Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA8433

Deflection processor for computer

controlled TV receivers

Product specification

File under Integrated Circuits, IC02

August 1991

Page 2

Philips Semiconductors Product specification

Deflection processor for computer

TDA8433

controlled TV receivers

FEATURES

• I2C-bus interface

• Input for vertical sync

• Sawtooth generator with amplitude

independent of frequency

• Vertical deflection output stage

driver

• East-west raster correction drive

output

• EHT modulation input

• Changes picture width and height

without affecting geometry.

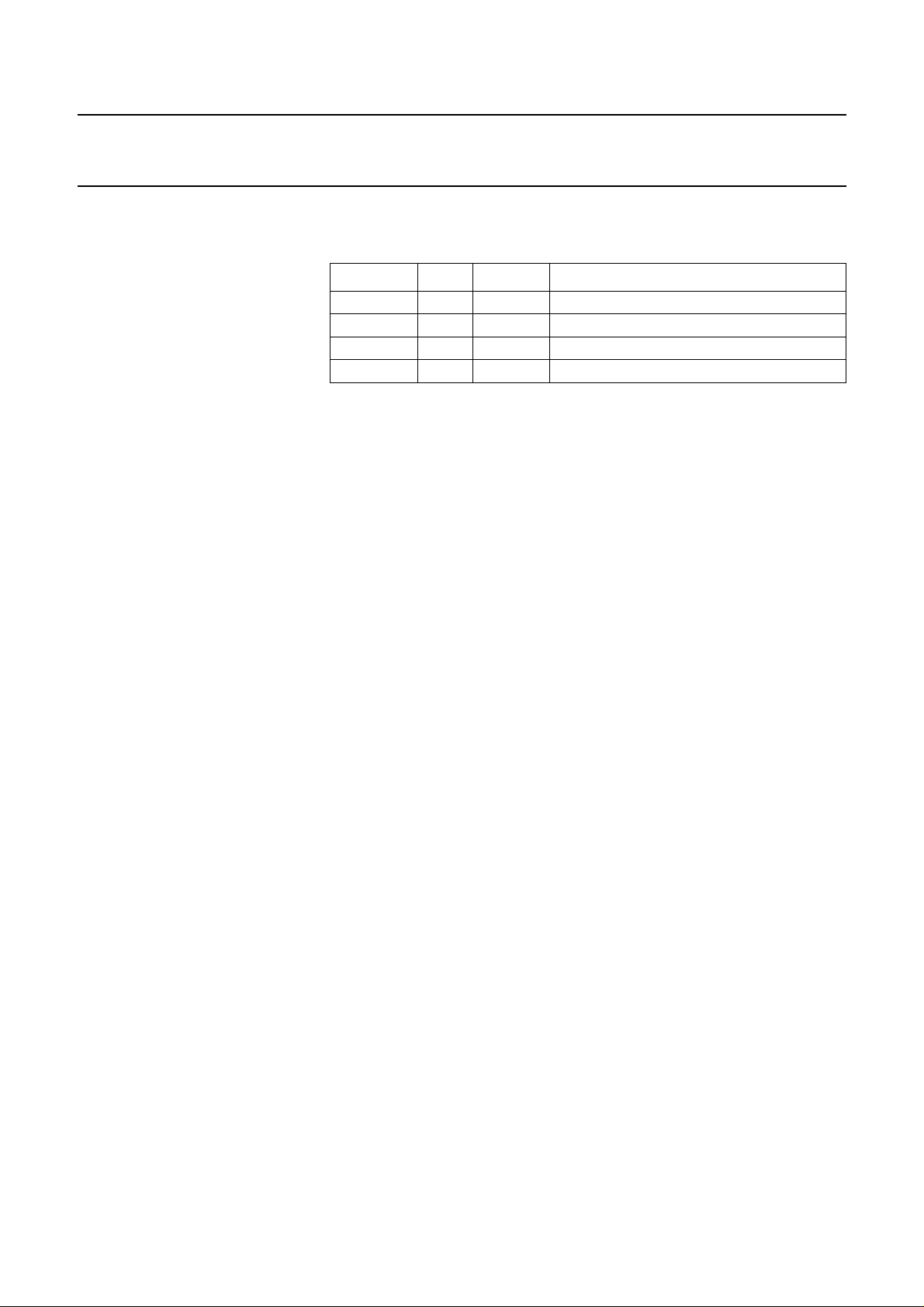

QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

CC

I

CC

V

2

V

21

supply voltage (pin 12) 10.8 12.0 13.2 V

supply current (pin 12) 12 20 27 mA

vertical sync trigger level − 3 − V

vertical feedback (note 1)

DC level −1.7 1.85 2.05 V

AC level 1.65 1.8 1.95 V

V

24

V

11-13

EHT compensation operating range 1.7 − 6V

inputs for control register data:

not locked to video − 0.7 1 V

at 50 Hz status 0.8 V

at 60 Hz status −−0.7 V

V

V

V

V

10-13

14-13

15

1

HCENT comparator switching level − V

SDA I2C-bus switching level data input − 3.5 − V

SCL I2C-bus switching level clock input − 3.5 − V

device selection where:

Ao = '1' 9.0 − V

Ao = '0' 0 − 2.0 V

GENERAL DESCRIPTION

The TDA8433 is an I2C-bus

controlled deflection processor which,

together with a sync processor (e.g.

TDA2579A, see Fig.6), contains the

control and drive functions of the

deflection part in a computer

controlled TV receiver. The TDA8433

replaces all picture geometry settings

which were previously set manually

during manufacture.

CC

P

−−V

CC

17

− V

CC

V

V

Note to quick reference data

1. VR

= 0; V-S-corr = 0; V

in

= 20 H; V

shift

ampl

= 20 H.

ORDERING INFORMATION

PACKAGE

EXTENDED TYPE NUMBER

PINS PIN POSITION MATERIAL CODE

TDA8433 24 DIL plastic SOT101

Note

1. SOT101-1; 1996 December 2.

August 1991 2

(1)

Page 3

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

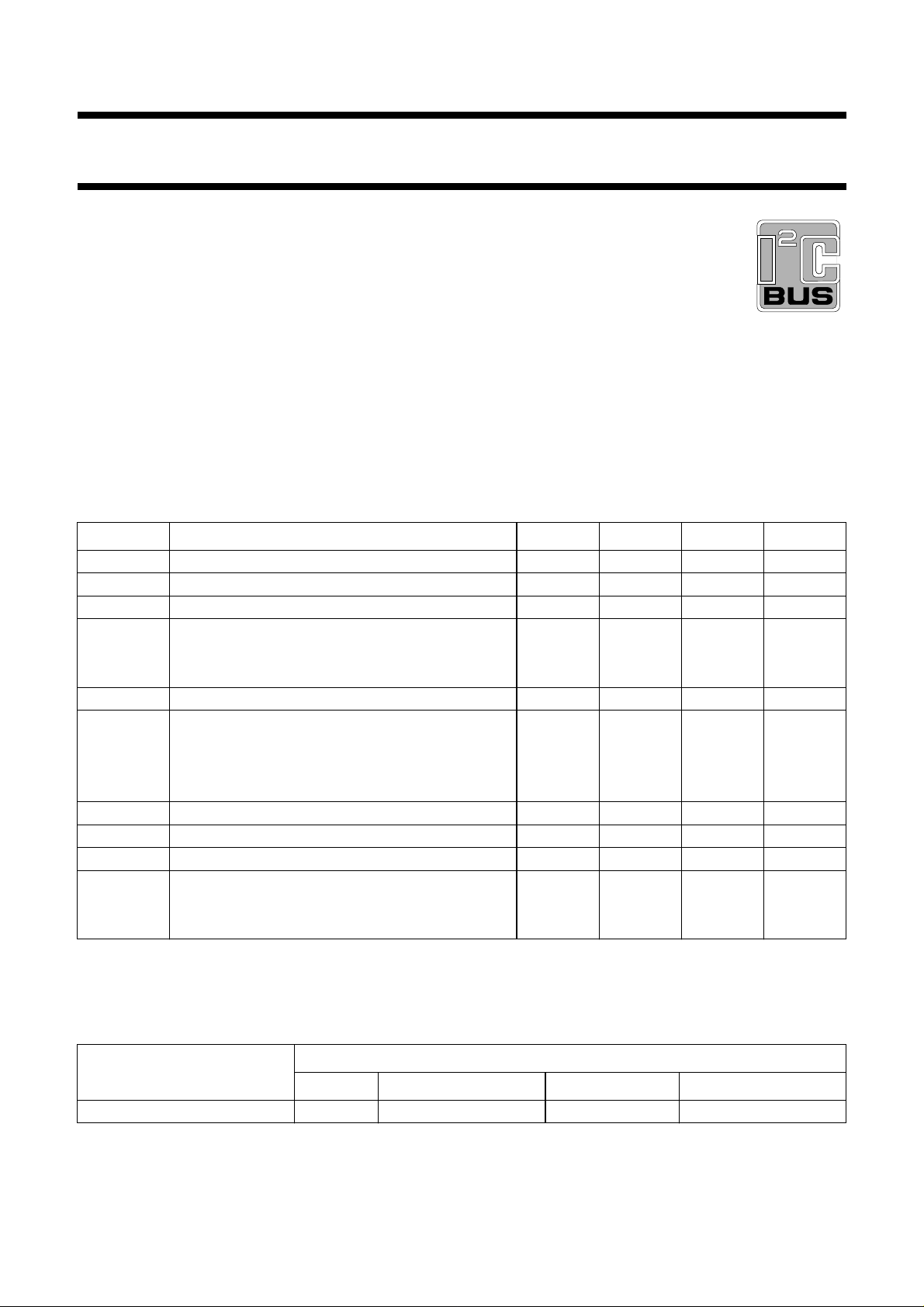

Fig.1 Block diagram.

August 1991 3

Page 4

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

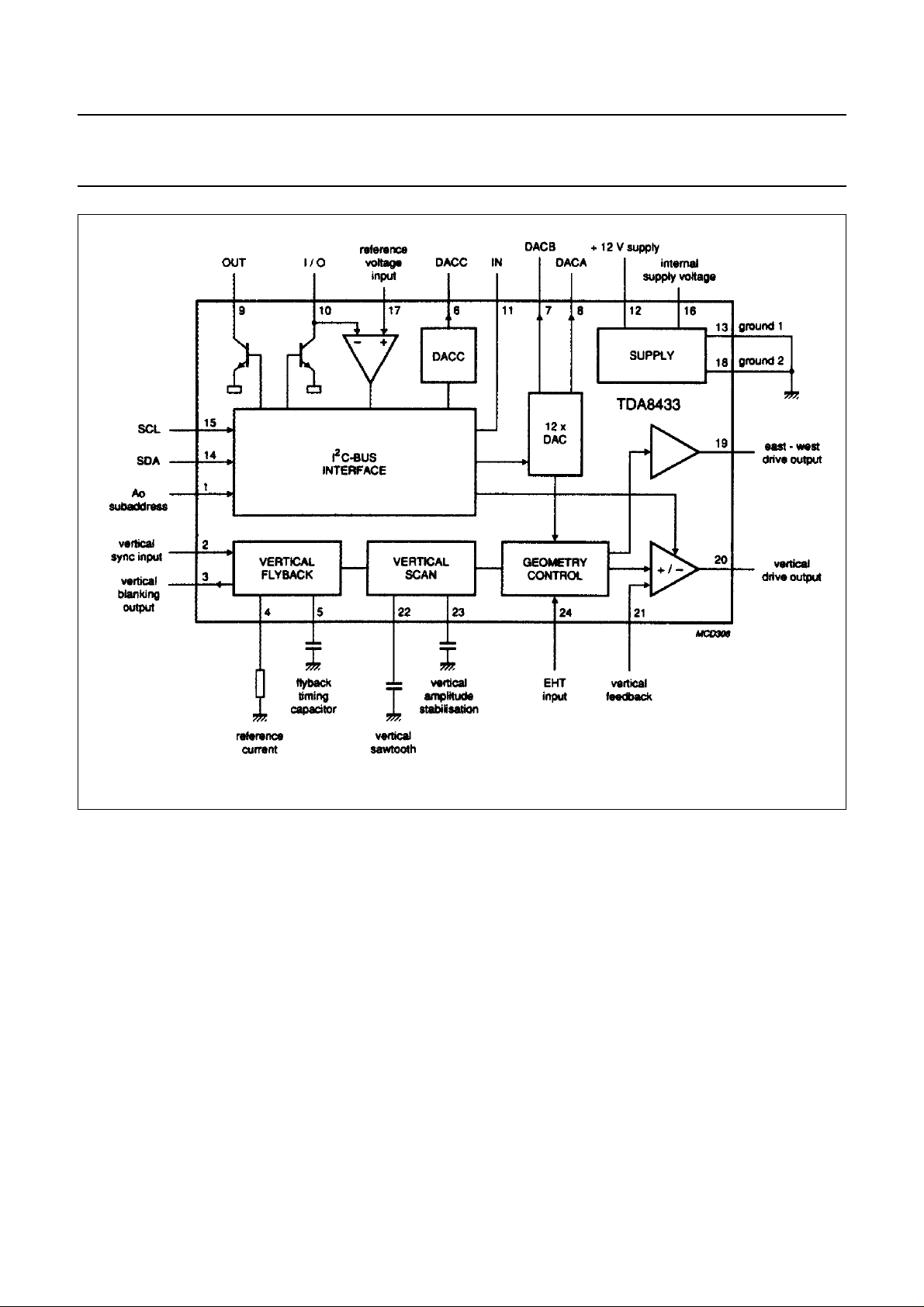

PINNING

PIN DESCRIPTION

1 Ao subaddress

2 vertical sync input

3 vertical blanking output

4I

5 vertical blanking/flyback timing capacitor

6 DACC (tau switching)

7 DACB (horizontal phase)

8 DACA (horizontal frequency)

9 OUT (video switch)

10 I/O (f

11 IN (HLOCKN −50/60 Hz)

12 positive supply +12 V

13 ground 1

14 serial data input

15 serial clock input

16 internal supply voltage

17 voltage reference for I/O

18 ground 2 (waveform)

19 east-west drive output

20 vertical drive output

21 vertical feedback

22 vertical sawtooth capacitor

23 vertical amplitude capacitor

24 EHT input

resistor

ref

o

adjustment)

TDA8433

Fig.2 Pinning diagram.

August 1991 4

Page 5

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

PIN FUNCTIONS

Pin 1 - Ao subaddress

The Ao bit is the least significant bit

of the bus-address. It enables two

TDA8433s, with different

addresses, to be connected to the

same bus.

Pin 2 - Vertical sync input

Positive trigger pulses of > 3 V are

sufficient to exceed the internal

threshold of the ramp generator.

Flyback and blanking will then start

and, during the blanking period, the

circuit will be inhibited for further

input pulses (see Fig.3). It should be

noted that the TDA8433 has no

vertical oscillator therefore, the sync

processor, which is used in this

combination, has to provide trigger

pulses as well when the video input

is absent.

Pin 3 - Vertical blanking

The positive going blanking pulse is

fed from a current source. The

blanking period is fixed by the

capacitor connected to pin 5 and the

resistor connected to pin 4 (see

Fig.3).

Pins 4 and 5 - Reference/flyback

timing

The external resistor connected

between pin 4 and ground provides

a reference current for the triangle

generator circuit. This circuit

generates the triangle waveform at

pin 5. The width of the blanking

pulse is set by the external

capacitor connected to pin 5.

Table 1 Sync processor time constants

VTRA VTRC OUTPUT TIME CONSTANT

'0' '0' 12 V automatic operation

'0' '1' 5.3 V medium

'1' '0' 1.5 V fast (video recorder)

'1' '1' 0.2 V not to be used

Pin 6 - DACC (tau switching)

The output voltage, which depends

on the VTRA and VTRC bits in the

I2C-bus control register, is connected

to the coincidence detector of the

sync processor. In this way the time

constants of the horizontal PLL (in the

sync processor) can be set. If the

TDA2579 is used (see Fig.6) the

effect will be as listed in Table 1.

Pin 7 - DACB (horizontal phase)

The voltage at pin 7 is fed to the

horizontal pulse modulator in the sync

processor. This voltage, together with

the signal produced by the phase 2

detector during horizontal flyback,

sets the phase of the horizontal

output with respect to the flyback

pulse in the horizontal output stage.

The voltage range is variable

between 0.05 V and 10 V.

Pin 8 - DACA (horizontal

frequency)

The frequency of the horizontal

oscillator in the external sync

processor is adjusted by the voltage

level at pin 8. The voltage is variable

in 63 steps from 0.05 V to 10 V (i.e.

0.158 V per step).

Pin 9 - OUT (video switch)

The output at pin 9 is controlled by the

CVBS bit from the control register

where

CVBS = logic 0; the output is HIGH

(open collector)

TDA8433

CVBS = logic 1; the output is LOW

(saturation voltage)

An external video selector can be

controlled by means of this switching

function.

Pins 10 and 17 - I/O and Voltage

reference

Pin 10 is connected to the output of

the phase 1 detector in the sync

processor. Whether the pin is used as

an input or an output is dependent on

the PHI1 bit of the horizontal

frequency (HFREQ) register. When

PHI = logic 0 (output transistor open)

pin 10 is used as an input. The DC

information at this pin is compared

with the reference voltage at pin 17

and is reflected in the HCENT of the

status register.

HCENT = logic 0; input > V

HCENT = logic 1; input < V

In this way the free running frequency

can be adjusted by computer while

the oscillator is locked. Alternatively,

when PHI1 = logic 1, pin 10 is

switched to ground. The free running

frequency of the oscillator can the be

adjusted while watching the screen

provided that pin 10 is connected to

the video input of the sync processor.

Pin 11 -IN (HLOCKN and 50/60 Hz)

This pin is connected to the combined

MUTE and 50/60 Hz pin of the sync

processor. The various DC levels

define the state of the HLOCKN and

50/60 Hz bits in the status register

(see Table 2.)

ref

ref

at V

at V

17

17

August 1991 5

Page 6

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

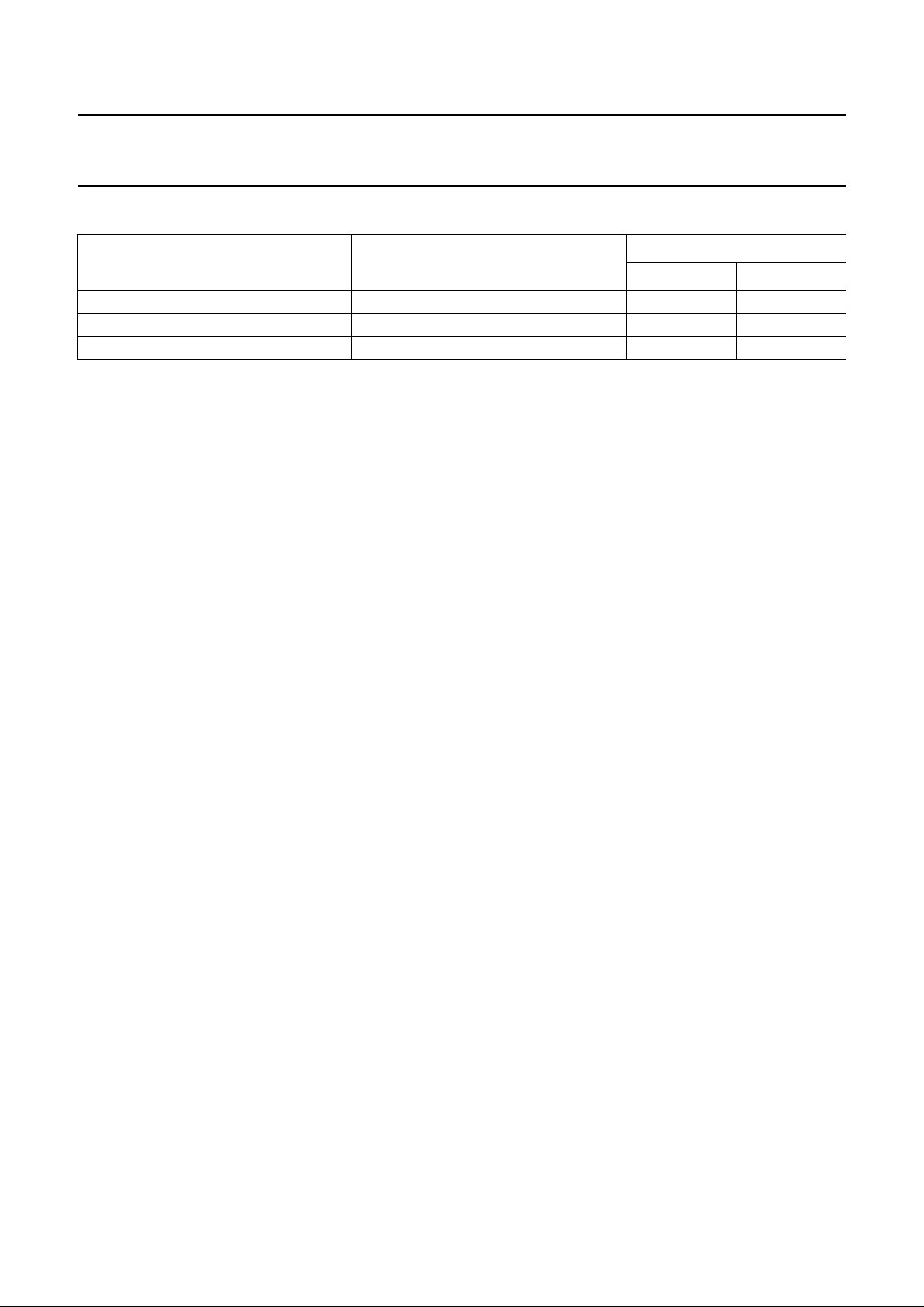

Table 2 Status register bits

STATE OF SYNC PROCESSOR

(TDA2579)

Not locked to computer video < 0.7 V(min.) '1' '0'

60 Hz transmitter found 0.7 to 0.75 V

50 Hz transmitter found > 0.75 V

Pin 12 - Positive supply (12 V)

The nominal supply voltage at pin 12

is 12 V which should remain within

the defined limits. The nominal

current consumption is 20 mA.

Pins 13 and 18 - Ground (1 and 2)

Ground 1 (pin 13) is for the bus

transceiver section

Ground 2 (pin 18) is for the sawtooth

and picture geometry control section.

Pins 14 and 15 - SDA and SCL

(serial data and serial clock)

Input serial data is applied to pin 14.

The serial clock input from the

2

I

C-bus is applied to pin 15.

Pin 16 - Internal supply voltage

(+5 V)

In some applications it may be

necessary to connect a capacitor to

this pin to avoid interference.

Pin 19 - East-west drive output

The output drive for the East-west

correction circuit has a nominal range

from 1.6 to 11.7 V and contains 5

programmable parameters (see

Fig.5). The parameters are:

• Picture width

• East-west raster correction

• East-west trapezium correction

• East-west corner correction

• Compensation for EHT variations

TYPICAL VOLTAGE AT PIN 11

CC

to V

CC

CC

Pins 20 and 21 - Vertical drive

output and vertical feedback input

The vertical comparator and drive

output stage is designed so that the

feedback signal applied to pin 21 can

be inverted in the comparator by the

V-out control bit. This enables the use

of two different vertical output stages.

One output stage is without an

internal comparator (e.g. TDA3654).

The feedback signal at pin 21 has a

negative slope during scan. During

power-up the IC is adapted (preset)

for this type of output stage. The other

output stage contains a comparator.

The drive for this output stage is

obtained by interconnecting pins 20

and 21 and switching the V-out

polarity. The V-out bit will then be set

to logic 1. In both cases the drive

signal available at pin 20 contains 5

parameters which can be set via the

2

I

C-bus control;

• Picture height

• Vertical linearity

• Vertical S-correction

• Vertical shift

• Extent of compensation for EHT

variations (see Fig.4.)

Pins 22 and 23 - Vertical

sawtooth/vertical amplitude

capacitor

The 100 nF capacitor connected to

pin 22 is charged and discharged by

two current sources in the vertical

ramp generator. In order to obtain an

HLOCKN 50/60 Hz

'0' '0'

'0' '1'

equal amplitude, at different

frequencies, an amplitude

comparator has been incorporated.

The circuit, together with the 330 nF

capacitor connected to pin 23, keeps

the sawtooth amplitude at reference

voltage level (7.1 V). The external

load of the amplitude stabilization

loop of pin 23 should be as low as

possible. The recommended value is

≥ 500 MΩ.

Pin 24 - EHT input (Modulation)

A voltage between 1.7 and 6 V

(depending on the EHT variations)

applied to pin 24 will modulate the

amplitude of the vertical drive

sawtooth and the East-west drive

output. In this way the effect of beam

current variations can be virtually

eliminated.

2

I

C-BUS CONTROL

The addresses for the I2C-bus are

100011Ao0 (write) and 100011Ao1

(read). The inclusion of the Ao bit

makes it possible to control two

different deflection processors. After

receiving the address byte the

I2C-bus transmits its status byte in

which the status of the control bits is

contained.

PONRES - Power-on-reset

After switch-on, or a power dip below

6.7 V, the PONRES bit is set to logic

1. After a status read operation

PONRES is reset to logic 0.

STATE OF

TDA8433

August 1991 6

Page 7

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

HLOCKN - Horizontal lock

This bit indicates whether the

horizontal oscillator in the sync

processor is locked to the video

signal. When the oscillator is locked

HLOCKN is set to logic 0

(V11> 0.7 V). When the oscillator is

not locked HLOCKN is set to logic 1

(V11< 0.7 V).

HCENT - Horizontal centre

This bit is set to logic 0 when the

horizontal oscillator frequency is too

> V

high (V

10

). The bit is set to logic

ref

Table 3 Registers

FUNCTION

H-frequency 00 PHI-X-6 01 00

H-phase 01 6 01 00

Picture height V

21/20

V-linearity 03 6 01 00

V-S correction 04 6 01 00

V-shift 05 6 01 00

V-compensation

V

= 1.7 V

24

Picture width 07 6 01 00

E-W parabola

(Reg: 07 = 0)

E-W corner

(Reg: 08 = 3F)

Trapezium

Reg: 07 = 00; 08 = 20H

H-compensation

Reg. 07 = 00; 08 = 0; 09 = 00

V

= 1.7 V

24

1 when the frequency is too low

V10< V

ref

).

IN - 50/60 Hz

The voltage at pin 11 also contains

the 50/60 Hz information where:

logic 0 = ≤ V

0.75 VCC(60 Hz or no

11

transmitter)

logic 1 = ≥ V110.75 VCC(50 Hz)

The sequence of data in the status

byte is: PONRES, HLOCKN,

50/60 Hz, 0 0 0 0.

SUB

ADDR

HEX

DATA

BITS

PRESET

VALUE

HEX

02 6 01 00

06 5 01 00

08 6 01 00

09 6 01 00

0A 6 01 00

0B 5 01 00

TDA8433

A write operation starts with address

byte 100011Ao0. The device is then

ready to receive the subaddress byte

e.g. trapezium (HEXOA) 00001010

followed by the data byte e.g. HEX20.

The DAC will then set the trapezium

correction signal into the selected

position (see Fig.5). If more data

bytes follow within one transmission

then, by means of an auto-increment,

the next highest subaddress will be

selected. Wrap-around occurs after

HEXOF.

SETT

HEX

3F

3F

3F

3F

3F

3F

1F

3F

3F

3F

3F

1F

MIN. TYP. MAX. UNIT

−

9.5

−

9.5

−

+15

0

13

0

15

+17

−17

tbf

−8

−

6.0

−

7.0

−

1.7

0.75

1.0

0

−

0.05100.2

11

0.05100.2

11

−19

+19

−

17

−

19

+19

−19

−22

−

1

21

1

−

+22

+22

0

−10−−12

1.6

6.6

0.07

7.5

0

2.2

1.25

1.9

tbf

10

2.4

7.2

0.1

8.5

tbf

2.8

−

−

−

−

V

V

V

V

%

%

%

%

%

%

%

%

−

%

V

V

V

V

V

V

V

V

%

%

August 1991 7

Page 8

Philips Semiconductors Product specification

Deflection processor for computer

TDA8433

controlled TV receivers

FUNCTION

SUB

ADDR

HEX

DATA

BITS

Not used 0C/0E −− −−−−

Control 0F X-VOUT − 40 11.5 11.9 V

VTRA−VTRC − 50 5.0 5.3 5.6 V

CVBS−X−X−X − 60 1.2 1.5 1.8 V

PHI1 bit 00 1 − 80 −−0.4

Not used 10−EF

Test functions F0−FF

PRESET

VALUE

HEX

SETT

HEX

MIN. TYP. MAX. UNIT

CC

V

70 0 0.2 0.5 V

40 5.5 7.5 9.5 kΩ

50 2.4 3.3 4.2 kΩ

60 0.7 1.0 1.35 kΩ

70 − 50 −Ω

00 −−(VBS) V

08 −−0.4

V

(1 mA)

V

(−2 mA)

00 −−V

CC

V

Note to Table 3

1. tbf = value to be fixed.

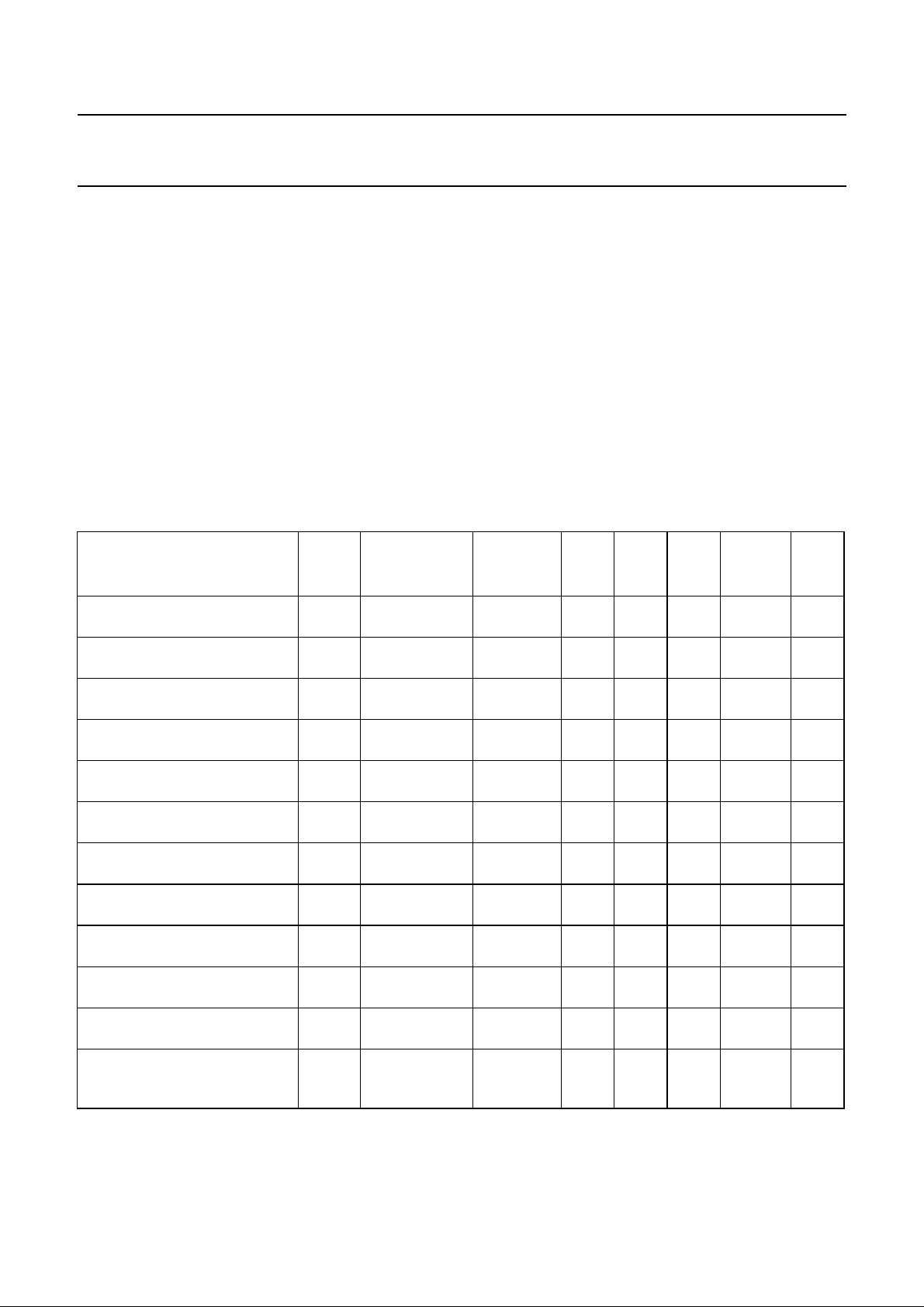

LIMITING VALUES

In accordance with the Absolute Maximum System (IEC 134)

SYMBOL PARAMETER MIN. MAX. UNIT

V

I

P

T

T

CC

CC

tot

amb

stg

supply voltage 10.8 13.2 V

supply current 12 27 mA

total power dissipation − 360 mW

operating ambient temperature range −25 +75 °C

storage temperature range −55 +150 °C

THERMAL RESISTANCE

SYMBOL PARAMETER TYP. MAX. UNIT

R

th j-a

from junction to ambient in free air − 35 K/W

August 1991 8

Page 9

Philips Semiconductors Product specification

Deflection processor for computer

TDA8433

controlled TV receivers

CHARACTERISTICS

= 12 V; V24 = 1/2 x VCC;T

V

CC

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

CC

I

CC

supply voltage (pin 12) 10.8 12.0 13.2 V

supply current (pin 12) 12 20 27 mA

Ao subaddresses (pin 1)

V

1

switching level allowed voltage

for AO= ‘0’

for Ao = '1' 9 − V

I

1

V

1

input current −− +10 µA

not allowed voltage range 2.0 − 8.9 V

Vertical sync input (pin 2)

V

2

I

2

switching level 2.5 3.0 3.5 V

current during non-active state V2 = 0 V − 310µA

Vertical blanking output (pin 3)

V

3(p-p)

pulse amplitude (peak-to-peak

value)

V

3

I

O

t

W

output voltage 1 mA load 10.0 10.5 − V

output source current 1 −−mA

pulse width R4 = 75 kΩ

= 25 °C; unless otherwise specified

amb

note 1 −

1 mA load −− V

C5 = 8.2 nF

2.3

−

−

−

2

CC

−2V

CC

V

V

V

− 1.13 − ms

Reference (pin 4)

V

4

I

4

reference voltage 6.8 7.15 7.5 V

current range 90 − 150 µA

Vertical blanking timing (pin 5)

V

5(p-p)

amplitude of triangular pulse

(peak-to-peak value)

t

W

I

5

I

5

width of triangular pulse − 1.3 − ms

sink current V5 = 3.5 V; I4 = 100 µA 85 105 125 µA

source current V5 = 3.5 V; I4 = 100 µA 80 100 120 µA

DACC output (pin 6)

V

6

voltages at VTR(A) and VTR(C)

where:

(A) = '0'; (C) = '0' 11.5 11.9 − V

(A) = '0'; (C) = '1' 5.0 5.3 5.6 V

(A) = '1'' (C) = '0' 1.2 1.5 1.8 V

(A) = '1'; (C) = '1' 0 0.2 0.5 V

R4 = 75 kΩ

C5 = 8.2 nF

7.5 7.9 8.3 V

August 1991 9

Page 10

Philips Semiconductors Product specification

Deflection processor for computer

TDA8433

controlled TV receivers

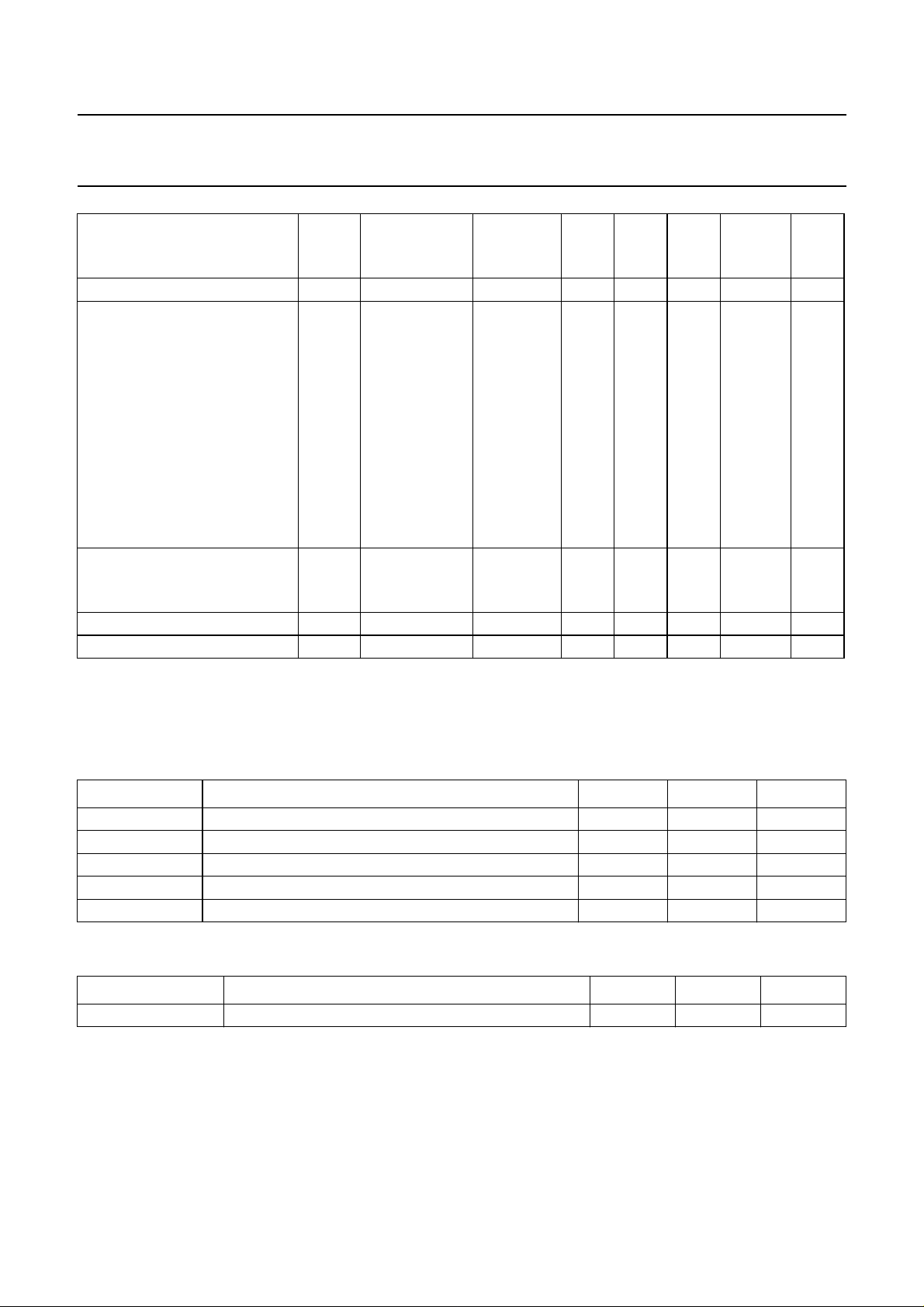

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

DACC output (pin 6)

Z

6

DACB horizontal phase (pin 7)

V

7

∆V

7

R

7

RR ripple rejection 26 −−dB

output impedance at VTR(A) and

VTR(C) where:

(A) = '0'; (C) = '0' 5.5 7.5 9.5 kΩ

(A) = '0'; (C) = '1' 2.4 3.3 4.2 kΩ

(A) = '1'; (C) = '0' 0.7 1.0 1.35 kΩ

(A) = '1'; (C) = '1' − 50 −Ω

output voltage

at HEX00 − 0.05 0.2 V

at HEX3F 9.4 10.0 11.0 V

variable DC output voltage for

0.05 − 10 V

setting horizontal frequency

internal resistance − 0.3 1.0 kΩ

step size note 3 10 − 190 %

DACA horizontal frequency (pin 8)

V

8

output voltage

at HEX00 − 0.05 0.2 V

at HEX3F 9.5 10.0 11.0 V

∆V

8

variable DC output voltage for

0.05 − 10 V

setting horizontal frequency

R

8

internal resistance − 0.3 1.0 kΩ

step size note 3 10 − 190 %

RR ripple rejection 26 −−dB

OUT video switch (pin 9)

F

OR EXTERNAL CVBS SWITCH WHEN CVBS BIT =1

V

I

9

L

saturation voltage I

= 1 mA −− 0.4 V

sink

leakage current −− 2 µA

I/O combined input/output (pin 10)

V

10

when used as an output (open

collector)

where PHI1 = '0' −− V

CC

V

where PHI1 = '1' −− 0.4 V

I

sink

V

10

I

10

sink current −− 2mA

when used as an input (switching

point HCENT is '0' to '1')

PHI1 = '0' V17−

35 mV

V

17

V17 +

V

35 mV

input current −− 2 µA

August 1991 10

Page 11

Philips Semiconductors Product specification

Deflection processor for computer

TDA8433

controlled TV receivers

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

IN HLOCKN and 50/60 Hz (pin 11)

V

11

V

11

V

11

I

11

SDA serial data input (pin 14)

V

14

I

14

SCL serial clock input (pin 15)

V

15

I

15

Internal supply voltage

V

16

V

17

I

17

E-W drive output (pin 19; see application information)

V

19

I

19

RR ripple rejection 24 30 − dB

R

I

t

R

Vertical drive output (pin 20; see application information)

V

20

I

20

RR ripple rejection note 2 35 40 − dB

HLOCKN switching level − 0.7 − V

switching level where:

LOCKN = '0' 1.0 −−V

LOCKN = '1' −− 0.4 V

switching level where:

50/60 Hz = '0' −− 0.7 V

50/60 Hz = '1' state 50 Hz 0.8 V

−−V

CC

CC

V

source current 10 25 35 µA

switching level where:

SDA = ‘0’ −− 1.5 V

SDA = ‘1’ 3.0 −−V

sink current − 0.5 10 µA

switching level where:

SDA = ‘0’ −− 1.5 V

SDA = ‘1’ 3.0 −−V

sink current − 0.5 10 µA

maximum allowed load 1 mA load 4.5 5.0 5.5 V

voltage reference for pin 10 (pin 17) 1.0 − Vcc− 1.5 V

input load current −− 2.0 µA

output voltage 1 mA load 0.5 − 11.5 V

output current ±1.0 −±2.0 mA

internal resistance − 12kΩ

response time − 2 −µs

output voltage 1 mA load 0.5 − 10.5 V

output current ±1.5 ±2.0 − mA

DAC stepsize note 3 10 − 190 %

Vertical feedback (pin 21; see application information: Register 02 = 20H, 03 = 0, 04 = 0, 05 = 20H, 06 = 0)

V

21

V

21(p-p)

DC input voltage 1.7 1.85 2.05 V

AC output voltage (peak-to-peak

note 2 1.65 1.8 1.95 V

value)

I

21

input current −− −3µA

August 1991 11

Page 12

Philips Semiconductors Product specification

Deflection processor for computer

TDA8433

controlled TV receivers

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Vertical sawtooth voltage (pin 22; see application information)

V

22

V

22

I

22

I

22

I

22

Z

AC impedance − 3 − MΩ

22

C

EXT

Vertical sawtooth stabilizer (pin 23; see application information)

I

23

I

23

C

EXT

I

L

EHT modulation input (pin 24; see application information)

V

24

I

24

Notes to the characteristics

1. Outside the test mode.

2. Test condition (hex values): register 02 = 3F; 03 = 00; 04 = 00; 05 = 20; 06 = 00; V22 = 1/2 V4; f = 50 Hz to 30 kHz.

top level of sawtooth 6.7 7.1 7.4 V

minimum level of sawtooth I

= 0.5 mA −− 50 mV

sink

discharge sink current V22= 3.5 V 6.5 9.5 15 mA

charge source current V23=5V;

120 35µA

V22= 3.5 V

control range 5 V to 1 V 80 135 190 µA

external capacitance − 100 − nF

discharge sink current V22= 2 V 200 250 300 µA

charge source current V22= 9.75 V 185 235 285 µA

external capacitance − 390 − nF

leakage current note 5 −− 0.015 µA

voltage operating range 1/7 VCC− 1/2 V

CC

V

input current − 0.5 2.0 µA

Value StepN Value StepN– 1–

3.

---------------------------------------------------------------------------------average step size

100% 63>N>1().×

4. Applies to both modes.

5. External load of this pin (leakage current capacitor etc.) should be ≥ 500 MΩ.

August 1991 12

Page 13

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

Fig.3 Vertical sawtooth timing.

August 1991 13

Page 14

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

Fig.4 Vertical raster-corrections.

August 1991 14

Page 15

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

Fig.5 East-west raster-corrections.

August 1991 15

Page 16

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

August 1991 16

Fig.6 Application diagram (continued in Fig.7).

Page 17

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

August 1991 17

Fig.7 Application diagram (continued from Fig.6).

Page 18

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

APPLICATION INFORMATION

The formulae from which the typical

vertical drive and typical E-W drive

waveforms are generated are given

in the following sub-paragraphs. For

this purpose a typical application

diagram for the vertical drive stage

is assumed to be as illustrated in

Fig.7. Pin 20 is the vertical drive

output which drives an inverting

power amplifier. The feedback

network, R1 to R4 and C1 and C2,

has two functions;

• To transfer the voltage on the

feedback pin (pin 21) to a voltage

across the feedback resistor R1

• To stabilize the voltage across C1

at a fixed value.

For this typical application the

formula for the vertical scan

waveform refers to the voltage at

pin 21. The formula for the E-W

drive waveform refers to the voltage

at pin 19.

Table 4 DAC variables

a: Picture height 0 < a < 1 64 steps (6 bits)

y: V-linearity 0 < y < 1 64 steps (6 bits)

s: V-S correction 0 < s < 1 64 steps (6 bits)

d: V-shift 0 < d < 1 64 steps (6 bits)

v: V-compensation 0 < v < 1 32 steps (5 bits)

w: Picture width 0 < w < 1 64 steps (6 bits)

p: E-W parabola 0 < p < 1 64 steps (6 bits)

c: E-W corner 0 < c < 1 64 steps (6 bits)

t: Trapezium 0 < t < 1 64 steps (6 bits)

h: H-compensation 0 < h < 1 32 steps (5 bits)

Further definitions

= Instantaneous sawtooth voltage (pin 22) normally; 0 < V

V

SAW

VCC = supply voltage applied to pin 12.

V

= EHT compensation voltage applied to pin 1, normally between 1/2 V

EHT

and 1/7 VCC.

V

= Internal offset voltage.

OFF

V

= Internal reference voltage of 7.1 V (also on pin 4)

int

TDA8433

< 7.1 V;

saw

CC

All DAC variables that control the

vertical and E-W drive waveforms

are normalized. Each DAC is

defined as having a control range

between 0 and 1. The 0

corresponds to a register value of

HEX00 and the 1 to a maximum

value of HEX1F (for a 5-bit DAC) or

HEX3F (for a 6-bit DAC).

A = 0.80 (a + 2)/3 P = 0.55 p

Y = 0.17 y C = 0.38 c

S = 0.42 s T = 0.32 (1 + 2t) volts

D = 2.4 − 0.7 d volts E = (V

W = 0.16 w Z = −1 + 2 x (V

/ 2 − V

CC

saw

EHT

) / 42

− T) V

int

If the Trapezium function (T) compensates for the internal offset voltage then the

actual formula for Z will simplify to:

Z = −1 + 2V

Since 0 V < V

saw/Vint

< 7.1 V, this is simply a negative going sawtooth and it follows

SAW

that: −1 < Z < 1.

August 1991 18

Page 19

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

Vertical drive waveform

The vertical drive waveform has

certain interactions between the

parameters whereby:

• The S-correction influences the

picture height

• The linearity correction can

influence the picture shift.

The alignment can be made

non-repetitive. Once correct values

for the V-S correction and V-linearity

are set, the picture height may be

changed without affecting the V-S

correction and V-linearity on the

screen.

The formula for the vertical drive

waveform at pin 21 is:

V

= D + 1.32 A {(Z − SA2 Z3)

vert

(1 − VE) + YZ2} volts.

Picture height

The amplitude of the sawtooth

waveform is controlled by 'A'. It

follows therefore that:

0.53 < A < 0.8

The nominal value for 'A' is found for

a = 0.5, therefore A = 0.67. By

programming the picture height, the

sawtooth amplitude can be adjusted

from −19% to +19%. Without

S-correction (S = O) and linearity

correction (Y = O), the nominal

sawtooth amplitude is (with A = 0.67);

1.32 x 0.67 x 2 = 1.77 V

(p-p)

V-linearity

This function is meant to compensate

for non-linearity of AC coupled

vertical output stages. The linearity

correction changes proportionally to

the picture height setting. The range

for linearity control is typically 17% of

the peak-to-peak value of the linear

sawtooth (see Fig.7).

V-S correction

The range for the V-S correction

2

) is defined as a percentage of

(SA

the undistorted peak-to-peak

sawtooth voltage (see Fig.7). The

actual S-correction component (SA2)

is dependent on the picture height

setting where:

At maximum picture height (A = 0.80)

: SA2 = 0.282

At nominal picture height (A = 0.62) :

SA2 = 0.197

At minimum picture height (A = 0.53)

: SA2 = 0.125

Picture shift

The DC level of the output is fixed by

'D'. It can be adjusted within a range

of −19% to +19%. In actual

application this will be used for

shifting the picture vertically.

V-compensation

The vertical deflection can be

modulated by the instantaneous

value of the signal applied to the EHT

compensation input. This external

signal should reflect the EHT

variations. The amount of deflection

reduction is in the range 0 to 10%, if

pin 24 is at (V

(maximum modulation i.e. 1.7 V

typical). Thus for maximum

modulation, the V-drive waveform

can be reduced to 90% of its value.

There is no reduction when the

EHT-compensation input is at

VCC / 2 V (i.e. 6 V typical).

/ 2) − 4.3 V

CC

TDA8433

Trapezium

The trapezium function is the only

IC-confined adjustment and is

intended to compensate for any

internal offsets. The function is called

Trapezium because of its effect on

the picture if an AC-coupled vertical

deflection stage is used. The

trapezium function can alter the

picture shift range by a maximum of

190 mV. If the trapezium function is

used for purposes other than

eliminating the internal offsets, then

the V-linearity can affect the actual

picture height. This can affect the

symmetry of the S-correction which,

in turn, can affect the V-linearity.

E-W drive waveform

In order to obtain independent control

of the picture width, parabola function

and the H-compensation on a screen

each function has been designed to

be dependent on the other two. With

reference to Fig.8, the voltage across

the H-deflection stage is:

V

= V

def1

Where:

V

supply

W = picture width alignment

P = parabola function

E = H-compensation

This shows for instance, that the

H-compensation is made dependent

on the actual value of the parabola

function. For a TV set which needs a

large parabola compensation and,

also, a large EHT-compensation, this

function allows an optimal

EHT-compensation independent of

the parabola function.

(1 − W) (1 − P) (1 − E)

supply

= supply voltage for

H-deflection stage

August 1991 19

Page 20

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

All correction voltages are related to

the supply voltage. The TDA8433 is

designed to accept a supply voltage

of 30 V. Normally higher voltages are

employed therefore a voltage

amplifier, with a gain of V

used between the TDA8433 and the

diode modulator.

The formula for the E-W drive output

voltage at pin 19 is:

V

= 30 x {1 − (1− W) (1 − PA2 Z2 +

E-W

CA4 Z4) (1 − 1.1 x hE)} + 1.8 V

As can be seen from the formula, the

picture width, parabola function and

H-compensation are influenced by

each other. The functions are

discussed separately with the other

compensations set to zero.

Picture width control (P-C-h-O)

It is possible to change the picture

width by adjusting 'W' from 0 to 0.16.

Thus the complete range for the

picture control width is −10 to +10%.

By only changing the picture width

control the output voltage at pin 19

can vary between 1.8 and 6.6 V

typical.

supply

/30, is

Parabola function

The parabola function is also

dependent on the picture height

function. The values given are valid

for a nominal height setting

(A = 0.67 V). The parabola function

consists of two parts:

• A parabola part - E-W parabola is

created by squaring a linear

sawtooth. The range of this pure

parabola varies from 0 to 25%

typical i.e. the amplitude of the

parabola waveform is

programmable from 0 to 7.5 V

(typical).

• A fourth order part - E-W corner is

created by squaring the parabola.

The range of this corner correction

varies from 0 to 7% (typical) i.e. the

amplitude of the corner correction

waveform is programmable from 0

to −2.2 V (typical). A negative

output voltage is not possible. The

E-W corner correction waveform

has to be subtracted from one of

the other alignment functions.

The split-up into the E-W parabola

and the E-W corner enables each

television set to be aligned with

straight vertical lines. The trapezium

is also related to the parabola

function. The main reason for the

trapezium correction is to

compensate for internal offsets in the

geometry control part. Therefore:

TDA8433

• The amount of trapezium

correction is fully dependent on the

amount of parabola correction and

corner correction that is needed.

With no parabola and corner

correction the trapezium output will

be zero.

• The maximum possible trapezium

output is 1.6 V (typical - see Fig.7).

This is the case where: a = 0.5, c =

0 and p = 1 i.e. no corner correction

and the maximum parabola

correction at nominal picture height

settings.

H-compensation control

The horizontal deflection can be

modulated by the instantaneous

value of the signal applied to the EHT

compensation input. This external

signal should reflect the EHT

variations. The amount of deflection

reduction is in the range 0 to 10% if

the input at pin 7 is at

(V

/2) −4.3 V (maximum

supply

modulation is 1.7 V typical). With

maximum modulation this range

corresponds to an output voltage of

0 to 3.3 V. There is no reduction when

the EHT-compensation input is at

V

/2 V (typical 6 V).

supply

August 1991 20

Page 21

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

Fig.8 Application diagram of an AC coupled amplifier stage.

Fig.9 Application diagram for driving the diode modulator.

August 1991 21

Page 22

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

Fig.10 Input/output pin-configuration of TDA8433 (continued in Fig.11).

August 1991 22

Page 23

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

TDA8433

Fig.11 Input/output pin-configuration of TDA8433 (continued from Fig.10).

August 1991 23

Page 24

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

PACKAGE OUTLINE

DIP24: plastic dual in-line package; 24 leads (600 mil)

D

seating plane

L

Z

24

e

b

TDA8433

SOT101-1

M

E

A

2

A

A

1

w M

b

1

13

c

(e )

1

M

H

pin 1 index

1

0 5 10 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

max.

mm

OUTLINE

VERSION

SOT101-1

1 2

min.

max.

1.7

1.3

0.066

0.051

IEC JEDEC EIAJ

051G02 MO-015AD

b

b

1

0.53

0.38

0.021

0.015

0.32

0.23

0.013

0.009

REFERENCES

cD E e M

32.0

31.4

1.26

1.24

12

scale

14.1

13.7

0.56

0.54

E

(1)(1)

e

L

3.9

3.4

EUROPEAN

PROJECTION

M

15.80

15.24

0.62

0.60

E

17.15

15.90

0.68

0.63

1

0.15

0.13

H

w

0.252.54 15.24

0.010.10 0.60

ISSUE DATE

92-11-17

95-01-23

Z

max.

2.25.1 0.51 4.0

0.0870.20 0.020 0.16

(1)

August 1991 24

Page 25

Philips Semiconductors Product specification

Deflection processor for computer

controlled TV receivers

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

Soldering by dipping or by wave

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

DEFINITIONS

(order code 9398 652 90011).

TDA8433

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

Repairing soldered joints

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

stg max

). If the

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

2

PURCHASE OF PHILIPS I

C COMPONENTS

2

Purchase of Philips I

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

August 1991 25

C components conveys a license under the Philips’ I2C patent to use the

Loading...

Loading...