Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA4881

Advanced monitor video controller

Preliminary specification

File under Integrated Circuits, IC02

November 1992

Page 2

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

FEATURES

• Fully DC controllable

• 3 separate video channels

• Input black level clamping

• White level adjustment for 2 channels only

GENERAL DESCRIPTION

The TDA4881 is a monolithic integrated RGB amplifier for

colour monitor systems with super VGA performance,

intended for DC or AC coupling of the colour signals to the

cathodes of the CRT. With special advantages the circuit

can be used in conjunction with the TDA4851.

• Brightness control with correct grey scale tracking

• Contrast control for all 3 channels simultaneously

• Cathode feedback to internal reference for cut-off

control, which allows unstabilized video supply voltage

• Current outputs for RGB signal currents

• RGB voltage outputs to external peaking circuits

• Blanking and switch-off input for screen protection

• Sync on green operation possible

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

P

I

P

V

l(b-w)

V

O(b-w)

positive supply voltage (pin 7) 7.2 8.0 8.8 V

supply current − 46 56 mA

input voltage (black-to-white, pins 2, 5 and 8) − 0.7 1.0 V

output voltage (black-to-white, pins 19, 16 and 13) nominal contrast and

− 0.8 − V

nominal gain

I

O(b-w)

I

M

output current (black-to-white, pins 20, 17 and 14) − 50 − mA

peak output current (pins 20, 17 and 14) −−100 mA

B bandwidth −3dB 70 −− MHz

G

G

C

∆V

T

nom

v

v

bl

amb

nominal gain − 1 − dB

gain control range for 2 channels (relative to G

contrast control range (relative to G

) −20 − +3 dB

nom

) −4 − +2 dB

nom

brightness control range nominal gain −80 − +240 mV

operating ambient temperature range 0 − +70 °C

ORDERING INFORMATION

EXTENDED

TYPE NUMBER

PINS PIN POSITION MATERIAL CODE

TDA4881 20 DIL plastic SOT146

Note

1. SOT146-1; 1996 November 27.

November 1992 2

PACKAGE

(1)

Page 3

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

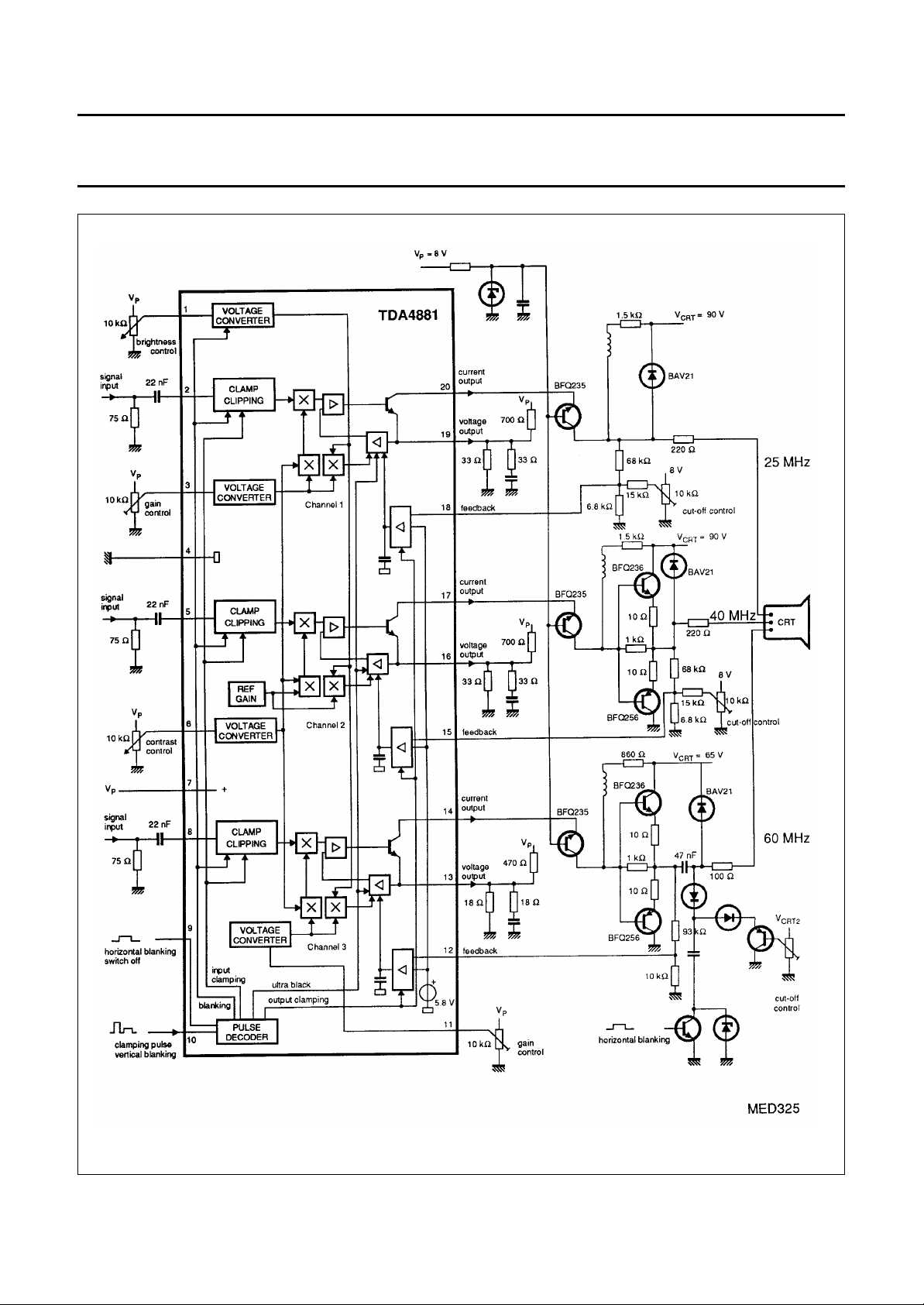

Fig.1 Block diagram and basic application circuit for DC and AC coupling.

November 1992 3

Page 4

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

PINNING

SYMBOL PIN DESCRIPTION

1 brightness control

2 signal input Channel 1

3 gain control Channel 1

5 signal input Channel 2

6 contrast control

7 supply voltage

8 signal input Channel 3

11 gain control Channel 3

12 feedback Channel 3

13 voltage output Channel 3

14 current output Channel 3

15 feedback Channel 2

16 voltage output Channel 2

17 current output Channel 2

18 feedback Channel 1

19 voltage output Channel 1

20 current output Channel 1

Fig.2 Pin configuration

BR

C

V

I1

G

C1

GND 4 ground

V

I2

C

C

V

P

V

I3

HBL 9 horizontal blanking, switch off

CL 10 input clamping, vertical blanking

G

C3

FB

3

V

O3

I

O3

FB

2

V

O2

I

O2

FB

1

V

O1

I

O1

November 1992 4

Page 5

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

FUNCTIONAL DESCRIPTION

RGB input signals (0.7 V

the TDA4881 (pins 2, 5 and 8) from a low ohmic source

and are clamped to an internal DC voltage (artificial black

level). Composite signals will not disturb normal

operations because an internal clipping circuit cuts all

signal parts below black level. Channels 1 and 3 have a

maximum total voltage gain of 6 dB (maximum contrast

and maximum individual channel gain), Channel 2 of 4 dB

(maximum contrast and nominal channel gain). With the

nominal channel gain of 1 dB and nominal contrast setting

the nominal black-to-white output amplitude is 0.8 V

DC voltages are used for brightness, contrast and gain

control.

Brightness control

shift of the three channels relative to a reference black

level. For nominal brightness (pin 1 open-circuit) the signal

black level is equal to the reference black level.

Contrast control

affects the three channels simultaneously.

To provide the correct white point, an individual

control

and 3 compared to the reference Channel 2. Gain setting

effects contrast and brightness to achieve correct grey

scale tracking. Each

output (pins 20, 17 and 14) and a voltage output (pins 19,

16 and 13). External cascode transistors reduce power

consumption of the IC and prevent breakdown of the

output transistors. Signal output currents and peaking

characteristics are determined by external components at

the voltage outputs and the video supply. The three

channels have separate internal feedback loops which

ensure large signal linearity and marginal signal distortion

in spite of output transistor thermal VBE variation.

The

only. The input signals have to be at black level during the

clamping pulse and are clamped to an internal artificial

(pins 3 and 11) adjusts the signals of Channels 1

clamping pulse

yields a simultaneous signal black level

is achieved by a voltage at pin 6 and

(pin 10) is used for

) are capacitively coupled into

(p-p)

output stage

provides a current

input clamping

(p-p)

gain

black level. The coupling capacitors are used in this way

for black level storage. Because the threshold for the

clamping pulse is higher than that for vertical blanking (pin

10) the rise and fall times of the clamping pulse have to be

faster than 75 ns/V (1 V to 3.5 V).

The

vertical blanking pulse

voltage (pin 10) is higher than the threshold voltage for

approximately 300 ns but does not exceed the threshold

for the clamping pulse in the time between. During the

vertical blanking pulse the input clamping is disabled to

avoid misclamping in the event of composite input signals.

The input signal is blanked and the artificial black level is

.

inserted instead. Additionally the brightness is internally

set to its nominal value, thus the output signal is at

reference black level. The DC value of the reference black

level will be adjusted by cut-off stabilization.

During

horizontal blanking

reference black level as previously described and

clamping

switch off

ultra black level for screen protection and spot

suppression during V-flyback. Ultra black level is the

lowest possible output voltage (at voltage outputs) and

does not depend on cut-off stabilization.

For

respectively

video signal at the cathode or the coupling capacitor is

divided by an adjustable voltage divider and fed to the

feedback inputs (pins 18, 15 and 12). During horizontal

blanking time this signal is compared with an internal DC

voltage of approximately 5.8 V. Any difference will lead to

a reference black level correction by charging or

discharging the integrated capacitor which stores the

reference black level information between the horizontal

blanking pulses.

is activated. If the voltage at pin 9 exceeds the

threshold the signal is blanked and switched to

cut-off stabilization

black level stabilization

will be detected if the input

(pin 9) the output signal is set to

(DC coupling to the CRT)

(AC coupling) the

output

November 1992 5

Page 6

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

Fig.3 Internal circuits.

November 1992 6

Page 7

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

LIMITING VALUES

In accordance with the Absolute Maximum System (IEC 134)

SYMBOL PARAMETER MIN. MAX. UNIT

V

V

V

I

I

P

T

T

T

V

P

i

ext

o

M

tot

stg

amb

j

ESD

supply voltage (pin 7) 0 8.8 V

input voltage range (pins 2, 5 and 8) −0.1 V

P

V

external DC voltage ranges

pins 20, 17 and 14 −0.1 V

P

V

pins 19, 16 and 13 no external voltages

pins 1, 3, 6 and 11 −0.1 V

pin 9 −0.1 V

pin 10 −0.7 V

P

+0.7 V

P

+0.7 V

P

V

average output current (pins 20, 17 and 14) 0 50 mA

peak output current (pins 20, 17 and 14) 0 100 mA

total power dissipation − 1200 mW

storage temperature range −25 +150 °C

operating ambient temperature range 0 +70 °C

junction temperature −25 +150 °C

electrostatic handling for all pins (note 1) −500 +500 V

Note to the Limiting Values

1. Equivalent to discharging a 200 pF capacitor through a 0 Ω series resistor.

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

th j-a

from junction to ambient in free air 65 K/W

November 1992 7

Page 8

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

CHARACTERISTICS

= 8.0 V, T

V

P

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

P

I

P

Video signal inputs

V

l(b-w)

I

2, 5, 8

Brightness control

V

1

R

1

∆V

bl1

V

N1

Contrast control (see note 2)

V

6

I

6

C

v

Tr tracking of RGB signals 2.5 V < V

Gain control

V

3, 11

R

3, 11

G

v

V

N3, N11

Feedback input

V

int

I

18, 15, 12

= +25 °C; all voltages measured to GND (pin 4); unless otherwise specified

amb

supply voltage range (pin 7) 7.2 8.0 8.8 V

supply current (pin 7) − 46 56 mA

input voltage

− 0.7 1.0 V

(black-to-white, pins 2, 5 and 8)

DC current no clamping −0.1 − 0.1 µA

during clamping ±50 −−µA

input voltage range see note 1 1.0 − 6.0 V

input resistance to V

N1

black level voltage change at nominal

gain (pins 19, 16 and 13)

V1= 1.0 V;

V

open-circuit

3, 11

= 6.0 V;

V

1

V

open-circuit

3, 11

− 50 − kΩ

−−80 − mV

− 240 − mV

input voltage for nominal brightness pin 1 open-circuit − 2.25 − V

input voltage range see note 1 1.0 − 6.0 V

current −5 −1 −µA

contrast relative to nominal contrast V6= 6.0 V;

V

open-circuit

3, 11

= 4.5 V;

V

6

V

open-circuit

3, 11

= 1.0 V;

V

6

V

open-circuit

3, 11

V

open-circuit

3, 11

< 6V;

6

− 3 − dB

− 0 − dB

−−20 − dB

− 0 0.5 dB

input voltage range see note 1 1.0 − 6.0 V

input resistance against V

N3, N11

gain relative to nominal gain V6= 4.5 V; V

= 4.5 V; V

V

6

=6V − 2 − dB

3, 11

=1V −−4−dB

3, 11

− 43 − kΩ

input voltage for nominal gain pin 3, 11 open-circuit − 4.6 − V

internal reference voltage see note 3 tbn 5.8 tbn V

output current during output clamping −1.5 −1.0 −0.1 µA

November 1992 8

Page 9

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Voltage outputs (pins 19, 16 and 13)

V

O(b-w)

signal output voltage

(black-to-white value)

V

bl

black level voltage during output clamping;

S/N signal-to-noise ratio see note 5 −−44 dB

Frequency response at voltage outputs

G

vf

gain decrease by frequency

response at pins 19, 16 and 13

t

rO

rise time at voltage output

(pins 19, 16 and 13)

V

open; V6= 4.5 V;

3, 11

V

= 0.7 V

l(b-w)

− 0.8 − V

0.3 − 1.0 V

depending on black

level adjustment;

see note 4

during switch-off − 0.1 0.3 V

70 MHz −−−3dB

10% to 90% amplitude;

− 4.5 5.0 ns

input rise time = 1 ns

Current outputs (pins 20, 17 and 14)

l

O(b-w)

V

20-19, 17-16, 14-13

signal current (black-to-white) − 50 − mA

HF saturation of output transistors IO=50mA −−2.0 V

Threshold voltages (see note 7)

V

9

threshold for horizontal blanking

(blanking, output clamping)

threshold for switch-off

(blanking, minimum black level,

no output clamping)

R

9

t

d9

input resistance referenced to ground 50 80 1 10 kΩ

delay between horizontal blanking

input and output signal blanking

V

10

threshold for vertical blanking

(blanking, no input clamping)

threshold for clamping

(input clamping, no blanking)

I

10

t

r,f10

t

w10

t

d10

input current −3 −1 −µA

rise and fall time for clamping pulse transition 1 to 3.5 V;

clamping pulse width V10= 3 V 0.6 −−µs

delay between vertical blanking input

and output signal blanking

with peaking; see note 6 −−100 mA

= 100 mA −−2.2 V

I

O

1.2 1.4 1.6 V

5.8 6.5 6.8 V

− 35 60 ns

see Fig.4 1.2 1.4 1.6 V

see Fig.4 2.6 3.0 3.5 V

−−75 ns/V

see Fig.4

see Fig.4 − 300 − ns

November 1992 9

Page 10

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

Notes to the characteristics

1. Typical range is 1 to 6 V, the range can be increased (e.g. 0 to 7 V) to slightly increase the control range.

2. Open contrast control pin leads to undefined contrast setting.

3. The internal reference voltage can be measured at pins 18, 15 and 12 during output clamping in closed feedback

loop.

4. Minimum guaranteed control range, the typical minimum black level voltage is 0.1 V.

5. The signal-to-noise ratio is calculated by the formula (frequency range 1 to 70 MHz):

peak-to-peak value of the nominal signal output voltage

---------------------------------------------------------------------------------------------------------------------------------------------------

6. The external RC combinations at pins 19, 16 and 13 enables peak currents during transients.

7. The internal threshold voltages are derived from an internally stabilized voltage. The internal pulses are generated if

the input pulses are higher than the thresholds.

RMS value of the noise output voltage

Fig.4 Timing of pulses at pin 10.

November 1992 10

Page 11

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

PACKAGE OUTLINE

DIP20: plastic dual in-line package; 20 leads (300 mil)

D

seating plane

L

Z

20

pin 1 index

e

b

SOT146-1

M

E

A

2

A

A

1

w M

b

1

11

E

c

(e )

1

M

H

1

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

max.

mm

OUTLINE

VERSION

SOT146-1

1 2

min.

max.

1.73

1.30

0.068

0.051

IEC JEDEC EIAJ

SC603

b

b

1

0.53

0.38

0.021

0.015

0.36

0.23

0.014

0.009

REFERENCES

cD E e M

(1) (1)

26.92

26.54

1.060

1.045

November 1992 11

6.40

6.22

0.25

0.24

10

(1)

M

e

L

1

3.60

8.25

3.05

7.80

0.14

0.32

0.12

0.31

EUROPEAN

PROJECTION

H

E

10.0

0.2542.54 7.62

8.3

0.39

0.010.10 0.30

0.33

ISSUE DATE

w

92-11-17

95-05-24

Z

max.

2.04.2 0.51 3.2

0.0780.17 0.020 0.13

Page 12

Philips Semiconductors Preliminary specification

Advanced monitor video controller TDA4881

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

Soldering by dipping or by wave

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

(order code 9398 652 90011).

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

Repairing soldered joints

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

stg max

). If the

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

November 1992 12

Loading...

Loading...