Page 1

Through-beam ultrasonic barrier UBE1000-18GM40-SE2-V1

Technical data

General specifications

Sensing range 15 ... 1000 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 255 kHz

Indicators/operating means

LED green Power on

LED yellow switching state

LED red error, object uncertain

Electrical specifications

Model Number

UBE1000-18GM40-SE2-V1

Single head system

Features

•Short design, 40mm

• Function indicators visible from all

directions

• Switch output

•Program input

• Integrated alignment aid

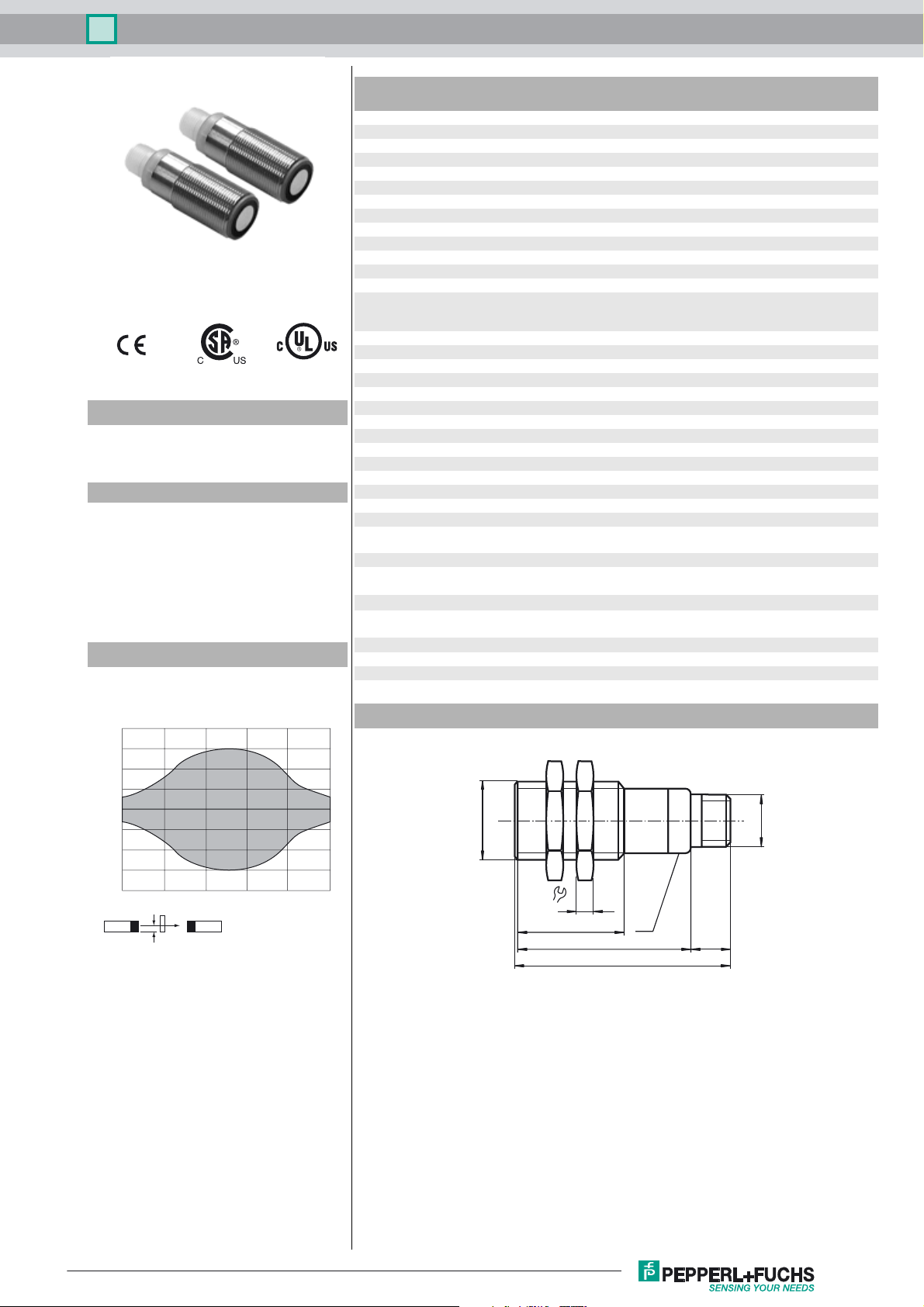

Diagrams

Characteristic response curve

Distance Y [mm]

20

15

10

5

0

-5

-10

-15

-20

0 200 400 600 800 1000

X

Y

Obstacle: flat plate 100 mm x 100 mm

Distance X [mm]

Operating voltage U

No-load supply current I

Time delay before availability t

Input

B

0

v

Input type 1 program input

Output

Output type PNP, NO

Rated operating current I

Voltage drop U

Switch-on delay t

d

Switching frequency f ≤ 100 Hz

e

on

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type Connector M12 x 1 , 4-pin

Degree of protection IP67

Material

Housing brass, nickel-plated

Transducer epoxy resin/hollow glass sphere mixture; foam polyurethane,

Mass 25 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007 + A1:2012

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated ≤36 V

Dimensions

M18 x 1

10 ... 30 V DC , ripple 10 %

≤ 20 mA

SS

≤ 200 ms

free air path: -U

input impedance: > 4,7 kΩ program pulse: ≥ 1 s

... +1 V, object: +6 V ... +UB

B

200 mA , short-circuit/overload protected

≤ 3 V

< 5 ms

cover PBT

IEC 60947-5-2:2007 + A1:2012

24

24.5

39.2

4

LED

10

50.2

M12 x 1

Release date: 2016-04-18 10:43 Date of issue: 2016-04-18 205346_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Page 2

Through-beam ultrasonic barrier UBE1000-18GM40-SE2-V1

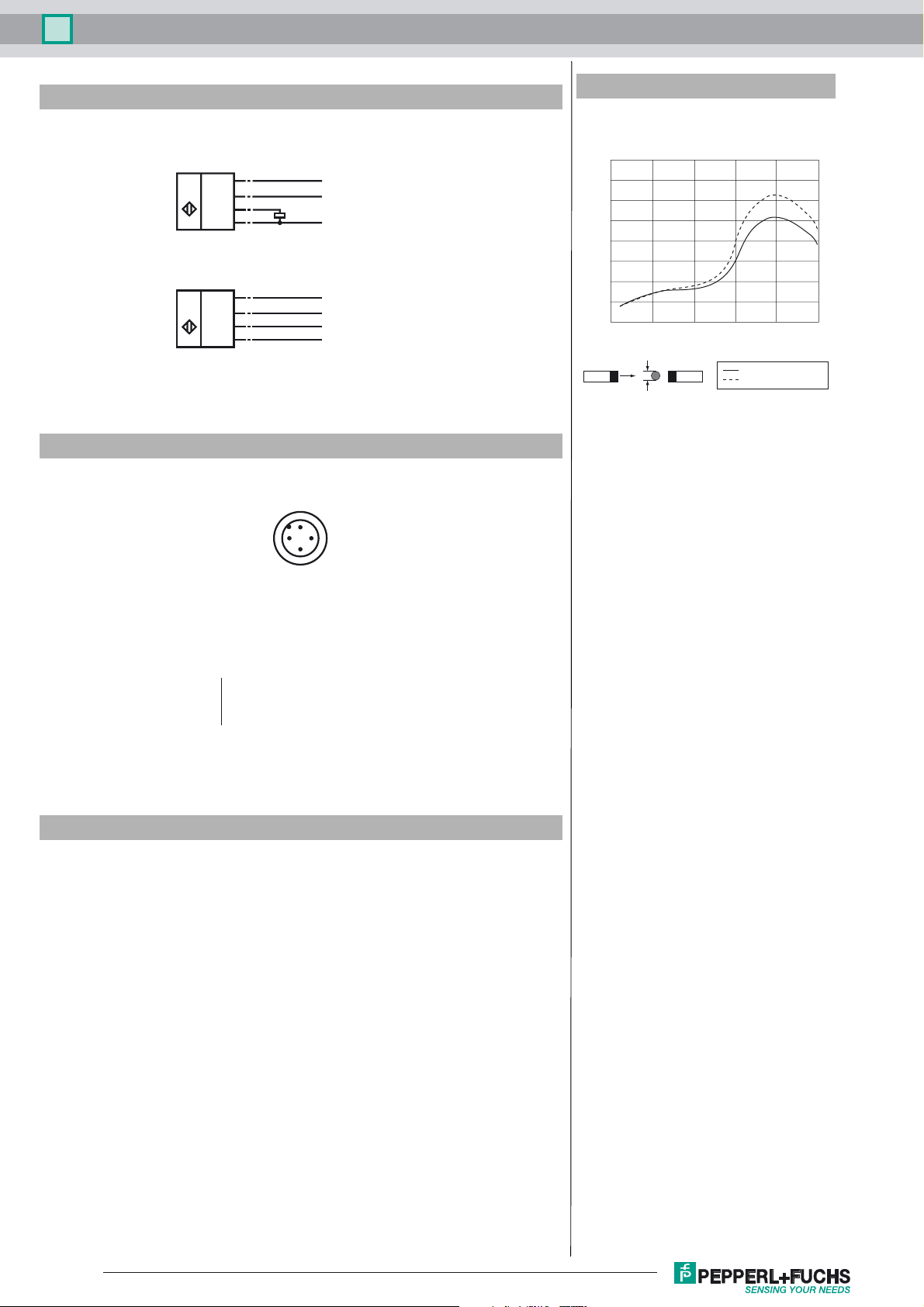

Electrical Connection

Standard symbol/Connection:

(version E2, pnp)

Receiver:

U

Emitter:

U

Core colours in accordance with EN 60947-5-2.

Pinout

Additional Information

Obstacle size

min. obstacle size d [mm]

80

(BN)

1

(WH)

2

4

(BK)

(BU)

3

(BN)

1

(WH)

2

(BK)

4

3

(BU)

+U

B

Teaching input

Switching output

-U

B

+U

B

Test input

n.c.

-U

B

1

70

60

50

40

30

20

10

0

0 200 400 600 800 1000

d

X

distance X [mm]

with Teach-In

without Teach-In

2

4

3

Wire colors in accordance with EN 60947-5-2

1 BN

2 WH

3 BU

4 BK

(brown)

(white)

(blue)

(black)

Accessories

UB-PROG2

Programming unit

OMH-04

Mounting aid for round steel ø 12 mm or sheet 1.5 mm ... 3 mm

BF 18

Mounting flange, 18 mm

BF 18-F

Mounting flange with dead stop, 18 mm

BF 5-30

Universal mounting bracket for cylindrical sensors with a diameter of 5 ... 30 mm

V1-G-2M-PVC

Female cordset, M12, 4-pin, PVC cable

V1-W-2M-PUR

Female cordset, M12, 4-pin, PUR cable

Function

A through-beam ultrasonic barrier always consists of a single emitter and a single

receiver. The function of a through-beam ultrasonic barrier is based in the interruption of the sound transmission to the receiver by the object to be detected.

The emitter sends an ultrasonic signal that is evaluated by the receiver. If the signal

is interrupted or muted by the object to be detected, the receiver switches.

No electrical connections are required between the emitter and receiver.

The function of through-beam ultrasonic barriers is not dependent on the position of

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Release date: 2016-04-18 10:43 Date of issue: 2016-04-18 205346_eng.xml

Page 3

Through-beam ultrasonic barrier UBE1000-18GM40-SE2-V1

their installation. We recommend, however, to install the emitter below in the case of vertical installations to prevent the accumulation of dust particles.

Startup and parameterising

For easy alignment of emitter and receiver towards each other, the receiver is equipped with an alignment aid. To activate the

alignment aid, the TEACH-Input of the receiver (pin 2) has to be connected to ground (-U

LED indicates the strength of the received ultrasonic signal. The better the alignment, the stronger the signal.

LED yellow, flashing frequency Description

slowly (appr. 1.5 Hz) no signal

medium (appr. 3 Hz) weak signal

fast (appr. 9 Hz) strong signal

Simultaneously the ultrasonic barrier evaluates the signal strength of the unobstructed signal path and generates the optimal

switching threshold. When disconnecting the TEACH-input from -U

, this threshold is stored non-volatile in the receivers me-

B

mory. In case of clear ultrasonic path (no object), only the receivers green LED is on.

TEACH-In of very small objects/obstacles

Like shown in the curve "obstacle size", the ultrasonic barrier offers the possibility to detect very small objects at a distance of

more than 300 mm.

- place the object to be detected in the desired distance inside the ultrasonic path

- connect TEACH-input of the receiver to +U

(yellow LED flashes slowly)

B

- disconnect TEACH-input

In case of successful TEACH-IN (object is detected reliable), the yellow LED is on and the taught detection threshold is stored

non-volatile to the receivers memory.

In case of unsuccessful TEACH-IN (object too small or too porous for ultrasonic sound),the red LED flashes 5 times and the

ultrasonic barrier continues normal operation with unmodified detection threshold value.

Test function

For test purpose, the ultrasonic emitter is equipped with a test input. In normal operation mode (test input not connected or connected to -U

), the green LED of the emitter is on. If the test input is connected to +UB , the ultrasonic emitter gets deactivated

B

and its LED changes into red. Simultaneously the receiver switches and its yellow LED goes on.

). The flashing frequency of the yellow

B

Release date: 2016-04-18 10:43 Date of issue: 2016-04-18 205346_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Loading...

Loading...