Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA8540

4 × 4 video switch matrix

Product specification

Supersedes data of April 1993

File under Integrated Circuits, IC02

Philips Semiconductors

1995 Feb 06

Page 2

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

FEATURES

• I2C-bus or non-I2C-bus mode (controlled by

DC voltages)

• S-VHS or CVBS processing

• 3-state switches for all channels

• Selectable gain for the video channels

• sub-address facility

• Slave receiver in the I2C mode

• Auxiliary logic outputs for audio switching

• System expansion possible up to 7 devices

(28 sources)

• Static short-circuit proof outputs

• ESD protection.

APPLICATIONS

GENERAL DESCRIPTION

The TDA8540 has been designed for switching between

composite video signals, therefore the minimum of four

input lines are provided as requested for switching

between two S-VHS sources. Each of the four outputs can

be set to a high impedance state, to enable parallel

connection of several devices.

• Colour Television (CTV) receivers

• Peritelevision sets

• Satellite receivers.

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

I

CC

I

SO

supply voltage 7.2 − 8.8 V

supply current − 20 30 mA

isolation ‘OFF’ state at f = 5 MHz 60 80 − dB

B 3 dB bandwidth 12 −−MHz

α

ct

crosstalk attenuation between

60 70 − dB

channels

ORDERING INFORMATION

TYPE

NUMBER

NAME DESCRIPTION VERSION

PACKAGE

TDA8540 DIP20 plastic dual in-line package; 20 leads (300 mil) SOT146-1

TDA8540T SO20 plastic small outline package; 20 leads; body width 7.5 mm SOT163-1

1995 Feb 06 2

Page 3

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

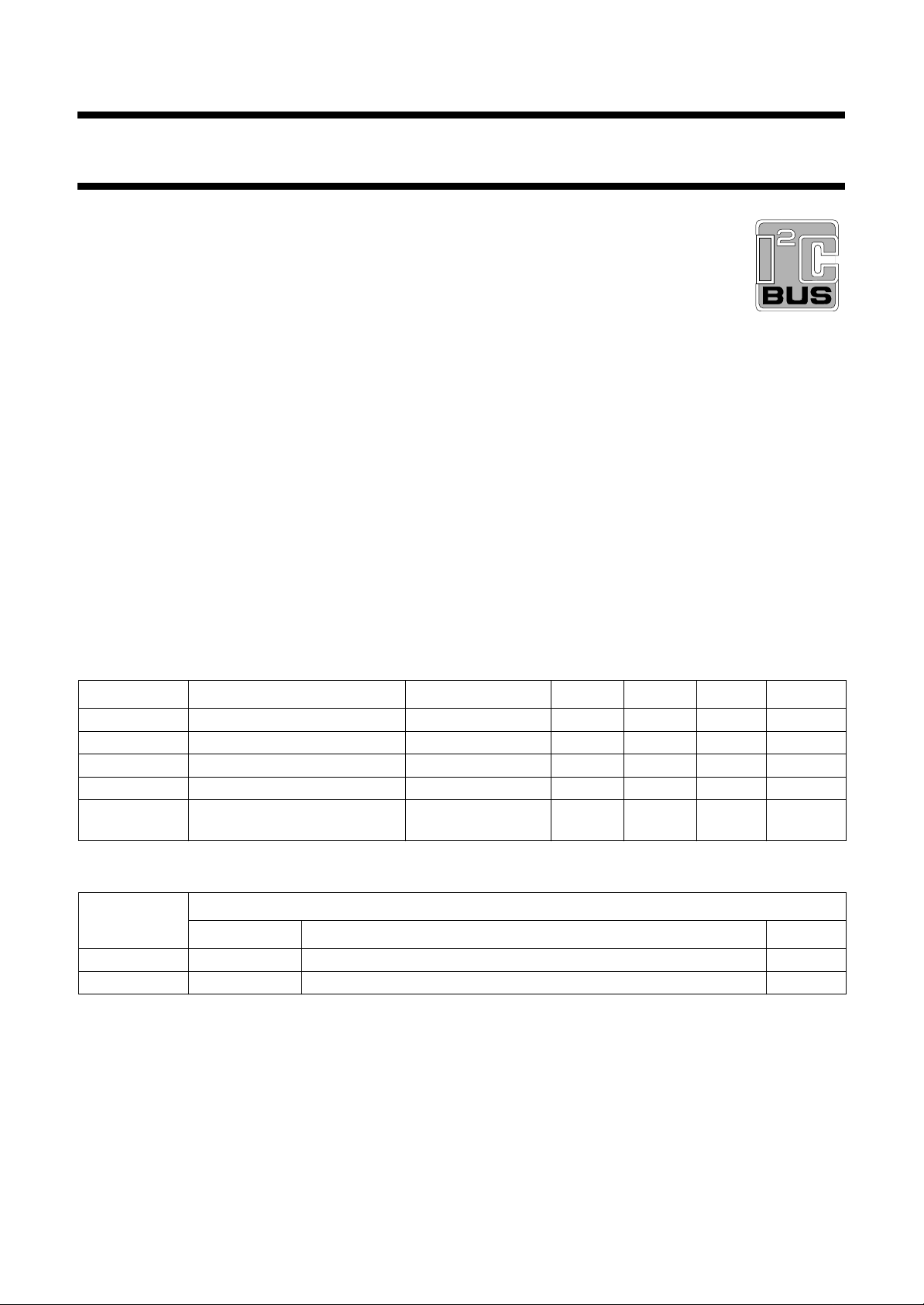

BLOCK DIAGRAM

handbook, full pagewidth

12

IN3

10

IN2

8

IN1

6

IN0

13

V

CC

DGND

AGND

20

9

PEAK-

CLAMP

PEAK-

CLAMP

PEAK-

CLAMP/

BIAS

PEAK-

CLAMP/

BIAS

CL0 to CL1

SUPPLY

power reset

SWITCH MATRIX

2

DECODER

1 OF 4

S0 S1 S2 SCL SDA

DECODER

1 OF 4

11 7 5 18 19

DECODER

1 OF 4

2

C RECEIVER

I

4444

DECODER

1 OF 4

2222

V

G0 to G3

4

TDA8540

CC(D0,1)

GAIN

GAIN

GAIN

GAIN

V

CC(D2,3)

415

DRIVER

DRIVER

DRIVER

DRIVER

EN0 to EN3

4

3

2

1

0

MLA279 - 2

3

OUT3

1

OUT2

14

OUT1

16

OUT0

17

D1

D0

2

Fig.1 Block diagram.

1995 Feb 06 3

Page 4

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

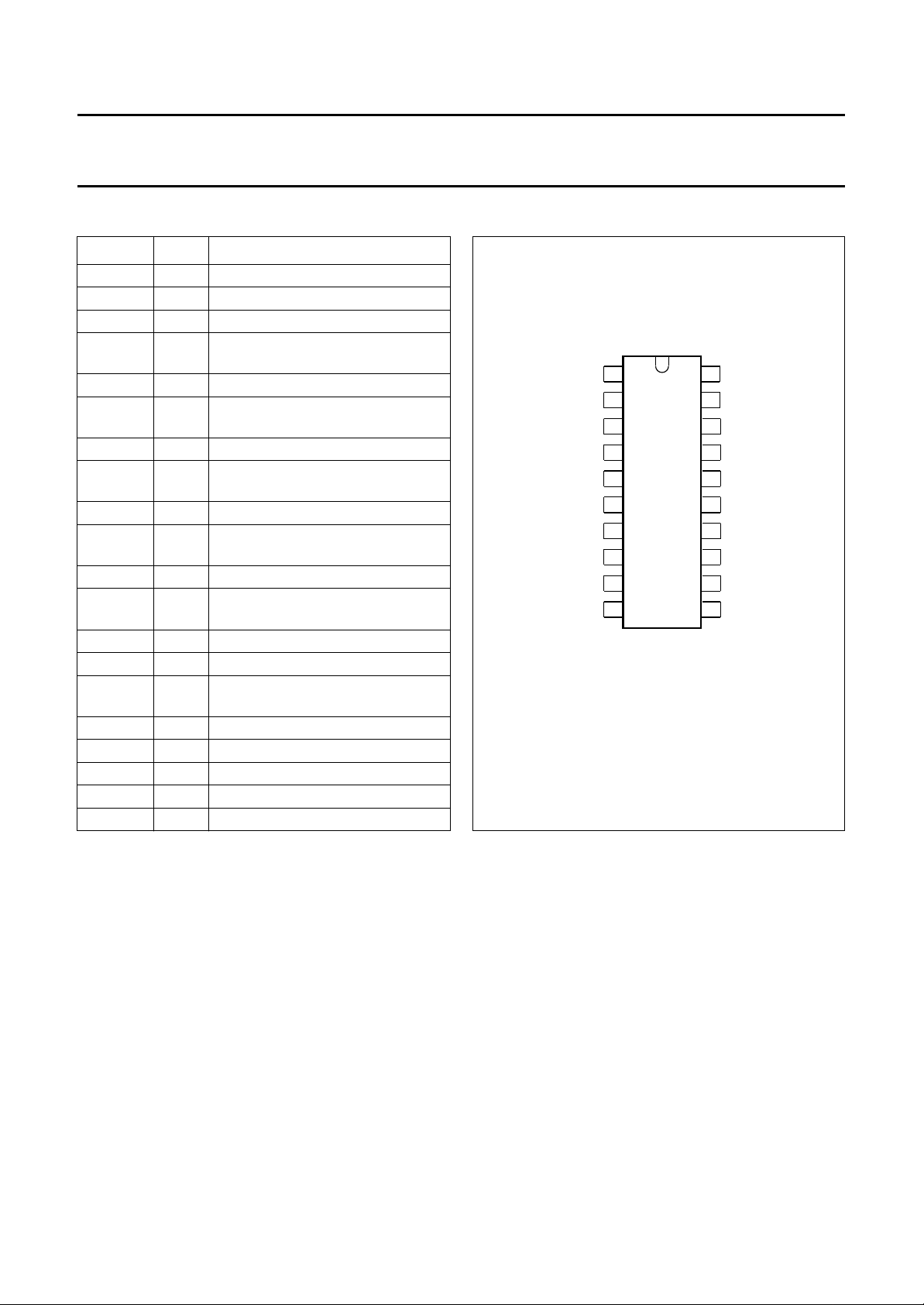

PINNING

SYMBOL PIN DESCRIPTION

OUT2 1 video output 2

D0 2 control output 0

OUT3 3 video output 3

V

CC(D2,3)

S2 5 sub-address input 2

IN0 6 video input 0 (CVBS or

S1 7 sub-address input 1

IN1 8 video input 1 (CVBS or

AGND 9 analog ground

IN2 10 video input 2 (CVBS or luminance

S0 11 sub-address input 0

IN3 12 video input 3 (CVBS or luminance

V

CC

OUT1 14 video output 1

V

CC(D0,1)

OUT0 16 video output 0

D1 17 control output 1

SCL 18 serial clock input

SDA 19 serial data input/output

DGND 20 digital ground

4 driver supply voltage; for

drivers 2 and 3

chrominance signal)

chrominance signal)

signal)

signal)

13 general supply voltage

15 driver supply voltage; for

drivers 0 and 1

handbook, halfpage

V

1

OUT2

D0

OUT3

CC(D2,3)

S2

IN0

S1

IN1

AGND

IN2

2

3

4

5

TDA8540

6

7

8

9

10

MLA277 - 2

20

19

18

17

16

15

14

13

12

11

Fig.2 Pinning configuration.

DGND

SDA

SCL

D1

OUT0

V

CC(D0,1)

OUT1

V

CC

IN3

S0

1995 Feb 06 4

Page 5

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

FUNCTIONAL DESCRIPTION

The TDA8540 is controlled via a bidirectional I2C-bus.

3 bits of the I2C address can be selected via the address

pin, thus providing a facility for parallel connection of

7 devices.

Control options via the I2C-bus:

• The input signals can be clamped at their negative peak

(top sync).

• The gain factor of the outputs can be selected between

1× or 2×.

• Each of the four outputs can individually be connected

to one of the four inputs.

• Each output can individually be set in a high impedance

state.

• Two binary output data lines can be controlled for

switching accompanying sound signals.

The SDA and SCL pins (pins 19 and 18) can be connected

2

to the I

C-bus or to DC switching voltage sources. Address

inputs S0 to S2 (pins 11, 7 and 5) are used to select

sub-addresses or switching to the non-I2C mode. Inputs

S0 to S2 can be connected to the supply voltage (HIGH) or

the ground (LOW). In this way no peripheral components

are required for selection.

2

Table 1 I

C-bus sub-addressing

SUB-ADDRESS

S2 S1 S0

A2 A1 A0

LLL000

LLH001

LHL010

LHH011

HLL100

HLH101

HHL110

2

H H H non I

2

C-bus control

I

C addressable

After power-up the outputs are initialized in the high

impedance state, and D0 and D1 are at a LOW level.

Detailed description of the I2C-bus specification, with

applications, is given in brochure

use it”

. This brochure may be ordered using the code

“The I2C-bus and how to

9398 393 40011.

The TDA8540 is aslave receiver and the protocol is given

in Table 2.

Table 2 The TDA8540 protocol

SEQUENCE

(1)

S

SLV

(2)

(3)

A

SUB A

(3)

DATA A

(3)

DATA A

Notes

1. S = START condition.

2. Data transmission to the TDA8540 starts with the slave address (SLV).

3. A = acknowledge bit, generated by TDA8540.

4. P = STOP condition.

Table 3 Data transmission to the TDA8540 begins with SLV

A6

MSB

1001A2

A5 A4 A3 A2 A1 A0

(1)

A1

(1)

Notes

1. A2 to A0: pin programmable slave address bits.

2. R/

W = 0; write only.

After the SLV, a second byte, SUB, is required for selecting the functions, as shown in Table 4.

A0

(1)

(3)

R/W

LSB

(2)

0

(4)

P

1995 Feb 06 5

Page 6

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

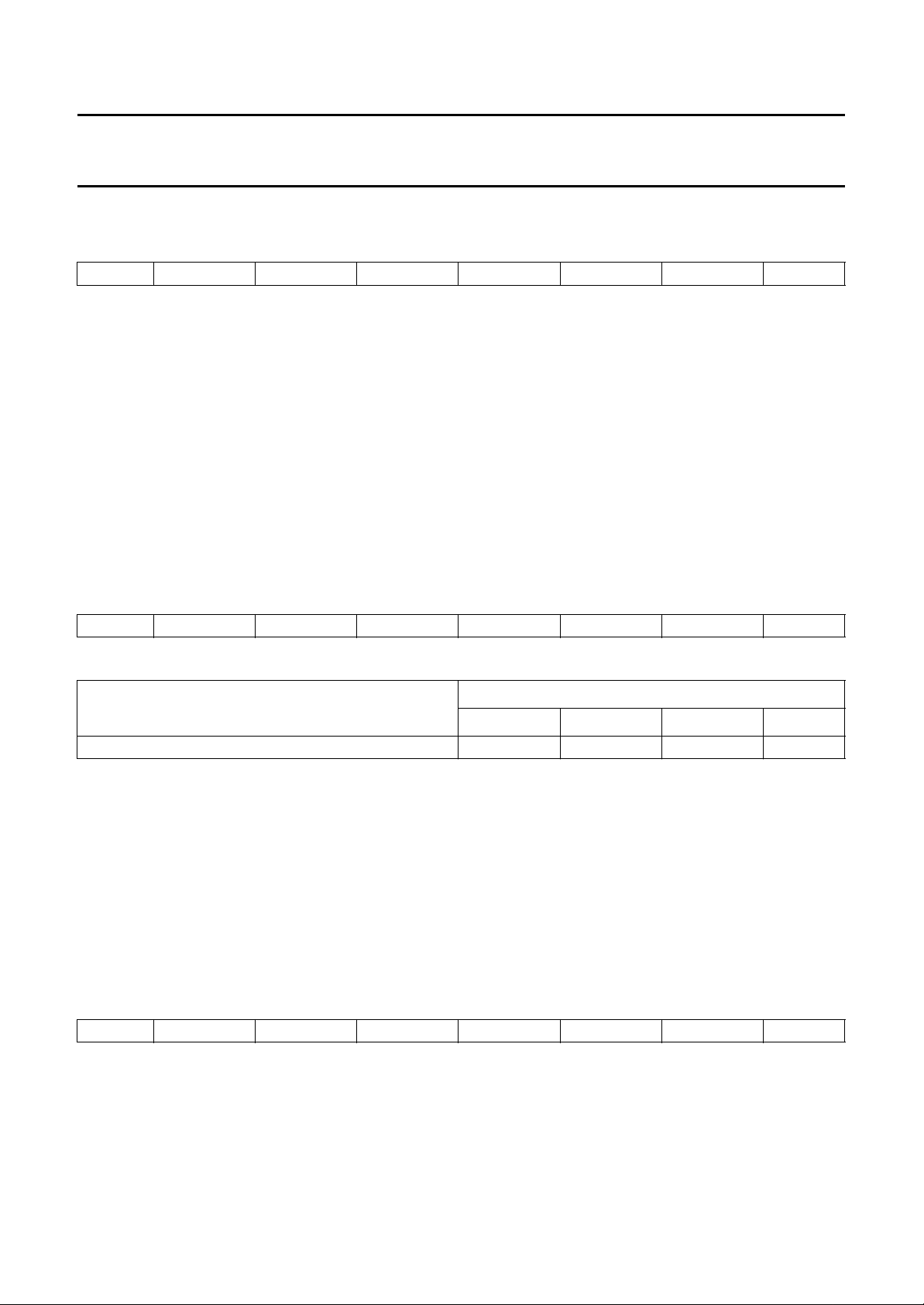

Table 4 The second byte: SUB

7MSB6543210LSB

000000RS1RS0

Options for SUB:

If SUB = 00H: access to switch control (SW1)

If SUB = 01H: access to gain/clamp/data control (GCO)

If SUB = 02H: access to output enable control (OEN).

Remarks:

If more than one data byte is sent, the SUB byte will be automatically incremented.

If more than 3 data bytes are sent, the internal counter will roll over and the device will then rewrite the first register.

Data Bytes

SWI (SUB = 00H): selects which input is connected to the different outputs, as shown in Table 5.

Table 5 SWI (SUB = 00H) selection of inputs connected to outputs

7MSB6543210LSB

S31 S30 S21 S20 S11 S10 S01 S00

Table 6 Selection of inputs

Sj1 AND Sj0

(1)

OUTPUT

00 01 10 11

OUTj IN0 IN1 IN2 IN3

Note

1. For j = 0 to 3.

Example: if S21 = 0 and S20 = 1, then OUT2 is connected to IN1.

GCO (SUB = 01H):

• Selects the gain of each output.

• Selects the clamp action or mean value on inputs 0 and 1.

• Determines the value of the auxiliary outputs D1 and D0.

Table 7 GCO byte

7MSB6543210LSB

G3

(1)

G2

(1)

G1

(1)

G0

(1)

CL1

(2)

CL0

(2)

D1

(3)

D0

(3)

Notes

1. For j = 0 to 3: if Gj = 0 (1), then output j has a gain of 2 (1).

2. If CL0 (CL1) = 0, then input signal on IN0 (IN1) is clamped.

3. For j = 0 or 1: if Dj = 0 (1), then logical output j is LOW (HIGH).

1995 Feb 06 6

Page 7

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

OEN (SUB = 02H): selects, for each output, if the output is active or high impedance, see Table 8.

Table 8 OEN (SUB = 02H) determines which output is active or high impedance

7MSB6543210LSB

(1)

X

Notes

1. X = don’t care.

2. For j = 0 to 3: if ENj = 0 (1), then OUT j is high impedance (active).

After a power-on reset:

• The outputs are set to a high impedance state; the outputs are connected to IN0; the gains are set at two and inputs

IN0 and IN1 are clamped.

• Programming of the device is necessary because the outputs are in high impedance state.

2

C-bus control

Non-I

(1)

X

(1)

X

(1)

X

EN3

(2)

EN2

(2)

EN1

(2)

EN0

(2)

If the S0, S1 and S2 pins are all connected to VCC the device will enter the non-I2C-bus mode.

After a power-on reset:

• Gain is set at two for all outputs.

• All inputs are clamped.

• All outputs are active.

• The matrix position is given by the SDA and SCL voltage level.

2

Table 9 Non-I

C-bus control

SCL AND SDA

OUTPUT

00 01 10 11

OUT3 IN3 IN2 IN1 IN0

OUT2 IN2 IN3 IN0 IN1

OUT1 IN1 IN0 IN3 IN2

OUT0 IN0 IN1 IN2 IN3

SCL and SDA act as normal input pins:

SCL interchanges (OUT3 and OUT2) with (OUT1 and OUT0).

SDA interchanges OUT3 with OUT2 and OUT1 with OUT0.

Remark: For use with chrominance signals, the clamp action must be overruled by external bias.

1995 Feb 06 7

Page 8

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

LIMITING VALUES

In accordance with the Absolute Maximum System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

CC

P

tot

V

CC(D0,1)

, V

CC(D2,3)

IN0 to IN3 video input voltage −0.3 +7.2 V

OUT0 to OUT3 video output voltage −0.3 +7.2 V

D0, D1 control output voltage −0.3 +7.2 V

SDA, SDL I

S0 to S2 sub-address input voltage −0.3 +8.8 V

T

stg

T

j

V

es

supply voltage (pin 13) −0.3 +9.1 V

total power dissipation − 750 mW

driver supply voltage −0.3 +13.8 V

2

C input/output voltage −0.3 +8.8 V

IC storage temperature −55 +125 °C

junction temperature − +150 °C

electrostatic handling HBM; note 1 −1500 +1500 V

MM; note 2 −200 +200 V

Notes

1. Human Body Model (HBM): in accordance with UZW-BO/FQ-A302.

2. Machine Model (MM): in accordance with UZW-BO/FQ-B302 (stress reference pins: AGND and DGND

short-circuited and V

CC

).

THERMAL CHARACTERISTICS

SYMBOL PARAMETER VALUE UNIT

R

th j-a

thermal resistance from junction to ambient in free air

SOT146-1 60 (typ.) K/W

SOT163-1 85 (typ.) K/W

OPERATING CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

General

V

CC

T

amb

supply voltage (pin 13) 7.2 − 8.8 V

operating ambient temperature 0 − 70 °C

Video inputs (pins 6, 8, 10 and 12)

C

I

V

I(p-p)

V

I(p-p)

external capacitor − 100 − nF

C signal amplitude (peak-to-peak value) note 1 −−1V

CVBS or Y-signal amplitude

note 2 −−1.5 V

(peak-to-peak value)

Video drivers (pins 4 and 15)

R

D

C

D

external collector resistor note 3 − 25 −Ω

external decoupling capacitor note 4 − 22 −µF

1995 Feb 06 8

Page 9

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Sub-address S0, S1 and S2 (pins 5, 7 and 11)

V

IH

V

IL

HIGH level input voltage 4 − V

LOW level input voltage 0 − 1V

Notes

1. Only for pins 6 and 8 when clamp action is not selected for these pins.

2. On all the video input pins, when non-I2C-bus control mode is selected or when clamp action is selected on

pins 6 and 8 (by I2C-bus control).

3. Connected between VCC and pin 4 or pin 15.

4. Connected between AGND and pin 4 or pin 15.

CHARACTERISTICS

V

CC

=8V; T

=25°C; gain condition, clamp condition and OFF state are controlled by the I2C-bus;

amb

unless otherwise specified.

CC

V

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

I

CC

supply current without load − 20 30 mA

OFF state − 12 − mA

Video inputs: IN0 to IN3 when the clamp is active (see Figs 3 and 4)

I

LI

V

clamp

I

clamp

input leakage current VI=3V − 0.4 1 µA

input clamping voltage II=5µA − 2.2 − V

input clamping current VI=0V 1.2 −−mA

Video inputs: IN0 and IN2 when the clamp is not active (see Fig.3)

V

bias

R

I

DC input bias level II=0 − 2.9 − V

input resistance − 10 − kΩ

Video outputs: OUT0 to OUT3 (see Fig.5)

Z

O

R

O

output impedance OFF state 100 −−kΩ

output resistance − 5 −Ω

ISO isolation OFF state; f = 5 MHz 60 −−dB

V

O

V

bias

G

v

output top sync level; (Y or CVBS) 0.4 0.7 1 V

output mean value for chrominance

signals

G = 2; load = 150 Ω 1.5 1.9 2.2 V

G = 1; without load 1 1.3 1.6 V

voltage gain G = 1; f=1MHz −1 0 +1 dB

G=2; f=1MHz 567dB

G

diff

ϕ

diff

differential gain note 1 − 0.5 3 %

differential phase note 1 − 0.6 − deg

NL non linearity note 2 − 0.5 2 %

α

ct

crosstalk attenuation between channels note 3 60 70 − dB

SVRR supply voltage rejection note 4 36 55 − dB

1995 Feb 06 9

Page 10

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

∆G maximum gain variation 100 kHz < f < 5 MHz − 0.5 − dB

100 kHz < f < 8.5 MHz − 1 − dB

100 kHz < f < 12 MHz − 3 − dB

α

ct

Auxiliary outputs D0 and D1 (open collector)

I

OH

V

OL

2

C-bus inputs SCL and SDA

I

I

IH

I

IL

C

i

2

C-bus output SDA

I

V

OL

Sub-address S0, S1 and S2

I

IH

I

IL

Notes

1. Gain set at 2; RL= 150 Ω; test signal D2 from CCIR 330.

2. Gain set at 2; RL= 150 Ω; test signal D1 from CCIR 17.

3. Measured from any selected input to output; f = 5 MHz; RL= 150 Ω; gain set at 2; VI= 1.5 V (peak-to-peak value).

This measurement requires an optimized board.

crosstalk attenuation of I2C-bus signals 60 −−dB

HIGH level output current VOH= 5.5 V −−10 µA

LOW level output voltage IOL=4mA −−0.4 V

HIGH level input current VIH= 3.0 V −−10 µA

LOW level input current VIL= 1.5 V −10 −−µA

input capacitance −−10 pF

LOW level output voltage IOL=3mA −−0.4 V

HIGH level input current VIH=V

CC

−−10 µA

LOW level input current VIL=0V −−10 µA

V

4. Supply voltage ripple rejection: ;

measured at f = 1 kHz with V

20 log

ripple (supply max)

The supply voltage rejection ratio is >36 dB at f

ripple (supply)

------------------------------------- V

ripple (on output)

= 100 mV (peak-to-peak value).

= 100 kHz.

max

1995 Feb 06 10

Page 11

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

ook, full pagewidth

IN0 or

IN1

V

ref =

2.2 V + V

be

CLAMP

CONTROL

TDA8540

Fig.3 IN0 and IN1 inputs.

6 V

MLA282 - 1

handbook, halfpage

IN2 or

IN3

V

ref =

2.2 V + V

be

TDA8540

Fig.4 IN2 and IN3 inputs.

6 V

MLA280

handbook, halfpage

VCCV

CC(D0,1)VCC(D2,3)

()

TDA8540

MLA281 - 1

Fig.5 Driver output stage.

OUT0 (OUT2)

OUT1 (OUT3)

1995 Feb 06 11

Page 12

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

APPLICATION INFORMATION

handbook, full pagewidth

video

sources

C

100 nF

C

100 nF

C

100 nF

C

100 nF

V

CC

V

CC

100 µF

i

IN3

12

i

IN2

10

i

IN1

8

i

IN0

6

13

25 Ω 25 Ω

R

D

22 µF 22 µF

C

D

V

CC(D2,3)

415

TDA8540

20

911751819

DGND AGND

S0 S1 S2 SCL SDA

address

inputs

V

CC(D0,1)

R

C

D

serial data

and

clock signals

D

3

1

14

16

17

2

V

CC

OUT3

OUT2

OUT1

OUT0

D1

D0

outputs

10

kΩ

10

kΩ

MLA278 - 3

digital

supply

(+5 V)

audio

source

control

VCC= analog supply (+8 V).

Fig.6 Application diagram.

1995 Feb 06 12

Page 13

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

PACKAGE OUTLINES

seating plane

3.60

3.05

2.0

max

26.92

26.54

3.2

4.2

max

max

0.51

min

2.54

(9x)

20

1

0.53

max

1.73 max

0.254

M

11

6.40

6.22

10

0.38 max

8.25

7.80

7.62

10.0

8.3

MSA258

Dimensions in mm.

Fig.7 Plastic dual in-line package; 20 leads (300 mil); DIP20; SOT146-1.

1995 Feb 06 13

Page 14

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

handbook, full pagewidth

S

pin 1

index

13.0

12.6

0.1 S

0.9

(4x)

0.4

1120

2.45

0.3

2.25

0.1

110

detail A

1.27

0.49

0.36

0.25 M

(20x)

7.6

7.4

10.65

10.00

1.1

0.5

1.1

1.0

0.32

0.23

0 to 8

MBC234 - 1

A

2.65

2.35

o

Dimensions in mm.

Fig.8 Plastic small outline package; 20 leads; body width 7.5 mm (SO20; SOT163-1).

1995 Feb 06 14

Page 15

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

SOLDERING

Plastic small outline packages

YWAVE

B

During placement and before soldering, the component

must be fixed with a droplet of adhesive. After curing the

adhesive, the component can be soldered. The adhesive

can be applied by screen printing, pin transfer or syringe

dispensing.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder bath is

10 s, if allowed to cool to less than 150 °C within 6 s.

Typical dwell time is 4 s at 250 °C.

A modified wave soldering technique is recommended

using two solder waves (dual-wave), in which a turbulent

wave with high upward pressure is followed by a smooth

laminar wave. Using a mildly-activated flux eliminates the

need for removal of corrosive residues in most

applications.

Y SOLDER PASTE REFLOW

B

Reflow soldering requires the solder paste (a suspension

of fine solder particles, flux and binding agent) to be

applied to the substrate by screen printing, stencilling or

pressure-syringe dispensing before device placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt, infrared, and

vapour-phase reflow. Dwell times vary between 50 and

300 s according to method. Typical reflow temperatures

range from 215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 min at 45 °C.

EPAIRING SOLDERED JOINTS (BY HAND-HELD SOLDERING

R

IRON OR PULSE

-HEATED SOLDER TOOL)

Fix the component by first soldering two, diagonally

opposite, end pins. Apply the heating tool to the flat part of

the pin only. Contact time must be limited to 10 s at up to

300 °C. When using proper tools, all other pins can be

soldered in one operation within 2 to 5 s at between 270

and 320 °C. (Pulse-heated soldering is not recommended

for SO packages.)

For pulse-heated solder tool (resistance) soldering of VSO

packages, solder is applied to the substrate by dipping or

by an extra thick tin/lead plating before package

placement.

Plastic dual in-line packages

BY DIP OR WAVE

The maximum permissible temperature of the solder is

260 °C; this temperature must not be in contact with the

joint for more than 5 s. The total contact time of successive

solder waves must not exceed 5 s.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified storage maximum. If the printed-circuit board has

been pre-heated, forced cooling may be necessary

immediately after soldering to keep the temperature within

the permissible limit.

EPAIRING SOLDERED JOINTS

R

Apply a low voltage soldering iron below the seating plane

(or not more than 2 mm above it). If its temperature is

below 300 °C, it must not be in contact for more than 10 s;

if between 300 and 400 °C, for not more than 5 s.

1995 Feb 06 15

Page 16

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

PURCHASE OF PHILIPS I

2

C COMPONENTS

2

Purchase of Philips I

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

C components conveys a license under the Philips’ I2C patent to use the

1995 Feb 06 16

Page 17

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

NOTES

1995 Feb 06 17

Page 18

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

NOTES

1995 Feb 06 18

Page 19

Philips Semiconductors Product specification

4 × 4 video switch matrix TDA8540

NOTES

1995 Feb 06 19

Page 20

Philips Semiconductors – a worldwide company

Argentina: IEROD, Av. Juramento 1992 - 14.b, (1428)

BUENOS AIRES, Tel. (541)786 7633, Fax. (541)786 9367

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. (02)805 4455, Fax. (02)805 4466

Austria: Triester Str. 64, A-1101 WIEN, P.O. Box 213,

Tel. (01)60 101-1236, Fax. (01)60 101-1211

Belgium: Postbus 90050, 5600 PB EINDHOVEN, The Netherlands,

Tel. (31)40 783 749, Fax. (31)40 788 399

Brazil: Rua do Rocio 220 - 5

CEP: 04552-903-SÃO PAULO-SP, Brazil.

P.O. Box 7383 (01064-970).

Tel. (011)821-2333, Fax. (011)829-1849

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS:

Tel. (800) 234-7381, Fax. (708) 296-8556

Chile: Av. Santa Maria 0760, SANTIAGO,

Tel. (02)773 816, Fax. (02)777 6730

Colombia: IPRELENSO LTDA, Carrera 21 No. 56-17,

77621 BOGOTA, Tel. (571)249 7624/(571)217 4609,

Fax. (571)217 4549

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. (032)88 2636, Fax. (031)57 1949

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. (9)0-50261, Fax. (9)0-520971

France: 4 Rue du Port-aux-Vins, BP317,

92156 SURESNES Cedex,

Tel. (01)4099 6161, Fax. (01)4099 6427

Germany: P.O. Box 10 63 23, 20043 HAMBURG,

Tel. (040)3296-0, Fax. (040)3296 213.

Greece: No. 15, 25th March Street, GR 17778 TAVROS,

Tel. (01)4894 339/4894 911, Fax. (01)4814 240

Hong Kong: PHILIPS HONG KONG Ltd., 15/F Philips Ind. Bldg.,

24-28 Kung Yip St., KWAI CHUNG, N.T.,

Tel. (852)424 5121, Fax. (852)480 6960/480 6009

India: Philips INDIA Ltd, Shivsagar Estate, A Block ,

Dr. Annie Besant Rd. Worli, Bombay 400 018

Tel. (022)4938 541, Fax. (022)4938 722

Indonesia: Philips House, Jalan H.R. Rasuna Said Kav. 3-4,

P.O. Box 4252, JAKARTA 12950,

Tel. (021)5201 122, Fax. (021)5205 189

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. (01)640 000, Fax. (01)640 200

Italy: PHILIPS SEMICONDUCTORS S.r.l.,

Piazza IV Novembre 3, 20124 MILANO,

Tel. (0039)2 6752 2531, Fax. (0039)2 6752 2557

Japan: Philips Bldg13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. (03)3740 5028, Fax. (03)3740 0580

Korea: (Republic of) Philips House, 260-199 Itaewon-dong,

Yongsan-ku, SEOUL, Tel. (02)794-5011, Fax. (02)798-8022

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA,

SELANGOR, Tel. (03)750 5214, Fax. (03)757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TX 79905,

Tel. 9-5(800)234-7381, Fax. (708)296-8556

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB

Tel. (040)783749, Fax. (040)788399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. (09)849-4160, Fax. (09)849-7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. (022)74 8000, Fax. (022)74 8341

th

floor, Suite 51,

Pakistan: Philips Electrical Industries of Pakistan Ltd.,

Exchange Bldg. ST-2/A, Block 9, KDA Scheme 5, Clifton,

KARACHI 75600, Tel. (021)587 4641-49,

Fax. (021)577035/5874546.

Philippines: PHILIPS SEMICONDUCTORS PHILIPPINES Inc,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. (02)810 0161, Fax. (02)817 3474

Portugal: PHILIPS PORTUGUESA, S.A.,

Rua dr. António Loureiro Borges 5, Arquiparque - Miraflores,

Apartado 300, 2795 LINDA-A-VELHA,

Tel. (01)4163160/4163333, Fax. (01)4163174/4163366.

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. (65)350 2000, Fax. (65)251 6500

South Africa: S.A. PHILIPS Pty Ltd.,

195-215 Main Road Martindale, 2092 JOHANNESBURG,

P.O. Box 7430 Johannesburg 2000,

Tel. (011)470-5911, Fax. (011)470-5494.

Spain: Balmes 22, 08007 BARCELONA,

Tel. (03)301 6312, Fax. (03)301 42 43

Sweden: Kottbygatan 7, Akalla. S-164 85 STOCKHOLM,

Tel. (0)8-632 2000, Fax. (0)8-632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. (01)488 2211, Fax. (01)481 77 30

Taiwan: PHILIPS TAIWAN Ltd., 23-30F, 66, Chung Hsiao West

Road, Sec. 1. Taipeh, Taiwan ROC, P.O. Box 22978,

TAIPEI 100, Tel. (02)388 7666, Fax. (02)382 4382.

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong,

Bangkok 10260, THAILAND,

Tel. (662)398-0141, Fax. (662)398-3319.

Turkey:Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. (0212)279 2770, Fax. (0212)282 6707

United Kingdom: Philips Semiconductors LTD.,

276 Bath Road, Hayes, MIDDLESEX UB3 5BX,

Tel. (0181)730-5000, Fax. (0181)754-8421

United States:811 East Arques Avenue, SUNNYVALE,

CA 94088-3409, Tel. (800)234-7381, Fax. (708)296-8556

Uruguay: Coronel Mora 433, MONTEVIDEO,

Tel. (02)70-4044, Fax. (02)92 0601

Internet: http://www.semiconductors.philips.com/ps/

For all other countries apply to: Philips Semiconductors,

International Marketing and Sales, Building BE-p,

P.O. Box 218, 5600 MD, EINDHOVEN, The Netherlands,

Telex 35000 phtcnl, Fax. +31-40-724825

SCD38 © Philips Electronics N.V. 1994

All rights are reserved. Reproduction in whole or in part is prohibited without the

prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation

or contract, is believed to be accurate and reliable and may be changed without

notice. No liability will be accepted by the publisher for any consequence of its

use. Publication thereof does not convey nor imply any license under patent- or

other industrial or intellectual property rights.

Printed in The Netherlands

533061/1500/03/pp20 Date of release: 1995 Feb 06

Document order number: 9397 747 30011

Philips Semiconductors

Loading...

Loading...