Page 1

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Precision Phase Lock Loop Motor – RPM

Control With Embedded DSP Filter

Algorithm for Loop Compensation

D

EEPROM Registers for User Adjustment of

PLL Loop Gain and DSP Filter Coefficients

(Pole/Zero)

D

Crystal Oscillator With EEPROM Adjustable

Divide-By for Versatile PLL Timebase

D

Standalone Operation With No Host

Processor Needed

D

RPM Lock Detection/Reporting

(±5% Window)

D

Synchronous Rectification,

Enabled (TPIC43T01)

Disabled (TPIC43T02)

D

Stalled Motor Timer/Shutdown

D

High-Side Current Limiting

D

High-Side Over-Current Shutdown

D

Differential Hall Effect Position Sensor

Inputs/Decode Provide Commutation

Control

D

Differential Variable Reluctance Speed

Sensor Inputs

D

Gate Drive for Six External N-Channel

Power FETs in Three Half-H Configuration

D

Charge Pump to Develop High-Side Gate

Drive V oltage

D

5 V Regulator – Designed for 10 mA

External Current

D

8 to 28 V Supply Voltage

D

Small Outline Surface-Mount Package

description

The TPIC43T01/02 is a monolithic motor control integrated circuit designed to provide RPM control to a 3-phase

brushless dc motor. The device provides two analog sensor input ports which include a speed sensor interface

and a Hall effect position interface. The speed feedback interface consists of an FG amplifier to receive an

external sinusoidal signal from a variable reluctance pickup and convert it to a digital speed signal for the control

circuit. When the motor speed is outside a ±5% window of the reference signal, an out-of-lock condition is

declared. The Hall ffect sensor input section receives low-level differential voltages from external naked Hall

elements and converts them to digital position reference signals for the control circuit for commutation control.

The core of the control circuit implements a digital signal processing algorithm consisting of a digital integrator

and filter with user adjustable parameters to optimize the closed loop performance of the control system. The

device contains an internal EEPROM to set integrator gain and digital filter coefficients. In addition, Texas

Instruments provides a PC based Windows compatible software package to input the motor and system

characteristics and convert them to control parameters for the TPIC43T01/02. The software generates a JEDEC

compatible file to program the device through a third party device programmer.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

IN2+

IN2–

IN3+

IN3–

FGOUT

FGIN–

FGIN+

CLT

CT

RT

OSC2

OSC1

V

DD

FGSOUT

GND

LD

FSEL

S/S

F/R

IN1–

IN1+

TEST

V

PP

PHA

UGA

LGA

UGB

PHB

LGB

LGC

UGC

PHC

SENSE

CP2

CP1

V

CP

PGND

V

CC

DA PACKAGE

(TOP VIEW)

Copyright 2000, Texas Instruments Incorporated

Windows is a trademark of Microsoft Corporation.

Page 2

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

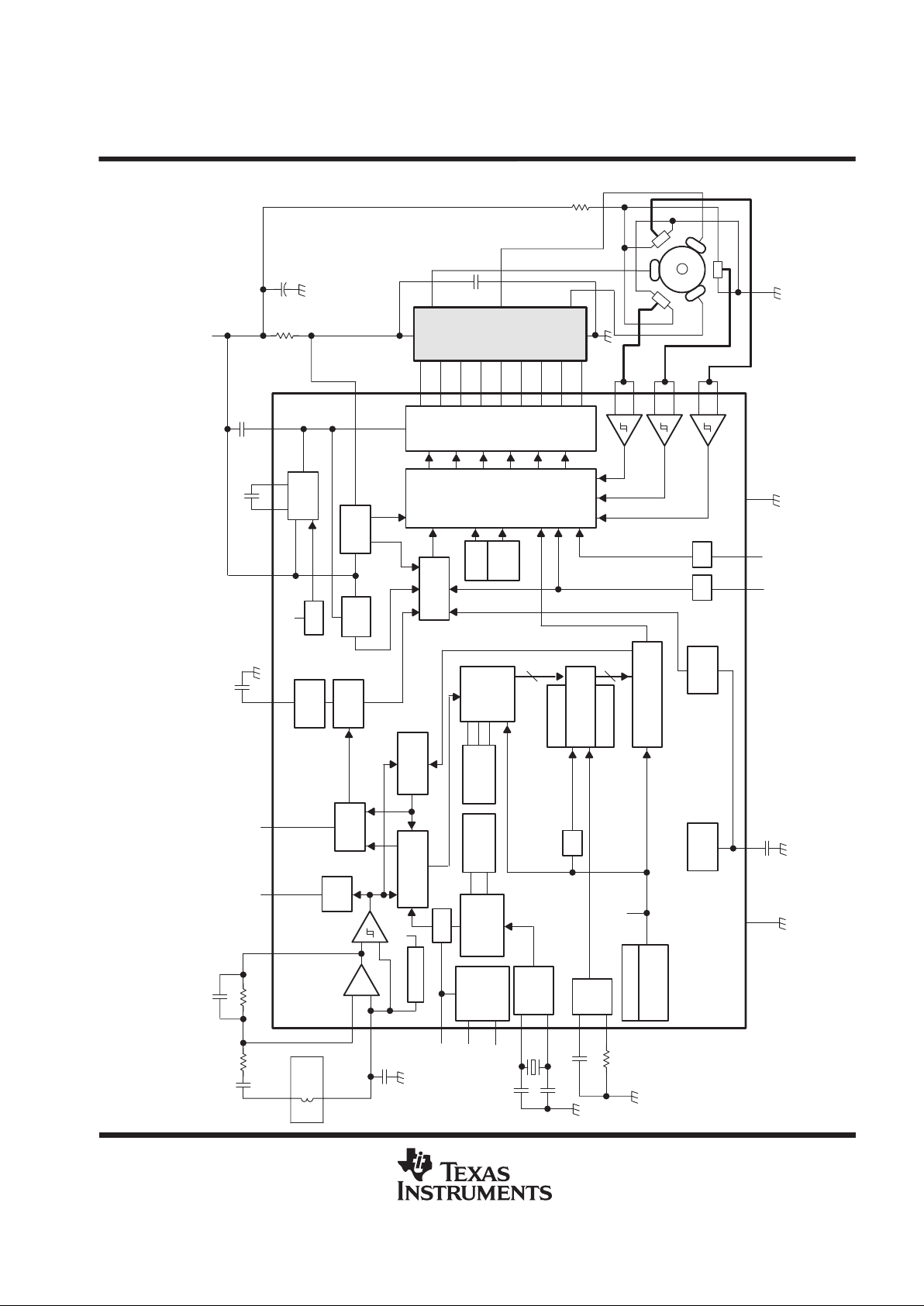

description (continued)

The TPIC43T01/02 provides pre-drive outputs to control six external N-channel FET switches connected in a

3-half H-bridge configuration to drive a 3-phase dc motor. A companion TI Power+ Arrays device is available,

the TPIC1310 3-half H-bridge power array, to provide up to 2.5 A motor drive capability. The TPIC1310 is a

monolithic gate protected DMOS power array available in the TI 15-pin PowerFLEX power package. The

TPIC43T01/02 gate drive outputs are designed to also drive discrete N-channel power FETs.

The TPIC43T01/02 provides onboard supervisory and shutdown logic to protect the device and motor from fault

conditions. Oscillators, charge pump, and voltage regulators have been integrated into the TPIC43T01/02 to

minimize the number of external discrete components required to support the motor system.

Power+ Arrays and PowerFLEX are trademarks of Texas Instruments Incorporated.

Page 3

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

• 3

A2

+

–

+

FGS

OUT

Lock

Detect

FGS Bias

VIN

÷ 2

Speed

Discrimination

EEPROM

Program

and Test

Logic

FG

Frequency

Select

FG Divide

Register 1

F0

F1

FG Ref

OSC

F

S

OSC

Freq Adj REG

5.8 MHz

OSC

Gain Select

Register

A0

A1

Digital

Integrator

OSC_INT

–

Digital

Filter

10

k2:3–Bit REG

k1:6–Bit REG

8

8–Bit PWM

Generator

÷

FILTCLK

F

S

Watchdog

Timer

Lock

OSC

Lock

Counter

Shutdown

Logic

÷ 32

Charge

Pump

CP

UVLO

Current

Limit

181 kHz

CPUV

OCSD

Gate Drive

Control and

Commutation

Logic

Sync

Rect

VDDUV S/S

PWM

S/S

F/R

ILIM

Pre-FET

Drivers

–

+

–

+

F/RS/S

V

DD

UVLO

5 V

VReg

OSC_INT

FGOUT FGSOUT LD CLT

V

CC

CP1 CP2

V

CP

SENSE

UGA

PHA

LGA

UGB

PHB

LGB

UGC

PHC

LGC

IN1+

IN1–

IN2+

IN2–

IN3+

IN3–

PGNDF/RS/SV

DD

GND

FGIN–

FGIN+

FSEL

V

PP

TEST

OSC1

OSC2

CT

RT

Power

Array

IC

3-Phase

Motor

Analog Hall-Effect

Position Sensors

CM = 22 µF

Rsense

0.2

CP = 0.01 µF

V

m

CS = 0.1–0.5 µF

CLT = 0.1 µF

150 pF

330 k

1 k

1 µF

Speed

Pickup

FG

0.01 µF

Cosc = 30 pF

Cosc = 30 pF

CT = 0.02 µF

RT = 12.5 k

1 µF

typical application

0.1 µF

1.5 k

Coast

Page 4

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

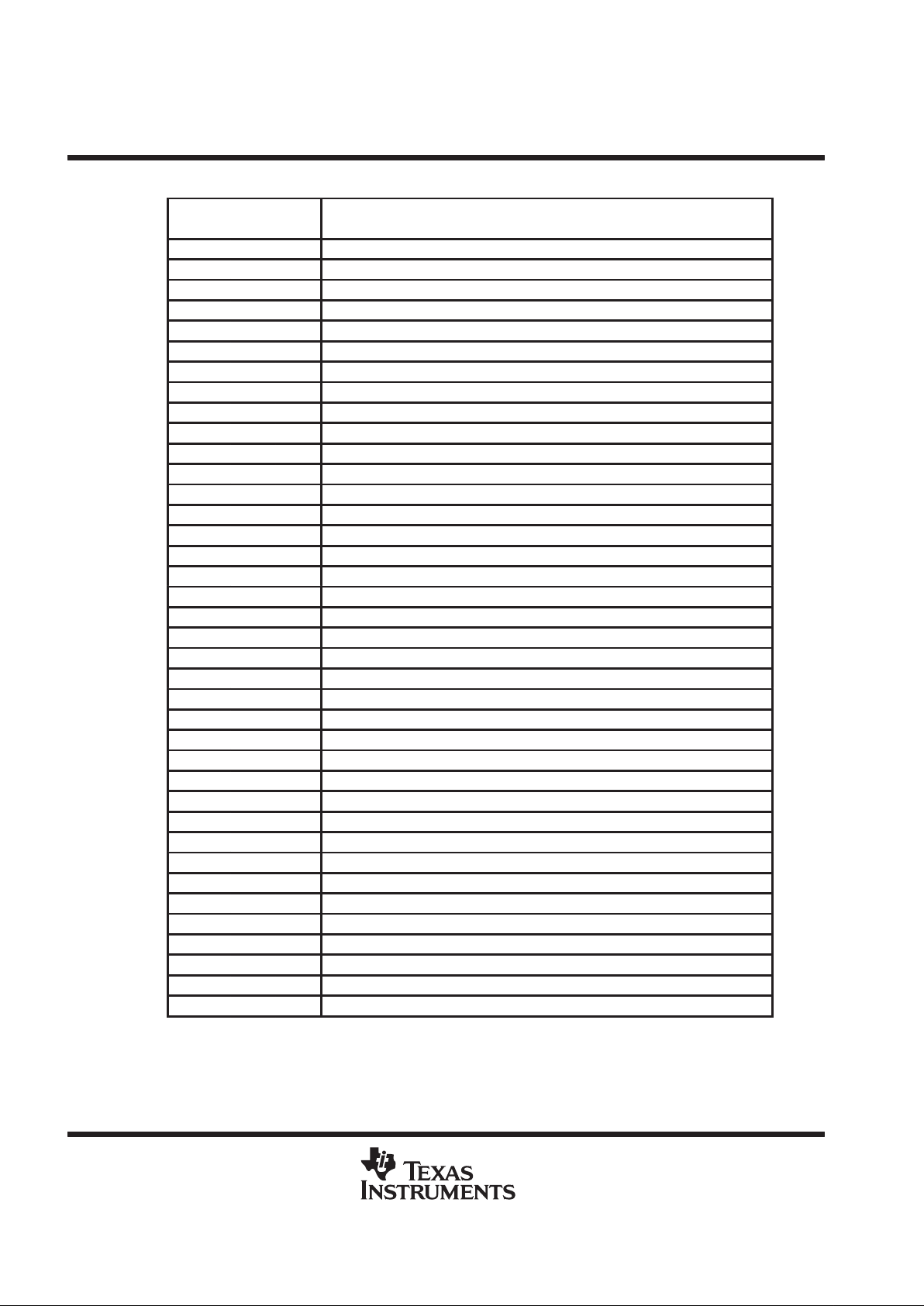

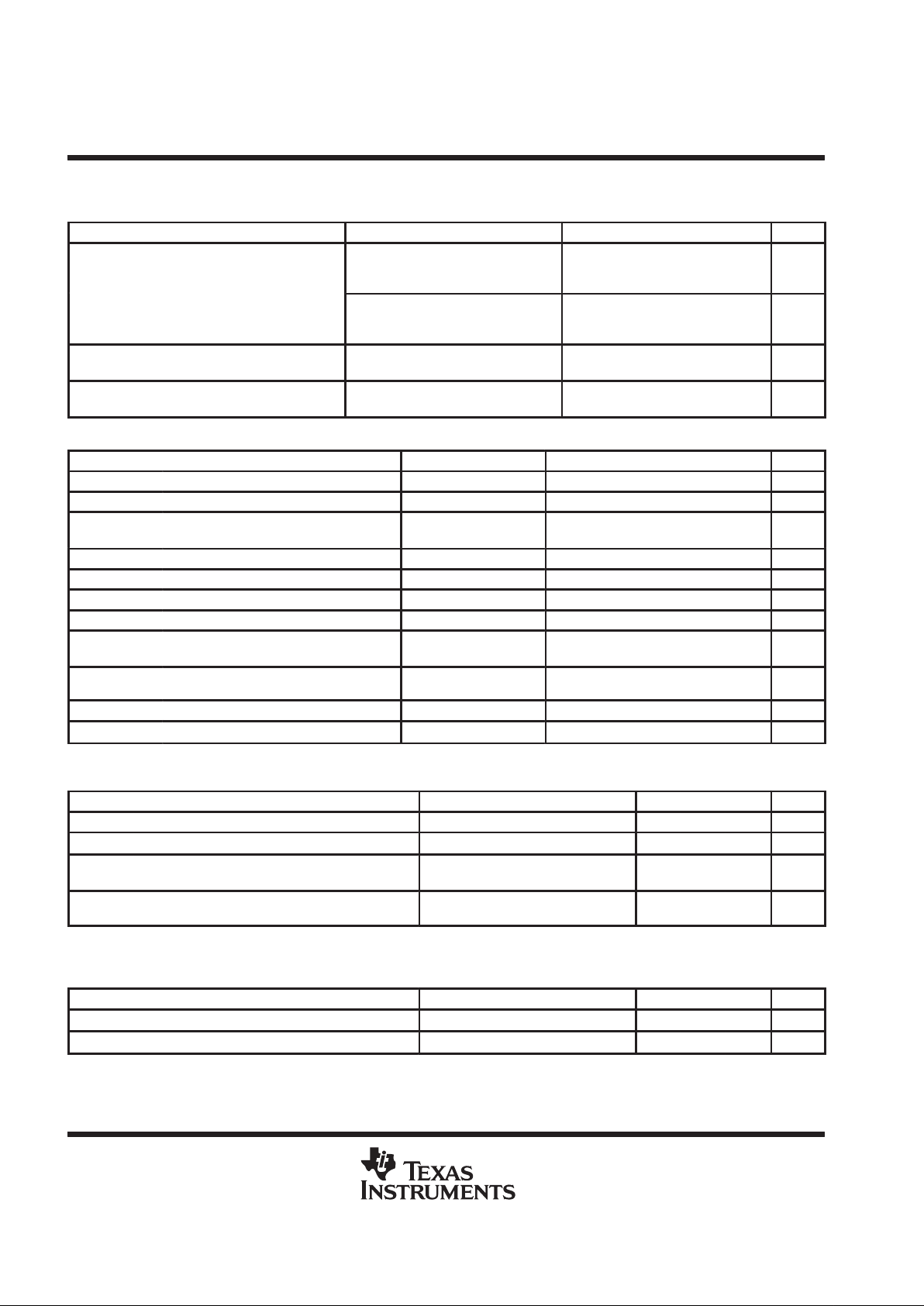

Terminal Functions

TERMINAL

NAME NO. I/O

DESCRIPTION

CLT 8 I Capacitor lock timer. CLT is a timing capacitor for the lock detect timer oscillator.

CP1 23 O Charge pump. CP1 is the switched capacitor output number 1.

CP2 24 O Charge pump. CP2 is the switched capacitor output number 2.

CT 9 I Timing capacitor. CT is the timing capacitor for the filter oscillator.

F/R 19 I Forward/Reverse. F/R is the forward/reverse direction data input.

FGIN– 6 I FGIN– is a inverting amplifier input.

FGIN+ 7 O FGIN+ is a noninverting amplifier input.

FGOUT 5 O FGOUT is a amplifier output.

FGSOUT 14 O FGSOUT is a buffered FGS comparator output.

FSEL 17 I Frequency select. FSEL is a frequency select input.

GND 15 Ground

IN1– 38 I Hall amplifier 1 inverting input

IN1+ 37 I Hall amplifier 1 noninverting input

IN2– 2 I Hall amplifier 2 inverting input

IN2+ 1 I Hall amplifier 2 noninverting input

IN3– 4 I Hall amplifier 3 inverting input

IN3+ 3 I Hall amplifier 3 non-inverting input

LD 16 O Lock Detect. LD is an active low, open-drain output.

LGA 32 I Lower gate drive A

LGB 29 I Lower gate drive B

LGC 28 I Lower gate drive C

OSC1 12 I Crystal oscillator input 1. OSC1 is an external OSC input.

OSC2 11 I Crystal oscillator input 2. OSC2 is an external OSC input.

PGND 21 PGND is the lower gate drive turnoff circuitry GND return.

PHA 34 I Phase A return

PHB 30 I Phase B return

PHC 26 I Phase C return

RT 10 O RT is the charge/discharge current setting resistor for filter and lock timer oscillators.

S/S 18 I Stop/Start. S/S = low to start.

SENSE 25 I Current limit sense. SENSE is the high-side current limit sense input.

TEST 36 I Test enable

UGA 33 I Upper gate drive A

UGB 31 I Upper gate drive B

UGC 27 I Upper gate drive C

V

CC

20 I Supply voltage

V

CP

22 O Charge-pump voltage source. VCP requires a storage capacitor.

V

DD

13 O 5 V Supply output

V

PP

35 I EEPROM programming voltage input

Page 5

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

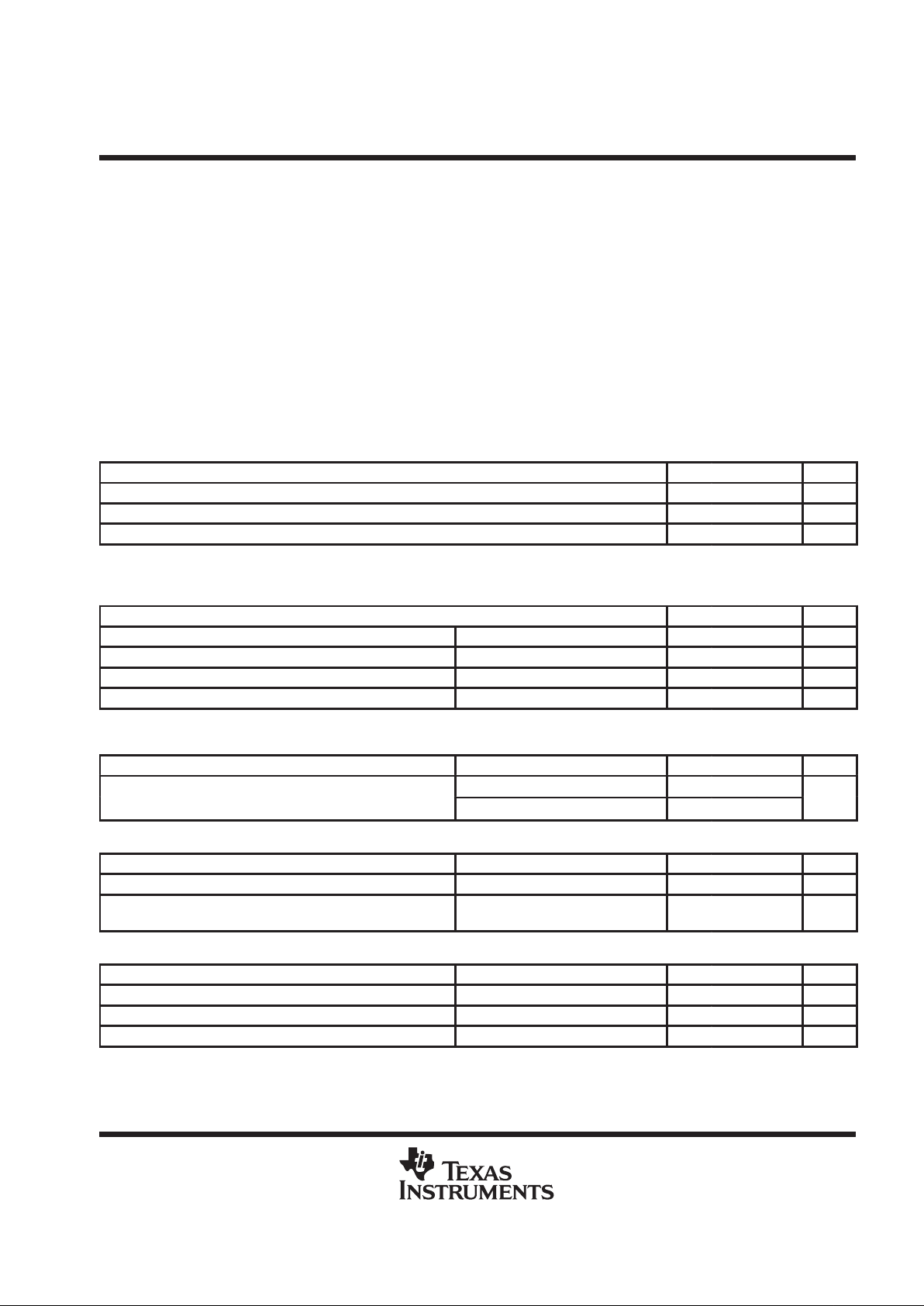

absolute maximum ratings over the recommended operating case temperature range (unless

otherwise noted)

†

Supply voltage range, VCC (see Note 1) 8 V to 30 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor drive voltage, V

(motor)

30 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charge pump output voltage, V

CP(max),

(V

CP

– VCC) V

CC

+ 20 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, TJ 0°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal resistance, junction to ambient, R

θJA

121°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: The device will function, but may not meet all electrical specifications over this voltage range.

recommended operating conditions

MIN TYP MAX UNIT

Supply voltage, V

CC

18 24 28 V

Extended supply voltage range, (see Note 1) 8 18 V

Operating case temperature, T

C

0 70 °C

NOTE 1: The device will function, but may not meet all electrical specifications over this voltage range.

EEPROM programming

MIN TYP MAX UNIT

VPP setup time, tsu(VPP) See Figure 20 2 µs

VPP pulse width duration, tw(VPP) See Figure 20 5 ms

VPP rise time, tr(VPP) See Figure 20 2 3 ms

VPP fall time, tf(VPP) See Figure 20 2 3 ms

electrical characteristics, TC = 25°C, V

CC

= 24V (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

S/S low, VCC = 28 V, I

(VCP)

= 2 mA

10 18

I

ccq

V

DD

quiescent current

S/S high, VCC = 28 V, I

(VCP)

= 0 mA

5 10

mA

VDD undervoltage lockout

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

DD(uvlo)

VDD under-voltage lockout threshold voltage 2.5 3.1 4 V

V

hys

VDD under-voltage lockout threshold voltage

hysteresis

1.1 V

5 V regulator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

DD

Output voltage IO = –10 mA 4.75 5 5.25 V

V

(REGIN)

Line regulation VCC = 8 V to 28 V 0 50 mV

V

(REGOUT)

Load regulation IO = 0 to –10 mA 20 100 mV

Page 6

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

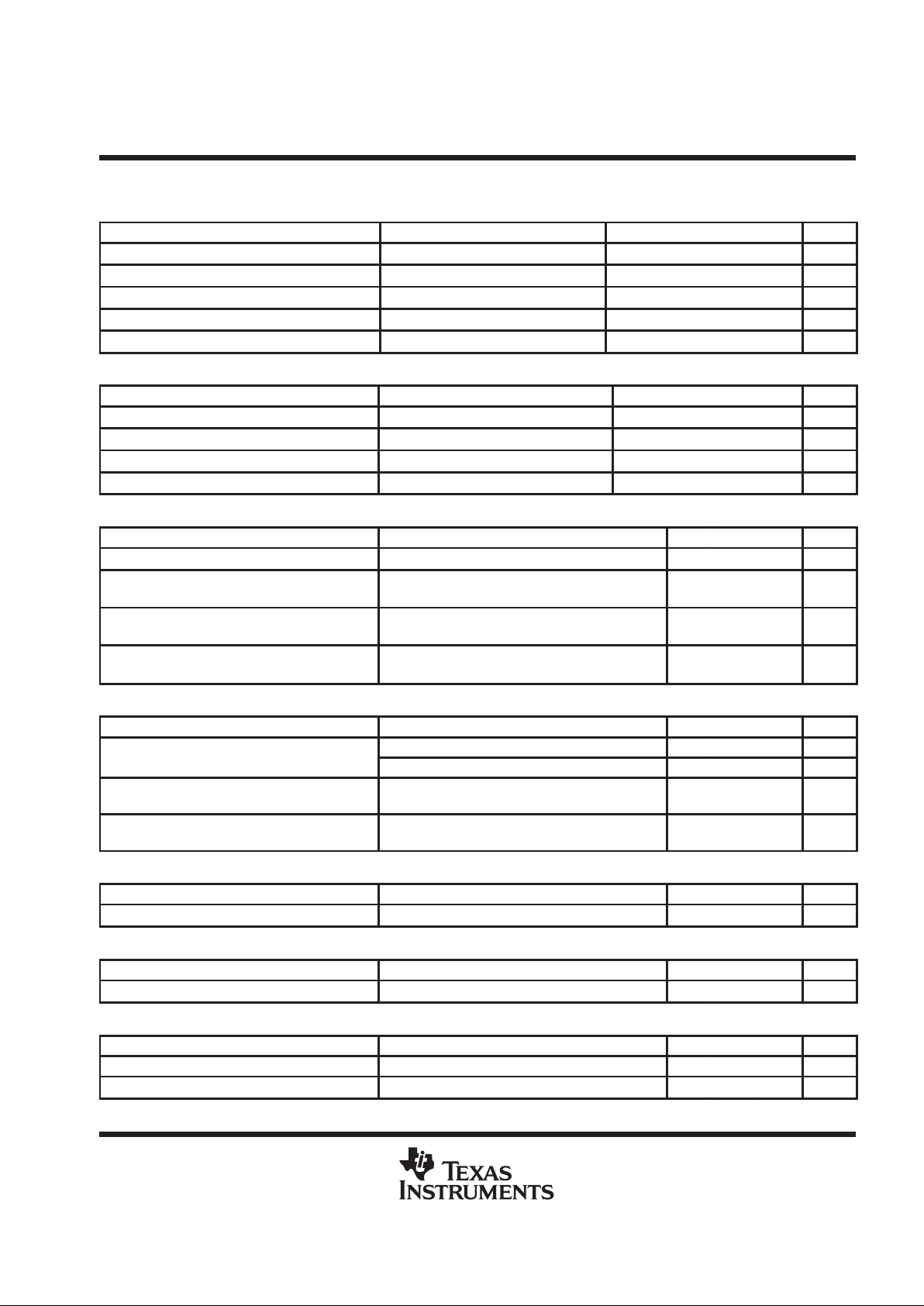

electrical characteristics, TC = 25°C, V

CC

= 24V (unless otherwise noted) (continued)

charge pump

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

p

IO = –1.5 mA, VCC = 18 V to 28 V,

CP = 0.01 µF, CS = 0.1 µF,

S/S = high

VCC + 14 VCC + 15 VCC + 17 V

V

O(CP)

Output voltage

IO = –1.5 mA, VCC = 8 V,

CP = 0.01 µF, CS = 0.1 µF,

S/S = high

VCC + 5.5 V

V

(CP–uvlo)

Under voltage lockout

IO = –1.5 mA, VCC = 8 V to 28 V,

S/S = high (VCP forced externally)

VCC + 5 VCC + 6 VCC + 7 V

V

hys(CP)

Under voltage lockout hysteresis

IO = –1.5 mA, VCC = 8 V to 28 V,

S/S = high (VCP forced externally)

0.6 V

FG signal conditioning

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IO(FG)

Amplifier input offset voltage Measured at FGOUT 0.5 ±7 mV

I

IB(FG)

Amplifier input bias current Measured at FGIN– 0.02 ±1 µA

V

OH(FG)

Amplifier high level output voltage

I

(FG)

= –200 µA,

IDD = 0

VDD–500 mV VDD–350 mV V

V

OL(FG)

Amplifier low level output voltage I

(FG)

= 200 µA, IDD = 0 100 500 mV

A

V

Amplifier open-loop gain (see Note 2) 45 dB

V

(FGsens)

FG input sensitivity (see Note 2) 100 x Gain, at 2 kHz, 3 mV

V

(FGbias)

FG bias voltage IFG = 0 µA, IDD = 0 2.375 2.5 2.625 V

V

IT+(FGOUT)

FG comparator positive threshold

FGOUT with respect to

V

(FGIN+),

See Figure 8

215 250 285 mV

V

IO(FGOUT)

FG comparator offset voltage

FGOUT with respect to

V

(FGIN+)

, See Figure 8

0.8 ±7 mV

V

OL(FGSOUT)

FGSOUT open drain saturation voltage IO = 2 mA 0.4 0.7 V

I

lkg(FGSOUT)

FGSOUT leakage current VO = 5 V 0.08 10 µA

NOTE 2: Design target only. Not tested in production.

Hall sensor signal conditioning

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

IB(HL)

Input bias current (see Note 2) ±4 µA

V

ICR(HL)

Common-mode input voltage range (see Note 3) 1.5 3.5 V

V

IT+(HL)

Input positive threshold voltage

With respect to V

(CM)

, 1.5 kΩ in series

with both inputs, See Figure 9

4 8 12 mV

V

IT–(HL)

Input negative threshold voltage

With respect to VCM, 1.5 kΩ in series

with both inputs, See Figure 9

–4 –8 –12 mV

NOTES: 2. Design target only. Not tested in production.

3. Not measured, forced during testing.

FG reference crystal oscillator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IT+(OSC1)

OSC1 input upper threshold (see Note 3) 2.7 V

V

IT–(OSC1)

OSC1 input lower threshold (see Note 3) 1 V

NOTES: 3. Not measured, forced during testing.

Page 7

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

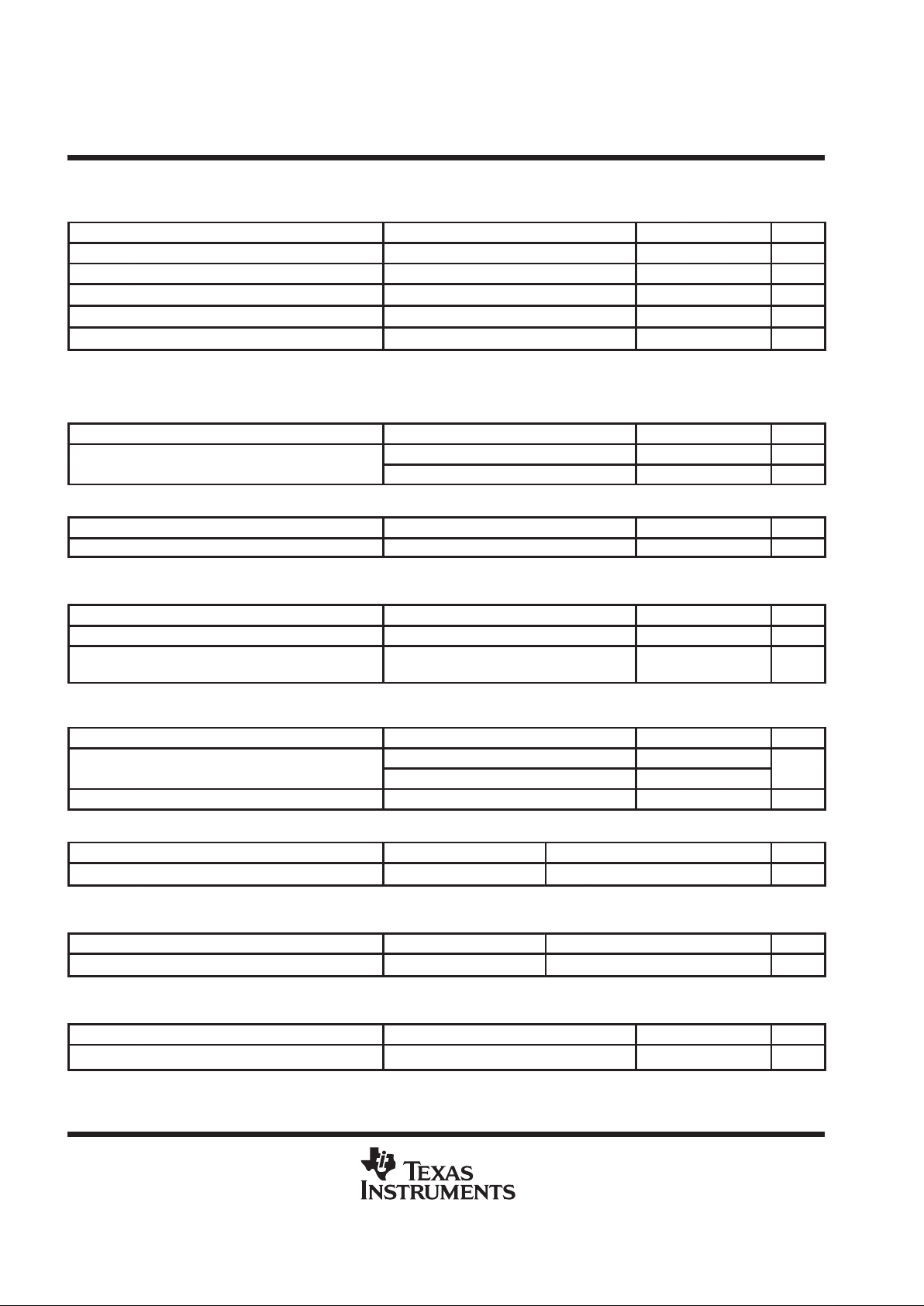

electrical characteristics, TC = 25°C, V

CC

= 24V (unless otherwise noted) (continued)

digital filter f

(s)

RC oscillator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

ref(RT)

RT reference voltage I

(RT)

= –160 µA 0.19 V

DD

0.2 V

DD

0.21 V

DD

V

V

IT+(CT)

CT upper threshold voltage 0.7 V

DD

V

V

IT–(CT)

CT lower threshold voltage 0.3 V

DD

V

V

(CT)

CT amplitude 1.9 2 2.1 V

I

(CT)

CT charge/discharge current Measured at V

IT+(CT)

and V

IT–(CT)

1.8 I

(RT)

±2 I

(RT)

2.2 I

(RT)

A

lock detection timer

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IT+(CLT)

CLT upper threshold voltage 0.7 V

DD

V

V

IT–(CLT)

CLT lower threshold voltage 0.3 V

DD

V

V

(CLT)

CLT amplitude 1.9 2 2.1 V

I

(CLT)

CLT charge/discharge current

Measured at VIT +

(CLT)

and V

IT–(CLT)

1.9 I

(RT)

±2 I

(RT)

2.3 I

(RT)

A

high side gate drive

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

C

Clamp voltage

UGX to PHX, I

(UGX)

= –100 µA

14 16 19 V

V

DS(UGX)

Source voltage drop

I

(UGX)

=–10 mA, VCP = VCC + 17 V,

Measure VCP – V

(UGX),VCC

= 18 V

1 1.2 V

Vsink

(UGX)

Sink voltage drop @10 mA

I

(UGX)

=10 mA, V

(PHx)

= 0,

Measure V

(UGX)

– V

(PHx) ,VCC

= 18 V

1.8 2 V

Vsink

(UGX)

Sink voltage drop @100 uA

I

(UGX)

=10 mA, V

(PHx)

= 0,

Measure V

(UGX)

– V

(PHx) ,VCC

= 18 V

0.56 0.7 V

low side gate drive

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

p

VCC = 18 to 28 V, I

(LGX)

= 0 14 16 19 V

V

O(REG15)

High level output voltage

VCC = 8 to 18 V, I

(LGX)

= 0 7.9 8 18 V

V

source(LGX)

Source voltage

I

(LGX)

= –10 mA, with respect to PGND,

VCC = 18 V

12 14.5 V

V

DS(LGX)

Sink voltage drop

I

(LGX)

= 10 mA, with respect to PGND,

VCC = 18 V

0.6 1 V

current limit control

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IT(lim)

Limit threshold voltage VCC – V

(SENSE)

0.46 0.5 0.54 V

over-current shutdown control

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IT(ocsd)

Detection threshold voltage VCC – V

(SENSE)

0.9 1 1.1 V

EEPROM programming

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

PP

VPP programming voltage 12 13 15 V

R

(VPP)

VPP pulldown resistance VPP = 1 V 15 23 35 kΩ

Page 8

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics, TC = 25°C, V

CC

= 24V (unless otherwise noted) (continued)

digital input pins

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IH

Digital input high level input voltage Interface from 3.3 V controller 2.2 V

V

IL

Digital input low level input voltage Interface from 3.3 V controller 1.1 V

I

(pullup)

Digital input pullup current, S/S, FSEL VIN = 2.2 V –9 –14 –18 µA

I

(F/R)

Digital input pulldown current, F/R VIN = 1.1 V 17.5 27 35 µA

I

(TEST)

TEST input pulldown current VIN = 1.1 V 130 200 250 µA

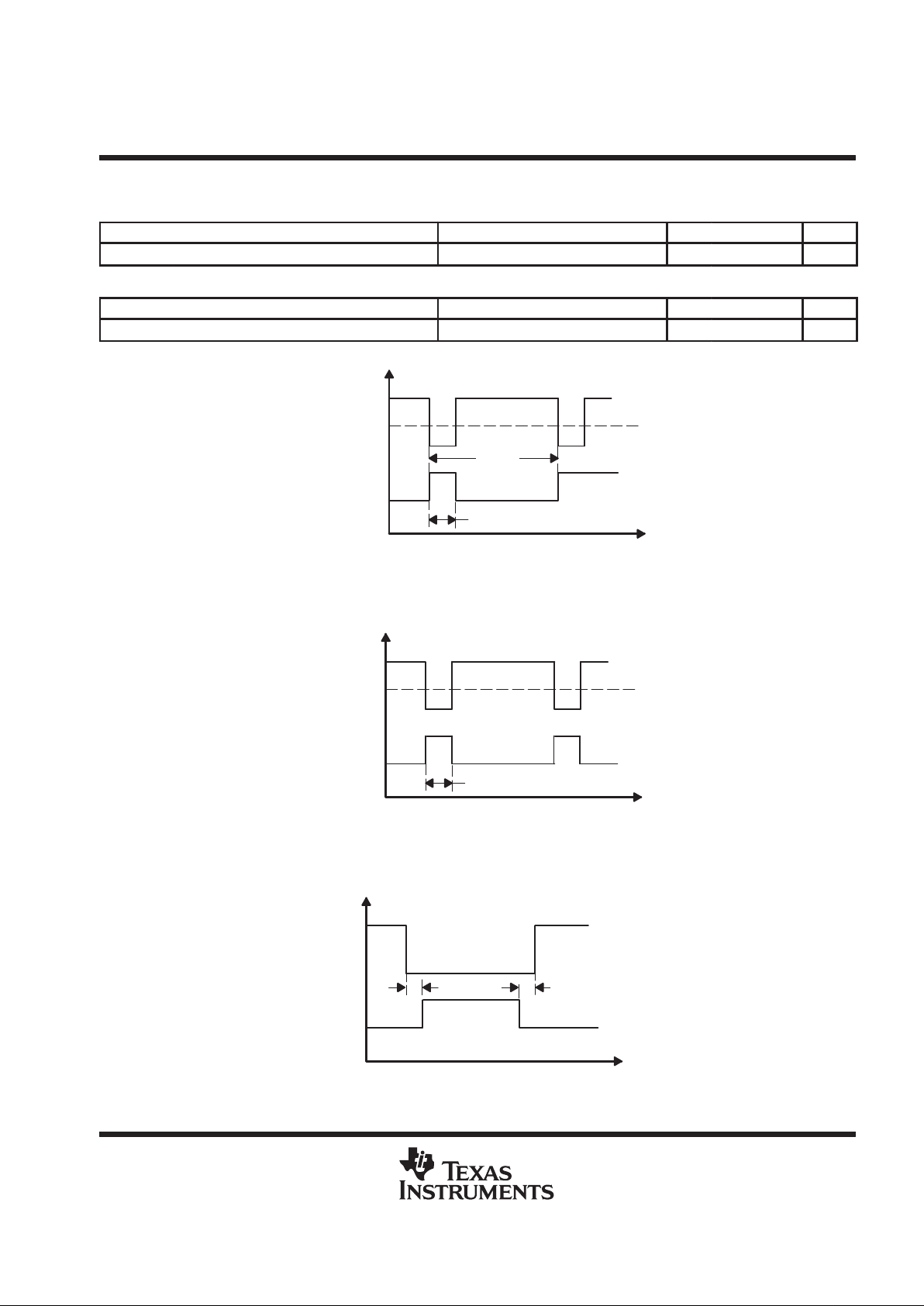

switching characteristics, T

C

= 25°C, VCC = 24 V

charge pump

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

180 kHz

f

(CP)

Switching frequenc

y

TC = 0 to 70°C 140 220 kHz

FG signal conditioning

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

BW Gain bandwidth (see Note 2) 200 kHz

NOTE 2. Design target only. Not tested in production.

FG reference crystal oscillator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

(OSC)

Crystal frequency range (see Note 2) 5 6.87 10 MHz

f

(OSC1)

OSC1 frequency range

OSC1 driven externally, see FG Reference

Oscillator section

1 10 MHz

NOTE 2. Design target only. Not tested in production.

PWM control

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

22.7

f

(PWM)

PWM frequenc

y

TC = 0 to 70°C

18 27

kH

z

t

(DT)

Gate drive dead time control See Figure 3 1 3.2 µs

digital filter f

(s)

RC oscillator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

(CT)

Oscillator frequency (see Note 2) 1/(2 × RT × CT) ±10% Hz

NOTE 2. Design target only. Not tested in production.

lock detection timer

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

(CLT)

CLT oscillator frequency (see Note 2) 1/(2 × RT × CLT) ±10% Hz

NOTE 2. Design target only. Not tested in production.

lock detection

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

LD

ERR

†

Lock detect threshold ±5 %

†

Non JEDEC symbol.

Page 9

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

switching characteristics, T

C

= 25°C, VCC = 24 V (continued)

current limit control

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

(DG)

Deglitch blanking time V

(SENSE)

– VL ≥ 100 mV, See Figure 1 0.5 3.7 6.5 µs

over-current shutdown control

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

(OCSD)

Response time See Figure 2 0.5 1.5 2.5 µs

High-Side Gate

Output

PWM

Cycle

t

(DG)

Amplitude

time

V

CC

V

L

V

(SENSE)

Figure 1. Current Limit Deglitch Blanking Time

High-Side Gate

Output

t

(OCSD)

Amplitude

time

V

CC

V

OCSD

V

(SENSE)

Figure 2. Over-Current Shutdown Response Time

Amplitude

time

UGx

t

(DT)

LGx

t

(DT)

Figure 3. Gate Drive Deadtime

Page 10

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

voltage regulator

The TPIC43T01/02 receives an 8 to 28 V supply voltage at the VCC pin and generates an internal 5 V, V

DD,

supply for the internal analog and digital logic. An external terminal for VDD is provided for a required external

1 µF compensation capacitor. The regulator can also supply up to 10 mA current from the VDD pin to external

circuitry .

oscillators

internal oscillator

The device generates an internal 5.8 MHz clock to supply a frequency input to internal control blocks as

presented in Figure 4. No external components are required.

5.8 MHz

Oscillator

÷ 32

Charge

Pump

ILIM/OCSD

Deglitch

Timer

8-Bit PWM

Generator

PWM, f∼23 kHz

Watchdog

÷ 8

Gate Drive

Dead Time

Control

Integrator

181 kHz

∼ 45 kHz

Figure 4. 5.8 MHz Internal Oscillator Fanout

FG reference oscillator

The FG reference oscillator provides a clock to the FG frequency control section of the device. The oscillator

requires an external 5 to 10 MHz crystal to select the primary frequency. The user can alternatively input a 1

to 10 MHz signal from a signal generator to the OSC1 input to replace the external crystal. Two EEPROM bits

allow programming four different crystal oscillator divide-by values for controlling the FG reference frequency .

The FSEL pin provides an additional divide-by-2 for on-the-fly FG frequency (RPM) selection. Table 1 shows

the divide-by count and resulting FG reference frequency based on the two EEPROM bits (address 1, bits 0–1)

and the FSEL pin input level.

Page 11

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

Table 1. FG Reference Frequency

EEPROM EEPROM FSEL PRE-DIVIDER TOTAL f

FG f

(ref)

@f

(osc)

ADDR 1, BIT 1 ADDR 1, BIT 0 INPUT DIVIDE BY

(osc)

DIVIDE-BY

1 MHZ 5 MHZ 10 MHZ

0 0 1 3 3072 326 1628 3256

0 0 0 6 6144 163 814 1628

0 1 1 4 4096 244 1221 2441

0 1 0 8 8192 122 610 1221

1 0 1 6 6144 163 814 1628

1 0 0 12 12,288 81 407 814

1 1 1 8

8192

†

122 610 1221

1 1 0 16

16,384

†

61 305 610

†

Equals default value

sampling frequency for the digital filter, f

(s)

, oscillator

An external resistor (RT) and capacitor (CT) must be connected from the respective RT and CT terminals to

GND to set the sampling frequency for the digital filter. Charge/discharge current at terminal CT will nominally

be ±2 × (1V/RT). Nominal period is determined by the formula: T

(CT)

= 2 × RT × CT (see Figure 5).

_

+

_

+

V

DD

I

(RT)

2I

(RT)

I

RT

RT

RTV

(RT)

= 1 V

CT

CT

_

+

1.5

3.5

R

S

Q

Clock To

Digital Filter

4I

(RT)

4:1

1:2

1:1

V

DD

1 V Internal

Reference

I

(RT)

Figure 5. Digital Filter Sampling Clock Generation

Page 12

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

lock timer oscillator/counter

Overall lock timer functionality is implemented by the combination of the oscillator and counter. The lock timer

oscillator is identical to the sampling frequency oscillator. The external resistor (RT) is used as the current

setting reference for both blocks. An external capacitor must be connected from the CLT terminal to GND to

set the period, T

(CLT)

, of the lock timer oscillator. The nominal period is determined by the formula:

T

CLT

= 2 × RT × CLT. When an out-of-lock signal is generated by the lock detect block (see lock detect section),

the lock timer counter will count at the frequency of the lock timer oscillator. Should the out-of-lock signal remain

for the duration of the counter completing 1023 counts, a lock timer time-out signal will then be generated which

the shutdown logic block will respond to (see shutdown section). The lock timer time-out is thus set by

T

CLT

× 1023.

power-up clear

An under-voltage lockout and power-up clear are provided to ensure FET drive outputs are set to a known state

during power-up. The device is held in a CLEAR state until the following three conditions are met:

1. VDD > V

DD(uvlo)

, after which a power-up clear (PUC) time will begin.

2. The PUC timer counts 3 cycles of internal 20 kHz signal (internal 5.8 MHz ÷ 255), or ≅ 132 µs.

3. The charge pump voltage, V

(CP)

, has charged to at least VCC + 5 V.

shutdown

The scheme for shutdown includes monitoring two conditions and latching the device in a CLEAR state should

an abnormal condition occur. Once shutdown is latched, the S/S input must be cycled high then low, or power

cycled OFF then ON to release shutdown and resume normal operation. If an abnormal condition still exists after

the S/S pin has been cycled, the device will relatch shutdown. A 1 on either S/S or V

DD

pins will clear the lock

timer. A VDD under-voltage-lockout detect will force a global clear. (see Table 2 and Figure 6).

Table 2. Shutdown Conditions

LATCHED SHUTDOWN

CONDITIONS

UNLATCHED SHUTDOWN CONDITIONS S/S

INTERNAL

LT

GATE

OCSD LT CP UV VDD UVLO INPUT

CLR

LTCLR

OUTPUTS

X X X X H 0 0 0

X X X

VDD < V

DD(uvlo)

X 0 0 0

V

(SENSE)

< V

(OCSD)

Out of

Lock < t

(LT)

V

O(CP)

> V

(CPUV)VDD

> V

DD(uvlo)

+ 3 counts H↓L 1 1 1

X X

VCP < V

(CPUV)

for > t

(DG)

X X X X 0

V

(SENSE)

> V

(OCSD)

for > t

(DG)

X X X X X X 0

X

Out of

Lock > t

(LT)

X X L X 1 0

Page 13

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

V

DD

UVLO

3 Counts

PUC

S/S

Internal

5.8 MHz

OSC

÷ 32

Charge Pump

UV

t

(DG)

PWM

(22 KHz)

CPUV

D Q

Q

CLR

ENA

Shutdown

Latch

V

DD

OSC

Lock

OSC

Lock

Detect

Lock

Counter

LTCLR

ILIM

OCSD

OCSD

LT

ENA

ENA

CLR

t

(DG)

Figure 6. Shutdown Logic Block Diagram

FG amplifier

The FG amplifier amplifies the ac signal from the FG variable-reluctance pickup and converts it to a digital signal

for internal use in the FG frequency control loop (see Figure 7). Figure 8 illustrates the generation of the

FGSOUT signal in the FG amplifier section. Two comparators driving an RS latch are used with the upper

comparator threshold (taken from the 5 V VDD band-gap buffer circuit feedback resistor string), while the lower

comparator threshold is connected to the FG bias voltage. This provides controlled hysteresis above the FGIN+

amplifier input reference voltage and zero-crossing detection at the input reference voltage.

_

+

_

+

R

S

Q

FG

Comparator

_

+

FGS Buffer

FG Amp

_

+

1/2 V

DD

+ 180 mV

1/2 V

DD

Band-Gap

Buffer

OP-Amp

FGSOUT

FGOUT

FGIN–

FGIN+

330 kΩ

1 kΩ

1 µF

FG

Winding

150 pF

Figure 7. FG Signal Conditioning Schematic

Page 14

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

V

IT+(FGOUT)

V

IO+(FGOUT)

FGOUT

V

(FGIN+)

FGSOUT

Figure 8. FG Signal Conditioning Block Waveforms

lock detect

The lock detect circuit monitors FGSOUT and flags when it is within ±5% of f

(ref)

. The circuit counts the number

of FG reference clocks which occur between the rising edges of FGSOUT to determine whether motor speed

has reached the locking range. When a lock occurs, the LD terminal transitions low. When the FGSOUT

frequency is not within the ±5% of f

(ref)

window, an internal

out-of-lock

signal is generated for the lock timer block

(see

lock timer

section).

Hall signal conditioning

The Hall signal conditioning block receives the low-level differential voltage from naked Hall elements and

implements symmetric threshold detection and hysteresis for noise rejection. The circuit has nominal input

voltage thresholds of ±7 mV at the INx+ pin with respect to the INx– pin. The common-mode input voltage range

is 1.5 V to 3.5 V (see Figure 9).

V

IT+(HL)

V

IT–(HL)

V

(Hall)

(INx+)

V

(CM)

(INx–)

Hall Amp

Output

(Internal)

Figure 9. Hall Signal Conditioning Waveforms

Page 15

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

rotor position sensing/commutation control

T o electronically commutate the three phases, the state of the three Hall-ef fect sensors is decoded to drive the

correct phases based on desired motor rotational direction and rotor position. This is accomplished by decoding

the Hall sensor gray-code with the F/R input condition as described in T able 3. If all three Hall inputs are detected

as identical states, this is an illegal condition and the device turns all outputs OFF.

Table 3. Hall Position Sensor Input Gray-Code Logic

COMMUTATION F/R = LOW F/R = HIGH PHASE A PHASE B PHASE C

STEP IN1 IN2 IN3 IN1 IN2 IN3 UPPER LOWER UPPER LOWER UPPER LOWER

A L L H H H L PWM Note 4 ON

B L H H H L L PWM Note 4 ON

C L H L H L H PWM Note 4 ON

D H H L L L H ON PWM Note 4

E H L L L H H ON PWM Note 4

F H L H L H L ON PWM Note 4

Illegal L L L L L L all OFF

Illegal H H H H H H all OFF

NOTE 4: For the Half-H in which GUx is being switched by PWM, the complimentary LGx can be EEPROM programmed by a single bit to enable

or disable synchronous rectification during t

(OFF)

of each PWM cycle. This allows configuration of the device for applications where

synchronous rectification can or cannot be used.

digital PWM operation

In Table 3, the term PWM represents the pulse-width-modulation duty-cycle. PWM switching is implemented

with the upper gate drive such that recirculation occurs in the lower external FET during the OFF portion of each

period. Coast mode is enabled or disabled using EEPROM address 0, bit 4. Synchronous rectification mode

is enabled or disabled using EEPROM address 0, bit 3.

An 8-bit digital PWM circuit uses an internal 5.8 Mhz oscillator as an input frequency. Each PWM period is

defined by 255 (28 –1) intervals where the number of ON intervals is controlled by the value of an 8-bit binary

input word from the digital filter output. The PWM generator is implemented such that duty cycle is:

Duty cycle

+

n

ǒ

28–1

Ǔ

+

n

255

Where:

n = decimal equivalent of the 8-bit binary input word

coast mode, (EEPROM address 0, bit 4, default = H)

When coast function is enabled (EEPROM address 0, bit 4 = H), the device uses a special mode to control speed

of the motor when it exceeds the selected reference speed. Referring to Figure 10, when FGSOUT frequency

exceeds f

(ref)

by 5%, resulting in a loss of lock detect, the high-side FET gate drives (UGx) are disabled and the

low-side FET drives (LGx) continue to sequence as per the commutation table. This will continue until FGSOUT

frequency drops below f

(ref)

, which re-enables the high-side gate drives. The coast mode will override

synchronous rectification mode if both are enabled (see following) after the FSGOUT signal exceeds f

(ref)

.

Page 16

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

Coast

Lock Detect

Range

f

(FGSOUT)

(Motor RPM)

+5%

f

(ref)

–5%

Figure 10. Coast Mode Operation

synchronous rectification mode (EEPROM address 0, bit 3, default = H for TPIC43T01, default = L for

TPIC43T02)

The TPIC43T01 is set up with synchronous rectification enabled. With synchronous rectification enabled

(EEPROM address 0, bit 3 = H), the complimentary LGx of the phase being pulse-width-modulated will turn ON

inversely to UGx during each PWM cycle. This provides a low resistance path through the low-side FET,

operating in inverse, for recirculating inductive current of the motor winding. This technique improves drive

efficiency over allowing the inductive energy to recirculate through the FET’s drain-body diode. Dead-time will

be controlled in each half-H between upper to lower and lower to upper transitions to prevent high current

conduction directly through the power FET s. During this dead-time, recirculation current, due to load inductance,

will occur in the lower FET body diode. After dead-time, the complimentary LGx will be turned on, thus reducing

power dissipation by using the lower FET in inverse to produce a lower voltage drop across

r

DS(ON)

than would

occur across VF of the FET drain-body diode (see Figure 11).

Sync Blanking

f

(FG)

(Motor RPM)

+5%

f

ref

–5%

Synchronous

Rectification

Synchronous

Rectification

Lock Detect

Range

Figure 11. Synchronous Rectification/Coast Mode Operation

The TPIC43T02 is set up with synchronous rectification disabled. With synchronous rectification disabled

(EEPROM address 0, bit 3 = L), the complimentary LGx will stay low during the OFF time of UGx, and inductive

current will thus recirculate through the lower external FET drain-body diode for the duration of t

(OFF)

.

Page 17

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

digital integrator gain selections

In Table 4, EEPROM bits can be set for different clocking rates of the digital integrator. In effect, this allows for

different integrator gain, thereby allowing the user to optimize loop performance (see Figure 12). The integrator

circuit actually utilizes 14 bits with a 4-bit pre-integrator prior to the 10 bits which are output to the digital filter.

This design increases resolution in the error detected by the speed discriminator while reducing the bit-count

output to the digital filter.

Table 4. Digital Integrator Gain Selection Table

EEPROM

ADDR 0

BIT 2

EEPROM

ADDR 0

BIT 1

EEPROM

ADDR 0

BIT 0

INTEGRATOR INPUT

FREQUENCY DIVIDE

DOWN

INTEGRATOR

GAIN ADJUST

TYPICAL INTEGRATOR

INPUT FREQUENCY

0 0 0 ÷ 1

†

0 dB 5.8 MHz

0 1 0 ÷ 2 –6 dB 2.9 MHz

0 0 1 ÷ 3 –9.5 dB 1.93 MHz

1 0 0 ÷ 4 –12 dB 1.45 MHz

0 1 1 ÷ 6 –15.5 dB 967 kHz

1 1 0 ÷ 8 –18 dB 725 kHz

1 0 1 ÷ 12 –21.5 dB 483 kHz

1 1 1 ÷ 16 –24 dB 363 kHz

†

Default setting for integrator clock.

Pre-

Integrator

(4 Bits)

Integrator

(10 Bits)

Digital

Filter

8-Bit

PWM

Generator

Divide-By

Gain

Adjust

Input Frequency

B0

B1

B2

5.8 MHz

OSC

Up

Down

Figure 12. Integrator Implementation

Page 18

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

digital filter coefficients

The two digital filter coefficients can be set by programming the EEPROM to select the pole and zero for the

digital filter. The pole and zero values are directly proportional to the digital filter sample rate, T

(s)

, and the filter

gain is independent of T

(s)

. The adjustment range of T

(s)

is from 250 µs to 1 ms (see Figure 13). The K1 lead

coefficient value is stored in bits 2–7 of Address 1 as a BCD equivalent of the K1 coefficient. K1 has a range

from 0 to 63, with a default setting of 28. See Table 5 for a typical range of pole and zero frequencies at

T

(s)

= 500 µs. The K2 coefficient value is stored in bits 5–7 of Address 0 (see Table 6 and Figure 14).

The gain of the digital filter is given by the equation:

OUT

+

IN [128 Z–K2] 0.25

Z–K1ń128

Where:

Z represents a delay of one period of the f

(s)

sampling clock.

The scaling factor of 0.25 in the above equation accounts for the difference in word lengths in the integrator

(10 bits), the filter (17 bits) and the PWM generator (8 bits).

Digital

Integrator

(10-Bit Data Word)

Σ

+

+

1/Z

Σ

–

K1

K2

+

PWM

Generator

(8-Bit Data Word)

Figure 13. Digital Filter System Diagram

Table 5. Filter Zero and Gain as a Function of K2, Ts = 500 µs

K1 = 14 (POLE = 704 Hz) K1 = 28 (POLE = 483 Hz) K1 = 56 (POLE = 263 Hz)

K2

ZERO (Hz) GAIN ZERO (Hz) GAIN ZERO (Hz) GAIN

127 6.2 0.28 4.8 0.32 3.7 0.45

126 12.4 0.28 9.7 0.32 7.3 0.45

125 18.4 0.42 14.5 0.48 11 0.68

124 24.7 0.28 19.3 0.32 14.6 0.45

123 30.9 0.35 24.2 0.4 18.3 0.56

122 37.1 0.42 29 0.48 21.9 0.68

121 43.3 0.25 33.9 0.28 25.6 0.39

120 49.4 0.28 38.7 0.32 29.2 0.45

Page 19

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

Table 6. Digital Coefficient Truth Table

EEPROM

ADDR 0

BIT 7

EEPROM

ADDR 0

BIT 6

EEPROM

ADDR 0

BIT 5

K2

COEFFICIENT

0 0 0 120

0 0 1 121

0 1 0 122

0 1 1 123

1 0 0 124

†

1 0 1 125

1 1 0 126

1 1 1 127

†

Default setting for the digital filter coefficient

15

5

40

0

120 121 122 123 124

Digital Filter Zero – Hz

30

20

35

K2 and K1 Filter Coefficient

50

125 126 127

45

25

10

Default Zero Setting

K1 = 14

K1 = 28

K1 = 56

DIGITAL FILTER ZERO

vs

K2 and K1 FILTER COEFFICIENT, (T

S

= 500 µs)

Figure 14. Digital Filter Coefficient

FG watchdog

The FG watchdog monitors FGOUT output, allowing an internal timer to count until a transition in FGOUT occurs

and clears the counter. Should timer time-out occur by reaching a count equivalent to 25 ms (512 counts of the

PWM clock), two actions are taken: 1) speed discriminator UP error output is set to 100%; 2) lock detect is set

and lock timer begins counting (see

lock timer oscillator/counter

section). These actions ensure the digital

integrator counts up (increasing motor drive PWM) at startup of the system, or, if the FG signal is lost during

operation and if no detection of an FG period of < 25 ms occurs for the duration of the lock timer, the IC will go

into shutdown mode, disabling the motor drive (see

shutdown

section).

Page 20

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

current limit/over-current shutdown

Referring to Figure 15, two comparators monitor the voltage drop across an external current sensing resistor,

R

(SENSE)

. The sensed voltage, V

(SENSE)

, is then compared against two VCC referred voltages, VL and V

(OCSD)

.

When V

(SENSE)

exceeds VL, the ILIM comparator outputs a high level. When V

(SENSE)

exceeds V

(OCSD)

, the

OCSD comparator also outputs a high level. The combination of these two comparator outputs is then used in

conjunction with a deglitch or blanking timer to discriminate between a high di/dt, short-duration current spike.

This spike is commonly caused by reverse recover time (t

rr

) current at the start of each PWM cycle and a portion

of the current waveform with lower di/dt. The lower di/dt is controlled by the L/R time constant of the motor

winding (see Figure 16). A comparator is also used to detect over current conditions caused by a shorted-load

or shorted phase-winding to GND (see Figure 17).

QD

Q CLK

CLR

_

+

_

+

V

(LM)

V

OCSD

OCSD

COMP

ILIM

COMP

R

2 × R

Digital

Deglitch

(0.5–2 µs)

PWM

Control

IDET

_

+

V

DD

V

ref

V

(thres)

Generation

ILIMIT

Block

OCSD

S/S

PWM_OFF

PWM_START

OSC

V

CC

Power

Drivers

SENSE

V

(sense)

R

(sense)

+

A

C

B

3-Phase

Motor

Figure 15. ILIMIT/OCSD Diagram

Page 21

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

current limit/over-current shutdown (continued)

The deglitch timer prevents the ILIM COMP high from being recognized unless it occurs for the duration of the

timer, after which a high IDET level occurs. This IDET level is used to terminate, or latch of f the upper gate drive

being driven by PWM for the remainder of the PWM interval. This ILIM latch and deglitch timer clears at the start

of each new PWM cycle; thus, a cycle-by-cycle PWM controlled current limit is implemented.

Current spike from trr

t

(DG)

= 0.5 to 6.5 µs

t

(DE-GLITCH)

Amplitude

V

OCSD

V

L

VCC – VSENSE

time

ILIM

COMP

IDET

OCSD

COMP

OCSD

Figure 16. Normal Motor Current Waveform With trr Spike at Start of PWM Cycle

Amplitude

High Ipeak from shorted phase winding

or shorted-phase-to-GND(> 5 A depending on the value of R

(SENSE)

)

V

OCSD

V

L

VCC – VSENSE

t

(ocsd)

= 0.5 to 2.5 µs

Combination of IDET high and OCSDCOMP high

sets OSCD latch

Latches high until S/S cycles

time

Figure 17. Motor Current Waveform With Shorted Phase W inding or Shorted Phase to GND

Page 22

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

EEPROM registers

There are two user configurable EEPROM bit registers accessible through the serial test interface when the

device is configured in TEST mode. This mode is enabled when the TEST pin is held high at 5 V . Once the device

is placed in TEST mode, either register can be programmed by transmitting a 16-bit word. The first three bits

of this transmission are the address and R/W for the register the user wishes to modify . The next five bits must

be held low, and the remaining eight bits are configuration bits. Each register must be programmed

independently, i.e. once the register value is written, the V

PP

pin must immediately be taken to 13.5 V in the

manner described in the

EEPROM Programming

section. The two EEPROM registers are summarized in

Table 7. A detailed definition outlining the function of each bit in the EEPROM is presented in the respective

functional description sections of this specification (see Notes 5 and 6).

Table 7. EEPROM Register Definition

EEPROM REGISTER CONFIGURATION BITS

ADDR

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0 K2 Coefficient Coast Enable

Synchronous

Rectification

Integrator Gain Select

TPIC43T01 default 1 0 0 1 1 0 0 0

TPIC43T02 default 1 0 0 1 0 0 0 0

1 K1 Coefficient FG Frequency Select

TPIC43T01 default 0 1 1 1 0 0 1 1

TPIC43T02 default 0 1 1 1 0 0 1 1

NOTES: 5. Bit 0 in the EEPROM register definition table corresponds to D0 and E0 in the serial protocol sequence.

6. Data read out of the EEPROM corresponds to the contents of the register at the time it is read. (A register can

be read after programming it in order to verify that the EEPROM was programmed properly.)

serial test interface

User-programmable functions are controlled using two 16-bit EEPROM registers. These registers are

programmed by placing the device in program/test mode by pulling the TEST pin high and transferring data

using the serial interface. Pins 14 and 17–19 are multipurpose pins, which are configured for serial test mode

when the TEST pin is high (see Table 8).

Table 8. Serial Test Interface Pin Definition

PIN

NAME NO.

PIN DESCRIPTION

SO 14 Serial data output. SO is an output terminal that reads data from the EEPROM.

SCLK 17 Serial clock. SCLK clocks the shift register. Serial data is clocked into the serial data input (SI) port on the rising edge of the

serial clock. Serial output data is clocked out of the serial data output (SO) port on the rising edge of the serial clock.

SIENB 18 Serial transfer enable. A low to high transition on the SIENB pin enables the serial interface to send or receive data (see Figure

2). The SIENB signal must be taken low after 16 bits of data has been transferred to insure data has been loaded into the proper

bit locations. During program mode, the VPP input is strobed after SIENB is taken low to program the EEPROM.

SI 19 Serial input. SI is an input terminal to load the EEPROM input register.

V

PP

35 EEPROM program voltage. VPP transfers data from the EEPROM input register to the respective address location.

TEST 36 Serial interface/test mode enable. TEST is taken high to enable the serial interface.

Page 23

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

23

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

EEPROM programming

Figure 18 presents the sequence of events required to program the onboard EEPROM. T o begin the procedure,

the device must be placed into test mode by setting VPP to GND, TEST to VDD and V

CC

> 8 V . The SIENB input

must transition high to enable the serial input port (see Figure 19). Serial data is clocked into SI on the rising

edges of SCLK. Sixteen bits of data must be transferred during each serial transfer and SIENB must be set to

0 after the sixteenth clock. The first two bits transferred select the EEPROM address to be manipulated. Address

bit A0 is the least significant bit (LSB). The third bit sets the interface into read or write mode. A 1 selects a read

operation from the EEPROM and a 0 selects a write operation to the EEPROM. Set the next five unused bits

to 0. The next 8 bits of data are used for write operations, and are unused and should be set to zero for read

operations. The definition of the data word is presented in T able 7. SIENB must be set to 0 after the 16-bit transfer

has been completed. When new data is being programmed into the EEPROM, the V

PP

pin must transition to

13.5 V for at least 5 ms and then back to GND (see Figure 20). This completes the serial transfer and

programming sequence. Another transfer can begin using the same procedure. Only one register can be

programmed at a time. The TEST pin must be set to 0 after programming has been completed to disable the

serial test mode and reconfigure the multipurpose pins for normal operation.

Start

Set VPP = GND; Set TEST = VDD, VCC > 8 V

Set SIENB = H

Shift Address and Data into SI

Set SIENB = L

Ramp VPP to 13.5 V then back to GND

Figure 18. Recommended EEPROM Programming Sequence

Page 24

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

R/W

1 2 3 4 5 6 7 8 9 10 11 1213 1415 16

XA0A1

00000

E0 E1 E2 E3 E4 E5 E6 E7 X

1XA0A1 X

D0 D1 D2 D3 D4 D5 D6 D7

0XA0A1

X

E0 E1 E2 E3 E4 E5 E6 E7 X

X

X

V

PP

SIENB

SCLK

SI

SO

SI

SI

To Read EEPROM Registers:

To Write EEPROM Registers:

Figure 19. Serial Protocol

tsu(VPP)

SIENB

90%

10%10%

V

PP

tf(VPP)tr(VPP)

tw(VPP)

V

PP

Figure 20. VPP Programming Waveforms

Page 25

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

25

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

charge pump

An external charge pump capacitor (CP) is connected across the CP1 and CP2 pins. An external storage

capacitor (CS) with a typical value of 0.01 µF is connected from VCP to VCC (see

functional block diagram

). The

charge pump output, VCP, powers the high-side gate drive circuitry for the pre-FET drivers. An internal CPUV

monitors the voltage between V

CP

and VCC and disables all outputs through a signal to the global shutdown

circuit until VCP – VCC ≥ 5 V. The VCP voltage level is internally regulated to VCC + 15 V (typical).

pre-FET drivers

The TPIC43T01/02 contains three pre-FET driver blocks, each with an upper and lower gate drive for driving

the gates of two external power NMOS FETs configured as a half H-power stage (see Figure 21). The

TPIC43T01/02 is designed to drive the TI TPIC1310 Power+ Array , but it is capable of driving discrete N-channel

FET devices as well. Each pre-FET gate output is capable of sourcing at least 60 mA peak current and sinking

at least 100 mA peak of current. The lower gate drive outputs provide VGS to the external FET from 14 to 20 V .

The upper gate drive outputs drive the external FET gate from VCP and provide VGS voltage protection (clamp

UGx pin with respect to Phx pin) to prevent the gate voltage from exceeding 19 V and damaging the external

FET in the event of a shorted-load or shorted-phase winding to ground.

3-Phase

Brushless Motor

Pre-Regulator

VCP

UGx

PHx

LGx

PGND

Half-H

Pre-FET

Drive Stage

Upper Gate

Drive

Lower Gate

Drive

Figure 21. Pre-FET Driver Output Stage

Page 26

TPIC43T01, TPIC43T02

THREE-PHASE BRUSHLESS MOTOR RPM CONTROLLERS

SLIS098 – APRIL 2000

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

DA (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

38 PIN SHOWN

4040066/C 10/95

0,25

0,75

0,50

0,15 NOM

Gage Plane

6,20

NOM

8,40

7,80

38

12,60

11,10

32

Seating Plane

12,4010,90

20

0,19

19

A

0,30

38

1

0,05 MIN

9,80

28

PINS **

A MAX

9,60

A MIN

DIM

1,20 MAX

10,90

11,10

30

M

0,13

0°–8°

0,10

0,65

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions include mold flash or protrusion.

D. Falls within JEDEC MO-153

Page 27

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...