Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA8385

Control circuit for a Self-Oscillating

Power Supply (SOPS)

Preliminary specification

Supersedes data of September 1991

File under Integrated Circuits, IC02

Philips Semiconductors

March 1994

Page 2

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

FEATURES

• Bandgap reference generator

• Slow-start circuitry

• Low-loss peak current sensing

• Over-voltage protection

• Hysteresis controlled stand-by

function

• Error amplifier with gain setting

• Programmable transfer character

generator

• Protection against open- and

short-circuited feedback loop

ORDERING INFORMATION

EXTENDED TYPE

NUMBER

TDA8385 16 DIL plastic SOT38WBE

PINS PIN POSITION MATERIAL CODE

• Over-load current fold back

characteristic

• LED driver

• Demagnetization protection

• Programmable determination of

switch-on moment of switching

transistor for low-switching losses

• Feed-forward input

• Regulation-indicator output

• Programmable minimum on-time of

switching transistor

• Accurate peak-current setting.

TDA8385

GENERAL DESCRIPTION

The TDA8385 is intended to be used

in combination with the opto-coupler

(CNR50) as a control unit for a

self-oscillating power supply.

PACKAGE

March 1994 2

Page 3

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

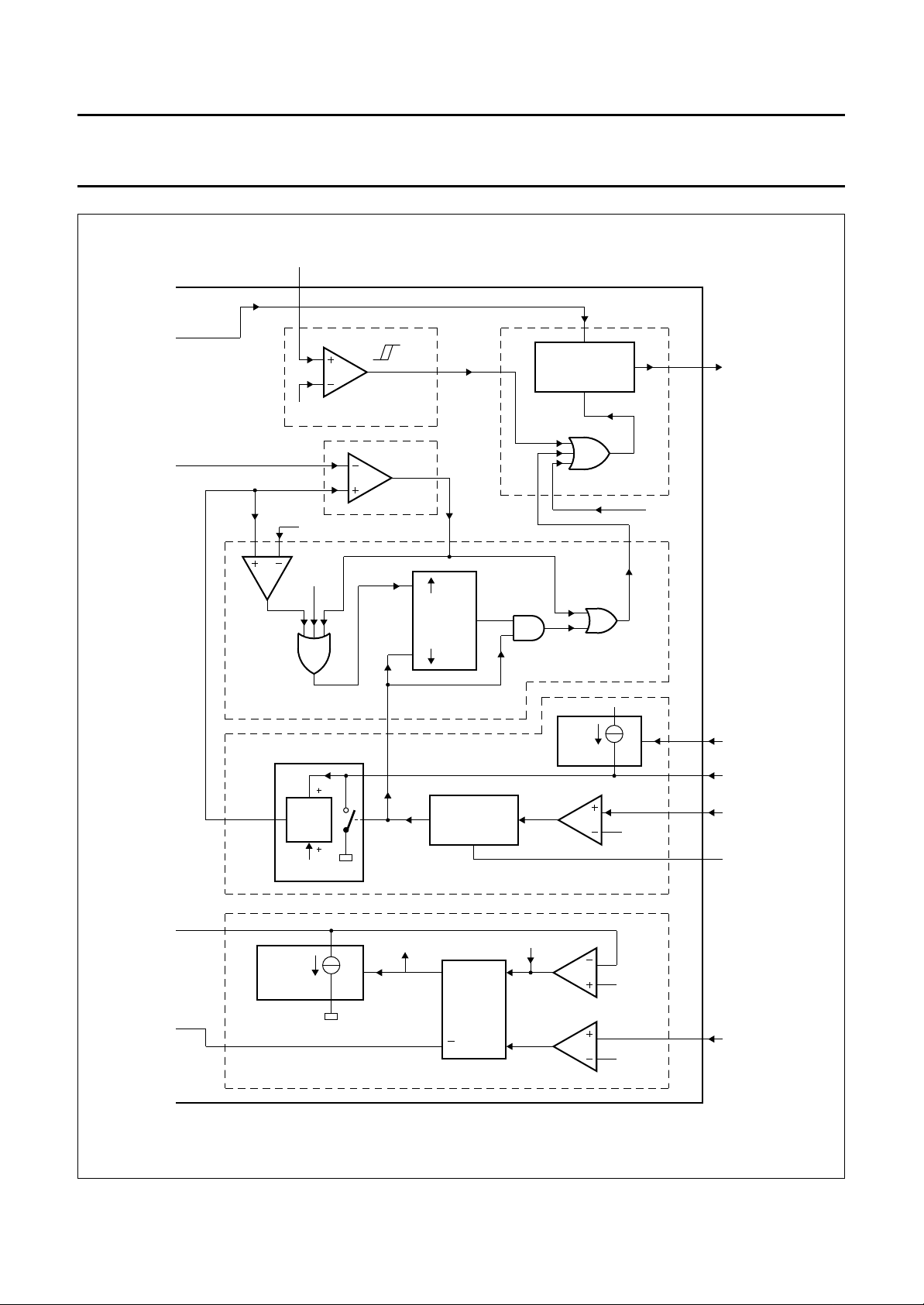

BLOCK DIAGRAMS

handbook, full pagewidth

current reference

setting

feed forward

input

regulation indicator

output

differential amplifier

output

I

ref

3

V

fo

13

1 RIO

11Vdiff

REFERENCE

BLOCK

I

ref

REGULATION

INDICATOR

V

DIFFERENTIAL AMPLIFIER

TDA8385

V

P GND

16 14

latch

V

diff

V

P (min)

DETECTOR

7

V

reset

2812

(28, 27, 23)

mv

V

ts

I

STABILIZED

SUPPLY

V

ref

29

stab

SUPPLY REFERENCES

V

ts

X

V

ref

(2.5 V)

3

feedback voltage

input

transistor-on

setting input

slow start voltage

input

V

9

T

on(min)

4

7Vss

fb

50 µA

5

CLAMP

TCG

2.5 V

4

+

T

V

on (min)

ss

reset (28)

quick

discharge

Fig.1 Block diagram; part A (continued in Fig.2; part B).

V

TCG

CONTROL PART

27

SLOW START

MINIMUM

VOLTAGE

CLAMP

50 µA

charge

19

6

III

VII

MCD417

March 1994 3

Page 4

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

handbook, full pagewidth

stand-by voltage input

V

10

sb

latch

2.5 V

V

r

V

sim

(28)18

2.5 V

25

STAND-BY

8

2 V

PWM

IV

S

IX

comparator

latch

OUTPUT

STAGE

17

LED DRIVER

TDA8385

LED

15

VI

Q (23)

2

TDA8385

LED driver output

26

demagnetization

100 mV

100 µA

slow

discharge

OVER-VOLTAGE PROTECTION

10

(17) (28)

21

FF

Q

R

13

V

c

DELAY

12

SAWTOOTH GENERATOR

QR

FF

23

S

Q

16

demagnetization

LED CONTROL

I

sim

0.2 I

11

24

22

14

12

I

I

12

9

peak

DEM

115 mV

II

115 mV

over voltage

2.5 V

VIII

V

12

current simulation

input

5

peak-current

setting input

15

demagnetization

input

6

delay setting

8

over-voltage

protection

Fig.2 Block diagram; part B (continued from Fig.1; part A).

March 1994 4

MCD418

Page 5

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

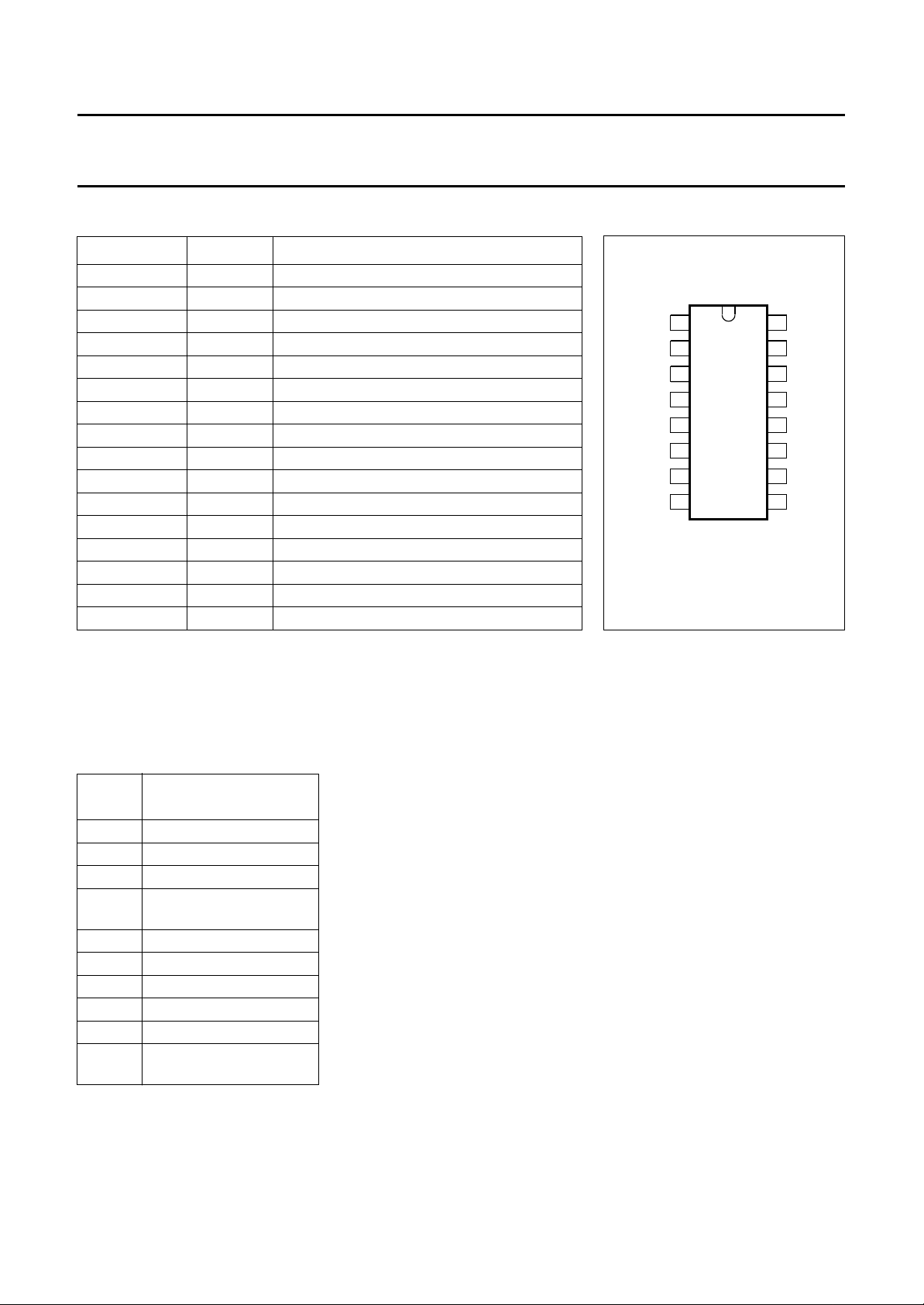

PINNING

SYMBOL PIN DESCRIPTION

RIO 1 regulation indicator output

LED 2 LED driver output

I

ref

T

on(min)

I

peak

DELAY 6 delay setting

V

ss

OVP 8 over-voltage protection

V

fb

V

sb

V

diff

I

sim

V

fo

GND 14 ground (0 V)

DEM 15 demagnetization input

V

P

3 current reference setting

4 transistor-on setting input

5 peak current setting input

7 slow start voltage input

9 feedback voltage input

10 stand-by voltage input

11 differential amplifier output

12 current simulation input

13 feed forward input

16 positive supply voltage

handbook, 2 columns

T

on(min)

DELAY

I

peak

OVP

RIO

LED

I

V

ref

1

2

3

4

5

6

7

ss

8

Fig.3 Pinning diagram.

TDA8385

TDA8385

MCD402

V

16

P

DEM

15

GND

14

V

13

fo

I

12

sim

V

11

diff

V

10

sb

V

9

fb

FUNCTIONAL DESCRIPTION

The TDA8385 can be divided into

10 functional blocks as shown in Fig.1

and Fig.2.

Block for Figs 1 and 2

BLOCK

NO.

DESCRIPTION

I supply references

II sawtooth generator

III control part

IV pulse width modulator

(PWM)

V LED control

VI LED driver

VII slow-start circuitry

VIII over-voltage protection

IX stand-by circuit

X regulation-indicator

output

These 10 functional blocks of Fig.1

and Fig.2 contain sub-sections

numbered 1 to 28 which are

cross-referenced in the following

description.

Supply references (Block I)

The TDA8385 is intended to be used

on the secondary side of the

self-oscillating power supply. It can be

supplied either by an auxiliary winding

of the transformer or an external

supply e.g. 50 Hz transformer.

Charging of the capacitor C

(see

P

Fig.16) takes place during transistor

on-time (Ton; see Fig.17). During

stand-by the IC is supplied by the

stand-by voltage Vsb (pin 10). The

operating voltage range is from 7.5 to

20 V. The supply current, inclusive

drive current for the LED, is less than

20 mA. A bandgap based reference

(2.5 V) generates a stabilized voltage

V

of 3.9 V to supply all internal

stab

circuits of the IC except the LED

driver. The LED driver is directly

supplied by VP. The reference block

generates all the reference voltages

in the circuit. By means of a resistor

connected to pin 3, a reference

current (I

) is defined.

ref

This current is reflected several times

and is used to obtain IC-independent

settings e.g. T

setting, delay

on(min)

setting, charging and discharging of

slow-start capacitor Css on pin 7

(see Fig.16).

The power supply is released by the

opto-coupler IC at an input voltage

level, which is high enough to

guarantee correct operation of the

TDA8385 e.g. VP = 10 V by sensing

the mains voltage VI. As soon as the

SOPS switching transistor (T1, see

Fig.16) is conductive the capacitor C

is charged. As long as the IC supply

voltage is below 7.5 V the LED driver

is blocked (see latch output;

sub-section 28) in order to guarantee

start-up of SOPS.

During the initialization phase the

quick-discharge-switch

(sub-section 27), set input of

flip-flop (13) and reset input of

flip-flop (23) are also activated.

As soon as the voltage of 7.5 V is

reached the control functions of the IC

are operative. Hysteresis on the

initialization level is 2.3 V.

P

March 1994 5

Page 6

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

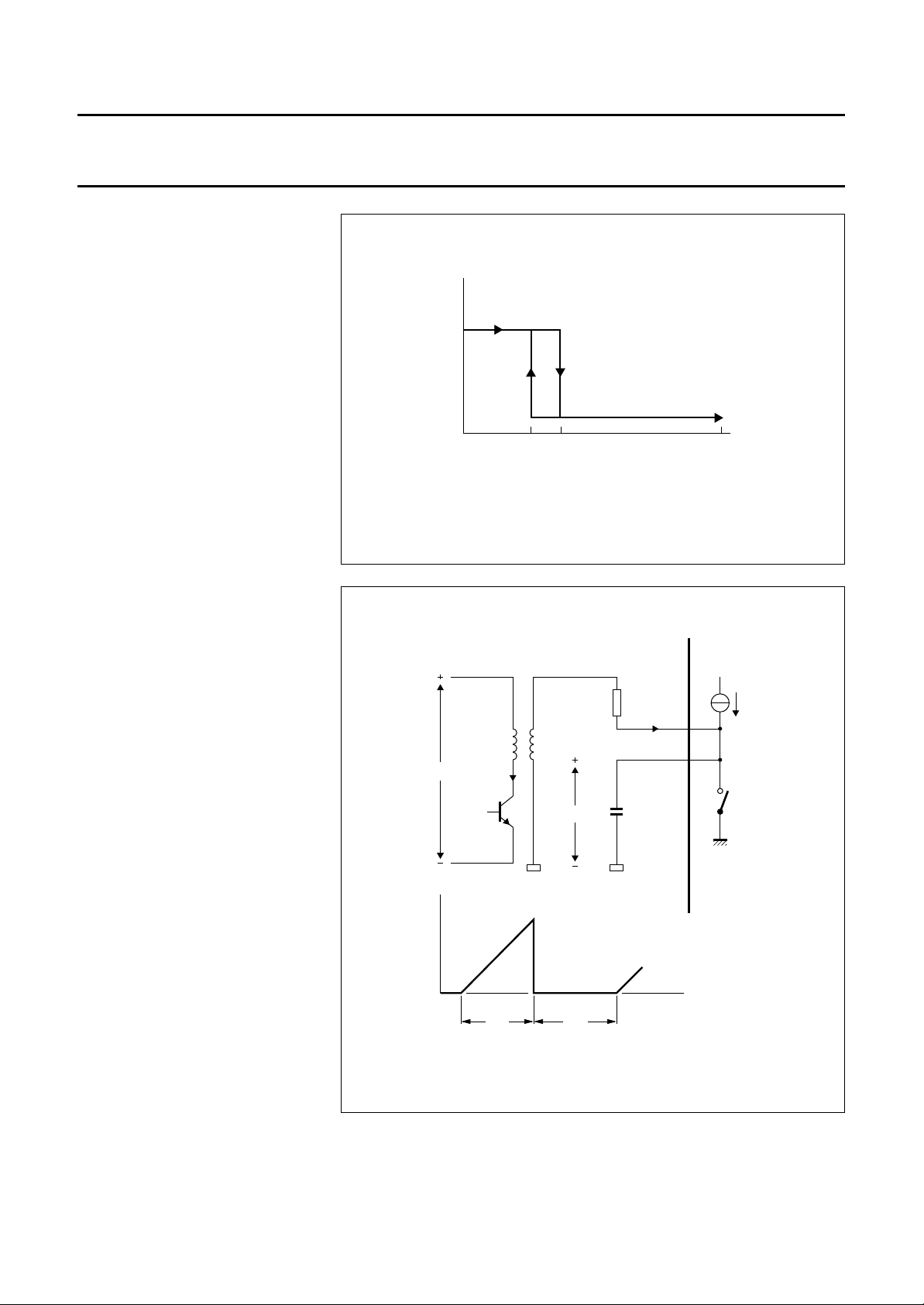

Sawtooth generator (Block II)

URRENT SIMULATION

C

(SEE FIGS 5 AND 16)

The current of the power supply

switching transistor is detected on the

secondary side by an indirect method

of current sensing.

Information of the collector current (Ic)

is obtained by integrating the voltage

of an auxiliary winding of the

transformer during transistor on-time

(Ton). An external capacitor C on pin 5

is charged during Ton by the current

source I

reflection of the current which flows

into pin 12. This current is obtained by

connecting an external resistor R12 to

the auxiliary transformer winding.

During transistor on-time this current

is related to the input voltage VI.

During transistor off time (T

capacitor C is discharged by switch

sw1. This switch is active during the

total T

voltage Vc is formed across C. This

sawtooth is a measure for the

collector current of the switching

transistor T1.

For the voltage Vc yields:

V

c

. The current I

sim

time. In this way a sawtooth

off

I

×

simTon

=

------------------------ C

sim

is the

) the

off

(1)

TDA8385

latch

initialization

operation

5.2 7.5 20

Fig.4 Latch initialization as a function of supply voltage VP.

L

n

n

p

h

V

I

T1

I

c

V

c

R12

C

I

12

VP(V)

12

5

I

sw1

MCD403

sim

I

sim

---------- -

----- n

R12

p

×

p

Where: p = reflection factor;

I

sim

--------I

12

0.2==

p

(2)

V

c

V

n

h

I

×=

(2) → (1) gives:

V

n

p

h

V

c

×

----- -

--- C

n

× T

---------- R12

p

I

×=

on

(3)

March 1994 6

t

T

on

T

off

MCD404

Fig.5 Determination of the peak current Ic.

Page 7

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

For ‘Ton’ yields:

VcC× np× R12×

T

=

---------------------------------------------- -

on

pn

× V

×

h

I

For the primary current Ic yields:

V

I

T

I

×=

-----

c

on

L

Substitution (4) into (5):

C

I

--- -

c

L

n

1

p

×

× R12× V

-- -

----- -

p

n

h

×=

c

Equation (6) shows that by limiting the

voltage V

the collector peak current

c

can be limited. The peak current is

limited by means of the clamping

circuit in the transfer character

generator (TCG); see Fig.1

sub-section 4.

D

ELAY SETTING (PIN 6)

The output of sub-section 11 is

(4)

extended by the delay circuit of

sub-section 12. The starting

(reference) point of the delay circuit is

the falling edge of the output of

demagnetizing comparator (11) The

(5)

delay can be determined externally by

capacitor (C

The switch-on moment of the

switching transistor can be

(6)

determined by capacitor C

A minimum delay time is required to

prevent transistor T1 from switching

during demagnetization of the

transformer because of oscillations

caused by the leakage inductance.

delay

) on pin 6.

delay

TDA8385

Control part (Block III)

The differential amplifier,

sub-section 3, compares the

feedback voltage (Vfb) with the

reference voltage V

the differential amplifier is available

on pin 11 to allow gain setting. The

differential amplifier is internally

compensated for 0 dB feedback

stability.

The feedback input (pin 9) is also

.

used as the input for the TCG

(see Fig.6) with which a current

foldback characteristic can be

obtained as shown in Fig.7.

. The output of

ref

The clamping level can be externally

influenced by means of a resistor

on pin 7.

The collector peak current can be

influenced in several ways:

• Resistor R12 on pin 12

• Capacitor C on pin 5

• Capacitor on pin 7

• Transfer ratio nh/n

p

• Inductance L

Before comparing the sawtooth

voltage Vc with the control voltage V

in the pulse width modulator, a

voltage of 100 mV is added to Vc. In

this way it will be possible for Vr to

become smaller than V

, which is

sim

important for a stabilized no-load

operation (see Fig.6 area 3).

D

EMAGNETIZATION INPUT (PIN 15)

This input prevents the switching

transistor from conducting during

demagnetization of the transformer in

order to prevent the transformer from

going into saturation. The output of

comparator (11) is HIGH as soon as

the voltage of the transformer winding

exceeds 115 mV.

(3)

V

mv

(4)

(2)

r

(1)

(5)

V

fb

(1), (2), (3) = V

(4), (5) = V

.

TCG

.

diff

V

clamp

V

Ton(min)

MCD405

Fig.6 Reference voltage (Vmv) as a function of feedback voltage (Vfb).

March 1994 7

Page 8

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

V

O

(5)

(1)

(1), (2), (3) = V

(4), (5) = V

.

TCG

.

diff

Fig.7 Current foldback characteristic; stabilized output voltage (VO)

as function of load current (IO).

(4)

(2)

(3)

I

O

MCD406

TDA8385

The voltage V

minimum on-time of the switching

transistor. This voltage can be

determined externally with a resistor

on pin 4. With this resistor the current

foldback characteristic can be

influenced (see dotted line in Figs 6

and 7).

The minimum on-time is of

importance for the following.

• Stand-by operation

• Starting-up of power supply

• Overload and short-circuit

conditions.

The output of the differential amplifier

(V

), the output of the TCG (V

diff

and the voltage Vss + V

compared in a minimum voltage

clamping circuit (see Fig.1

sub-section 6). The output voltage is

equal to the lowest input voltage.

Some relevant characteristics of the

control part are depicted in Fig.8.

Ton(min)

determines the

TCG

are

Ton(min)

)

I

V

c

handbook, full pagewidth

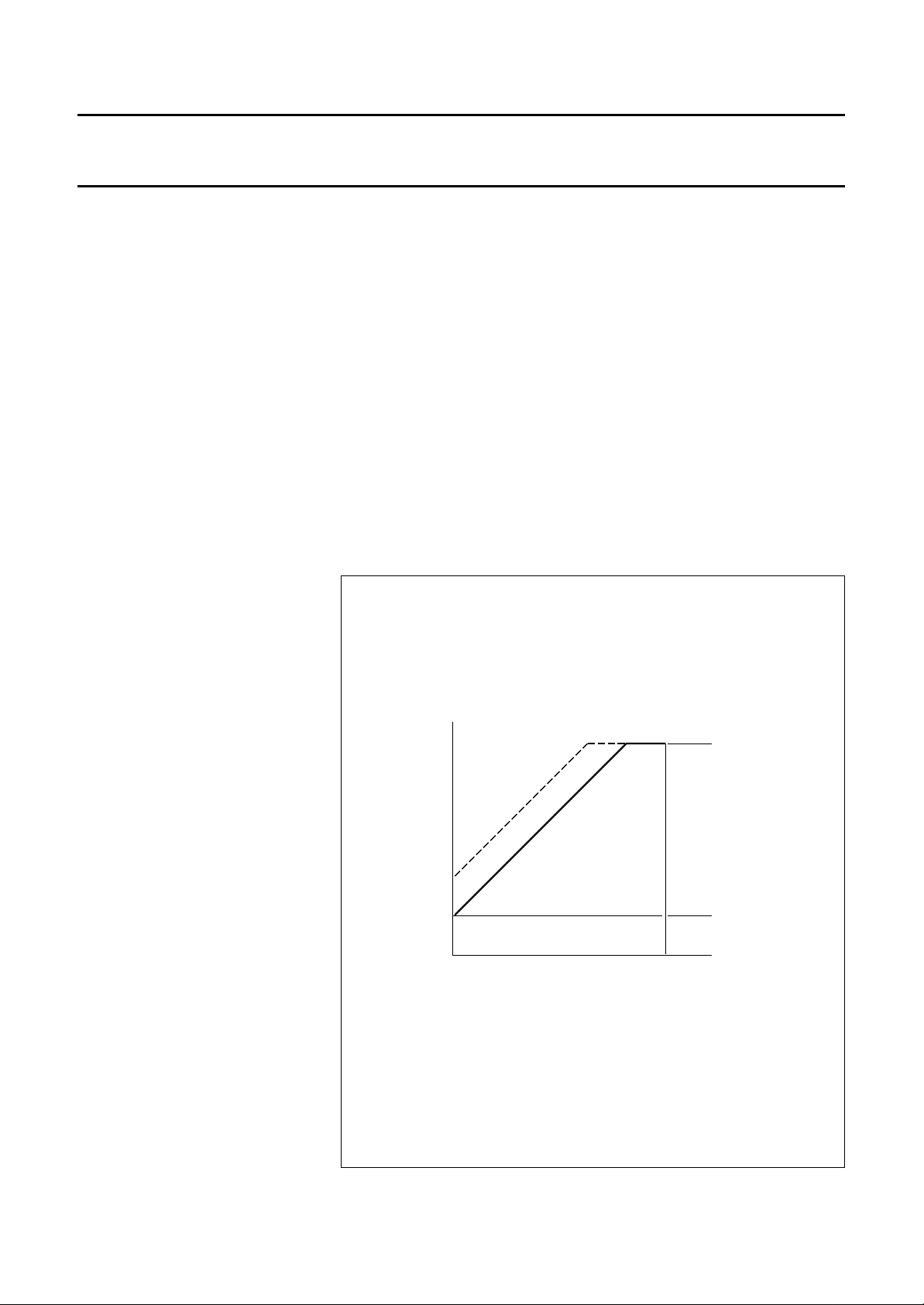

The voltage Vmv determines the collector peak current Ic of transistor T1. The right-hand curve is passed through at start-up. When the feedback voltage

slowly increases from zero, the peak current starts at I

the regulation slope is reached, which is approximately V

The plateau of the top between the points x and y has to be kept as small as possible.

The voltage V

Due to the characteristic of the TCG open- and short-circuit feedback loop will result in low peak current.

An additional signal on pin 13 can be supplied which is subtracted from the signal Vmv. This input can be used for feed forward information.

If no feed forward information is used, pin 13 should be connected to ground.

I

c (max)

I

c (min)

V

+

V

Ton(min)

ss

decreases with the decreasing load. For good no-load operation the peak current has to be made zero with V

diff

mv

xy

and rises along the straight line until I

c(min)

.

ref

V

TCG

V

diff

V

mv

external peak-current

setting (pin 7)

V

ref

V

fb

MCD407

is reached. At a slightly higher feedback voltage

c(max)

.

diff

Fig.8 Characteristics of the control part.

March 1994 8

Page 9

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

Pulse width modulator (Block IV)

The pulse width modulator compares

the control voltage Vr with the

sawtooth voltage V

sim

. If V

sim

> V

r

output sub-section 8 is HIGH the LED

is switched on and then the switching

transistor is switched off. In this way

the output voltage is controlled.

XAMPLE

E

If the load decreases, VO increases

and therefore Vr decreases. This

causes the LED to start conducting

prematurely, which implies that the

switching transistor is turned off

sooner. The consequence is that the

collector peak current decreases and

hence less energy is stored in the

transformer and VO will decrease.

LED control (Block V)

If either output of sub-section 8 or

output of sub-section 16 are HIGH the

LED is conductive. In order to

improve the start-up behaviour of the

power supply, the demagnetization

signal of sub-section 12 will only

activate the LED driver if flip-flop (13)

has previously been set. The set

signal is generated in the following

three ways.

1. Pulse width modulator

(sub-section 8)

2. Comparator (18)

P(min)

detector

3. V

Set signal (2.) and (3.) are added as

extra security to guarantee a

demagnetization pulse in the event of

the switching transistor not having

enough base current. In that situation

e.g. at start-up, no comparator signal,

set signal (3.) is generated by

sub-section 8.

LED driver (Block VI)

The LED driver (pin 2) is blocked if the

supply voltage VP is in the

initialization phase (see Fig.4). The

output stage is a push-pull stage,

which can sink 5 mA and source

10 mA.

Slow-start circuit (Block VII)

The slow-start circuit is active at

start-up, over voltage protection or

after an overload (short-circuited),

and stand-by mode. The voltage V

and therefore the voltage Vmv and the

peak current Ic slowly increase at

start-up.

By means of sub-section 27 the slow

start voltage Vss is clamped to the

voltage Vfb. If the feedback voltage is

reduced, e.g. as overload, the

slow-start capacitor is discharged to

the level of Vfb. In this way a slow

start-up is also guaranteed after an

overload, short-circuit situation or

after a stand-by mode. The circuit of

sub-section 27 is not active during an

over voltage protection.

When the supply voltage VP is below

the reset-level of 5.2 V

(sub-section 28) the slow-start

capacitor is quickly discharged.

The slow-start input (pin 7) can also

be used for I

connecting a resistor to this pin.

Over voltage protection (Block VIII)

The operation of the over voltage

protection circuit is, in the event of the

IC being SOPS-supplied, quite

different from when the IC is

externally supplied.

c(max)

setting by

TDA8385

O

PERATION WHEN THE IC IS

EXTERNALLY SUPPLIED

When the voltage on pin 8 exceeds

2.5 V the slow-start capacitor is

slowly discharged. During discharge

the LED is permanently conducting.

Discharge is stopped when Vss is

below 115 mV. Flip-flop (23) will then

be reset and the circuit is ready again

for a new slow-start procedure.

During an over voltage sub-section 27

is not active so that the output voltage

VO cannot influence the slow-start

ss

discharge procedure.

PERATION WHEN IC IS

O

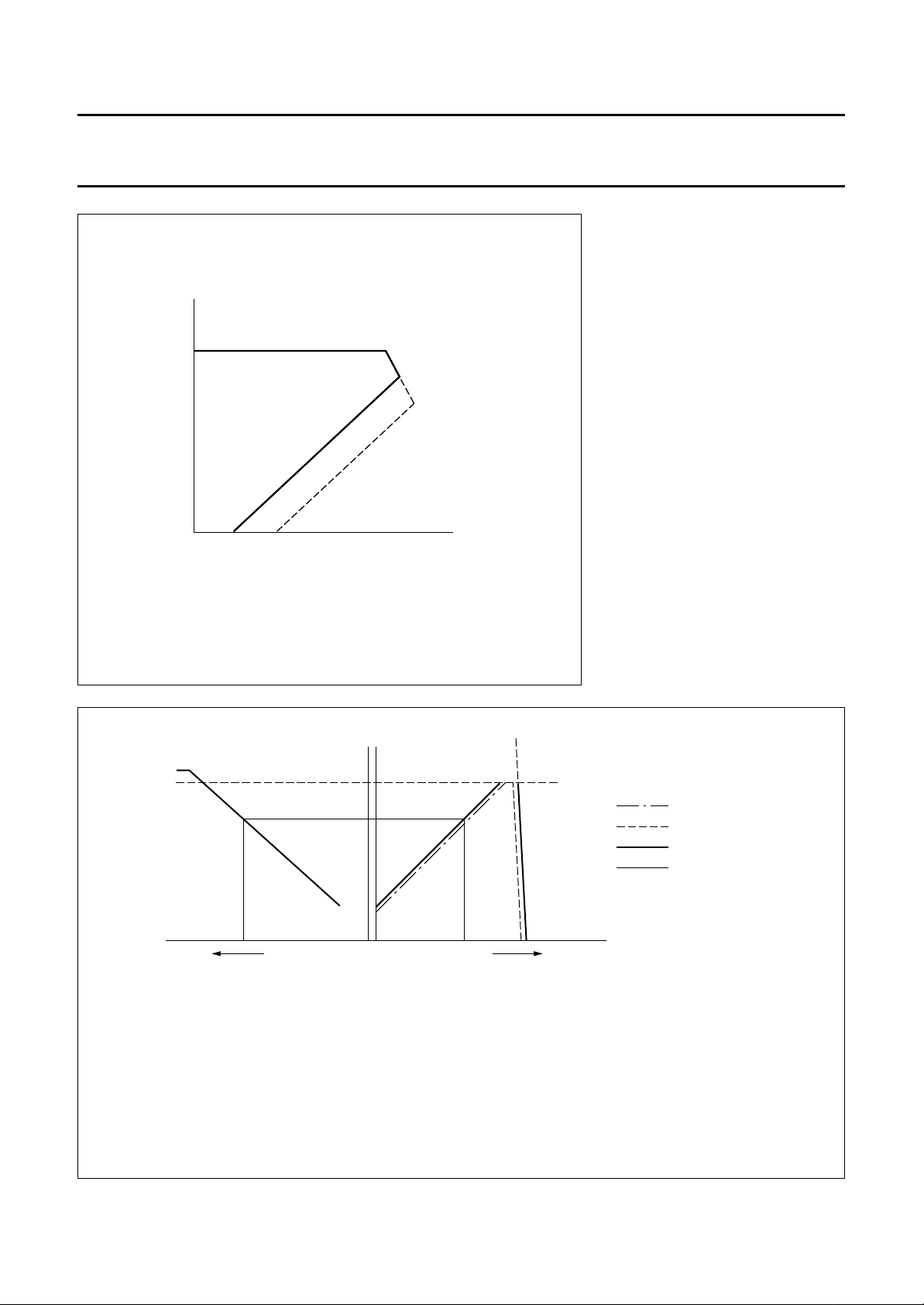

SOPS-SUPPLIED (SEE FIGS 9 AND 10)

When the voltage on pin 8 exceeds

2.5 V the slow-start capacitor is

slowly discharged. During discharge

of Css the supply capacitor CP is also

discharged. Because the capacitors

CP and Css have almost the same

value and the supply current I

(≈15 mA) is much larger than the slow

discharge current (≈50 µA), the LED

will be switched off by means of the

V

detection circuit (5.2 V). At that

P(min)

moment the switching transistor will

be switched on again until the 7.5 V

level is reached. During this

hysteresis interval the slow-charge

capacitor is quickly discharged. At the

7.5 V level the LED will be switched

on again because flip-flop (23) output

is still HIGH.

The same procedure will be repeated

several times until the slow-start

capacitor reaches the 115 mV reset

level. At that moment the slow-start

procedure is started again.

If there is still an over voltage the

procedure will be repeated.

Figure 10 is a detailed exposure of

Fig.11.

P

March 1994 9

Page 10

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

handbook, full pagewidth

(1) For detail see Fig.10.

I

c

V

ss

Fig.9 Over voltage protection.

(1)

TDA8385

t

MCD408

t

Q

V

(V)

V

ss

(V)

I

FF23

P

7.5 V

5.2 V

0

t

slow discharge

quick discharge

0

c

delay

t

t

t

Fig.10 Detailed over voltage protection of Fig.9.

March 1994 10

t

MCD409

Page 11

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

TDA8385

Power Supply (SOPS)

Stand-by circuit (Block IX)

During stand-by operation the voltage Vsb is supplied from the SOPS via thyristor TH1 (see Fig.16). In the stand-by state,

SOPS operates in a burst mode. When the voltage on pin 10 exceeds 2.5 V the LED driver is permanently activated. The

LED driver is released again if the voltage is below 2 V (see Fig.11).

handbook, full pagewidth

V

sb

(V)

0

2.5 V

2 V

t

output sub-section 25

I

LED

(mA)

0

0

Fig.11 Stand-by operation; burst mode.

t

5 mA

t

MCD410

March 1994 11

Page 12

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

TDA8385

Power Supply (SOPS)

Regulation indicator output (Block X)

Pin 1 can be used to reset the logic circuit in the TV receiver at power on and off. Sub-section 29 has an open-collector

output. The output of this block is LOW during the regulation mode (V

handbook, full pagewidth

V

2.5

0

V

diff

< Vts; see Fig.12).

diff

V

fb

V

ts

t

V

P

0

V

RIO

0

A desired delay at power-on reset can be made externally.

Fig.12 Regulation indicator output; pin 1.

t

V

: open-collector output

RIO

t

MCD411

March 1994 12

Page 13

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

TDA8385

Power Supply (SOPS)

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

All voltages are measured with respect to ground; positive current flow into the IC; all pins not mentioned in the voltage

list are not allowed to be voltage driven. The voltage ratings are valid provided other ratings are not violated; current

ratings are valid provided the power rating is not violated.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

Voltages

V

P

V

n

V

3

V

8,10

V

12

V

15

Currents

I

1

I

n

I

3

I

5, 6

I

7

I

11

I

16

Temperatures

T

amb

T

stg

Power dissipation

P

tot

supply voltage pin 2 connected −0.5 20 V

pin 2 open-circuit −0.5 18 V

voltage on pins 1, 2, 4, 7, 9 and 13 −0.5 +18 V

voltage on pin 3 −0.5 +6 V

voltage on pins 8 and 10 −0.5 +3.9 V

voltage on pin 12 −0.1 +0.5 V

voltage on pin 15 −0.5 +0.5 V

current on pin 1 0 2 mA

current on pins 2, 12 and 15 −10 +10 mA

current on pin 3 −10mA

current on pins 5 and 6 −1+1mA

current on pin 7 −1 +25 mA

current on pin 11 −10 +0.5 mA

current on pin 16 0 20 mA

operating ambient temperature −25 +70 °C

storage temperature −55 +150 °C

total power dissipation − 500 mW

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

th j-a

from junction to ambient in free air 55 K/W

March 1994 13

Page 14

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

TDA8385

Power Supply (SOPS)

CHARACTERISTICS

= 15 V; I3 = 200 µA; T

V

P

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

P

V

16

V

16(hys)

I

16

V

11

supply voltage (pin 16) 7.9 − 20 V

supply initialization level 7.1 7.5 7.9 V

internal fixed hysteresis 2.5 − 2.55 V

supply current active LED output −− 20 mA

supply voltage ripple rejection see Figs 13 and 14 − 60 − mV

Reference voltage

V

3

reference voltage at pin 3 0.52 0.55 0.58 V

Error amplifier

V

9

I

9

I

11

I

11

G

o

threshold voltage error amplitude 2.4 2.5 2.6 V

input current feedback input −− 0.5 µA

sink current output V11 = 80 mV 400 −−µA

source current output V11 = 2.5 V 500 −−µA

open loop gain − 100 − dB

B unity gain bandwidth − 600 − kHz

/∆T temperature coefficient −±300 × 10−6− K

∆V

9

V

5

threshold for switching output V

= 25 °C; unless otherwise specified.

amb

= 1.25 V;

diff

V4 = 2 V; V13 = 0 V;

V7> V9; I2 = 2 mA

− V

diff

− V

(1)

− V

os

−1

Transfer characteristic generator

I4/I

V

3

5

current ratio V4 = 0.5 V 0.23 0.25 0.27

threshold for switching output V4 = 0.5 V; V13 = 0 V;

T

on(min)

= 20% V9 = 0.4 V − 0.9 − V

V

fb

= 50% V9 = 1 V 1.4 − V

V

fb

= 80% V9 = 1.6 V − 2.1 − V

V

fb

clamp V

t

PLH

response time pulse width

modulation pin 5 to pin 2

LOW-to-HIGH

t

PHL

response time pulse width

modulation pin 5 to pin 2

HIGH-to-LOW

Feed forward

V

5

threshold for switching output

(Vfo)

I

13

input bias current V13 = 0 V −−1µA

V7> V9; I2 = 2 mA

V9 = 0 V 0.4 − V

= 2.25 V 2.4 − V

9

0.5 − V

os

1.5 − V

os

− 2.6 − V

os

0.6 − V

os

− V

os

1.6 − V

os

− V

os

V

os

V

os

V

os

note 2 −− 700 ns

note 2 −− 1µs

V4 = 0.5 V; V13 = 0 V;

0.6 − V

0.7 − V

os

0.8 − V

os

V

os

V7 = V9 = 3 V;

I2 = 2 mA; V11 = 1 V

March 1994 14

Page 15

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

TDA8385

Power Supply (SOPS)

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Slow-start

I

7/I3

I

7

V

7

V

5

Output stage

V

2(sat)

I

2

V

2

Current simulation

I5/I

12

V

12

V

5(sat)

∆V threshold for switching output;

Demagnetization input

t

demLH

t

demHL

V

15

V

15

C

15

I

15

charge current ratio V7 = 0.5 V 0.22 0.24 0.26

quick discharge current V7 = 1 V 20 −−mA

= 100 mV 50 −−µA

V

7

clamping level I7 = 100 µA 2.8 3.0 3.2 V

threshold for switching output

(Vss)

V4 = 0.5 V; V13 = 0 V;

V7 = 1 V; I2 = 2 mA;

1.4 − V

1.5 − V

os

1.6 − V

os

V

os

V9 = 2 V

saturation voltage I2 = 2 mA −−300 mV

source current V2 = 2 V

operating 4.8 5.3 6.3 mA

initialization phase −−50 µA

open output voltage HIGH I2 = 5 mA 12 −−V

current ratio V5 = 1 V; I12 = 0.5 mA 0.19 0.2 0.21

simulation input voltage I12 = 0.5 mA −− 1.1 V

saturation voltage V15 = V6 = 0 V;

−− 300 mV

I5 = 1 mA

= V6 = 0 V;

V

15

−− 200 mV

I5 = 200 µA

voltage difference between pins 5

and 11; offset simulation voltage

)

(V

os

delay from pin 15 to pin 5

LOW-to-HIGH

delay from pin 15 to pin 5

V4 = 0.5 V; V13 = 0 V;

V7 = V9 = 3 V;

I2 = 2 mA;

V11 = 0.5 V

see Fig.15;

pin 6 not connected

see Fig.15 −− 1µs

60 100 140 mV

−− 500 ns

HIGH-to-LOW

clamping level I15 = 10 mA

positive −− 1.2 V

negative −− −1V

demagnetization threshold

90 115 140 mV

voltage

input capacitance −− 10 pF

input bias current V15 = 60 mV −− 0.5 µA

March 1994 15

Page 16

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

TDA8385

Power Supply (SOPS)

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Delay setting

I

6/I3

I

6

V

6

V

6(sat)

t

dLH

t/c delay setting (t = C

Stand-by

V

10H

V

10(hys)

t

dLH

t

dHL

I

10

Over voltage protection

V

8

t

dLH

t

dHL

V

7

I

7/I3

I

8

Regulation indicator output

V

1

I

1

Notes

1. Vos = V

2. V5 pulse = 1 V; V4 = 0.5 V; V9 = V7= 3 V; V11 = 0.5 V; V13 = 0 V; I2 = 2 mA.

charge current ratio V6 = 1 V 1.1 1.2 1.3

charge current initialization phase V6 = 1 V; V16 = 5 V 2 −−mA

clamping level 2.8 − 3.2 V

saturation voltage V15 = 140 mV − 50 100 mV

delay from pin 6 to pin 2;

V6 crossing the 2.5 V level;

LOW-to-HIGH

C6 = 470 pF;

V5 = 0 V; I2 = 2 mA;

V15 see Fig.15;

−− 1.2 µs

excluding capacitive

tolerances

× V/I) V6 = 2.5 V;

6

− 10 − ns/pF

I3 = 250 µA

threshold level HIGH 2.4 2.5 2.6 V

hysteresis 450 500 550 mV

delay to output pin 10 to pin 2

−− 1µs

LOW-to-HIGH

delay to output pin 10 to pin 2

−− 1µs

HIGH-to-LOW

input current V10 = 2.3 V −− 5µA

threshold level 2.4 2.5 2.6 V

delay to output pin 8 to pin 2

−− 1µs

LOW-to-HIGH

delay to output pin 8 to pin 2

−− 1µs

HIGH-to-LOW

reset level 90 − 140 mV

slow discharge current ratio V7 = 1 V 0.12 0.23 0.31

input current V8 = 3 V −− 1µA

saturation voltage I1 = 1 mA −−300 mV

leakage current V1 = V

offset.

16

−− 1µA

March 1994 16

Page 17

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

V

P

2 V15 V

t

Frequency = 50 kHz.

Slew rate = 0.2 µs.

Fig.13 Supply voltage ripple rejection;

VP as a function of time.

MCD412

V

diff

(pin 11)

Frequency = 50 kHz.

Slew rate = 0.2 µs.

Fig.14 Supply voltage ripple rejection;

V

as a function of time.

diff

TDA8385

~

3 V

~

MCD413

t

Table 1 Condition of test circuit used for Figs 13 and 14.

PINS STATUS

1, 2, 4 to 6, 12, 13 not connected

8 to 10, 14, 15 ground

3R

7C

16 V

11 V

= 2.7 kΩ

ref

= 4.7 µF

ss

; see Fig.13

P

; see Fig.14

diff

March 1994 17

Page 18

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

handbook, full pagewidth

demagnetization input

peak-current setting input

(pin 15)

(pin 5)

115 mV

90%

t

demLH demHL

TDA8385

~

+ 0.8 V

~

0 V

~

– 0.8 V

~

1 V

10%

t

0 V

MCD414

Fig.15 Timing diagram; demagnetization delay time.

March 1994 18

Page 19

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

APPLICATION INFORMATION

O

V

9118

R15

2

1

TDA8385

151016

1/2 CNR50

13

ss

C

delay

C

C

1456 473

12

TDA8385

MCD415

ref

R

Ton(min)

R

o

C

stab

V

f

V

s

n

TH1

p

n

c

I

A

RC

T1

1/2 CNR50

P

V

A

n

P

C

R12

h

handbook, full pagewidth

Fig.16 Application circuit of SOPS with stand-by facility.

I

V

(mains)

March 1994 19

Page 20

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

V

handbook, full pagewidth

V

f

I

c

O

n

s

V

I

n

p

TDA8385

T

on

storage time and delay

T

off

(SOPS)

output sub-section 11

output sub-section 12

DEMAGNETIZATION

V

c

V

sim

output sub-section 8

COMPARATOR

output sub-section 13

output sub-section 16

DEMAGNETIZATION

output sub-section 14

Q

LED driver

Vr(output sub-section 7)

(output sub-section 10)V

sim

(sub-section 13)

delay

SET

(sub-section 13)

RESET

comparator (18)

level = 1 V

t

MCD416

Fig.17 Application timing diagram.

March 1994 20

Page 21

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

PACKAGE OUTLINE

22.00

21.35

seating plane

3.9

3.4

2.2

max

2.54

(14x)

1.4 max

0.53

max

1.2 min

0.254

TDA8385

8.25

7.80

5.1

max

M

0.32 max

7.62

9.5

8.3

MSA349

Dimensions in mm.

Fig.18 16-lead dual in-line; plastic with internal heat spreader; opposite bent leads (SOT38WBE).

16

1

9

6.48

6.14

8

March 1994 21

Page 22

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

TDA8385

Power Supply (SOPS)

SOLDERING

Plastic dual in-line packages

Y DIP OR WAVE

B

The maximum permissible

temperature of the solder is 260 °C;

this temperature must not be in

contact with the joint for more than

5 s. The total contact time of

successive solder waves must not

exceed 5 s.

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

The device may be mounted up to the

seating plane, but the temperature of

the plastic body must not exceed the

specified storage maximum. If the

printed-circuit board has been

pre-heated, forced cooling may be

necessary immediately after

soldering to keep the temperature

within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron

below the seating plane (or not more

than 2 mm above it). If its temperature

is below 300 °C, it must not be in

contact for more than 10 s; if

between 300 and 400 °C, for not

more than 5 s.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

March 1994 22

Page 23

Philips Semiconductors Preliminary specification

Control circuit for a Self-Oscillating

Power Supply (SOPS)

TDA8385

NOTES

March 1994 23

Page 24

Philips Semiconductors – a worldwide company

Argentina: IEROD, Av. Juramento 1992 - 14.b, (1428)

BUENOS AIRES, Tel. (541)786 7633, Fax. (541)786 9367

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. (02)805 4455, Fax. (02)805 4466

Austria: Triester Str. 64, A-1101 WIEN, P.O. Box 213,

Tel. (01)60 101-1236, Fax. (01)60 101-1211

Belgium: Postbus 90050, 5600 PB EINDHOVEN, The Netherlands,

Tel. (31)40 783 749, Fax. (31)40 788 399

Brazil: Rua do Rocio 220 - 5

CEP: 04552-903-SÃO PAULO-SP, Brazil.

P.O. Box 7383 (01064-970).

Tel. (011)829-1166, Fax. (011)829-1849

Canada: INTEGRATED CIRCUITS:

Tel. (800)234-7381, Fax. (708)296-8556

DISCRETE SEMICONDUCTORS: 601 Milner Ave,

SCARBOROUGH, ONTARIO, M1B 1M8,

Tel. (0416)292 5161 ext. 2336, Fax. (0416)292 4477

Chile: Av. Santa Maria 0760, SANTIAGO,

Tel. (02)773 816, Fax. (02)777 6730

Colombia: Carrera 21 No. 56-17, BOGOTA, D.E., P.O. Box 77621,

Tel. (571)217 4609, Fax. (01)217 4549

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. (032)88 2636, Fax. (031)57 1949

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. (9)0-50261, Fax. (9)0-520971

France: 4 Rue du Port-aux-Vins, BP317,

92156 SURESNES Cedex,

Tel. (01)4099 6161, Fax. (01)4099 6427

Germany: P.O. Box 10 63 23, 20095 HAMBURG ,

Tel. (040)3296-0, Fax. (040)3296 213

Greece: No. 15, 25th March Street, GR 17778 TAVROS,

Tel. (01)4894 339/4894 911, Fax. (01)4814 240

Hong Kong: 15/F Philips Ind. Bldg., 24-28 Kung Yip St.,

KWAI CHUNG, Tel. (0)4245 121, Fax. (0)4806 960

India: PHILIPS ELECTRONICS & ELECTRICALS Ltd.,

Components Dept., Shivsagar Estate, Block 'A',

Dr. Annie Besant Rd., Worli, BOMBAY 400 018,

Tel. (022)4938 541, Fax. (022)4938 722

Indonesia: Philips House, Jalan H.R. Rasuna Said Kav. 3-4,

P.O. Box 4252, JAKARTA 12950,

Tel. (021)5201 122, Fax. (021)5205 189

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. (01)640 000, Fax. (01)640 200

Italy: Viale F. Testi, 327, 20162 MILANO,

Tel. (02)6752.1, Fax. (02)6752.3350

Japan: Philips Bldg13-37, Kohnan 2-chome, Minato-ku, KOKIO 108,

Tel. (03)3740 5101, Fax. (03)3740 0570

Korea: (Republic of) Philips House, 260-199 Itaewon-dong,

Yongsan-ku, SEOUL, Tel. (02)794-5011, Fax. (02)798-8022

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA,

SELANGOR, Tel. (03)757 5511, Fax. (03)757 4880

Mexico: Philips Components, 5900 Gateway East, Suite 200,

EL PASO, TX 79905, Tel. 9-5(800)234-7381, Fax. (708)296-8556

Netherlands: Postbus 90050, 5600 PB EINDHOVEN,

Tel. (040)78 37 49, Fax. (040)78 83 99

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. (09)849-4160, Fax. (09)849-7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. (22)74 8000, Fax. (22)74 8341

th

floor, Suite 51,

Pakistan: Philips Markaz, M.A. Jinnah Rd., KARACHI 3,

Tel. (021)577 039, Fax. (021)569 1832

Philippines: PHILIPS SEMICONDUCTORS PHILIPPINES Inc,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. (02)810 0161, Fax. (02)817 3474

Portugal: Av. Eng. Duarte Pacheco 6, 1009 LISBOA Codex,

Tel. (01)683 121, Fax. (01)658 013

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. (65)350 2000, Fax. (65)251 6500

South Africa: 195-215 Main Road, Martindale,

P.O. Box 7430,JOHANNESBURG 2000,

Tel. (011)470-5433, Fax. (011)470-5494

Spain: Balmes 22, 08007 BARCELONA,

Tel. (03)301 6312, Fax. (03)301 42 43

Sweden: Kottbygatan 7, Akalla. S-164 85 STOCKHOLM,

Tel. (0)8-632 2000, Fax. (0)8-632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. (01)488 2211, Fax. (01)481 7730

Taiwan: 23-30F, 66, Chung Hsiao West Road, Sec. 1, P.O. Box

22978, TAIPEI 10446, Tel. (2)388 7666, Fax. (2)382 4382

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

60/14 MOO 11, Bangna - Trad Road Km. 3

Prakanong, BANGKOK 10260,

Tel. (2)399-3280 to 9, (2)398-2083, Fax. (2)398-2080

Turkey: Talatpasa Cad. No. 5, 80640 LEVENT/ISTANBUL,

Tel. (0212)279 2770, Fax. (0212)269 3094

United Kingdom: Philips Semiconductors Limited, P.O. Box 65,

Philips House, Torrington Place, LONDON, WC1E 7HD,

Tel. (071)436 41 44, Fax. (071)323 03 42

United States:INTEGRATED CIRCUITS:

811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. (800)234-7381, Fax. (708)296-8556

DISCRETE SEMICONDUCTORS: 2001 West Blue Heron Blvd.,

P.O. Box 10330, RIVIERA BEACH, FLORIDA 33404,

Tel. (800)447-3762 and (407)881-3200, Fax. (407)881-3300

Uruguay: Coronel Mora 433, MONTEVIDEO,

Tel. (02)70-4044, Fax. (02)92 0601

For all other countries apply to: Philips Semiconductors,

International Marketing and Sales, Building BAF-1,

P.O. Box 218, 5600 MD, EINDHOVEN, The Netherlands,

Telex 35000 phtcnl, Fax. +31-40-724825

SCD29 © Philips Electronics N.V. 1994

All rights are reserved. Reproduction in whole or in part is prohibited without the

prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation

or contract, is believed to be accurate and reliable and may be changed without

notice. No liability will be accepted by the publisher for any consequence of its

use. Publication thereof does not convey nor imply any license under patent- or

other industrial or intellectual property rights.

Printed in The Netherlands 9397 730 30011

Philips Semiconductors

Loading...

Loading...