input

When reset

Input

Held

Held

Held

CE reset

CE reset

CE reset

When the clock

is stopped

Held

When the clock

is stopped

Held

When the clock

is stopped

Held

• P2A2-P2A0

• 3-bit I/O port

• Input/output can be specified bit by bit.

• FCG1, FCG0

• External gate counter input

Output formatFunction

—

—

CMOS push-pull

CMOS push-pull

CMOS push-pull

When reset

Power-on reset WDT&SP reset

Input

(P2A2-P2A0)

Input

(P2A2-P2A0)

CE reset

Held

(P2A2-P2A0)

When the clock

is stopped

Held

(P2A2-P2A0)

9

Page 10

µ

PD17P709

Pin No.

17

18

to

20

21

33

75

22

to

25

26

27

28

29

Symbol

P1B3

P1B2/PWM2

to

P1B0/PWM0

GND2

GND1

GND0

P0D3/AD3

to

P0D0/AD0

P1C3/AD5

P1C2/AD4

P1C1/AMIFC

P1C0/FMIFC

Function

Output for port 1B and D/A converter

• P1B3-P1B0

• 4-bit output port

• PWM2-PWM0

• 8-bit or 9-bit D/A converter output

When reset

Power-on reset WDT&SP reset

Low-level output

(P1B3-P1B0)

Ground

Input for port 0D and A/D converter

Low-level output

(P1B3-P1B0)

CE reset

Held

• P0D3-P0D0

• 4-bit input port

• A pull-down resistor can be set bit by bit.

• AD3-AD0

• Analog input for 8-bit-resolution A/D converter

When reset

Power-on reset WDT&SP reset

Input with pull-

down resistors

(P0D3-P0D0)

Input for port 1C, A/D converter, and IF counter

Input with pulldown resistors

(P0D3-P0D0)

CE reset

Held

• P1C3-P1C0

• 4-bit input port

• AD5, AD4

• Analog input for 8-bit-resolution A/D converter

• FMIFC, AMIFC

• Frequency counter input

Output format

N-ch open-drain

(12-V withstand

voltage)

When the clock

is stopped

Held

(P1B3-P1B0)

—

—

When the clock

is stopped

Held

—

10

Power-on reset

Input

(P1C3-P1C0)

When reset

WDT&SP reset

Input

(P1C3-P1C0)

CE reset

• P1C3/AD5,

P1C2/AD4

Held

• P1C1/AMIFC,

P1C0/FMIFC

Input

(P1C1, P1C0)

When the clock

is stopped

• P1C3/AD5,

P1C2/AD4

Held

• P1C1/AMIFC,

P1C0/FMIFC

Input

(P1C1, P1C0)

Page 11

µ

PD17P709

Pin No.

30

79

31

32

34

35

36

37

38

39

40

43

to

46

Symbol

VDD1

VDD0

VCOH

VCOL

EO0

EO1

TEST

P1D3

P1D2

P1D1/BEEP1

P1D0/BEEP0

P2B3

to

P2B0

Function

Power supply. Apply the same voltage to the VDD1 and VDD0 pins.

• When the CPU and peripheral functions are operating: 4.5 to 5.5 V

• When only the CPU is operating: 3.5 to 5.5 V

• When the clock is stopped: 2.2 to 5.5 V

Input for PLL local oscillation (VCO) frequency

• VCOH

• Active when VHF mode is selected by software. Otherwise, pulled

down.

• VCOL

• Active when HF or MW mode is selected by software. Otherwise,

pulled down.

Inputs to these pins are to be AC-amplified. Cut, therefore, the DC

components in the input signals by using capacitors.

Output from the charge pump of the PLL frequency synthesizer. The

result of phase comparison between the divided local oscillation frequency and reference frequency is output.

When reset

Power-on reset

High-impedance

output

Test input pin.

Be sure to connect it to GND.

Output for port 1D and BEEP

WDT&SP reset

High-impedance

output

CE reset

High-impedance

output

When the clock

is stopped

High-impedance

output

• P1D3-P1D0

• 4-bit I/O port

• Input/output can be specified bit by bit.

• BEEP1, BEEP0

• BEEP output

When reset

Power-on reset

Input

(P1D3-P1D0)

4-bit I/O port.

Input/output can be specified bit by bit.

Power-on reset

Input

WDT&SP reset

Input

(P1D3-P1D0)

When reset

WDT&SP reset

Input

CE reset

Held

(P1D3-P1D0)

CE reset

Held

When the clock

is stopped

Held

(P1D3-P1D0)

When the clock

is stopped

Held

Output format

—

—

CMOS tristate

—

CMOS push-pull

CMOS push-pull

47

to

50

P3C3

to

P3C0

4-bit I/O port.

Input/output can be specified in 4-bit units.

When reset

Power-on reset WDT&SP reset

Input

Input

Held

CE reset

CMOS push-pull

When the clock

is stopped

Held

11

Page 12

µ

PD17P709

Pin No.

51

to

54

55

to

58

59

to

62

63

64

65

66

67

68

69

70

Symbol Function

P3D3

to

P3D0

P2C3

to

P2C0

P0C3

to

P0C0

P0A3/SDA

P0A2/SCL

P0A1/SCK0

P0A0/SO0

P0B3/SI0

P0B2/SCK1

P0B1/SO1

P0B0/SI1

4-bit I/O port.

Input/output can be specified in 4-bit units.

When reset

Power-on reset WDT&SP reset

Input

4-bit I/O port.

Input/output can be specified bit by bit.

Power-on reset WDT&SP reset

Input

4-bit I/O port.

Input/output can be specified bit by bit.

Power-on reset WDT&SP reset

Input

Input/output for P0A or P0B and serial interface

Input

When reset

Input

When reset

Input

• P0A3-P0A0

• 4-bit I/O port

• Input/output can be specified bit by bit.

• P0B3-P0B0

• 4-bit I/O port

• Input/output can be specified bit by bit.

• SDA, SCL

• Serial data and serial clock I/O when the 2-wire serial I/O or I2C bus

of serial interface 0 is selected.

• SCK0, SO0, SI0

• Serial clock I/O, serial data output, and serial data input when the

3-wire serial I/O of serial interface 0 is selected.

• SCK1, SO1, SI1

• Serial clock I/O, serial data output, and serial data input when the

3-wire serial I/O of serial interface 1 is selected.

When reset

Power-on reset WDT&SP reset

Input

P0A3-P0A0

P0B3-P0B0

Input

P0A3-P0A0

P0B3-P0B0

CE reset

Held

CE reset

Held

CE reset

Held

CE reset

Held

P0A3-P0A0

P0B3-P0B0

Output format

CMOS push-pull

When the clock

is stopped

Held

CMOS push-pull

When the clock

is stopped

Held

CMOS push-pull

When the clock

is stopped

Held

N-ch open-drain

CMOS push-pull

When the clock

is stopped

Held

P0A3-P0A0

P0B3-P0B0

12

71

to

73

P2D2

to

P2D0

3-bit I/O port.

Input/output can be specified bit by bit.

When reset

Power-on reset WDT&SP reset

Input

Input

CE reset

Held

CMOS push-pull

When the clock

is stopped

Held

Page 13

µ

PD17P709

Pin No. Symbol

74

76

77

78

REG

XOUT

XIN

CE

CPU regulator.

Use 0.1-µF capacitor to connect it to GND.

A crystal is connected to these pins.

Input for device operation selection, CE reset, and interrupt signals

• Device operation selection

When CE is high, the PLL frequency synthesizer can be operated.

When CE is low, the PLL frequency synthesizer is automatically

disabled by the device.

• CE reset

Setting CE from low to high resets the device upon the detection of a

rising edge of the internal basic timer setting pulse.

A reset timing delay can also be specified.

• Interrupt

A vectored interrupt occurs upon the detection of a falling edge of the

input signal.

80

RESET

1.2 PROM PROGRAMMING MODE

Reset input

Function

Output format

—

—

—

—

Pin No. Symbol

26

to

29

21

33

75

36

30

79

51

to

58

77

MD3

to

MD0

GND2

GND1

GND0

VPP

VDD1

VDD0

D7

to

D0

CLK

Input for operating mode selection for program memory write, read, or

verification

Ground

Pin to which program voltage is applied during program memory write,

read, or verification. +12.5 V is applied.

Power supply pins. +6 V is applied during program memory write, read,

or verification.

8-bit data I/O for program memory write, read, or verification

Clock input for address updating during program memory write, read, or

verification

Output formatFunction

—

—

—

—

CMOS push-pull

—

Remark The pins other than those listed above are not used in PROM programming mode. For the handling

of the unused pins, see PIN CONFIGURATION, (2) PROM programming mode.

13

Page 14

1.3 EQUIVALENT CIRCUIT OF PINS

(1) P0A (P0A1/SCK0, P0A0/SO0)

P0B (P0B3/SI0, P0B2/SCK1, P0B1/SO1, P0B0/SI1)

P0C (P0C3, P0C2, P0C1, P0C0)

P1D (P1D3, P1D2, P1D1/BEEP1, P1D0/BEEP0)

P2A (P2A2, P2A1/FCG1, P2A0/FCG0)

P2B (P2B3, P2B2, P2B1, P2B0)

P2C (P2C3, P2C2, P2C1, P2C0)

P2D (P2D2, P2D1, P2D0)

P3A (P3A3, P3A2, P3A1, P3A0)

P3B (P3B3, P3B2, P3B1, P3B0)

P3C (P3C3, P3B2, P3C1, P3C0)

P3D (P3D3, P3D2, P3D1, P3D0)

µ

PD17P709

(I/O)

V

DD

CKSTOP

V

DD

Note

Note In this circuit, a current drained by noise does not increase even if the circuit is in the floating state, because

of the internal signal being output when the clock stop instruction is executed.

14

Page 15

(2) P0A (P0A3/SDA, P0A2/SCL) (I/O)

µ

PD17P709

V

DD

CKSTOP

Note

Note In this circuit, a current drained by noise does not increase even if the circuit is in the floating state, because

of the internal signal being output when the clock stop instruction is executed.

(3) P1B (P1B3, P1B2/PWM2, P1B1/PWM1, P1B0/PWM0) (Output)

(4) P0D (P0D3/AD3, P0D2/AD2, P0D1/AD1, P0D0/AD0) (Input)

A/D converter

V

DD

CKSTOP

P0DPLD flag

High on-state resistor

Note

Note In this circuit, a current drained by noise does not increase even if the circuit is in the floating state, because

of the internal signal being output when the clock stop instruction is executed.

15

Page 16

(5) P1A (P1A1) (Input)

(6) P1C (P1C3/AD5, P1C2/AD4) (Input)

µ

PD17P709

V

DD

V

DD

A/D converter

(7) P1C (P1C1/AMIFC, P1C0/FMIFC) (Input)

VDD

VDD

General-purpose port

High on-state resistor

VDD

Frequency counter

16

Page 17

(8) CE

RESET

INT0, INT1, INT2

P1A (P1A3/INT4, P1A2/INT3, P1A0/TM0G)

OUT (Output), XIN (Input)

(9) X

(Schmitt-triggered input)

V

DD

µ

PD17P709

X

(10) EO1, EO0 (Output)

X

OUT

VDD

High on-state

resistor

DWN

UP

V

DD

Internal clock

V

DD

IN

High on-state

resistor

17

Page 18

(11) VCOH, VCOL (Input)

µ

PD17P709

High on-state

resistor

V

DD

High on-state

resistor

V

DD

18

Page 19

1.4 HANDLING UNUSED PINS

The unused pins should be handled as indicated in Table 1-1.

µ

PD17P709

Pin

P0D3/AD3-P0D0/AD0

P1C3/AD5

P1C2/AD4

P1C1/AMIFC

P1C0/FMIFC

P1A3/INT4

P1A2/INT3

P1A1

P1A0/TM0G

P1B3

P1B2/PWM2-P1B0/PWM0

P0A3/SDA

P0A2/SCL

P0A1/SCK0

P0A0/SO0

P0B3/SI0

Port pins

P0B2/SCK1

P0B1/SO1

P0B0/SI1

P0C3-P0C0

P1D3

P1D2

P1D1/BEEP1

P1D0/BEEP0

P2A2

P2A1/FCG1

P2A0/FCG0

P2B3-P2B0

P2C3-P2C0

P2D2-P2D0

Note 2

Note 2

Table 1-1 Handling Unused Pins

I/O format

Input

N-ch open-drain

output

Note 3

I/O

Recommended handling

Connect each pin to GND through a resistor.

Specify as a port and connect each pin to VDD or GND through

a resistor.

Connect each pin to GND through a resistor.

Specify low output, in the software, and leave open.

Specify as a general-purpose input port, in the software, and

connect each pin to VDD or GND through a resistor.

Note 1

Note 1

Note 1

Note 1

(1/2)

Notes 1. When making an external connection to V

DD with a pull-up resistor, or to GND with a pull-down resistor,

note the following: If the resistance of the pull-up or pull-down resistor is too high, the pin approaches

the high impedance state, thus increasing the through current drawn by the port. In general, pull-up and

pull-down resistors should have a resistance of between 20 and 50 kilohms, depending on the application

circuit.

2. Do not specify AMIFC or FMIFC. If AMIFC or FMIFC is specified, current drain increases.

3. I/O ports become general-purpose input ports upon power-on reset, reset by the RESET pin, watchdog

timer reset, or stack overflow/underflow reset.

19

Page 20

µ

PD17P709

(2/2)

Pin

P3A3-P3A0

P3B3-P3B0

P3C3-P3C0

Port pins

P3D3-P3D0

CE

EO1

EO0

INT0-INT2

RESET

TEST

Other than port pins

VCOH

VCOL

I/O format

Note 2

I/O

Input

Output

Input

Input

Input

—

Recommended handling

Specify as a general-purpose input port, in the software, and

connect each pin to VDD or GND through a resistor.

Connect to VDD through a resistor.

Leave each pin open.

Connect each pin to GND through a resistor.

Connect to VDD through a resistor.

Connect directly to GND.

Disable PLL, in the program, and leave each pin open.

Note 1

Note 1

Note 1

Note 1

Notes 1. When making an external connection to VDD with a pull-up resistor, or to GND with a pull-down resistor,

note the following: If the resistance of the pull-up or pull-down resistor is too high, the pin approaches

the high impedance state, thus increasing the through current drawn by the port. In general, pull-up and

pull-down resistors should have a resistance of between 20 and 50 kilohms, depending on the application

circuit.

2. I/O ports become general-purpose input ports upon power-on reset, reset by the RESET pin, watchdog

timer reset, or stack overflow/underflow reset.

20

Page 21

µ

PD17P709

1.5 NOTES ON USE OF THE CE, INT0-INT4, AND RESET PINS (ONLY IN NORMAL OPERATION MODE)

The CE, INT0-INT4, and RESET pins can be used as the test mode selection pin for testing the internal operation

µ

of the

PD17P709 (IC test), besides the usage shown in Section 1.1.

Applying a voltage exceeding VDD to the CE, INT0-INT4, or RESET pin causes the µPD17P709 to enter test mode.

When noise exceeding VDD comes in during normal operation, the device may not operate normally.

For example, if the wiring from the CE, INT0-INT4, or RESET pin is too long, noise may be induced on the wiring,

causing this mode switching.

When installing the wiring, lay the wiring in such a way that noise is suppressed as much as possible. If noise

yet arises, use an external part to suppress it as shown below.

• Connect a diode with low V

DD.

and V

Diode with

low V

F

CE, INT0-INT4, RESET

F between the pin • Connect a capacitor between the pin and VDD.

V

DD

V

DD

CE, INT0-INT4, RESET

VDD

VDD

1.6 NOTES ON USE OF THE TEST PIN (ONLY IN NORMAL OPERATION MODE)

Applying V

DD to the TEST pin causes the

µ

PD17P709 to enter test mode or program memory write/verify mode.

Keep the wiring as short as possible and connect the TEST pin directly to the GND pin.

When the wiring between the TEST pin and GND pin is too long or external noise enters the TEST pin, a voltage

difference may occur between the TEST pin and GND pin. When this happens, your program may malfunction.

GND TEST

Keep the wiring as short as possible.

21

Page 22

µ

PD17P709

2. ONE-TIME PROM (PROGRAM MEMORY) WRITE, READ, AND VERIFICATION

The program memory built into the µPD17P709 is a one-time PROM (16384 × 16 bits) that is electrically writable.

In normal operation, this PROM is accessed on a 16-bit word basis. During program memory write, read, and

verification, the PROM is accessed on an 8-bit word basis. The higher 8 bits of a 16-bit word are located at an evennumbered address, and the lower 8 bits are located at an odd-numbered address.

For PROM write, read, and verification, PROM programming mode must be specified, and the pins listed in Table

2-1 are used.

In this case, address input is not used. Instead, clock input on the CLK pin is used to update addresses.

Table 2-1 Pins Used for Program Memory Write, Read, and Verification

Pin

VPP

CLK

MD0-MD3

D0-D7

VDD0, VDD1

Used to apply the program voltage (+12.5 V)

Used to apply an address update clock

Used to select an operating mode

Used to input/output 8-bit data

Used to apply the power supply voltage (+6 V)

Function

For writing to the built-in PROM, a specified PROM programmer and dedicated programmer adapter are to be used.

The following PROM programmers and programmer adapters are usable:

PROM programmer

PG-1500

+

PA-17KDZ

(adapter for PG-1500)

Programmer adapter

PA-17P709GC

Third-party PROM programmers are also available: For example, AF-9703, AF-9704, AF-9705, and AF-9706

(manufactured by Ando Electric Co., Ltd.)

22

Page 23

Fig. 2-1 PA17P709GC and PA-17KDZ

µ

PD17P709

PA-17P709GC

PA-17KDZ

To PG-1500

2.1 OPERATING MODES FOR PROGRAM MEMORY WRITE, READ, AND VERIFICATION

µ

PD17P709 is placed in program memory write, read, and verify mode when +6 V is applied to the VDD pin,

The

and +12.5 V to the VPP pin.

In this mode, one of the operating modes indicated in Table 2-2 is set, depending on the setting of the MD0 to

MD3 pins.

The input pins that are not used for program memory write, read, and verification are connected to GND through

a pull-down resistor (470 ohms). (See PIN CONFIGURATION, (2) PROM programming mode.)

Table 2-2 Operating Modes for Program Memory Write, Read, and Verication

Operating mode specification

VPP

+12.5V

VDD

+6V

MD0

H

L

L

H

MD1

L

H

L

X

MD2

H

H

H

H

MD3

L

Program memory address zero-clear mode

Write mode

H

Read/verify mode

H

Program inhibit mode

H

Operating mode

Remark X: L or H

23

Page 24

µ

PD17P709

2.2 PROGRAM MEMORY WRITE PROCEDURE

The program memory write procedure is described below. The procedure allows high-speed write operation.

(1) Connect the unused pins to GND through pull-down resistors. The CLK pin must be low.

(2) Apply 5 V to the V

(3) Apply 5 V to the V

DD pin. The VPP pin must be low.

PP pin after waiting 10

µ

s.

(4) Specify program memory address zero-clear mode, using the mode setting pins.

(5) Apply 6 V to VDD, and 12.5 V to VPP.

(6) Program inhibit mode

(7) Write data in 1-ms write mode.

(8) Program inhibit mode

(9) Verify mode. When data has been written normally, proceed to step (10). When data has not been written

normally, repeat steps (7) to (9).

(10) Perform an additional write operation ((X: Number of write operations performed in steps (7) to (9)) × 1 ms).

(11) Program inhibit mode

(12) Apply four pulses to the CLK pin to increment the program memory address by 1.

(13) Repeat steps (7) to (12) until the last address is reached.

(14) Program memory address zero-clear mode

(15) Change the voltage applied to the V

DD and VPP pins to 5 V.

(16) Turn off the power.

Steps (2) to (12) are illustrated below.

Reset

DD

+ 1

V

V

DD

V

DD

GND

PP

V

PP

V

V

DD

GND

CLK

D0-D7

MD0

MD1

Hi-Z Hi-Z Hi-Z Hi-Z

Data input

Repeat X times

Write Verify

Data

output

Additional

write

Data input

Address

increment

24

MD2

MD3

Page 25

µ

PD17P709

2.3 PROGRAM MEMORY READ PROCEDURE

(1) Connect the unused pins to GND through pull-down resistors. The CLK pin must be low.

(2) Apply 5 V to the V

DD pin. The VPP pin must be low.

(3) Apply 5 V to the VPP pin after waiting 10 µs.

(4) Specify program memory address zero-clear mode, using the mode setting pins.

(5) Apply 6 V to V

DD, and 12.5 V to VPP.

(6) Program inhibit mode

(7) Verify mode. When a clock pulse signal is applied to the CLK pin, data is output for each address every

four clock pulses.

(8) Program inhibit mode

(9) Program memory address zero-clear mode

(10) Change the voltage applied to the V

DD and VPP pins to 5 V.

(11) Turn off the power.

Steps (2) to (9) are illustrated below.

Reset

V

DD

V

PP

VDD + 1

V

GND

V

V

GND

CLK

D0-D7

MD0

MD1

MD2

DD

PP

DD

Hi-Z Hi-Z

Data output Data output

“L”

MD3

25

Page 26

3. ELECTRICAL CHARACTERISTICS

ABSOLUTE MAXIMUM RATINGS (TA = 25 °C)

µ

PD17P709

Parameter Unit

Supply voltage

PROM program voltage

Input voltage

Output voltage

High output current

Low output current

Output withstand voltage

Total loss

Operating ambient

temperature

Storage temperature

Symbol

VDD

VPP

VI

VO

IOH

IOL

VBDS

Pt

TA

Tstg

Condition

At other than CE, INT0-INT4, and RESET pins

CE, INT0-INT4, and RESET pins

At other than P1B0-P1B3

At one pin

Total for P2A0-P2A2, P3A0-P3A3, and

P3B0-P3B3

Total for P0A0-P0A3, P0B0-P0B3, P0C0-P0C3,

P1D0-P1D3, P2B0-P2B3, P2C0-P2C3,

P2D0-P2D2, P3C0-P3C3, and P3D0-P3D3

At one pin of P1B0-P1B3

At one pin of other than P1B0-P1B3

Total for P2A0-P2A2, P3A0-P3A3, and

P3B0-P3B3

Total for P0A0-P0A3, P0B0-P0B3, P0C0-P0C3,

P1D0-P1D3, P2B0-P2B3, P2C0-P2C3,

P2D0-P2D2, P3C0-P3C3, and P3D0-P3D3

Total for P1B0-P1B3

P1B0-P1B3

Rating

–0.3 to +6.0

–0.3 to +13.5

–0.3 to VDD + 0.3

–0.3 to VDD + 0.6

–0.3 to VDD + 0.3

–8.0

–15.0

–25.0

12.0

8.0

15.0

25.0

25.0

14.0

200

–40 to +85

–55 to +125

V

V

V

V

V

mA

mA

mA

mA

mA

mA

mA

mA

V

mW

°C

°C

Caution Absolute maximum ratings are rated values beyond which physical damage will be caused to the

product; if the rated value of any of the parameters in the above table is exceeded, even

momentarily, the quality of the product may deteriorate. Always use the product within its rated

values.

RECOMMENDED OPERATING RANGES (T

Parameter Condition Unit

Supply voltage V

Symbol

VDD1

VDD2

While the CPU and PLL are operating

While the CPU is operating but the PLL is

halted

A = –40 to +85 °C)

Min.

4.5

3.5

Typ.

5.0

5.0

Max.

5.5

5.5

RECOMMENDED OUTPUT WITHSTAND VOLTAGE (TA = –40 to +85 °C)

Parameter Condition UnitMin. Typ.12Max.

Output withstand voltage V

Symbol

VBDS

P1B0-P1B3

26

V

Page 27

DC CHARACTERISTICS (TA = –40 to +85 °C, VDD = 3.5 to 5.5 V)

µ

PD17P709

Parameter Condition

Supply current

Data hold voltage

Data hold current

High input voltage

Low input voltage

High output current

Low output current

High input current

Output-off leakage

current

High input leakage

current

Low input leakage

current

Symbol

IDD1

IDD2

VDDR1

VDDR2

VDDR3

IDDR1

IDDR2

VIH1

VIH2

VIH3

VIL1

VIL2

VIL3

IOH1

IOH2

IOL1

IOL2

IOL3

IIH

ILO1

ILO2

ILIH

ILIL

The CPU is operating but the PLL is halted, with a

sinusoidal wave applied to the XIN pin.

(fIN = 4.5 MHz ±1%, VIN = VDD)

The CPU and PLL are halted, with a sinusoidal wave

applied to the XIN pin.

(fIN = 4.5 MHz ±1%, VIN = VDD)

The HALT instruction is used.

The crystal oscillator is operating.

The crystal oscillator is

halted.

The crystal oscillator is

halted.

P0A0, P0B1, P0C0-P0C3, P1A0, P1A1, P1C0-P1C3,

P1D0-P1D3, P2A2, P2B0-P2B3, P2C0-P2C3, P2D0-P2D2,

P3A0-P3A3, P3B0-P3B3, P3C0-P3C3, P3D0-P3D3

P0A1-P0A3, P0B0, P0B2, P0B3, P2A0, P2A1, CE,

INT0-INT4, RESET

P0D0-P0D3

P0A0, P0B1, P0C0-P0C3, P1A0, P1A1,P1C0-P1C3,

P1D0-P1D3, P2A2, P2B0-P2B3, P2C0-P2C3, P2D0-P2D2,

P3A0-P3A3, P3B0-P3B3, P3C0-P3C3, P3D0-P3D3

P0A1-P0A3, P0B0, P0B2, P0B3, P2A0, P2A1, CE,

INT0-INT4, RESET

P0D0-P0D3

P0A0-P0A3, P0B0-P0B3, P0C0-P0C3, P1D0-P1D3,

P2A0-P2A2, P2B0-P2B3, P2C0-P2C3, P2D0-P2D2,

P3A0-P3A3, P3B0-P3B3, P3C0-P3C3, P3D0-P3D3

EO0, EO1 VDD = 4.5 to 5.5 V, VOH = VDD – 1 V

P0A0-P0A3, P0B0-P0B3, P0C0-P0C3, P1D0-P1D3,

P2A0-P2A2, P2B0-P2B3, P2C0-P2C3, P2D0-P2D2,

P3A0-P3A3, P3B0-P3B3, P3C0-P3C3, P3D0-P3D3

EO0, EO1 VDD = 4.5 to 5.5 V, VOL = 1 V

P1B0-P1B3 VOL = 1 V

P0D0-P0D3 are pulled down. VIN = VDD

P1B0-P1B3 VIN = 12 V

EO0, EO1 VIN = VDD, VIN = 0 V

Input pin VIN = VDD

Input pin VIN = 0 V

The timer flip-flop is used for

detecting power failure.

Data memory contents are held.

VDD = 5 V, TA = 25 °C

VOH = VDD – 1 V

VOL = 1 V

Min.

3.5

2.2

2.0

0.7VDD

0.8VDD

0.55VDD

0

0

0

–1.0

–3.0

1.0

3.0

7.0

5.0

Typ.

1.5

0.7

2.0

2.0

3.0

1.5

5.5

5.5

5.5

4.0

30.0

VDD

VDD

VDD

0.3VDD

0.2VDD

0.15VDD

150

1.0

±1.0

1.0

–1.0

UnitMax.

mA

mA

V

V

V

µ

µ

V

V

V

V

V

V

mA

mA

mA

mA

mA

µ

µ

µ

µ

µ

A

A

A

A

A

A

A

27

Page 28

AC CHARACTERISTICS (TA = –40 to +85 °C, VDD = 5 V ±10%)

µ

PD17P709

Parameter Condition Unit

Operating frequency

SIO0 input frequency

SIO1 input frequency

Symbol

fIN1

fIN2

fIN3

fIN4

fIN5

fIN6

fIN7

fIN8

VCOL pin in MF mode

VCOL pin in HF mode, with a sinusoidal wave applied to

the VIN pin = 0.1Vp-p

VCOH pin in VHF mode, with a sinusoidal wave applied to

the VIN pin = 0.1Vp-p

AMIFC pin, with a sinusoidal wave applied to the

VIN pin = 0.15Vp-p

FMIFC pin in FMIF count mode, with a sinusoidal wave

applied to the VIN pin = 0.20Vp-p

FMIFC pin in AMIF count mode, with a sinusoidal wave

applied to the VIN pin = 0.15Vp-p

External clock

External clock

Sinusoidal wave applied to the

VIN pin = 0.15Vp-p

Sinusoidal wave applied to the

VIN pin = 0.20Vp-p

Note

Note

Min.

0.8

0.5

10

60

0.4

10

0.4

Typ.

Max.

3

3

40

130

0.5

11

0.5

1

0.7

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

Note The condition of sinusoidal wave input VIN = 0.1Vp-p is the rated value when the µPD17P709 alone is

operating. Where influence of noise must be taken into consideration, operation under input amplitude

condition of V

IN = 0.15Vp-p is recommended.

A/D CONVERTER CHARACTERISTICS (T

Parameter Condition

Total error in A/D

conversion

Total error in A/D

conversion

Symbol

8 bits

8 bits TA = 0 to 85 °C

REFERENCE CHARACTERISTICS (T

Parameter Condition

Supply current

Symbol

IDD3

The CPU and PLL are operating, with a sinusoidal wave

applied to the VCOH pin.

(fIN = 130 MHz, VIN = 0.3Vp-p)

A = –40 to +85 °C, VDD = 5 V ±10%)

A = +25 °C, VDD = 5.0 V)

Min. UnitMax.

Min. UnitMax.

Typ.

Typ.

6.0

±3.0

±2.5

12.0

LSB

LSB

mA

28

Page 29

DC PROGRAMMING CHARACTERISTICS (TA = 25 °C, VDD = 6.0 ±0.25 V, VPP = 12.5 ±0.5 V)

µ

PD17P709

Parameter

Input high voltage

Input low voltage

Input leakage current

Output high voltage

Output low voltage

VDD supply current

VPP supply current

Symbol

VIH1

VIH2

VIL1

VIL2

ILI

VOH

VOL

IDD

IPP

Condition

Other than CLK

CLK

Other than CLK

CLK

VIN = VIL or VIH

IOH = –1 mA

IOL = 1 mA

MD0 = VIL, MD1 = VIH

Cautions 1. VPP must be under +13.5 V including overshoot.

2. VDD must be applied before VPP on and must be off after VPP off.

AC PROGRAMMING CHARACTERISTICS (T

Parameter Symbol

Address setup time

MD1 setup time (referred to MD0↓)

Data setup time (referred to MD0↓)

Address hold time

Data hold time (referred to MD0↑)

Data output float delay from MD0↑

VPP setup time (referred to MD3↑)

VDD setup time (referred to MD3↑)

Initial program pulse width

Additional program pulse width

MD0 setup time (referred to MD1↑)

Data output delay from MD0↓

MD1 hold time (referred to MD0↑)

MD1 recovery time (referred to MD0↓)

Program counter reset time

CLK input high, low level range

CLK input frequency

Initial mode set time

MD3 setup time (referred to MD1↑)

MD3 hold time (referred to MD1↓)

MD3 setup time (referred to MD0↓)

Data output delay from address increment

Data output hold time from address increment

MD3 hold time (referred to MD0↑)

Data output float delay from MD3↓

Reset setup time

Note 2

(referred to MD0↓)

Note 2

(referred to MD0↑)

Note 2

Note 2

A = 25 °C, VDD = 6.0 ±0.25 V, VPP = 12.5 ±0.5 V)

tAS

tM1S

tDS

tAH

tDH

tDF

tVPS

tVDS

tPW

tOPW

tM0S

tDV

tM1H

tM1R

tPCR

tXH,tXL

fX

tI

tM3S

tM3H

tM3SR

tDAD

tHAD

tM3HR

tDFR

tRES

Note 1

tAS

tOES

tDS

tAH

tDH

tDF

tVPS

tVCS

tPW

tOPW

tCES

tDV

tOEH

tOR

—

—

—

—

—

—

—

tACC

tOH

—

—

—

Condition

MD0 = MD1 = VIL

tM1H + tM1R ≥ 50 µs

When reading

program memory

Min.

0.7VDD

VDD – 0.5

0

0

VDD –1.0

Min.

2

2

2

2

2

0

2

2

0.95

0.95

2

2

2

10

0.125

2

2

2

2

0

2

10

Typ.

Typ.

1.0

Max.

VDD

VDD

0.2VDD

0.4

10

1.0

30

30

Max.

130

1.05

21.0

1

4.19

2

130

2

Unit

V

V

V

V

µ

A

V

V

mA

mA

Unit

µ

s

µ

s

µ

s

µ

s

µ

s

ns

µ

s

µ

s

ms

ms

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

MHz

µ

s

µ

s

µ

s

µ

s

µ

s

ns

µ

s

µ

s

µ

s

µ

Notes 1. Symbols used for the

PD27C256 (The µPD27C256 is used only for maintenance.)

2. The internal address signal is incremented by 1 on the falling edge of the third clock (CLK) pulse, with

four CLK pulses treated as one cycle. Internal addresses are not connected to pins.

29

Page 30

Write program memory timing

RES

t

µ

PD17P709

tVPS

tVDS

VPP

VDD

DD + 1

V

VPP

VDD

GND

V

DD

GND

CLK

D0-D7

tI

Data input

tDS

tDH

tDV

MD0

tPW

tM1R

MD1

tPCR

tM1S tM1H

MD2

tM3S

MD3

Remark The dashed line indicates high-impedance.

Data

output

tDF

tM0S

Data input

tDS

tOPW

tDH

tXH

tAH

tXL

tAS

Data

input

tM3H

Read program memory timing

t

V

V

PP

V

DD

D0-D7

V

GND

DD

V

GND

CLK

MD0

MD1

MD2

V

+ 1

RES

PP

DD

DD

t

I

L

t

t

VPS

t

VDS

Hi-Z Hi-Z

PCR

t

XH

t

XL

Data output Data output

t

DV

t

t

DAD

HAD

t

M3HR

t

DFR

30

MD3

t

M3SR

Page 31

4. PACKAGE DRAWING

80 PIN PLASTIC QFP (14×14)

ITEM MILLIMETERS INCHES

NOTE

Each lead centerline is located within 0.13 mm (0.005 inch) of

its true position (T.P.) at maximum material condition.

L 0.8±0.2 0.031

+0.009

–0.008

M 0.15 0.006

N 0.10 0.004

P 2.7 0.106

A 17.2±0.4 0.677±0.016

B 14.0±0.2 0.551

+0.009

–0.008

C 14.0±0.2 0.551

+0.009

–0.008

D 17.2±0.4 0.677±0.016

F 0.825 0.032

G 0.825 0.032

H 0.30±0.10 0.012

+0.004

–0.005

I 0.13 0.005

J 0.65 (T.P.) 0.026 (T.P.)

Q 0.1±0.1 0.004±0.004

R5°±5° 5°±5°

+0.10

–0.05

+0.004

–0.003

M

M

L

K

J

H

Q

P

N

R

detail of lead end

I

G

K 1.6±0.2 0.063±0.008

60

61

40

80

1

21

20

41

A

B

CD

F

S

S80GC-65-3B9-4

S 3.0 MAX. 0.119 MAX.

µ

PD17P709

31

Page 32

µ

PD17P709

5. RECOMMENDED SOLDERING CONDITIONS

The conditions listed below shall be met when soldering the µPD17P709.

For details of the recommended soldering conditions, refer to our document

Manual

(C10535E).

Please consult with our sales offices in case any other soldering process is used, or in case soldering is done under

different conditions.

Table 5-1 Soldering Conditions for Surface-Mount Devices

µ

PD17P709GC-3B9: 80-pin plastic QFP (14 × 14 mm, 0.65-mm pitch)

Soldering process Recommended conditionsSoldering conditions

Infrared ray reflow

VPS

Wave soldering

Partial heating method

Peak package's surface temperature: 235 °C

Reflow time: 30 seconds or less (at 210 °C or more)

Maximum allowable number of reflow processes: 2

Peak package's surface temperature: 215 °C

Reflow time: 40 seconds or less (at 200 °C or more)

Maximum allowable number of reflow processes: 2

Solder temperature: 260 °C or less

Flow time: 10 seconds or less

Number of flow processes: 1

Preheating temperature: 120 °C max. (measured on the

package surface)

Terminal temperature: 300 °C or less

Heat time: 3 seconds or less (for one side of a device)

SMD Surface Mount Technology

IR35-00-2

VP15-00-2

WS60-00-1

—

Caution Do not apply more than a single process at once, except for “Partial heating method.”

32

Page 33

APPENDIX DEVELOPMENT TOOLS

The following support tools are available for developing programs for the µPD17P709.

Hardware

µ

PD17P709

Name

In-circuit emulator

IE-17K

IE-17K-ET

EMU-17K

SE board

(SE-17709)

Emulation probe

(EP-17K80GC)

Conversion socket

(EV-9200GC-80

PROM Programmer

(PG-1500)

Programmer adapter

(PA-17P709GC)

Note 1

Note 2

Note 3

Description

The IE-17K, IE-17K-ET, and EMU-17K are in-circuit emulators applicable to the 17K series.

The IE-17K and IE-17K-ET are connected to the host machine (PC-9800 series or IBM PC/

ATTM) through the RS-232C interface. The EMU-17K is inserted into the extension slot of

the host machine (PC-9800 series).

Use the system evaluation board (SE board) corresponding to each product together with

one of these in-circuit emulators.

an advanced debug environment.

The EMU-17K also enables user to check the contents of the data memory in real time.

The SE-17709 is an SE board for the µPD17709 sub-series. It is used alone for evaluating

the system. It is also used for debugging, in combination with an in-circuit emulator.

The EP-17K80GC is an emulation probe for the µPD17P709GC. When used with the EV9200GC-80

The EV-9200GC-80 is a conversion socket for the 80-pin plastic QFP (14 × 14 mm). It is

)

used to connect the EP-17K80GC to the target system.

The PG-1500 is a PROM programmer for the µPD17P709.

Use this PROM programmer with the PA-17KDZ (adapter for the PG-1500) and PA17P709GC programmer adapter, to program the µPD17P709.

The PA-17P709GC is a socket unit for the µPD17P709. It is used with the PG-1500.

Note 3

, this emulation probe connects the SE board to the target system.

SIMPLEHOST

TM

, a man machine interface, implements

Notes 1. Low-end model, operating on an external power supply

2. The EMU-17K is a product of I.C Corporation. Contact I.C Corporation (Tokyo, 03-3733-1163) for

details.

3. The EP-17K80GC is supplied together with one EV-9200GC-80. A set of five EV-9200GC-80s is also

available.

Remark Third-party PROM programmers are also available: For example, AF-9703, AF-9704, AF-9705, and AF-

9706 (manufactured by Ando Electric Co., Ltd.). These PROM programmers can be used with the PA17P709GC programmer adapter. For details, contact Ando Electric Co., Ltd. (Tokyo, 03-3733-1151).

33

Page 34

Software

µ

PD17P709

Name

17K series

assembler

(AS17K)

Device file

(AS17704)

Support software

(

SIMPLEHOST

Description

AS17K is an assembler

applicable to the 17K series.

In developing µPD17P709

programs, AS17K is used in

combination with a device file

(AS17704).

AS17704 has a device file for

the µPD17P709 .

It is used together with the

assembler (AS17K), which is

applicable to the 17K series.

SIMPLEHOST

)

WindowsTM, provides a man

machine interface in developing programs by using a

personal computer and incircuit emulator.

, running under

Host

machine

PC-9800

series

IBM

PC/AT

PC-9800

series

IBM

PC/AT

PC-9800

series

IBM

PC/AT

MS-DOS

PC DOS

MS-DOS

PC DOS

MS-DOS

PC DOS

TM

TM

OS

Windows

Distribution

media

5.25-inch,

2HD

3.5-inch,

2HD

5.25-inch,

2HC

3.5-inch,

2HC

5.25-inch,

2HD

3.5-inch,

2HD

5.25-inch,

2HC

3.5-inch,

2HC

5.25-inch,

2HD

3.5-inch,

2HD

5.25-inch,

2HC

3.5-inch,

2HC

Part number

µ

S5A10AS17K

µ

S5A13AS17K

µ

S7B10AS17K

µ

S7B13AS17K

µ

S5A10AS17704

µ

S5A13AS17704

µ

S7B10AS17704

µ

S7B13AS17704

µ

S5A10IE17K

µ

S5A13IE17K

µ

S7B10IE17K

µ

S7B13IE17K

Remark The following table lists the versions of the operating systems described in the above table.

OS Versions

MS-DOS Ver. 3.30 to Ver.5.00A

PC DOS Ver. 3.1 to Ver. 5.0

Windows Ver. 3.0 to Ver. 3.1

Note

Note

Note MS-DOS versions 5.00 and 5.00A

and PC DOS Ver. 5.0 are provided

with a task swap function. This

function, however, cannot be used

in these software packages.

34

Page 35

µ

PD17P709

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note: Strong electric field, when exposed to a MOS device, can cause destruction of

the gate oxide and ultimately degrade the device operation. Steps must be taken

to stop generation of static electricity as much as possible, and quickly dissipate

it once, when it has occurred. Environmental control must be adequate. When

it is dry, humidifier should be used. It is recommended to avoid using insulators

that easily build static electricity. Semiconductor devices must be stored and

transported in an anti-static container, static shielding bag or conductive

material. All test and measurement tools including work bench and floor should

be grounded. The operator should be grounded using wrist strap. Semiconductor devices must not be touched with bare hands. Similar precautions need to

be taken for PW boards with semiconductor devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note: No connection for CMOS device inputs can be cause of malfunction. If no

connection is provided to the input pins, it is possible that an internal input level

may be generated due to noise, etc., hence causing malfunction. CMOS device

behave differently than Bipolar or NMOS devices. Input levels of CMOS devices

must be fixed high or low by using a pull-up or pull-down circuitry. Each unused

pin should be connected to VDD or GND with a resistor, if it is considered to have

a possibility of being an output pin. All handling related to the unused pins must

be judged device by device and related specifications governing the devices.

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note: Power-on does not necessarily define initial status of MOS device. Production

process of MOS does not define the initial operation status of the device.

Immediately after the power source is turned ON, the devices with reset function

have not yet been initialized. Hence, power-on does not guarantee out-pin

levels, I/O settings or contents of registers. Device is not initialized until the

reset signal is received. Reset operation must be executed immediately after

power-on for devices having reset function.

35

Page 36

[MEMO]

µ

PD17P709

Caution This product contains an I2C bus interface circuit.

When using the I

guarantee the following only when the customer informs NEC of the use of the interface:

Purchase of NEC I

these components in an I

Specification as defined by Philips.

2

C bus interface, notify its use to NEC when ordering custom code. NEC can

2

C components conveys a license under the Philips I2C Patent Rights to use

2

C system, provided that the system conforms to the I2C Standard

36

Page 37

µ

PD17P709

Regional Information

Some information contained in this document may vary from country to country. Before using any NEC

product in your application, pIease contact the NEC office in your country to obtain a list of authorized

representatives and distributors. They will verify:

•

Device availability

•

Ordering information

•

Product release schedule

•

Availability of related technical literature

•

Development environment specifications (for example, specifications for third-party tools and

components, host computers, power plugs, AC supply voltages, and so forth)

•

Network requirements

In addition, trademarks, registered trademarks, export restrictions, and other legal issues may also vary

from country to country.

NEC Electronics Inc. (U.S.)

Santa Clara, California

Tel: 800-366-9782

Fax: 800-729-9288

NEC Electronics (Germany) GmbH

Duesseldorf, Germany

Tel: 0211-65 03 02

Fax: 0211-65 03 490

NEC Electronics (UK) Ltd.

Milton Keynes, UK

Tel: 01908-691-133

Fax: 01908-670-290

NEC Electronics Italiana s.r.1.

Milano, Italy

Tel: 02-66 75 41

Fax: 02-66 75 42 99

NEC Electronics (Germany) GmbH

Benelux Office

Eindhoven, The Netherlands

Tel: 040-2445845

Fax: 040-2444580

NEC Electronics (France) S.A.

Velizy-Villacoublay, France

Tel: 01-30-67 58 00

Fax: 01-30-67 58 99

NEC Electronics (France) S.A.

Spain Office

Madrid, Spain

Tel: 01-504-2787

Fax: 01-504-2860

NEC Electronics (Germany) GmbH

Scandinavia Office

Taeby, Sweden

Tel: 08-63 80 820

Fax: 08-63 80 388

NEC Electronics Hong Kong Ltd.

Hong Kong

Tel: 2886-9318

Fax: 2886-9022/9044

NEC Electronics Hong Kong Ltd.

Seoul Branch

Seoul, Korea

Tel: 02-528-0303

Fax: 02-528-4411

NEC Electronics Singapore Pte. Ltd.

United Square, Singapore 1130

Tel: 253-8311

Fax: 250-3583

NEC Electronics Taiwan Ltd.

Taipei, Taiwan

Tel: 02-719-2377

Fax: 02-719-5951

NEC do Brasil S.A.

Sao Paulo-SP, Brasil

Tel: 011-889-1680

Fax: 011-889-1689

J96. 8

37

Page 38

µ

PD17P709

SIMPLEHOST

MS-DOS and Windows are trademarks of Microsoft Corporation.

PC/AT and PC DOS are trademarks of IBM Corporation.

The export of this product from Japan is regulated by the Japanese government. To export this product may be prohibited

without governmental license, the need for which must be judged by the customer. The export or re-export of this product

from a country other than Japan may also be prohibited without a license from that country. Please call an NEC sales

representative.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

is a trademark of NEC Corporation.

M4 96. 5

Loading...

Loading...