Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA5153

Pre-amplifier for Hard Disk Drive

(HDD) with MR-read/inductive write

heads

Preliminary specification

File under Integrated Circuits, IC11

1997 Jul 02

Page 2

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

CONTENTS

1 FEATURES

2 APPLICATIONS

3 GENERAL DESCRIPTION

4 ORDERING INFORMATION

5 QUICK REFERENCE DATA

6 BLOCK DIAGRAM

7 PINNING

8 FUNCTIONAL DESCRIPTION

8.1 Read mode

8.2 Write mode

8.3 Sleep mode

8.4 Standby mode

8.5 Active mode

8.6 Bi-directional serial interface

8.7 Addressing

8.8 Programming data

8.9 Reading data

8.10 Operation of the serial interface

8.10.1 Configuration

8.10.2 Power control

8.10.3 Head select

8.10.4 Servo write

8.10.5 Test

8.10.5.1 MR head test

8.10.5.2 Temperature monitor

8.10.5.3 Thermal asperity detector

8.10.6 Write amplifier programmable capacitors

8.10.7 High frequency gain attenuator pole register

8.10.8 High frequency gain boost register

8.10.9 Settle pulse

8.10.10 Address registers

8.11 Head unsafe

8.12 HUS survey

9 LIMITING VALUES

10 HANDLING

11 THERMAL RESISTANCE

12 RECOMMENDED OPERATION

CONDITIONS

13 CHARACTERISTICS

14 PACKAGE OUTLINE

15 SOLDERING

16 DEFINITION

17 LIFE SUPPORT APPLICATIONS

TDA5153

1997 Jul 02 2

Page 3

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

1 FEATURES

• Designed for 4 (TDA5153BG) or 6 dual-stripe

MR-read/inductive write heads

• Current bias-current sense architecture

• Single supply voltage (5.0 V ±10%); a separate write

drivers supply pin can be biased from VCC to 8 V +10%

• MR elements connected to ground (GND)

• Equal bias currents in the two MR stripes of each head

• On-chip AC couplings eliminate MR head DC offset

• 3-wire serial interface for programming

• Programmable high-frequency zero-pole gain boost

• Programmable write driver compensation capacitance

• Programmable MR bias currents and write currents

• 1-bit programmable read gain

• Sleep, standby, active and test modes available

• Measurement of head resistances in test mode

• In test mode, one MR bias current may be forced to a

minimum current

• Short write current rise and fall times with near rail-to-rail

voltage swing

• Head unsafe pin for signalling of abnormal conditions

and behaviour

• Low supply voltage write-current inhibit (active or

inactive)

• Supports servo writing

• Provides temperature monitor

• Thermal asperity detection with programmable

threshold level

• Requires only one external resistor.

2 APPLICATIONS

• Hard Disk Drive (HDD).

TDA5153

3 GENERAL DESCRIPTION

The 5.0 V pre-amplifier for HDD described here is

designed for five terminals, dual stripe Magneto-Resistive

(MR)-read/inductive-write heads. The disks of the disk

drive are connected to ground. To avoid voltage

break-through between the heads and the disk, the MR

elements of the heads are also connected to ground. The

symmetry of the dual-stripe head-amplifier combination

automatically distinguishes between the differential

signals such as signals and the common-mode effects like

interference. The latter are rejected by the amplifier.

The IC incorporates read amplifiers, write amplifiers, serial

interface, digital-to-analog converters, reference and

control circuits which operate on a single supply voltage of

5V±10%. The output drivers have a separate supply

voltage pin which can be connected to a higher supply

voltage of up to 8 V +10%. The complementary output

stages of the write amplifier allow writing with near

rail-to-rail peak voltages across the inductive write head.

The read amplifier has a low input impedance. The DC

offset between the two stripes of the MR head is eliminated

using on-chip AC coupling. Fast settling features are used

to keep the transients short. As an option, the read

amplifier may be left biased during writing so as to reduce

the duration of these transients even more. Series

inductance in the leads between the amplifier and MR

heads influences the bandwidth which can be

compensated by using a programmable high-frequency

gain-boost (HF zero). HF noise and bandwidth can be

attenuated using a programmable high-frequency

gain-attenuator (HF pole).

On-chip digital-to-analog converters for MR bias currents

and write currents are programmed via a 3-wire serial

interface. Head selection, mode control, testing and servo

writing can also be programmed using the serial interface.

In sleep mode the CMOS serial interface is operational.

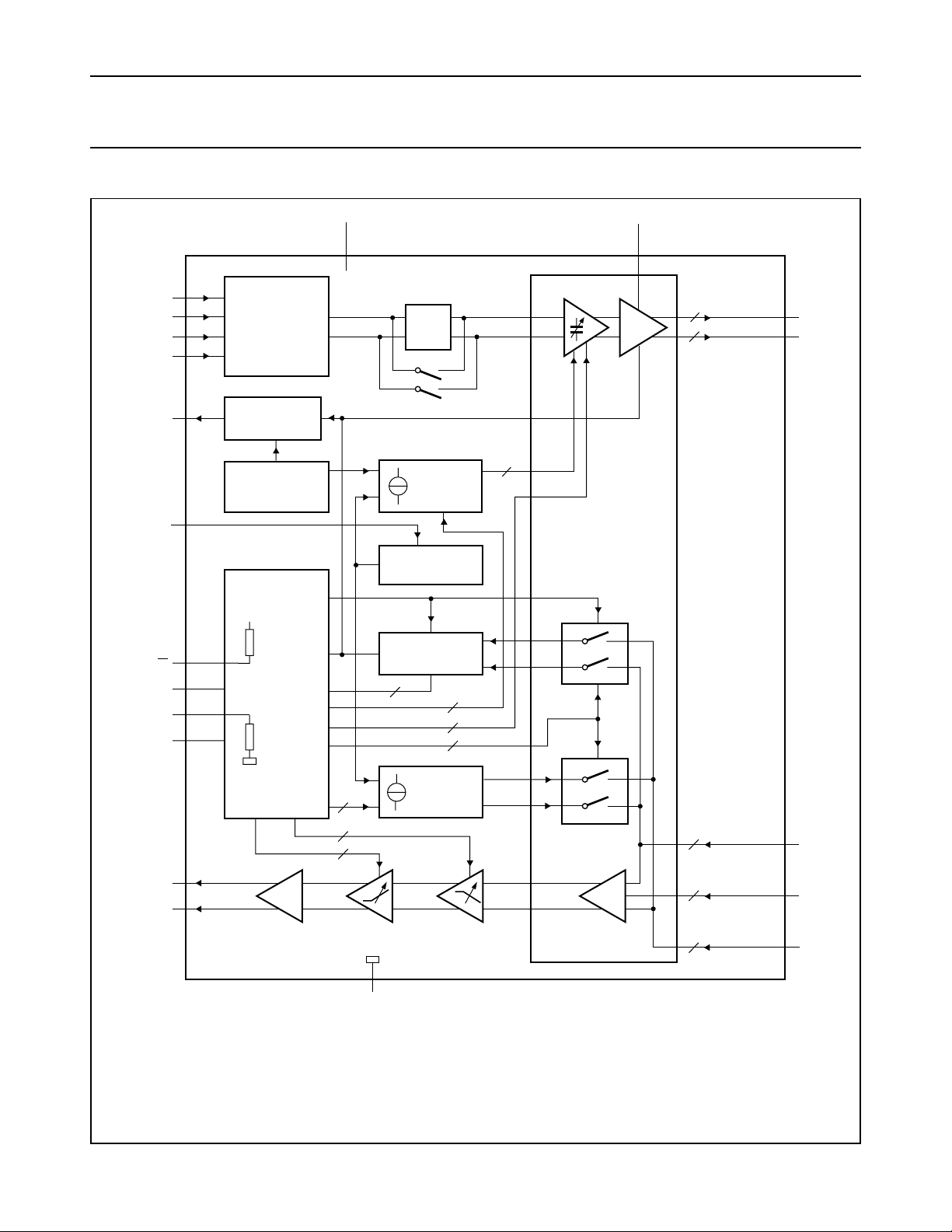

Figure 1 shows the block diagram of the device.

4 ORDERING INFORMATION

TYPE

NUMBER

TDA5153X − naked die −

TDA5153AG;

TDA5153BG

1997 Jul 02 3

NAME DESCRIPTION VERSION

LQFP48 plastic low profile quad flat package; 48 leads; body 7 × 7 × 1.4 mm SOT313-2

PACKAGE

Page 4

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

5 QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

V

CC(WD)

F noise figure R

V

nir

G

v(dif)

B

−3db

CMRR common mode rejection ratio;

PSRR power supply rejection ratio

t

, t

r

f

I

MR(PR)

I

WR(PR)(b-p)

f

SCLK

supply voltage 4.5 5.0 5.5 V

write drivers supply voltage V

=28Ω; IMR=10mA;

MR

T

=25°C; f = 20 MHz

amb

input referred noise voltage; see

note 3 in Chapter 13

RMR=28Ω; IMR=10mA;

T

=25°C; f = 20 MHz

amb

CC

− 3.0 3.2 dB

− 0.9 1.0 nV/√Hz

8.0 8.8 V

differential voltage gain from head inputs to RDx, RDy;

RMR=28Ω; IMR=10mA

d4 = logic 0 − 160 −

d4 = logic 1 − 226 −

−3 dB frequency bandwidth upper bandwidth without gain

− 220 − MHz

boost (4 nH lead inductance)

IMR= 10 mA; f < 1 MHz − 45 − dB

R

mismatch <5%

MR

I

= 10 mA; f < 100 MHz − 25 − dB

MR

f < 1 MHz − 80 − dB

(input referred);

mismatch <5%

R

MR

f < 100 MHz − 50 − dB

rise/fall times (10% to 90%) Lh= 150 nH; IWR=35mA;

f = 20 MHz

programming MR bias current R

programming write current

V

V

ext

R

ext

= 8.0 V −−1.8 ns

CC(WD)

= 6.5 V −−2.1 ns

CC(WD)

=10kΩ 5 − 20.5 mA

=10kΩ 20 − 51 mA

range (base-to-peak)

serial interface clock rate −−25 MHz

1997 Jul 02 4

Page 5

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

6 BLOCK DIAGRAM

handbook, full pagewidth

WDlx

WDly

(1)

IWDlx

(1)

IWDly

HUS

R

ext

2

3

1

12

WRITE DRIVER

INPUT

HEAD UNSAFE

INDICATOR

LOW SUPPLY

VOLTAGE

INDICATOR

V

CC

11

TDA5153

FF

WRITE

CURRENT

SOURCE

VOLTAGE

REFERENCE

TDA5153

V

CC(WD)

(5 to 8 V)

48

(2)

15

(3)

6

(3)

6

(3)

6

WRITE DRIVER

AND

READ PREAMP

(3)

(6×)

, 20, 26,

33, 39, 44

(2)

14

, 19, 25,

32, 38, 43

(2)

nWy

nWx

(2)

+V

CC

4

R/W

SEN

RDx

RDy

7

5

6

9

10

SCLK

SDATA

Pin numbers correspond to TDA5153AG and TDA5153BG only. See Fig.3 and Chapter 7 for pinning of TDA5153X.

(1) Only available on naked die.

(2) Absent on TDA5153BG (4 channel version).

(3) 4 on TDA5153BG.

SERIAL

INTERFACE

20 kΩ

5

4

4

GND n

TAS

DETECTOR

4

head select

CURRENT

SOURCE

8, 13

5

3

(3)

6

R

MR

6

6

6

(3)

(3)

(3)

(2)

18

, 23, 29,

36, 42, 47

(2)

17

, 22, 28,

35, 41, 46

(2)

16

, 21, 27,

34, 40, 45

(2)

(2)

(2)

MGK422

nRy

nGND

nRx

Fig.1 Block diagram.

1997 Jul 02 5

Page 6

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

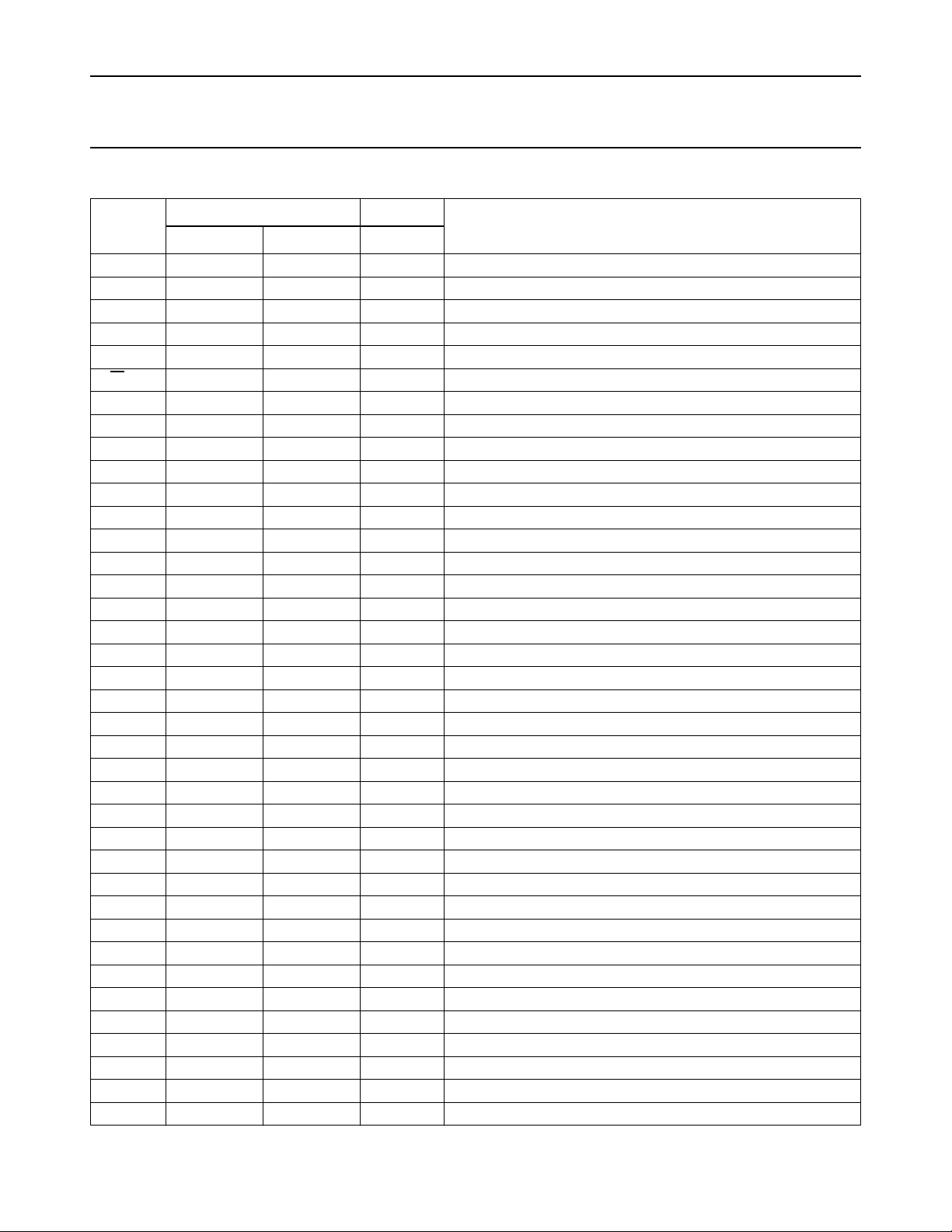

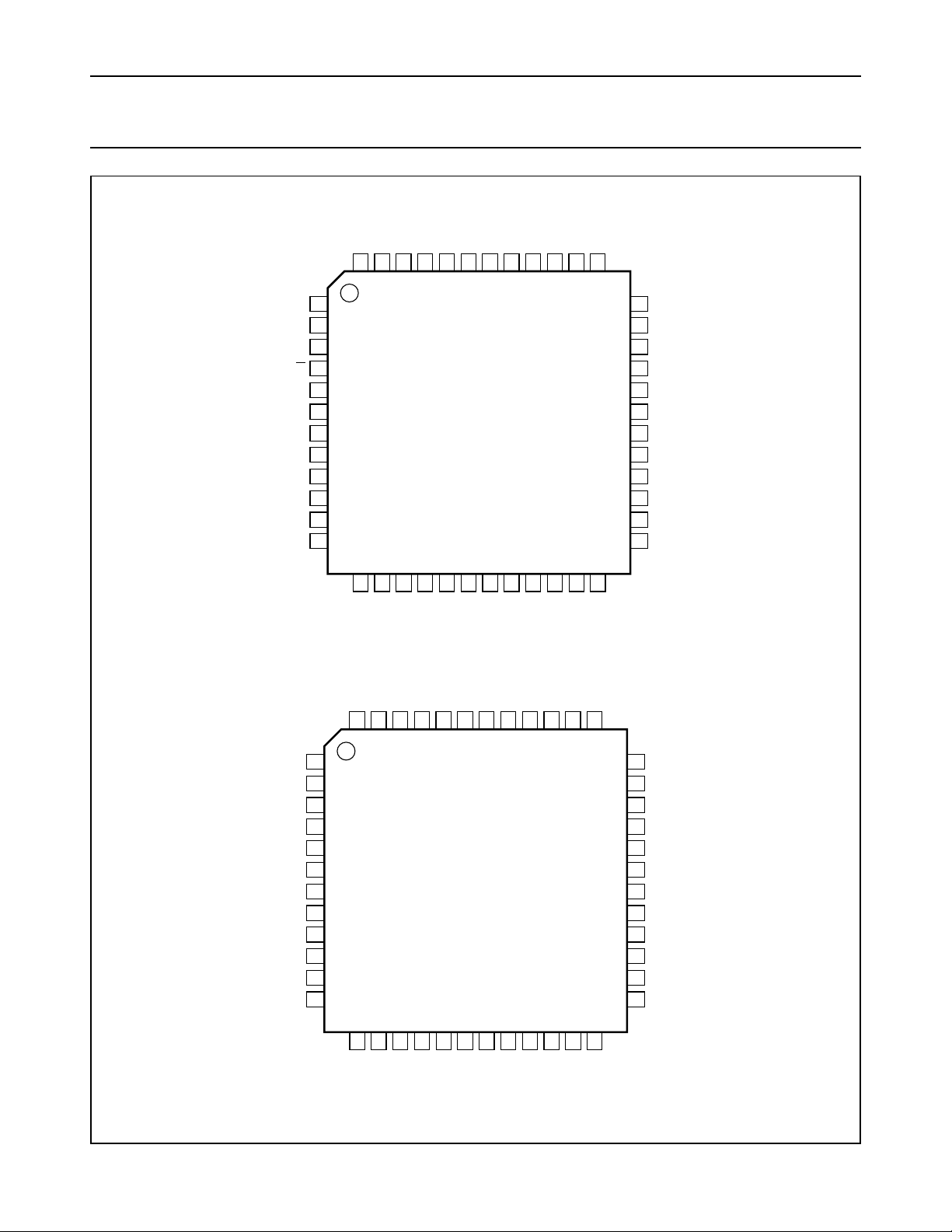

7 PINNING

SYMBOL

HUS 1 1 1 head unsafe output

WDIx 2 2 2 write data input (differential; voltage input)

WDIy 3 3 3 write data input (differential; voltage input)

IWDIx −−4 write data input (differential; current input)

IWDIy −−5 write data input (differential; current input)

W 4 4 6 read/write (read = HIGH; write = LOW)

R/

SEN 5 5 7 serial bus enable

SDATA 6 6 8 serial bus data

SCLK 7 7 9 serial bus clock

GND1 8 8 10 ground connection 1

RDx 9 9 11 read data output (differential x − y)

RDy 10 10 12 read data output (differential x − y)

GND3 −−13 ground connection 3

V

CC

R

ext

GND2 13 13 16 ground connection 2

0Wx 14 − 17 inductive write head connection for head H0 (differential x − y)

0Wy 15 − 18 inductive write head connection for head H0 (differential x − y)

0Rx 16 − 19 MR-read head connection for head H0 (differential x − y)

0GND 17 − 20 ground connection for head H0

0Ry 18 − 21 MR-read head connection for head H0 (differential x − y)

n.c. − 14 − not connected

n.c. − 15 − not connected

n.c. − 16 − not connected

n.c. − 17 − not connected

n.c. − 18 − not connected

1Wx 19 19 22 inductive write head connection for head H1 (differential x − y)

1Wy 20 20 23 inductive write head connection for head H1 (differential x − y)

1Rx 21 21 24 MR-read head connection for head H1 (differential x − y)

1GND 22 22 25 ground connection for head H1

1Ry 23 23 26 MR-read head connection for head H1 (differential x − y)

n.c. 24 24 − not connected

2Wx 25 25 27 inductive write head connection for head H2 (differential x − y)

2Wy 26 26 28 inductive write head connection for head H2 (differential x − y)

2Rx 27 27 29 MR-read head connection for head H2 (differential x − y)

2GND 28 28 30 ground connection for head H2

2Ry 29 29 31 MR-read head connection for head H2 (differential x − y)

n.c. 30 30 − not connected

TDA5153AG TDA5153BG TDA5153X

PIN PAD

DESCRIPTION

11 11 14 supply voltage

12 12 15 10 kΩ external resistor

1997 Jul 02 6

Page 7

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

SYMBOL

n.c. 31 31 − not connected

3Wx 32 32 32 inductive write head connection for head H3 (differential x − y)

3Wy 33 33 33 inductive write head connection for head H3 (differential x − y)

3Rx 34 34 34 MR-read head connection for head H3 (differential x − y)

3GND 35 35 35 ground connection for head H3

3Ry 36 36 36 MR-read head connection for head H3 (differential x − y)

n.c. 37 37 − not connected

4Wx 38 38 37 inductive write head connection for head H4 (differential x − y)

4Wy 39 39 38 inductive write head connection for head H4 (differential x − y)

4Rx 40 40 39 MR-read head connection for head H4 (differential x − y)

4GND 41 41 40 ground connection for head H4

4Ry 42 42 41 MR-read head connection for head H4 (differential x − y)

5Wx 43 − 42 inductive write head connection for head H5 (differential x − y)

5Wy 44 − 43 inductive write head connection for head H5 (differential x − y)

5Rx 45 − 44 MR-read head connection for head H5 (differential x − y);

5GND 46 − 45 ground connection for head H5

5Ry 47 − 46 MR-read head connection for head H5 (differential x − y)

n.c. − 43 − not connected

n.c. − 44 − not connected

n.c. − 45 − not connected

n.c. − 46 − not connected

n.c. − 47 − not connected

V

CC(WD)

GND4 −−48 ground connection 4

TDA5153AG TDA5153BG TDA5153X

PIN PAD

DESCRIPTION

48 48 47 supply voltage for the write drivers

1997 Jul 02 7

Page 8

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

handbook, full pagewidth

HUS

WDIx

WDIy

R/W

SEN

SDATA

SCLK

GND1

RDx

RDy

V

CC

R

ext

CC(WD)

V

48

1

2

3

4

5

6

7

8

9

10

11

12

5Ry

47

5Rx

5GND

464544

TDA5153AG

5Wy

5Wx

43

4Ry

42

4GND

41

4Rx

40

4Wy

39

4Wx

38

n.c.

TDA5153

36

3Ry

35

3GND

34

3Rx

33

3Wy

32

3Wx

31

n.c.

n.c.

30

29

2Ry

2GND

28

27

2Rx

26

2Wy

2Wx

25

handbook, full pagewidth

HUS

WDIx

WDIy

R/W

SEN

SDATA

SCLK

GND1

RDx

RDy

V

CC

R

ext

13

14

151617

0Wx

0Wy

GND2

CC(WD)

n.c.

V

n.c.

48

47

46

1

2

3

4

5

6

7

8

9

10

11

12

0Rx

0GND

n.c.

n.c.

n.c.

45

44

43

TDA5153BG

18

0Ry

19

1Wx

4Ry

42

20

1Wy

4GND

41

21

1Rx

4Rx

40

4Wy

39

22

1GND

23

1Ry

4Wx

38

24 37

n.c.

n.c.

MGK424

36

35

34

33

32

31

30

29

28

27

26

25

3Ry

3GND

3Rx

3Wy

3Wx

n.c.

n.c.

2Ry

2GND

2Rx

2Wy

2Wx

13

14

15

16

17

n.c.

n.c.

n.c.

GND2

n.c.

Fig.2 Pin configurations.

1997 Jul 02 8

18

n.c.

19

1Wx

20

1Wy

21

1Rx

22

1GND

23

1Ry

24 37

n.c.

MGK420

Page 9

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

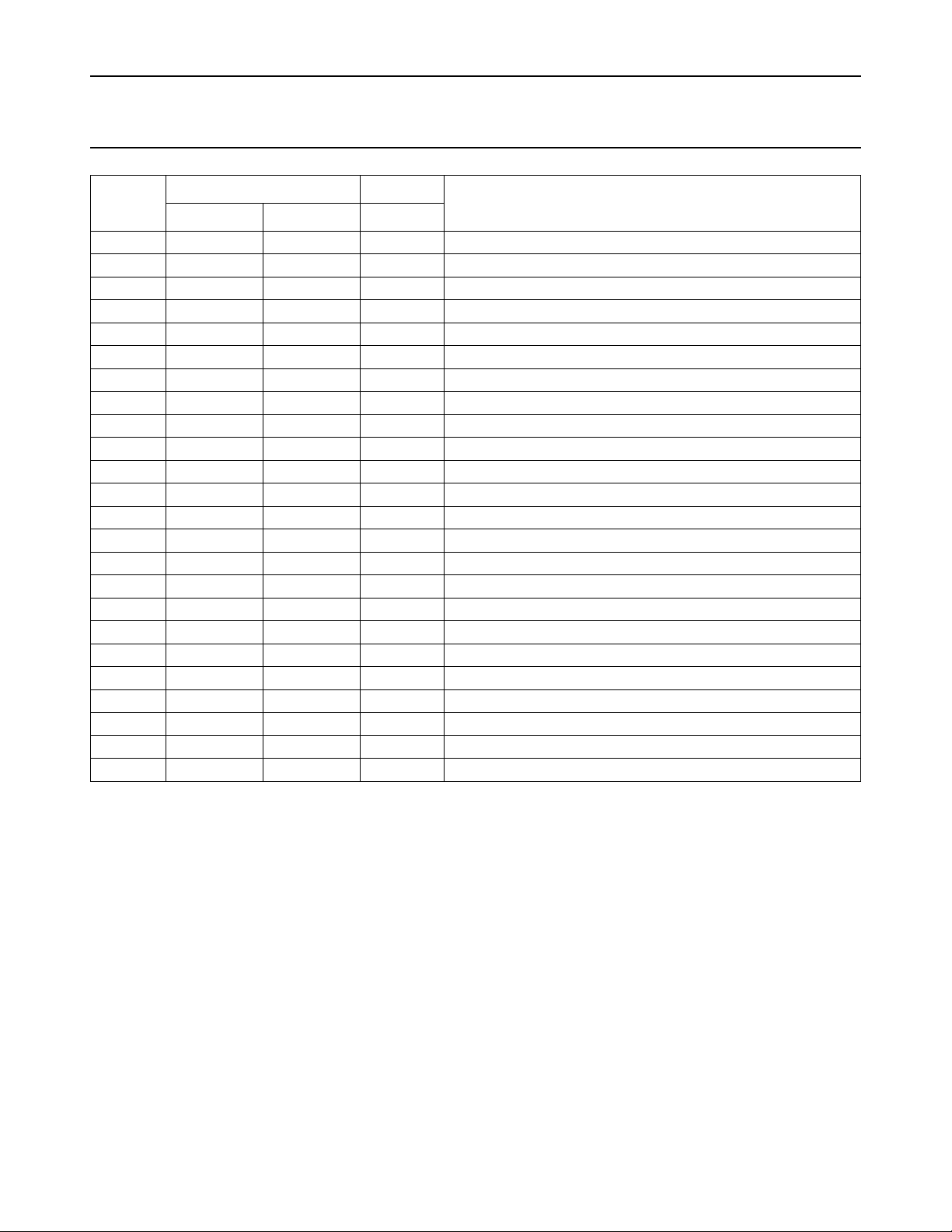

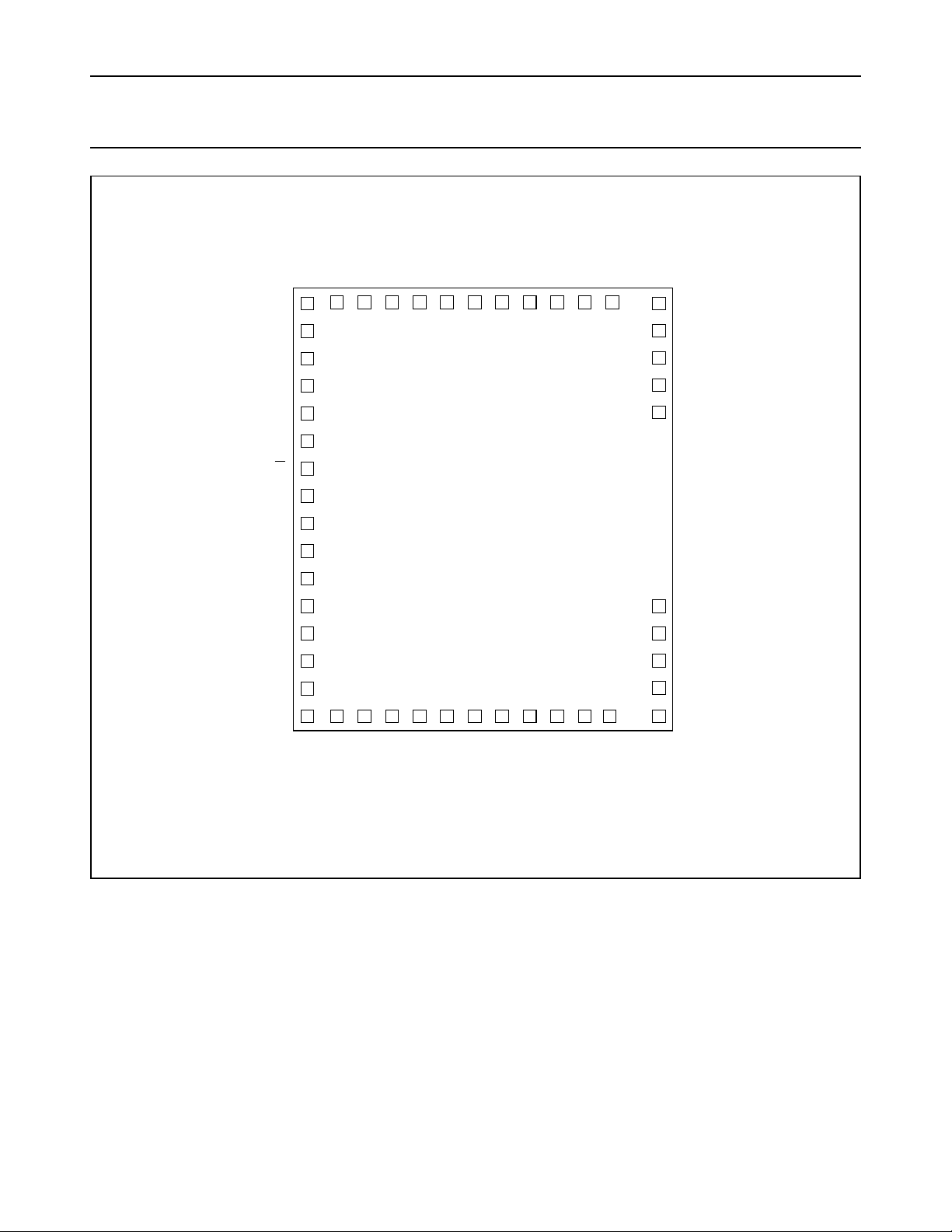

handbook, full pagewidth

CC(WD)

5Ry

5GND

5Rx

5Wy

TDA5153X

GND4

HUS

WDIx

WDIy

IWDIx

IWDIy

R/W

SEN

SDATA

SCLK

V

48

47 46 45 44 43 42 41 40 39 38 37

1

2

3

4

5

6

7

8

9

5Wx

4Ry

4GND

4Rx

4Wy

4Wx

TDA5153

3Ry

36

3GND

35

3Rx

34

3Wy

33

3Wx

32

GND1

RDx

RDy

GND3

V

CC

R

ext

10

11

12

13

14

16 17 18 19 20 21 22 23 24 25 26

15

GND2

0Wx

0Wy

0Rx

0GND

0Ry

1Wx

1Wy

1Rx

Fig.3 TDA5153X pad configuration.

1GND

1Ry

31

30

29

28

27

MGK421

2Ry

2GND

2Rx

2Wy

2Wx

1997 Jul 02 9

Page 10

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

8 FUNCTIONAL DESCRIPTION

8.1 Read mode

The read mode disables the write circuitry to save power

while reading. The read circuitry is de-activated for write,

sleep and standby modes. The read circuitry may also be

biased during write mode to shorten transients.

The selected head is connected to a multiplexed low-noise

read amplifier. The read amplifier has low-impedance

inputs nRx and nRy (n is the number of the head) and

low-impedance outputs RDx and RDy. The signal polarity

is non-inverting from x and y inputs to x and y outputs.

Ambient magnetic fields at the MR elements result in a

relative change in MR resistance

∆R

MR

--------------- R

MR

This change produces a current variation

∆R

MR

×

=

∆ I

MRIMR

where I

is the bias current in the MR element.

MR

The current variation is amplified to form the read data

output signal voltage, which is available at RDx − RDy.

AC coupling between MR elements and amplifier stages

prevents the amplifier input stages from overload by DC

voltages across the MR elements. A fast settling

procedure shortens DC settling transients.

An on-chip generated stable temperature reference

voltage (1.32 V), available at the R

across an external resistor (10 kΩ) to form a global

reference current for the write and the MR bias currents.

The MR bias current DACs are programmed through the

serial interface according to the following formula

MR

10 kΩ

------------------ 2R

⋅

ext

I

(in mA), where d4 to d0 are bits (either logic 0 or logic 1).

At power-up, all bits are set to logic 0, which results in a

default MR current of 5 mA. The adjustable range of the

MR currents is 5 mA to 20.5 mA. The MR bias currents are

equal for the two stripes of each head. The gain amplifier

is 1-bit programmable. The amplifier gain can be set to its

nominal value or to the nominal value +3 dB.

8.2 Write mode

To minimize power dissipation, the read circuitry may be

disabled in write mode. The write circuitry is disabled in

,

--------------- R

MR

pin, is dropped

ext

10 16 d4⋅ 8d3⋅ 4d2⋅ 2d1⋅ d0+ ++++()=

TDA5153

read, sleep and standby modes. In write mode, a

programmable current is forced through the selected two

terminals inductive write head. The push-pull output

drivers yield near rail-to-rail voltage swing for fast current

polarity switching.

The differential write data input WDIx − WDIy is PECL

(Positive Emitter Coupled Logic) compatible. The write

data flip-flop can either be used or passed-by. In the case

that the write data flip-flop is used, current polarity is

toggled at the falling edges of the V

data=VWDIx

Switching to Write Mode initializes the data flip-flop so that

the write current flows in the write head from x to y. In the

case that the write data flip-flop is not used, the signal

polarity is non-inverting from x and y inputs to x and y

outputs.

The write current magnitude is controlled through on-chip

DACs. The write current is defined as follows:

10 kΩ

I

WR

----------------

20 16 d4⋅ 8d3⋅ 4d2⋅ 2d1⋅ d0+ ++++()=

R

ext

(in mA) where d4 to d0 are bits (either logic 0 or logic 1).

The adjustable range of the write current is 20 mA to

51 mA. At power-up, the default values

d4 = d3 = d2 = d1 = d0 = logic 0 are initialized,

corresponding to I

= 20 mA. IWR is the current provided

WR

by the write drivers: the current in the write coil and in the

damping resistor together. The static current in the write

coil is

I

WR

,

---------------- R

h

1

+

------ R

d

where R

R

d

is the resistance of the coil including leads and

h

is the damping resistor.

8.3 Sleep mode

In sleep mode, the device is accessible via the serial

interface. All circuits are inactive, except the circuits of the

CMOS serial interface and the circuit which forces the data

registers to their default values at power-up and which

fixes the DC level of RDx − RDy (required when operating

with more than one amplifier). Typical static current

consumption is −30 µA. Dynamic current consumption

during operation of the serial interface in the sleep mode

and owing to external activity at the inputs to the serial

interface is not included. In all modes including the sleep

mode, data registers can be programmed. Sleep is the

default mode at power-up. Switching to other modes takes

less than 0.1 ms.

− V

WDIy

.

1997 Jul 02 10

Page 11

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

8.4 Standby mode

The circuit can be put in standby mode using the serial

interface. In standby mode, typical DC current

consumption is 330 µA. Transients from standby mode to

active mode are two orders of magnitude shorter than from

sleep mode to active mode. This is important in the case

of cylinder mode operation with multiple amplifiers.

All amplifiers can operate from standby mode and all head

switch times can be kept just as short as in the case of

operation with a single amplifier. Head switching times are

summarized in the switching characteristics.

8.5 Active mode

Active mode is either read mode or write mode depending

on the R/

8.6 Bi-directional serial interface

The serial interface is used for programming of the device

and for reading of status information. 16 bits (8 bits for

data and 8 for address) are used to program the device.

The serial interface requires 3 pins: SDATA, SCLK and

SEN. These pins (and R/

input R/W has an internal 20 kΩ pull-up resistor and the

SEN logic input has an internal 20 kΩ pull-down resistor.

Thus, in case the SEN line is opened, no data will be

registered and in case the R/W line is opened, the device

will never be in write mode.

SDATA: serial data; bi-directional data interface. In all

circumstances, the LSB is transmitted first.

SCLK: serial clock; 25 MHz clock frequency.

SEN: serial enable; data transfer takes place when SEN is

HIGH. When SEN is LOW, data and clock signals are

prohibited from entering the circuit.

Three phases in the communication are distinguishable:

addressing, programming and reading. Each

communication sequence starts with an addressing

phase, followed by either a programming phase or a

reading phase.

W pin.

W) are CMOS inputs. The logic

TDA5153

8.7 Addressing

When SEN goes HIGH, bits are latched in at rising edges

of SCLK. The first eight bits a7 to a0, starting with a0, are

shifted serially into an address register. If SEN goes LOW

before 16 bits have been received, the operation is

ignored. When more than 16 bits (address and data) are

latched in before SEN goes LOW, the first 8 bits are

interpreted as an address and the last 8 bits as data.

SEN should go HIGH at least 5 ns before the first rising

edge of SCLK. Data should be valid at least 5 ns before

and after a rising edge of SCLK. The bits a7 to a4

constitute the register address.To validate the

communication with the preamplifier, bits a1, a2 and a3

have to be programmed as (1, 0, 0).

If bit a0 = logic 0, a programming sequence starts.

If bit a0 = logic 1, reading data from the pre-amplifier can

start.

8.8 Programming data

If a0 = logic 0, the last eight bits d7 to d0 before SEN goes

LOW are shifted into an input register. Bits d6 and d7 are

don’t care. When SEN goes LOW, the communication

sequence is ended and the data in the input register is

copied in parallel to the data register that corresponds to

the decoded address a7 to a4. SEN should go LOW at

least 5 ns after the last rising edge of SCLK.

8.9 Reading data

Immediately after the IC detects that a0 = logic 1, data

from the data register (address a7 to a4) is copied in

parallel to the input register. Two wait clock cycles must

follow before the controller can start inputting data. At the

first falling edge of SCLK after the 2 wait rising edges of

SCLK, the LSB d0 is placed on SDATA line followed by d1

at the next falling edge of SCLK etc. If SEN goes LOW

before 8 address bits (a7 to a0) have been detected, the

communication is ignored.

1997 Jul 02 11

Page 12

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

handbook, full pagewidth

SEN

SCLK

SDATA

>5 ns >5 ns

0d0a1 d1a2 d2a3 d3a4 d4a5 d5a6 a7 d6 d7

address data

TDA5153

MGK423

handbook, full pagewidth

SEN

SCLK

SDATA

Fig.4 Timing diagram of the serial interface operation; writing sequence (a0 = 0).

1d0a1 d1a2 d2a3 d3a4 d4a5 d5a6 a7

address data

wait

cycles

MGK419

Fig.5 Timing diagram of the serial interface operation; reading sequence (a0 = 1).

1997 Jul 02 12

Page 13

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

8.10 Operation of the serial interface

data

=

ONFIGURATION

V

–

WDIxVWDIy

-------------------------------------2

=28Ω. If d4 = logic 1, the

MR

8.10.1 C

d0

By default (d0 = logic 0), write data passes from the

write data input via the data flip-flop to the write driver.

The write driver toggles the current in the head at the

falling edges of

V

When d0 = logic 1, the flip-flop is not used. The signal

polarity is non-inverting from WDIx and WDIy to Wx and

Wy.

d1

By default (d1 = logic 0) the pre-amplifier senses PECL

write signals at WDIx and WDIy. d1 should remain

logic 0.

d2

By default, (d2 = logic 0) the write current is inhibited

under low supply voltage conditions. The write current

inhibit is made inactive by programming d2 to logic 1.

d3

By default (d3 = logic 0), in write mode low supply

voltage, open head, and other conditions are monitored

and flagged at HUS. If d3 = logic 1, HUS is LOW in write

mode and HIGH in read mode.

d4

The amplifier read gain may be programmed in the

configuration register. By default (d4 = logic 0), the read

gain is typically 160 with R

read amplifier typical gain is 3 dB higher (i.e. 226 if

RMR=28Ω).

TDA5153

If d1 = d0 = logic 1, the circuit goes in active mode, (read

or write mode depending on the R/

8.10.3 H

EAD SELECT

d2, d1 and d0 are used to select head H0 to H5 for the

6 channel version and to select head H1 to H4 for the

4 channel version.

8.10.4 S

ERVO WRITE

The circuit is prepared for servo writing. However, the chip

will not be guaranteed.

8.10.5 T

EST

d2 = d1 = d0 = logic 0. The circuit is not in test mode. This

is the default situation.

8.10.5.1 MR head test

d2 = logic 0, d1 = logic 0, d0 = logic 1. In read mode, the

voltages at Rx and Ry (at the top of the MR elements) of

the selected head are fed to RDx and RDy outputs. By

measuring the output voltages single-ended at two

different I

currents, the MR resistance can be accurately

MR

measured according to the following formula:

R

MRx

RDx1VRDx2

=

-------------------------------------- I

–

MRx1IMRx2

for the x side for instance.

V

–

Open head and head short-circuited to ground conditions

can therefore be detected.

d2 = logic 0, d1 = logic 1, d0 = logic 0. Same as before,

with the difference that I

is fixed to a minimum constant

MR2

value of 5 mA. Measuring in the same way as above with

I

> 5 mA, enables the detection of MR elements

MR1

connected together.

W input).

d5

In order to minimize the write-to-read recovery times,

the first stage of the read amplifier may be kept biased

during write mode. By default, (d5 = logic 0) the read

amplifier is powered-down during write mode, and the

fast settling procedure is activated after write-to-read

switching. If d5 = logic 1 the read amplifier is kept biased

during write mode, and the fast settling procedure still

occurs if the head is changed or the MR current is

re-programmed.

8.10.2 P

OWER CONTROL

By default d0 = d1 = logic 0, the pre-amplifier powers-up in

sleep mode. If d1 = logic 0, d0 = logic 1 or d1 = logic 1,

d0 = logic 0 the circuit goes in standby mode.

1997 Jul 02 13

8.10.5.2 Temperature monitor

d2 = logic 0, d1 = logic 1, d0 = logic 1. The temperature

monitor voltages are connected to RDx and RDy. The

output differential voltage depends on the temperature

according to: ,

dV 0.00364– T 1.7+×= 0 T 140 °C<<

The temperature may be measured with a typical precision

of 5 °C.

Page 14

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

8.10.5.3 Thermal asperity detector

d2 = logic 1, d1 = don’t care, d0 = either logic or 1. Unlike

the above tests, the thermal asperity detection does not

use the RDx to RDy outputs. Thus, the reader is fully

operational. In case a thermal asperity is detected, it is

flagged at the HUS pin.

The threshold voltage for the thermal asperity detection is

2-bit programmable. These 2 bits consist of d0 (LSB) of

the test mode register (address = 0XXX0110), as the

MSB, and b2 of the compensation register

(address = 0XXX0111).

V

where d0 is d0 of test mode register and b2 is d2 of

capacitor compensation register.

8.10.6 WRITE AMPLIFIER PROGRAMMABLE CAPACITORS

By default (d2 = d1 = d0 = logic 0) the programmable

capacitors are zero. These capacitors are used to improve

the performance of the write amplifier according to the

write amplifier output load.

210 560 d0⋅ 280 b2⋅++()µV=

th

,

TDA5153

attenuator provides a pole which limits the bandwidth and

reduces the high-frequency noise. The HF pole can be

used in combination with the HF zero in order to boost the

HF gain locally and yet limit the very high frequency noise

enhancement.

8.10.8 H

By default (d3 = d2 = d1 = d0 = logic 0), the high

frequency gain boost is not active. The gain boost provides

a zero which allows to optimize the bandwidth of the read

amplifier and to correct for attenuation caused by series

inductances in the leads between the MR-heads and the

read amplifier inputs.

8.10.9 S

By default (d2 = d1 = d0 = logic 0) the settle pulse has a

nominal duration of 3 µs. Its value can be programmed

from 2.125 µs to 3 µs according to the following formula:

t

st

IGH FREQUENCY GAIN BOOST REGISTER

ETTLE PULSE

2

-------------------------------------------------------------------------4d2⋅ 2d1⋅ 1d0⋅ 1+++()

1

µ s+=

8.10.7 H

By default (d3 = d2 = d1 = d0 = logic 0), the high

frequency gain attenuator is not active. The gain

8.10.10 A

A7 A6 A5 A4 A3 A2 A1 A0 DESCRIPTION

00000010configuration register:

00010010power control register:

00100010head select register:

IGH FREQUENCY GAIN ATTENUATOR POLE

REGISTER

DDRESS REGISTERS; note 1

d0 = 0: use data flip-flop; d0 = 1: by-pass data flip-flop

d1 = 0: the WDI inputs are PECL levels; d1 = 1: invalid

d2 = 0: write current inhibit active; d2 = 1: write current inhibit inactive

read mode: d3 = 0: HUS active; d3 = 1: HUS HIGH

write mode: d3 = 0: HUS active; d3 = 1: HUS LOW

d4 = 0: read gain nominal; d4 = 1: read gain nominal + 3 dB

d5 = 0: read amplifier OFF during write mode; d5 = 1: read amplifier ON

during write mode

(d1, d0) = (0, 0): sleep mode

(d1, d0) = (1, 0) or (0, 1): standby mode

(d1, d0) = (1, 1): active mode (write or read)

6 channels: (d2,d1,d0) = (0,0,0) to (1,0,1): H0 to H5

4 channels: (d2,d1,d0) = (0, 0, 1) to (1, 0, 0): H1 to H4

1997 Jul 02 14

Page 15

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

A7 A6 A5 A4 A3 A2 A1 A0 DESCRIPTION

00110010

01000010

01010010servo write register:

01100010test mode register:

01110010compensation capacitor register:

10000010

10010010

10100010

11110011chip ID register:

a7a6a5a40011when a0 = 1, data from the register with address a7 to a4 is read out on

MR current DAC register:

10 kΩ

I

MR

0.5

× 10 16 d4⋅ 8d3⋅ 4d2⋅ 2d1⋅ 1d0⋅+++++()mA×=

----------------

R

ext

write current DAC register:

I

WR

----------------

R

ext

20 16 d4⋅ 8d3⋅ 4d2⋅ 2d1⋅ 1d0⋅+ ++++()mA×=

10 kΩ

(d0, d1) = (0, 0) = one head

(d0, d1) = (1, 1) = all heads

(d2,d1,d0) = (0,0,0) = not in test mode

(d2,d1,d0) = (0,0,1) = read head test (I

(d2,d1,d0) = (0,1,0) = read head test (I

MR1=IMR2

= 5 mA fixed)

MR2

(d2,d1,d0) = (0,1,1) = temperature monitor

(d2,d1,d0) = (1, X, d0) = thermal asperity detection

V

210 560 d0⋅ 280 b2⋅++()µV=

th

equivalent differential capacitance:

, see note 2

4d2⋅ 2d1⋅ 1d0⋅++()2pF×

high frequency gain attenuator register:

nominal pole frequency:

------------------------------------------------------------------------------ 8d3⋅ 4d2⋅ 2d1⋅ 1d0⋅+++

800 MHz

high-frequency gain boost register:

nominal zero frequency:

------------------------------------------------------------------------------ 8d3⋅ 4d2⋅ 2d1⋅ 1d0⋅+++

800 MHz

settle time register:

settle time:

ID 8 d3⋅ 4d2⋅ 2d1⋅ 1d0⋅+++=

2

t

st

-------------------------------------------------------------------------4d2⋅ 2d1⋅ 1d0⋅ 1+++()

1

, d3 to d0 are preset to (0, 0, 1, 1)

SDATA

)

µ s+=

Notes

1. Not used bits in the registers (indicated by X) are don’t care. Default data, initialized at power-up, is zero in all

registers. For VCC< 2.5 V, the register contents are not guaranteed.

2. Vth programming uses both test mode register and compensation capacitor register. d0 in the formula above is the

LSB of the test mode register and b2 is the data bit d2 of the compensation register.

1997 Jul 02 15

Page 16

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

8.11 Head unsafe

The HUS pin is an open-collector output. Consequently,

when the pin is not connected to an external pull-up

resistor, HUS is LOW. HUS pins can be connected

together in case of operation with more than one amplifier.

It is used to detect abnormal/unexpected operation.

Sleep mode: HUS is HIGH, to permit working with more

than one amplifier.

Standby mode: HUS is HIGH, to permit working with

more than one amplifier.

Read mode:

• if in the configuration register d3 = 1, HUS is HIGH

• if in the configuration register d3 = 0, HUS goes LOW

for:

–R

pin open, short-circuited to ground or to V

ext

(read current too low or too high)

– Low VCC and V

conditions. A low supply

CC(WD)

voltage detector is placed close to the VCC and

V

CC(WD)

pins.

Detection of low VCC (main general supply): a VCC supply

voltage below 4.0 V ±5% is flagged to the HUS pin.

The voltage detection range is then 4.2 to 3.8 V with an

hysteresis of 110 mV ±10%. Detection of low V

(writer dedicated supply): a fault will be flagged at HUS pin

if V

drops 0.8 V ±10% below VCC. One must be

CC(WD)

aware that such a detection is only aimed to warn for a

catastrophic situation. Indeed, V

should never be

CC(WD)

below VCC.

CC

CC(WD)

TDA5153

Test mode: HUS is HIGH except when the TAS detector

is ON. If a thermal asperity is detected, HUS goes LOW.

Servo write mode: HUS is LOW

Write mode:

• if in the configuration register d3 = 1, HUS is LOW

• if in the configuration register d3 = 0, HUS goes HIGH

for: the write current may be inhibited if d1 = 0 in the

configuration register.

–R

pin open, short-circuited to ground or to V

ext

(write current too low or too high)

– Write data input frequency too low (WDIx − WDIy)

– Write head Wx − Wy open, Wx or Wy short-circuited

to ground (switching to write mode makes HUS LOW;

after the transient the HUS detection circuitry is

activated; the target for the head-open detect time is

15 ns)

– Write-head still left biased while not selected

– Low VCC and V

conditions (write current inhibit

CC(WD)

can be active or inactive).

The same detector is used for read and write mode. HUS

goes LOW again between 0.5 and 1 µs after the last

unsafe condition was detected.

CC

8.12 HUS survey HUS DATA BIT D3

MODE STATE 0 1

Sleep mode −− HIGH HIGH

Standby mode −− HIGH HIGH

Read mode ACTIVE HIGH

(1)

(1)

(2)

HIGH HIGH

HIGH HIGH

LOW LOW

Active mode

Read

Write

A-test mode

TAS mode ACTIVE ACTIVE

Write mode ACTIVE LOW

A-test mode

Servo mode

Notes

1. HUS survey: A-test mode = analog test mode.

2. In servo mode, the performance of the IC is not guaranteed.

1997 Jul 02 16

Page 17

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

9 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

V

CC(WD)

V

IL

V

IH

V

n1

V

n2

V

n3

I

nGND

T

stg

T

j

supply voltage −0.5 +6.0 V

write driver supply voltage −0.5 +9.5 V

LOW level digital input voltage −0.5 +5.5 V

HIGH level digital input voltage −0.5 +5.5 V

voltage on all pins except VCC, read inputs nRx, nRy and

−0.5 +5.5 V

write outputs nWx, nWy (n = 0 to 9)

but not higher than − V

+ 0.5 V

CC

voltage on write driver outputs nWx, nWy −0.5 +8.8 V

but not higher than − V

CC(WD)

+ 0.8 V

voltage on read inputs nRx, nRy −0.5 1 V

current through pins nGND − 0.1 A

storage temperature −65 +150 °C

junction temperature − 150 °C

10 HANDLING

Inputs and outputs are protected against electrostatic discharge in normal handling. However, to be totally safe, it is

desirable to take normal precautions appropriate to handling MOS device.

11 THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITION VALUE UNIT

R

th j-a

thermal resistance from junction to ambient

TDA5153AG, TDA5153BG in free air 70 K/W

TDA5153X see note 1

Note

1. The TDA5153X is shipped in naked dies. The thermal resistance depends on the flex used.

1997 Jul 02 17

Page 18

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

12 RECOMMENDED OPERATION CONDITIONS

SYMBOL PARAMETER CONDITIONS MIN. TYP MAX. UNIT

V

CC

V

CC(WD)

V

IH

V

IL

V

i(dif)(p-p)

V

IH(PECL)

V

IL(PECL)

T

amb

T

j

R

MR

∆R

MR

L

l(tot)

R

l(tot)

V

MR

V

sig(dif)(p-p)

L

wh

R

wh

C

wh

R

ext

supply voltage range note 1 4.5 − 5.5 V

write driver supply voltage note2 V

CC

HIGH level input voltage (CMOS) 3.5 − V

− 8.8 V

CC

V

LOW level input voltage (CMOS) 0 − 0.8 V

differential input voltage

note 3 0.4 0.7 1.5 V

(peak-to-peak value)

HIGH level PECL input voltage note 3 1.5 2.85 V

CC

V

LOW level PECL input voltage note 3 − 2.15 − V

ambient temperature 0 − 70 °C

junction temperature reading −−110 °C

writing (V

=8V) −−130 °C

CC(WD)

MR element resistance 15 28 34 Ω

RMR mismatch note 4 −−4Ω

total lead inductance to the head in each lead; note 5 − 35 − nH

total lead resistance to the head in each lead; note 5 − 1.5 −Ω

voltage on top of MR elements note 6 −−0.5 V

differential MR head input signal

0.4 1 2 mV

(peak-to-peak value)

write head inductance including lead; note 5 − 0.15 −µH

write head resistance including lead; note 5 − 10 −Ω

write head capacitance including lead; note 5 − 5 − pF

external reference resistor − 10 − k Ω

V

I

ref

ref

=

---------- R

ext

Notes

1. A supply by-pass capacitor from VCC to ground or a low-pass filter may be used to optimize the PSRR.

2. The supply voltage V

must never be below VCC in normal mode, and two diode voltages above VCC in servo

CC(WD)

mode.

3. The given values should be interpreted in such a way that the single-ended voltage could swing 0.2 to 0.75 V and

that the common mode voltage should be such that for any of the two states, V

IH(max)<VCC

and V

IL(min)

> 1.5 V.

PECL voltage swing: a wider peak-to-peak voltage swing can be used. In that case a current will flow through the

WDI inputs. This current is approximately equal to

WDIx WDIy–()1.4–

----------------------------------------------------------200

4. The mismatch refers to the resistance of the two stripes of the same head. This is defined as follows:

∆R

MR

= R

MR1

− R

MR2

5. These parameters depend on the head model. The values given are those used for testing.

6. The combination of maximum head resistance, lead resistance and bias current is not permitted. To avoid voltage

break-through between heads and disk, the voltage over the MR elements is limited by two diodes.

1997 Jul 02 18

Page 19

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

13 CHARACTERISTICS

= 5.0 V; V

V

CC

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Read characteristics

I

MR

∆I

MR

G

v(dif)

R

i(dif)

C

i(dif)

THD total harmonic distortion − 1 − %

B

L

B

H

F noise figure; note 3 RMR=28Ω; IMR= 10mA;

V

nir

f

B(L)

f

B(H)

α

cs

PSRR power supply rejection ratio; note 5 f < 1 MHz; I

CMRR common mode rejection ratio;

DR rejection of SCLK and SDATA;

V

O(R)(dif)

Z

o(R)

=8V; V

CC(WD)

MR current adjust range R

tolerance (excluding R

IMRI

–

MR(PR)

--------------------------------- I

MR(PR)

MR(PR)

=10mA

with I

GND

=0V; T

)

ext

=25°C; unless otherwise specified.

amb

=10kΩ; 0.5 mA steps 5 − 20.5 mA

ext

−±4−%

differential voltage gain; note 1 from head inputs to RDx, RDy;

RMR=28Ω; IMR=10mA;

f = 20 MHz;

d4 = 0 − 160 −

d4 = 1 − 226 −

differential input resistance IMR=10mA − 13 −Ω

differential input capacitance − 16 − pF

signal gain pass band edge; note 2 −3dB −−100 kHz

signal gain pass band edge without

gain boost; note 2

−3 dB (4 nH lead inductance) − 220 − MHz

−3 dB (50 nH lead inductance) − 170 − MHz

− 3.0 3.2 dB

T

=25°C; f = 20 MHz

amb

input referred noise voltage; note 3 RMR=28Ω; IMR= 10mA;

T

=25°C; f = 20 MHz

amb

+3 dB noise low corner frequency RMR=28Ω; IMR= 10 mA;

T

=25°C; no lead

amb

− 0.9 1.0 nV/√Hz

− 400 kHz

inductance

+3 dB noise upper corner

frequency

RMR=28Ω; IMR= 10 mA;

T

=25°C; no lead

amb

− 220 MHz

inductance

channel separation; note 4 unselected head − 50 dB

=10mA − 80 dB

MR

f < 100 MHz; I

=10mA − 50 dB

MR

from nRx − nRy to RDx − RDy;

note 5

R

mismatch < 5%;

MR

IMR= 10 mA;

f<1MHz − 45 dB

f < 100 MHz − 25 dB

note 6

output DC offset voltage in read

mode (differential after DC settling)

from SCLK, SDATA inputs to

the RDx − RDy outputs; note 7

DC voltage between

RDx − RDy (in read mode)

− 50 dB

−−±0.2 V

output impedance in read mode single ended − 16 −Ω

1997 Jul 02 19

Page 20

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

I

o(max)(dif)

V

o(cm)

∆V

ocm

---------------∆V

CC

Z

o(n)(dif)

Write characteristics

I

WR

∆I

WR

V

s(max)(p-p)

R

o(dif)

, t

t

r

f

t

as

t

pd

α

cs

Switching characteristics

f

SCLK

∆V

o(cm)

t

rec(W-R)

t

sw(R)

t

off(R)

maximum differential output

− 4 − mA

current

common mode output voltage in

RDx, RDy 1.0 1.5 2.0 V

read mode

common mode DC supply rejection

− 20 − dB

in read mode

differential output impedance in

− 50 − kΩ

other modes (write, standby, sleep)

write current adjust range (in the

R

=10kΩ; 1 mA steps 20 35 51 mA

ext

write drivers)

tolerance (excluding R

–

I

WRIRW(PR)

----------------------------------- I

RW(PR)

maximum voltage swing

(peak-to-peak value)

ext

);

I

V

V

=35mA −±7−%

WR(PR)

=5V −−8V

CC(WD)

= 8 V (differential) −−13 V

CC(WD)

differential output resistance − 200 −Ω

write current rise/fall time without

flip-flop (10% to 90%); note 8

V

=8V; Lh= 150 nH,

CC(WD)

Rh=10Ω; IWR= 35 mA;

−− 1.8 ns

f = 20 MHz

write current asymmetry; note 9 percentage of tr/t

f

−−5%

(tr, tf and logic asymmetry)

propagation delay 50% of

(WDIx/WDIy) to 50% of (Wx, Wy)

write head short circuited; data

flip-flop by passed

−−5ns

channel separation unselected head − 45 − dB

serial interface clock rate −−25 MHz

output common mode DC voltage

IMR= 10 mA; IWR=35mA − 200 − mV

change from Read to Write modes

write to read recovery time

(AC and DC settling); note 10

from 50% of the rising edge of

R/W to steady state read-back

signal: AC and DC settling at

90% (without load at

RDx − RDy)

read amplifier OFF: d5 = 0 − 3 4.5 µs

read amplifier ON: d5 = 1 − 100 150 µs

head switching (in read mode),

standby to read active and MR

current change recovery time;

from falling edge of SEN to

steady state read-back signal;

(without load at RDx − RDy)

− 3 4.5 µs

(AC and DC settling); note 11

read amplifier off time from falling edge of R/W to

−−50 ns

read head inactive

1997 Jul 02 20

Page 21

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

t

st(W)

t

off(W)

t

sw(W)

t

sw(S)

DC characteristics

I

CC(R)

I

CC(W)

I

DD(stb)

I

DD(S)

V

ref

write settle times; note 12 from 50%of the falling edge of

−−70 ns

R/W to 90% of the steady state

write current (in Write Mode)

write amplifier off time from rising edge of R/W to

−−50 ns

IWR-programmed /10

(IWR= 35 mA)

head switching (in write mode),

and standby to write head active

sleep to (and from) any other

from falling edge of SEN to

write head active

− 50 70 ns

−−100 µs

modes

supply current; note 13 read mode; IMR=10mA − 72 80 mA

supply current; note 14 write mode; IWR=35mA

from V

from V

(5 V) − 33 41 mA

CC

(5 to 8 V) − 54 61 mA

CC(WD)

standby mode supply current − 0.25 1 mA

sleep mode supply current static − 0.025 − mA

reference voltage for R

ext

− 1.32 − V

Notes to the characteristics

1. The differential voltage gain depends on the MR

resistance. It can be improved by programming the

d4 bit in the configuration register using the serial

interface.

2. The gain boost implements a pole-zero combination:

The +3 dB gain boost corner frequency is

------------------------------------------------------------------------------------8d3⋅ 4d2⋅ 2d1⋅ 1d0⋅+++()

800 MHz

The −3 dB gain attenuation corner frequency is

------------------------------------------------------------------------------------8d3⋅ 4d2⋅ 2d1⋅ 1d0⋅+++()

800 MHz

where d3, d2, d1, d0 are bits (0, 1) to be programmed

via the Serial Interface. In practical use, the bandwidth

is limited by the inductance of the connection between

the MR heads and the pre-amplifier.

3. Noise calculation

a) Definitions: The amplifier has a low-ohmic input.

No lead resistance is taken into account. The input

referred noise voltage, excluding the noise of the

MR resistors, is defined as follows:

2

V

nir

where G

no

-------- G

is the voltage gain and Vno is the noise

v

v

4kT R

+()× V–=

MR1RMR2

2

V

voltage at the output of the amplifier, k is the

Boltzmann constant and T is the temperature in K.

The noise figure is defined as follows:

2

V

no

F 10 log

× dB=

----------------------------------------------------------- 4kT R

-------- G

v

+()×

MR1RMR2

in 1 Hz bandwidth. Note that R

includes all

MR

resistances between Rx or Ry to ground.

b) Noise figure versus I

and RMR: Table 1 shows

MR

the variation of the noise figure with IMR (mA) and

RMR (Ω).

c) Input noise voltage consideration: the input

referred noise voltage calculation can significantly

be different (from 1.0 to 0.44 nV/√Hz for instance)

by taking into account an equivalent

signal-to-noise ratio when using two MR stripes

(28 Ω for each stripe) or one MR stripes (42 W).

It assumes that the signal coming from the head is

larger for a dual stripe head than for a single stripe

head (50% extra signal for dual stripe head).

4. The channel separation is defined by the ratio of the

gain response of the amplifier using the selected head

H(n) to the gain response of the amplifier using the

adjacent head H(n ±1), Head H(n) being selected.

1997 Jul 02 21

Page 22

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

5. The PSRR (in dB) is defined as input referred ratio:

G

v

PSRR 20 log

Where Gv is the differential input to differential output

gain, and G

gain. The CMRR (in dB) is defined as input referred

CMRR 20 log

ratio:

where G

gain and G

is the differential input to differential output

v

cm

output gain. Flex and board lay-out may affect

significantly these parameters.

6. This refers to the crosstalk from SCLK and SDATA

inputs via the read inputs to RDx − RDy. Two cases

can be distinguished:

a) With SEN LOW, SCLK and SDATA are prohibited

from entering the device and crosstalk is low.

b) Programming via the serial interface is done with

SEN HIGH. Then crosstalk can occur. A careful

design of the board or flex-foil is required in order

not to get crosstalk via this path.

7. A 200 mV peak-to-peak signal is applied to SCLK or

SDATA inputs at 25 MHz, and measurement is

performed at RDx − RDy.

×=

------G

p

is the power supply to differential output

p

G

v

×=

---------- G

cm

is the common mode input to differential

TDA5153

8. The rise and fall times depend on the write

amplifier-write head combination. L

the components on the evaluation board. Parasitic

capacitances also limit the performance.

9. The write current rise/fall time asymmetry is defined by

–

t

rtf

-----------------------

+()

2t

rtf

10. Write-to-read recovery time includes the write mode to

read mode switching using the R/

head (see Fig.6). The AC signal reaches its full

amplitude few tenth of ns after appearing at the reader

RDx and RDy outputs.

11. In read mode, the head switching, standby to read

active switching and changing MR current include fast

current settling (see Fig.7). Same note regarding the

AC signals at the reader outputs as above.

12. Write settle time includes read mode to write mode

switching using the R/W pin.

13. The typical supply current in read mode depends on

the bias current for the MR element.

14. The typical supply current in write mode also depends

on the write current.

and Rh represent

h

W pin on the same

Table 1 Noise figure

RMR(Ω)

20 2.7 2.9 3.1

25 2.8 3.0 3.3

30 2.9 3.1 3.5

F (dB)

IMR= 7 mA IMR=10mA IMR=15mA

1997 Jul 02 22

Page 23

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

handbook, full pagewidth

R/W

RDx-RDy

t

rec(W-R)

t

off(R)

TDA5153

MGG985

handbook, full pagewidth

Fig.6 Timing diagram of the reader: write-to-read switching on the same logic head.

SEN

RDx-RDy

t

sw(R)

MGG986

Fig.7 Timing diagram of the reader: typical head, current and standby-to-read characteristics.

1997 Jul 02 23

Page 24

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

14 PACKAGE OUTLINE

LQFP48: plastic low profile quad flat package; 48 leads; body 7 x 7 x 1.4 mm

c

y

X

36

37

25

Z

24

E

A

TDA5153

SOT313-2

e

w M

pin 1 index

48

1

e

DIMENSIONS (mm are the original dimensions)

mm

A

A1A2A3bpcE

max.

0.20

0.05

1.45

1.35

1.60

UNIT

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

b

p

0.25

w M

D

H

D

0.27

0.17

12

Z

D

(1) (1)(1)

D

0.18

7.1

0.12

6.9

b

p

13

v M

B

v M

0 2.5 5 mm

scale

(1)

eH

H

7.1

6.9

0.5

9.15

8.85

D

E

A

B

9.15

8.85

H

E

LLpQZywv θ

E

0.75

0.45

A

2

A

A

1

detail X

0.69

0.59

0.12 0.10.21.0

Q

(A )

3

θ

L

p

L

Z

E

D

0.95

0.55

0.95

0.55

o

7

o

0

OUTLINE

VERSION

SOT313-2

IEC JEDEC EIAJ

REFERENCES

1997 Jul 02 24

EUROPEAN

PROJECTION

ISSUE DATE

93-06-15

94-12-19

Page 25

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

15 SOLDERING

15.1 Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

15.2 Reflow soldering

Reflow soldering techniques are suitable for all LQFP

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

15.3 Wave soldering

Wave soldering is not recommended for LQFP packages.

This is because of the likelihood of solder bridging due to

closely-spaced leads and the possibility of incomplete

solder penetration in multi-lead devices.

(order code 9398 652 90011).

TDA5153

If wave soldering cannot be avoided, the following

conditions must be observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave)

soldering technique should be used.

• The footprint must be at an angle of 45° to the board

direction and must incorporate solder thieves

downstream and at the side corners.

Even with these conditions, do not consider wave

soldering LQFP packages LQFP48 (SOT313-2),

LQFP64 (SOT314-2) or LQFP80 (SOT315-1).

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

15.4 Repairing soldered joints

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

1997 Jul 02 25

Page 26

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

TDA5153

with MR-read/inductive write heads

16 DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

17 LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

1997 Jul 02 26

Page 27

Philips Semiconductors Preliminary specification

Pre-amplifier for Hard Disk Drive (HDD)

with MR-read/inductive write heads

NOTES

TDA5153

1997 Jul 02 27

Page 28

Philips Semiconductors – a worldwide company

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +61 2 9805 4455, Fax. +61 2 9805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 200 733, Fax. +375 172 200 773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 689 211, Fax. +359 2 689 102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. +45 32 88 2636, Fax. +45 31 57 0044

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615800, Fax. +358 9 61580920

France: 4 Rue du Port-aux-Vins, BP317, 92156 SURESNES Cedex,

Tel. +33 1 40 99 6161, Fax. +33 1 40 99 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 23 53 60, Fax. +49 40 23 536 300

Greece: No. 15, 25th March Street, GR 17778 TAVROS/ATHENS,

Tel. +30 1 4894 339/239, Fax. +30 1 4814 240

Hungary: see Austria

India: Philips INDIA Ltd, Shivsagar Estate, A Block, Dr. Annie Besant Rd.

Worli, MUMBAI 400 018, Tel. +91 22 4938 541, Fax. +91 22 4938 722

Indonesia: see Singapore

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, PO Box 18053,

TEL AVIV 61180, Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IV Novembre 3,

20124 MILANO, Tel. +39 2 6752 2531, Fax. +39 2 6752 2557

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. +81 3 3740 5130, Fax. +81 3 3740 5077

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381

Middle East: see Italy

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Ul. Lukiska 10, PL 04-123 WARSZAWA,

Tel. +48 22 612 2831, Fax. +48 22 612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 7430 Johannesburg 2000,

Tel. +27 11 470 5911, Fax. +27 11 470 5494

South America: Rua do Rocio 220, 5th floor, Suite 51,

04552-903 São Paulo, SÃO PAULO - SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 829 1849

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 3 301 6312, Fax. +34 3 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 632 2000, Fax. +46 8 632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2686, Fax. +41 1 481 7730

Taiwan: Philips Semiconductors, 6F, No. 96, Chien Kuo N. Rd., Sec. 1,

TAIPEI, Taiwan Tel. +886 2 2134 2865, Fax. +886 2 2134 2874

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. +90 212 279 2770, Fax. +90 212 282 6707

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 181 730 5000, Fax. +44 181 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 625 344, Fax.+381 11 635 777

For all other countries apply to: Philips Semiconductors, Marketing & Sales Communications,

Building BE-p, P.O. Box 218, 5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. 1997 SCA54

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Internet: http://www.semiconductors.philips.com

Printed in The Netherlands 297027/25/01/pp28 Date of release: 1997Jul 02 Document order number: 9397 750 01904

Loading...

Loading...