Page 1

Ultrasonic sensor UBC250-12GM-I-V1

Technical data

General specifications

Sensing range 30 ... 250 mm

Adjustment range 50 ... 250 mm

Dead band 0 ... 30 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 310 kHz

Response delay approx. 50 ms

Electrical specifications

Model Number

UBC250-12GM-I-V1

Single head system

Features

• High chemical resistance through

PTFE coated transducer surface

• Stainless Steel enclosure

•Analog output 4mA...20mA

• Temperature compensation

• Measuring window adjustable

•Program input

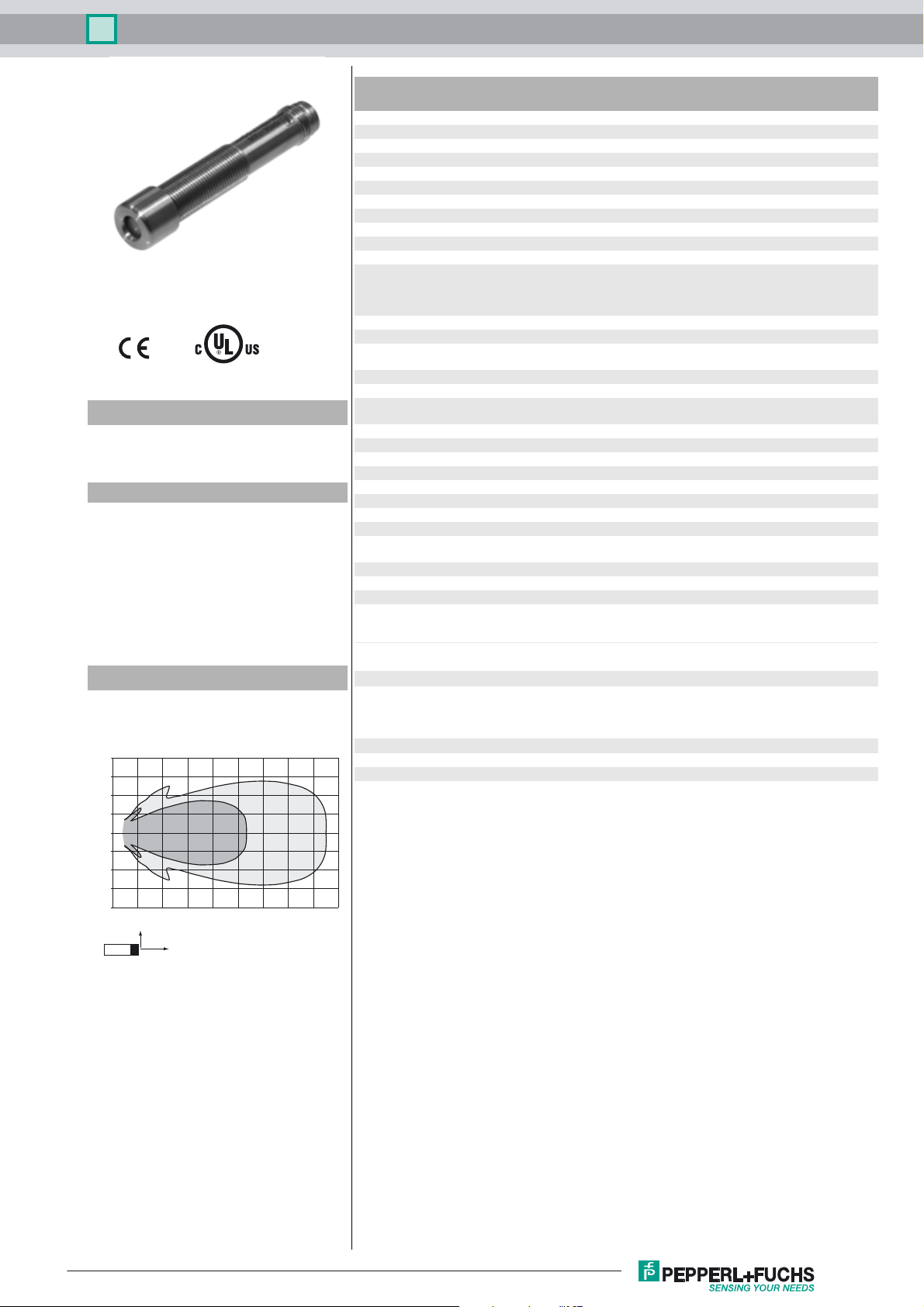

Diagrams

Characteristic response curve

Distance Y [mm]

200

150

100

50

0

-50

-100

-150

-200

0 100 200 300 400 500 600 700 800 900

Y

X

Curve 1: flat surface 100 mm x 100 mm

Curve 2: round bar, Ø 25 mm

12

Distance X [mm]

Operating voltage U

No-load supply current I

Input

Input type 1 program input

Output

Output type 1 analog output 4 ... 20 mA

Resolution 0.17 mm

Deviation of the characteristic curve ± 1 % of full-scale value

Repeat accuracy ± 0.5 % of full-scale value

Load impedance 0 ... 300 Ω at UB > 10 V;

Temperature influence ± 1.5 % of full-scale value

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type Connector M12 x 1 , 4-pin

Degree of protection IP68 / IP69K

Material

Housing stainless steel 1.4404 / AISI 316L

Transducer PTFE (diaphragm surface)

Mass 35 g

Factory settings

Output evaluation limit A1: 50 mm

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007+A1:2012

Approvals and certificates

UL approval cULus Listed, Class 2 Power Source

CCC approval CCC approval / marking not required for products rated ≤36 V

B

0

10 ... 30 V DC , ripple 10 %

≤ 30 mA

lower evaluation limit A1: -U

A2: +4 V ... +U

input impedance: > 4.7 kΩ, pulse duration: ≥ 1 s

0 ... 500 Ω at U

O-ring for cover seal: Viton

evaluation limit A2: 250 mm

output function: rising ramp

IEC 60947-5-2:2007 + A1:2012

EN 60947-5-7:2003

IEC 60947-5-7:2003

B

> 15 V

B

SS

... +1 V, upper evaluation limit

B

Release date: 2017-07-12 08:58 Date of issue: 2017-07-12 256533_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Page 2

Ultrasonic sensor UBC250-12GM-I-V1

Dimensions

Additional Information

Programming the analog output mode

Rising ramp

A1 < A2:

Falling ramp

A2 < A1:

12

4

17

43

65

72.5

4

M12 x 1

ø 7

ø 15

A1

A2

object range

A2

A1

Electrical Connection

Standard symbol/Connections:

(version I)

U

Core colors in accordance with EN 60947-5-2.

Pinout

Wire colors in accordance with EN 60947-5-2

1 BN

2 WH

3 BU

4 BK

1 (BN)

2 (WH)

4 (BK)

3 (BU)

2

1

3

(brown)

(white)

(blue)

(black)

+ U

B

Teach input

Analog output

- U

B

4

Release date: 2017-07-12 08:58 Date of issue: 2017-07-12 256533_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Page 3

Ultrasonic sensor UBC250-12GM-I-V1

Accessories

UB-PROG2

Programming unit

BF 5-30

Universal mounting bracket for cylindrical sensors with a diameter of 5 ... 30 mm

BF 12

Mounting flange, 12 mm

V1-G-2M-PVC

Female cordset, M12, 4-pin, PVC cable

V1-W-2M-PUR

Female cordset, M12, 4-pin, PUR cable

Adjusting the evaluation limits

The ultrasonic sensor features an analogue output with two teachable evaluation limits. These are set by applying the supply voltage -U

limit A1 is taught with -U

Two different output functions can be set:

1. Analogue value increases with rising distance to object (rising ramp)

2. Analogue value falls with rising distance to object (falling ramp)

TEACH-IN rising ramp (A2 > A1)

- Position object at lower evaluation limit

- TEACH-IN lower limit A1 with - U

- Position object at upper evaluation limit

- TEACH-IN upper limit A2 with + U

TEACH-IN falling ramp (A1 > A2):

- Position object at lower evaluation limit

- TEACH-IN lower limit A2 with + U

- Position object at upper evaluation limit

- TEACH-IN upper limit A1 with - U

or +UB to the TEACH-IN input. The supply voltage must be applied to the TEACH-IN input for at least 1 s. The evaluation

B

, A2 with +UB.

B

B

B

B

B

Installation conditions

If the sensor is installed at places, where the environment temperature can fall below 0 °C, for the sensors fixation, one of the

mounting flanges BF 12 or BF 5-30 must be used. In case of direct mounting of the sensor in a through hole, it has to be fixed at

the middle of the housing thread.

Note

If the sensor is used in an environment with strong electromagnetic interference, we recommend non-conductive mounting. For this, use

the accompanying plastic nuts or the BF12 mounting flange.

Please observe proper application when using the accompanying plastic nuts. The hole for the sensor must be ≥ 14 mm.

Release date: 2017-07-12 08:58 Date of issue: 2017-07-12 256533_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Loading...

Loading...