Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD17P068

4-BIT SINGLE-CHIP MICROCONTROLLER

WITH ON-CHIP HARDWARE FOR TV SYSTEMS

The µPD17P068 is a one-time PROM version of the µPD17068 that has on-chip mask ROM.

The µPD17P068, which can be programmed only once, is suited for testing during development of µPD17068

systems and limited production runs.

µ

Use this data sheet together with

µ

PD17P068 does not provide a level of reliability intended for mass production of the customer's

The

products. Use it only for functional evaluation when experimenting or doing product trial tests.

PD17068 documents.

FEATURES

• Compatible with the

µ

PD17068

• One-time PROM : 12160 × 16 bits

• Operating voltage : VDD = 5 V ± 10 %

ORDERING INFORMATION

Part Number Package

µ

PD17P068GF-3BA 100-pin plastic QFP (14 × 20mm)

Document No. U10336EJ1V0DS00

Date Published November 1995 P

Printed in Japan

The information in this document is subject to change without notice.

©

1995

Page 2

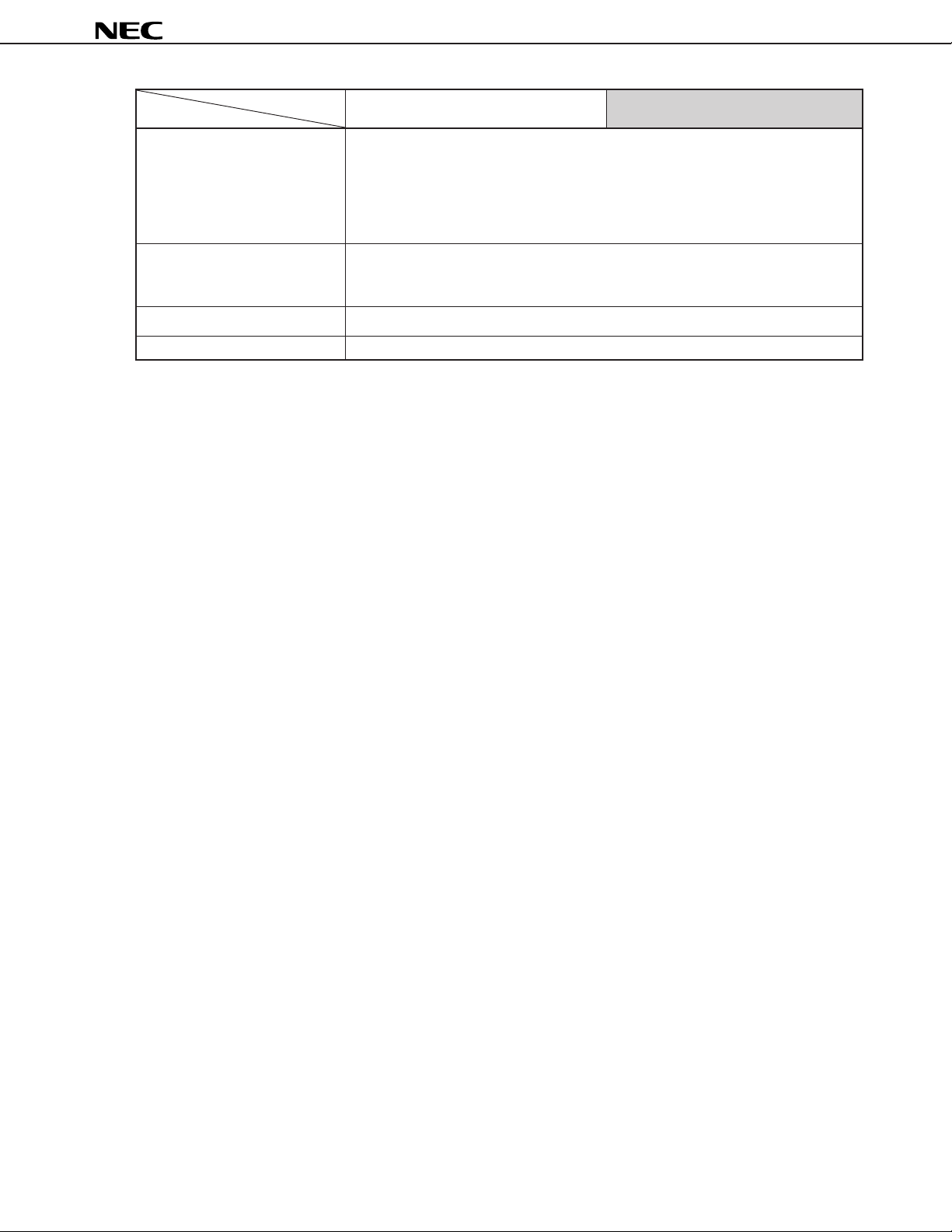

FUNCTIONAL OUTLINE

µ

PD17P068

Part Number

Item

Program memory (ROM) • 12160 × 16 bits

Table reference area: 12160 × 16 bits

Character ROM (CROM) • 6144 × 16 bits

Data memory (RAM)

Video RAM (VRAM) • 672 × 4 bits (also used as data memory (RAM))

System register • 12 × 4 bits

Register file • 12 × 4 bits

General port register • 12 × 4 bits

Instruction execution time • 2 µs (when using 8-MHz crystal resonator)

Stack levels • 12 levels (stack manipulation possible)

General ports • Input ports : 4

IDC

(Image Display Controller)

• 1007 × 4 bits (including area serving also as VRAM)

Data buffer: 4 × 4 bits, general register: 16 × 4 bits

• I/O ports : 19

• Output ports : 21

• Number of displayable characters : 192 characters max. per screen

• Display format : 16 × 16-dot mode 15 lines × 24 columns

• Character types : 255 types (user programmable)

• Character format : 16 × 16 dots and 14 × 16 dots selectable

• Color : 15 colors

• Character size : Vertical : 16 sizes (specifiable for

µ

PD17068

Mask ROM One-time PROM

(up to 350 characters with program)

: 14 × 16-dot mode 17 lines × 24 columns

(2 dots can be placed between

characters)

Horizontal : 24 sizes (specifiable for

µ

PD17P068

each line)

each character)

• 2 systems

Serial interface Serial interface 0 (compatible with 2-wire system, 3-wire system and I2C Bus)

Serial interface 1 (3-wire system)

D/A converter • 8 bits × 9 channels (PWM output, 12.5 V max.)

A/D converter • 6 bits × 8 channels (successive approximation by software)

• 10 channels (maskable interrupt)

Interrupt External interrupt : 3 channels (INT0, INTNC, VSYNC, HSYNC)

Internal interrupt : 7 channels (timer 0, 1, serial interface 0, 1, basic timer 2,

VRAM pointer, timer 0 overflow)

2

Page 3

µ

PD17P068

Part Number

Item

Timer 0 : 10 µs to 204.75 ms (interrupt)

Timer 1 : 1 µs to 256 ms (interrupt)

Timer

Reset • Reset with CE pin (CE pin: Low level → High level)

Supply voltage VDD = 5 V ± 10 %

Package 100-pin plastic QFP (14 × 20 mm)

Basic timer 0 : 1, 5, 100 ms (carry)

Basic timer 1 : 125 µs, 1 ms, 5 ms, 100 ms, external (carry)

Basic timer 2 : 125 µs, 1 ms, 5 ms, 100 ms, external (interrupt)

Watch timer : Date, Hour, Minute, Second (counter)

• Power-on reset

• Power interruption detection

µ

PD17068

µ

PD17P068

3

Page 4

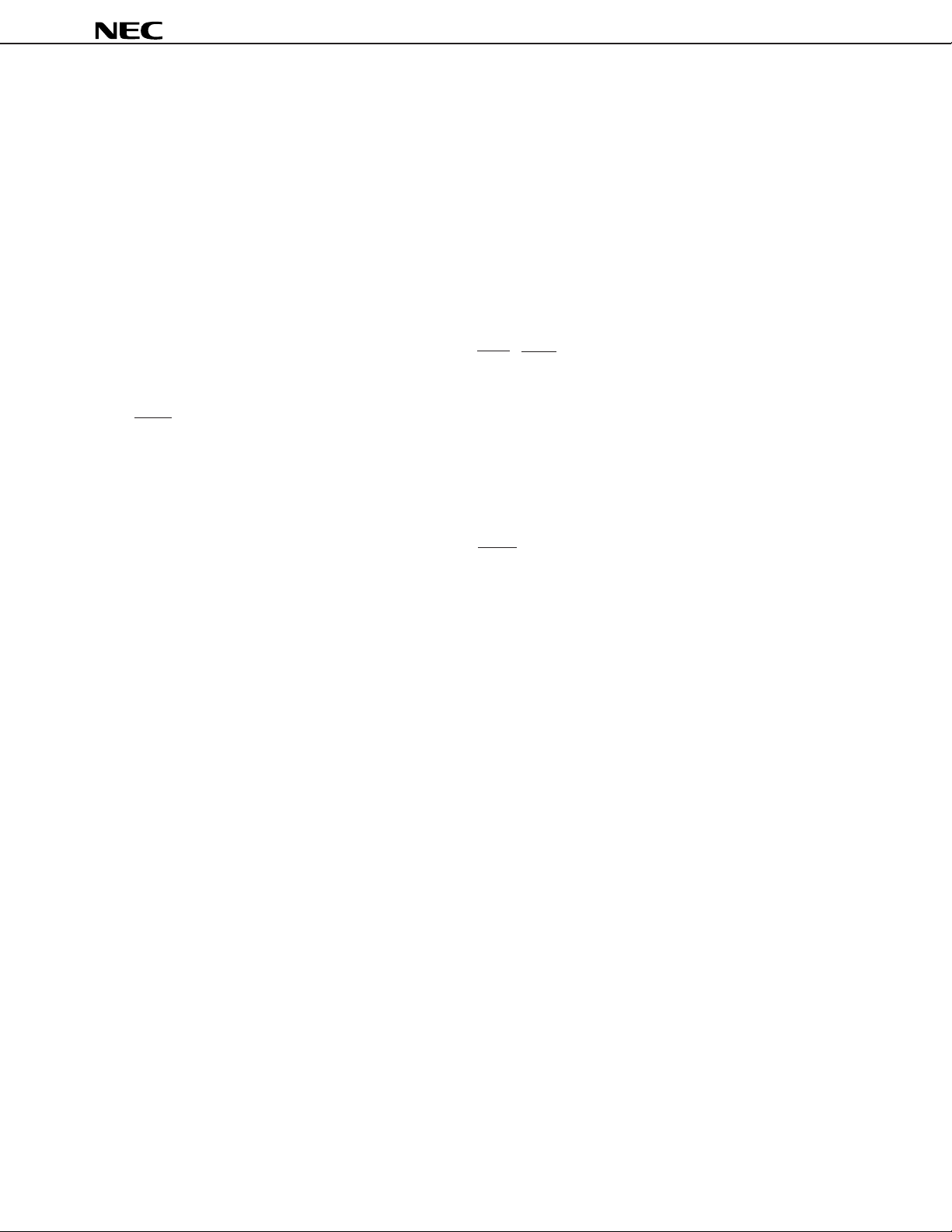

BLOCK DIAGRAM

VCO

PSC

EO

IN

OSC

OSC

OUT

H

SYNC

V

SYNC

RED

GREEN

BLUE

BLANK

2

)

I (P0B

3

HSCNT (P0B

)

PLL

OSC

Circuit

IDC

Hsync

Counter

RAM

×

1007 4 bits

VRAM

×

(672 4 bits)

SYSTEM REG.

RF

ALU

A/D

Converter

D/A

Converter

OSC

Watch

Timer

µ

PD17P068

ADC

0

ADC1(P0D0/MD0/XT

ADC

2

(P0D1/MD1/XTIN)

3

(P0D2/MD2)

ADC

4

(P0D3/MD3)

ADC

5

(P1C0/D0)

ADC

7

(P1C2/D2)

ADC

PWM0(P2C0)

PWM

3

(P2C3)

PWM

4

(P2B0)

PWM

7

(P2B3)

8

(P2A0)

PWM

XTIN(P0D1/ADC2)

XT

OUT

(P0D0/ADC1)

1

CKOUT (P1B

)

OUT

)

0

-P0A

P0A

P0B0-P0B

P0C0-P0C

P0D0-P0D

P1A0-P1A

P1B0-P1B

4-D7

(D

P1C0-P1C

P1D0-P1D

P2A

P2B0-P2B

P2C0-P2C

P2D0-P2D

XIN/CLK

X

)

OUT

4

3

4

3

3

4

4

3

3

4

4

3

Instruction

Decoder

One-time PROM

×

12160 16 bits

CROM

×

6144 16 bits

Program Counter

Port

3

4

4

3

0

Stack

×

12 14 bits

Timer0

Timer1

Basic

Timer0

Basic

Timer1

Basic

Timer2

TMIN (P1B3)

SDA (P0A0)

3

4

4

3

2

3

Main

Oscillator

CPU

Peripheral

Serial

I/O0

Serial

I/O1

SCL (P0A1)

0

(P0A2)

SCK

SO

0

(P0A3)

SI

0

(P0B0)

SCK1(P2D0)

SO1(P2D1)

SI1(P2D2)

STP

/P1B

RLS

GND0, GND

4

V

CE

DD

2

1

Reset

Interrupt

INTNC(VPP)

INT

0

Page 5

PIN CONFIGURATION (Top View)

(1) Normal operation mode

P1D3CEPSCEOGND2GND1NCNCNCNC

100

99 98 97 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

3/TMIN

P1B

P1B

2 /RLS STP

P1B

1/CKOUT

0 /PWM8

P2A

P2D

P2D 1 /SO1

P2D 0 /SCK1

OSCOUT

OSCIN

P1D2

P1D1

P1D0

INT0

NC

NC

P1B

NC

NC

P1A

P1A2

NC

NC

NC

P1A

P1A0

NC

NC

NC

2/SI1

NC

GND0

1

2

3

4

5

6

7

8

9

0

10

11

12

3

13

14

15

16

17

1

18

19

20

21

22

23

24

25

26

27

28

29

30

VCO

DD1

NC

DD0

V

V

XIN

NC

µ

PD17P068GF-3BA

XOUT

µ

PD17P068

INT NC

XTOUT/ADC1 /P0D0

XTIN /ADC 2/P0D1

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

P0D2 /ADC3

P0D3 /ADC4

P1C0 /ADC5

P1C1 /ADC6

NC

2/ADC7

P1C

P1C3

NC

ADC

0

NC

P0C0

NC

1

P0C

NC

P0C

2

NC

P0C3

NC

P2C

0/PWM0

NC

1/PWM1

P2C

NC

2/PWM2

P2C

NC

3/PWM3

P2C

NC

P2B0 /PWM4

P2B1 /PWM5

P2B2 /PWM6

P2B3 /PWM7

RED

NC

GREEN

BLUE

BLANK

SYNC

H

NC

VSYNC

NC

P0B3 /HSCNT

NC

2/I

P0B

1

P0B

NC

NC

P0B0/SI0

P0A3/SO0

P0A1 /SCL

P0A2/SCK0

P0A0 /SDA

5

Page 6

(2) PROM programming mode

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

(OPEN)

(L)

(OPEN)

D

D

(OPEN)

D

D

(OPEN)

(L)

(OPEN)

GND

(OPEN)

(L)

7

6

5

4

0

2

1

(L)

(OPEN)

(L)

(OPEN)

GND

GND

(OPEN)

DD1VDD0

V

CLK

(OPEN)

VPPMD0MD

99 98 97 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81

µ

PD17P068GF-3BA

µ

PD17P068

1

MD

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

2

MD

3

D

0

D

1

(OPEN)

2

D

D

3

(OPEN)

(OPEN)

(L)

(L)

(OPEN)

(L)

(OPEN)

(L)

(OPEN)

(L)

(OPEN)

Caution Contents in parentheses indicate how to handle unused pins in PROM programming mode.

L: Connect to GND via a resistor (470 Ω) separately.

OPEN: Leave unconnected.

6

Page 7

µ

PD17P068

PIN IDENTIFICATIONS

ADC0-ADC7 : A/D converter input P1C0-P1C3 : Port 1C

BLANK : Blanking signal output P1D0-P1D3 : Port 1D

BLUE : Character signal output P2A0 : Port 2A

CE : Chip enable P2B

CKOUT : Watch timer adjustment P2C0-P2C3 : Port 2C

output P2D0-P2D2 : Port 2D

CLK : Address update clock input PSC : Pulse swallow control output

0-D7 : Data input/output PWM0-PWM8 : Pulse-width modulation output

D

EO : Error out RED : Character signal output

0-GND2 : Ground RLSSTP : Clock stop release signal input

GND

GREEN : Character signal output SCK0, SCK1 : Shift clock input/output

HSCNT : Horizontal synchronizing SCL : Shift clock input/output

signal counter input SDA : Serial data input/output

SYNC : Horizontal synchronizing Sl0, Sl1 : Serial data input

H

signal input SO0 , SO1:Serial data output

I : Character signal output TMIN : Event input of basic timer 1 or 2

0, INTNC : External interrupt request VCO : Local oscillation input

INT

signal input VDD0, VDD1 : Positive power supply

0-MD3 : Operation mode select VPP : Program voltage application

MD

NC : No connection VSYNC : Vertical synchronizing signal input

OSCIN, OSCOUT : LC oscillation for IDC XIN, XOUT : Main clock oscillation

0-P0A3 : Port 0A XTIN, XTOUT : Watch timer oscillation

P0A

P0B0-P0B3 : Port 0B

P0C0-P0C3 : Port 0C

0-P0D3 : Port 0D

P0D

P1A0-P1A3 : Port 1A

P1B0-P1B3 : Port 1B

0-P2B3 : Port 2B

7

Page 8

µ

PD17P068

CONTENTS

1. PIN FUNCTIONS ................................................................................................................................. 9

1.1 Normal Operation Mode ........................................................................................................................... 9

1.2 PROM Programming Mode .................................................................................................................... 13

1.3 Pin Equivalent Circuits .......................................................................................................................... 14

1.4 Handling of Unused Pins....................................................................................................................... 19

1.5 Notes on Using the CE and INTNC Pins (Only in Normal Operation Mode) ................................... 21

2. WRITE, READ, AND VERIFY OF ONE-TIME PROM (PROGRAM MEMORY)............................ 22

2.1 Operation Modes in Program Memory Write/Read/Verify................................................................. 23

2.2 PROM Write Procedure .......................................................................................................................... 24

2.3 PROM Read Procedure .......................................................................................................................... 25

3. ELECTRICAL SPECIFICATIONS .................................................................................................... 26

4. PACKAGE DRAWING ...................................................................................................................... 31

APPENDIX DEVELOPMENT TOOLS.................................................................................................... 32

8

Page 9

µ

PD17P068

1. PIN FUNCTIONS

1.1 Normal Operation Mode

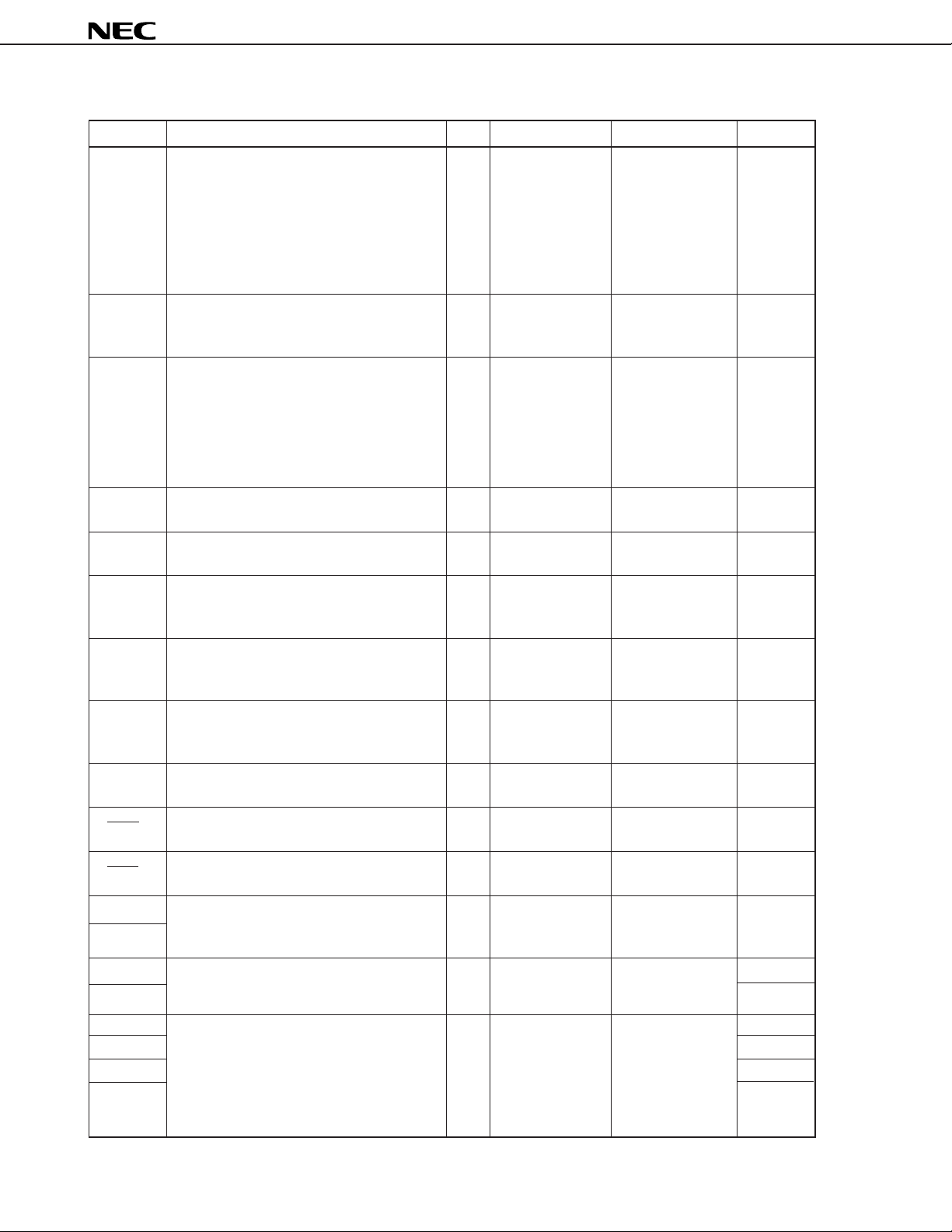

(1) Port pins

Pin Name Description I/O Output Type When Reset Shared by

P0A0 SDA

P0A1 SCL

P0A2 SCK0

P0A3 SO0

P0B0 Sl0

P0B1 —

P0B2 l

P0B3 HSCNT

P0C0

—

P0C3

P0D0 ADC1/XTOUT

P0D1 ADC2/XTIN

P0D2 ADC3

P0D3 ADC4

P1A0

—

P1A3

P1B0 —

P1B1 CKOUT

P1B2 RLSSTP

P1B3 TMIN

P1C0 ADC5

P1C2 ADC7

P1C3 —

P1D0

—

P1D3

P2A0 PWM8

P2B0 PWM4

P2B3 PWM7

4-bit I/O port.

These pins serve as a bit-selectable N-ch open drain

4-bit input/output port. All these pins

are set to input pins when power (VDD) I/O Input

is turned on, when clock is stopped, or

when reset signal is input to the CE pin.

4-bit I/O port.

These pins serve as a bit-selectable 4-bit

input/output port. All these pins are set to

input pins when power (VDD) is turned

on, when clock is stopped, or when reset

signal is input to the CE pin.

These pins serve as a 4-bit output port.

The output state of each pin is undefined O CMOS push-pull Undefined output

after power (VDD) is turned on.

These pins serve as a 4-bit input port. I — Input with pull-

These pins serve as a 4-bit output port. O Middle voltage, Undefined output

4-bit I/O port.

These pins serve as a bit-selectable 4-bit I/O CMOS push-pull Input

input/output port.

4-bit I/O port. These pins serve as 4-bit- I/O CMOS push-pull Input

selectable 4-bit I/O port.

These pins serve as a 4-bit output port. O CMOS push-pull Undefined output

This pin serves as a 1-bit output port. O Undefined output

These pins serve as a 4-bit output port. O Undefined output

CMOS push-pull

I/O CMOS push-pull Input

down resistor

N-ch open-drain

high current

N-ch open-drain

Middle voltage

N-ch open-drain

Middle voltage

P2C0 PWM0

P2C3 PWM3

P2D0 SCK1

P2D1 SO1

P2D2 Sl1

These pins serve as a 4-bit output port. O Undefined output

These pins serve as a bit-selectable 3-bit

input/output port. All these pins are set to

input pins when power (VDD) is turned on, I/O CMOS push-pull Input

when clock is stopped, or when reset

signal is input to the CE pin.

N-ch open-drain

Middle voltage

9

Page 10

µ

PD17P068

(2) Non-port pins

Pin Name Description I/O Output Type When Reset Shared by

This pin outputs signals from the charge

pump of the PLL frequency synthesizer.

If the frequency divided from the local

EO oscillator (VCO) frequency is higher (lower) O CMOS 3-state High-impedance —

than the reference frequency, high (low)

level is output from this pin, respectively.

When the two frequencies match, this pin

is placed in the high-impedance state.

This pin outputs pulse swallow control

PSC signal. This signal switches division ratio O CMOS push-pull Output —

for the dedicated prescaler µPB595.

This pin is the input of the local oscillator.

The output signal coming from the local

oscillator (VCO) in the tuner and divided by

VCO the dedicated prescaler µPB595 should be I — —

input to this pin, where the µPB595 is a

two-module prescaler capable of frequency

division up to 1 GHz.

Internally

pulled down

HSCNT I — Input P0B3

BLANK O CMOS push-pull Low level output —

RED data that correspond the R signal (one of O CMOS push-pull Low level output —

GREEN that correspond the G signal (one of the O CMOS push-pull Low level output —

BLUE that correspond the B signal (one of the O CMOS push-pull Low level output —

I O CMOS push-pull Input P0B2

HSYNC I — Input —

VSYNC I — Input —

OSCIN

OSCOUT

ADC0

ADC1

ADC2

ADC3

ADC4

ADC5

ADC7

This pin is the input of the H sync signal

counter.

This active-high pin outputs blanking

signals to delete video signals.

This active-high pin outputs character

the RGB signals of IDC).

This active-high pin outputs character data

RGB signals of IDC).

This active-high pin outputs character data

RGB signals of IDC).

This pin outputs character data that

correspond the I signal of IDC.

The H sync signals for IDC should be

input to this pin in an active-low manner.

The V sync signals for IDC should be input

to this pin in an active-low manner.

These are the input and output pins of the

LC oscillation circuit for IDC. Adjust the — — — —

oscillation frequency to 10 MHz.

These are the analog input pins of the

6-bit resolution A/D converter.

These are the analog input pins of the

6-bit resolution A/D converter.

I — Input

I — Input

P0D0/XTOUT

P0D1/XTIN

P0D2

P0D3

P1C0

P1C2

—

10

Page 11

µ

PD17P068

Pin Name Description I/O Output Type When Reset Shared by

PWM0 P2C0

PWM3 P2C3

PWM4 These are the output pins of the O N-ch open-drain P2B0

8-bit resolution D/A converter. Middle-voltage

PWM7 P2B3

PWM8 P2A0

TMIN This pin is the input of basic timer 1 or 2. I — Input P1B3

Low-level output

or high impedance

XTIN

XTOUT

CKOUT O CMOS push-pull Input P1B1

SCK0 P0A2

SCK1 P2D0

Sl0 P0B0

Sl1 P2D2

SO0 P0A3

SO1 P2D1

SCL These pins input and output shift clocks. I/O N-ch open-drain Input P0A1

SDA These pins input and output serial data. I/O N-ch open-drain Input P0A0

INT0 request is issued at the rising or falling I — Input —

INTNC commands from a remote control unit I — Input —

A 32.768-kHz crystal resonator for watch

timer operation should be connected to — — —

these pins.

This pin outputs the signal to control the

watch timer.

These pins input and output shift clocks. I/O CMOS push-pull Input

These pins input serial data. I — Input

These pins output serial data. O CMOS push-pull Input

This pin inputs interrupt request signal

from external device. An interrupt

edge of the input signal applied to this

pin.

This pin inputs interrupt request signal

with noise canceller. Using this pin to

input signals with noise such as

simplifies programming processes.

The interrupt request issuing timing is

programmable to either rising or falling

edge of the input signal to this pin.

P0D1/ADC2

P0D0/ADC1

11

Page 12

µ

PD17P068

Pin Name Description I/O Output Type When Reset Shared by

This pin selects a device to be activated,

or resets this device.

(1) Use as input of device selection signal

When CE=high, PLL synthesizer and

IDC operate. When CE=low, their

CE operation are disabled (stops). I — Input —

(2) Use as reset input

When CE changes from low to high,

this device is reset in synchronization

with the carry FF operation for the

internal basic interval timer 0.

RLSSTP I — Input P1B2

XIN

XOUT

VDD0 pins when all functions operate.

VDD1 system reset sequence is started and the

GND0

GND2

NC This pin should be left unconnected. — — — —

This pin inputs the clock stop release

signal.

An 8-MHz crystal resonator for main

clock generation should be connected to — — — —

these pins.

These pins supply positive power voltage

for this device. The power supply voltage

of 5 V ± 10 % should be applied to these

When IDC is disabled, the voltage range

from 4.0 to 5.5 V is allowed. When clock

is stopped, the applied voltage to these

pins may be lowered down to 2.5 V.

Because this device internally has the — — — —

power-on reset circuit, the voltages applied

to these pins are changed from 0 to 4.0 V,

program is implemented from address 0H.

To assure normal operations of the

power-on reset circuit, the rise time from

0 to 4.0 V should be shorter than 500 ms.

These pins supply the ground level for

this device.

— — — —

12

Page 13

1.2 PROM Programming Mode

Pin Name Description I/O Output Type

D0 8-bit data input/output pins used in

program memory write, read, verify I/O CMOS push-pull

D7 modes.

MD0 Input pins that select an operation mode

in program memory write, read, verify I —

MD3 modes.

µ

PD17P068

CLK I—

VPP pin in program memory write, read, verify — —

VDD0

VDD1

GND0

Ground pin — —

GND2

Clock input for address update in program

memory write, read, verify modes.

Programming voltage (+12.5 V) application

modes.

Positive power supply.

+5 V should be applied to these pins in — —

program memory write, read, verify modes.

Remark The other pins are not used in the PROM programming mode. How to handle the other pins are

described in the section "PIN CONFIGURATION (2) PROM programming mode".

13

Page 14

1.3 Pin Equivalent Circuits

µ

PD17P068

(1) P0A (P0A

3/SO0, P0A2/SCK0)

P0B (P0B2/l, P0B1, P0B0/Sl0)

P1B (P1B2/RLSSTP, P1B1/CKOUT, P1B0)

P1C (P1C

3, P1C2/ADC7, P1C1/ADC6, P1C0/ADC5)

(Input/output)

A/D converter (P1C/ADC only)

V

DD

RESET (other than P1C)

Read instruction (P1C only)

V

DD

(2) P2D (P2D

2/Sl1, P2D1/SO1, P2D0/SCK1) : (Input/output)

V

DD

V

DD

RESET

14

Page 15

(3) P0A (P0A1/SCL, P0A0/SDA) : (Input/output)

µ

PD17P068

V

DD

(4) P0C (P0C

P1D (P1D3, P1D2, P1D1, P1D0)

RED, GREEN, BLUE, BLANK

3, P0C2, P0C1, P0C0)

(Output)

PSC

V

(5) P1A (P1A

P2A (P2A

3, P1A2, P1A1, P1A0)

0/PWM8)

P2B (P2B3/PWM7, P2B2/PWM6, P2B1/PWM5, P2B0/PWM4)

P2C (P2C3/PWM3, P2C2/PWM2, P2C1/PWM1, P2C0/PWM0)

DD

(Output)

(6) P0D (P0D3/ADC4, P0D2/ADC3, P0D1/ADC2/XTIN, P0D0/ADC1/XTOUT) : (Input)

V

DD

High on-resistance

15

Page 16

(7) ADC0 : (Input)

µ

PD17P068

V

DD

(8) P0B

3/HSCNT : (Input/output)

V

DD

RESET

V

DD

Port

V

DD

H sync signal counter

16

V

DD

Page 17

(9) P1B3/TMIN : (Input/output)

VDD

RESET

µ

PD17P068

VDD

VDD

Port

VDD

Timer counter

(10) H

SYNC, VSYNC, CE, INT0, INTNC : (Schmitt triggered input)

V

DD

17

Page 18

(11) XIN, OSCIN :

XOUT, OSCOUT :

High on-resistance

V

DD

µ

PD17P068

V

DD

X

OUT

(12) EO : (Output)

(13) VCO : (Input)

XIN, OSC

, OSC

OUT

IN

V

DD

18

V

DD

V

DD

(Input)

Page 19

1.4 Handling of Unused Pins

The following are recommended for handling unused pins.

Table 1-1. Handling of Unused Pins (1/2)

(a) Port pins

Pin Name Input/Output Circuit Type Recommended Handling when in Unused State

P0A0/SDA Input/output

P0A1/SCL to VDD or GND through a resistor.

P0A2/SCK0

P0A3/SO0

P0B0/SI0

P0B1

P0B2/I

P0B3/HSCNT

P0C0-P0C3 CMOS push-pull output Open

P0D0/ADC1/XTOUT Input Individually connect to GND through a resistor.

P0D1/ADC2/XTIN

P0D2/ADC3, P0D3/ADC4

P1A0-P1A3 N-ch open-drain output Specify low-level output by software, then open.

P1B0 Input/output

P1B1/CKOUT to VDD or GND through a resistor.

P1B2/RLSSTP

P1B3/TMIN

P1C0/ADC5-P1C2/ADC7

P1C3

P1D0-P1D3 CMOS push-pull output Open

P2A0/PWM8 N-ch open-drain output Specify low-level output by software, then open.

P2B0/PWM4-P2B3/PWM7

P2C0/PWM0-P2C3/PWM3

P2D0/SCK1 Input/output

P2D1/SO1 to VDD or GND through a resistor.

P2D2/SI1

Note 1

Note 1

Note 1

Specify a general-purpose input port by software and connect each pin

Note 2

Specify a general-purpose input port by software and connect each pin

Note 2

Specify a general-purpose input port by software and connect each pin

Note 2

µ

PD17P068

Note 2

Notes 1. Input ports go to input mode when the power supply rises, when the clock stops, and on CE reset.

2. Be careful of the fact that when an external pull-up (connection to VDD through a resistor) or pull-down

(connection GND through a resistor) is made, if the pull-up or pull-down is done through a resistor with

a high value, because the pin comes near to being in high impedance, the consumed (through) current

increases. This also depends on the application circuit, but a typical value for a pull-up or pull-down resistor

is a few tens of kΩ.

19

Page 20

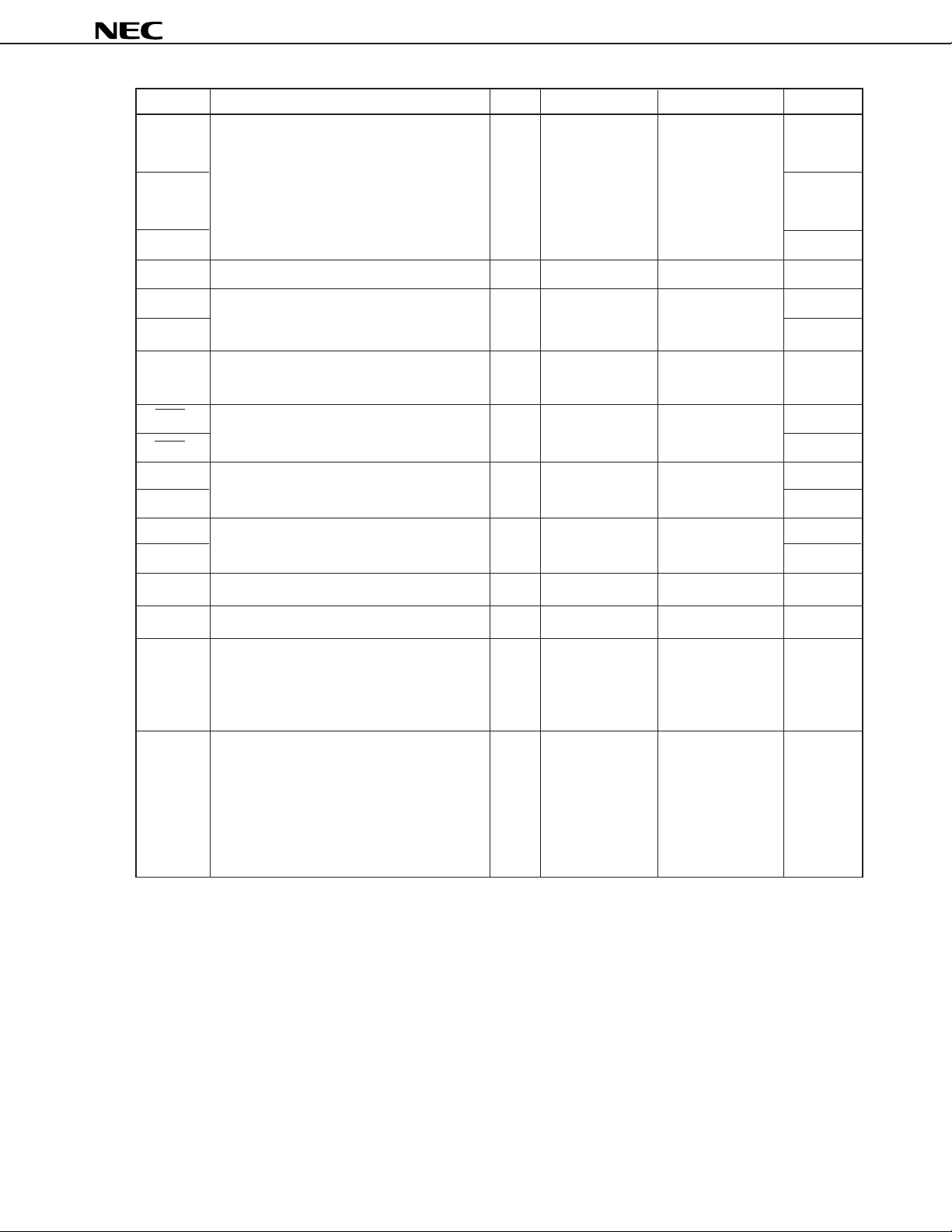

Table 1-1. Handling of Unused Pins (2/2)

(b) Pins other than ports

Pin Name Input/Output Circuit Type Recommended Handling when in Unused State

ADC0 Input Connect to VDD or GND through a resistor.

BLANK Output Open

BLUE Output Open

CE Input Connect to VDD through a resistor.

EO Output Open

GREEN Output Open

HSYNC Input Connect to VDD or GND through a resistor.

INT0 Input Connect to VDD or GND through a resistor.

INTNC Input Connect to VDD or GND through a resistor.

OSCIN Input Connect to VDD through a resistor.

OSCOUT Output Open

PSC Output Open

RED Output Open

VCO

Input with pull-down resistor

Open

VSYNC Input Connect to VDD or GND through a resistor.

Note

Note

Note

Note

Note

Note

Note

µ

PD17P068

Note Be careful of the fact that when an external pull-up (connection to VDD through a resistor) or pull-down

(connection GND through a resistor) is made, if the pull-up or pull-down is done through a resistor with a high

value, because the pin comes near to being in high impedance, the consumed (through) current increases.

This also depends on the application circuit, but a typical value for a pull-up or pull-down resistor is a few tens

of kΩ.

20

Page 21

µ

PD17P068

1.5 Notes on Using the CE and INTNC Pins (Only in Normal Operation Mode)

In addition to the functions shown in 1.1 Normal Operation Mode, the CE pin also has the function of setting

µ

a test mode (for IC testing) in which the internal operations of the

PD17P068 are tested.

Also, the INTNC pin has the function of the VPP pin for program memory write/verify.

When a voltage higher than V

DD is applied to either of these pins, the test or program memory write/verify

mode is set. This means that, even during normal operation, the µPD17P068 may be set in the test mode if

noise exceeding VDD is applied.

For example, if the wiring length of the CE or INT

NC pin is too long, noise superimposed on the wiring line

of the pin may cause the above problem.

Therefore, keep the wiring length of these pins as short as possible to suppress the noise; otherwise, take

noise preventive measures as shown below by using external components.

• Connect diode with low V

F between VDD • Connect capacitor between VDD

and CE/INTNC pin and CE/INTNC pin

V

DD

Diode with

low V

F

CE, INT

V

DD

NC

CE, INT

V

DD

V

DD

NC

21

Page 22

µ

PD17P068

2. WRITE, READ, AND VERIFY OF ONE-TIME PROM (PROGRAM MEMORY)

The program memory contained in the µPD17P068 is the 12160 × 16-bit one-time PROM that can electrically

be written one time only. This PROM is accessed in 16 bits per word in normal operation mode, and in 8 bits

per word in write, read, verify modes. The 16 bits of a word in normal mode are divided into higher 8 bits and

lower 8 bits which are assigned to even and odd addresses, respectively.

When the PROM is written, read, or verified, set this device into the PROM mode. In this mode, these pins

are used as shown in the table below. Notice that no address input pins are provided. Addresses are

automatically updated by the clock signal supplied from the CLK pin.

Table 2-1. Pins Used in Program Memory Write, Read, and Verify Modes

Pin Function

VPP Programming voltage (+12.5 V) application

CLK Address update clock input

MD0-MD3 Operation mode selection

D0-D7 8-bit data input/output

VDD0, VDD1 Power supply voltage (+5 V) application

To write the internal PROM, use the NEC-specified PROM programming equipment (PROM programmer) and

program adapter as listed below.

PROM programmer AF-9703 (Ando Electric Corporation)

AF-9704 (Ando Electric Corporation)

AF-9705 (Ando Electric Corporation)

AF-9706 (Ando Electric Corporation)

Program adapter AF-9808L (Ando Electric Corporation)

Remark For details on these PROM programmer and program adapter, consult with Ando Electric

Corporation (03-3733-1151 Tokyo, Japan).

22

Page 23

2.1 Operation Modes in Program Memory Write/Read/Verify

µ

PD17P068

When +5 V is applied to the V

memory write/read/verify modes. Operation mode is determined by the setting of MD0 to MD3 pins as indicated

in the table below.

All input pins irrelevant to the program memory write/read/verify operation should be left unconnected or

connected to GND via a pull-down resistor of 470 Ω (Refer to the section "PIN CONFIGURATION (2) PROM

programming mode). "

Table 2-2. Operation Modes in Program Memory Write/Read/Verify

Pin States

VPP VDD MD0 MD1 MD2 MD3

+12.5 V +5 V

Remark X: L or H

DD pin and +12.5 V is applied to the VPP pin, this device enters the program

Operation Mode

H L H L Program memory address 0 clear

L H H H Write

L L H H Read, Verify

H X H H Program inhibit

23

Page 24

µ

PD17P068

2.2 PROM Write Procedure

Data can be written to the PROM in high speeds by using the following procedures.

(1) Set the pins not used for programming as indicated in section "PIN CONFIGURATION (2) PROM

programming mode." Set the CLK pin to low level.

(2) Supply +5 V to the V

(3) Provide a 10-

µ

DD and VPP pins.

s wait state.

(4) Program memory address 0 clear mode is entered.

(5) Supply +6 V to the VDD pin, and +12.5 V to the VPP pin.

(6) Program inhibit mode is entered.

(7) Provide write data for 1 ms in write mode.

(8) Program inhibit mode is entered.

(9) Use the verify mode to test data. If the data has been written, proceed to (10). If not, repeat steps

(7) to (9).

(10) Provide write data (for additional writing) for 1 ms times the number of repeats performed between

steps (7) to (9).

(11) Program inhibit mode is entered.

(12) Provide four pulses to the CLK pin to increment the address.

(13) Repeat steps (7) to (12) until the last address is reached.

(14) Program memory address 0 clear mode.

(15) Supply +5 V to V

DD and VPP pins.

(16) Turn off the power for this device.

The procedures from (2) to (12) are illustrated in the chart below.

D

V

V

CLK

0-D7

MD

MD

Repeat X times

Write Verify

V

PP

V

DD

PP

GND

DD

+ 1

V

DD

V

DD

GND

Data input

0

1

Data

output

Additional

write

Hi-ZHi-Z Hi-ZHi-Z

Data input

Address

increment

24

MD

MD

2

3

Page 25

µ

PD17P068

2.3 PROM Read Procedure

Data can be read from the PROM by using the following procedures.

(1) Set the pins not used for programming as indicated in section "PIN CONFIGURATION (2) PROM

programming mode." Set the CLK pin to low level.

(2) Supply +5 V to the V

(3) Provide a 10-

µ

DD and VPP pins.

s wait state.

(4) Program memory address 0 clear mode is entered.

(5) Supply +6 V to the VDD pin, and +12.5 V to the VPP pin.

(6) Program inhibit mode is entered.

(7) Use the verify mode to output data. Provide clock pulses to the CLK pin to output the data of an address.

The address is automatically incremented every four clock pulses. Repeat the four-pulse cycles until

the last address is reached.

(8) Program inhibit mode is entered.

(9) Program memory address 0 clear mode.

(10) Supply +5 V to the V

DD and VPP pins.

(11) Turn off the power for this device.

The procedures from (2) to (9) are illustrated in the chart below.

CLK

D

MD

MD

MD

V

V

0-D7

V

PP

DD

V

PP

GND

V

DD

+1

DD

V

DD

GND

Data output

0

1

2

"L"

Data output

Hi-ZHi-Z

MD

3

25

Page 26

µ

PD17P068

3. ELECTRICAL SPECIFICATIONS

Absolute Maximum Ratings (TA = 25 ˚C)

Parameter Symbol Conditions Ratings Unit

Supply voltage VDD −0.3 to +6.0 V

Input voltage VI −0.3 to VDD + 0.3 V

Output voltage VO Except for P1A, P2B, P2C −0.3 to VDD + 0.3 V

High-level output current IOH 1 pin −12 mA

All pins −20 mA

Low-level output current IOL1 1 pin (except for P1A) 12 mA

All pins (except for P1A) 20 mA

IOL2 1 pin (P1A only) 17 mA

All pins (P1A only) 60 mA

Output withstand voltage VBDS P1A, P2A, P2B, P2C 13 V

Storage temperature Tstg −55 to +125 ˚C

Caution Product quality may suffer if the absolute maximum ratings are exceeded for even a single

parameter or even momentarily. That is, the absolute maximum ratings are rated values at which

the product is on the verge of suffering physical damage, and therefore the product must be used

under conditions which ensure that the absolute maximum ratings are not exceeded.

Recommended Operating Range (T

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Supply voltage VDD1 4.5 5.0 5.5 V

VDD2 Only CPU operates 4.0 5.0 5.5 V

VDD3 Only watchdog timer operates (CPU stops) 2.3 5.0 5.5 V

Data retention voltage VDDR Clock stops 2.3 5.5 V

Output withstand voltage VBDS P1A, P2A, P2B, P2C 12.5 V

Supply voltage rise time trise VDD = 0 → 4.5 V 3 500 ms

Input amplitude VIN VCO 0.7 5.5 VP−P

A = 25 ˚C)

26

Page 27

µ

PD17P068

DC Characteristics (Reference characteristics: TA = −40 to +85 ˚C, V DD = 5 V ± 10 %)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Supply current IDD1 Operation of all functions 11 23 mA

VDD = 5 V, TA = 25 ˚C, fVCO = 20 MHz

VIN = 0.7 VP-P, IDC operation

OSCIN = 10 MHz, XIN pin square wave input

(fIN = 8 MHz, VIN = VDD)

IDD2 CPU and PLL operation 7 12 mA

VDD = 5 V, TA = 25 ˚C, f VCO = 20 MHz

VIN = 0.7 VP-P, XIN pin square wave input

(fIN = 8 MHz, VIN = VDD)

IDD3 Only CPU operates 6.5 9 mA

VDD = 5 V, TA = 25 ˚C, X IN pin square wave input

(fIN = 8 MHz, VIN = VDD)

IDD4 HALT instruction 2.5 4.5 mA

VDD = 5 V, TA = 25 ˚C, X IN pin square wave input

(fIN = 8 MHz, VIN = VDD)

Data retention current IDDR1 Main clock stop, watch timer operation 5 10

VDD = 2.5 V, TA = 25 ˚C

Main clock stop, watch timer operation 15 25

VDD = 5 V, TA = 25 ˚C

IDDR2 Main clock stop, watch timer operation 2 15

VDD = 5 V, TA = 25 ˚C

High-level input voltage VIH1 P0A, P0B, P1B, P1C, P2D 0.7VDD V

VIH2 CE, INT0, INTNC, VSYNC, HSYNC 0.8VDD V

VIH3 P0D 0.7VDD V

Low-level input voltage VIL1 P0A, P0B, P0D, P1B, P1C, P2D 0.2 VDD V

VIL2 CE, INT0, INTNC, VSYNC, HSYNC 0.2 VDD V

High-level output current IOH1 P0A2, P0A3, P0B, P0C, P1B, P1C, P1D, P2D, −1 −5mA

BLANK, RED, GREEN, BLUE, PSC

VOH = VDD − 1 V

IOH2 EO VOH = VDD − 1 V −1 − 2.5 mA

Low-level output current IOL1 P0A2 , P0A3, P0B, P0C, P1B, P1C, P1D, P2D, 1 10 mA

PSC VOL = 1 V

IOL11 BLANK, RED, GREEN, BLUE VOL = 1 V 1 8.5 mA

IOL2 EO VOL = 1 V 1 6 mA

IOL3 P0A0, P0A1 VOL = 1 V 1 4.0 mA

IOL4 PWM (P2A, P2B, P2C) VOL = 1 V 1 1.5 mA

IOL5 P1A VOL = 1 V 15 30 mA

High-level input current IIH VCO VIH = VDD 0.1 0.65 1.3 mA

High-level output leakage ILOH P1A, P2A, P2B, P2C VO = 12.5 V 0.5

Output off leakage current IL EO VO = VDD or 0 V ±10

Internal pull-down resistor RPD1 P0D (KEY) VIH = VDD 19 41 85 kΩ

RPD2 P0D (KEY) VIH = VDD = 5 V 23 41 72 kΩ

RPD3 P0D (KEY) VIH = VDD = 5 V, TA = 25 ˚C 29 41 47 kΩ

−3

±1

µ

A

µ

A

µ

A

µ

A

µ

A

27

Page 28

µ

PD17P068

AC Characteristics (Reference characteristics: TA = −40 to +85 ˚C, V DD = 5 V ± 10 %)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Input frequency 1 fVCO VCO square wave input VIN = 0.7 VP−P 0.7 20 MHz

Input frequency 2 fTMR TMIN (P1B3) Duty 50 % 45 65 Hz

Input frequency 3 fHS HSCNT (P0B3) 10 20 kHz

A/D Converter Characteristics (Reference characteristics: TA = −10 to +50 ˚C, V DD = 5 V ± 10 %)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

A/D conversion absolute accuracy

A/D conversion resolution ADC0-ADC7 6 bit

A/D input impedance ADC0-ADC7 1MΩ

ADC0-ADC7 ±1 ±1.5 LSB

DC Programming Characteristics (TA = 25 ˚C, V DD = 6.0 ± 0.25 V, VPP = 12.5 ± 0.5 V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

High-level input voltage VIH1 Except for CLK 0.7 VDD VDD V

VIH2 CLK VDD − 0.5 VDD V

Low-level input voltage VIL1 Except for CLK 0 0.3 VDD V

VIL2 CLK 0 0.4 V

Input leakage current ILI VIN = VIL or VIH ±10

High-level output voltage VOH IOH = −1 mA VDD − 1.0 V

Low-level output voltage VOL IOL = 1 mA 1.0 V

VDD supply current IDD 30 mA

VPP supply current IPP MD0 = VIL, MD1 = VIH 30 mA

µ

A

Cautions 1. VPP must not exceed +13.5 V including overshoot.

2. VDD should be applied before VPP and cut after VPP.

28

Page 29

µ

PD17P068

AC Programming Characteristics (TA = 25 ˚C, V DD = 6.0 ± 2.5 V, VPP = 12.5 ± 0.5 V)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Address setup time

MD1 setup time (vs. MD0↓)tM1S 2

Data setup time (vs. MD0↓)tDS 2

Address hold time

Data hold time (vs. MD0↑)tDH 2

MD0↑→ data output float delay time tDF 0 130 ns

VPP setup time (vs. MD3↑)tVPS 2

VDD setup time (vs. MD3↑)tVDS 2

Initial program pulse width tPW 0.95 1.0 1.05 ms

Additional program pulse width tOPW 0.95 21.0 ms

MD0 setup time (vs. MD1↑)tM0S 2

MD0↓→ data output delay time tDV MD0 = MD1 = VIL 1

MD1 hold time (vs. MD0↑)tM1H tM1H + tM1R ≥ 50 µs2

MD1 recovery time (vs. MD0↓)tM1R 2

Program counter reset time tPCR 10

CLK input high-/low-level width tXH, tXL 0.125

CLK input frequency fX 4.19 MHz

Initial mode setting time tI 2

MD3 setup time (vs. MD1↑)tM3S 2

MD3 hold time (vs. MD1↓)tM3H 2

MD3 setup time (vs. MD0↓)tM3SR When program memory is read 2

Address

Address

MD3 hold time (vs. MD0↑)tM3HR 2

MD3↓→ data output float delay time tDFR 2

Note

Note

Note

(vs. MD0↓)tAS 2

Note

(vs. MD0↑)tAH 2

→ data output delay time tDAD 2

→ data output hold time tHAD 0 130 ns

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

Note The internal address increment (+1) is performed on the fall of the 3rd clock, where 4 clocks comprise one

cycle. The internal clock is not connected to a pin.

29

Page 30

Program Memory Write Timing

t

t

PCR

VPS

t

VDS

Data input Data input

t

DS

t

M1S

t

M3S

V

PP

V

PP

V

DD

GND

DD

+ 1

V

V

DD

V

DD

GND

CLK

D0-D

7

t

I

MD

0

MD

1

MD

2

µ

PD17P068

t

XH

t

XL

t

DH

t

AH

t

AS

t

M3H

t

t

M0S

Hi-ZHi-Z Hi-Z Hi-ZHi-Z

DF

Data input

t

DS

t

OPW

Data

output

t

DH

t

DV

t

PW

t

M1R

t

M1H

MD

3

Program Memory Read Timing

PP

V

V

PP

V

DD

GND

DD

+ 1

V

V

DD

V

DD

GND

CLK

D0-D

7

t

I

MD

0

t

VPS

t

VDS

t

XH

t

t

XL

t

DV

DAD

t

HAD

Data outputData output

t

M3HR

t

Hi-ZHi-Z

DFR

30

MD

MD

MD

1

"L"

t

PCR

2

t

M3SR

3

Page 31

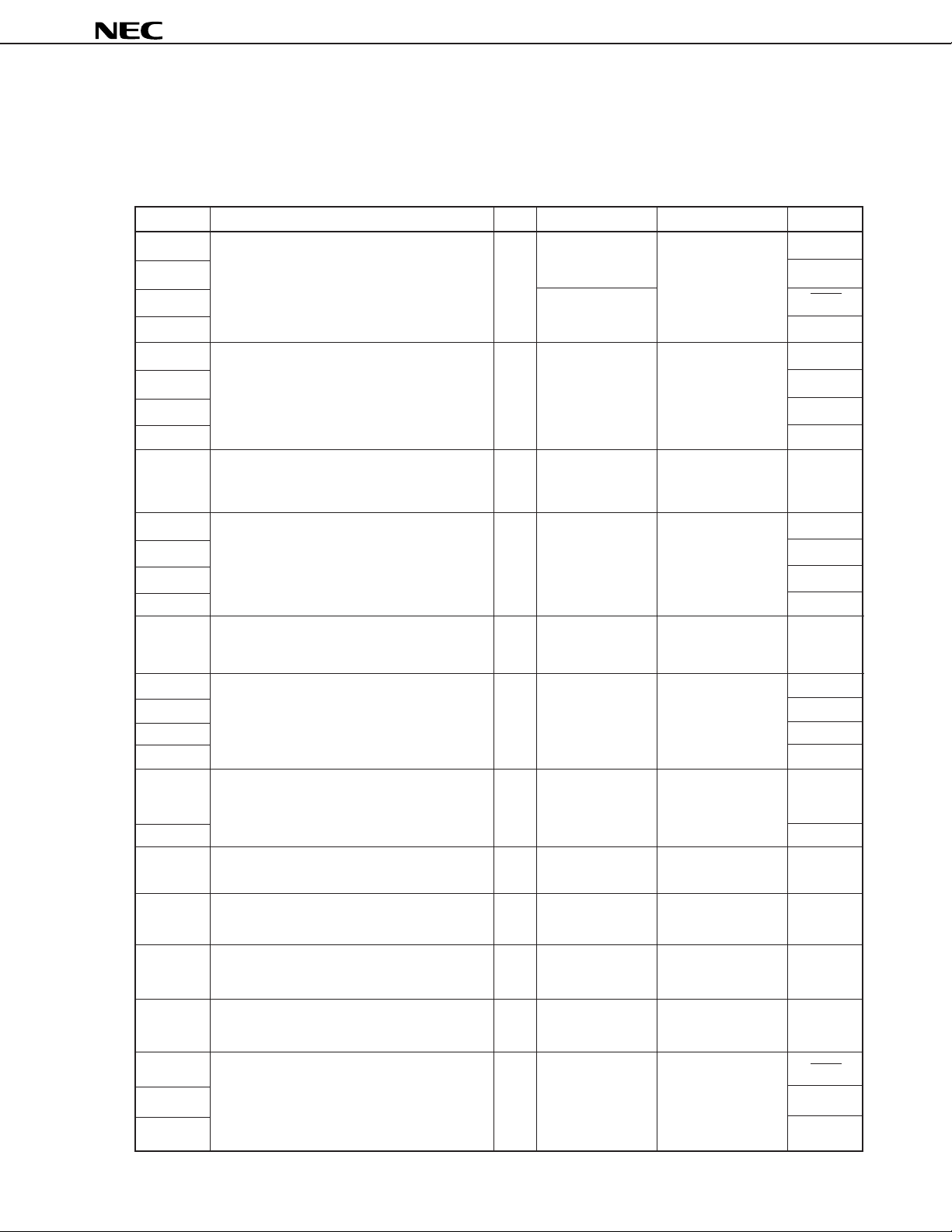

4. PACKAGE DRAWING

100 PIN PLASTIC QFP (14 20)

µ

PD17P068

A

B

80

81

100

1

51

30

50

31

F

G

H

M

I

P

N

NOTE

Each lead centerline is located within 0.15 mm (0.006 inch) of

its true position (T.P.) at maximum material condition.

detail of lead end

CD

S

Q

R

J

K

M

L

ITEM MILLIMETERS INCHES

A 23.2±0.2 0.913

B 20.0±0.2 0.787

C 14.0±0.2 0.551

D

17.2±0.2

F

0.8

G

0.6

H 0.30±0.10 0.012

I

0.15

J

0.65 (T.P.)

K 1.6±0.2 0.063±0.008

L 0.8±0.2 0.031

M 0.15 0.006

N 0.10

P 2.7 0.106

Q

R5°±5° 5°±5°

S 3.0 MAX.

+0.10

–0.05

0.125±0.075 0.005±0.003

+0.009

–0.008

+0.009

–0.008

+0.009

–0.008

0.677±0.008

0.031

0.024

+0.004

–0.005

0.006

0.026 (T.P.)

+0.009

–0.008

+0.004

–0.003

0.004

0.119 MAX.

S100GF-65-3BA-3

31

Page 32

µ

APPENDIX DEVELOPMENT TOOLS

The following tools are available to provide µPD17P068’s program development environment.

Hardware

Product Description

The IE-17K, IE-17K-ET, and EMU-17K are in-circuit emulators common to the

In-circuit emulator 17K series. The IE-17K and IE-17K-ET should be connected with the host

computer (PC-9800 series or IBM PC/ATTM ) through an RS-232-C cable. The

IE-17K EMU-17K should be installed to an extension slot in the host computer

IE-17K-ET

EMU-17K

SE board This SE board is for the µPD17068, 17P068, and 17008. This board can perform

(SE-17008) an in-circuit emulator.

Emulation probe This probe is used when emulating the µPD17P068GF.

Note 1

Note 2

(PC-9800 series). Each of the three products function as a dedicated emulator

for each device by connecting it with an individual system evaluation board

(SE board). Using

interface, makes user’s debugging environment more powerful. If the EMU-

17K is used, user can monitor the contents of the data memory in real time.

evaluations of user’s system. To debug user’s programs, use it together with

SIMPLEHOST

which features an excellent user-machine

PD17P068

(EP-17068GF)

Conversion socket This socket converts pin arrangement for the 100-pin plastic QFP (14 × 20 mm)

to connect the emulation probe EP-17068GF to the target system.

Note 4

Note 4

Note 4

Note 4

Note 4

Note 3

)

)

To perform programming, the program adapter AF-9808L is required to connect

to the PROM programmer.

PROM in the µPD17P068.

(EV-9200GF-100

PROM programmer These products write programs to the internal PROM of the µPD17P068.

AF-9703

AF-9704

AF-9705

AF-9706

Program adapter This adapter is used together with the PROM programmer to program the

(AF-9808L

Notes 1. Inexpensive type: Power supply is required to connect externally.

2. Manufactured by IC Corporation. For details, call 03-3447-3793 Tokyo, Japan.

3. If the EP-17068GF is purchased, one EV-9200GF-100 is attached as a companion product. EV-9200GF-

100s can separately be purchased in 5-piece units.

4. Manufactured by Ando Electric Corporation. For details, call 03-3733-1151 Tokyo, Japan.

32

Page 33

Software

µ

PD17P068

Product Description OS Media Ordering Code

This assembler can be used

17K series

assembler

(AS17K)

Device file

(AS17068)

Support

software

(

SIMPLEHOST

for all 17K series devices.

To develop program of the

µ

PD17P068, the device file

(AS17068) are also required.

This product is the device

file for the µPD17P068. PC-9800 series MS-DOS

This device file is used

together with the assembler

AS17K. IBM PC/AT PC DOS

This software is used to

develop programs using an

in-circuit emulator and the

host computer.

This product runs under

)

Windows

vides users with an excellent

user-machine interface.

TM

system and pro-

Host

Computer

PC-9800 Series MS-DOS

IBM PC/AT PC

TM

DOS

PC-9800 Series MS-DOS

IBM PC/AT PC DOS

TM

Windows

5 inch 2HDµS5A10AS17K

3.5 inch 2HDµS5A13AS17K

5 inch 2HCµS7B10AS17K

3.5 inch 2HCµS7B13AS17K

5 inch 2HDµS5A10AS17068

3.5 inch 2HDµS5A13AS17068

5 inch 2HCµS7B10AS17068

3.5 inch 2HCµS7B13AS17068

5 inch 2HD

3.5 inch 2HDµS5A13lE17K

5 inch 2HC

3.5 inch 2HCµS7B13lE17K

µ

S5A10lE17K

µ

S7B10lE17K

Remark These products run with the versions of the operation systems shown below.

OS Version

MS-DOS Ver.3.30 to Ver.5.00A

PC DOS Ver.3.1 to Ver.5.0

Windows Ver.3.0 to Ver.3.1

Note

Note

Note With these products, the task swap function

is disabled though the Ver.5.00/5.00A of

MS-DOS and Ver.5.0 of the PC DOS support

the task swap function.

33

Page 34

[MEMO]

µ

PD17P068

34

Page 35

µ

PD17P068

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note: Strong electric field, when exposed to a MOS device, can cause destruction

of the gate oxide and ultimately degrade the device operation. Steps must

be taken to stop generation of static electricity as much as possible, and

quickly dissipate it once, when it has occurred. Environmental control must

be adequate. When it is dry, humidifier should be used. It is recommended

to avoid using insulators that easily build static electricity. Semiconductor

devices must be stored and transported in an anti-static container, static

shielding bag or conductive material. All test and measurement tools

including work bench and floor should be grounded. The operator should

be grounded using wrist strap. Semiconductor devices must not be touched

with bare hands. Similar precautions need to be taken for PW boards with

semiconductor devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note: No connection for CMOS device inputs can be cause of malfunction. If no

connection is provided to the input pins, it is possible that an internal input

level may be generated due to noise, etc., hence causing malfunction. CMOS

devices behave differently than Bipolar or NMOS devices. Input levels of

CMOS devices must be fixed high or low by using a pull-up or pull-down

circuitry. Each unused pin should be connected to VDD or GND with a

resistor, if it is considered to have a possibility of being an output pin. All

handling related to the unused pins must be judged device by device and

related specifications governing the devices.

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note: Power-on does not necessarily define initial status of MOS device. Produc-

tion process of MOS does not define the initial operation status of the device.

Immediately after the power source is turned ON, the devices with reset

function have not yet been initialized. Hence, power-on does not guarantee

out-pin levels, I/O settings or contents of registers. Device is not initialized

until the reset signal is received. Reset operation must be executed immediately after power-on for devices having reset function.

35

Page 36

µ

PD17P068

Purchase of NEC I2C components conveys a license under the Philips I2C Patent Rights to use these

2

components in an I

by Philips.

C system, provided that the system conforms to the I2C Standard Specification as defined

SIMPLEHOST

MS-DOS and Windows are trademarks of Microsoft Corp.

PC/AT and PC DOS are trademarks of IBM Corp.

The export of this product from Japan is regulated by the Japanese government. To export this product may be prohibited

without governmental license, the need for which must be judged by the customer. The export or re-export of this product

from a country other than Japan may also be prohibited without a license from that country. Please call an NEC sales

representative.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customer must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

“Standard“, “Special“, and “Specific“. The Specific quality grade applies only to devices developed based on

a customer designated “quality assurance program“ for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices in “Standard“ unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact NEC Sales Representative in advance.

Anti-radioactive design is not implemented in this product.

is a registered trademark of NEC Corp.

36

M4 94.11

Loading...

Loading...