Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD178P018

8-BIT SINGLE-CHIP MICROCONTROLLER

DESCRIPTION

The µPD178P018 is a device in which the on-chip mask ROM of the µPD178018 is replaced with a one-time

PROM or EPROM.

Because this device can be programmed by users, it is ideally suited for system evaluation, small-lot and multiple-

device production, and early development and time-to-market.

The µPD178P018 is a PROM version corresponding to the µPD178004, 178006, and 178016.

µ

Caution The

PD178P018KK-T does not maintain planned reliability when used in your system’s massproduced products. Please use only experimentally or for evaluation purposes during trial manufacture.

For more information on functions, refer to the following User’s Manuals. Be sure to read them when

designing.

µ

PD178018 Subseries User’s Manual: U11410E

78K/0 Series User’s Manual Instruction: U12326E (In Preparation)

FEATURES

• Pin-compatible with mask ROM version (except for VPP pin)

• Internal PROM: 60 Kbytes

•µPD178P018GC : One-time programmable (ideally suited for small-lot production)

•

µ

PD178P018KK-T : Reprogrammable (ideally suited for system evaluation)

• Internal high-speed RAM: 1024 bytes

• Internal expansion RAM: 2048 bytes

• Buffer RAM: 32 bytes

• Can be operated in the same power supply voltage as the mask ROM version

(During PLL operation: V

The electrical specifications (power supply current, etc.) and PLL analog specifications of the

differ from that of mask ROM versions. So, these differences should be considered and verified before

application sets are mass-produced.

DD = 4.5 to 5.5 V)

µ

PD178P018

In this document, the term PROM is used in parts common to one-time PROM versions and EPROM versions.

The information in this document is subject to change without notice.

Document No. U12298EJ1V0DS00 (1st Edition)

Date Published May 1997 N

Printed in Japan

©

1997

Page 2

APPLICATIONS

Car stereo, home stereo systems

ORDERING INFORMATION

Part Number Package Internal ROM Quality Grade

µ

PD178P018GC-3B9 80-pin plastic QFP (14 × 14 mm, 0.65-mm pitch) One-Time PROM Standard

µ

PD178P018KK-T

Note

80-pin ceramic WQFN (14 × 14 mm, 0.65-mm pitch) EPROM Not applicable

Note Under planning

Please refer to "Quality grade on NEC Semiconductor Devices" (Document number C11531E) published by

NEC Corporation to know the specification of quality grade on the devices and its recommended applications.

µ

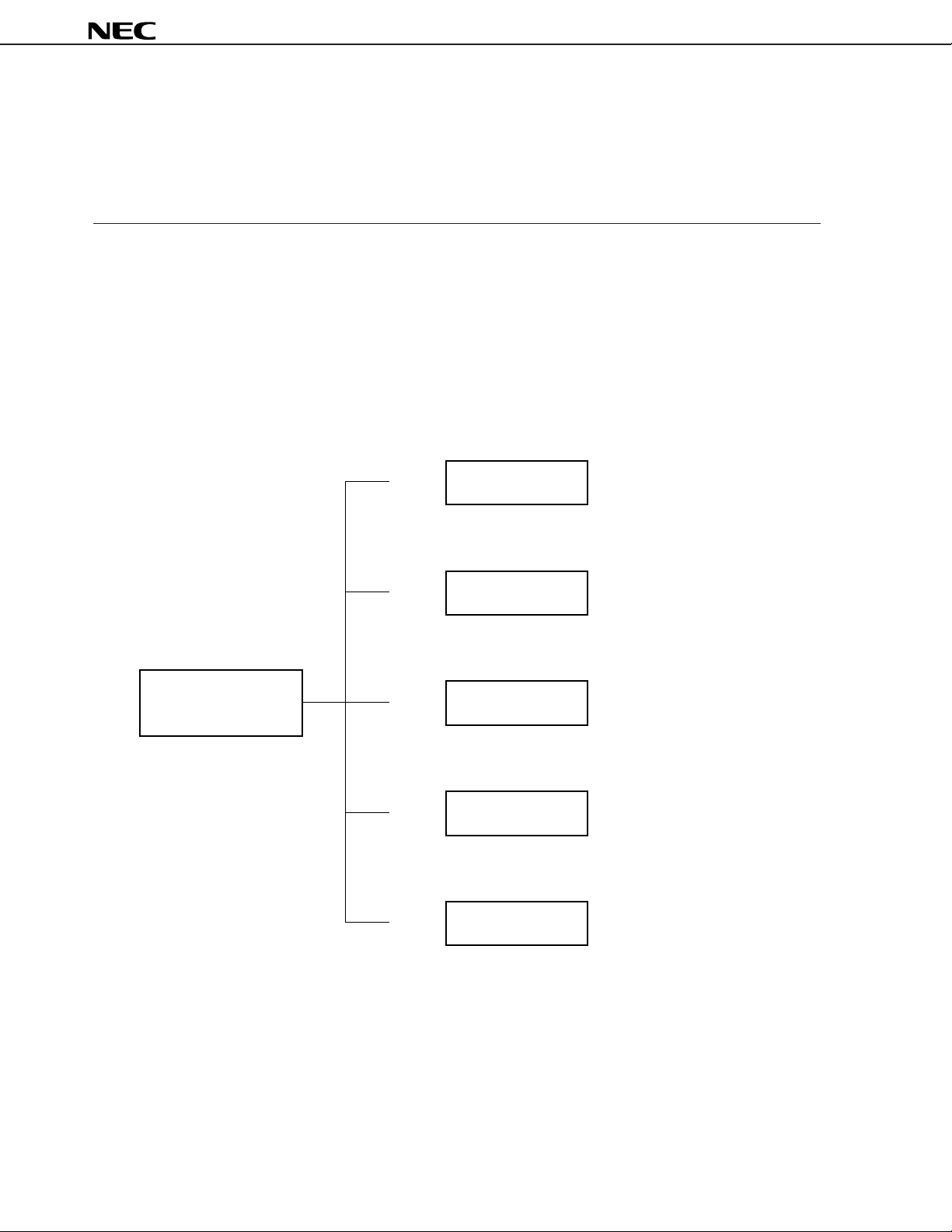

PD178018 SUBSERIES EXPANSION

PD178P018

80 pins PROM: 60 KB RAM: 3 KB

µ

µ

PD178P018

PD178018 Subseries

µ

80 pins ROM: 60 KB RAM: 3 KBPD178018

80 pins ROM: 48 KB RAM: 3 KB

80 pins ROM: 48 KB RAM: 1 KB

80 pins ROM: 32 KB RAM: 1 KB

µ

PD178016

µ

PD178006

µ

µ

PD178004

2

Page 3

µ

PD178P018

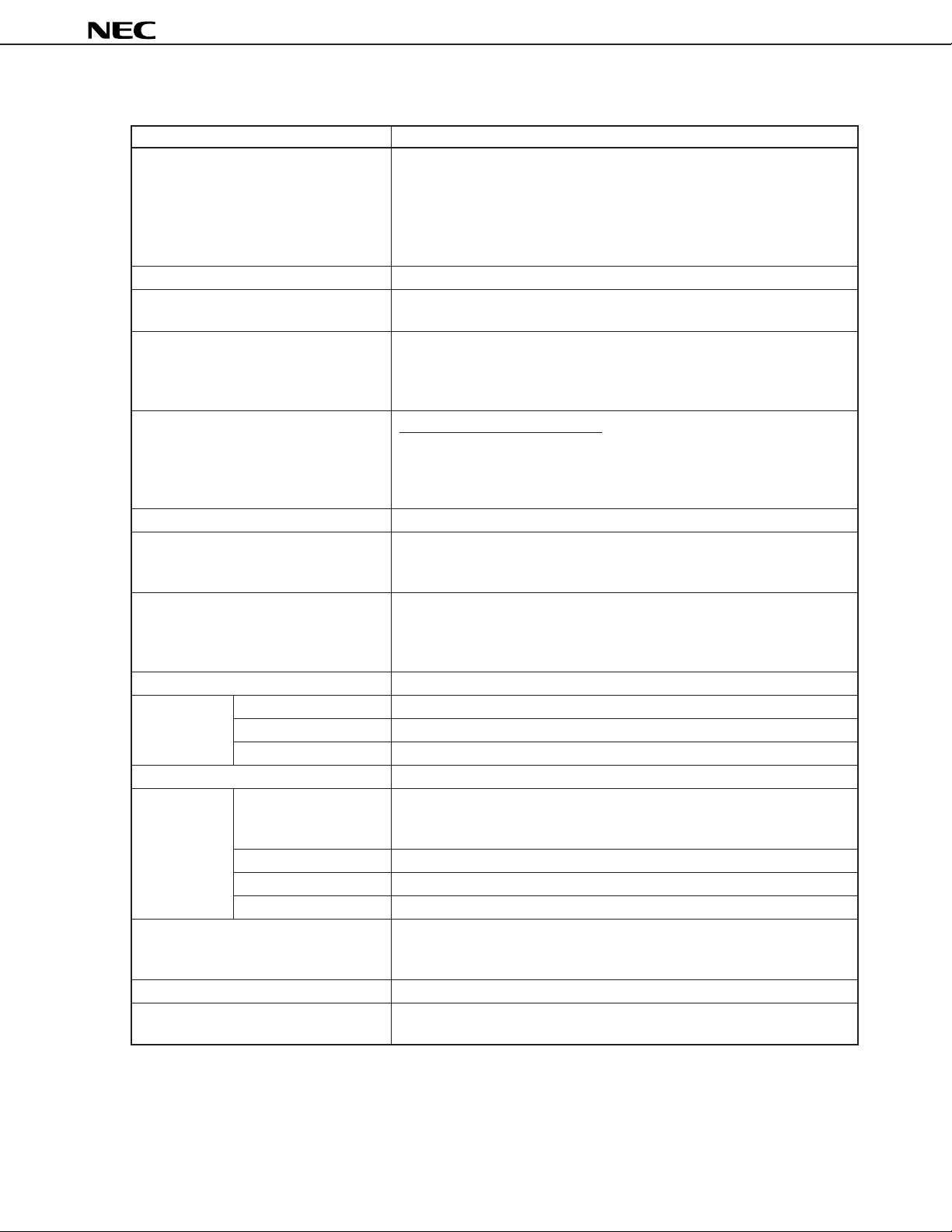

FUNCTION DESCRIPTION

Item Function

Internal memory • PROM : 60 Kbytes

• RAM

High-speed RAM : 1024 bytes

Expansion RAM : 2048 bytes

Buffer RAM : 32 bytes

General register 8 bits × 32 registers (8 bits × 8 registers × 4 banks)

Instruction cycle With variable instruction execution time function

0.44 µs/0.88 µs/1.78 µs/3.56 µs/7.11 µs/14.22 µs (with 4.5-MHz crystal resonator)

Instruction set • 16-bit operation

• Multiply/divide (8 bits × 8 bits, 16 bits ÷ 8 bits)

• Bit manipulate (set, reset, test, Boolean operation)

• BCD Adjust, etc.

I/O port Total : 62 pins

• CMOS input : 1 pin

• CMOS I/O : 54 pins

• N-ch open-drain I/O : 4 pins

• N-ch open-drain output : 3 pins

A/D converter 8-bit resolution × 6 channels

Serial interface • 3-wire/SBI/2-wire/I2C bus

• 3-wire serial I/O mode

(with automatic transmit/receive function of up to 32 bytes): 1 channel

Timer • Basic timer (timer carry FF (10 Hz)) : 1 channel

• 8-bit timer/event counter : 2 channels

• 8-bit timer (D/A converter: PWM output): 1 channel

• Watchdog timer : 1 channel

Buzzer (BEEP) output 1.5 kHz, 3 kHz, 6 kHz

Vectored Maskable interrupt Internal: 8, external: 7

interrupt Non-maskable interrupt Internal: 1

Software interrupt Internal: 1

Test input Internal: 1

PLL frequency Division mode Two types

synthesizer • Direct division mode (VCOL pin)

• Pulse swallow mode (VCOH and VCOL pins)

Reference frequency 11 types selectable by program (1, 1.25, 2.5, 3, 5, 6.25, 9, 10, 12.5, 25, 50 kHz)

Charge pump Error out output: 2

Phase comparator Unlock detectable by program

Frequency counter • Frequency measurement

• AMIFC pin: for 450-kHz count

• FMIFC pin: for 450-kHz/10.7-MHz count

D/A converter (PWM output) 8-/9-bit resolution × 3 channels (shared by 8-bit timer)

Standby function • HALT mode

• STOP mode

Note

mode selectable : 1 channel

(1/2)

Note When using the I2C bus mode (including when this mode is implemented by program without using the

peripheral hardware), consult your local NEC sales representative when you place an order for mask.

3

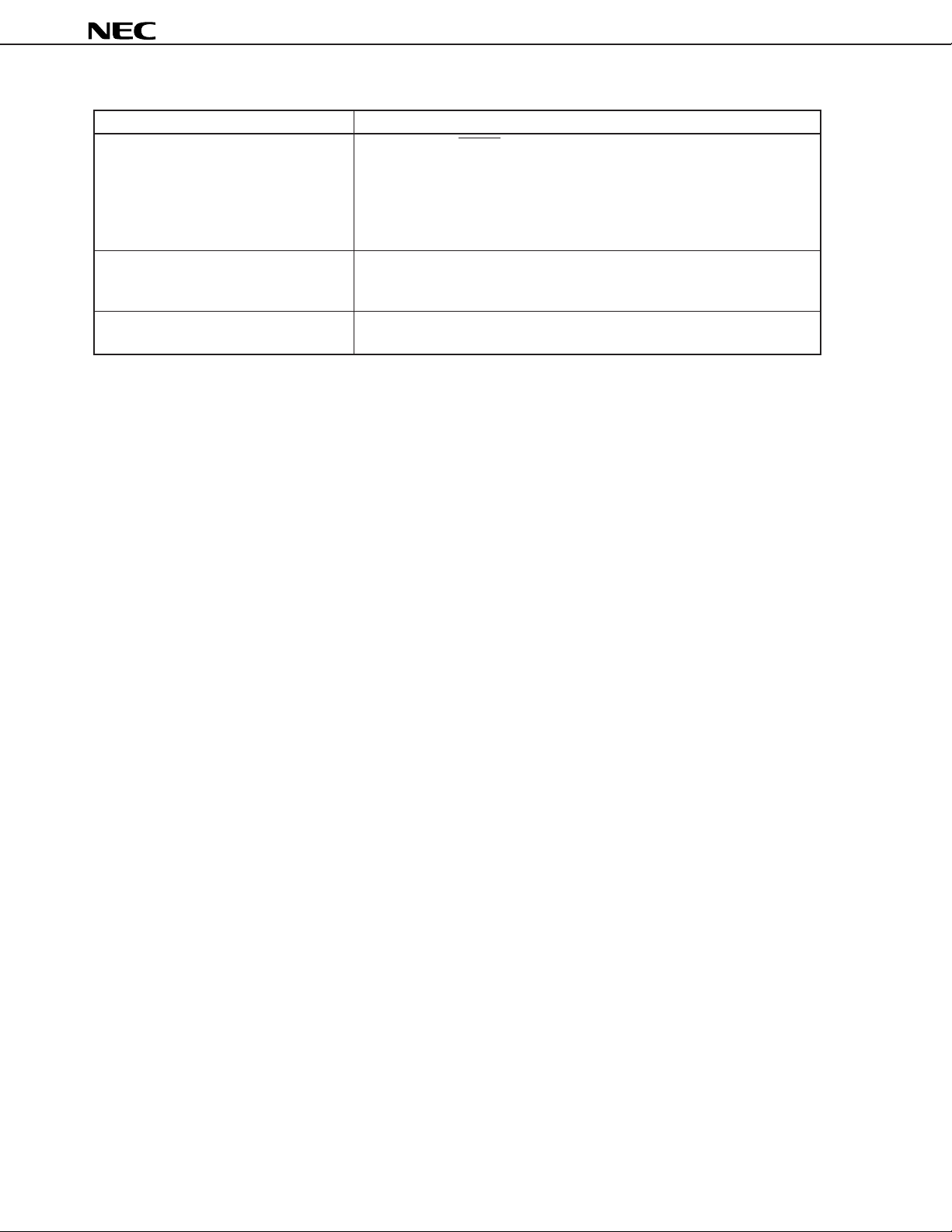

Page 4

µ

PD178P018

Item Function

Reset • Reset via the RESET pin

• Internal reset by watchdog timer

• Reset by power-ON clear circuit (3-value detection)

• Detection of less than 4.5 V

• Detection of less than 3.5 V

• Detection of less than 2.5 V

Power supply voltage • VDD = 4.5 to 5.5 V (with PLL operating)

•VDD = 3.5 to 5.5 V (with CPU operating, CPU clock: fX/2 or less)

•VDD = 4.5 to 5.5 V (with CPU operating, CPU clock: fX)

Package • 80-pin plastic QFP (14 × 14 mm, 0.65-mm pitch)

• 80-pin ceramic WQFN (14 × 14 mm, 0.65-mm pitch)

Note

(CPU clock: fX)

Note

(CPU clock: fX/2 or less and on power application)

Note

(in STOP mode)

Note These voltage values are maximum values. The reset is actually executed at a voltage lower than these

values.

(2/2)

4

Page 5

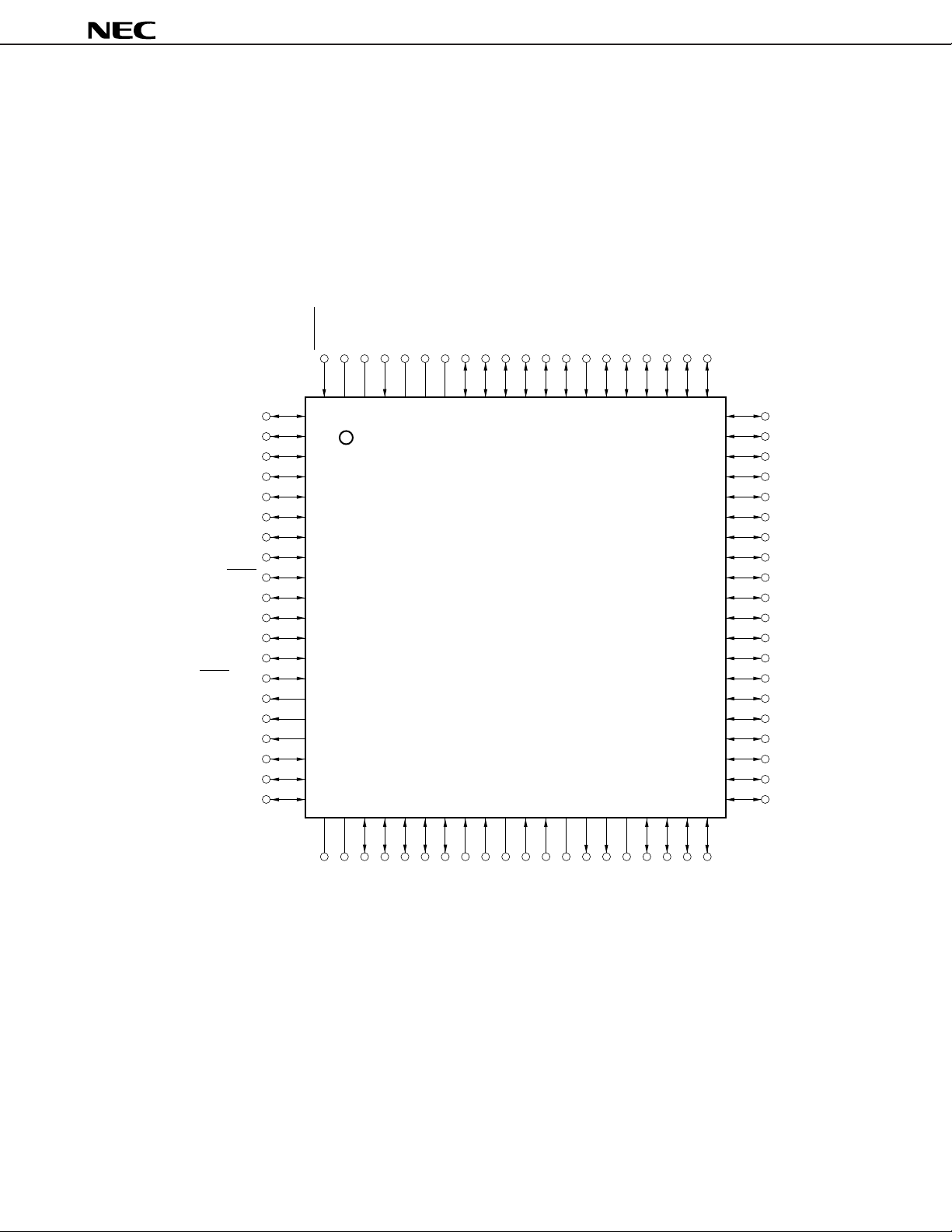

PIN CONFIGURATIONS (TOP VIEW)

(1) Normal operating mode

• 80-PIN PLASTIC QFP (14 × 14 mm, 0.65-mm pitch)

µ

PD178P018GC-3B9

• 80-PIN CERAMIC WQFN (14 × 14 mm, 0.65-mm pitch)

µ

PD178P018KK-T

RESET

P10/ANI0

P11/ANI1

P12/ANI2

P13/ANI3

P14/ANI4

P15/ANI5

P20/SI1

P21/SO1

P22/SCK1

P23/STB

P24/BUSY

P25/SI0/SB0/SDA0

P26/SO0/SB1/SDA1

P27/SCK0/SCL

P132/PWM0

P133/PWM1

P134/PWM2

P40

P41

P42

VDDREGOSCX1X2

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2122 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

GND

REGCPU

P06/INTP6

P05/INTP5

P04/INTP4

P03/INTP3

P02/INTP2

P01/INTP1

P00/INTP0

P125

P124

P123

P122

P121

µ

PD178P018

P120

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

P37

P36/BEEP

P35

P34/TI2

P33/TI1

P32

P31

P30

P67

P66

P65

P64

P63

P62

P61

P60

P57

P56

P55

P54

GNDPORT

Cautions 1. Connect the V

2. Connect the VDDPORT and VDDPLL pins to VDD.

3. Connect the GNDPORT and GNDPLL pins to GND.

4. Connect each of the REGOSC and REGCPU pins to GND via a 0.1-µF capacitor.

P43

P44

P45

P46

P47

DDPORT

V

PP pin to GND directly.

AMIFC

DDPLL

FMIFC

V

VCOL

VCOH

EO0

GNDPLL

EO1

PP

V

P50

P51

P52

P53

5

Page 6

µ

PD178P018

AMIFC : AM Intermediate Frequency Counter Input

ANI0 to ANI5 : A/D Converter Input

BEEP : Buzzer Output

BUSY : Busy Output

EO0, EO1 : Error Out Output

FMIFC : FM Intermediate Frequency Counter Input

GND : Ground

GNDPLL : PLL Ground

GNDPORT : Port Ground

INTP0 to INTP6 : Interrupt Inputs

P00 to P06 : Port 0

P10 to P15 : Port 1

P20 to P27 : Port 2

P30 to P37 : Port 3

P40 to P47 : Port 4

P50 to P57 : Port 5

P60 to P67 : Port 6

P120 to P125 : Port 12

P132 to P134 : Port 13

PWM0 to PWM2 : PWM Output

REGCPU : Regulator for CPU Power Supply

REGOSC : Regulator for Oscillator

RESET : Reset Input

SB0, SB1 : Serial Data Bus Input/Output

SCK0, SCK1 : Serial Clock Input/Output

SCL : Serial Clock Input/Output

SDA0, SDA1 : Serial Data Input/Output

SI0, SI1 : Serial Data Input

SO0, SO1 : Serial Data Output

STB : Strobe Output

TI1, TI2 : Timer Clock Input

VCOL, VCOH : Local Oscillation Input

DD : Power Supply

V

V

DDPLL : PLL Power Supply

DDPORT : Port Power Supply

V

V

PP : Programming Power Supply

X1, X2 : Crystal Resonator Connection

6

Page 7

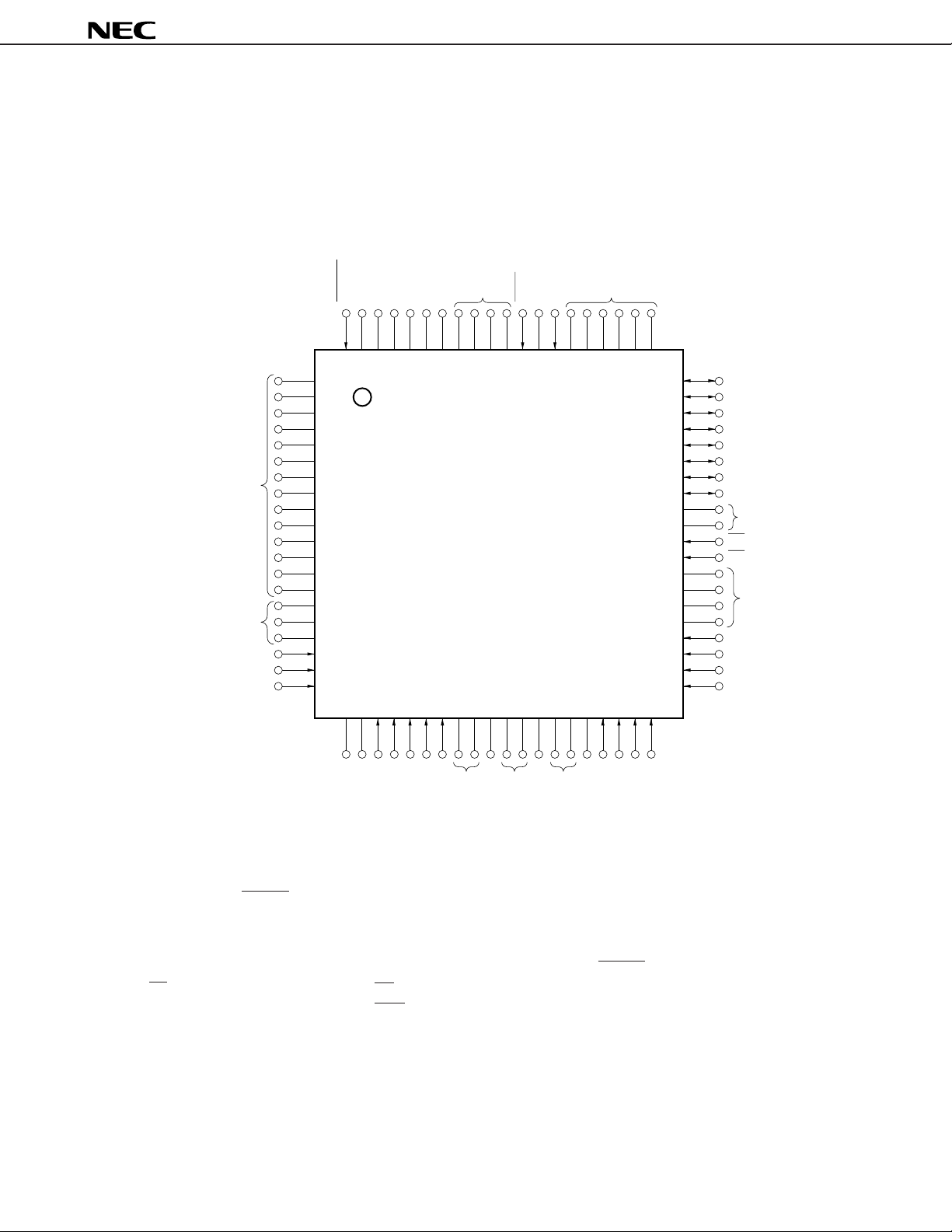

(2) PROM programming mode

µ

PD178P018

• 80-PIN PLASTIC QFP (14 ×

µ

PD178P018GC-3B9

• 80-PIN CERAMIC WQFN

(L)

A0

A1

A2

Note

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

µ

PD178P018KK-T

Open

14 mm)

(L)

RESET

VDDVDD(L)

80 79 78 77767574 73 72717069 68 67 66656463 62 61

21 22 23 24252627 28 29303132 33 34 35363738 39 40

Open

GND

DD

V

PGM

(L)

A9

(L)

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

D7

D6

D5

D4

D3

D2

D1

D0

(L)

CE

OE

(L)

A15

A14

A13

A12

Open

PP

A8

V

A16

A10

A11

DD

A3A4A5A6A7

V

GND

(L)

DD

V

(L)

GND

Note Under planning

Cautions 1. (L) : Individually connect to GND via a pull-down resistor.

2. GND : Connect to GND.

3. RESET : Set to the low level.

4. Open : Leave open.

A0 to A16 : Address Bus

CE : Chip Enable

D0 to D7 : Data Bus

GND : Ground

OE : Output Enable

PGM : Program

RESET : Reset

V

DD : Power Supply

PP : Programming Power Supply

V

7

Page 8

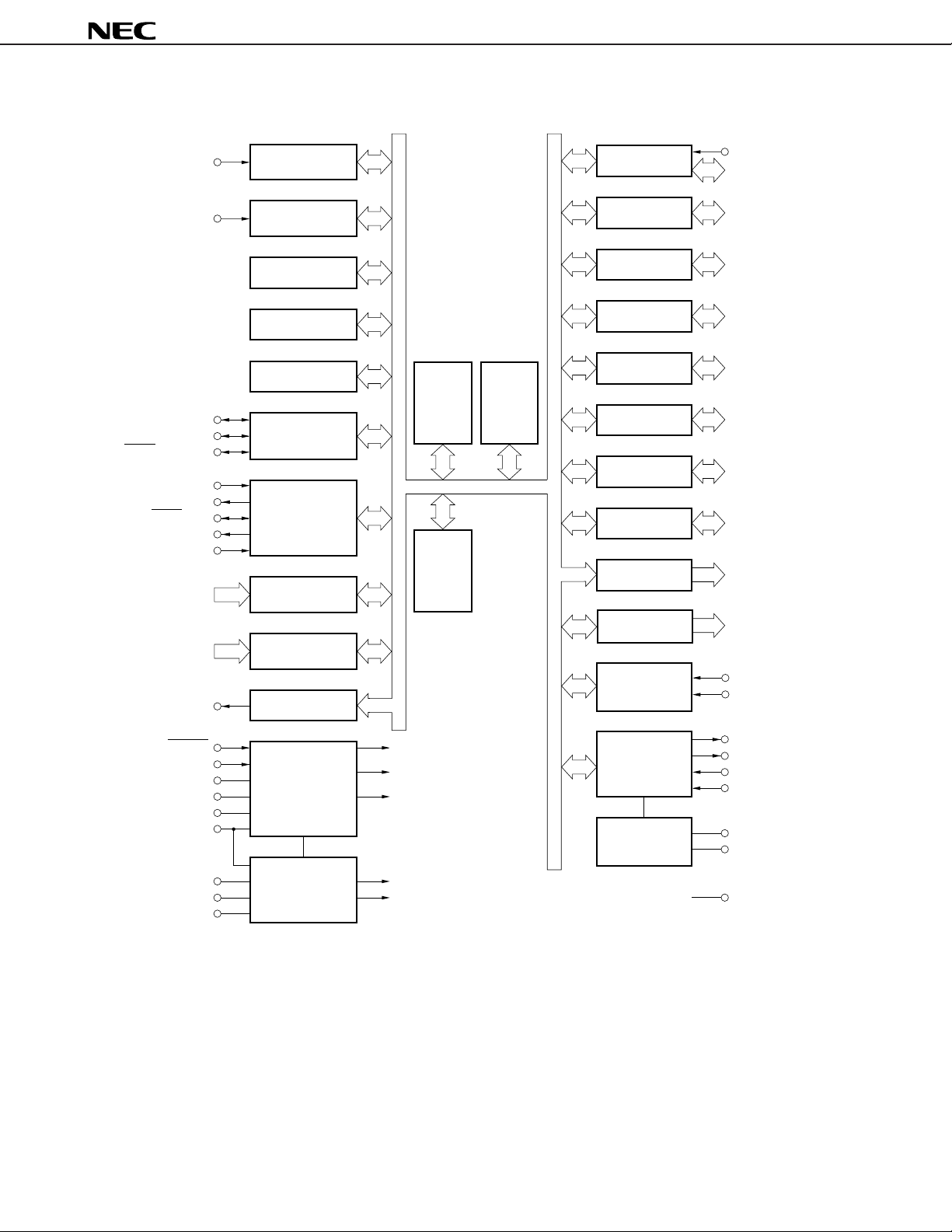

BLOCK DIAGRAM

µ

PD178P018

TI1/P33

TI2/P34

SI0/SB0/SDA0/P25

SO0/SB1/SDA1/P26

SCK0/SCL/P27

SI1/P20

SO1/P21

SCK1/P22

STB/P23

BUSY/P24

ANI0/P10 to

ANI5/P15

INTP0/P00 to

INTP6/P06

BEEP/P36

8-bit TIMER/

EVENT COUNTER 1

8-bit TIMER/

EVENT COUNTER 2

8-bit TIMER3

WATCHDOG TIMER

BASIC TIMER

SERIAL

INTERFACE 0

SERIAL

INTERFACE 1

A/D CONVERTER

6

INTERRUPT

7

CONTROL

BUZZER OUTPUT

78K/0

CPU

CORE

RAM

(3072 Bytes)

PROM

(60 K Bytes)

PORT 0

PORT 1

PORT 2

PORT 3

PORT 4

PORT 5

PORT 6

PORT 12

PORT 13

D/A CONVERTER

(PWM)

FREQUENCY

COUNTER

P00

6

P01 to P06

6

P10 to P15

P20 to P27

8

8

P30 to P37

8

P40 to P47

8

P50 to P57

8

P60 to P67

6

P120 to P125

3

P132 to P134

PWM0/P132 to

3

PWM2/P134

AMIFC

FMIFC

RESET

V

DD

X1

X2

PORT

SYSTEM

CONTROL

RESET

CPU

PERIPHERAL

PLL

EO0

EO1

VCOL

VCOH

GNDPORT

V

REGOSC

REGCPU

DD

V

VOLTAGE

REGULATOR

OSC

V

CPU

PLL

VOLTAGE

REGULATOR

V

DD

PLL

GNDPLL

PP

V

GND

8

Page 9

µ

PD178P018

CONTENTS

1. PIN FUNCTION LIST.......................................................................................................................... 10

1.1 Pins in Normal Operating Mode ............................................................................................... 10

1.2 Pins in PROM Programming Mode........................................................................................... 12

1.3 Pins Input/Output Circuits and Recommended Connection of Unused Pins ...................... 13

2. PROM PROGRAMMING ..................................................................................................................... 16

2.1 Operating Modes........................................................................................................................ 16

2.2 PROM Write Procedure ............................................................................................................. 18

2.3 PROM Read Procedure.............................................................................................................. 22

3. PROGRAM ERASURE (µPD178P018KK-T ONLY) ....................................................................... 23

4. OPAQUE FILM ON ERASURE WINDOW (µPD178P018KK-T ONLY)........................................ 23

5. ONE-TIME PROM VERSION SCREENING .................................................................................... 23

6. ELECTRICAL SPECIFICATIONS ...................................................................................................... 24

7. PACKAGE DRAWINGS ..................................................................................................................... 46

8. RECOMMENDED SOLDERING CONDITIONS ................................................................................. 48

APPENDIX A. DEVELOPMENT TOOLS ................................................................................................ 49

APPENDIX B. RELATED DOCUMENTS ................................................................................................ 53

9

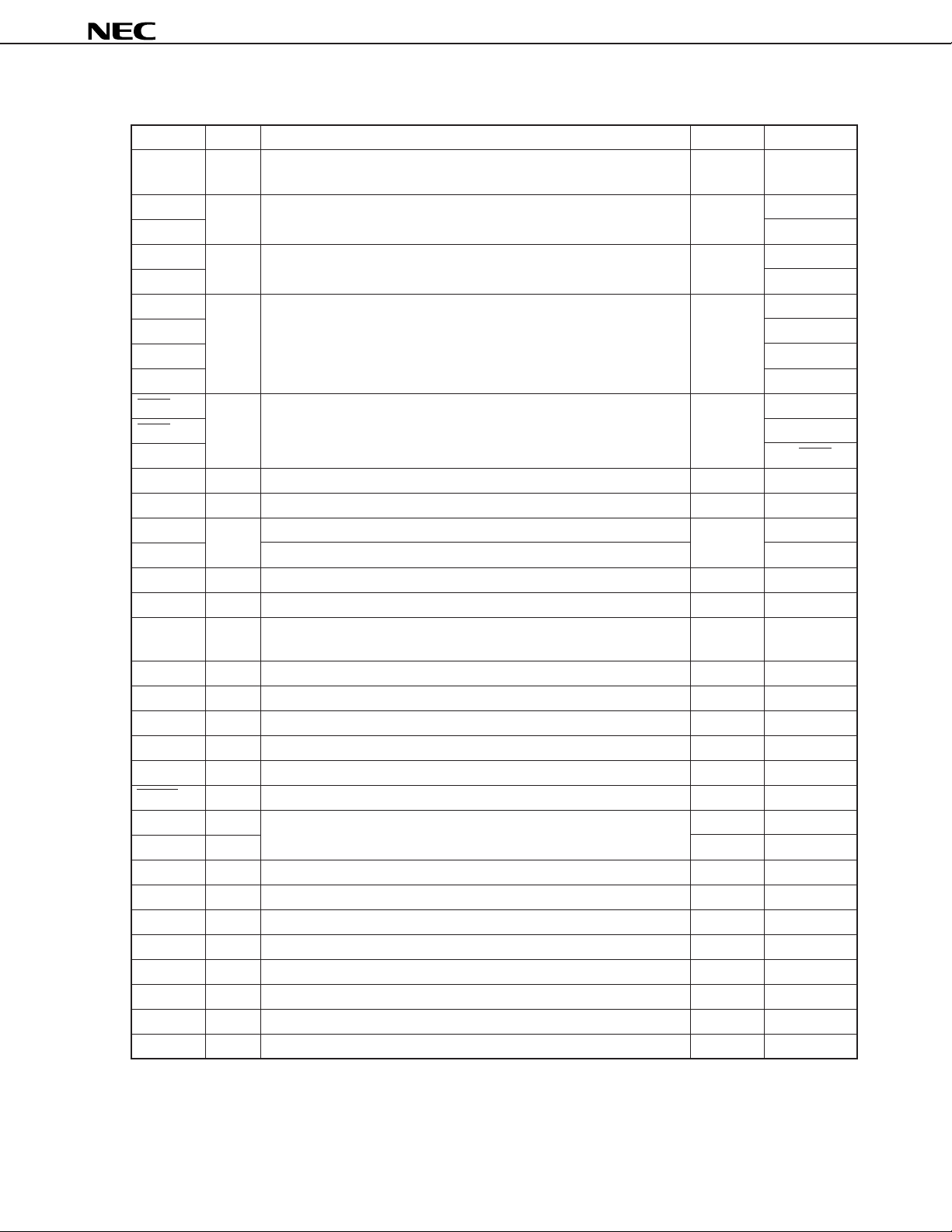

Page 10

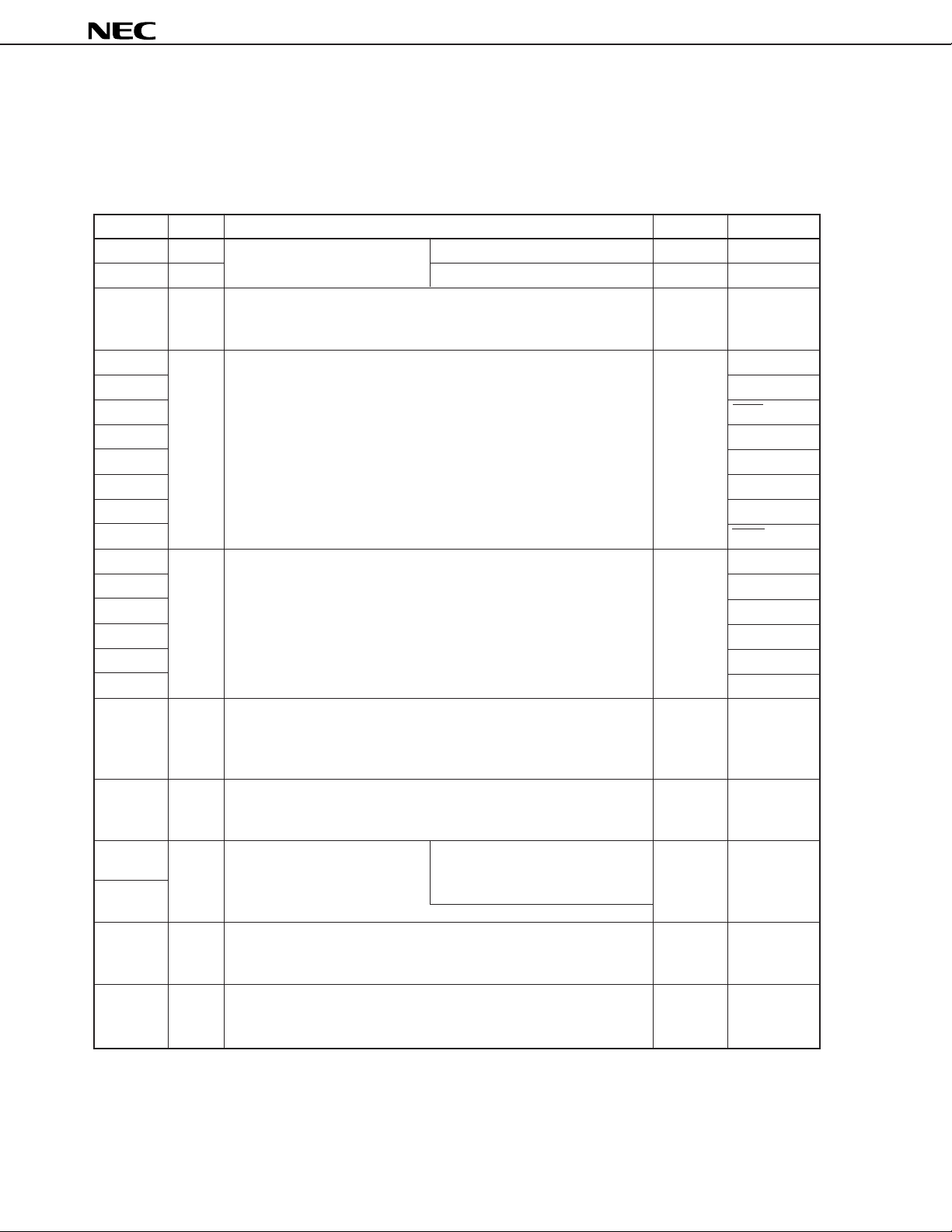

1. PIN FUNCTION LIST

1.1 Pins in Normal Operating Mode

(1) Port pins

µ

PD178P018

Pin Name I/O Function After Reset

P00 Input Port 0. Input only Input INTP0

P01 to P06 I/O 7-bit input/output port.

P10 to P15 I/O Port 1. Input ANI0 to ANI5

6-bit input/output port.

Input/output mode can be specified bit-wise.

P20 I/O Port 2. Input SI1

P21 8-bit input/output port. SO1

P22 Input/output mode can be specified bit-wise. SCK1

P23 STB

P24 BUSY

P25 SI0/SB0/SDA0

P26

P27 SCK0/SCL

P30 to P32 I/O Port 3. Input —

P33 8-bit input/output port. TI1

P34 Input/output mode can be specified bit-wise. TI2

P35 —

P36 BEEP

P37 —

P40 to P47 I/O Port 4. Input —

8-bit input/output port.

Input/output mode can be specified in 8-bit units.

Test input flag (KRIF) is set to 1 by falling edge detection.

P50 to P57 I/O Port 5. Input —

8-bit input/output port.

Input/output mode can be specified bit-wise.

P60 to P63 I/O Port 6. Middle voltage N-ch open-drain Input —

8-bit input/output port. input/output port.

P64 to P67 Input/output mode can be LEDs can be driven directly.

specified bit-wise.

P120 to I/O Port 12. Input —

P125 6-bit input/output port.

Input/output mode can be specified bit-wise.

P132 to Output Port 13. — PWM0 to

P134 3-bit output port. PWM2

N-ch open-drain output port.

Input/output mode can be specified bit-wise.

Input INTP1 to INTP6

Alternate Function

SO0/SB1/SDA1

10

Page 11

(2) Non-port pins (1 of 2)

µ

PD178P018

Pin Name I/O Function After Reset

INTP0 to Input External maskable interrupt inputs with specifiable valid edges (rising Input P00 to P06

INTP6 edge, falling edge, both rising and falling edges).

SI0 Input Serial interface serial data input Input

SI1 P20

SO0 Output Serial interface serial data output Input

SO1 P21

SB0 I/O Serial interface serial data input/output Input P25/SI0/SDA0

SB1

SDA0 P25/SI0/SB0

SDA1 P26/SO0/SB1

SCK0 I/O Serial interface serial clock input/output Input P27/SCL

SCK1 P22

SCL P27/SCK0

STB Output Serial interface automatic transmit/receive strobe output Input P23

BUSY Input Serial interface automatic transmit busy input Input P24

TI1 Input External count clock input to 8-bit timer (TM1) Input P33

TI2 External count clock input to 8-bit timer (TM2) P34

BEEP Output Buzzer output Input P36

ANI0 to ANI5

PWM0 to Output PWM output — P132 to P134

PWM2

EO0, EO1 Output Error out output from charge pump of the PLL frequency synthesizer — —

VCOL Input Inputs PLL local band oscillation frequency (In HF, MF mode). — —

VCOH Input Inputs PLL local band oscillation frequency (In VHF mode). — —

AMIFC Input Inputs AM intermediate frequency counter. — —

FMIFC Input Inputs FM intermediate frequency counter. — —

RESET Input System reset input — —

X1 Input Crystal resonator connection for system clock oscillation — —

X2 — ——

REGOSC — Regulator for oscillator. Connected to GND via a 0.1-µF capacitor. — —

REGCPU — Regulator for CPU power supply. Connected to GND via a 0.1-µF capacitor. — —

VDD — Positive power supply — —

GND — Ground ——

VDDPORT — Positive power supply for port block — —

GNDPORT — Ground for port block — —

VDDPLL — Positive power supply for PLL — —

GNDPLL — Ground for PLL — —

Input A/D converter analog input Input P10 to P15

Alternate Function

P25/SB0/SDA0

P26/SB1/SDA1

P26/SO0/SDA1

11

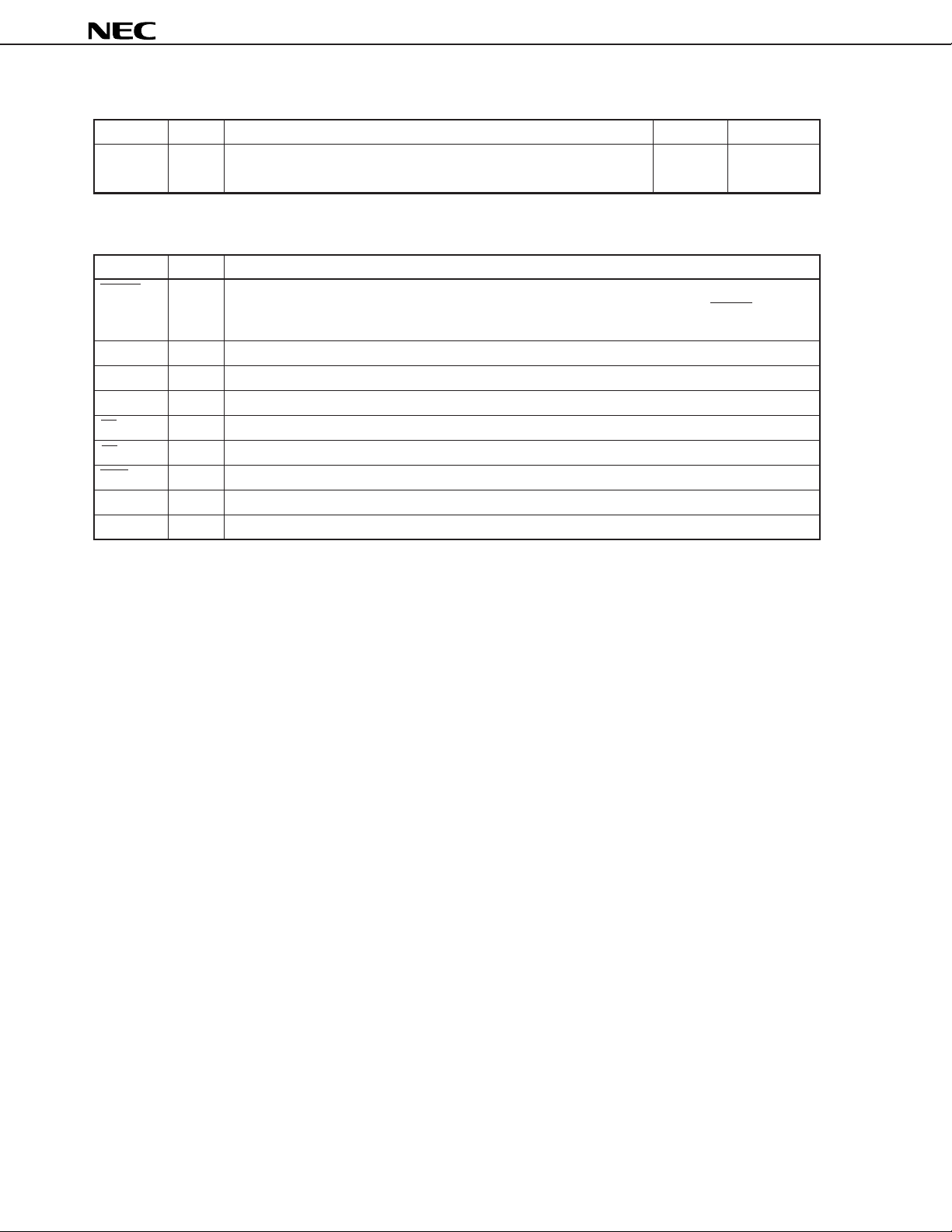

Page 12

(2) Non-port pins (2/2)

µ

PD178P018

Pin Name I/O Function After Reset

VPP — High-voltage applied during program write/verification. — —

Connected directly to GND in normal operating mode.

Alternate Function

1.2 Pins in PROM Programming Mode

Pin Name I/O Function

RESET Input PROM programming mode setting

When +5 V or +12.5 V is applied to VPP pin and a low-level signal is applied to the RESET pin, this

chip is set in the PROM programming mode.

VPP Input PROM programming mode setting and high-voltage applied during program write/verification.

A0 to A16 Input Address bus

D0 to D7 I/O Data bus

CE Input PROM enable input/program pulse input

OE Input Read strobe input to PROM

PGM Input Program/program inhibit input in PROM programming mode.

VDD — Positive power supply

GND — Ground potential

12

Page 13

µ

PD178P018

1.3 Pins Input/Output Circuits and Recommended Connection of Unused Pins

Table 1-1 shows the input/output circuit types of pins and the recommended conditions for unused pins.

Refer to Figure 1-1 for the configuration of the input/output circuit of each type.

Table 1-1. Type of I/O Circuit of Each Pin

Pin Name I/O Circuit Type I/O Recommended Connections of Unused Pins

P00/INTP0 2 Input Connected to GND or GNDPORT

P01/INTP1 to P06/INTP6 8 I/O Set in general-purpose input port mode by software and

P10/ANI0 to P15/ANI5 11-A individually connected to VDD, VDDPORT, GND, or GNDPORT

P20/SI1 8 via a resistor.

P21/SO1 5

P22/SCK1 8

P23/STB 5

P24/BUSY 8

P25/SI0/SB0/SDA0 10

P26/SO0/SB1/SDA1

P27/SCK0/SCL

P30 to P32 5

P33/TI1, P34/TI2 8

P35 5

P36/BEEP

P37

P40 to P47 5-G

P50 to P57 5

P60 to P63 13

P64 to P67 5

P120 to P125

P132/PWM0 to P134/PWM2 19 Output Set to the low-level output by software and open

EO0 DTS-EO1 Open

EO1 DTS-EO2

VCOL, VCOH DTS-AMP Input Set to disabled status by software and open

AMIFC, FMIFC

VPP — — Connected to GND or GNDPORT directly

13

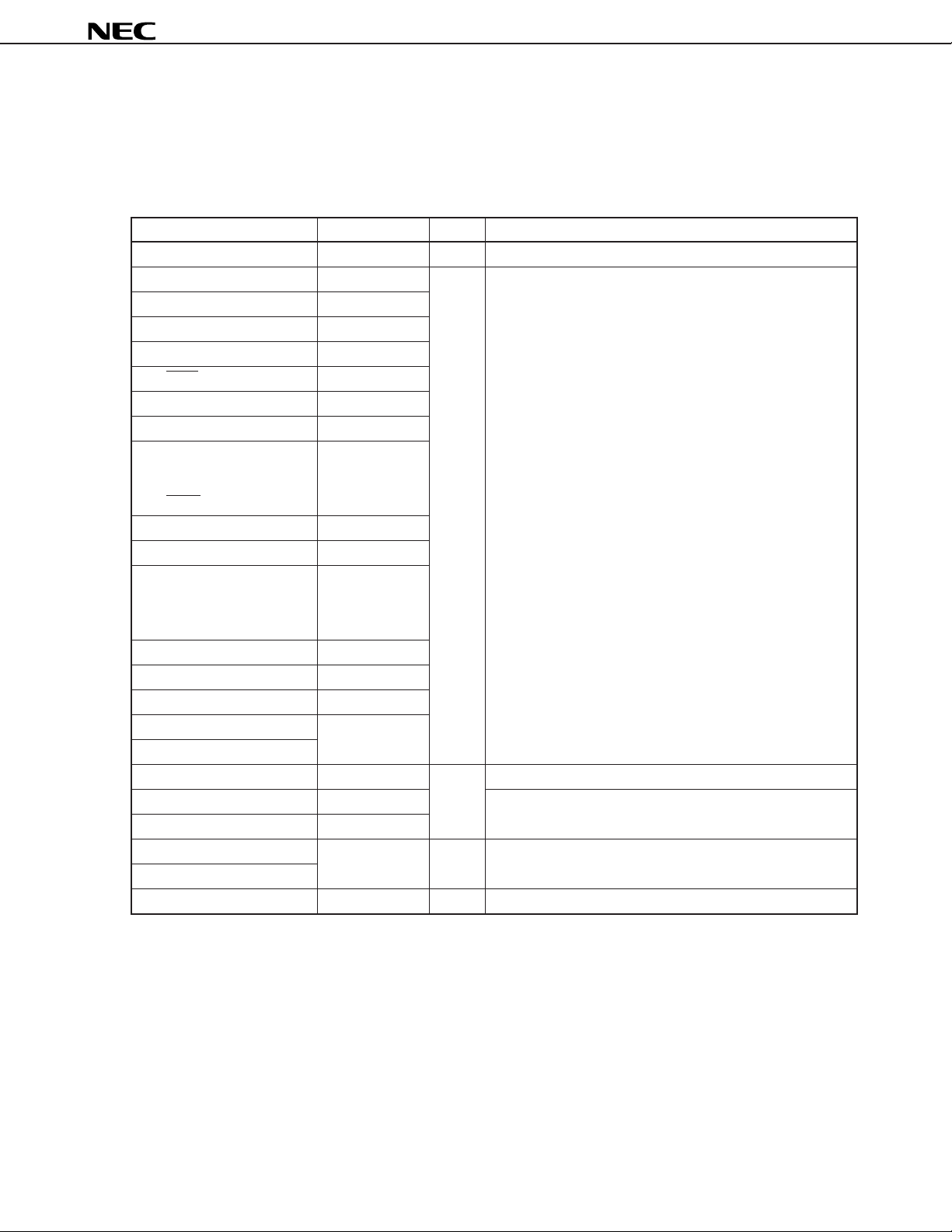

Page 14

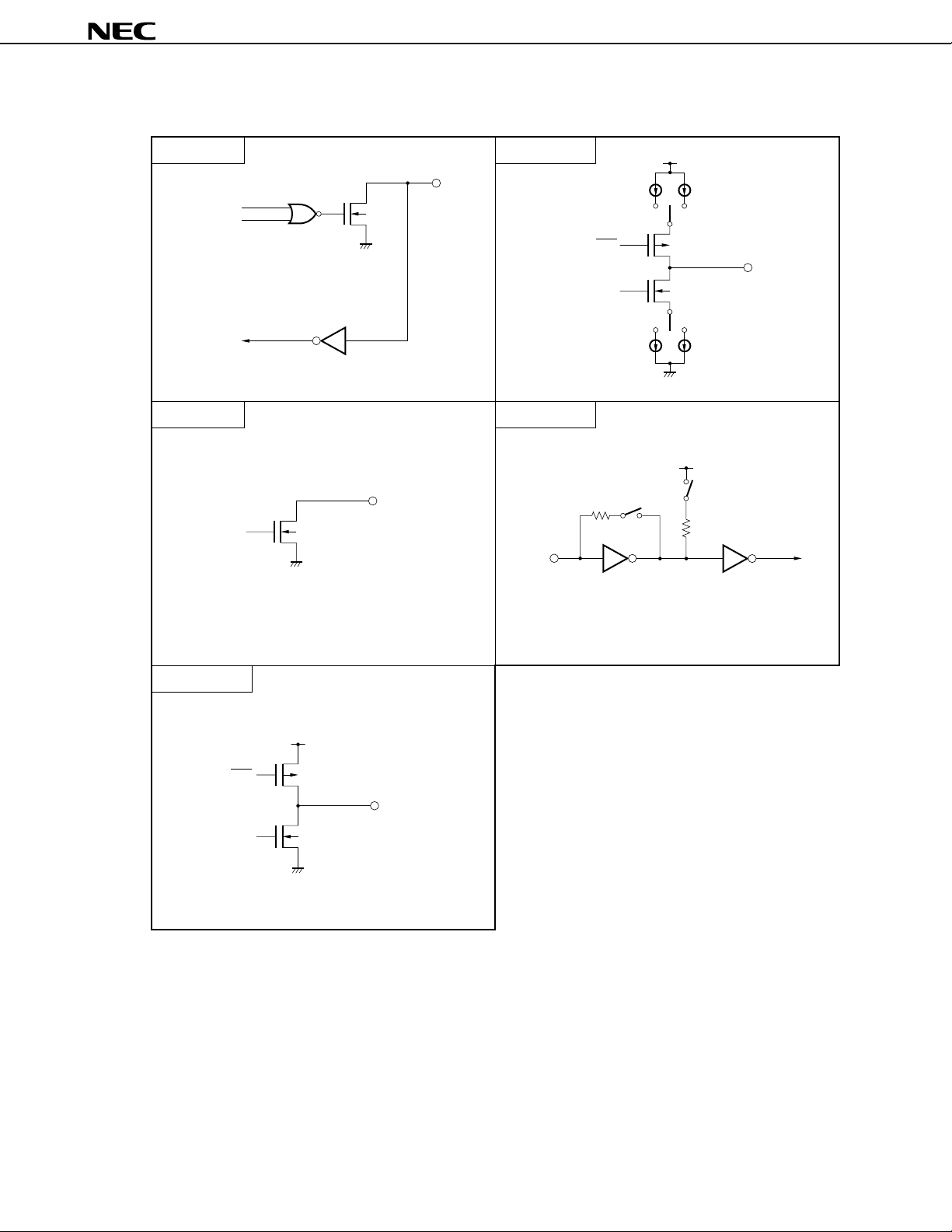

Figure 1-1. Types of Pin Input/Output Circuits (1/2)

Type 2 Type 8

data

IN

output

disable

Schmitt-Triggered Input with Hysteresis Characteristics

V

DD

P-ch

N-ch

µ

PD178P018

IN/OUT

Type 5

data

V

DD

P-ch

Type 10

IN/OUT

output

disable

N-ch

open drain

output disable

input

enable

Type 5-G Type 11-A

V

data

output

disable

DD

P-ch

IN/OUT

N-ch

data

output

disable

comparator

input

enable

data

P-ch

+

–

N-ch

V

REF

(Threshold voltage)

V

DD

P-ch

N-ch

V

P-ch

N-ch

IN/OUT

DD

IN/OUT

Remark All V

14

DD and GND in the above figures are the positive power supply and ground potential of the ports,

and should be read as V

DDPORT and GNDPORT, respectively.

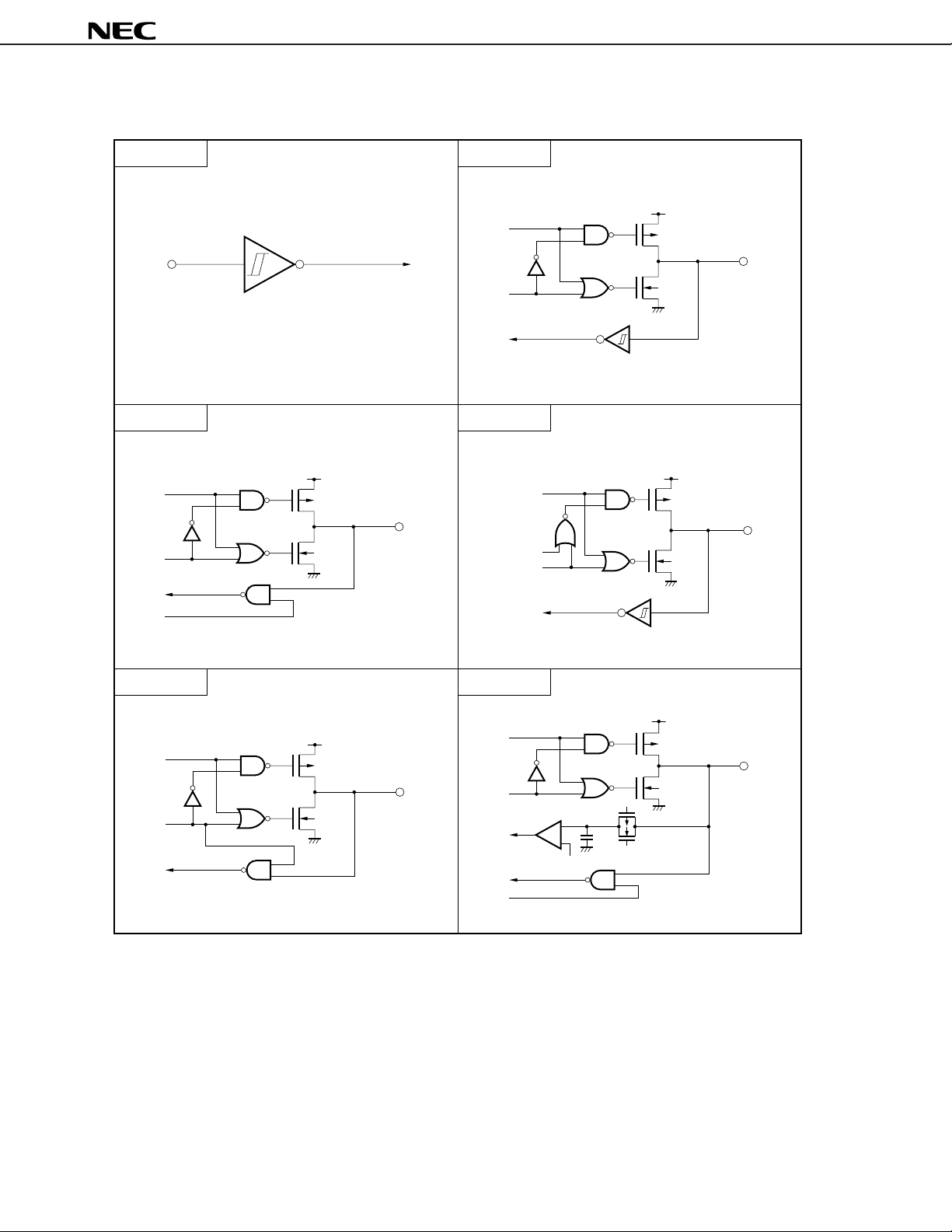

Page 15

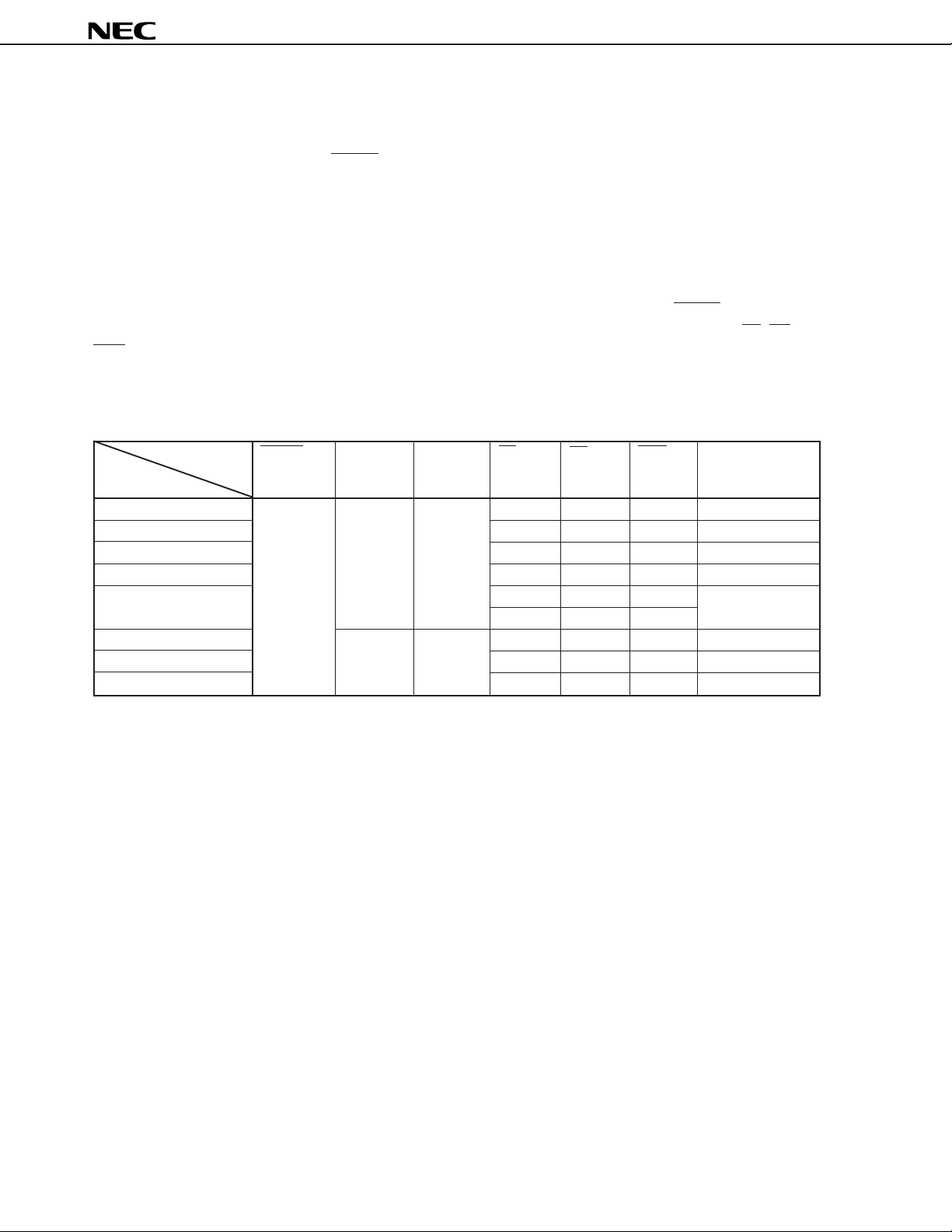

Figure 1-1. Types of Pin Input/Output Circuits (2/2)

µ

PD178P018

Type 13 Type DTS-EO2

IN/OUT

output disable

data

Middle-Voltage Input Buffer

Type 19

N-ch

N-ch

Type DTS-AMP

OUT

IN

DW

UP

DD

V

P-ch

N-ch

GNDPLL

V

PLL

DD

OUT

PLL

Type DTS-EO1

DW

Remark All V

and should be read as V

DD

PLL

V

P-ch

OUT

UP

DD and GND in the above figures are the positive power supply and ground potential of the ports,

N-ch

GNDPLL

DDPORT and GNDPORT, respectively.

15

Page 16

µ

PD178P018

2. PROM PROGRAMMING

The µPD178P018 has an internal 60-Kbyte PROM as a program memory. For programming, set the PROM

programming mode with the V

PP and RESET pins. For the connection of unused pins, refer to “PIN CONFIGURA-

TIONS (TOP VIEW) (2) PROM programming mode.”

Caution Programs must be written in addresses 0000H to EFFFH (the last address EFFFH must be

specified). They cannot be written by a PROM writer which cannot specify the write address.

2.1 Operating Modes

When +5 V or +12.5 V is applied to the V

PP pin and a low-level signal is applied to the RESET pin, the PROM

programming mode is set. This mode will become the operating mode as shown in Table 2-1 when the CE, OE, and

PGM pins are set as shown.

Further, when the read mode is set, it is possible to read the contents of the PROM.

Table 2-1. Operating Modes of PROM Programming

Pin RESET VPP VDD CE OE PGM D0 to D7

Operating Mode

Page data latch L +12.5 V +6.5 V H L H Data input

Page write H H L High-impedance

Byte write L H L Data input

Program verify L L H Data output

Program inhibit x H H High-impedance

xLL

Read +5 V +5 V L L H Data output

Output disable L H x High-impedance

Standby H x x High-impedance

Remark x : L or H

16

Page 17

µ

PD178P018

(1) Read mode

Read mode is set if CE = L and OE = L are set.

(2) Output disable mode

Data output becomes high-impedance, and is in the output disable mode, if OE = H is set.

µ

Therefore, it allows data to be read from any device by controlling the OE pin, if multiple

connected to the data bus.

(3) Standby mode

Standby mode is set if CE = H is set.

In this mode, data outputs become high-impedance irrespective of the OE status.

(4) Page data latch mode

Page data latch mode is set if CE = H, PGM = H, and OE = L are set at the beginning of page write mode.

In this mode, 1 page 4-byte data is latched in an internal address/data latch circuit.

(5) Page write mode

After 1 page 4 bytes of addresses and data are latched in the page data latch mode, a page write is executed

by applying a 0.1-ms program pulse (active low) to the PGM pin with CE = H and OE = H. Then, program

verification can be performed, if CE = L and OE = L are set.

If programming is not performed by a one-time program pulse, X times (X ≤ 10) write and verification operations

should be executed repeatedly.

PD178P018s are

(6) Byte write mode

Byte write is executed when a 0.1-ms program pulse (active low) is applied to the PGM pin with CE = L and OE

= H. Then, program verification can be performed if OE = L is set.

If programming is not performed by a one-time program pulse, X times (X ≤ 10) write and verification operations

should be executed repeatedly.

(7) Program verify mode

Program verify mode is set if CE = L, PGM = H, and OE = L are set.

In this mode, check if a write operation is performed correctly after the write.

(8) Program inhibit mode

Program inhibit mode is used when the OE pin, V

in parallel and a write is performed to one of those devices.

When a write operation is performed, the page write mode or byte write mode described above is used. At this

time, a write is not performed to a device which has the PGM pin driven high.

PP pin, and D0 to D7 pins of multiple

µ

PD178P018s are connected

17

Page 18

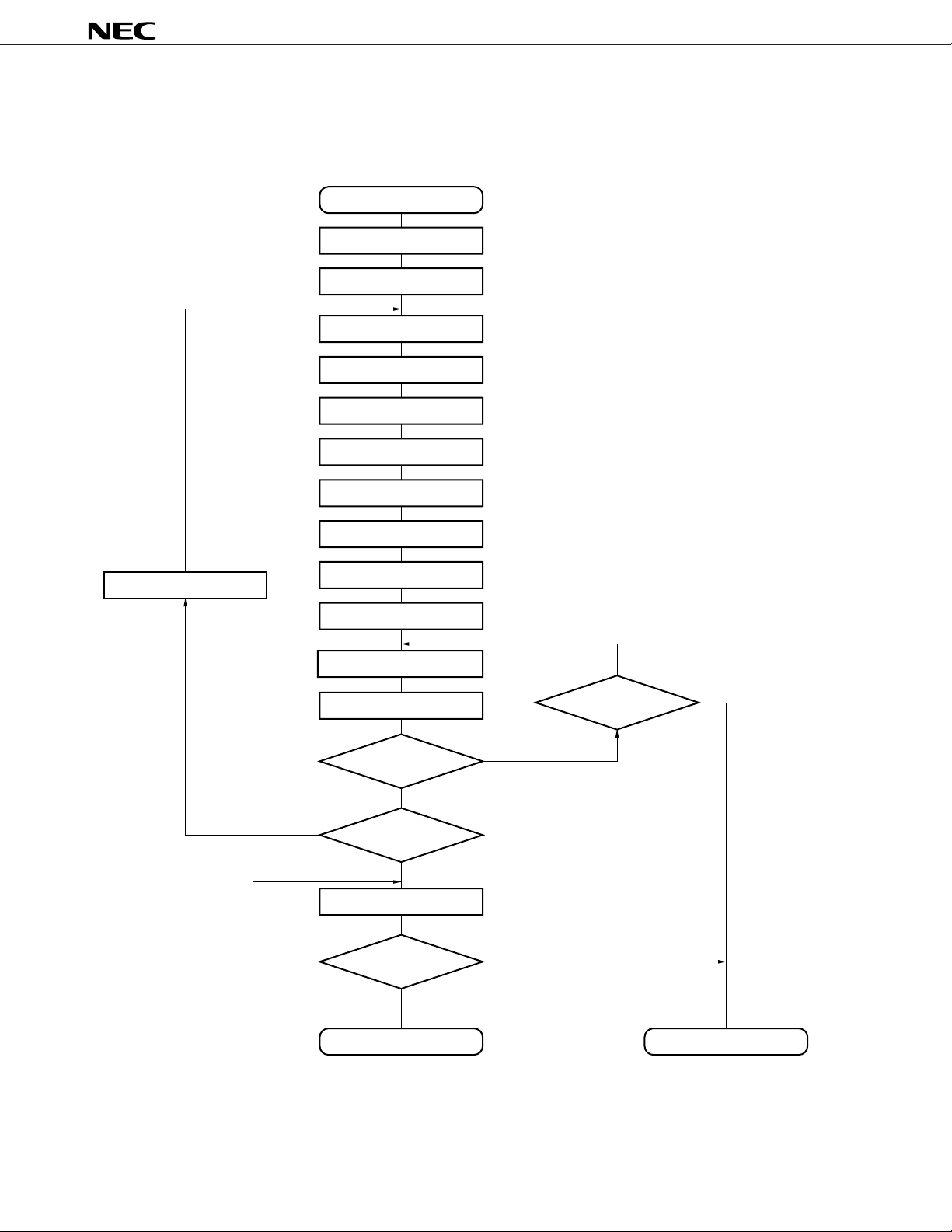

2.2 PROM Write Procedure

Figure 2-1. Page Program Mode Flow Chart

Start

Address = G

DD

= 6.5 V, V

V

Address = Address + 1

X = 0

Latch

Latch

PP

= 12.5 V

µ

PD178P018

Address = Address + 1

Address = Address + 1

Address = Address + 1

0.1-ms program pulse

No

Address = N?

V

DD

= 4.5 to 5.5 V, V

Latch

Latch

X = X + 1

Verify

4 bytes

Pass

Yes

PP

= V

No

X = 10?

Fail

DD

Yes

Remark G = Start address

N = Program last address

18

Pass

Verify

all bytes

All Pass

Write end Defective product

Fail

Page 19

A2 to A16

A0, A1

D0 to D7

V

V

PP

V

µ

PD178P018

Figure 2-2. Page Program Mode Timing

Page Data Latch Program VerifyPage Program

Data Input Data Output

PP

DD

V

CE

PGM

OE

VDD + 1.5

DD

V

V

V

V

DD

IH

V

IL

IH

V

IL

IH

V

IL

19

Page 20

Figure 2-3. Byte Program Mode Flow Chart

Start

Address = G

DD

V

= 6.5 V, V

X = 0

PP

= 12.5 V

µ

PD178P018

Address = Address + 1

Remark G = Start address

N = Program last address

No

Pass

X = X + 1

0.1-ms program pulse

Vefity

Pass

Address = N?

Yes

DD

= 4.5 to 5.5 V, V

V

Verify

all bytes

All Pass

Write end Defective product

PP

= V

No

X = 10?

Fail

DD

Fail

Yes

20

Page 21

Figure 2-4. Byte Program Mode Timing

Program Program Verify

A0 to A16

D0 to D7 Data Input Data Output

V

PP

PP

V

V

DD

VDD + 1.5

V

DD

V

DD

µ

PD178P018

V

IH

CE

V

IL

IH

V

PGM

V

IL

IH

V

OE

V

IL

Cautions 1. VDD should be applied before VPP, and removed after VPP.

2. V

PP must not exceed +13.5 V including overshoot.

3. Reliability may be adversely affected if removal/reinsertion is performed while +12.5 V is being

applied to VPP.

21

Page 22

µ

PD178P018

2.3 PROM Read Procedure

The contents of PROM are readable to the external data bus (D0 to D7) according to the read procedure shown

below.

(1) Fix the RESET pin at low level, supply +5 V to the V

“PIN CONFIGURATIONS (TOP VIEW) (2) PROM programming mode”.

(2) Supply +5 V to the V

(3) Input address of read data into the A0 to A16 pins.

(4) Read mode

(5) Output data to D0 to D7 pins.

The timings of the above steps (2) to (5) are shown in Figure 2-5.

DD and VPP pins.

PP pin, and connect all other unused pins as shown in

Figure 2-5. PROM Read Timings

Address InputA0 to A16

CE (Input)

OE (Input)

Hi-Z Hi-Z

Data OutputD0 to D7

22

Page 23

µ

PD178P018

3. PROGRAM ERASURE (µPD178P018KK-T ONLY)

The µPD178P018KK-T is capable of erasing (FFH) the data written in a program memory and rewriting.

To erase the programmed data, expose the erasure window to light having a wavelength shorter than about 400

nm. Normally, irradiate ultraviolet rays of 254-nm wavelength. The amount of exposure required to completely erase

the programmed data is as follows:

2

• UV intensity x erasure time: 30 W•s/cm

• Erasure time: 40 min. or more (When a UV lamp of 12,000

needed because of deterioration in performance of the UV lamp, soiled erasure window, etc.)

When erasing the contents of the data, set up the UV lamp within 2.5 cm from the erasure window. Further, if a

filter is provided for a UV lamp, irradiate the ultraviolet rays after removing the filter.

or more

µ

W/cm2 is used. However, a longer time may be

4. OPAQUE FILM ON ERASURE WINDOW (µPD178P018KK-T ONLY)

To protect from an intentional erasure by rays other than that of the lamp for erasing EPROM contents, or to protect

internal circuit other than EPROM from misoperating by rays, cover the erasure window with an opaque film when

EPROM contents erasure is not performed.

5. ONE-TIME PROM VERSION SCREENING

The one-time PROM version (µPD178P018GC-3B9) cannot be tested completely by NEC before it is shipped,

because of its structure. It is recommended to perform screening to verify PROM after writing necessary data and

performing high-temperature storage under the condition below.

Storage Temperature Storage Time

125°C 24 hours

23

Page 24

µ

PD178P018

6. ELECTRICAL SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS (TA = 25°C)

Parameter Symbol Test Conditions Ratings Unit

Power supply voltage VDD –0.3 to +7.0 V

VPP –0.3 to +13.5 V

Input voltage VI1 Excluding P60 to P63 –0.3 to VDD + 0.3 V

VI2 P60 to P63 N-ch open-drain –0.3 to +16 V

VI3 A9 PROM programming mode –0.3 to +13.5 V

Output voltage VO –0.3 to VDD + 0.3 V

Output withstand VBDS P132 to P134 N-ch open-drain 16 V

voltage

Analog input voltage

Output current high IOH 1 pin –10 mA

Output current low IOL

Operating ambient TA –40 to +85 °C

temperature

Storage temperature T stg –65 to +150 °C

VAN P10 to P15 Analog input pin –0.3 to VDD + 0.3 V

P01 to P06, P30 to P37, P56, P57, P60 to P67, –15 mA

P120 to P125 total

P10 to P15, P20 to P27, P40 to P47, P50 to P55, –15 mA

P132 to P134 total

Note

1 pin Peak value 15 mA

r.m.s. value 7.5 mA

Note r.m.s. (root mean square) value should be calculated as follows: [r.m.s value] = [Peak value] × √duty

Caution Product quality may suffer if the absolute maximum rating is exceeded for even a single

parameter even momentarily. That is, the absolute maximum ratings are rated values at which

the product is on the verge of suffering physical damage, and therefore the product must be

used under conditions which ensure that the absolute maximum ratings are not exceeded.

Remark The characteristics of an alternate-function pin and a port pin are the same unless specified otherwise.

RECOMMENDED SUPPLY VOLTAGE RANGES (T

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Power supply voltage VDD1 During CPU operation and PLL operation. 4.5 5.5 V

VDD2 While the CPU is operating and the PLL is stopped. 3.5 5.5 V

Cycle Time: TCY ≥ 0.89 µs

VDD3 While the CPU is operating and the PLL is stopped. 4.5 5.5 V

Cycle Time: TCY = 0.44 µs

A = –40 to +85°C)

Remark TCY: Cycle Time (Minimum instruction execution time)

24

Page 25

µ

PD178P018

DC CHARACTERISTICS (TA = –40 to +85°C, VDD = 3.5 to 5.5 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Input voltage high VIH1 P10 to P15, P21, P23, 0.7VDD VDD V

P30 to P32, P35 to P37,

P40 to P47, P50 to P57,

P64 to P67, P120 to P125

VIH2 P00 to P06, P20, P22, 0.85VDD VDD V

P24 to P27, P33, P34,

RESET

VIH3 P60 to P63 0.7VDD 15 V

(N-ch open-drain)

Input voltage low VIL1 P10 to P15, P21, P23, 0 0.3VDD V

P30 to P32, P35 to P37,

P40 to P47, P50 to P57,

P64 to P67, P120 to P125

VIL2 P00 to P06, P20, P22, 0 0.15VDD V

P24 to P27, P33, P34,

RESET

VIL3 P60 to P63 4.5 V ≤ VDD ≤ 5.5 V 0 0.3V DD V

(N-ch open-drain) 3.5 V ≤ VDD < 4.5 V 0 0.2VDD V

Output voltage high VOH1 4.5 V ≤ VDD ≤ 5.5 V, VDD – 1.0 V

IOH = –1 mA

3.5 V ≤ VDD < 4.5 V, VDD – 0.5 V

IOH = –100 µA

Output voltage low VOL1 P50 to P57, P60 to P63 VDD = 4.5 to 5.5 V, 0.4 2.0 V

IOH = 15 mA

P01 to P06, P10 to P15, V DD = 4.5 to 5.5 V, 0.4 V

P20 to P27, P30 to P37, I OL = 1.6 mA

P40 to P47, P64 to P67,

P120 to P125,

P132 to P134

VOL2 SB0, SB1, SCK0 VDD = 4.5 to 5.5 V, 0.2VDD V

N-ch open-drain pulled-up

(R = 1 KΩ)

(1/3)

Remark The characteristics of an alternate-function pin and a port pin are the same unless specified otherwise.

25

Page 26

µ

PD178P018

DC CHARACTERISTICS (TA = –40 to +85°C, VDD = 3.5 to 5.5 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Input leakage ILIH1 P00 to P06, P10 to P15, VIN = VDD 3

current high P20 to P27, P30 to P37,

P40 to P47, P50 to P57,

P64 to P67, P120 to P125,

RESET

ILIH2 P60 to P63 VIN = 15 V 80

Input leakage ILIL1 P00 to P06, P10 to P15, VIN = 0 V –3

current low P20 to P27, P30 to P37,

P40 to P47, P50 to P57,

P64 to P67, P120 to P125,

RESET

ILIL2 P60 to P63 –3

Output leakage ILOH P132 to P134 VOUT = 15 V 3

current high

Output leakage ILOL P132 to P134 VOUT = 0 V –3

current low

Output off leak ILOF EO0, EO1 VOUT = VDD, ±1

current VOUT = 0 V

Note

Note When an input instruction is executed, the low-level input leakage current for P60 to P63 becomes –200

µ

A (MAX.) only in one clock cycle (at no wait). It remains at –3 µA (MAX.) for other than an input instruction.

(2/3)

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

Remark The characteristics of an alternate-function pin and a port pin are the same unless specified otherwise.

REFERENCE CHARACTERISTICS (TA = 25°C, VDD = 5 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Output current high IOH1 EO0 VOUT = VDD – 1 V –4 mA

EO1 (EOCON0 = 1) –6 mA

EO1 (EOCON0 = 0) –2 mA

Output current low IOL1 EO0 VOUT = 1 V 6 mA

EO1 (EOCON0 = 1) 8 mA

EO1 (EOCON0 = 0) 3 mA

(1/2)

26

Page 27

µ

PD178P018

DC CHARACTERISTICS (TA = –40 to +85°C, VDD = 3.5 to 5.5 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Power supply IDD1 While the CPU is operating TCY = 0.89 µs

Note 1

current

IDD2

IDD3 While the CPU is operating TCY = 0.89 µs

IDD4 Pin X1 sine wave TCY = 0.44 µs

Data hold VDDR1 When the crystal is oscillating TCY = 0.44 µs 4.5 5.5 V

power supply

voltage

Data hold

power supply current

VDDR2 TCY = 0.89 µs 3.5 5.5 V

VDDR3 When the crystal oscillation is stopped 2.7 5.5 V

IDDR1 While the crystal oscillation TA = 25°C, VDD = 5V 2 4

IDDR2

and the PLL is stopped

fX = 4.5-MHz operation

and the PLL is stopped

HALT Mode.

input VIN = VDD VDD = 4.5 to 5.5 V

fX = 4.5-MHz operation

When power off by Power On Clear is detected

is stopped

TCY = 0.44 µs

VDD = 4.5 to 5.5 V

Note 2

Note 3

Note 2

Note 3

2.5 15 mA

4.0 27 mA

14mA

1.6 6 mA

230

Notes 1. The port current is not included.

2. When the Processor Clock Control register (PCC) is set at 00H, and the Oscillation Mode Select

register (OSMS) is set to 00H.

3. When PCC is set to 00H and OSMS is set to 01H.

(3/3)

µ

A

µ

A

Remarks 1. T

CY: Cycle Time (Minimum instruction execution time)

2. fx: System clock oscillation frequency.

REFERENCE CHARACTERISTICS (T

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Power supply IDD5 During CPU operation TCY = 0.44 µs

current and PLL operation.

VCOH pin sine wave

input

fIN = 130 MHz,

VIN = 0.15 Vp-p

A = 25°C, VDD = 5 V)

Note

7mA

Note When the Processor Clock Control register (PCC) is set to 00H, and the Oscillation Mode Select register

(OSMS) is set to 01H.

Remark T

CY: Cycle Time (Minimum instruction execution time)

(2/2)

27

Page 28

AC CHARACTERISTICS

µ

PD178P018

(1) BASIC OPERATION (T

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Cycle time TCY fXX = fX/2

(Minimum instruction

execution time)

TI1, TI2 input fTI 4.5 ≤ VDD ≤ 5.5 V 0 4.5 MHz

frequency

TI1, TI2 input high/ tTIH, 4.5 ≤ VDD ≤ 5.5 V 111 ns

low-level width

Interrupt input high/ TINTH, INTP0 8/fsam

low-level width

RESET low-level tRSL 10

width

tTIL 3.5 V ≤ VDD < 4.5 V 1.8

TINTL INTP1 to INTP6 10

A = –40 to +85°C, VDD = 3.5 to 5.5 V)

Note 1

, fX = 4.5-MHz operation 0.89 14.22

Note 2

fXX = fX

fX = 4.5-MHz operation

3.5 V ≤ VDD < 4.5 V 0 275 kHz

, 4.5 ≤ VDD ≤ 5.5 V 0.44 7.11

3.5 ≤ VDD < 4.5 V 0.89 7.11

Note 3

Notes 1. When the Oscillation Mode Selection register (OSMS) is set to 00H.

2. When OSMS is set to 01H.

3. In combination with bits 0 (SCS0) and 1 (SCS1) of the Sampling Clock Select register (SCS),

selection of f

Remarks 1. f

2. f

sam is possible among fXX/2

XX: System clock frequency (fX or fX/2)

X: System clock oscillation frequency

N

, fXX/32, fXX/64, and fXX/128 (when N = 0 to 4).

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

T

CY vs VDD

(when system clock fXX is operating at fX/2)

60

10

s]

µ

CY [

2.0

1.0

Cycle Time T

0.5

0.4

0

123456

Power Supply Voltage VDD [V] Power Supply Voltage VDD [V]

Operation

Guaranteed

Range

T

CY vs VDD

(when system clock fXX is operating at fX)

60

10

s]

µ

Operation

2.0

1.0

Cycle Time TCY [

0.5

0.4

0

123456

Guaranteed

Range

28

Page 29

µ

PD178P018

(2) SERIAL INTERFACE (TA = –40 to +85°C, VDD = 3.5 to 5.5 V)

(a) Serial interface channel 0

(i) 3-wire serial I/O mode (SCK0 ... internal clock output)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK0 cycle time tKCY1 4.5 V ≤ VDD ≤ 5.5 V 800 ns

3.5 V ≤ VDD < 4.5 V 1600 ns

SCK0 high-/low-level width tKH1, 4.5 V ≤ VDD ≤ 5.5 V

tKL1 3.5 V ≤ VDD < 4.5 V

SI0 setup time (to SCK0↑)tSIK1 4.5 V ≤ VDD ≤ 5.5 V 100 ns

3.5 V ≤ VDD < 4.5 V 150 ns

SI0 hold time (from SCK0↑)tKSI1 400 ns

SO0 output delay time from SCK0↓ tKSO1 C = 100 pF

Note

tKCY1/2 – 50

tKCY1/2 – 100

ns

ns

300 ns

Note C is the load capacitance of the SO0 output line.

(ii) 3-wire serial I/O mode (SCK0 ... external clock input)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK0 cycle time tKCY2 4.5 V ≤ VDD ≤ 5.5 V 800 ns

3.5 V ≤ VDD < 4.5 V 1600 ns

SCK0 high-/low-level width tKH2, 4.5 V ≤ VDD ≤ 5.5 V 400 ns

tKL2 3.5 V ≤ VDD < 4.5 V 800 ns

SI0 setup time (to SCK0↑)tSIK2 100 ns

SI0 hold time (from SCK0↑)tKSI2 400 ns

SO0 output delay time from SCK0↓ tKSO2 C = 100 pF

Note

300 ns

SCK0 rising or falling edge time tR2, tF2 1000 ns

Note C is the load capacitance of the SO0 output line.

29

Page 30

µ

PD178P018

(iii) SBI mode (SCK0 ... internal clock output)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK0 cycle time tKCY3 4.5 V ≤ VDD ≤ 5.5 V 800 ns

3.5 V ≤ VDD < 4.5 V 3200 ns

SCK0 high-/low-level width tKH3, 4.5 V ≤ VDD ≤ 5.5 V

tKL3 3.5 V ≤ VDD < 4.5 V

SB0, SB1 setup time (to SCK0↑)tSIK3 4.5 V ≤ VDD ≤ 5.5 V 100 ns

3.5 V ≤ VDD < 4.5 V 300 ns

SB0, SB1 hold time (from SCK0↑)

SB0, SB1 output delay time from tKSO3 R = 1 kΩ 4.5 V ≤ VDD ≤ 5.5 V 0 250 ns

SCK0↓

SB0, SB1↓ from SCK0

SCK0↓ from SB0, SB1↓ tSBK tKCY3 ns

SB0, SB1 high-level width tSBH tKCY3 ns

SB0, SB1 low-level width tSBL tKCY3 ns

↑

tKSI3 tKCY3/2 ns

C = 100 pF

tKSB tKCY3 ns

Note

3.5 V ≤ VDD < 4.5 V 0 1000 ns

tKCY3/2 – 50

tKCY3/2 – 150

Note R and C are the load resistance and load capacitance of the SB0 and SB1 output lines.

(iv) SBI mode (SCK0 ... external clock input)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK0 cycle time tKCY4 4.5 V ≤ VDD ≤ 5.5 V 800 ns

3.5 V ≤ VDD < 4.5 V 3200 ns

ns

ns

SCK0 high-/low-level width tKH4, 4.5 V ≤ VDD ≤ 5.5 V 400 ns

tKL4 3.5 V ≤ VDD < 4.5 V 1600 ns

SB0, SB1 setup time (to SCK0↑)tSIK4 4.5 V ≤ VDD ≤ 5.5 V 100 ns

3.5 V ≤ VDD < 4.5 V 300 ns

SB0, SB1 hold time (from SCK0↑)

SB0, SB1 output delay time from tKSO4 R = 1 kΩ 4.5 V ≤ VDD ≤ 5.5 V 0 300 ns

SCK0↓

SB0, SB1↓ from SCK0

SCK0↓ from SB0, SB1↓ tSBK tKCY4 ns

SB0, SB1 high-level width tSBH tKCY4 ns

SB0, SB1 low-level width tSBL tKCY4 ns

SCK0 rising or falling edge time tR4, tF4 1000 ns

↑

tKSI4 tKCY4/2 ns

C = 100 pF

tKSB tKCY4 ns

Note

3.5 V ≤ VDD < 4.5 V 0 1000 ns

Note R and C are the load resistance and load capacitance of the SB0 and SB1 output lines.

30

Page 31

µ

PD178P018

(v) 2-wire serial I/O mode (SCK0 ... internal clock output)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK0 cycle time tKCY5 R = 1 kΩ 1600 ns

SCK0 high-level width tKH5

C = 100 pF

Note

tKCY5/2 – 160

ns

SCK0 low-level width t KL5 4.5 V ≤ VDD ≤ 5.5 V

3.5 V ≤ VDD < 4.5 V

SB0, SB1 setup time (to SCK0↑)tSIK5 4.5 V ≤ VDD ≤ 5.5 V 300 ns

3.5 V ≤ VDD < 4.5 V 350 ns

SB0, SB1 hold time (from SCK0↑)

SB0, SB1 output delay time from tKSO5 0 300 ns

SCK0↓

tKSI5 600 ns

tKCY5/2 – 50

tKCY5/2 – 100

400 ns

ns

ns

Note R and C are the load resistance and load capacitance of the SCK0, SB0, and SB1 output lines.

(vi) 2-wire serial I/O mode (SCK0 ... external clock input)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK0 cycle time tKCY6 1600 ns

SCK0 high-level width tKH6 650 ns

SCK0 low-level width t KL6 800 ns

SB0, SB1 setup time (to SCK0↑)tSIK6 100 ns

SB0, SB1 hold time (from SCK0↑)

SB0, SB1 output delay time from tKSO6 R = 1 kΩ 4.5 V ≤ VDD ≤ 5.5 V 0 300 ns

SCK0↓

tKSI6 tKCY6/2 ns

C = 100 pF

Note

3.5 V ≤ VDD < 4.5 V 0 500 ns

SCK0 at rising or falling edge time tR6, tF6 1000 ns

Note R and C are the load resistance and load capacitance of the SB0 and SB1 output lines.

31

Page 32

µ

PD178P018

(vii) I2C bus mode (SCL ... internal clock output)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCL cycle time tKCY7 R = 1 kΩ 10

SCL high-level width tKH7

SCL low-level width tKL7 tKCY7 – 50 ns

SDA0, SDA1 setup time (to SCL↑)

SDA0, SDA1 hold time tKSI7 0ns

(from SCL↓)

SDA0, SDA1 output delay time tKSO7 4.5 V ≤ VDD ≤ 5.5 V 0 300 ns

(from SCL↓)

SDA0, SDA1↓ from SCL↑ or tKSB 200 ns

SDA0, SDA1↑ from SCL

SCL↓ from SDA0, SDA1↓ tSBK 400 ns

SDA0, SDA1 high-level width tSBH 500 ns

↑

tSIK7 200 ns

C = 100 pF

Note

3.5 V ≤ VDD < 4.5 V 0 500 ns

tKCY7 – 160

µ

ns

s

Note R and C are the load resistance and load capacitance of the SCL, SDA0, and SDA1 output lines.

(viii) I2C bus mode (SCL ... external clock input)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCL cycle time tKCY8 1000 ns

SCL high-/low-level width tKH8, tKL8 400 ns

SDA0, SDA1 setup time (to SCL↑)

SDA0, SDA1 hold time tKSI8 0ns

(from SCL↓)

SDA0, SDA1 output delay time tKSO8 R = 1 kΩ 4.5 V ≤ VDD ≤ 5.5 V 0 300 ns

from SCL↓

SDA0, SDA1↓ from SCL↑ or tKSB 200 ns

SDA0, SDA1↑ from SCL↑

SCL↓ from SDA0, SDA1↓ tSBK 400 ns

SDA0, SDA1 high-level width tSBH 500 ns

SCL rising or falling edge time tR8, tF8 1000 ns

tSIK8 200 ns

C = 100 pF

Note

3.5 V ≤ VDD < 4.5 V 0 500 ns

Note R and C are the load resistance and load capacitance of the SDA0 and SDA1 output lines.

32

Page 33

µ

PD178P018

(b) Serial interface channel 1

(i) 3-wire serial I/O mode (SCK1 ... internal clock output)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK1 cycle time tKCY9 4.5 V ≤ VDD ≤ 5.5 V 800 ns

3.5 V ≤ VDD < 4.5 V 1600 ns

SCK1 high-/low-level width tKH9, 4.5 V ≤ VDD ≤ 5.5 V

tKL9 3.5 V ≤ VDD < 4.5 V

SI1 setup time (to SCK1↑)tSIK9 4.5 V ≤ VDD ≤ 5.5 V 100 ns

3.5 V ≤ VDD < 4.5 V 150 ns

SI1 hold time (from SCK1↑)tKSI9 400 ns

SO1 output delay time (from SCK1↓)

tKSO9 C = 100 pF

Note

tKCY9/2 – 50

tKCY9/2 – 100

ns

ns

300 ns

Note C is the load capacitance of the SO1 output line.

(ii) 3-wire serial I/O mode (SCK1 ... external clock input)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK1 cycle time tKCY10 4.5 V ≤ VDD ≤ 5.5 V 800 ns

3.5 V ≤ VDD < 4.5 V 1600 ns

SCK1 high-/low-level width tKH10, 4.5 V ≤ VDD ≤ 5.5 V 400 ns

tKL10 3.5 V ≤ VDD < 4.5 V 800 ns

SI1 setup time (to SCK1↑)tSIK10 100 ns

SI1 hold time (from SCK1↑)tKSI10 400 ns

SO1 output delay time (from SCK1↓

)tKSO10 C = 100 pF

Note

300 ns

SCK1 rising or falling edge time tR10, tF10 1000 ns

Note C is the load capacitance of the SO1 output line.

33

Page 34

µ

PD178P018

(iii) 3-wire serial I/O mode with automatic transmit/receive function (SCK1 ... internal clock

output)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK1 cycle time tKCY11 4.5 V ≤ VDD ≤ 5.5 V 800 ns

3.5 V ≤ VDD < 4.5 V 1600 ns

SCK1 high-/low-level width tKH11, 4.5 V ≤ VDD ≤ 5.5 V

tKL11 3.5 V ≤ VDD < 4.5 V

SI1 setup time (to SCK1↑)tSIK11 4.5 V ≤ VDD ≤ 5.5 V 100 ns

3.5 V ≤ VDD < 4.5 V 150 ns

SI1 hold time (from SCK1↑)tKSI11 400 ns

SO1 output delay time (from SCK1↓

STB↑ from SCK1

Strobe signal high-level width tSBW

Busy signal setup time tBYS 100 ns

(to busy signal detection timing)

Busy signal hold time tBYH 4.5 V ≤ VDD ≤ 5.5 V 100 ns

(from busy signal detection timing)

SCK1↓ from busy inactive tSPS 2tKCY11 ns

↑

)tKSO11 C = 100 pF

tSBD

3.5 V ≤ VDD < 4.5 V 150 ns

Note

tKCY11/2 – 50

tKCY11/2 – 100

300 ns

tKCY11/2 – 100 tKCY11/2 + 100

tKCY11 – 30 tKCY11 + 30

ns

ns

ns

ns

Note C is the load capacitance of the SO1 output line.

(iv) 3-wire serial I/O mode with automatic transmit/receive function (SCK1 ... external clock

input)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK1 cycle time tKCY12 4.5 V ≤ VDD ≤ 5.5 V 800 ns

3.5 V ≤ VDD < 4.5 V 1600 ns

SCK1 high-/low-level width tKH12, 4.5 V ≤ VDD ≤ 5.5 V 400 ns

tKL12 3.5 V ≤ VDD < 4.5 V 800 ns

SI1 setup time (to SCK1↑)tSIK12 100 ns

SI1 hold time (from SCK1↑)tKSI12 400 ns

SO1 output delay time (from SCK1↓

SCK1 rising or falling edge time tR12, tF12 1000 ns

)tKSO12 C = 100 pF

Note

300 ns

Note C is the load capacitance of the SO1 output line.

34

Page 35

AC Timing Test Point (Excluding X1 Input)

0.8V

DD

0.2V

DD

TI Timing

TI1, TI2

Interrupt Input Timing

Test Points

t

TIL

1/f

µ

PD178P018

0.8V

DD

0.2V

DD

TI

t

TIH

INTP0 to INTP6

RESET Input Timing

RESET

t

INTL

t

INTH

t

RSL

35

Page 36

Serial Transfer Timing

3-Wire Serial I/O Mode:

SCK0, SCK1

t

KLm

µ

PD178P018

t

KCYm

t

KHm

t

Rn

t

t

SIKm

KSIm

t

Fn

SI0, SI1

t

KSOm

SO0, SO1

Remark m = 1, 2, 9, 10

n = 2, 10

SBI Mode (Bus Release Signal Transfer):

SCK0

tKSB tSBL tSBH tSBK

Input Data

Output Data

tKCY3, 4

tKL3, 4 tKH3, 4

tF4tR4

tSIK3, 4

tKSI3, 4

SB0, SB1

36

tKSO3, 4

Page 37

SBI Mode (Command Signal Transfer):

SCK0

t

KSB

SB0, SB1

2-Wire Serial I/O Mode:

µ

PD178P018

t

KCY3, 4

t

KL3, 4

t

R4

t

SBK

t

KH3, 4

t

KSO3, 4

t

F4

t

SIK3, 4

t

KSI3, 4

2

I

C Bus Mode:

SCL

SDA0, SDA1

t

SBH

SB0, SB1

F8

t

t

SBK

SCK0

t

KL7, 8

t

KCY5, 6

t

KL5, 6

t

R6

t

t

KH7, 8

SIK5, 6

t

KSO5, 6

t

R8

t

KSI7, 8

t

KCY7, 8

t

KSO7, 8

t

KH5, 6

t

SIK7, 8

t

KSI5, 6

t

F6

t

KSB

t

SBK

t

KSB

37

Page 38

3-Wire Serial I/O Mode with Automatic Transmit/Receive Function:

µ

PD178P018

SO1

SI1

D2 D1 D0

D2 D1 D0

t

t

KH11, 12

KSI11, 12

t

F12

t

SIK11, 12

t

KSO11, 12

SCK1

t

t

KL11, 12

t

KCY11, 12

R12

t

SBD

t

SBW

STB

3-Wire Serial I/O Mode with Automatic Transmit/Receive Function (Busy Processing):

789

Note

Note

10

t

t

BYS

BYH

10+n

Note

t

D7

D7

1SCK1

SPS

BUSY

(Active high)

Note The signal is not actually driven low here; it is shown as such to indicate the timing.

38

Page 39

µ

PD178P018

A/D CONVERTER CHARACTERISTICS (TA = –40 to +85°C, VDD = 4.5 to 5.5 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Resolution 8 8 8 bit

Conversion total ±3.0 LSB

error

Conversion time tCONV 22.2 44.4

Sampling time tSAMP 15/fXX

Analog input VIAN 0VDD V

voltage

Remarks 1. fXX : System clock frequency (fX/2)

X: System clock oscillation frequency

2. f

PLL CHARACTERISTICS (TA = –40 to +85°C, VDD = 4.5 to 5.5 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Operating fIN1 VCOL Pin MF Mode Sine wave input VIN = 0.1 Vp-p 0.5 3 MHz

frequency

fIN2 VCOL Pin HF Mode Sine wave input VIN = 0.2 Vp-p 9 55 MHz

fIN3 VCOH Pin VHF Mode Sine wave input VIN = 0.15 Vp-p 60 160 MHz

µ

s

µ

s

IFC CHARACTERISTICS (TA = –40 to +85°C, VDD = 4.5 to 5.5 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Operating fIN4 AMIFC Pin AMIF Count Mode 0.4 0.5 MHz

frequency Sine wave input VIN = 0.1 Vp-p

fIN5 FMIFC Pin FMIF Count Mode 10 11 MHz

Sine wave input VIN = 0.1 Vp-p

fIN6 FMIFC Pin AMIF Count Mode 0.4 0.5 MHz

Sine wave input VIN = 0.1 Vp-p

Note

Note

Note

Note The condition of a sine wave input of VIN = 0.1 Vp-p is the standard value for operation of this device during

stand-alone operation, so in consideration of the effect of noise, it is recommended that operation be at

an input amplitude condition of VIN = 0.15 Vp-p.

39

Page 40

PROM PROGRAMMING CHARACTERISTICS

DC CHARACTERISTICS

µ

PD178P018

(1) PROM Write Mode (T

Parameter Symbol Symbol

Input voltage, high VIH VIH 0.7VDD VDD V

Input voltage, low VIL VIL 0 0.3VDD V

Output voltage, high VOH VOH IOH = –1 mA VDD – 1.0 V

Output voltage, low VOL VOL IOL = 1.6 mA 0.4 V

Input leakage current ILI ILI 0 ≤ VIN ≤ VDD –10 +10 µA

VPP supply voltage VPP VPP 12.2 12.5 12.8 V

VDD supply voltage VDD VCC 6.25 6.5 6.75 V

VPP supply current IPP IPP PGM = VIL 50 mA

VDD supply current IDD ICC 50 mA

A = 25 ±5°C, VDD = 6.5 ±0.25 V, VPP = 12.5 ±0.3 V)

Note

Test Conditions MIN. TYP. MAX. Unit

(2) PROM Read Mode (TA = 25 ±5°C, VDD = 5.0 ±0.5 V, VPP = VDD ±0.6 V)

Parameter Symbol Symbol

Input voltage, high VIH VIH 0.7VDD VDD V

Input voltage, low VIL VIL 0 0.3VDD V

Output voltage, high VOH1 VOH1 IOH = –1 mA VDD – 1.0 V

VOH2 VOH2 IOH = –100 µAVDD – 0.5 V

Output voltage, low VOL VOL IOL = 1.6 mA 0.4 V

Input leakage current ILI ILI 0 ≤ VIN ≤ VDD –10 +10 µA

Output leakage current ILO ILO 0 ≤ VOUT ≤ VDD, OE = VIH –10 +10 µA

VPP supply voltage VPP VPP VDD – 0.6 V DD VDD + 0.6 V

VDD supply voltage VDD VCC 4.5 5.0 5.5 V

VPP supply current IPP IPP VPP = VDD 100 µA

VDD supply current IDD ICCA1 CE = VIL, VIN = VIH 50 mA

Note

Test Conditions MIN. TYP. MAX. Unit

Note Corresponding µPD27C1001A symbol.

40

Page 41

AC CHARACTERISTICS

(1) PROM Write Mode

µ

PD178P018

(a) Page program mode (T

Parameter Symbol

Address setup time (to OE ↓)tAS tAS 2 µs

OE setup time tOES tOES 2 µs

CE setup time (to OE ↓)tCES tCES 2 µs

Input data setup time (to OE ↓)tDS tDS 2 µs

Address hold time (from OE ↑)tAH tAH 2 µs

Input data hold time (from OE ↑)tDH tDH 2 µs

Data output float delay time tDF tDF 0 250 ns

from OE ↑

VPP setup time (to OE ↓)tVPS tVPS 1.0 ms

VDD setup time (to OE ↓)tVDS tVCS 1.0 ms

Program pulse width tPW tPW 0.095 0.1 0.105 ms

Valid data delay time from OE ↓ tOE tOE 1 µs

OE pulse width during data tLW tLW 1 µs

latching

PGM setup time tPGMS tPGMS 2 µs

CE hold time tCEH tCEH 2 µs

OE hold time tOEH tOEH 2 µs

A = 25 ±5°C, VDD = 6.5 ±0.25 V, VPP = 12.5 ±0.3 V)

Note

Symbol

tAHL tAHL 2 µs

tAHV tAHV 0 µs

Test Conditions MIN. TYP. MAX. Unit

(b) Byte program mode (TA = 25 ±5°C, VDD = 6.5 ±0.25 V, VPP = 12.5 ±0.3 V)

Parameter Symbol

Address setup time (to PGM ↓)tAS tAS 2 µs

OE set time tOES tOES 2 µs

CE setup time (to PGM ↓)tCES tCES 2 µs

Input data setup time (to PGM ↓)tDS tDS 2 µs

Address hold time (from OE ↑)tAH tAH 2 µs

Input data hold time tDH tDH 2 µs

(from PGM ↑)

Data output float delay time tDF tDF 0 250 ns

from OE ↑

VPP setup time (to PGM ↓)tVPS tVPS 1.0 ms

VDD setup time (to PGM ↓)tVDS tVCS 1.0 ms

Program pulse width tPW tPW 0.095 0.1 0.105 ms

Valid data delay time from OE ↓ tOE tOE 1 µs

OE hold time tOEH —2µs

Symbol

Note

Test Conditions MIN. TYP. MAX. Unit

Note Corresponding µPD27C1001A symbol.

41

Page 42

(2) PROM Read Mode (TA = 25 ±5°C, VDD = 5.0 ±0.5 V, VPP = VDD ±0.6 V)

µ

PD178P018

Parameter Symbol

Data output delay time from tACC tACC CE = OE = VIL 800 ns

address

Data output delay time CE ↓ tCE tCE OE = VIL 800 ns

Data output delay time OE ↓ t OE tOE CE = VIL 200 ns

Data output float delay time tDF tDF CE = VIL 060ns

from OE ↑

Data hold time to address tOH tOH CE = OE = VIL 0ns

Symbol

Note

Test Conditions MIN. TYP. MAX. Unit

Note Corresponding µPD27C1001A symbol.

(3) PROM Programming Mode Setting (T

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

PROM programming mode tSMA 10 µs

setup time

A = 25°C, VSS = 0 V)

42

Page 43

PROM Write Mode Timing (page program mode)

Page Data Latch Page Program Program Verify

A2 to A16

µ

PD178P018

V

DD

V

CE

PGM

OE

A0, A1

D0 to D7

PP

VDD + 1.5

t

LW

t

AHL

t

DH

Data Input

t

AHV

t

DF

Hi-Z Hi-Z

t

PGMS

t

CES

t

CEH

t

PW

Data

t

OE

Output

t

OES

t

t

OEH

AH

t

AS

t

DS

Hi-Z

t

VPS

V

PP

V

DD

t

VDS

V

DD

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

43

Page 44

PROM Write Mode Timing (byte program mode)

Program Program Verify

A0 to A16

t

AS

µ

PD178P018

t

DF

Hi-Z Hi-Z Hi-Z

t

DS

V

PP

V

DD

t

VPS

Data Input Data Output

t

DH

V

PP

D0 to D7

VDD + 1.5

V

DD

V

DD

IH

V

t

VDS

CE

V

IL

IH

V

t

CES

t

PW

PGM

V

IL

IH

V

t

OES

t

OE

OE

V

IL

Cautions 1. VDD should be applied before VPP, and removed after VPP.

PP must not exceed +13.5 V including overshoot.

2. V

3. Reliability may be adversely affected if removal/reinsertion is performed while + 12.5 V is being

applied to VPP.

t

AH

t

OEH

PROM Read Mode Timing

A0 to A16 Effective Address

IH

V

CE

V

IL

IH

V

CE

t

OE

V

D0 to D7

IL

t

ACC

Note1

Hi-Z

Note 1

t

OE

t

OH

Data Output

Note 2

t

DF

Hi-Z

Notes 1. If you want to read within the range of tACC, make the OE input delay time from the fall of CE a maximum

of t

ACC – tOE.

DF is the time from when either OE or CE first reaches VIH.

2. t

44

Page 45

PROM Programming Mode Setting Timing

DD

V

V

DD

0

RESET

V

DD

V

PP

0

A0 to A16 Effective Address

t

SMA

µ

PD178P018

45

Page 46

7. PACKAGE DRAWINGS

80 PIN PLASTIC QFP (14×14)

µ

PD178P018

A

B

61

60

41

40

CD

80

1

20

21

F

G

M

H

I

P

J

K

N

L

NOTE

Each lead centerline is located within 0.13 mm (0.005 inch) of

its true position (T.P.) at maximum material condition.

detail of lead end

S

Q

R

M

ITEM MILLIMETERS INCHES

A 17.2±0.4 0.677±0.016

B 14.0±0.2 0.551

C 14.0±0.2 0.551

D 17.2±0.4 0.677±0.016

F 0.825 0.032

G 0.825 0.032

H 0.30±0.10 0.012

I 0.13 0.005

J 0.65 (T.P.) 0.026 (T.P.)

K 1.6±0.2 0.063±0.008

L 0.8±0.2 0.031

M 0.15 0.006

N 0.10 0.004

P 2.7 0.106

Q 0.1±0.1 0.004±0.004

R5°±5° 5°±5°

S 3.0 MAX. 0.119 MAX.

+0.10

–0.05

+0.009

–0.008

+0.009

–0.008

+0.004

–0.005

+0.009

–0.008

+0.004

–0.003

S80GC-65-3B9-4

46

Page 47

80 PIN CERAMIC WQFN

µ

PD178P018

A

B

T

U1

U

NOTE

Each lead centerline is located within 0.06

mm (0.003 inch) of its true position (T.P.) at

maximum material condition.

K

C

D

W

G

F

Z

ITEM MILLIMETERS INCHES

A

B

C

D

F

G

H

I

J

K

Q

R

S

T R 2.0 R 0.079

U

U1 2.1 0.083

W

Z 0.10 0.004

14.0±0.2

13.6

13.6

14.0±0.2

1.84

3.6 MAX.

0.45±0.10

0.06

0.65 (T.P.)

1.0±0.15

C 0.3

0.825

0.825

9.0

0.75±0.15

M

IH

J

X80KW-65A-1

0.551±0.008

0.535

0.535

0.551±0.008

0.072

0.142 MAX.

+0.004

0.018

–0.005

0.003

0.024 (T.P.)

+0.007

0.039

–0.006

C 0.012

0.032

0.032

0.354

+0.006

0.030

–0.007

Q

80

1

S

R

47

Page 48

µ

PD178P018

8. RECOMMENDED SOLDERING CONDITIONS

This product should be soldered and mounted under the conditions recommended in the table below.

For detail of recommended soldering conditions, refer to the information document “Semiconductor Device

Mounting Technology Manual” (C10535E).

For soldering methods and conditions other than those recommended below, contact an NEC sales representa-

tive.

Table 8-1. Surface Mounting Type Soldering Conditions

µ

PD178P018GC-3B9: 80-pin plastic QFP (14 × 14 mm, 0.65-mm pitch)

Soldering Method

Infrared reflow

VPS

Wave soldering

Partial heating

Soldering Conditions

Package peak temperature: 235°C, Duration: 30 sec. max. (at 210°C or above),

Number of times: Three times max.

Exposure limit: 7 days

(Points to note)

Do not bake components in any packaging except heat-resistant trays, that is

components in magazines, tape, or non-heat-resistant trays.

Package peak temperature: 215°C, Duration: 40 sec. max. (at 200°C or above),

Number of times: Three times max.

Exposure limit: 7 days

(Points to note)

Do not bake components in any packaging except heat-resistant trays, that is

components in magazines, tape, or non-heat-resistant trays.

Solder bath temperature : 260°C max., Duration : 10 sec. max., Number of times

: once, Preheating temperature : 120°C max.

(package surface temperature)

Exposure limit: 7 days

(Points to note)

Do not bake components in any packaging except heat-resistant trays, that is

components in magazines, tape, or non-heat-resistant trays.

Pin temperature: 300°C max. Duration: 3 sec. max. (per pin row)

Note

(20 hours pre-baking is required at 125°C afterwards)

Note

(20 hours pre-baking is required at 125°C afterwards)

Note

(20 hours pre-baking is required at 125°C afterwards)

Recommended

Condition Symbol

IR35-207-3

VP15-207-3

WS60-207-1

—

Note Exposure limit before soldering after the dry pack package is opened. Storage conditions: 25°C and

relative humidity at 65% or less.

Caution Do not use different soldering method together (except for partial heating).

48

Page 49

µ

PD178P018

APPENDIX A. DEVELOPMENT TOOLS

The following development tools are available for system development using the µPD178P018 Subseries.

LANGUAGE PROCESSING SOFTWARE

RA78K/0

CC78K/0

DF178018

CC78K/0-L

Notes 1, 2, 3, 4

Notes 1, 2, 3, 4

Notes 1, 2, 3, 4

Notes 1, 2, 3, 4

78K/0 Series common assembler package

78K/0 Series common C compiler package

µ

PD178018 Subseries common device file

78K/0 Series common C compiler library source file

PROM WRITING TOOLS

PG-1500 PROM writer

PG-178P018GC

Program writer adapters connected to a PG-1500

PA-178P018KK-T

PG-1500 controller

Notes 1, 2

PG-1500 control program

DEBUGGING TOOLS

IE-78000-R In-circuit emulator common to 78K/0 Series

IE-78000-R-A In-circuit emulator common to 78K/0 Series (for the integrated debugger)

IE-78000-R-BK Break board common to 78K/0 Series

IE-178018-R-EM Emulation board common to µPD178018 Subseries

EP-78230GC-R Emulation probe common to µPD78234 Subseries

EV-9200GC-80 Socket for mounting on target system board created for 80-pin plastic QFP (GC-3B9 type)

EV-9900 Jig used when removing the µPD178P018KK-T from the EV-9200GC-80.

SM78K0

ID78K0

SD78K/0

DF178018

Notes 5, 6, 7

Notes 4, 5, 6, 7

Notes 1, 2

Notes 1, 2, 4, 5, 6, 7

78K/0 series common system simulator

Integrated debugger for IE-78000-R-A

IE-78000-R screen debugger

µ

PD178018 Subseries device file

REAL-TIME OS

RX78K/0

MX78K0

Notes 1, 2, 3, 4

Notes 1, 2, 3, 4

78K/0 Series real-time OS

78K/0 Series OS

Notes 1. PC-9800 Series (MS-DOSTM) based

2. IBM PC/AT

3. HP9000 series 300

4. HP9000 series 700

TM

and compatibles (PC DOSTM/IBM DOSTM/MS-DOS) based

TM

(HP-UX™) based

TM

(HP-UXTM) based, SPARCstationTM (SunOSTM) based, EWS4800 series (EWS-

UX/V) based

5. PC-9800 series (MS-DOS + WindowsTM) based

6. IBM PC/AT and compatibles (PC DOS/IBM DOS/MS-DOS + Windows) based

7. NEWSTM (NEWS-OSTM) based

49

Page 50

FUZZY INFERENCE DEVELOPMENT SUPPORT SYSTEM

µ

PD178P018

FE9000

FT9080

FI78K0

FD78K0

Note 1

Note 1

/FT9085

Notes 1, 3

Notes 1, 3

/FE9200

Note 2

Note 3

Fuzzy knowledge data creation tool

Translator

Fuzzy inference module

Fuzzy inference debugger

Notes 1. PC-9800 series (MS-DOS) based

2. IBM PC/AT and its compatibles (PC DOS/IBM DOS/MS-DOS + Windows) based

3. IBM PC/AT and its compatibles (PC DOS/IBM DOS/MS-DOS) based

Remarks 1. Please refer to the 78K/0 Series Selection Guide (U11126E) for information on third party

development tools.

2. The RA78K/0, CC78K/0, SD78K/0, ID78K/0, SM78K/0, and RX78K/0 are used in combination with

the DF178018.

50

Page 51

CONVERSION SOCKET DRAWING AND RECOMMENDED FOOTPRINT

Figure A-1. Drawing of EV-9200GC-80 (for Reference only)

Based on EV-9200GC-80

(1) Package drawing (in mm)

µ

PD178P018

E

C

D

No.1 pin index

EV-9200GC-80

1

A

B

F

G

H

I

ITEM MILLIMETERS INCHES

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

M

N O

18.0

14.4

14.4

18.0

4-C 2.0

0.8

6.0

16.0

18.7

6.0

16.0

18.7

8.2

8.0

2.5

2.0

0.35

φ

2.3

φ

1.5

R

J

Q

P

EV-9200GC-80-G1E

0.709

0.567

0.567

0.709

4-C 0.079

0.031

0.236

0.63

0.736

0.236

0.63

0.736

0.323

0.315

0.098

0.079

0.014

φ

0.091

φ

0.059

S

L

K

51

Page 52

Figure A-2. Recommended Footprint of EV-9200GC-80 (for Reference only)

Based on EV-9200GC-80

(2) Pad drawing (in mm)

G

J

K

F

E

D

L

C

B

A

HI

µ

PD178P018

EV-9200GC-80-P1E

ITEM MILLIMETERS INCHES

+0.001

–0.002

+0.001

–0.002

0.776

0.591

0.591

0.776

0.236

0.236

0.014

φ

0.093

φ

0.091

φ

0.062

+0.003

–0.002

+0.003

–0.002

+0.001

–0.001

+0.001

–0.002

+0.001

–0.002

A

B

C

D

E

F

G

H

I

J

K

L

Caution

19.7

15.0

±

0.65

0.02 × 19=12.35

±

0.65

0.02 × 19=12.35

±

0.026 × 0.748=0.486

0.05

±

0.026 × 0.748=0.486

0.05

15.0

19.7

6.0±0.05

6.0±0.05

0.35±0.02

φ

2.36±0.03

φ

2.3

φ

1.57±0.03

Dimensions of mount pad for EV-9200 and that for target

device (QFP) may be different in some parts. For the

recommended mount pad dimensions for QFP, refer to

"SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY

MANUAL" (C10535E).

+0.003

–0.002

+0.003

–0.002

52

Page 53

APPENDIX B. RELATED DOCUMENTS

DEVICE DOCUMENTS

µ

PD178P018

Title

µ

PD178018 Subseries User’s Manual U11410J U11410E

78K/0 Series User’s Manual—Instruction U12326J IEU-1372

78K/0 Series Instruction Set U10904J —

78K/0 Series Instruction Table U10903J —

µ

PD178018 Subseries Special Function Register Table To be prepared —

78K/0 Series Application Note Basics (II) U10121J U10121E

Document No. Document No.

(Japanese) (English)

Development Tool Documents (User’s Manual)

Title

RA78K Series Assembler Package Operation EEU-809 EEU-1399

Language EEU-815 EEU-1404

RA78K Series Structured Assembler Preprocessor EEU-817 EEU-1402

CC78K Series C Compiler Operation EEU-656 EEU-1280

Language EEU-655 EEU-1284

CC78K/0 C Compiler Operation U11517J U11517E

Language U11518J U11518E

CC78K/0 C Compiler Application Note

CC78K Series Library Source File U12322J —

PG-1500 PROM Programmer U11940J EEU-1335

PG-1500 Controller PC-9800 Series (MS-DOS) Based EEU-704 EEU-1291

PG-1500 Controller IBM PC Series (PC DOS) Based EEU-5008 U10540E

IE-78000-R U11376J U11376E

IE-78000-R-A U10057J U10057E

IE-78000-R-BK EEU-867 EEU-1427

IE-178018-R-EM U10668J U10668E

EP-78230 EEU-985 EEU-1515

SM78K0 System Simulator Windows Based Reference U10181J U10181E

SM78K Series System Simulator U10092J U10092E

Programming Know-how

External Parts User

Open Interface

Specifications

Document No. Document No.

(Japanese) (English)

EEA-618 EEA-1208

ID78K0 Integrated Debugger EWS Based Reference U11151J —

ID78K0 Integrated Debugger PC Based Reference U11539J U11539E

ID78K0 Integrated Debugger Windows Based Guide U11649J U11649E

SD78K/0 Screen Debugger PC-9800 Series (MS-DOS) Based

SD78K/0 Screen Debugger IBM PC/AT (PC DOS) Based Introduction EEU-5024 EEU-1414

Introduction EEU-852 U10539E

Reference U10952J —

Reference U11279J U11279E

Caution The contents of the above documents are subject to change without notice. Please ensure that

the latest versions are used in design work, etc.

53

Page 54

RELATED DOCUMENTS FOR EMBEDDED SOFTWARE (USER’S MANUAL)

µ

PD178P018

Title

78K/0 Series Realtime OS Basics U11537J —

Installation U11536J —

Technical U11538J —

78K/0 Series OS MX78K0 Basics EEU-5010 —

Fuzzy Knowledge Data Creation Tool EEU-829 EEU-1438

78K/0, 78K/II, 87AD Series EEU-862 EEU-1444

Fuzzy Inference Development Support System—Translator

78K/0 Series Fuzzy Inference Development Support System—

78K/0 Series Fuzzy Inference Development Support System EEU-921 EEU-1458

—Fuzzy Inference Debugger

Fuzzy Inference Module

Document No. Document No.

(Japanese) (English)

EEU-858 EEU-1441

OTHER DOCUMENTS

Title

IC Package Manual C10943X

Semiconductor Device Mounting Technology Manual C10535J C10535E

Quality Guides on NEC Semiconductor Devices C11531J C11531E

NEC Semiconductor Device Reliability and Quality Control System C10983J C10983E

Electrostatic Discharge (ESD) Test MEM-539 —

Semiconductor Device Quality Assurance Guide C11893J C11893E

Microcomputer-related Product Guide (Products by other Manufacturers) U11416J —

Document No. Document No.

(Japanese) (English)

Caution The contents of the above documents are subject to change without notice. Ensure that the

latest versions are used in design work, etc.

54

Page 55

[MEMO]

µ

PD178P018

55

Page 56

[MEMO]

µ

PD178P018

56

Page 57

[MEMO]

µ

PD178P018

57

Page 58

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note: Strong electric field, when exposed to a MOS device, can cause destruction of

the gate oxide and ultimately degrade the device operation. Steps must be

taken to stop generation of static electricity as much as possible, and quickly

dissipate it once, when it has occurred. Environmental control must be

adequate. When it is dry, humidifier should be used. It is recommended to avoid

using insulators that easily build static electricity. Semiconductor devices

must be stored and transported in an anti-static container, static shielding bag

or conductive material. All test and measurement tools including work bench

and floor should be grounded. The operator should be grounded using wrist

strap. Semiconductor devices must not be touched with bare hands. Similar

precautions need to be taken for PW boards with semiconductor devices on it.

µ

PD178P018

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note: No connection for CMOS device inputs can be cause of malfunction. If no

connection is provided to the input pins, it is possible that an internal input level

may be generated due to noise, etc., hence causing malfunction. CMOS device

behave differently than Bipolar or NMOS devices. Input levels of CMOS devices

must be fixed high or low by using a pull-up or pull-down circuitry. Each unused

pin should be connected to VDD or GND with a resistor, if it is considered to have

a possibility of being an output pin. All handling related to the unused pins must

be judged device by device and related specifications governing the devices.

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note: Power-on does not necessarily define initial status of MOS device. Production

process of MOS does not define the initial operation status of the device.

Immediately after the power source is turned ON, the devices with reset function

have not yet been initialized. Hence, power-on does not guarantee out-pin

levels, I/O settings or contents of registers. Device is not initialized until the

reset signal is received. Reset operation must be executed immediately after

power-on for devices having reset function.

58

Page 59

µ

PD178P018

Regional Information

Some information contained in this document may vary from country to country. Before using any NEC

product in your application, please contact the NEC office in your country to obtain a list of authorized

representatives and distributors. They will verify:

• Device availability

• Ordering information