Page 1

查询UCC15701供应商

Advanced Voltage Mode Pulse Width Modulator

FEATURES

700kHz Operation

•

Integrated Oscillator/ Voltage Feed

•

Forward Compensation

Accurate Duty Cycle Limit

•

Accurate Volt-second Clamp

•

Optocoupler Interface

•

Fault Counting Shutdown

•

Fault Latch off or Automatic Shutdown

•

Soft Stop Optimized for Synchronous

•

Rectification

1A Peak Gate Drive Output

•

• 130µA Start-up Current

• 750µA Operating Current

TYPICAL APPLICATION DIAGRAM

DESCRIPTION

The UCC35701/UCC35702 family of pulse width modulators is intended for

isolated switching power supplies using primary side control. They can be

used for both off-line applications and DC/DC converter designs such as in

a distributed power system architecture or as a telecom power source.

The devices feature low startup current, allowing for efficient off-line start

ing, yet have sufficient output drive to switch power MOSFETs in excess of

500kHz.

Voltage feed forward compensation is operational over a 5:1 input range

and provides fast and accurate response to input voltage changes over a

4:1 range. An accurate volt-second clamp and maximum duty cycle limit

are also featured.

Fault protection is provided by pulse by pulse current limiting as well as the

ability to latch off after a programmable number of repetitive faults has oc

curred.

Two UVLO options are offered. UCC35701 family has turn-on and turn-off

thresholds of 13V/9V and UCC35702 family has thresholds of 9.6V/8.8V.

The UCC35701/2 and the UCC25701/2 are offered in the 14 pin SOIC (D),

14 pin PDIP (N) or in 14 pin TSSOP (PW) packages. The UCC15701/2 is

offered in the 14 pin CDIP (J) package.

application

INFO

available

UCC15701/2

UCC25701/2

UCC35701/2

-

-

VREF

CF

R

F

R4

R5

R2

C3

R3

R1

CT

CS

R8

VFF

6

7RT

UCC35701

10 CT

9 VSCLAMP

11 SYNC

14 SS

1 COUNT

12 VREF

8FB

R12

C5

C6

VINSUPPLY

R6

3VDD

C1

R8

4OUT

R10

2ILIM

C2

5PGND

RGND

13GND

R11

R13

R14

C7

R15

RCS

R7

V

C6

OUT

V

OUT

V

IN

C4

RETURN

SLUS293A - JANUARY 2000

UDG-98005-1

Page 2

ABSOLUTE MAXIMUM RATINGS

Supply voltage (Supply current limited to 20mA) . . . . . . . . 15V

Supply Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20mA

Input pins ( ILIM,VFF,RT,CT,VSCLAMP,SYNC,SS) . . . . . . 6V

Output Current (OUT) DC. . . . . . . . . . . . . . . . . . . . . +/–180mA

Output Current (OUT) Pulse (0.5ms) . . . . . . . . . . . . . . +/–1.2A

Storage Temperature. . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . +300°C

Note: All voltages are with respect to GND. Currents are posi

tive into the specified terminal. Consult Packaging Section of

the Databook for thermal limitations and considerations of

packages.

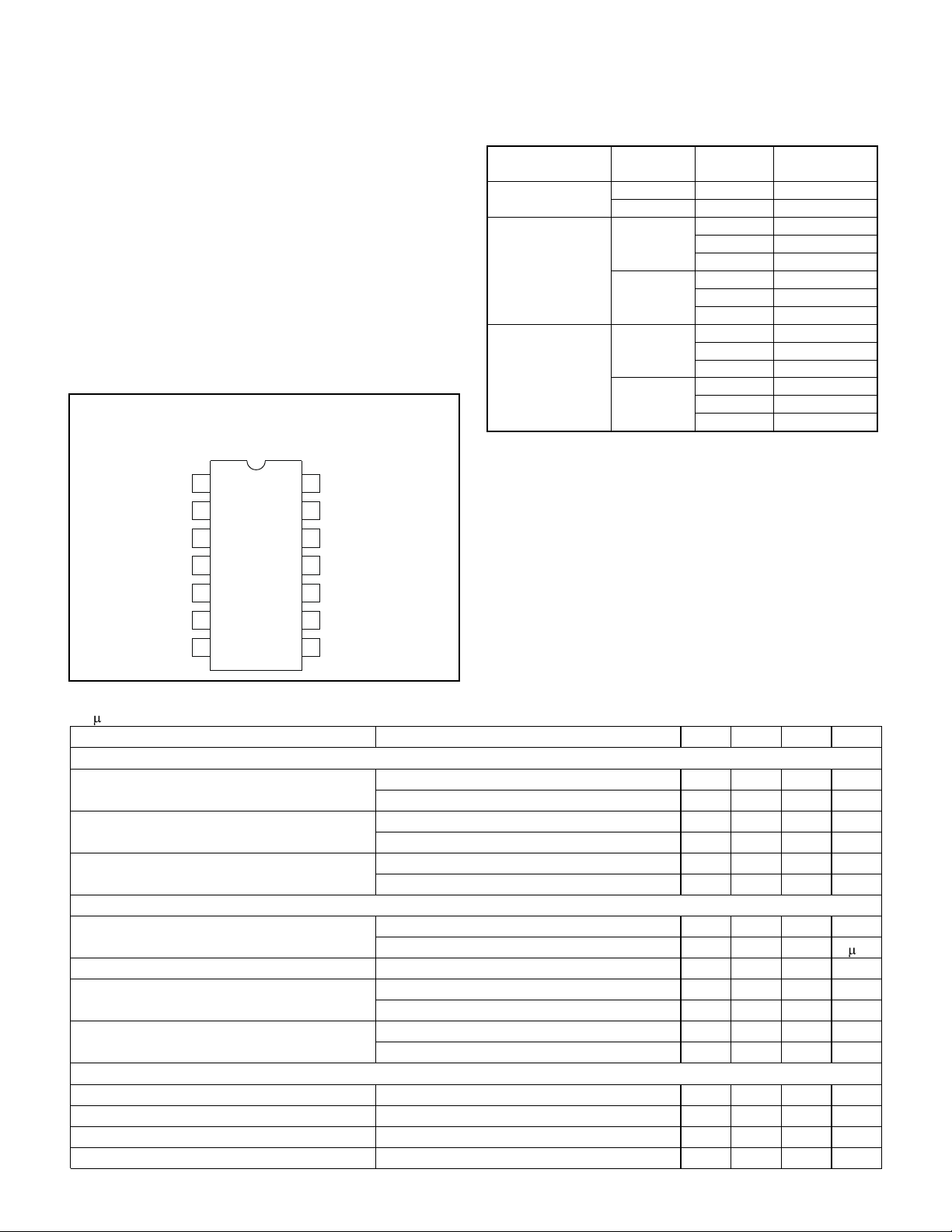

CONNECTION DIAGRAMS

DIL-14, SOIC-14,TSSOP-14 (TOP VIEW)

N or J, D, PW PACKAGE

SS

COUNT

ILIM

1

2

14

GND

13

UCC15701/2

UCC25701/2

UCC35701/2

ORDERING INFORMATION

TA=T

J

–55°C to +125°C

–40°C to +85°C

-

0°C to +70°C

The D and PW packages are available taped and reeled. Add

TR suffix to the device type (e.g., UCC35701DTR).

UVLO

Package Part Number

Option

13V / 9V CDIP-14 UCC15701J

9.6V / 8.8V CDIP-14 UCC15702J

SOIC-14 UCC25701D

13V / 9V

PDIP-14 UCC25701N

TSSOP-14 UCC25701PW

SOIC-14 UCC25702D

9.6V / 8.8V

PDIP-14 UCC25702N

TSSOP-14 UCC25702PW

SOIC-14 UCC35701D

13V / 9V

PDIP-14 UCC35701N

TSSOP-14 UCC35701PW

SOIC-14 UCC35702D

9.6V / 8.8V

PDIP-14 UCC35702N

TSSOP-14 UCC35702PW

VREF

VDD

3

OUT

4

PGND

5

6

VFF

7

RT

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, V

12

11

10

9

8

SYNC

CT

VSCLAMP

FB

= 11V, RT = 60.4k, CT= 330pF, C

DD

REF=CVDD

0.1 F, VFF= 2.0V, and no load on the outputs.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

UVLO Section

Start Threshold (UCCX5701) 12 13 14 V

(UCCX5702) 8.8 9.6 10.4 V

Stop Threshold (UCCX5701) 8 9 10 V

(UCCX5702) 8.0 8.8 9.6 V

Hysteresis (UCCX5701) 3 4 V

(UCCX5702) 0.3 0.8 V

Supply Current

Start-up Current (UCCX5701) V

(UCCX5702) V

I

Active VDDComparator On 0.75 1.5 mA

DD

Clamp Voltage (UCCX5701) IDD= 10mA 13.5 14.3 15 V

V

DD

(UCCX5702) I

Clamp – Start Threshold (UCCX5701) 1.3 V

V

DD

= 11V, VDDComparator Off 130 200 µA

DD

= 8V, VDDComparator Off 120 190 A

DD

= 10mA 13 13.8 15 V

DD

(UCCX5702) 4.2 V

Voltage Reference

V

REF

Line Regulation V

Load Regulation I

Short Circuit Current V

VDD= 10V to 13V, I

= 10V to 13V 20 mV

DD

= 0mA to 2mA 2 mV

VREF

= 0V, TJ = 25°C 20 50 mA

REF

= 0mA to 2mA 4.9 5 5.1 V

VREF

2

=

Page 3

UCC15701/2

UCC25701/2

UCC35701/2

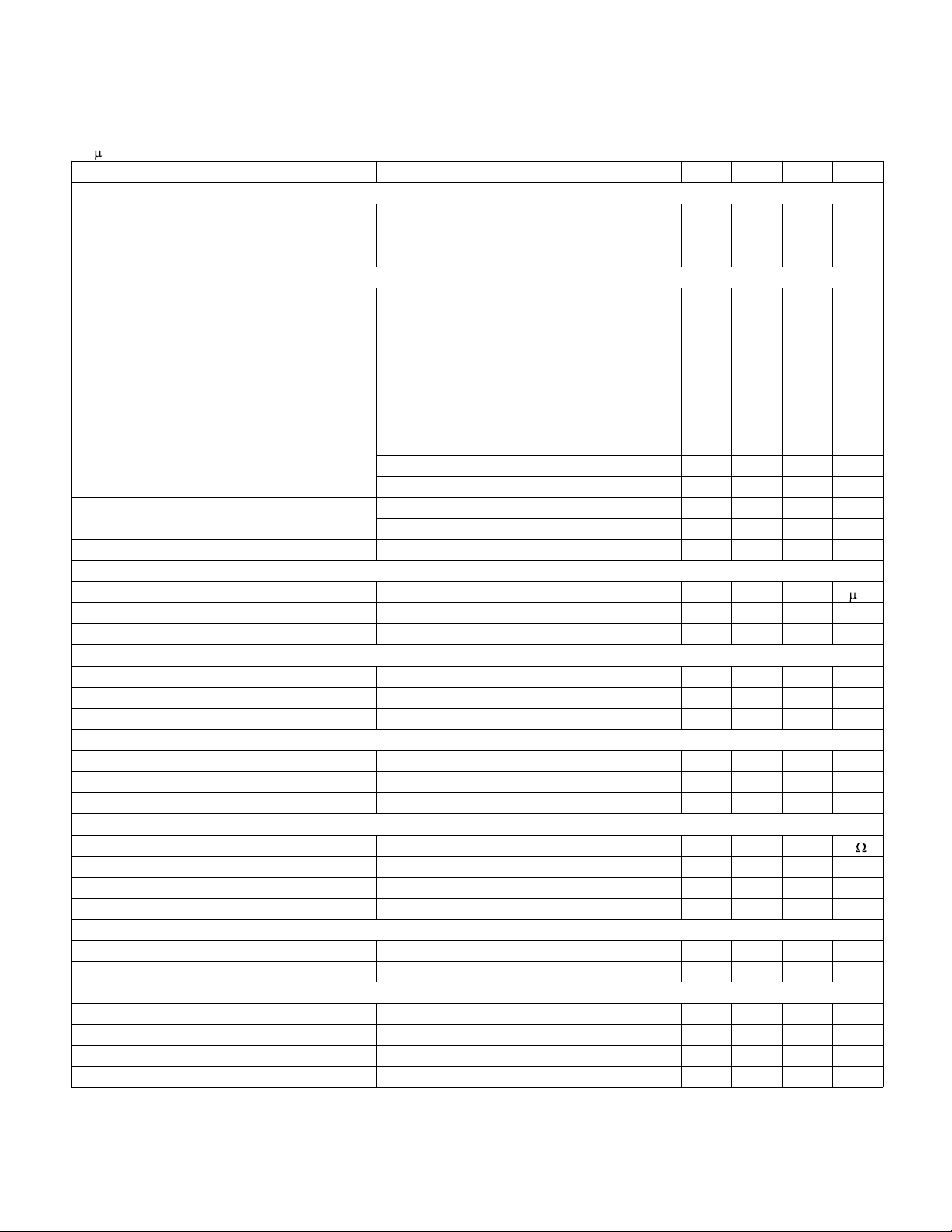

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, VDD= 11V, RT = 60.4k, CT= 330pF, C

REF=CVDD

=

0.1 F, VFF= 2.0V, and no load on the outputs.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Line Sense

Vth High Line Comparator 3.9 4 4.1 V

Vth Low Line Comparator 0.5 0.6 0.7 V

Input Bias Current –100 100 nA

Oscillator Section

Frequency V

Frequency V

= 0.8V to 3.2V 90 100 110 kHz

FF

= 0.6V to 3.4V (Note 1) 90 100 110 kHz

FF

SYNC VIH 2V

SYNC VIL 0.8 V

SYNC Input Current VSYNC = 2.0V 3 10 µA

RT Voltage VFF = 0.4V 0.5 0.6 0.7 V

VFF = 0.8V 0.75 0.8 0.85 V

VFF = 2.0V 1.95 2.0 2.05 V

VFF = 3.2V 3.15 3.2 3.25 V

VFF = 3.6V 3.3 3.4 3.5 V

Peak Voltage VFF = 0.8V (Note 1) 0.8 V

C

T

VFF = 3.2V (Note 1) 3.2 V

C

Valley Voltage (Note 1) 0 V

T

Soft Start/Shutdown/Duty Cycle Control Section

Charging Current 10 18 30 A

I

SS

Discharging Current 300 500 750 µA

I

SS

Saturation V

= 11V, IC Off 25 100 mV

DD

Fault Counter Section

Threshold Voltage VFF = 0.8V to 3.2V 3.8 4 4.2 V

Saturation Voltage VFF = 0.8V to 3.2V 100 mV

Count Charging Current 10 18 30 µA

Current Limit Section

Input Bias Current –100 0 100 nA

Current Limit Threshold 180 200 220 mV

Shutdown Threshold 500 600 700 mV

Pulse Width Modulator Section

FB Pin Input Impedance VFB = 3V 30 50 100 k

Minimum Duty Cycle VFB <= 1V 0 %

Maximum Duty Cycle VFB >= 4.5V, VSCLAMP >= 2.0V 95 99 100 %

PWM Gain VFF = 0.8V 35 50 70 %/V

Volt Second Clamp Section

Maximum Duty Cycle VFF = 0.8V, VSCLAMP = 0.6V 69 74 79 %

Minimum Duty Cycle VFF = 3.2V, VSCLAMP = 0.6V 17 19 21 %

Output Section

VOH I

VOL I

Rise Time C

Fall Time C

= –100mA, (VDD–V

OUT

= 100mA 0.4 1 V

OUT

= 1000pF 20 100 ns

LOAD

= 1000pF 20 100 ns

LOAD

) 0.4 1 V

OUT

Note 1: Guaranteed by design. Not 100% tested in production.

3

Page 4

DETAILED BLOCK DIAGRAM

2*I

RT

6VFF

7RT

10CT

I

RT

PEAK

UCC15701/2

UCC25701/2

UCC35701/2

S

R

Q

D

3µA

PWM

11 SYNC

3VDD

SS

HIGH LINE

LOW LINE

DQ

R

0.2V

VALLEY

V

REF

SQ

R

D

D

13/9V (35701)

9.6/8.8V (35702)

4.5V

VDD

5.0V

REF

RUN

25*I

0.2V

I

4V

RQ

S

D

SHUTDOWN

LATCH

SSDONE

FAULT

LATCH

RQ

S

4OUT

5PGND

12 VREF

13

GND

UDG-98004

0.7V

+

8FB

1.5R

9VSCLAMP

V

REF

I

14

0.6V

2ILIM

0.2V

1COUNT

R

4V

0.6V

CURRENT FAULT

CURRENT LIMIT

PWM

SSDONE

PIN DESCRIPTIONS

VDD: Power supply pin. A shunt regulator limits supply

voltage to 14V typical at 10mA shunt current.

PGND: Power Ground. Ground return for output driver

and currents.

GND: Analog Ground. Ground return for all other circuits.

This pin must be connected directly to PGND on the

board.

OUT: Gate drive output. Output resistance is 10Ω maxi

mum.

VFF: Voltage feedforward pin. This pin connects to the

power supply input voltage through a resistive divider and

provides feedforward compensation over a 0.8V to 3.2V

range. A voltage greater than 4.0V or less than 0.6V on

this pin initiates a soft stop cycle.

RT: The voltage on this pin mirrors VFF over a 0.8V to

3.2V range. A resistor to ground sets the ramp capacitor

charge current. The resistor value should be between

20k and 200k.

CT: A capacitor to ground provides the oscillator/

feedforward sawtooth waveform. Charge current is 2 •

, resulting in a CT slope proportional to the input volt

I

RT

age. The ramp voltage range is GND to V

Period and oscillator frequency is given by:

VC

•

RT T

T

=

F

•

2

≈

RT CT

I

2

•

tRC

+≈••

RT

DISCH T T

05.

RT

.

4

-

Page 5

PIN DESCRIPTIONS (cont.)

VSCLAMP: Voltage at this pin is compared to the CT

voltage, providing a constant volt-second limit. The com

parator output terminates the PWM pulse when the ramp

voltage exceeds VSCLAMP. The maximum on time is

given by:

VCT

VSCLAMP

t

=

ON

The maximum duty cycle limit is given by:

t

D

==

MAX

FB: Input to the PWM comparator. This pin is intended

to be driven with an optocoupler circuit. Input impedance

is 50kΩ. Typical modulation range is 1.6V to 3.6V.

SYNC: Level sensitive oscillator sync input. A high level

forces the gate drive output low and resets the ramp capacitor. On-time starts at the negative edge the pulse.

There is a 3µA pull down current on the pin, allowing it to

be disconnected when not used.

VREF: 5.0V trimmed reference with 2% variation over

line, load and temperature. Bypass with a minimum of

0.1µF to ground.

SS: Soft Start pin. A capacitor is connected between this

pin and ground to set the start up time of the converter.

After power up (V

fault condition has been cleared, the soft start capacitor

is charged to V

source. While the soft start capacitor is charging, and

•

I

•2

RT

V

ON VSCLAMP

T

V

RT

>13V AND V

DD

by a nominal 18µA internal current

REF

>4.5V), or after a

REF

UCC15701/2

UCC25701/2

UCC35701/2

while V

-

output voltage of the converter is determined by the soft

start circuitry.

At High Line or Low Line fault conditions, the soft start

capacitor is discharged with a controlled discharge cur

rent of about 500µA. During the discharge time, the duty

cycle of the converter is gradually decreased to zero.

This soft stop feature allows the synchronous rectifiers to

gradually discharge the output LC filter. An abrupt shut

off can cause the LC filter to oscillate, producing unpre

dictable output voltage levels.

All other fault conditions (UVLO, VREF Low, Over Cur

rent (0.6V on ILIM) or COUNT) will cause an immediate

stop of the converter.Furthermore, both the Over Current

fault and the COUNT fault will be internally latched until

V

DD

threshold at the input of the Low Line comparator.

After all fault conditions are cleared and the soft start ca-

pacitor is discharged below 200 mV, a soft start cycle will

be initiated to restart the converter.

ILIM: Provides a pulse by pulse current limit by terminating the PWM pulse when the input is above 200mV. An

input over 600mV initiates a latched soft stop cycle.

COUNT: Capacitor to ground integrates current pulses

generated when ILIM exceeds 200mV. A resistor to

ground sets the discharge time constant. A voltage over

4V will initiate a latched soft stop cycle.

< (0.4 • V

SS

), the duty cycle, and therefore the

FB

drops below 9V or VFFgoes below the 600mV

-

-

-

APPLICATION INFORMATION

(Note: Refer to the Typical Application Diagram on the first

page of this datasheet for external component names.) All the

equations given below should be considered as first order ap

proximations with final values determined empirically for a spe

cific application.

Power Sequencing

VDD is normally connected through a high impedance

(R6) to the input line, with an additional path (R7) to a

low voltage bootstrap winding on the power transformer.

VFF is connected through a divider (R1/R2) to the input

line.

For circuit activation, all of the following conditions are re

quired:

1. VFF between 0.6V and 4.0V (operational input voltage

range).

2. VDD has been under the UVLO stop threshold to reset

the shutdown latch.

3. VDD is over the UVLO start threshold.

The circuit will start at this point. I

will increase from

VDD

the start up value of 130 A to the run value of 750 A.

-

The capacitor on SS is charged with a 18 A current.

-

When the voltage on SS is greater than 0.8V, output

pulses can begin, and supply current will increase to a

level determined by the MOSFET gate charge require

ments to I

~ 1mA + QT • fs. When the output is ac

VDD

tive, the bootstrap winding should be sourcing the supply

current. If VDD falls below the UVLO stop threshold, the

controller will enter a shutdown sequence and turn the

controller off, returning the start sequence to the initial

condition.

-

VDD Clamp

An internal shunt regulator clamps VDD so the voltage

does not exceed a nominal value of 14V. If the regulator

is active, supply current must be limited to less than

20mA.

5

-

-

Page 6

APPLICATION INFORMATION (cont.)

Output Inhibit

During normal operation, OUT is driven high at the start

of a clock period and is driven low by voltages on CT, FB

or VSCLAMP.

The following conditions cause the output to be immedi

ately driven low until a clock period starts where none of

the conditions are true:

> 0.2V

1. I

LIM

2. FB or SS is less than 0.8V

Current Limiting

ILIM is monitored by two internal comparators. The cur

rent limit comparator threshold is 0.2V. If the current limit

comparator is triggered, OUT is immediately driven low

and held low for the remainder of the clock cycle, provid

ing pulse-by-pulse over-current control for excessive

loads. This comparator also causes C

the remainder of the clock cycle.

If repetitive cycles are terminated by the current limit

comparator causing COUNT to rise above 4V, the shutdown latch is set. The COUNT integration delay feature

will be bypassed by the shutdown comparator which has

a 0.6V threshold. The shutdown comparator immediately

sets the shutdown latch. R

in parallel with CFresets the

F

COUNT integrator following transient faults. R

greater than (4 • R4) • (1 – D

MAX

).

Latched Shutdown

If ILIM rises above 0.6V, or COUNT rises to 4V, the shut

down latch will be set. This will force OUT low, discharge

SS and COUNT, and reduce I

to approximately 750 A.

DD

When, and if, VDDfalls below the UVLO stop threshold,

the shutdown latch will reset and IDDwill fall to 130 A,

allowing the circuit to restart. If V

UVLO stop threshold (within the UVLO band), an alter

nate restart will occur if VFF is momentarily reduced be

low 1V. External shutdown commands from any source

may be added into either the COUNT or ILIM pins.

Voltage Feedforward

The voltage slope on CT is proportional to line voltage

over a 4:1 range and equals 2•VFF/(RT•CT).The capaci

tor charging current is set by the voltage across R

V(RT) tracks VFF over a range of 0.8V to 3.2V. A chang

ing line voltage will immediately change the slope of

V(CT), changing the pulse width in a proportional man

ner without using the feedback loop, providing excellent

dynamic line regulation.

to be charged for

F

F

remains above the

DD

must be

UCC15701/2

UCC25701/2

UCC35701/2

VFF is intended to operate accurately over a 4:1 range

between 0.8V and 3.2V. Voltages at VFF below 0.6V or

above 4.0V will initiate a soft stop cycle and a chip re

start when the under/over voltage condition is removed.

Volt-Second Clamp

A constant volt-second clamp is formed by comparing

the timing capacitor ramp voltage to a fixed voltage de

rived from the reference. Resistors R4 and R5 set the

volt-second limit. For a volt-second product defined as

VIN • t

ON(max)

-

-

RR

12+

The duty cycle limit is then:

V

VSCLAMP

V

The maximum duty cycle is realized when the

feedforward voltage is set at the low end of the operating

range (V

The absolute maximum duty cycle is:

D

MAX

Frequency Set

The frequency is set by a resistor from RT to ground and

-

a capacitor from CT to ground. The frequency is approxi

mately:

External synchronization is via the SYNC pin. The pin

has a 1.5V threshold , making it compatible with 5V and

3.3V CMOS logic. The input is level sensitive, with a high

input forcing the oscillator ramp low and the output low.

An active pull down on the SYNC pin allows it to be un

connected when not used.

Gate Drive Output

The UCC35701/2 is capable of a 1A peak output current.

Bypass with at least 0.1

tor must have a low equivalent series resistance and in

.

T

ductance. The connection from OUT to the power

MOSFET gate should have a 2 or greater damping re

sistor and the distance between chip and MOSFET

should be minimized. A low impedance path must be es

tablished between the MOSFET source (or ground side

of the current sense resistor), the V

PGND. PGND should then be connected by a single path

(shown as RGND) to GND.

, the required voltage at VSCLAMP is:

R

2

••

Vt

()

IN

•

RC

TT

, or

VFF

FF

==•

F

=

V

= 0.8V).

VV

VSCLAMP REF

2

RC

•

()

TT

ON

V

VSCLAMP

•

IN

()

max

2

R

12

RR

+

.

.

R

RR

+08 08545..

F directly to PGND. The capaci

DD capacitor and

-

-

-

-

-

-

-

-

6

Page 7

APPLICATION INFORMATION (cont.)

Transitioning From UCC3570 To UCC35701

The UCC35701/2 is an advanced version of the popular,

low power UCC3570 PWM. Significant improvements

were made to the IC’s oscillator and PWM control sec

tions to enhance overall system performance. All of the

key attributes and functional blocks of the UCC3570 were

maintained in the UCC35701/2. A typical application us

ing UCC3570 and UCC35701/2 is shown in Fig. 6 for

comparison.

The advantages of the UCC35701/2 over the UCC3570

are as follows.

Improved oscillator and PWM control section.

•

A precise maximum volt-second clamp circuit. The

•

UCC3570 has a dual time base between oscillator and

feedforward circuitry. The integated time base in

UCC35701/2 improves the duty cycle clamp accuracy,

providing better than ± 5% accurate volt- second

clamp over full temperature range.

• Separately programmable oscillator timing resistor

(RT) and capacitor (CT) circuits provide a higher

degree of versatility.

UCC15701/2

UCC25701/2

UCC35701/2

UCC35701/2 is pin to pin compatible to UCC3570 but is

not a direct drop-in replacement for UCC3570 sockets.

The changes required to the power supply printed circuit

board of for existing UCC3570 designs are minimal. For

conversion, only one extra resistor to set the volt-second

clamp needs to be added to the existing PC board lay

outs. In addition, some component values will need to be

changed due to the functionality change in of four of the

IC pins.

The Pinout Changes from UCC3570 are as follows.

Pin 7 was changed from SLOPE to RT (for timing

•

resistor)

Pin 8 was changed from ISET to VSCLAMP (requiring

•

one additional resistor from pin 9 to VREF)

Pin 10 was changed from RAMP to CT (single timing

•

capacitor)

Pin 11 was changed from FREQ to SYNC (input only)

•

Additional Information

Please refer to the following two Unitrode application

topics on UCC3570 for additional information.

-

• An independent SYNC input pin for simple external

synchronization.

• A smaller value filter capacitor (0.1

F) can be used

with the enhanced reference voltage.

TYPICAL WAVEFORMS

[1] Application Note U-150,

Applying the UCC3570 Voltage-Mode PWM Controller to Both Off-line and DC/DC

Converter Designs

[2] Design Note DN-62,

ogy, Voltage Mode vs. Current Mode

by Robert A. Mammano

Switching Power Supply Topol-

by Robert

Mammano

FEEDBK

VSCLAMP

CT

SOFTST

SOFT START HIGH DC LOW DC ZERO DC

SOFT STOP

V-S CLAMP

Figure 1. Timing diagram for PWM action with forward, soft start and volt-second clamp.

7

UDG-98207

Page 8

UCC15701/2

UCC25701/2

UCC35701/2

TYPICAL WAVEFORMS (cont.)

Figure 2. Timing diagram for oscillator waveforms showing feedforward action and synchronization.

VFF

CT

SYNC

UDG-98208

TYPICAL CHARACTERISTIC CURVES

1000

100

FREQUENCY [kHz]

10

20 60 100 140 180 220

RT [KΩ]

Figure 3. Oscillator frequency vs. RT and CT.

100pF

150pF

220pF

330pF

470pF

1.03

1.02

1.01

1.00

0.99

NORMALIZED DUTY CYCLE

0.98

0.97

VFF=3.2

VFF=0.8

-55 -35 -15 5 25 45 65 85 105 125

TEMPERATURE [°C]

Figure 5. Normalized maximum duty cycle vs.

temperature.

Figure 4. Oscillator frequency vs. temperature.

8

Page 9

APPLICATION INFORMATION (cont.)

V

IN+

R1

R2

R3

C

R

R4

C

T

R

T

C

SS

C

F

R

F

C3

R7

VFF

6

SLOPE

7

RAMP

10

ISET

9

FREQ

11

14

SS

1

COUNT

12

VREF

8

FB

UCC3570

R12

VDD

OUT

ILIM

PGND

GND

C5

UCC15701/2

UCC25701/2

UCC35701/2

R5

3

C1

4

2

5

13

R11

R13

C6

R6

V

C4

R8

R9

C2

R

SNS

R

GND

V

OUT

R14

C7

R15

OUT

V

IN+

R2

R3

C

T

R4

R

NEW

C

SS

C

F

R

F

C3

R7

UCC35701

R1

6

7

10

9

11

14

1

12

8

VFF

RT

CT

VSCLAMP

SYNC

SS

COUNT

VREF

FB

VDD

OUT

ILIM

PGND

GND

C5

R12

R5

3

4

2

5

13

R11

C6

R6

V

C4

C1

R8

R9

C2

R

SNS

R

GND

V

R13

C7

OUT

R14

R15

OUT

Figure 6. Single-ended forward circuit comparison between UCC3750 and UCC37501.

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

9

UDG-98210

Page 10

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...