Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA5145

Brushless DC motor drive circuit

Product specification

Supersedes data of March 1992

File under Integrated Circuits, IC11

Philips Semiconductors

June 1994

Page 2

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

FEATURES

• Full-wave commutation (using push/pull drivers at the

output stages) without position sensors

• Built-in start-up circuitry

• Three push-pull outputs:

– output current 2.0 A (typ.)

– built-in current limiter

– soft-switching outputs for low Electromagnetic

Interference (EMI)

• Thermal protection

• Flyback diodes

• Tacho output without extra sensor

• Motor brake facility

• Direction control input

• Reset function

• Transconductance amplifier for an external control

transistor.

APPLICATIONS

• General purpose spindle driver e.g.:

– Hard disk drive

– Tape drive

– Optical disk drive.

GENERAL DESCRIPTION

The TDA5145 is a bipolar integrated circuit used to drive

3-phase brushless DC motors in full-wave mode. The

device is sensorless (saving of 3 hall-sensors) using the

back-EMF sensing technique to sense the rotor position.

It includes bidirectional control, brake function and has a

special circuit built-in to reduce the EMI (soft switching

output stages).

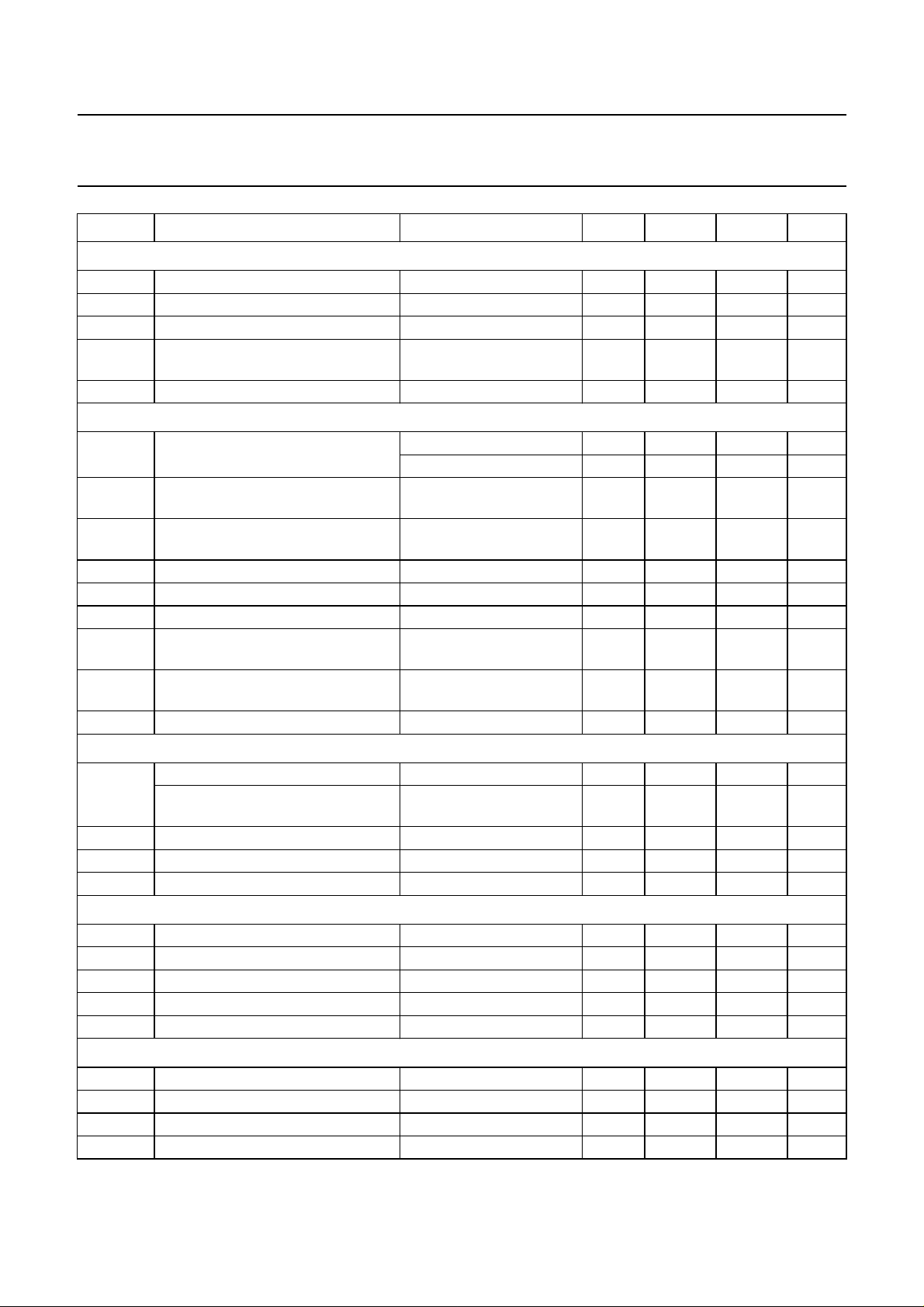

QUICK REFERENCE DATA

Measured over full voltage and temperature range.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

P

V

VMOT

supply voltage note 1 4 − 18 V

input voltage to the output driver

note 2 1.7 − 16 V

stages

V

I

DO

LIM

drop-out output voltage IO= 100 mA − 0.90 1.05 V

current limiting V

= 10 V; RO= 1.2 Ω 1.8 2.0 2.5 A

VMOT

Notes

1. An unstabilized supply can be used.

2. V

= VP; +AMP IN = −AMP IN = 0 V; all outputs IO = 0 mA.

VMOT

ORDERING INFORMATION

PACKAGE

TYPE NUMBER

PINS PIN POSITION MATERIAL CODE

TDA5145 28 DIL plastic SOT117-1

TDA5145T 28 SOL plastic SOT136-1

June 1994 2

Page 3

Philips Semiconductors Product specification

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

BBBBBBBBBBBBBB

B

B

B

B

B

BBBBBBBBBBBB

B

B

B

B

B

B

B

BBBBBBBBBBBBB

B

B

B

BBBBBBBBB

B

B

B

B

B

BBBBBBBBBBBBB

B

B

B

B

B

B

B

B

B

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBB

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

BBBBBBBBBBBBBBBBBBBB

B

B

B

B

BBBBBBBBB

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

Brushless DC motor drive circuit TDA5145

BLOCK DIAGRAM

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

Pin numbers for both DIL and SOL packages are identical.

June 1994 3

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBBBBBB

BBBBBBBB

BBBBBBBB

BBBBBBBB

BBBBBBBB

BBBBBBBB

BBBBBBBB

BBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

BBBBBBBBBBBBB

Fig.1 Block diagram.

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBB

Page 4

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

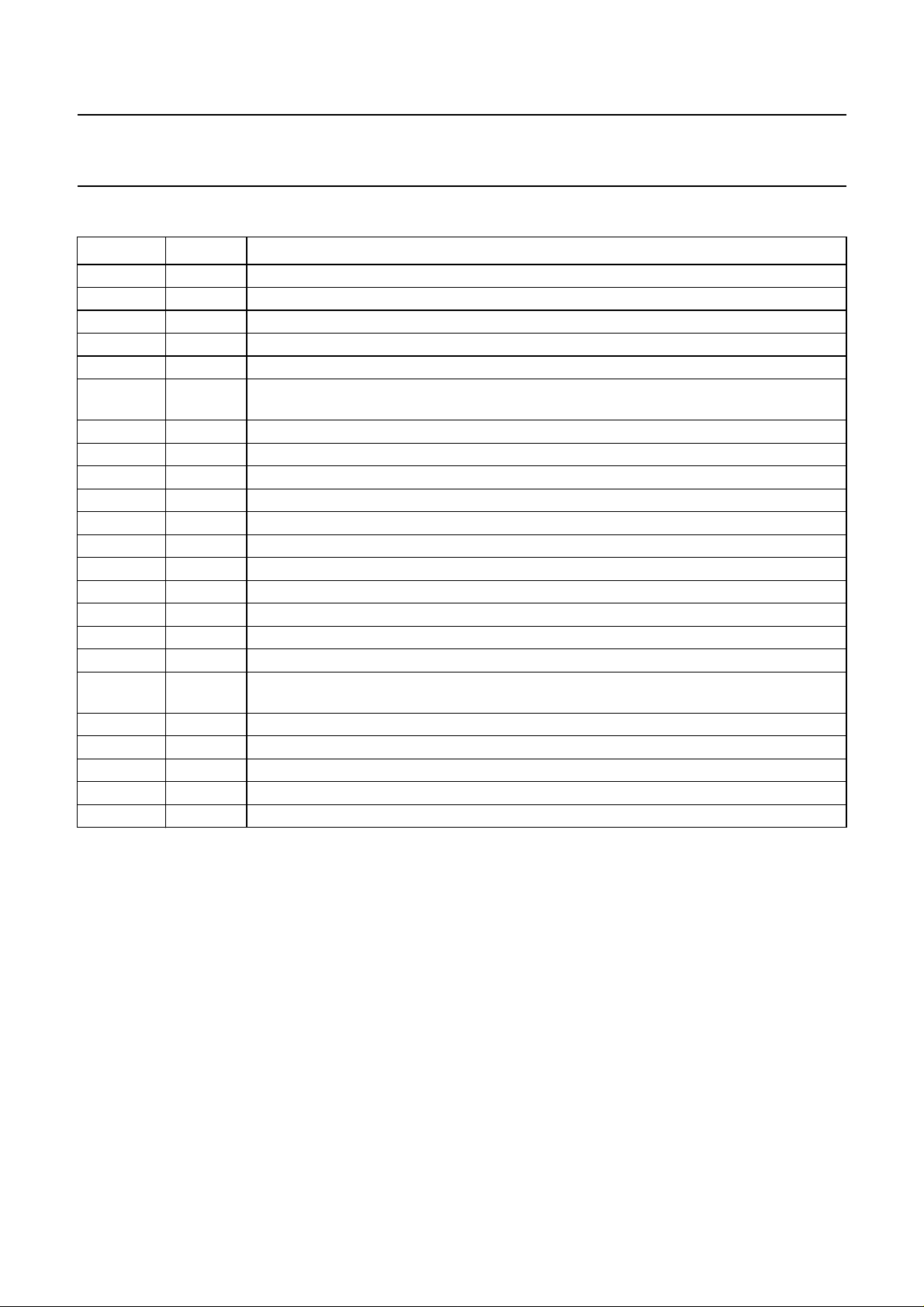

PINNING

SYMBOL PIN

MOT1 1 and 2 driver output 1

TEST 3 test input/output

n.c. 4 not connected

MOT2 5 and 6 driver output 2

VMOT 7 and 8 input voltage for the output driver stages

BRAKE 9 brake input; this pin may not be left floating, a LOW level voltage must be applied to disable

DIR 10 direction control input; this pin may not be left floating

FG 11 frequency generator: output of the rotation speed (open collector digital output)

GND2 12 ground supply return for control circuits

V

P

CAP-CD 14 external capacitor connection for adaptive communication delay timing

CAP-DC 15 external capacitor connection for adaptive communication delay timing copy

CAP-ST 16 external capacitor connection for start-up oscillator

CAP-TI 17 external capacitor connection for timing

+AMP IN 18 non-inverting input of the transconductance amplifier

−AMP IN 19 inverting input of the transconductance amplifier

n.c. 20 not connected

RESET 21 reset input; this pin may not be left floating, a LOW level voltage must be applied to disable

AMP OUT 22 transconductance amplifier output (open collector)

MOT3 23 and 24 driver output 3

n.c. 25 not connected

MOT0 26 input from the star point of the motor coils

GND1 27 and 28 ground (0 V) motor supply return for output stages

(1)

this function

13 supply voltage

this function

DESCRIPTION

Note

1. Pin numbers for both DIL and SOL packages are identical.

June 1994 4

Page 5

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

FUNCTIONAL DESCRIPTION

The TDA5145 offers a sensorless three phase motor drive

function. It is unique in its combination of sensorless motor

drive and full-wave drive. The TDA5145 offers protected

outputs capable of handling high currents and can be used

with star or delta connected motors. It can easily be

adapted for different motors and applications. The

TDA5145 offers the following features:

• Sensorless commutation by using the motor EMF.

• Built-in start-up circuit.

• Optimum commutation, independent of motor type or

motor loading.

• Built-in flyback diodes.

• Three phase full-wave drive.

• High output current (2.0 A).

• Outputs protected by current limiting and thermal

protection of each output transistor.

• Low current consumption by adaptive base-drive.

• Soft-switching pulse output for low radiation.

• Accurate frequency generator (FG) by using the

motor EMF.

• Direction of rotation controlled by one pin.

• Uncommitted operational transconductance amplifier

(OTA), with a high output current, for use as a control

Fig.2 Pin configuration.

amplifier.

• Brake function.

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

P

V

I

supply voltage − 18 V

input voltage; all pins except

VI< 18 V −0.3 VP + 0.5 V

VMOT

V

VMOT

V

O

V

I

VMOT input voltage −0.5 17 V

output voltage

AMP OUT and FG GND V

MOT0, MOT1, MOT2 and MOT3 −1V

input voltage CAP-ST, CAP-TI,

− 2.5 V

P

VMOT

+ V

DHF

V

V

CAP-CD and CAP-DC

T

stg

T

amb

P

tot

V

es

storage temperature −55 +150 °C

operating ambient temperature 0 +70 °C

total power dissipation see Figs 3 and 4 −− W

electrostatic handling see Chapter “Handling” − 2000 V

June 1994 5

Page 6

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

3.08

1.75

P

(W)

6

tot

4

2

0

50

0 200

50 100 150

70

T ( C)

handbook, halfpage

Fig.3 Power derating curve (SOT117-1; DIL28).

HANDLING

amb

MBD866

o

MBD557

o

T ( C)

amb

P

(W)

1.62

3

tot

2

1

0

50

0 200

50 100 150

Fig.4 Power derating curve (SOT136-1; SO28L).

Every pin withstands the ESD test according to

“MIL-STD-883C class 2”

. Method 3015 (HBM 1500 Ω, 100 pF) 3 pulses +

and 3 pulses − on each pin referenced to ground.

CHARACTERISTICS

= 14.5 V; T

V

P

=25°C; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

P

I

P

V

VMOT

supply voltage note 1 4 − 18 V

supply current note 2 − 6.8 7.8 mA

input voltage to the output driver

see Fig.1 1.7 − 16 V

stages

Thermal protection

T

SD

local temperature at temperature

130 140 150 °C

sensor causing shut-down

∆T reduction in temperature before

after shut-down − T

− 30 − K

SD

switch-on

June 1994 6

Page 7

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

MOT0; centre tap

V

I

I

I

V

CSW

∆V

CSW

input voltage −0.5 − V

input bias current 0.5 V < VI< V

comparator switching level note 3 ±20 ±25 ±30 mV

variation in comparator switching

levels

V

hys

comparator input hysteresis − 75 −µV

MOT1, MOT2 and MOT3; see Fig.5

V

∆V

DO

OL

drop-out output voltage IO= 100 mA − 0.9 1.05 V

variation in saturation voltage

between lower transistors

∆V

OH

variation in saturation voltage

between upper transistors

I

LIM

t

r

t

f

V

DHF

V

DLF

I

DM

current limiting V

rise time switching output V

fall time switching output V

diode forward voltage (diode DH)I

diode forward voltage (diode DL)I

peak diode current note 5 −− 2.5 A

+AMP IN and −AMP IN

V

I

input voltage −0.3 − VP− 1.7 V

differential mode voltage without

‘latch-up’

I

b

C

I

V

offset

input bias current −− 650 nA

input capacitance − 4 − pF

input offset voltage −− 10 mV

AMP OUT (open collector)

I

V

V

sink

sat

O

output sink current 40 −−mA

saturation voltage II=40mA − 1.5 2.1 V

output voltage −0.5 − +18 V

SR slew rate R

G

tr

transfer gain 0.3 −−S

DIR

V

IH

V

IL

I

IL

I

IH

HIGH level input voltage 4 V < VP< 18 V 2.0 −−V

LOW level input voltage 4 V < VP<18V −− 0.8 V

LOW level input current −−20 −µA

HIGH level input current − 20 −µA

VMOT

− 1.5 V −10 −−µA

VMOT

−− 3mV

I

= 1000 mA − 1.6 1.85 V

O

IO= 100 mA −− 180 mV

IO= −100 mA −− 180 mV

= 10 V; RO= 1.2 Ω 1.8 2.0 2.5 A

VMOT

= 15 V; see Fig.6 5 10 15 µs

VMOT

= 15 V; see Fig.6 10 15 20 µs

VMOT

=−500 mA;

O

−− 1.5 V

notes 4 and 5; see Fig.1

= 500 mA;

O

−1.5 −−V

notes 4 and 5; see Fig.1

−− ±V

= 330 Ω; CL=50pF − 60 − mA/µs

L

P

V

V

June 1994 7

Page 8

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

RESET

V

IH

HIGH level input voltage reset mode;

4V<VP<18V

V

IL

LOW level input voltage normal mode;

4V<VP<18V

I

IL

I

IH

LOW level input current VI= 2.0 V −−20 −µA

HIGH level input current VI= 0.8 V − 20 −µA

BRAKE

V

IH

HIGH level input voltage brake mode;

4V<VP<18V

V

IL

LOW level input voltage normal mode;

4V<VP<18V

I

IL

I

IH

LOW level input current VI= 2.0 V −−20 −µA

HIGH level input current VI= 0.8 V − 20 −µA

FG (open collector)

V

OL

V

OH(max)

t

THL

LOW level output voltage IO= 1.6 mA −− 0.4 V

maximum HIGH level output voltage V

HIGH-to-LOW transition time CL= 50 pF; RL=10kΩ− 0.5 −µs

ratio of FG frequency and

commutation frequency

δ duty factor − 50 − %

2.0 −−V

−− 0.8 V

2.0 −−V

−− 0.8 V

P

−−V

− 1:2 −

CAP-ST

I

sink

I

source

V

SWL

V

SWH

CAP-TI

I

sink

I

source

V

SWL

V

SWM

V

SWH

CAP-CD

I

sink

I

source

I

sink/Isource

V

IL

V

IH

output sink current 1.5 2.0 2.5 µA

output source current −2.5 −2.0 −1.5 µA

LOW level switching voltage − 0.20 − V

HIGH level switching voltage − 2.20 − V

output sink current − 28 −µA

output source current 0.2 V < V

0.3V<V

< 0.3 V −−57 −µA

CAP-TI

< 2.2 V −−5−µA

CAP-TI

LOW level switching voltage − 50 − mV

MIDDLE level switching voltage − 0.30 − V

HIGH level switching voltage − 2.20 − V

output sink current 10.6 16.2 22 µA

output source current −5.3 −8.1 −11 µA

ratio of sink to source current 1.85 2.05 2.25

LOW level input voltage 850 875 900 mV

HIGH level input voltage 2.3 2.4 2.55 V

June 1994 8

Page 9

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

CAP-DC

I

sink

I

source

I

sink/Isource

V

IL

V

IH

Notes

1. An unstabilized supply can be used.

2. V

VMOT=VP

3. Switching levels with respect to MOT1, MOT2 and MOT3.

4. Drivers are in the high-impedance OFF-state.

5. The outputs are short-circuit protected by limiting the current and the IC temperature.

output sink current 10.1 15.5 20.9 µA

output source current −20.9 −15.5 −10.1 µA

ratio of sink to source current 0.9 1.025 1.15

LOW level input voltage 850 875 900 mV

HIGH level input voltage 2.3 2.4 2.55 V

, all other inputs at 0 V; all outputs at VP; IO= 0 mA.

Fig.5 Switching levels with respect to MOT1, MOT2 and MOT3.

Fig.6 Output transition time measurement.

June 1994 9

Page 10

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

APPLICATION INFORMATION

(1) Value selected for 3 Hz start-up oscillator frequency.

Fig.7 Application diagram without use of the operational transconductance amplifier (OTA).

Introduction (see Fig.8)

Full-wave driving of a three phase motor requires three

push-pull output stages. In each of the six possible states

two outputs are active, one sourcing (H) and one sinking

(L). The third output presents a high impedance (Z) to the

motor, which enables measurement of the motor

back-EMF in the corresponding motor coil by the EMF

comparator at each output. The commutation logic is

responsible for control of the output transistors and

selection of the correct EMF comparator. In Table 1 the

sequence of the six possible states of the outputs has

been depicted.

The zero-crossing in the motor EMF (detected by the

comparator selected by the commutation logic) is used to

calculate the correct moment for the next commutation,

that is, the change to the next output state. The delay is

calculated (depending on the motor loading) by the

adaptive commutation delay block.

Because of high inductive loading the output stages

contain flyback diodes. The output stages are also

protected by a current limiting circuit and by thermal

protection of the six output transistors.

Table 1 Output states.

STATE MOT1

(1)

MOT2

(1)

MOT3

(1)

1ZLH

2HLZ

3HZL

4ZHL

5LHZ

6LZH

Note

1. H = HIGH state;

L = LOW state;

Z = high-impedance OFF-state.

The detected zero-crossings are used to provide speed

information. The information has been made available on

the FG output pin. This is an open collector output and

provides an output signal with a frequency that is half the

commutation frequency.

The system will only function when the EMF voltage from

the motor is present. Therefore, a start oscillator is

June 1994 10

Page 11

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

provided that will generate commutation pulses when no

zero-crossings in the motor voltage are available.

A timing function is incorporated into the device for internal

timing and for timing of the reverse rotation detection.

The TDA5145 also contains an uncommitted

transconductance amplifier (OTA) that can be used as a

control amplifier. The output is capable of directly driving

an external power transistor.

The TDA5145 is designed for systems with low current

consumption: use of I2L logic, adaptive base drive for the

output transistors (patented).

Adjustments

The system has been designed in such a way that the

tolerances of the application components are not critical.

However, the approximate values of the following

components must still be determined:

• The start capacitor; this determines the frequency of the

start oscillator.

• The two capacitors in the adaptive commutation delay

circuit; these are important in determining the optimum

moment for commutation, depending on the type and

loading of the motor.

• The timing capacitor; this provides the system with its

timing signals.

T

HE START CAPACITOR (CAP-ST)

f

osc

=

1

---------------------------------- K

I× p×

t

---------------------- -

2π

J

where:

K

= torque constant (N.m/A)

t

I = current (A)

p = number of magnetic pole-pairs

J = inertia J (kg.m2)

Example: J = 72 × 10−6kg.m2, K = 25 × 10−3N.m/A,p=6

and I = 0.5 A; this gives f

= 5 Hz. If the damping is high

osc

then a start frequency of 2 Hz can be chosen or

t = 500 ms, thus C = 0.5/2 = 0.25 µF (choose 220 nF).

T

HE ADAPTIVE COMMUTATION DELAY (CAP-CD AND

CAP-DC)

In this circuit capacitor CAP-CD is charged during one

commutation period, with an interruption of the charging

current during the diode pulse. During the next

commutation period this capacitor (CAP-CD) is discharged

at twice the charging current. The charging current is

8.1 µA and the discharging current 16.2 µA; the voltage

range is from 0.9 to 2.2 V. The voltage must stay within

this range at the lowest commutation frequency of

interest, f

C

==

:

C1

8.1 10

×

-------------------------f 1.3×

6–

6231

(C in nF)

------------ f

C1

This capacitor determines the frequency of the start

oscillator. It is charged and discharged, with a current of

2 µA, from 0.05 to 2.2 V and back to 0.05 V. The time

taken to complete one cycle is given by:

t

= (2.15 × C) s (with C in µF)

start

The start oscillator is reset by a commutation pulse and so

is only active when the system is in the start-up mode. A

pulse from the start oscillator will cause the outputs to

change to the next state (torque in the motor). If the

movement of the motor generates enough EMF the

TDA5145 will run the motor. If the amount of EMF

generated is insufficient, then the motor will move one step

only and will oscillate in its new position. The amplitude of

the oscillation must decrease sufficiently before the arrival

of the next start pulse, to prevent the pulse arriving during

the wrong phase of the oscillation. The oscillation of the

motor is given by:

June 1994 11

If the frequency is lower, then a constant commutation

delay after the zero-crossing is generated by the discharge

from 2.2 to 0.9 V at 16.2 µA;

maximum delay = (0.076 × C) ms (with C in nF)

Example: nominal commutation frequency = 900 Hz and

the lowest usable frequency = 400 Hz; so:

CAP-CD

6231

------------ 400

(choose 18 nF)

15.6==

The other capacitor, CAP-DC, is used to repeat the same

delay by charging and discharging with 15.5 µA. The same

value can be chosen as for CAP-CD. Figure 9 illustrates

typical voltage waveforms.

Page 12

Philips Semiconductors Product specification

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

BBBBBBBBBBBB

B

B

B

B

BBBBBBBBBB

BBBBBBBBBB

B

B

BBBBBBB

B

B

B

B

BBBBBBBBBB

B

B

B

B

B

B

B

B

B

B

BBBBBBBB

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

BBBBBB

Brushless DC motor drive circuit TDA5145

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBBBB

BBBBBBBBB

BBBBBBBBB

BBBBBBBBB

BBBBBBBBB

BBBBBBB

BBBBBBB

BBBBBBB

BBBBBBB

BBBBBBB

BBBBBBB

BBBBBBB

BBBBBBB

BBBBBBB

BBBBBBB

BBBBBBBBB

BBBBBBBBB

BBBBBBBBB

BBBBBBBBB

BBBBBBBBBB

BBBBBBBBBB

BBBBBBBBBB

BBBBBBBBBB

BBBBBBBBBB

BBBBBB

BBBBBB

BBBBBB

BBBBBB

BBBBBB

June 1994 12

Fig.8 Typical application of the TDA5145 as a scanner driver, with use of OTA.

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

BBBBBBBBBBBBBBB

Page 13

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

Fig.9 CAP-CD and CAP-DC typical voltage waveforms in normal running mode.

THE TIMING CAPACITOR (CAP-TI)

Capacitor CAP-TI is used for timing the successive steps

within one commutation period; these steps include some

internal delays.

The most important function is the watchdog time in which

the motor EMF has to recover from a negative diode-pulse

back to a positive EMF voltage (or vice versa). A watchdog

timer is a guarding function that only becomes active when

the expected event does not occur within a predetermined

time.

The EMF usually recovers within a short time if the motor

is running normally (<<ms). However, if the motor is

motionless or rotating in the reverse direction, then the

time can be longer (>>ms).

A watchdog time must be chosen so that it is long enough

for a motor without EMF (still) and eddy currents that may

stretch the voltage in a motor winding; however, it must be

short enough to detect reverse rotation. If the watchdog

time is made too long, then the motor may run in the wrong

direction (with little torque).

The capacitor is charged, with a current of 57 µA, from

0.2 to 0.3 V. Above this level it is charged, with a current of

5 µA, up to 2.2 V only if the selected motor EMF remains

in the wrong polarity (watchdog function). At the end, or, if

the motor voltage becomes positive, the capacitor is

discharged with a current of 28 µA. The watchdog time is

the time taken to charge the capacitor, with a current of

5 µA, from 0.3 to 2.2 V.

To ensure that the internal delays are covered CAP-TI

must have a minimum value of 2 nF. For the watchdog

function a value for CAP-TI of 10 nF is recommended.

To ensure a good start-up and commutation, care must be

taken that no oscillations occur at the trailing edge of the

flyback pulse. Snubber networks at the outputs should be

critically damped.

Typical voltage waveforms are illustrated by Fig.10.

June 1994 13

Page 14

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

If the chosen value of CAP-TI is too small oscillations can occur in certain positions of a blocked rotor. If the chosen value is too large, then it

is possible that the motor may run in the reverse direction (synchronously with little torque).

Fig.10 Typical CAP-TI and V

voltage waveforms in normal running mode.

MOT1

Other design aspects

There are other design aspects concerning the application

of the TDA5145 besides the commutation function. They

are:

• Generation of the tacho signal FG

• General purpose operational transconductance

amplifier (OTA)

• Motor control

• Direction function

• Brake function

• Reliability.

FG

SIGNAL

The FG signal is generated in the TDA5145 by using the

zero-crossing of the motor EMF from the three motor

windings. Every zero-crossing in a (star connected) motor

winding is used to toggle the FG output signal. The FG

frequency is therefore half the commutation frequency. All

transitions indicate the detection of a zero-crossing.

The accuracy of the FG output signal depends on the

symmetry of the motor's electromagnetic construction,

which also effects the satisfactory functioning of the motor

itself.

frequency of 25 × 6 × 6 = 900 Hz, and generates a tacho

signal of 450 Hz.

T

HE OPERATIONAL TRANSCONDUCTANCE AMPLIFIER (OTA)

The OTA is an uncommitted amplifier with a high output

current (40 mA) that can be used as a control amplifier.

The common mode input range includes ground (GND)

and rises to V

− 1.7 V. The high sink current enables the

P

OTA to drive a power transistor directly in an analog

control amplifier.

Although the gain is not extremely high (0.3 S), care must

be taken with the stability of the circuit if the OTA is used

as a linear amplifier as no frequency compensation has

been provided.

The convention for the inputs (inverting or not) is the same

as for a normal operational amplifier: with a resistor (as

load) connected from the output (AMP OUT) to the positive

supply, a positive-going voltage is found when the

non-inverting input (+AMP IN) is positive with respect to

the inverting input (−AMP IN). Confusion is possible

because a ‘plus’ input causes less current, and so a

positive voltage.

Example: a 3-phase motor with 6 magnetic pole-pairs at

1500 rpm and with a full-wave drive has a commutation

June 1994 14

Page 15

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

MOTOR CONTROL

DC motors can be controlled in an analog manner using

the OTA.

For the analog control an external transistor is required.

The OTA can supply the base current for this transistor

and act as a control amplifier (see Fig.8).

D

IRECTION FUNCTION

If the voltage at pin 10 is <0.8 V, the motor is running in

one direction (depending on the motor connections). If the

voltage at pin 10 >2.0 V, the motor is running in the other

direction.

BRAKE

FUNCTION

If the voltage at pin 9 is >2.0 V, the motor brakes. In that

condition, the 3 outputs MOT1, MOT2 and MOT3 are

Table 3 Switching sequence after a reset pulse.

DIR

(1)

RESET

(1)

MOT1

(1)

H H Z L H reset

H L Z L H normal direction mode

HLHLZ

HLHZL

HLZHL

HLLHZ

HLLZH

L H H L Z reset

L L H L Z reverse direction mode

LLZLH

LLLZH

LLLHZ

LLZHL

LLHZL

forced at a LOW voltage level and the current limitation is

done internally by the sink drivers.

RESET

FUNCTION

If the voltage at pin 21 is >2.0 V, the output states are

shown in Table 2.

Table 2 Output states if V

RESET

> 2.0 V.

DRIVER OUTPUT STATE

MOT1 Z

MOT2 L

MOT3 H

Note

1. Z = high-impedance OFF-state; L = LOW state;

H = HIGH state.

MOT2

(1)

DIR

(1)

FUNCTION

sequence

sequence

(1)

Note

1. Z = high-impedance OFF-state; L = LOW state; H = HIGH state.

June 1994 15

Page 16

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

Table 4 Priority of function.

BRAKE

(1)

TEST

(1)

RESET

(1)

L L L normal

L L H reset

L H L test

L H H test

H L L brake

H L H brake

H H L brake

H H H brake

Note

1. L = LOW state; H = HIGH state.

FUNCTION

RELIABILITY

It is necessary to protect high current circuits and the

output stages are protected in two ways:

• Current limiting of the ‘lower’ output transistors. The

‘upper’ output transistors use the same base current as

the conducting ‘lower’ transistor (+15%). This means

that the current to and from the output stages is limited.

• Thermal protection of the six output transistors is

achieved by each transistor having a thermal sensor

that is active when the transistor is switched on. The

transistors are switched off when the local temperature

becomes too high.

June 1994 16

Page 17

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

PACKAGE OUTLINES

handbook, full pagewidth

seating plane

3.9

3.4

1.7

max

28

1

2.54

(13x)

36.0

35.0

1.7 max

0.53

max

15

14

0.51

min

14.1

13.7

max

0.254

4.0

15.80

15.24

5.1

max

M

0.32 max

15.24

17.15

15.90

MSA264

Dimensions in mm.

Fig.11 Plastic dual in-line package; 28 leads (600 mil) (SOT117-1; DIP28).

June 1994 17

Page 18

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

handbook, full pagewidth

S

pin 1

index

114

0.9

0.4

(4x)

18.1

17.7

1.27

0.49

0.36

0.1 S

1528

0.25 M

(28x)

2.45

2.25

0.3

0.1

10.65

10.00

detail A

7.6

7.4

1.1

0.5

1.1

1.0

0.32

0.23

0 to 8

MBC236 - 1

A

2.65

2.35

o

Dimensions in mm.

Fig.12 Plastic small outline package; 28 leads; large body (SOT136-1; SO28L).

June 1994 18

Page 19

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

SOLDERING

Plastic small-outline packages

YWAVE

B

During placement and before soldering, the component

must be fixed with a droplet of adhesive. After curing the

adhesive, the component can be soldered. The adhesive

can be applied by screen printing, pin transfer or syringe

dispensing.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder bath is

10 s, if allowed to cool to less than 150 °C within 6 s.

Typical dwell time is 4 s at 250 °C.

A modified wave soldering technique is recommended

using two solder waves (dual-wave), in which a turbulent

wave with high upward pressure is followed by a smooth

laminar wave. Using a mildly-activated flux eliminates the

need for removal of corrosive residues in most

applications.

B

Y SOLDER PASTE REFLOW

Reflow soldering requires the solder paste (a suspension

of fine solder particles, flux and binding agent) to be

applied to the substrate by screen printing, stencilling or

pressure-syringe dispensing before device placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt, infrared, and

vapour-phase reflow. Dwell times vary between 50 and

300 s according to method. Typical reflow temperatures

range from 215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 min at 45 °C.

EPAIRING SOLDERED JOINTS (BY HAND-HELD SOLDERING

R

IRON OR PULSE

-HEATED SOLDER TOOL)

Fix the component by first soldering two, diagonally

opposite, end pins. Apply the heating tool to the flat part of

the pin only. Contact time must be limited to 10 s at up to

300 °C. When using proper tools, all other pins can be

soldered in one operation within 2 to 5 s at between 270

and 320 °C. (Pulse-heated soldering is not recommended

for SO packages.)

For pulse-heated solder tool (resistance) soldering of VSO

packages, solder is applied to the substrate by dipping or

by an extra thick tin/lead plating before package

placement.

Plastic dual in-line packages

BY DIP OR WAVE

The maximum permissible temperature of the solder is

260 °C; this temperature must not be in contact with the

joint for more than 5 s. The total contact time of successive

solder waves must not exceed 5 s.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified storage maximum. If the printed-circuit board has

been pre-heated, forced cooling may be necessary

immediately after soldering to keep the temperature within

the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron below the seating plane

(or not more than 2 mm above it). If its temperature is

below 300 °C, it must not be in contact for more than 10 s;

if between 300 and 400 °C, for not more than 5 s.

June 1994 19

Page 20

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

June 1994 20

Page 21

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

NOTES

June 1994 21

Page 22

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

NOTES

June 1994 22

Page 23

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDA5145

NOTES

June 1994 23

Page 24

Philips Semiconductors – a worldwide company

Argentina: IEROD, Av. Juramento 1992 - 14.b, (1428)

BUENOS AIRES, Tel. (541)786 7633, Fax. (541)786 9367

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. (02)805 4455, Fax. (02)805 4466

Austria: Triester Str. 64, A-1101 WIEN, P.O. Box 213,

Tel. (01)60 101-1236, Fax. (01)60 101-1211

Belgium: Postbus 90050, 5600 PB EINDHOVEN, The Netherlands,

Tel. (31)40 783 749, Fax. (31)40 788 399

Brazil: Rua do Rocio 220 - 5

CEP: 04552-903-SÃO PAULO-SP, Brazil.

P.O. Box 7383 (01064-970).

Tel. (011)821-2327, Fax. (011)829-1849

Canada: INTEGRATED CIRCUITS:

Tel. (800)234-7381, Fax. (708)296-8556

DISCRETE SEMICONDUCTORS: 601 Milner Ave,

SCARBOROUGH, ONTARIO, M1B 1M8,

Tel. (0416)292 5161 ext. 2336, Fax. (0416)292 4477

Chile: Av. Santa Maria 0760, SANTIAGO,

Tel. (02)773 816, Fax. (02)777 6730

Colombia: IPRELENSO LTDA, Carrera 21 No. 56-17,

77621 BOGOTA, Tel. (571)249 7624/(571)217 4609,

Fax. (571)217 4549

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. (032)88 2636, Fax. (031)57 1949

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. (9)0-50261, Fax. (9)0-520971

France: 4 Rue du Port-aux-Vins, BP317,

92156 SURESNES Cedex,

Tel. (01)4099 6161, Fax. (01)4099 6427

Germany: PHILIPS COMPONENTS UB der Philips G.m.b.H.,

P.O. Box 10 63 23, 20043 HAMBURG,

Tel. (040)3296-0, Fax. (040)3296 213.

Greece: No. 15, 25th March Street, GR 17778 TAVROS,

Tel. (01)4894 339/4894 911, Fax. (01)4814 240

Hong Kong: PHILIPS HONG KONG Ltd., Components Div.,

6/F Philips Ind. Bldg., 24-28 Kung Yip St., KWAI CHUNG, N.T.,

Tel. (852)424 5121, Fax. (852)428 6729

India: Philips INDIA Ltd, Components Dept,

Shivsagar Estate, A Block ,

Dr. Annie Besant Rd. Worli, Bombay 400 018

Tel. (022)4938 541, Fax. (022)4938 722

Indonesia: Philips House, Jalan H.R. Rasuna Said Kav. 3-4,

P.O. Box 4252, JAKARTA 12950,

Tel. (021)5201 122, Fax. (021)5205 189

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. (01)640 000, Fax. (01)640 200

Italy: PHILIPS COMPONENTS S.r.l.,

Viale F. Testi, 327, 20162 MILANO,

Tel. (02)6752.3302, Fax. (02)6752 3300.

Japan: Philips Bldg13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. (03)3740 5028, Fax. (03)3740 0580

Korea: (Republic of) Philips House, 260-199 Itaewon-dong,

Yongsan-ku, SEOUL, Tel. (02)794-5011, Fax. (02)798-8022

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA,

SELANGOR, Tel. (03)750 5214, Fax. (03)757 4880

Mexico: Philips Components, 5900 Gateway East, Suite 200,

EL PASO, TX 79905, Tel. 9-5(800)234-7381, Fax. (708)296-8556

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB

Tel. (040)783749, Fax. (040)788399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. (09)849-4160, Fax. (09)849-7811

th

floor, Suite 51,

Norway: Box 1, Manglerud 0612, OSLO,

Tel. (022)74 8000, Fax. (022)74 8341

Pakistan: Philips Electrical Industries of Pakistan Ltd.,

Exchange Bldg. ST-2/A, Block 9, KDA Scheme 5, Clifton,

KARACHI 75600, Tel. (021)587 4641-49,

Fax. (021)577035/5874546.

Philippines: PHILIPS SEMICONDUCTORS PHILIPPINES Inc,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. (02)810 0161, Fax. (02)817 3474

Portugal: PHILIPS PORTUGUESA, S.A.,

Rua dr. António Loureiro Borges 5, Arquiparque - Miraflores,

Apartado 300, 2795 LINDA-A-VELHA,

Tel. (01)14163160/4163333, Fax. (01)14163174/4163366.

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. (65)350 2000, Fax. (65)251 6500

South Africa: S.A. PHILIPS Pty Ltd., Components Division,

195-215 Main Road Martindale, 2092 JOHANNESBURG,

P.O. Box 7430 Johannesburg 2000,

Tel. (011)470-5911, Fax. (011)470-5494.

Spain: Balmes 22, 08007 BARCELONA,

Tel. (03)301 6312, Fax. (03)301 42 43

Sweden: Kottbygatan 7, Akalla. S-164 85 STOCKHOLM,

Tel. (0)8-632 2000, Fax. (0)8-632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. (01)488 2211, Fax. (01)481 77 30

Taiwan: PHILIPS TAIWAN Ltd., 23-30F, 66, Chung Hsiao West

Road, Sec. 1. Taipeh, Taiwan ROC, P.O. Box 22978,

TAIPEI 100, Tel. (02)388 7666, Fax. (02)382 4382.

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong,

Bangkok 10260, THAILAND,

Tel. (662)398-0141, Fax. (662)398-3319.

Turkey:Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. (0212)279 2770, Fax. (0212)269 3094

United Kingdom: Philips Semiconductors Limited, P.O. Box 65,

Philips House, Torrington Place, LONDON, WC1E 7HD,

Tel. (071)436 41 44, Fax. (071)323 03 42

United States:INTEGRATED CIRCUITS:

811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. (800)234-7381, Fax. (708)296-8556

DISCRETE SEMICONDUCTORS: 2001 West Blue Heron Blvd.,

P.O. Box 10330, RIVIERA BEACH, FLORIDA 33404,

Tel. (800)447-3762 and (407)881-3200, Fax. (407)881-3300

Uruguay: Coronel Mora 433, MONTEVIDEO,

Tel. (02)70-4044, Fax. (02)92 0601

For all other countries apply to: Philips Semiconductors,

International Marketing and Sales, Building BAF-1,

P.O. Box 218, 5600 MD, EINDHOVEN, The Netherlands,

Telex 35000 phtcnl, Fax. +31-40-724825

SCD31 © Philips Electronics N.V. 1994

All rights are reserved. Reproduction in whole or in part is prohibited without the

prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation

or contract, is believed to be accurate and reliable and may be changed without

notice. No liability will be accepted by the publisher for any consequence of its

use. Publication thereof does not convey nor imply any license under patent- or

other industrial or intellectual property rights.

Printed in The Netherlands

373061/1500/02/pp24 Date of release: June 1994

Document order number: 9397 735 50011

Philips Semiconductors

Loading...

Loading...