Datasheet UER-5-3000-D12, UER-3.3-3650-D48, UER-3.3-3650-D12, UER-15-1000-D48, UER-15-1000-D12 Datasheet (DATEL)

...Page 1

Single Output

UER Models

Features

Low-Cost, Wide-Input-Range

12-15 Watt, DC/DC Conv erters

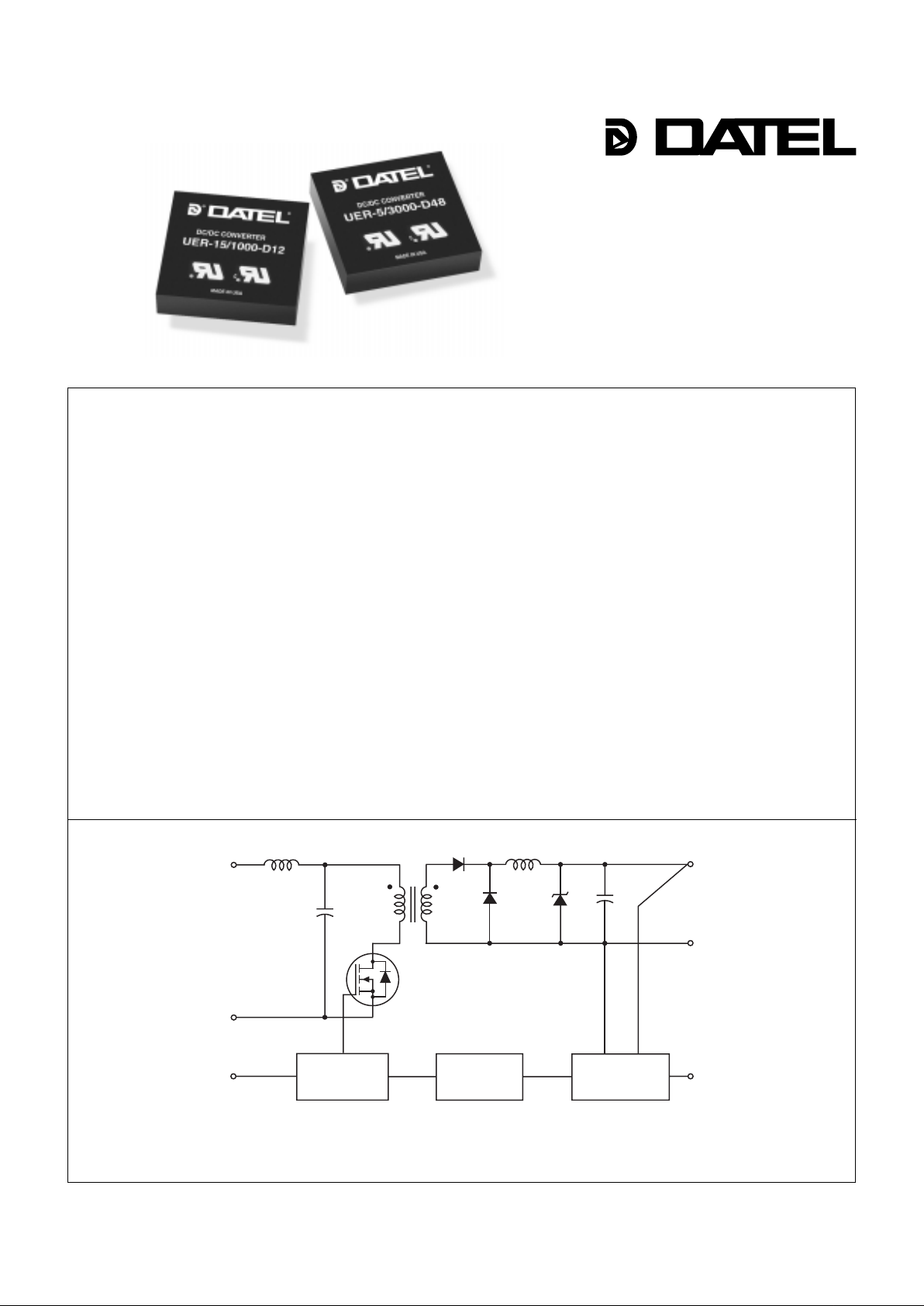

Figure 1. Simplified Schematic

DATEL, Inc., Mansfield, MA 02048 (USA) • Tel: (508)339-3000, (800)233-2765 Fax: (508)339-6356 • Email: sales@datel.com • Inter net: www.datel.com

COMMON

+V

OUT

+V

IN

–V

IN

ON/OFF

CONTROL

V

OUT

TRIM

REFERENCE &

ERROR AMP

OPTO

ISOLATION

PWM

CONTROLLER

INNOVATION and EX C ELL E N C E

®

®

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

Low cost

Rugged, fully potted, diallyl phthalate

plastic packages

Industry-standard form factor (2" x 2")

and pinout

3.3, 5, 12 or 15 V olt outputs

Wide input voltage ranges:

9-36V or 18-72V

No external components required

Guaranteed efficiencies to 82%

Fully isolated (750Vdc guaranteed)

and I/O protected

V

OUT trim and on/off control

UL, CSA, IEC safety approvals

Modifications and customs for OEM’ s

DATEL’s UER Model single-output s witching DC/DC converters were designed for

cost-sensitive, moderate-power (12-15 Watts) applications requiring a reliable, off-theshelf solution but not demanding all the high-performance characteristics of DATEL ’s ASeries UWR Model converters. Offering slightly wider electrical tolerances and slightly

lower power densities (8.33W/in

3

), UER devices achieve their low cost through the use

of plastic packaging (UL94V -0 rated material) and the exploitation of traditional, yet

highly automated, SMT -on-pcb construction techniques. The result is a contemporary

power converter whose cost/performance/reliability ratio far exceeds the competition.

UER Model DC/DC converters offer the ultra-wide, 9-to-36V and 18-to-72V, input

voltage ranges that have come to be associated with D ATEL power converters. Output

voltages are 3.3V , 5V, 12V or 15V. Line and load regulation are both guaranteed not to

exceed ±1%. All models incorporate internal input/output filtering and require no

external components for normal operation. All units guarantee output ripple/noise less

than 100mVp-p.

These fully isolated (750Vdc guaranteed) devices are input overvoltage and

reverse-polarity protected and employ output current limiting to protect both the power

converter and its load. They off er V

OUT trim and remote on/off control capabilities. They

function well in harsh environments and are popular for both commercial and industrial

usage in computer, telecom, aerospace and process-control applications.

The industry-standard, 2" x 2", package size and pinout of the UER Models makes

them ideal replacements for other, more costly, less reliable power converters. They

are equally well suited for new design-ins in systems demanding both low cost and high

reliability .

Page 2

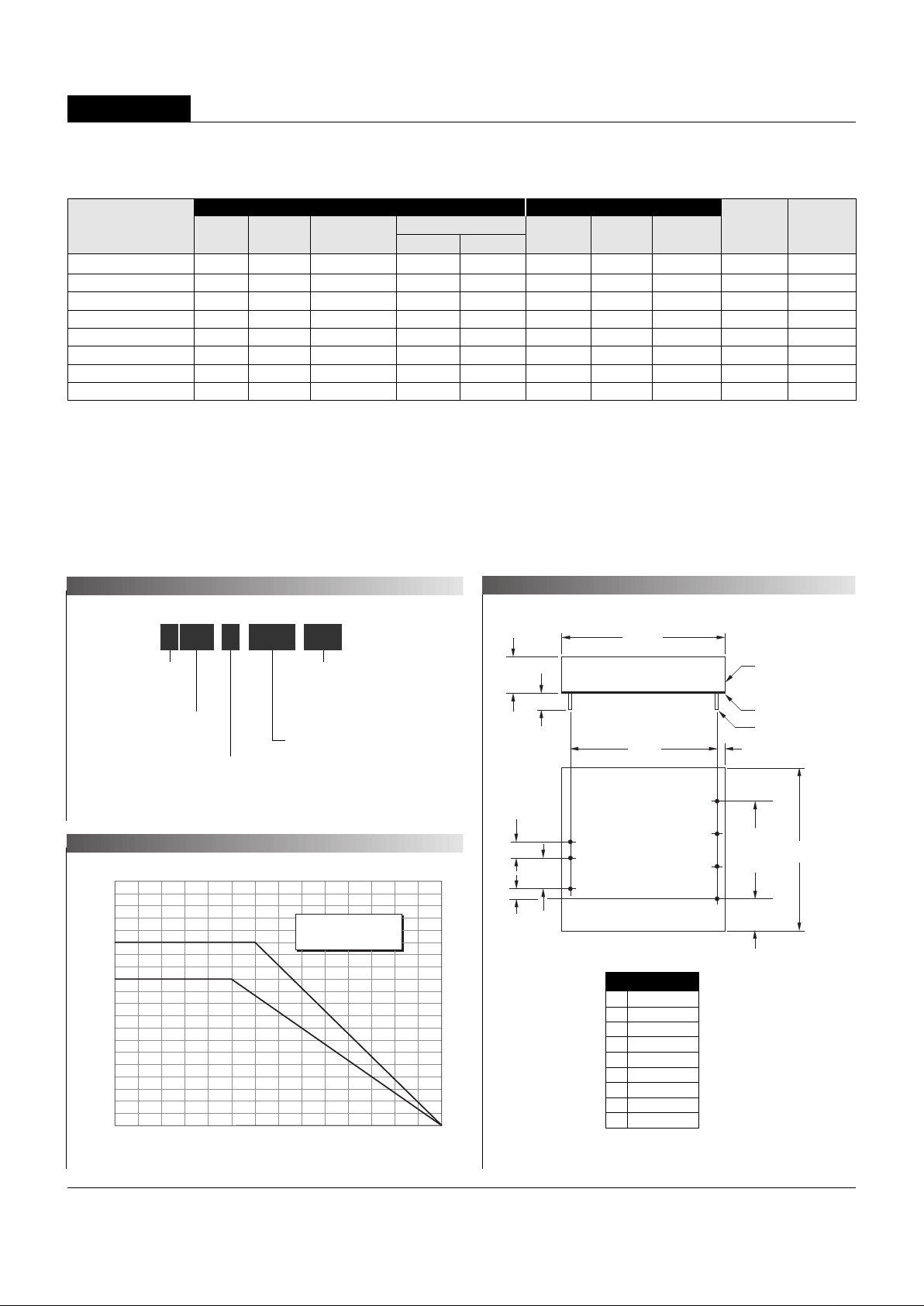

XER Series

12-15W, SINGLE OUTPUT DC/DC CONVERTERS

2

PART NUMBER STRUCTURE

MECHANICAL SPECIFICATIONS

TEMPERATURE DERATING

Performance Specifications and Ordering Guide

➀

➀

T ypical at TA = +25°C under nominal line voltage and full-load conditions, unless otherwise noted.

➁

Ripple/Noise (R/N) measured over a 20MHz bandwidth.

➂

For 3.3V and 5V outputs, listed specifications apply over the 10% to 100% load range. For 12V and 15V outputs, 20% to 100% load range.

➃

Nominal line voltage, no-load/full-load conditions.

Ripple/Noise

➁

(mVp-p, Max.)

VOUT

(Volts)

Package

(Case,

Pinout)

Efficiency

(Min.)

Regulation (Max.)

Line

VIN Nom.

(Volts)

Range

(Volts)Model

IOUT

(mA, Max.)

IIN ➃

(mA, Max.)

Load

➂

UER-3.3/3650-D12 3.3 3650 75 ±1.0% ±1.0% 24 9-36 45/672 77% C4, P6

UER-3.3/3650-D48 3.3 3650 75 ±1.0% ±1.0% 48 18-72 25/336 77% C4, P6

UER-5/3000-D12 5 3000 100 ±1.0% ±1.0% 24 9-36 45/789 80% C4, P6

UER-5/3000-D48 5 3000 100 ±1.0% ±1.0% 48 18-72 25/395 80% C4, P6

UER-12/1250-D12 12 1250 100 ±1.0% ±1.0% 24 9-36 45/770 82% C4, P6

UER-12/1250-D48 12 1250 100 ±1.0% ±1.0% 48 18-72 25/385 82% C4, P6

UER-15/1000-D12 15 1000 100 ±1.0% ±1.0% 24 9-36 45/770 82% C4, P6

UER-15/1000-D48 15 1000 100 ±1.0% ±1.0% 48 18-72 25/385 82% C4, P6

Output Input

Nominal Output Voltage:

3.3, 5, 12 or 15 Volts

Maximum Output Current

in mA

Low-Cost, Economy Package

Wide Range Input

Output Configuration:

U = Unipolar

Input Volta ge Range:

D12 = 9-36 Volts (24V nominal)

D48 = 18-72 Volts (48V nominal)

U ER 3000 D48-/ -5

BOTTOM VIEW

1.800

(45.72)

0.10

(2.54)

2.00

(50.80)

8

5

6

7

0.40

(10.16)

0.200

(5.08)

0.400

(10.16)

0.100

(2.54)

1

2

4

PLASTIC CASE

INSULATED BASE

0.040 ±0.002 DIA.

(1.016 ±0.051)

2.00

(50.80)

0.20 MIN

(5.08)

0.50

(12.70)

1.200

(30.48)

3 EQ. SP. @

0.400 (10.16)

Case C4

I/O Connections

Pin

1

2

3

4

5

6

7

8

Function P6

+Input

–Input

No Pin

On/Off Control

No Pin

+Output

Common

Trim

Output Power (Watts)

Ambient Temperature (°C)

–25 0 35 40 45 50 55 6 0 6 5 7 0 7 5 8 0 8 5 9 0 95

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

3.3V OUTPUTS A

ALL OTHERS B

B

A

Page 3

UER Models

12-15W, SINGLE OUTPUT DC/DC CONVERTERS

3

Floating Outputs

Since these are isolated DC/DC converters, their outputs are "floating." Users

may ground either the Common (pin 7) for normal usage or the positive side

(+Output, pin 6) to effectively re verse the output polarity .

Filtering and Noise Reduction

All UER 12-15 Watt DC/DC Converters achieve their rated ripple and noise

specifications without the use of external input/output capacitors. In critical

applications, input/output noise may be further reduced by installing electrolytic

capacitors across the input terminals and/or low-ESR tantalum or electrolytic

capacitors across the output terminals. The caps should be located as close to

the power converters as possible. T ypical values are listed belo w. In man y

applications, using values greater than those listed will yield better results.

In critical, space-sensitive applications, D A TEL may be ab le to tailor the

internal input/output filtering of these units to meet your specific requirements.

Contact our Applications Engineering Group for additional details.

T o Reduce Input Ripple

"D12" Models 20µF, 50V

"D48" Models 20-50µF , 100V

T o Reduce Output Ripple

3.3V Outputs 100µF, 6V, Low ESR

5V Outputs 47µF, 10V , Low ESR

12/15V Outputs 22µF, 20V , Low ESR

Performance/Functional Specifications

T ypical @ TA = +25°C under nominal line voltage and full-load conditions, unless noted.

➀

TECHNICAL NOTES

Input Voltage:

"D12" Models 44 Volts

"D48" Models 88 Volts

Input Reverse-Polarity Protection Current must be <10A. Brief

duration only. Fusing recommended.

Output Overvoltage Protection:

3.3V Outputs No protection

5V Outputs 6.8 Volts, limited duration

12V Outputs 15 Volts, limited duration

15V Outputs 18 Volts, limited duration

Output Current Current limited. Max. current and

short-circuit duration are model

dependent.

Storage Temperature –40 to +100°C

Lead Temperature (soldering, 10 sec.) +300°C

These are stress ratings. Exposure of devices to any of these conditions may adversely

affect long-term reliability. Proper operation under conditions other than those listed in the

Performance/Functional Specifications Table is not implied.

Absolute Maximum Ratings

Input

Input V oltage Range:

"D12" Models 9-36 Volts (24V nominal)

"D48" Models 18-72 Volts (48V nominal)

Input Current See Ordering Guide

Input Filter Type

➁

LC

Overvoltage Shutdown:

"D12 Models" 40 Volts

"D48 Models" 80 Volts

Reverse-Polarity Protection Yes (Instantaneous , 10A maximum)

On/Off (Sync) Control (Pin 4)

➂

TTL high = off, low (or open) = on

Output

VOUT Accuracy (50% load) ±1%, maximum

Temperature Coefficient ±0.02% per °C

Ripple/Noise (20MHz BW)

➁

See Ordering Guide

Line/Load Regulation See Ordering Guide

Efficiency See Ordering Guide

Isolation V oltage

➃

750Vdc, minimum

Isolation Capacitance 550pF

Short-Circuit Protection Continuous, auto-recovery

Overvoltage Protection Zener/transorb clamp, magnetic feedback

Dynamic Characteristics

Transient Response (50% load step) 200µsec max. to ±1.5% of final value

Switching Frequency 160kHz

Environmental

Operating Temperature (ambient):

➄

Without Derating –25 to +50/55°C (Model dependent)

With Derating to +95°C (See Derating Curves)

Storage Temperature –40 to +100°C

Physical

Dimensions 2" x 2" x 0.50" (51 x 51 x 12.7mm)

Shielding None

Case Connection None

Case Material Diallyl phthalate, UL94V-0 rated

Pin Material Brass, solder coated

Weight 2.7 ounces (75.6 grams)

➀

3.3/5V devices require a minimum 10% loading and 12/15V devices require a minimum

20% loading to maintain specified regulation. Operation under no-load conditions will not

damage these devices; however they may not meet all listed specifications.

➁

Application-specific input/output filtering can be recommended and perhaps added

internally upon request. Contact DATEL Applications Engineering for details.

➂

Applying a voltage to the Control pin when no input power is applied to the converter can

cause permanent damage to the converter.

➃

Devices can be screened or modified for higher guaranteed isolation voltages.

Contact DA TEL Applications Engineering f or details.

➄

Devices can be warranted or screened for –40°C operation.

Contact DA TEL Applications Engineering f or details.

Page 4

DATEL makes no representation that the use of its products in the circuits described herein, or the use of other technical information contained herein, will not infringe upon existing or future patent rights. The descriptions contained herein

do not imply the granting of licenses to make, use, or sell equipment constructed in accordance therewith. Specifications are subject to change without notice. The DATEL logo is a registered DATEL, Inc. trademark.

DATEL (UK) LTD. Tadley, England Tel: (01256)-880444

DATEL S.A.R.L. Montigny Le Bretonneux, France Tel: 01-34-60-01-01

DATEL GmbH München, Germany Tel: 89-544334-0

DATEL KK Tokyo, Japan Tel: 3-3779-1031, Osaka Tel: 6-354-2025

DS-0328 9/98

DATEL, Inc. 11 Cabot Boulevard, Mansfield, MA 02048-1151

Tel: (508) 339-3000 (800) 233-2765 Fax: (508) 339-6356

Internet: www.datel.com Email: sales@datel.com

Data Sheet Fax Back:(508) 261-2857

INNOVATION and EX C ELL E N C

E

®

®

ISO 9001

I

SO 9001

REGISTERED

XER Series

12-15W, SINGLE OUTPUT DC/DC CONVERTERS

Input Fusing

Certain applications and/or safety agencies may require the installation of fuses

at the inputs of power conversion components. F or D ATEL UER

12-15 Watt DC/DC Converters, you should use slow-blow type fuses with

values no greater than the following:

V

IN Range Fuse Value

"D12" 3A

"D48" 2A

On/Off Control

The On/Off Control pin (pin 4) may be used for remote on/off operation.

A TTL logic high (+2 to +5 V olts , 250µA max.) applied to pin 4 disables the

converter. A TTL logic low (0 to +0.8 Volts, 70µA max.), or no connection,

enables the converter. Control voltages should be referenced to pin 2

(–Input). Applying a voltage to the Control pin when no input power is applied to

the converter can cause permanent damage to the converter.

Synchronization

In critical applications employing multiple switching DC/DC converters, it may

be desirable to intentionally synchronize the switching of selected converters

(so the system noise can be reduced with notch filtering) or to purposely

desynchronize the converters (to lessen the current-carrying requirements on

intermediate dc buses). For multiple UER DC/DC Converters, an external clock

can be applied to pin 4 (Control) of each device. It should be a square wave with

a maximum 1µsec "high" duration and an amplitude between +2V and +5V (see

On/Off Control) referenced to pin 2 (–Input). The frequency of the synchronizing

clock should be higher than that of any individual converter. Therefore, it should

be 185kHz ±5kHz.

Output Trimming

V

OUT may be trimmed ±5% via a single external trimpot or fixed resistor. The

trimpot should be connected as shown in Figure 2a with its wiper connected to

pin 8 (T rim). The trimpot can be used to determine the value of a single fix ed

resistor which should be connected as shown in Figure 2b. Connect the resistor

between pin 8 (T rim) and pin 6 (+Output) to trim "down" the output voltage.

Connect the resistor between pins 8 and 7 (Common) to trim "up" the output

voltage. Fixed resistors should be metal-film types with absolute TCR’s less

than 100ppm/°C to ensure stability .

Trim

Down

Trim Up

+INPUT

–INPUT

OUTPUT

TRIM

COMMON

1

2

6

7

8

LOAD

Trim Down

Trim Up

+INPUT

–INPUT

OUTPUT

TRIM

COMMON

1

2

6

7

8

LOAD

20kΩ

5-10

Turns

Figure 2a. Trim Connections Using a Trimpot

Figure 2b. Trim Connections Using Fixed Resistors

DA TEL’s world-class design, dev elopment and manufacturing team stands

ready to work with you to deliver the exact power converter you need for your

demanding, large volume, OEM applications. And ... we’ll do it on time and

within budget!

Our experienced applications and design staffs; quick-turn prototype capability;

highly automated, SMT assembly facilities; and in-line SPC quality-control

techniques combine to give us the unique ability to design and deliver any

quantity of power conv erters to the highest standards of quality and reliability.

We have compiled a large library of DC/DC designs that are currently used in a

variety of telecom, medical, computer, railwa y , aerospace and industrial

applications. We may already have the converter you need.

Contact us. Our goal is to provide you the highest-quality, most cost-effective

power converters available.

CUSTOM CAPABILITIES

Loading...

Loading...