Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA8501

PAL/NTSC encoder

Preliminary specification

File under Integrated Circuits, IC02

April 1993

Page 2

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

FEATURES

• Two input stages: R, G, B and −(R−Y), −(B−Y), Y with

multiplexing

• Chrominance processing, highly integrated, includes

low frequency filters for the colour difference signals,

and after the modulator a bandpass filter

• Fully controlled modulator produces a signal according

to the PAL or NTSC standard without adjustments

• A free running oscillator. Can be tuned by crystal or by

an external frequency source

• Output stages with separated Y + SYNC and

chrominance (Y + C, SVHS), and a CVBS output. Signal

amplitudes are correct for 75 Ω driving via an external

emitter follower. Internal generation of NTSC setup

• Sync separator circuit and pulse shaper, to generate the

required pulses for the processing, clamping, blanking,

FH/2, and burst pulse

• H/2 control pin. In PAL mode the internally generated

H/2 is connected to this pin and the phase of this signal

can be reset

• Internal bandgap reference.

GENERAL DESCRIPTION

The TDA8501 is a highly integrated PAL/NTSC encoder IC

which is designed for use in all applications where R, G

and B or Y, U and V signals require transformation to PAL

or NTSC values.The specification of the input signals are

fully compatible with the specification of those of the

TDA8505 SECAM-encoder.

ORDERING INFORMATION

EXTENDED TYPE

NUMBER

TDA8501 24 DIL plastic SOT234AH2

TDA8501T 24 SO plastic SOT137AH1

Note

1. SOT234-1; 1996 December 2.

2. SOT137-1; 1996 December 2.

PINS PIN POSITION MATERIAL CODE

PACKAGE

(1)

(2)

April 1993 2

Page 3

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

April 1993 3

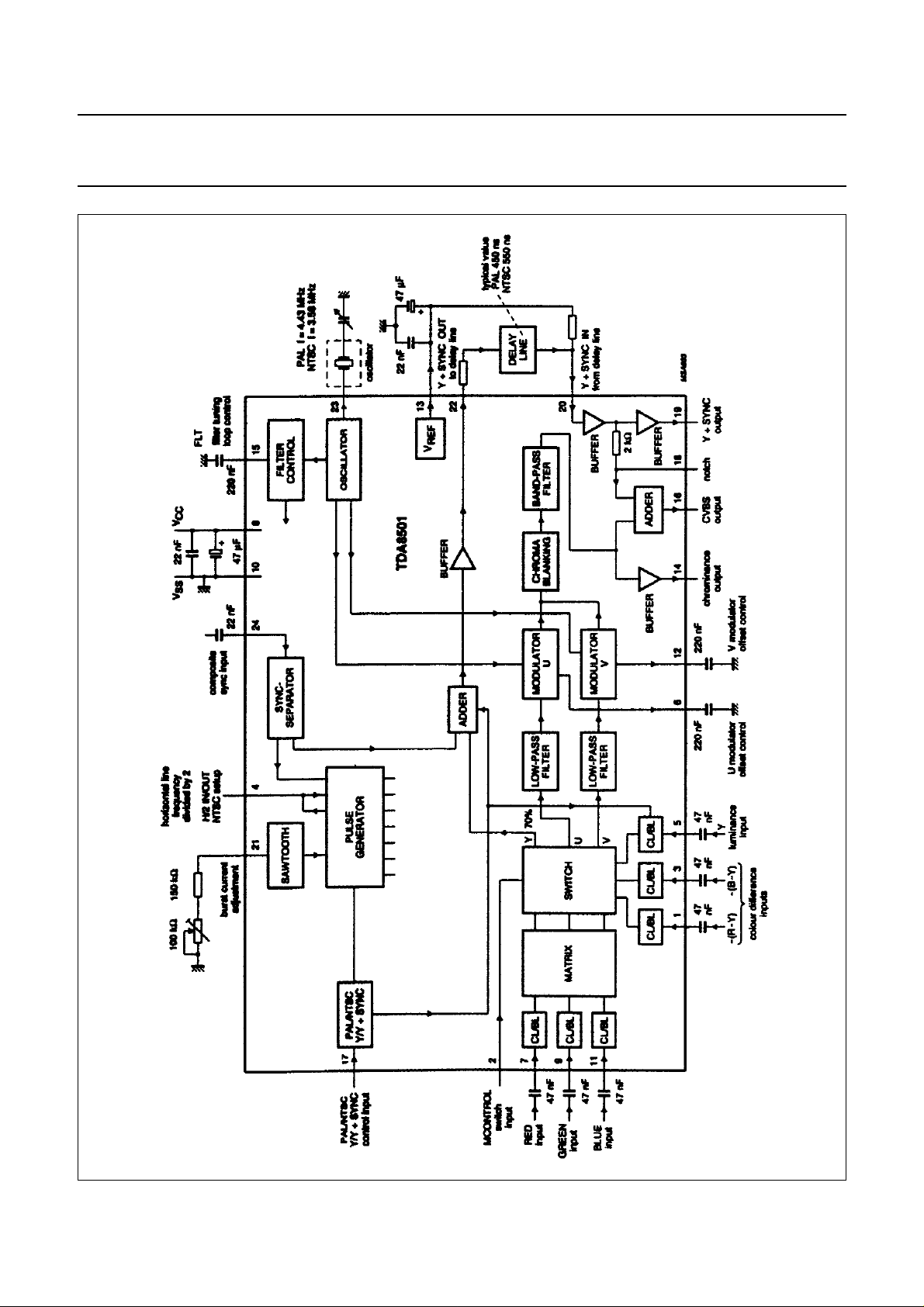

Fig.1 Block diagram.

Page 4

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

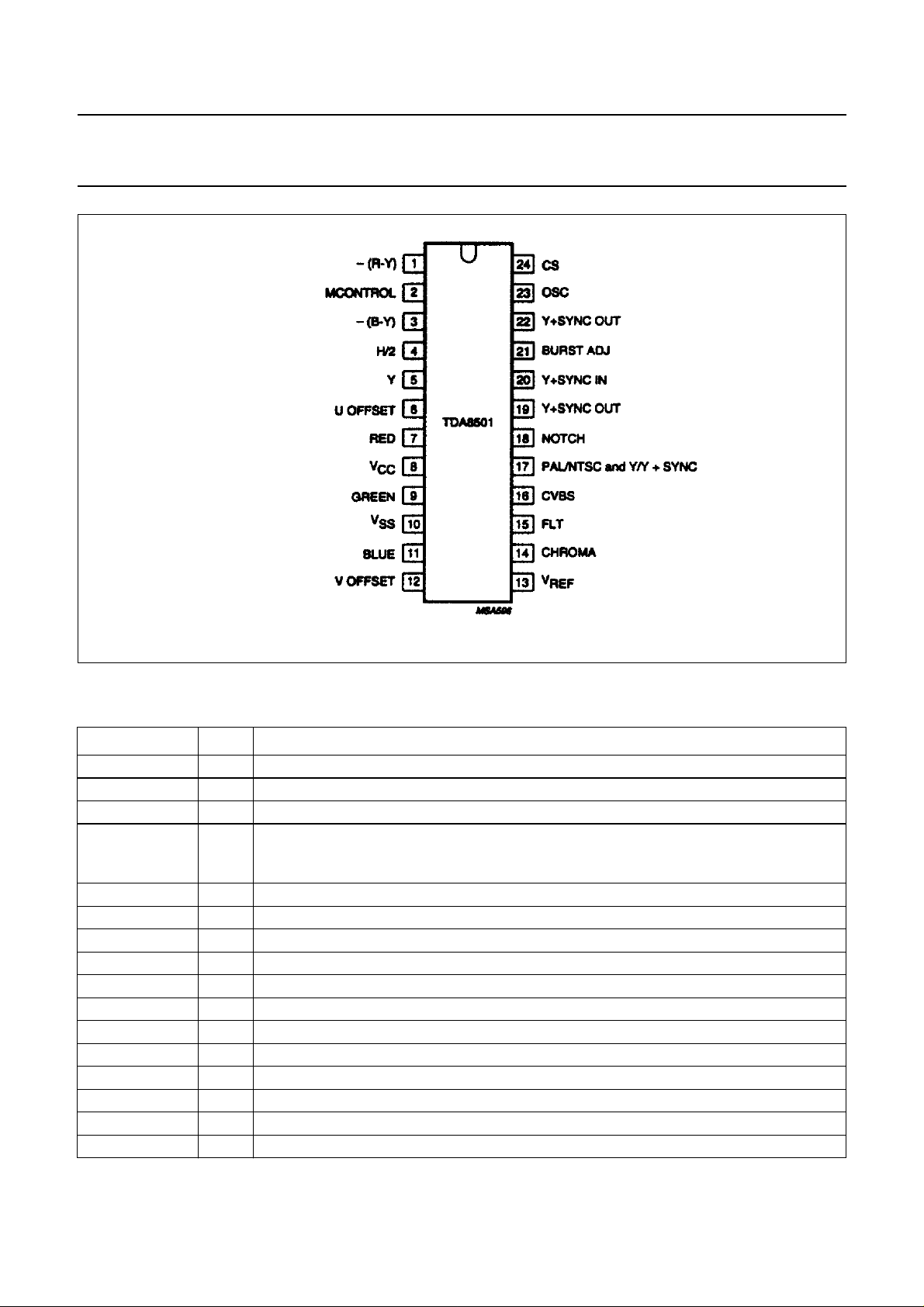

Fig.2 Pin configuration.

PINNING

U and V respectively, are the terms used to describe the colour difference signals at the output of the matrix.

SYMBOL PIN DESCRIPTION

−(R−Y) 1 colour difference input signal, for EBU bar (75%) 1.05 V (p-p)

MCONTROL 2 multiplexer switch control input; HIGH = RGB, LOW = −(R−Y), −(B−Y), Y

−(B−Y) 3 colour difference input signal, for EBU bar (75%) 1.33 V (p-p)

H/2 4 line pulse input/output divided-by-2 for synchronizing the internal H/2, if not used, this pin

dependent on mode selected, is either left open-circuit, or connected to VCC or to ground

(note 1)

Y 5 luminance input signal 1 V nominal without sync

U OFFSET 6 U modulator offset control capacitor

R 7 RED input signal for EBU bar of 75% 0.7 V (p-p)

V

CC

8 supply voltage; 5 V nominal

G 9 GREEN input signal for EBU bar of 75% 0.7 V (p-p)

V

SS

10 ground (0 V)

B 11 BLUE input signal for EBU bar of 75% 0.7 V (p-p)

V OFFSET 12 V modulator offset control capacitor

V

REF

13 2.5 V internal reference voltage output

CHROMA 14 chrominance output

FLT 15 filter tuning loop capacitor

CVBS 16 composite PAL or NTSC output, 2 V (p-p) nominal

April 1993 4

Page 5

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

SYMBOL PIN DESCRIPTION

PAL/NTSC and

Y/Y + SYNC

NOTCH 18 Y +SYNC output via an internal resistor of 2 kΩ; a notch filter can be connected to this pin

Y +SYNC OUT 19 2 V (p-p) nominal Y +SYNC output

Y +SYNC IN 20 Y +SYNC input; (from pin 22) connected to the output of the external delay line

BURST ADJ 21 burst current adjustment via external resistor

Y +SYNC OUT 22 Y +SYNC output 1 V (p-p) nominal, connected to the input of the external delay line

OSC 23 oscillator tuning: connected to either a crystal in series with capacitor to ground, or to an

CS 24 composite sync input, 0.3 V (p-p) nominal

Notes

1. Pin 4: in PAL mode, if not connected to external H2 pulse, this pin is the output for the internally generated H/2 signal.

Pin 4: in NTSC mode, for internal set-up this pin is connected to ground; when internal set-up is switched off, this pin

is connected to VCC.

2. The listed voltages connected to pin 17 (if VCC = + 5 V) enable the following Y (via pin 5) input signal states:

0 V = PAL mode; at pin 5, Y without sync and input blanking on

5 V = NTSC mode; at pin 5, Y without sync and input blanking on

1.8 V = PAL mode; at pin 5, Y with sync and input blanking off

3.2 V = NTSC mode; at pin 5, Y with sync and input blanking off

17 four level control pin (note 2)

external frequency source via a resistor in series with a capacitor

April 1993 5

Page 6

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

FUNCTIONAL DESCRIPTION

The TDA8501 device comprises:

• encoder circuit

• oscillator and filter control

• sync separator and pulse shaper.

Within this functional description, the term Y is used to

describe the luminance signal and the terms U and V

respectively, are used to describe the colour difference

signals.

Encoder circuit

INPUT STAGE

The input stage of the device uses two signal paths (see

Fig.1). Fast switching between the two signal paths is

achieved by means of the signal path selection switch

MCONTROL (pin 2).

AND G INPUT SIGNALS PATH

R, B

One signal path provides the connection for R, G and B

signal inputs (via pins 7, 9 and 11) which are connected to

a matrix via clamping and line blanking circuits. The signal

outputs from the matrix are U, V and Y.

For an EBU colour bar of 75% the amplitude of the signal

must be 0.7 V (peak-to-peak):

The Y input signal (via pin 5) differs from other signal

inputs, in that the timing of the internal clamp is after the

sync period.

The amplitude and polarity of these colour difference and

luminance input signals are processed to provide suitable

switch inputs of U, V and Y signal values.

The condition for 75% colour bar is:

pin 1 −(R−Y) = 1.05 V (peak-to-peak)

pin 3 −(B−Y) = 1.33 V (peak-to-peak)

pin 5 Y = 1 V (peak-to-peak) without sync

When selected (via MCONTROL), the U and V signals (via

the switch) are routed to the low pass filters. The Y signal

(via the switch) is routed via the adder and buffer to pin 22

(Y +SYNC OUT to delay line). Dependent on pin 17

conditioning, the Y signal may have external or internal

sync added (see section Four level control pin).

F

OUR LEVEL CONTROL PIN

The Y input signal (via pin 5) is conditioned by use of the

4-level control pin (pin 17) to emulate either the PAL or

NTSC modes, with sync and input blanking off or without

sync and input blanking on.

U = 0.493 (B−Y)

V = 0.877 (R−Y)

Y = 0.299 R +0.587 G +0.114 B

When selected (via MCONTROL), the U, V signals from

the matrix are routed through the selection switch to the

low pass filters. The Y signal from the matrix is routed

through the selection switch to the adder and combined

with the sync pulse from the sync separator and then

connected via a buffer internally to pin 22 (Y + SYNC OUT

to delay line).

−(R−Y), −(B−Y)

AND Y INPUT SIGNALS PATH

A second signal path provides the connection for negative

colour difference signal inputs−(R−Y),−(B−Y) i.e. V, U (via

pins 1, 3) and luminance Y (via pin 5), which are routed

directly to the switch inputs via clamping and line blanking

circuits.

Pin 17 may be hard wire connected to either ground (LOW

for PAL mode) or VCC (HIGH for NTSC mode). External

resistors can further modify the voltage level input at pin 17

to condition (pin 5) Y with sync and input blanking off or Y

without sync and input blanking on. (see section

PAL/NTSC and Y/Y +SYNC).

AND V SIGNALS

U

In PAL and NTSC modes the U and V (colour difference)

signals at the output of the switch are configured differently

as follows:

PAL mode:

• after the adding of the burst pulse to U and V, these

signals are connected to the input of the low pass filters.

During the vertical sync period the burst pulse is

suppressed.

NTSC mode:

• the burst pulse is only added to U and the gain of the U

and V signals is 0.95 of the gain in PAL mode. During

the vertical sync period the burst pulse is suppressed.

April 1993 6

Page 7

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

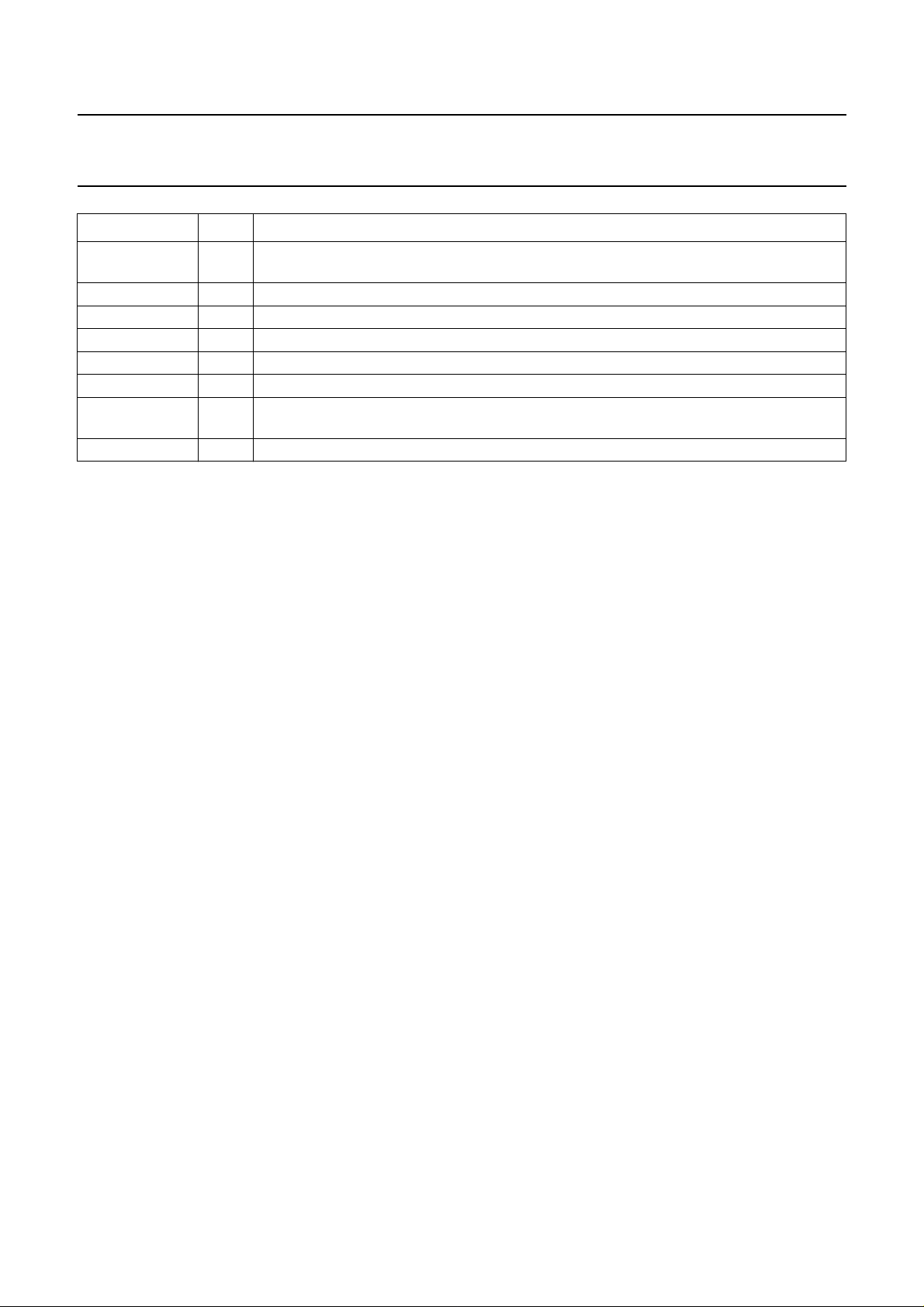

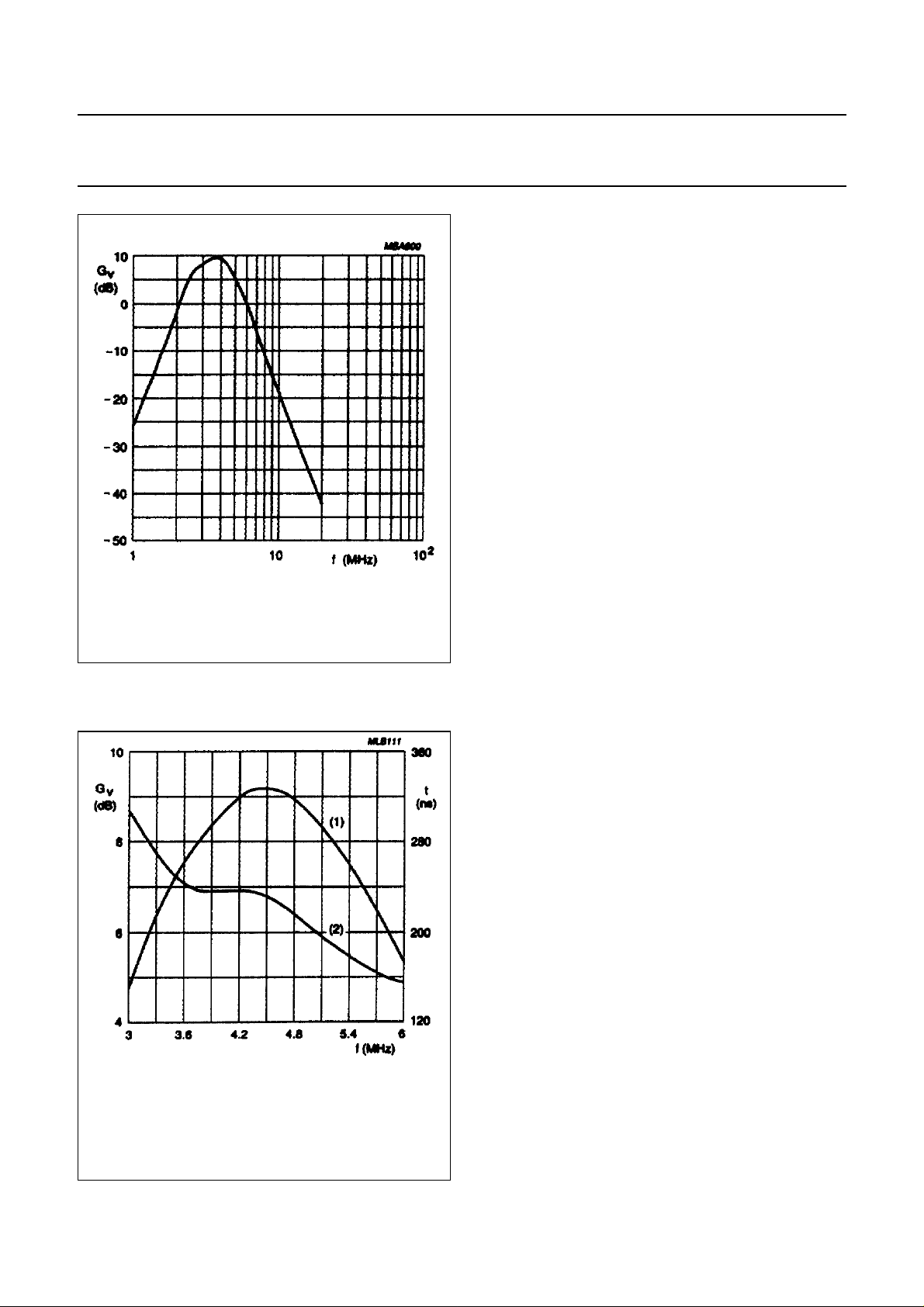

Low pass filters

The −3dB nominal frequency response level of the low

pass filters are different in PAL and NTSC modes.

PAL mode: bandwidth = 1.35 MHz nominal (see Fig.3).

NTSC mode: bandwidth = 1.1 MHz nominal (see Fig.4).

The signal outputs of the low pass filters are connected to

the signal inputs of the U and V modulators.

U

AND VMODULATORS

Two four-quadrant multipliers are used for quadrature

amplitude modulation of the U and V signals. The level of

harmonics produced by the modulated signals are

minimal, because of real multiplication with sinewave

carriers.

The unbalance of the modulators is minimized by means

(1) frequency response.

(2) group delay.

Fig.3 Low pass filter response for colour

difference signals (PAL mode).

of a control loop and two external capacitors, pin 6 for the

U modulator and pin 12 for the V modulator. The timing of

the control loop is triggered by the H/2 pulse, so that during

one sync period the U control is active and during the next

sync period the V control is active. In this way, when U and

V are both zero, the suppressed carrier is guaranteed to be

at a low level.

(1) frequency response.

(2) group delay.

Fig.4 Low pass filter response for colour

difference signals (NTSC mode).

The internal oscillator circuit generates two sinewave

carriers (0 degree and 90 degree). The '0 degree' (0)

carrier is connected to the U modulator and the '90 degree'

(1) carrier is connected to the V modulator.

PAL mode:

• switched sequentially by the H/2 pulse, the V signal is

modulated alternately with the direct and inverse carrier.

• the internal H/2 pulse can be forced into a specific phase

by means of an external pulse connected to pin 4 (H/2).

Forcing is active at HIGH level. If not used pin 4 can be

left open-circuit or connected to ground. If pin 4 is left

open, the internally generated H/2 pulse (output) is

connected to this pin.

NTSC mode:

• alternation of the V modulation is not allowed. If pin 4 is

not used for set-up control (see Y +SYNC, CVBS and

Chrominance outputs), it can be left open-circuit or

connected to ground.

April 1993 7

Page 8

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

CHROMINANCE BLANKING

The signal outputs from the modulators are connected to

the signal input of the chrominance blanking circuit. To

avoid signal distortion that may be caused by the control

loop, the signal outputs of the modulators are blanked

during the sync period. This prevents signal distortion

during the adding of the sync pulse at the CVBS output

circuit.

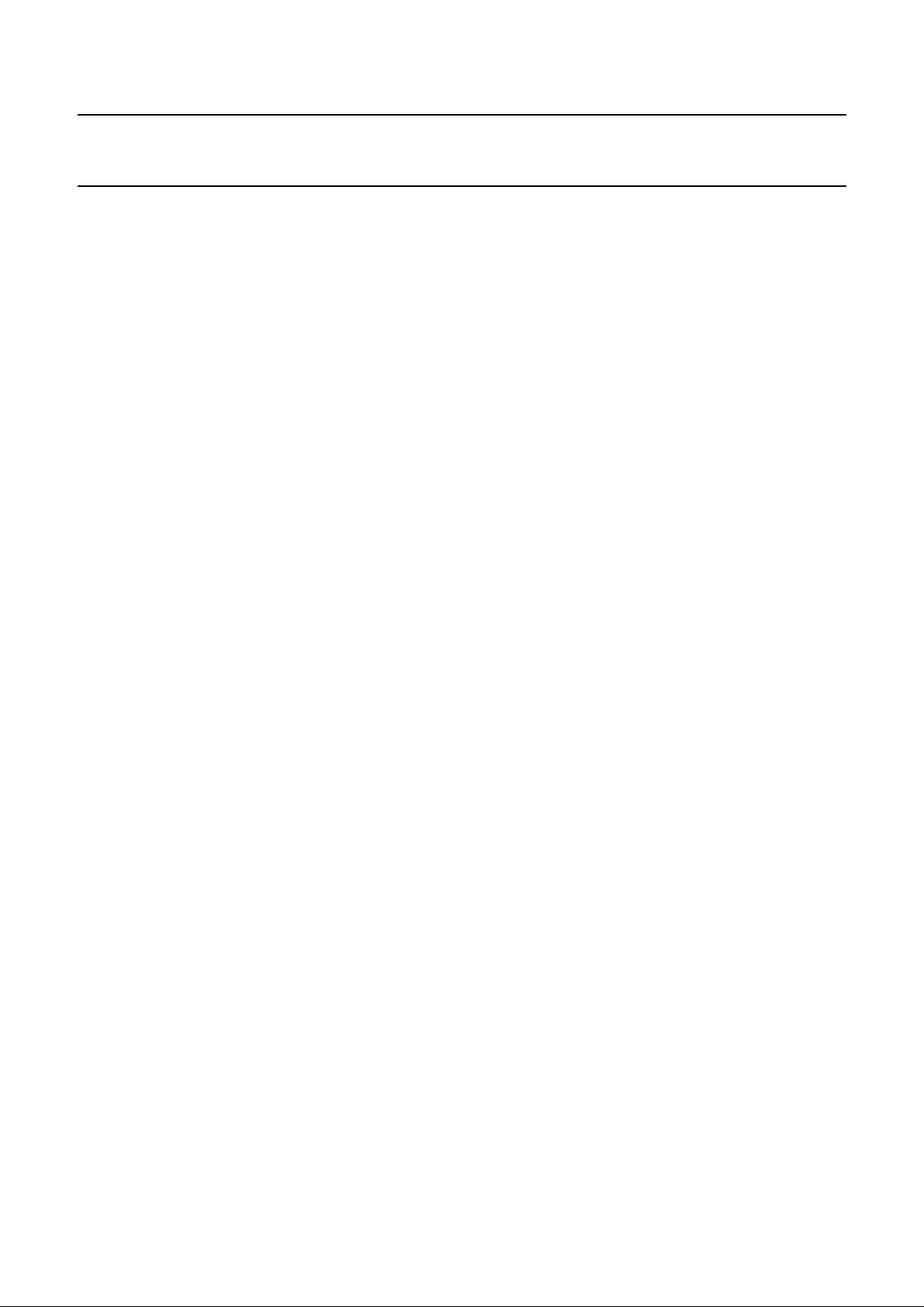

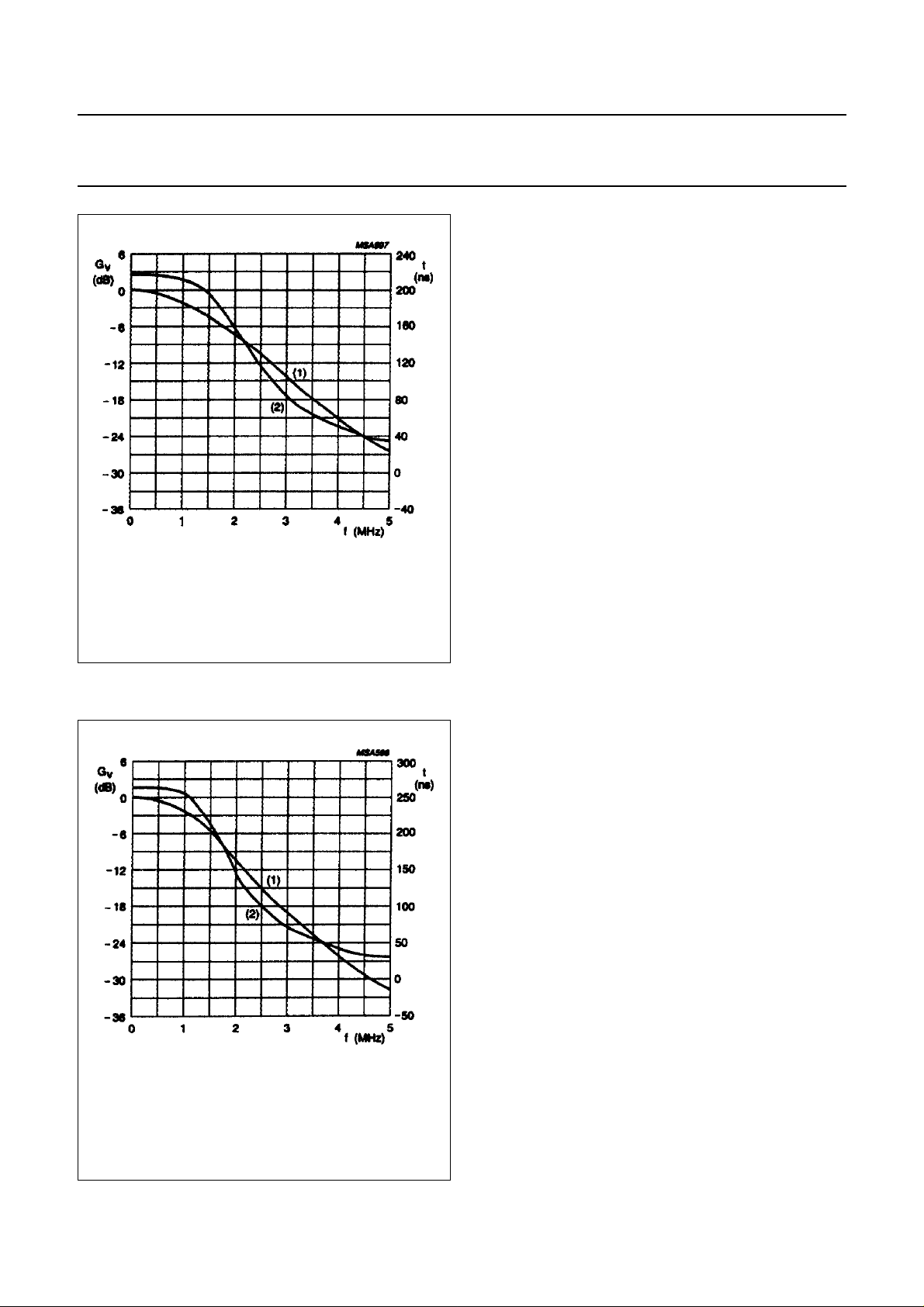

BANDPASS FILTER

A wide symmetrical bandpass filter is used so that a

maximum performance of the chrominance for Y +C

(SVHS) is guaranteed. This wide curve is possible

because of the minimal signal level of the harmonics within

the modulators see Figs (PAL mode: 5 and 6);

(NTSC mode: 7 and 8) which illustrate the nominal

response for PAL and NTSC modes.

Fig.5 Band pass filter nominal frequency

response (PAL mode).

(1) frequency response.

(2) group delay.

Fig.6 Band pass filter nominal frequency/group

delay response (PAL mode).

April 1993 8

Page 9

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

Y +SYNC, CVBS AND CHROMINANCE OUTPUTS

The Y signal from the matrix, or the Y signal from pin 5,

(selected via the switch) is added with the composite sync

signal of the sync separator (dependent on pin 17

conditioning). The output of the adder, nominal 1 V

(peak-to-peak), is connected to pin 22 (see Fig.1). Pin 22

is connected to an external delay line.

The delay line is necessary for correct timing of the

Y + SYNC signal with the chrominance signal. The output

Fig.7 Band pass filter nominal frequency

response (NTSC mode).

resistor of the delay line is connected to V

output of the external delay line is connected to (input)

pin 20.

The Y +SYNC (delayed) input signal at pin 20 is amplified

via a buffer to a level of 2 V (peak-to-peak) nominal and

connected to pin 19 (Y + SYNC output).

The Y + SYNC (delayed) input signal at pin 20 is also

connected via an internal resistor of 2 kΩ to the input of the

CVBS adder stage. After the internal resistor of 2 kΩ, and

before the input of the CVBS adder, an external notch filter

can be connected via pin 18.

The chrominance output of the bandpass filter is added

with Y +SYNC signal via the CVBS adder. The CVBS

(combined video and blanking signal) output of the adder

is connected to pin 16 with a nominal amplitude of 2 V

(peak-to-peak).

(pin 13). The

REF

(1) frequency response.

(2) group delay.

Fig.8 Band pass filter nominal frequency/group

delay response (NTSC mode).

The chrominance output of the bandpass filter is amplified

via a buffer and connected to pin 14. The chrominance

amplitude corresponds with the value of Y + SYNC signal

output at pin 19. Together both outputs give the

Y +C (SVHS) signals.

B

LACK AND BLANKING LEVELS IN PAL AND NTSC MODES

PAL mode: Fig.9 illustrates the nominal Y + SYNC signal

at pin 22, the difference between black and blanking level

is 0 mV.

NTSC mode: Fig.10 illustrates the nominal Y + SYNC

signal at pin 22, the difference between black and blanking

level is 53 mV.

Because of the difference between the black and blanking

level in the NTSC mode, there are two options for NTSC.

April 1993 9

Page 10

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

NTSC option with internal set-up generation

Pin 4 connected to ground or left open-circuit. The set-up

is generated internally and the input signals have the

values already specified in section Input stage. The set-up

is not suppressed during vertical sync.

NTSC option without internal set-up generation

Pin 4 connected to VCC. This option places some

restrictions on the input signals as follows:

• if the output signal must be according to the NTSC

standard, the input signals must be generated with a

specific set-up level

• for R, G and B inputs a set-up level of 53 mV is required,

therefore the specified amplitude must be 753 mV

(peak-to-peak) instead of 700 mV (peak-to-peak)

• for U, V and Y inputs a set-up level for Y of 76 mV is

required, therefore the specified amplitude must be

1076 mV (peak-to-peak) (without sync) instead of 1 V

(peak-to-peak). This option, combined with U, V and Y

Fig.9 Nominal Y + SYNC signal level at pin 22

(PAL mode).

inputs, is not possible if VCC is < 4.75 V.

Fig.10 Nominal Y +SYNC signal level at pin 22

(NTSC mode).

April 1993 10

Page 11

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

Oscillator and Filter Control

The internal crystal oscillator is connected to pin 23 which

provides for the external connection of a crystal in series

with a trimmer to ground. It is possible to connect an

external signal source to pin 23, via a capacitor in series

with a resistor. The signal shape is not important.

Figure 11 shows the external components connected to

pin 23 and the required conditions. The minimum AC

current of 50 µA must be determined by the resistors

(R

and R

int

) and the voltage of the signal source. For

ext

example, in this way an external sub-carrier, locked to the

sync, can be used.

PAL mode: frequency of the oscillator is

4.433618 MHz.

NTSC mode: frequency of the oscillator is

3.579545 MHz.

The −3 dB of the low pass filters and the centre frequency

of the bandpass filter are controlled by the filter control

loop and directly coupled to the value of the frequency of

the oscillator. The external capacitor of the control loop is

connected to pin 15.

Sync separator and Pulse shaper

The composite sync (CS) input at pin 24 (via the sync

separator) together with a sawtooth generator provide the

source for all pulses necessary for the processing.

Pulses are used for:

• clamping

• video blanking

• H/2

• chrominance blanking

• burst pulse generation for adding to U, V

• pulses for the modulator offset control.

The value of the sawtooth generator output (current) is

determined by the value of a fixed resistor to ground which

is connected externally at pin 21 (BURST ADJ). When

finer tolerance of the burst position is required, the fixed

resistor is connected in series with a variable

potentiometer to ground. By use of the potentiometer the

burst position at the outputs can be finely adjusted, after

which the pulse width of the burst and the position and

pulse width of all other internal pulses are then

determined. When using a fixed resistor with a tolerance of

2%, a tolerance of 10% of the burst position can be

expected. Timing diagrams of the pulses are provided by

Figs 12 and 13.

Fig.11 Tuning circuit for external signal source.

H/2 at pin 4 is only necessary in the PAL mode when the

internal H/2 pulse requires locking with an external H/2

phase (two or more encoders locked in same phase). The

forcing of the internal H/2 to a desired phase is possible by

means of an external pulse. Forcing is active at HIGH

level.

For the functioning of Pin 4 in the NTSC mode see also

section Black and Blanking levels in PAL and NTSC

modes.

April 1993 11

Page 12

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

April 1993 12

Fig.12 Sync separator and pulse shaper pulses.

Page 13

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

April 1993 13

Fig.13 Sync separator and pulse shaper pulse timing levels.

Page 14

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

PAL/NTSC and Y/Y + SYNC

Pin 17 is used as a four level control pin to condition the Y/Y + SYNC input signal (via pin 5). Pin 17 is normally connected

to ground for PAL mode, or to VCC for the NTSC mode. By use of external resistors (potential divider connected to

pin 17), the input blanking at pin 5 can be switched on and off. (see Table 1 and Fig 14).

Table 1 PAL/NTSC Y/Y +SYNC pin 5 options (pin 17 connection configurations).

MODE PIN 5 STATUS PIN 17 CONNECTION REQUIREMENT

PAL Y without sync and input blanking on pin 17 LOW, connected to V

NTSC Y without sync and input blanking on pin 17 HIGH, connected to V

PAL Y with sync and input blanking off pin 17 with 39 kΩ connected to VCC and 22 kΩ connected to V

NTSC Y with sync and input blanking off pin 17 with 22 kΩ connected to VCC and 39 kΩ connected to V

LIMITING VALUES

In accordance with the Absolute Maximum System (IEC134); all voltages referenced to V

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

T

stg

T

amb

positive supply voltage 0 5.5 V

storage temperature −65 +150 °C

operating ambient temperature −25 +70 °C

SS

CC

(pin 10).

SS

SS

SS

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

th j-a

from junction to ambient in free air

SOT234 66 K/W

SOT137 75 K/W

DC CHARACTERISTICS

V

= 5 V; T

CC

= 25 °C; all voltages referenced to ground (pin 10); unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply (pin 8)

V

I

P

V

CC

CC

tot

REF

supply voltage 4.5 5.0 5.5 V

supply current − 40 − mA

total power dissipation − 200 − mW

reference voltage output (pin 13) 2.425 2.5 2.575 V

April 1993 14

Page 15

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

AC CHARACTERISTICS

= 5 V; T

V

CC

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Encoder circuit

Input stage (pins 1, 3, 5, 7, 9 and 11); black level = clamping level

V

n(max)

V

n(min)

I

bias

V

I

input clamping impedance

Z

I

G gain tolerance of Y, −(R−Y) and

= 25 °C; composite sync signal connected to pin 24; unless otherwise specified.

amb

maximum signal

from black level positive − 1.2 − V

from black level negative only pins 1, 3 and 5 − 0.9 − V

input bias current VI = V

13

input voltage clamped input capacitor

−−< 1 µA

tbf V

13

tbf V

connected to ground

I

= 1 mA − 80 −Ω

I

= 1 mA − 80 −Ω

I

O

matrix and gain tolerance of R, G

−−< 5%

and B signals

−−< 5%

−(B−Y)

MCONTROL (pin 2; note 1)

V

IL

LOW level input voltage

Y, −(R−Y) and −(B−Y)

V

IH

HIGH level input voltage

R, G and B

I

I

t

sw

input current −−−3µA

switching time − 50 − ns

U modulator offset control (pin 6)

V

6

I

LI

V

LL

V

HL

DC voltage control level − 2.5 − V

input leakage current −−100 nA

limited level voltage LOW − 1.8 − V

limited level voltage HIGH − 3.2 − V

V modulator offset control (pin 12)

V

12

I

LI

V

LL

V

HL

DC voltage control level − 2.5 − V

input leakage current −−100 nA

limited level voltage LOW − 1.8 − V

limited level voltage HIGH − 3.2 − V

Y + SYNC (pin 22 out to delay circuit)

R

O

I

sink

I

source

V

BL

output resistance −−< 25 Ω

maximum sink current 350 −−µA

maximum source current 1000 −−µA

black level output voltage − 2.5 − V

0 − 0.4 V

1 − 5V

April 1993 15

Page 16

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

PAL mode; pin 17 = 0 V

V

SYNC

V

Y

V

DIF

NTSC mode; pin 17 = 5 V and pin 4 open-circuit or ground

V

SYNC

V

Y

V

DIF

BW frequency response pin 22 with external

t

d

t

d

α Chrominance cross talk 0 dB = 1330 mV

sync voltage amplitude 285 300 315 mV

Y voltage amplitude 665 700 735 mV

difference between black and

− 0 − mV

blanking level

sync voltage amplitude 270 286 300 mV

Y voltage amplitude 628 661 694 mV

difference between black and

− 53 − mV

blanking level

10 −−MHz

load of R = 10 kΩ and

C = 10 pF

group delay tolerance −−20 ns

sync delay from pin 24 to pin 22 220 290 360 ns

Y delay from pin 5 to pin 22 − 10 − ns

−−−60 dB

(peak-to-peak)

= 75% RED

Y + SYNC IN (pin 20 from delay circuit; note 2)

I

bias

V

I

input bias current −−1µA

maximum voltage amplitude −−1V

Y + SYNC OUT (pin 19 output Y (SVHS); note 2)

R

O

I

sink

I

source

V

BL

output resistance − 120 −Ω

maximum sink current 650 −−µA

maximum source current 1000 −−µA

black level output voltage − 1.65 − V

GY+ SYNC gain;

from pin 20 to pin 19

BW frequency response pin 19 with external

load of R = 10 kΩ and

C = 10 pF

group delay tolerance −−20 ns

α Chrominance cross talk 0 dB = 1330 mV

(peak-to-peak)

= 75% RED

− 12 − dB

10 −−MHz

−−−54 dB

April 1993 16

Page 17

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

NOTCH (pin 18)

R

O

V

CC

I

sink

Chrominance output (pin 14)

I

sink

I

source

R

O

∆V

DC

PAL mode; pin 17 = 0 V

V

O

NTSC mode; pin 17 = 5 V

V

O

LPF Low-pass filters see Figs 3 and 4

BPF Band-pass filters see Figs 5 and 6

V

n

BP burst phase; 0 degrees = phase U carrier

α Y + SYNC cross talk

output resistance 1750 2000 2500 Ω

DC voltage level − 2.5 − V

maximum sink current 350 −−µA

maximum sink current 700 −−µA

maximum source current 1000 −−µA

output resistance − 120 −Ω

variation of DC voltage level

−−5mV

when chrominance signal is

blanked and chrominance signal is

not blanked

chrominance output voltage

480 600 720 mV

(peak-to-peak) amplitude burst

ratio: chrominance

2.1 2.2 2.3

(75% RED)/burst

chrominance output voltage

460 570 680 mV

(peak-to-peak) amplitude burst

ratio: chrominance

2.1 2.2 2.3

(75% RED)/burst

carrier suppression when

input-signals are 0 V

phase accuracy (difference

0 dB = 1330 mV

(peak-to-peak)

− 37 − dB

−−2 degrees

between 0 and 90 degree carriers)

noise level (RMS value) −−4mV

PAL mode −±135 − degrees

NTSC mode − 180 − degrees

(0 to 6 MHz)

0 dB = 1400 mV

(peak-to-peak)

−−−60 dB

April 1993 17

Page 18

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

CVBS output (pin 16)

I

sink

I

source

V

O

G Y +SYNC gain;

G chrominance difference;

G

ø

G

V

R

O

Oscillator output (pin 23)

OSC series-resonance the resonance resistance of the crystal should be < 60 Ω and the

maximum sink current 650 −−µA

maximum source current 1000 −−µA

DC voltage level Y +SYNC = 0 − 1.6 − V

− 12 − dB

from pin 20 to pin 16

− 0 − dB

from pin 14 to pin 16

differential phase note 3 −−3 degrees

differential gain note 4 −−3dB

output resistance − 120 −Ω

parallel capacitance of the crystal should be < 10 pF.

Filter tuning loop (pin 15)

V

V

V

V

DC

DC

DCL

DCH

DC control voltage level NTSC − 0.83 − V

DC control voltage level PAL − 0.88 − V

limited DC-level LOW IO = 200 µA − 0.27 − V

limited DC-level HIGH II = 200 µA − 1.8 − V

H2 (pin 4)

V

IL

V

IH

I

I

I

O

V

O

V

O

I

sink

I

source

LOW level input voltage inactive 0 − 1V

HIGH level input voltage active 4 − 5V

current for forcing HIGH 220 −−µA

current for forcing LOW 260 −−µA

voltage out LOW −−< 0.5 V

voltage out HIGH 4 −−V

maximum sink current 50 −−µA

maximum source current 50 −−µA

Composite sync input (pin 24)

V

SYNC

SYNC pulse amplitude 75 300 600 mV (p-p)

slicing level − 50 − %

I

I

I

O

input current − 4 −µA

maximum output current during

SYNC

− 100 −µA

BURST ADJ (pin 21; note 5)

BP DC voltage level − V

April 1993 18

REF

(V13)

− V

Page 19

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Control pin PAL/NTSC and Y/Y + SYNC (pin 17; note 6)

V

I

V

I

V

I

V

I

I

bias

Notes

1. The threshold level of this pin is 700 mV ±20 mV. The specification of the HIGH and LOW levels is according to the

SCART fast blanking.

2. Pin 20 condition: black level of input signal must be 2.5 V; amplitude 0.5 V (peak-to-peak) nominal.

3. Definition:

PAL mode and blanking pin 5

0 − 1V

active

internal sync added to Y

PAL mode and blanking pin 5

1.6 − 2.0 V

inactive

internal sync not added to Y

NTSC mode and blanking pin 5

4 − 5V

active

internal sync added to Y

NTSC mode and blanking pin 5

3 − 3.4 V

inactive

internal sync not added to Y

input bias current −−−10 µA

maximum phase−minimum phase=difference phase

4. Definition:

maximum gain minimum gain–

---------------------------------------------------------------------------------maximum gain

100× difference gain %=

5. The output impedance of this pin is low (< 100 Ω). The nominal value of the external resistor is 196 kΩ (see also

section Sync separator and Pulse shaper).

6. The threshold levels are: 0.25 times V

, 0.5 times VCC and 0.75 times VCC.

CC

April 1993 19

Page 20

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

Table 2 Internal circuitry.

PIN NAME CIRCUIT DESCRIPTION

1 −(R−Y) −(R−Y) input; connected via

47 nF capacitor

1.05 V (p-p) for EBU bar of 75%

see also pins 3, 5, 7, 9 and 11

2 MCONTROL multiplexer switch control input

< 0.4 V Y, U and V

>1 V R, G and B

3 −(B−Y) see pin 1 −(B−Y) input; connected via

47 nF capacitor

1.33 (p-p) for EBU bar of 75%

4 H/2

IN/OUT

H/2 input

PAL MODE:

pin open, output of internal H/2

Forcing possibility

NTSC mode:

0 V set-up

5 V no set-up

April 1993 20

Page 21

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

PIN NAME CIRCUIT DESCRIPTION

5 Y see pin 1 Y input; connected via 47 nF

capacitor

1 V (p-p) for EBU bar of 75%

6 U OFFSET 220 nF (low-leakage) connected

to ground see also pin 12

7 R see pin 1 RED input; connected via 47 nF

capacitor

0.7 V (p-p) for EBU bar of 75%

8V

9 G see pin 1 GREEN input; connected via

10 V

CC

SS

supply voltage

5 V nominal

47 nF capacitor

0.7 V (p-p) for EBU bar of 75%

ground

11 B see pin 1 BLUE input; connected via

47 nF capacitor

0.7 V (p-p) for EBU bar of 75%

April 1993 21

Page 22

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

PIN NAME CIRCUIT DESCRIPTION

12 V OFFSET see pin 6 220 nF (low-leakage) connected

to ground

13 V

REF

2.5 V reference voltage

decoupling with 47 µF and 22 nF

capacitors

14 CHROMA chrominance output; together with

pin 19 the Y + C (SVHS) output

15 FLT filter control pin

220 nF capacitor to ground

April 1993 22

Page 23

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

PIN NAME CIRCUIT DESCRIPTION

16 CBVS CVBS output

17 PAL/NTSC

Y/Y+SYNC

18 NOTCH pin for external notch filter

4-level control pin

Pin 5:

0 V PAL, Y

1.8 V PAL Y+SYNC

3.2 V NTSC Y +SYNC

5 V NTSC Y

April 1993 23

Page 24

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

PIN NAME CIRCUIT DESCRIPTION

19 Y+SYNC OUT output of the Y +SYNC signal;

together with pin 14 the Y +C

(SVHS) output

20 Y+SYNC IN input of the delayed Y+SYNC

signal of the delay line

black level must be 2.5 V

21 BURST ADJ external resistor to ground for

adjusting the position of the burst

April 1993 24

Page 25

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

PIN NAME CIRCUIT DESCRIPTION

22 Y+SYNC OUT output of the Y+SYNC signal,

connected to the delay line via a

resistor

23 OSC subcarrier-crystal in series with a

trimmer, or an external

subcarrier signal, via 1 nF in

series with a resistor

24 CS composite SYNC signal input

amplitude < 600 mV (p-p)

April 1993 25

Page 26

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

April 1993 26

Fig.14 Application diagram.

Page 27

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

PACKAGE OUTLINES

SDIP24: plastic shrink dual in-line package; 24 leads (400 mil)

D

seating plane

L

Z

24

pin 1 index

e

b

b

1

13

SOT234-1

M

E

A

2

A

A

1

w M

c

E

(e )

M

1

H

1

0 5 10 mm

scale

DIMENSIONS (mm are the original dimensions)

A

A

A

UNIT b

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

mm

OUTLINE

VERSION

SOT234-1

max.

4.7 0.51 3.8

12

min.

max.

IEC JEDEC EIAJ

1.3

0.8

b

1

0.53

0.40

REFERENCES

cEe M

0.32

0.23

(1) (1)

D

22.3

21.4

April 1993 27

9.1

8.7

12

(1)

Z

L

3.2

2.8

EUROPEAN

PROJECTION

M

10.7

10.2

E

12.2

10.5

e

1

w

H

0.181.778 10.16

ISSUE DATE

92-11-17

95-02-04

max.

1.6

Page 28

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

SO24: plastic small outline package; 24 leads; body width 7.5 mm

D

c

y

Z

24

pin 1 index

1

e

13

12

w M

b

p

SOT137-1

E

H

E

Q

A

2

A

1

L

p

L

detail X

(A )

A

X

v M

A

A

3

θ

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT137-1

A

max.

2.65

0.10

A

1

0.30

0.10

0.012

0.004

A2A

2.45

2.25

0.096

0.089

IEC JEDEC EIAJ

075E05 MS-013AD

0.25

0.01

b

3

p

0.49

0.32

0.36

0.23

0.019

0.013

0.014

0.009

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

(1)E(1) (1)

cD

15.6

7.6

7.4

0.30

0.29

1.27

0.050

15.2

0.61

0.60

REFERENCES

April 1993 28

eHELLpQ

10.65

10.00

0.419

0.394

1.4

0.055

1.1

0.4

0.043

0.016

1.1

1.0

0.043

0.039

PROJECTION

0.25

0.25 0.1

0.01

0.01

EUROPEAN

ywv θ

Z

0.9

0.4

8

0.004

ISSUE DATE

0.035

0.016

95-01-24

97-05-22

0

o

o

Page 29

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

(order code 9398 652 90011).

SDIP

SOLDERING BY DIPPING OR BY WAVE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

stg max

). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

SO

REFLOW SOLDERING

Reflow soldering techniques are suitable for all SO

packages.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

AVE SOLDERING

W

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

EPAIRING SOLDERED JOINTS

R

Fix the component by first soldering two diagonally-

opposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

April 1993 29

Page 30

Philips Semiconductors Preliminary specification

PAL/NTSC encoder TDA8501

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

April 1993 30

Loading...

Loading...