Page 1

DATA SHEET

BIPOLAR ANALOG INTEGRATED CIRCUIT

µ

PC2766GR/GS

WIDE BAND IQ DEMODULATOR FOR DIGITAL VIDEO/DATA RECEIVER

DESCRIPTION

The µPC2766GR/GS is a Silicon monolithic IC designed for use as IQ demodulator in wide dynamic range

compressed video or spread spectrum receivers. This IC consists of a wide band RF amplifier, gain control amplifier,

dual balanced mixers (DBM), Lo buffers, and I & Q output buffer amplifiers.

µ

The package is 20 pin SSOP (shrink small outline package:

for high-density surface mount.

FEATURES

• Broadband operation RF & LO up to 1 000 MHz

IF (IQ) up to 200 MHz

• Wideband IQ phase and amplitude balance Amplitude balance ±0.3 dB (TYP.)

Phase balance ±0.3 degree (TYP.)

• AGC dynamic range 45 dB

• Low distortion; IM

• Supply Voltage 5 V

• Packaged in 20 pin SSOP or 20 pin SOP suitable for high-density surface mount

3 30 dBc

PC2766GR) or 20 pin SOP (µPC2766GS) suitable

ORDERING INFORMATION

PART NUMBER PACKAGE PACKAGE STYLE

µ

PC2766GR-E1

µ

PC2766GS-E1

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for availability

and additional information.

20 pin plastic SSOP (225 mil)

20 pin plastic SOP (300 mil)

Caution electro-static sensitive device

Embossed tape 12 mm wide. 2.5 k/REEL

Pin 1 indicates pull-out direction of tape

Embossed tape 24 mm wide. 2.5 k/REEL

Pin 1 indicates pull-out direction of tape

Document No. P10193EJ4V0DS00 (4th edition)

Date Published October 1999 N CP(K)

Printed in Japan

The mark shows major revised points.

©

1995, 1999

Page 2

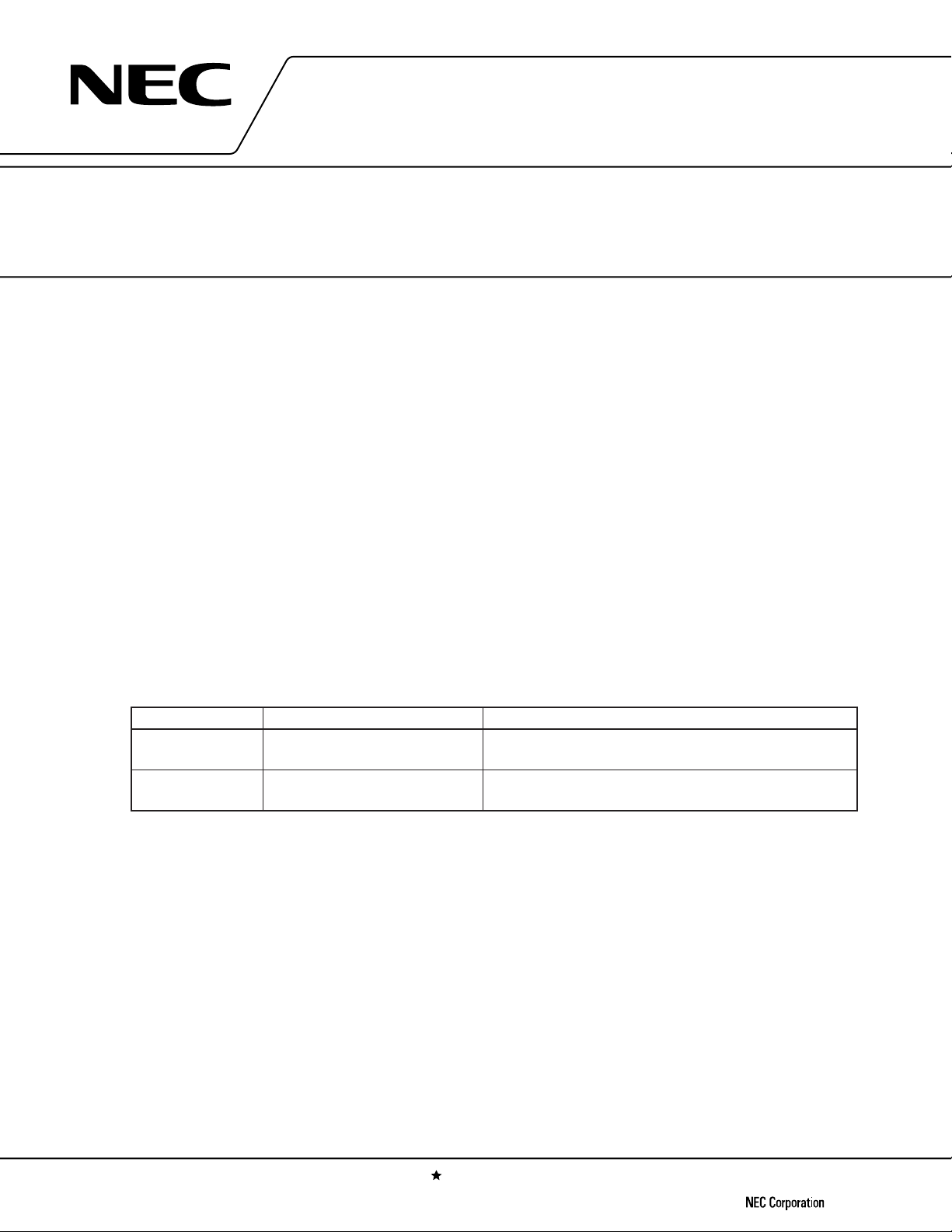

INTERNAL BLOCK DIAGRAM

µ

PC2766GR/GS

I out I out GND

20 19 18 17 16 15 14 13 12 11

I-IF Amp.

I-Lo.Buff.Amp I-Lo.Buff.Amp

I-MIX.

23

1

I trim Vcc

IF. I

Lo I Lo I Lo Q Lo Q GND

IF. I

RF AGC

RF Pre.Amp AGC cont.

4

VccRFGNDRFRF in RF in GNDRFVagc Vcc

678910

5

Q out Q out

IF. Q

I-IF Amp.

Q-MIX.

IF. Q

Q trim

2

Data Sheet P10193EJ4V0DS00

Page 3

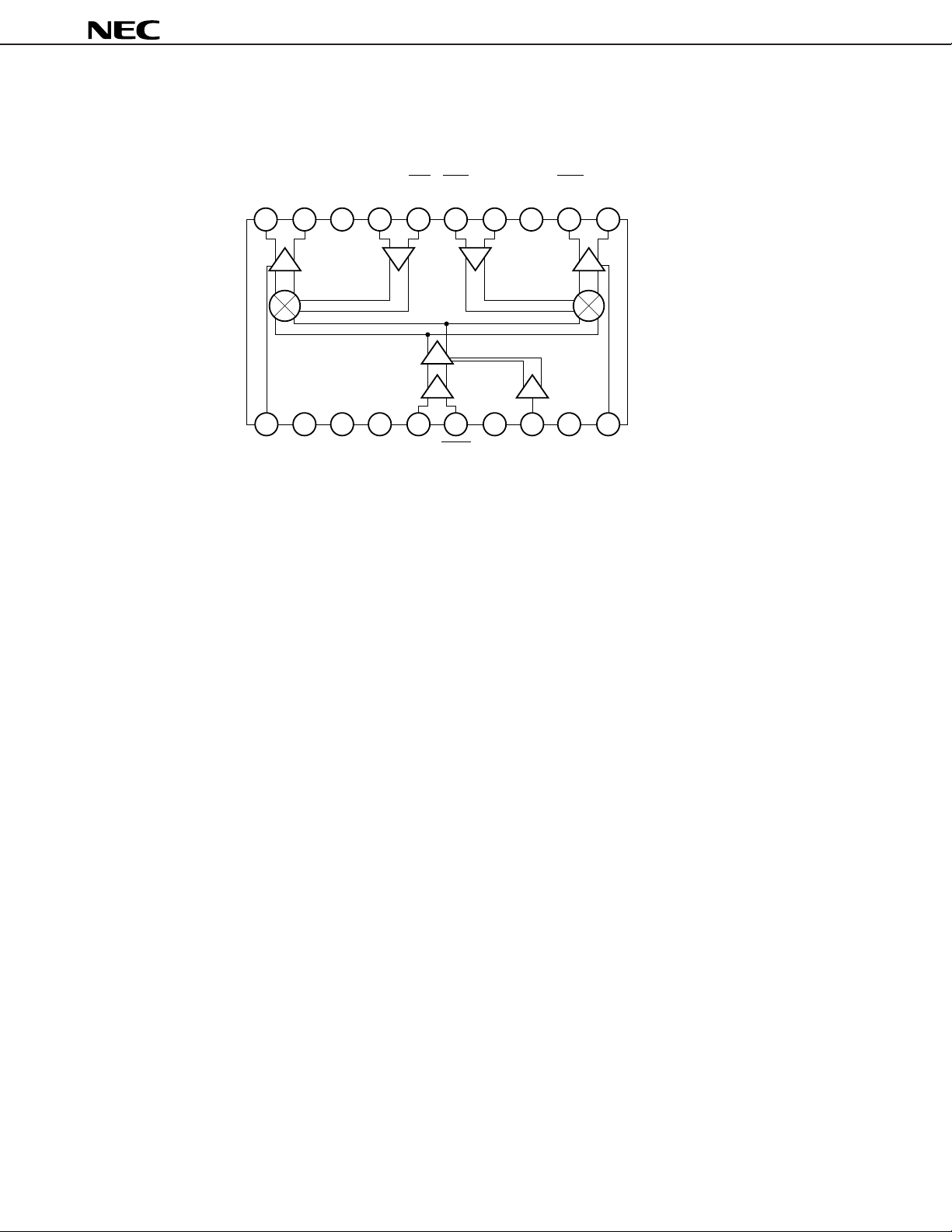

PIN FUNCTIONS

5

6

To next

block

V

CC

10

µ

PC2766GR/GS

PIN No. PIN NAME

1 I Trim 4.2 Trimming pin for I-IF output.

2VCCIF I 5.0 Power supply pin for I-MIXER.

3VCCRF 5.0 Power supply pin for RF and AGC

4 GND RF 0.0 Ground pin of RF and AGC block.

5 RFin 2.6 RF input pin. In case of single input,

6 RFin 2.6

PIN VOLTAGE

TYP. (V)

FUNCTION AND EXPLANATION EQUIVALENT CIRCUIT

block.

6 pin should be grounded through

capacitor.

V

CC

1

7 GND RF 0.0 Ground pin of RF and AGC block.

8VAGC 0 to 5 Gain control pin.

CC

• VAGC = 0 V: Full gain

• VAGC = 5 V: Maximum reduction

9VCCIF Q 5.0 Power supply pin for Q-MIXER.

10 Q Trim 4.2 Trimming pin for Q-IF output.

8

V

Data Sheet P10193EJ4V0DS00

3

Page 4

µ

PC2766GR/GS

PIN No. PIN NAME

11 Qout 3.3 Q-IF output pin. 11 pin and 12 pin

12 Qout 3.3

13 GNDIF Q 0.0 Ground pin of Q-IF block.

14 Lo Q 2.2 Oscillator signal input pin of

15 Lo Q 2.2

PIN VOLTAGE

TYP. (V)

FUNCTION AND EXPLANATION EQUIVALENT CIRCUIT

are balance outputs.

Q-MIXER. In case of single input,

15 pin should be grounded through

capacitor.

12

V

CC

11

From

before

block

+

_

CC

V

1514

16 Lo I 2.2 Oscillator signal input pin of

I-MIXER. In case of single input,

16 pin should be grounded through

capacitor.

17 Lo I 2.2

18 GNDIF I 0.0 Ground pin of I-IF block.

19 Iout 3.3 I-IF output pin. 19 pin and 20 pin

are balance outputs.

20 Iout 3.3

19

CC

V

20

_

16

V

CC

From

before

block

17

+

4

Data Sheet P10193EJ4V0DS00

Page 5

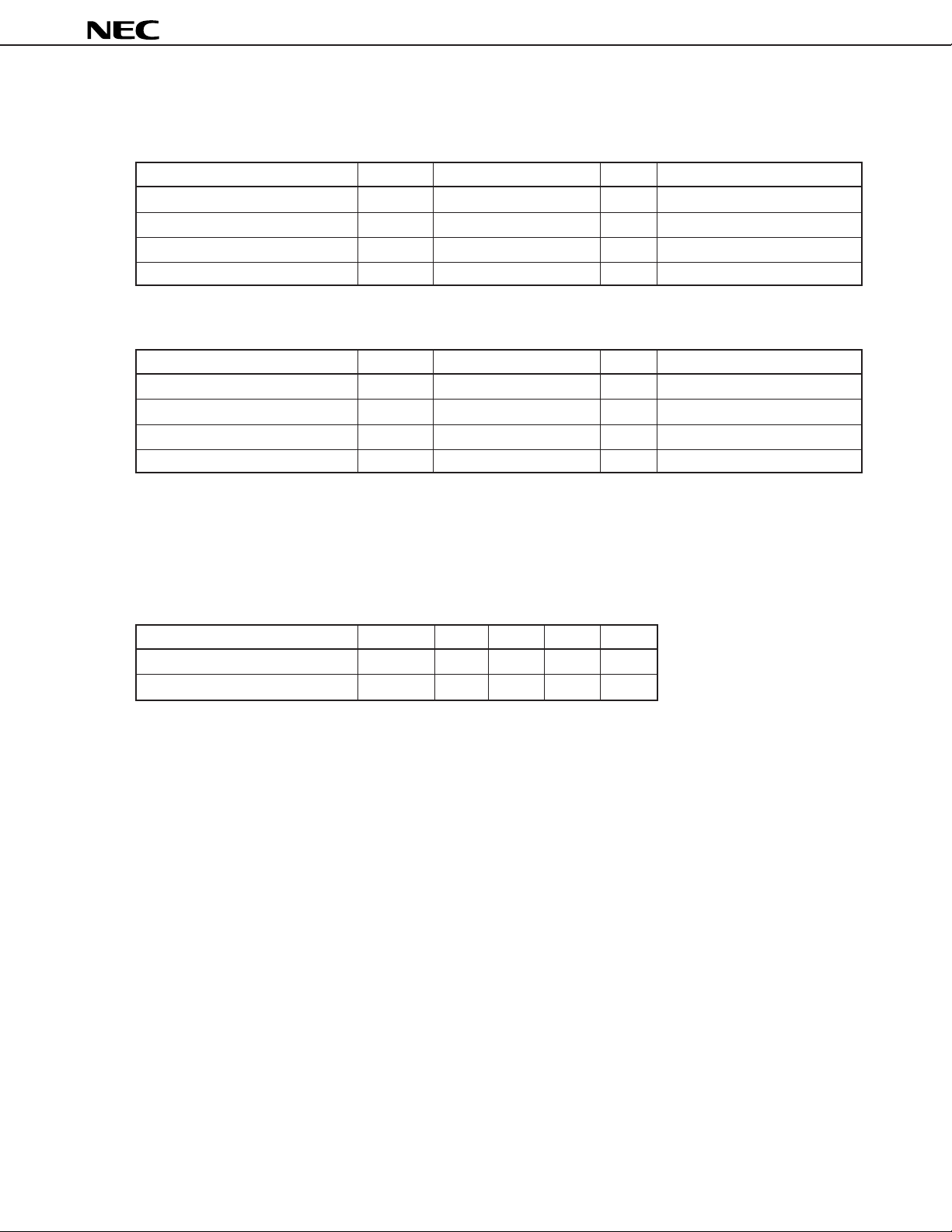

ABSOLUTE MAXIMUM RATINGS (TA = 25 °C)

µ

PC2766GR

PARAMETER SYMBOL RATING UNIT TEST CONDITIONS

Supply voltage VCC 6.0 V

Power dissipation PD 430 mW TA = 85 °C

Operating temperature range TA –40 to +85 °C

Storage temperature range Tstg –55 to +150 °C

µ

PC2766GS

PARAMETER SYMBOL RATING UNIT TEST CONDITIONS

Supply voltage VCC 6.0 V

Power dissipation PD 650 mW TA = 85 °C

Operating temperature range TA –40 to +85 °C

Storage temperature range Tstg –55 to +150 °C

µ

PC2766GR/GS

Note 1

Note 1

Note 1 Mounted on 50 × 50 × 1.6 mm double epoxy glass board.

RECOMMENDED OPERATING RANGE

µ

PC2766GR/GS

PARAMETER SYMBOL MAX. TYP. MIN. UNIT

Supply voltage VCC 4.5 5.0 5.5 V

Operating temperature range TA –40 +25 +85 °C

Data Sheet P10193EJ4V0DS00

5

Page 6

µ

PC2766GR/GS

ELECTRICAL CHARACTERISTICS (VCC = 5 V, TA = 25 °C,ZL = 250 Ω)

µ

PC2766GR/GS

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

Supply current ICC – 60 78 mA no input signal

RF input bandwidth RF BW DC - DC - – MHz fIF = 40 MHz, fRF > fLO

IF output bandwidth IF BW DC 200 – MHz fRF = 480 MHz, PLO = –10 dBm

Gain control range GGC 40 45 – dB fRF = 480 MHz, fIF = 40 MHz

IQ phase balance

IQ amplitude balance

Output voltage VO 1.2 1.5 – V P-P fRF = 480 MHz, fIF = 40 MHz

∆φ

∆

G–±0.3 ±0.5 dB fRF = 480 MHz, fIF = 40 MHz

750 1000 IQ phase balance ≤ ±1.5°

fRF > fLO, –3 dB down, Vagc = 0 V

PRF = –30 dBm,

Vagc = 0 – 5 V

– ±0.3 ±1.5 deg fRF = 480 MHz, fIF = 40 MHz

PRF = –30 dBm, PLO = –10 dBm

PRF = –30 dBm, PLO = –10 dBm

Vagc = 0 V

PLO = –10 dBm, ZL = 250 Ω

PLO = –10 dBm

Conversion gain CG 15 20 25 dB fRF = 480 MHz, fIF = 40 MHz

Vagc = 0 V

STANDARD CHARACTERISTICS (REFERENCE VALUES) (VCC = 5 V, TA = 25 °C,ZL = 250 Ω)

µ

PC2766GR/GS

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

Noise figure NF – 21 – dB fRF = 480 MHz, fIF = 40 MHz

PLO = –10 dBm, Vagc = 0 V

LO to RF isolation LO-RFisol –55–dBfLO = 440 MHz, PLO = –10 dBm

Vagc = 0 V

LO to IF isolation LO-IFisol –10–dBfLO = 440 MHz, PLO = –10 dBm

Vagc = 0 V

3rd order intermodulation IM3 – 30 – dBc fRF1 = 480 MHz, fRF2 = 490 MHz

distortion fLO = 440 MHz, Pin = –20 dBm

PLO = –10 dBm, Vagc = 1 V

Saturated output level PO(SAT) – +2 – dBm f RF = 480 MHz, fIF = 40 MHz

PRF = –10 dBm

6

Data Sheet P10193EJ4V0DS00

Page 7

µ

PC2766GR/GS

TYPICAL CHARACTERISTICS

CG vs. fRF (Iout) CG vs. fRF (Qout)

35

fIF = 40 MHz

LO

= _10 dBm

P

30

dB

Vagc = 0 V

_

Note 2

25

20

15

10

TA = 25 ˚C

Conversion Gain

_

CG

5

30

25

dB

_

20

15

TA = 85 ˚C

0.1 0.5 1 5 0.1 0.5 1 50.05

TA = _40 ˚C

TA = _40 ˚C

TA = 85 ˚C

fRF _ RF Frequency _ GHz fRF _ RF Frequency _ GHz

CG vs. fIF (Iout) CG vs. fIF (Qout)

fRF = 480 MHz

P

TA = 25 ˚C

P

Vagc = 0 V

Note 2

– on Measurement Circuit – (Note 2 Lower local)

35

fIF = 40 MHz

LO

= _10 dBm

P

dB

_

30

Vagc = 0 V

Note 2

25

20

Conversion Gain

_

15

TA = 25 ˚C

CG

10

5

30

RF

= _30 dBm

LO

= _10 dBm

_

dB

25

TA = _40 ˚C

TA = 25 ˚C

20

15

TA = 85 ˚C

TA = _40 ˚C

TA = 85 ˚C

fRF = 480 MHz

P

RF

= _30 dBm

P

LO

= _10 dBm

Vagc = 0 V

Note 2

10

Conversion Gain

_

55

CG

0

_

5

40 100

60 80 200 300 40 10060 80 200 300

10

Conversion Gain

_

CG

0

_

5

fIF _ IF Frequency _ MHz fIF _ IF Frequency _ MHz

5

fRF = 480 MHz

f

IF

LO

P

0

= 40 MHz

= _10 dBm

dBm

_

Vagc = 0 V

Note 2

_

5

_

10

_

15

Output Power Level

_

_

20

Pout

_

25

_

40

_

Pin _ Input Power Level _ dBm

Pin vs. Pout (Iout)

_

30

20

VCC = 5.5 V

VCC = 5.0 V

VCC = 4.5 V

_

10

5

fRF = 480 MHz

f

IF

= 40 MHz

dBm

_

P

0

LO

= _10 dBm

Vagc = 0 V

Note 2

_

5

_

10

_

15

Output Power Level

_

_

20

Pout

_

25

_

0

40

Pin vs. Pout (Qout)

VCC = 5.5 V

VCC = 5.0 V

VCC = 4.5 V

_

30

_

20

_

10

Pin _ Input Power Level _ dBm

0

Data Sheet P10193EJ4V0DS00

7

Page 8

µ

PC2766GR/GS

dBc

_

I

Q

I-Q Phase Balance ( )˚

dBm

_

0

_

5

_

10

_

15

_

20

10

0

_

10

_

20

_

30

IQ PHASE BALANCE vs. f

fIF = 40 MHz

P

RF

= _30 dBm

P

LO

= _10 dBm

Note 2

f

RF1

= 480 MHz

f

RF2

= 490 MHz

f

LO

= 440 MHz

P

LO

= _10 dBm

Pin = _20 dBm

each

Vagc = 1.0 V

TA = 85 ˚C

TA = 25 ˚C

0.50.10.05 1 5

RF

_ RF Frequency _ GHz

f

IM3 vs. Pin (Iout)

VCC = 4.5 V

RF

TA = _40 ßC

VCC = 5.0 V

VCC = 5.5 V

2

IQ AMPLITUDE BALANCE vs. f

1.5

I

Q

1

0.5

TA = 25 ˚C

TA = 85 ˚C

0

_

0.5

_

1

fIF = 40 MHz

P

RF

1.5

P

LO

Note 2

_

2

10

f

RF1

f

RF2

f

LO

= 440 MHz

0

P

LO

Pin = _20 dBm

each

10

Vagc = 1.0 V

20

30

= _30 dBm

= _10 dBm

= 480 MHz

= 490 MHz

= _10 dBm

f

RF

_ RF Frequency _ GHz

_

I-Q Amplitude Balance [ ] (dB)

dBc

_

dBm

_

_

_

_

RF

TA = _40 ˚C

0.50.10.05 1 5

IM3 vs. Pin (Qout)

VCC = 4.5 V

VCC = 5.0 V

VCC = 5.5 V

_

Output Power Level

40

_

_

Third Intermodulation Distortion

Pout

50

_

3

_

IM

60

_

40

_

30

_

Pin _ Input Power Level _ (dBm)

CG vs. Vagc (Iout)

20

dB

_

10

0

_

10

Conversion Gain

_

CG

_

20

_

30

245

103

Vagc _ AGC Voltage _ V

20

fRF = 480 MHz

f

P

P

V

Note 2

_

10 0

IF

= 40 MHz

RF

= _30 dBm

LO

= _10 dBm

CC

= 5.0 V

_

Output Power Level

40

_

_

50

Third Intermodulation Distortion

Pout

_

3

_

IM

60

_

40

_

30

_

Pin _ Input Power Level _ (dBm)

CG vs. Vagc (Qout)

20

dB

_

10

0

_

10

Conversion Gain

_

CG

_

20

_

30

245

103

Vagc _ AGC Voltage _ V

20

fRF = 480 MHz

f

P

P

V

Note 2

_

10 0

IF

= 40 MHz

RF

= _30 dBm

LO

= _10 dBm

CC

= 5.0 V

8

Data Sheet P10193EJ4V0DS00

Page 9

µ

PC2766GR/GS

0

dBc

_

_

10

_

20

_

30

_

40

Third Intermodulation Distortion

_

_

50

3

012 435

IM

f

RF1

= 480 MHz

f

RF2

= 490 MHz

f

LO

= 440 MHz

Pin = _20 dBm each

P

LO

= _10 dBm

Vagc _ AGC Voltage _ V

IM3 vs. CG (Iout)

0

f

RF1

IM3 vs. Vagc (Iout)

dBc

_

= 480 MHz

f

RF2

= 490 MHz

f

LO

= 440 MHz

_

10

Pin = _20 dBm each

P

LO

= _10 dBm

Vagc = 0 to 5 V

_

20

_

30

0

dBc

_

_

10

_

20

_

30

_

40

Third Intermodulation Distortion

_

_

50

3

012 435

IM

f

RF1

= 480 MHz

f

RF2

= 490 MHz

f

LO

= 440 MHz

Pin = _20 dBm each

P

LO

= _10 dBm

Vagc _ AGC Voltage _ V

IM3 vs. CG (Qout)

0

f

RF1

IM3 vs. Vagc (Qout)

dBc

_

= 480 MHz

f

RF2

= 490 MHz

f

LO

= 440 MHz

_

10

Pin = _20 dBm each

P

LO

= _10 dBm

Vagc = 0 to 5 V

_

20

_

30

_

40

Third Intermodulation Distortion

_

_

50

3

IM

_30_

20

_

10 10020

CG _ Conversion Gain _ dB

_

40

Third Intermodulation Distortion

_

_

50

3

IM

_

30_20

_

10 10020

CG _ Conversion Gain _ dB

Data Sheet P10193EJ4V0DS00

9

Page 10

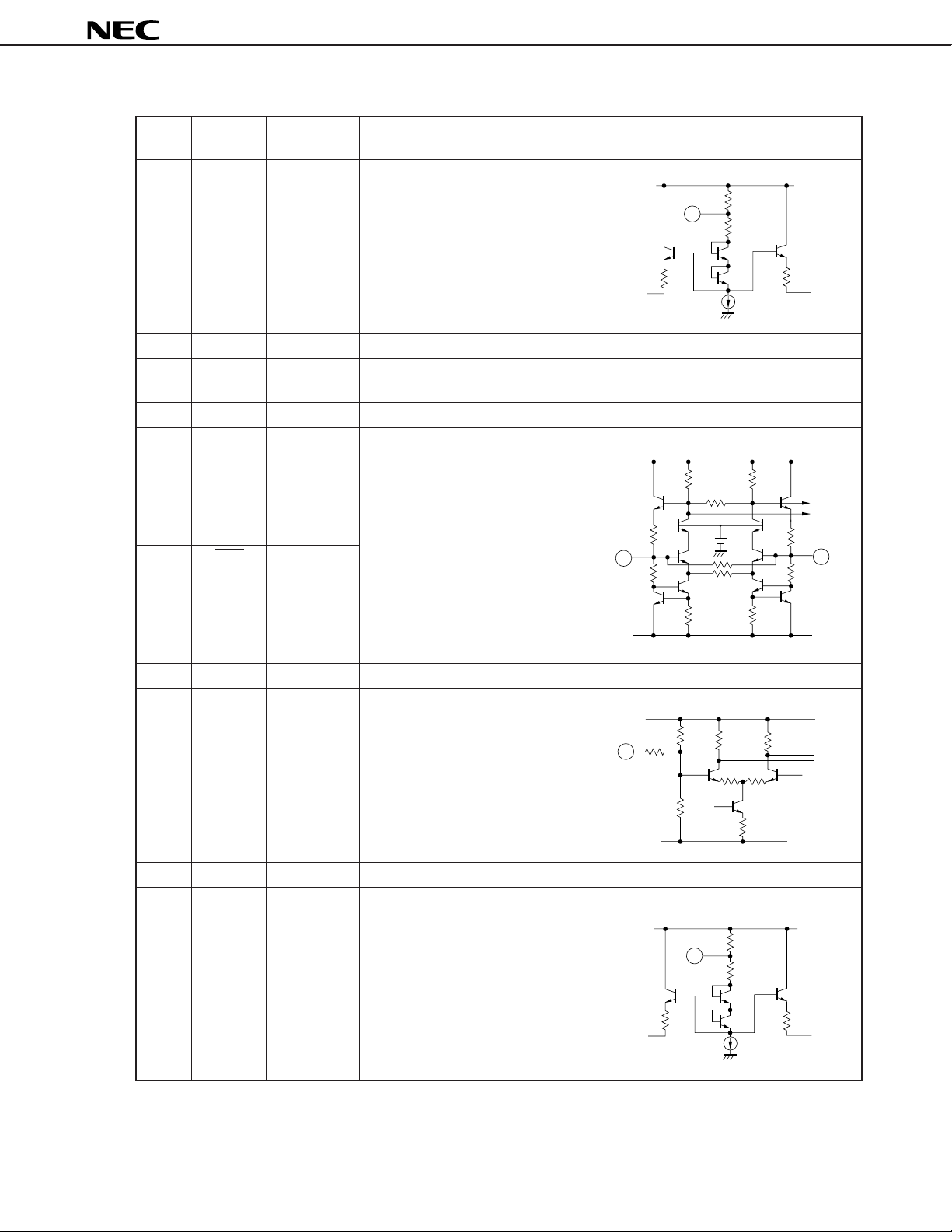

MEASUREMENT CIRCUIT

(@ ZL = 250 Ω)

Spectrum

Analyzer

µ

PC2766GR/GS

Note 3

8 pF

50 Ω 50 Ω

I out

300 nH

250 Ω

1 000 pF 1 000 pF 1 000 pF 1 000 pF 1 000 pF 1 000 pF

20 19 18 17 16 15 14 13 12 11

I-IF Amp.

I-Lo.Buff.Amp Q-Lo.Buff.Amp

I-MIX.

RF AGC

OSC IN

Power

Divider

Q-IF Amp.

Q-MIX.

300 nH

250 Ω

1 000 pF

Q out

200 Ω200 Ω

Note 3

8 pF

1 000 pF

RF Pre.Amp. AGC cont.

1

2

34

1 000 pF 1 000 pF 1 000 pF 1 000 pF1 000 pF 1 000 pF

1 000 pF

5

SG

RF IN Vagc Vcc

6

Note 3 is Low pass filter in order to eliminate local leak.

7

89

10

1 000 pF

10

Data Sheet P10193EJ4V0DS00

Page 11

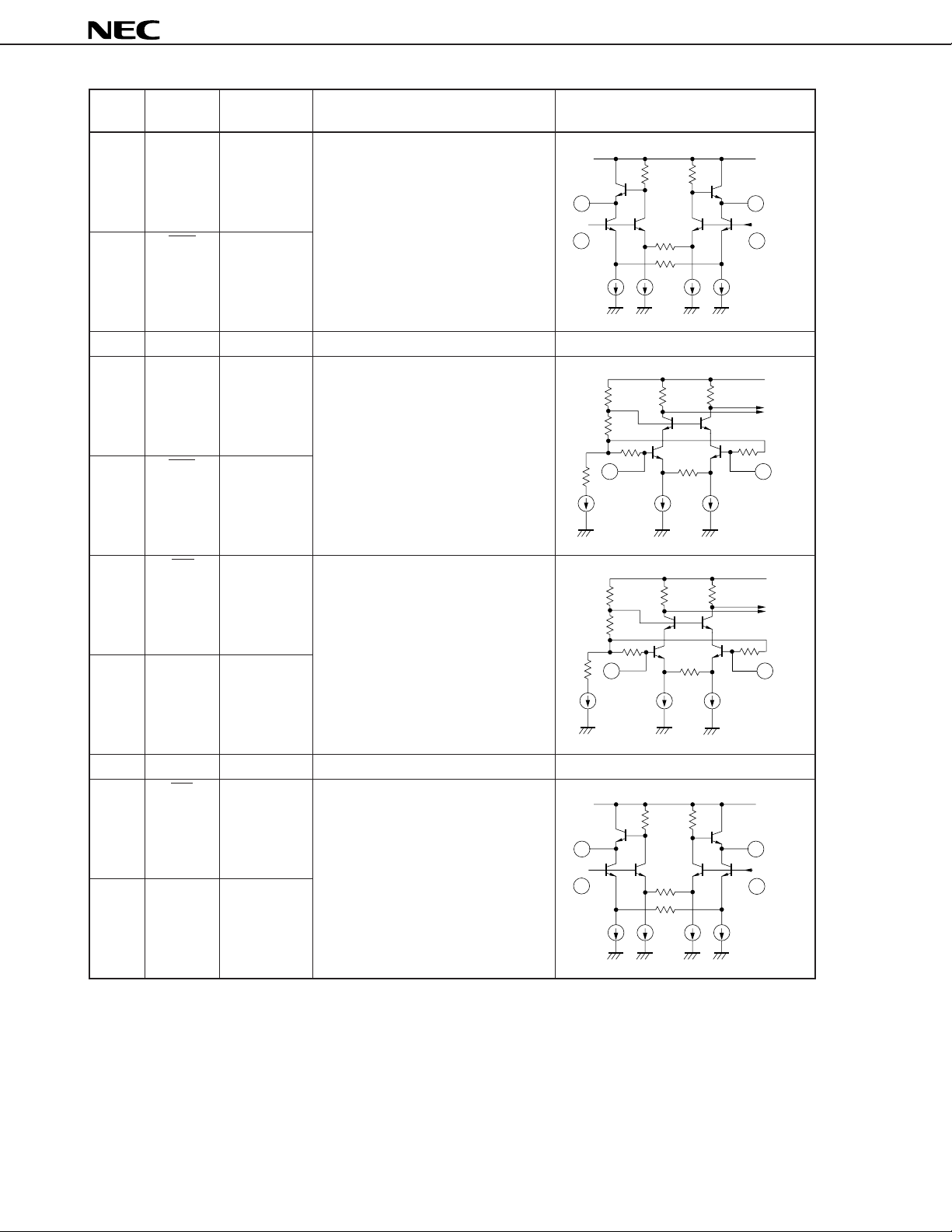

APPLICATION CIRCUIT EXAMPLE

OSC IN

90˚ PHASE SHIFTER

90˚0˚

µ

PC2766GR/GS

I out Q out

I out

LPFLPF

1 000 pF 1 000 pF 1 000 pF 1 000 pF

20 19 18 16 15 14 13 12 11

I-IF Amp.

I-Lo.Buff.Amp. Q-Lo.Buff.Amp.

I-MIX.

12345678910

1 000 pF 1 000 pF 1 000 pF

17

RF AGC

RF Pre.Amp. AGC cont.

1 000 pF 1 000 pF

Q out

LPF

Q-IF Amp.

Q-MIX.

1 000 pF

LPF

5 kΩ

I Bias Trim

1 000 pF

1 000 pF1 000 pF

RF IN Vagc Vcc

1 000 pF

5 kΩ

Q Bias Trim

Data Sheet P10193EJ4V0DS00

11

Page 12

PACKAGE DIMENSIONS

20 PIN PLASTIC SSOP (225 mil) (UNIT: mm)

µ

PC2766GR/GS

20

11

110

6.7 ± 0.3

1.8 MAX.

1.5 ± 0.1

detail of lead end

3˚

6.4 ± 0.2

4.4 ± 0.1

+7˚

–3˚

1.0 ± 0.2

0.5 ± 0.2

0.65

0.22

+0.10

–0.05

0.10

0.15

M

0.575 MAX.

0.15

+0.10

–0.05

0.1 ± 0.1

NOTE Each lead centerline is located within 0.10 mm of its true position (T.P.) at maximum material condition.

12

Data Sheet P10193EJ4V0DS00

Page 13

20 PIN PLASTIC SOP (300 mil) (UNIT: mm)

110

µ

PC2766GR/GS

1120

detail of lead end

+7°

3°

–3°

12.7±0.3

7.7±0.3

1.55±0.1

0.4±0.1

1.27

0.12

0.78 MAX.

M

0.10

0.20

5.6±0.2

0.6±0.2

+0.10

–0.05

0.1±0.1

1.8 MAX.

NOTE

Each lead centerline is located within 0.12 mm of its true position (T.P.) at maximum material condition.

1.1

Data Sheet P10193EJ4V0DS00

13

Page 14

µ

PC2766GR/GS

RECOMMENDED SOLDERING CONDITIONS

The following conditions (see table below) must be met when soldering this product.

Please consult with our sales offices in case other soldering process is used or in case soldering is done under

different conditions.

For details of recommended soldering conditions for surface mounting, refer to information document

SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL (C10535E).

µ

PC2766GR

Soldering process Soldering conditions Symbol

Infrared ray reflow Peak package’s surface temperature: 235 °C or below, IR35-00-3

Reflow time: 30 seconds or below (210 °C or higher),

Number of reflow process: 3, Exposure limit

VPS Peak package’s surface temperature: 215 °C or below, VP15-00-3

Reflow time: 40 seconds or below (200 °C or higher),

Number of reflow process: 3, Exposure limit

Wave soldering Solder temperature: 260 °C or below, WS60-00-1

Flow time: 10 seconds or below,

Number of flow process: 1, Exposure limit

Partial heating method Terminal temperature: 300 °C or below,

Flow time: 3 seconds or below,

Exposure limit

Note

: None

Note

Note

: None

Note

: None

: None

Note Exposure limit before soldering after dry-pack package is opened.

Storage conditions: 25 °C and relative humidity at 65 % or less.

Caution Do not apply more than single process at once, except for “Partial heating method”.

14

Data Sheet P10193EJ4V0DS00

Page 15

[MEMO]

µ

PC2766GR/GS

Data Sheet P10193EJ4V0DS00

15

Page 16

µ

PC2766GR/GS

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated “quality assurance program“ for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98.8

Loading...

Loading...