Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA4657

Generic multi-standard decoder

Preliminary specification

File under Integrated Circuits, IC02

June 1993

Page 2

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

FEATURES

• Low voltage (8 V)

• Low power dissipation (250 mW)

• Automatic standard recognition

GENERAL DESCRIPTION

The TDA4657 is a monolithic integrated multi-standard

colour decoder for PAL, SECAM and NTSC 4.43 MHz with

negative colour difference output signals. It is adapted to

the integrated baseband delay line TDA4660/61.

• No adjustments required

• Reduced external components

• Not all time constants integrated

(ACC, SECAM de-emphasis).

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

P

I

P

P

tot

supply voltage 7.2 8.0 8.8 V

supply current VP= 8.0 V; without load 25 31 37 mA

total power dissipation VP= 8.0 V; without load − 248 296 mW

Inputs

V

9

chrominance input voltage

note 1 20 200 400 mV

(peak-to-peak value)

V

20

sandcastle input voltage −−13.2 V

Outputs

V

1

colour difference output signals

independent of supply voltage; note 2

(peak-to-peak value)

−(R−Y) output PAL and NTSC 4.43 MHz 442 525 624 mV

SECAM 950 1050 1150 mV

V

3

−(B−Y) output PAL and NTSC 4.43 MHz 559 665 791 mV

SECAM 1200 1330 1460 mV

Notes to the quick reference data

1. Within 2 dB output voltage deviation.

2. Burstkey width 4.3 µs

Burst width 2.25 µs,

ratio burst chrominance amplitude 1/2.2.

ORDERING INFORMATION

EXTENDED

TYPE NUMBER

PINS PIN POSITION MATERIAL CODE

TDA4657 20 DIL plastic SOT146

TDA4657T 20 SO plastic SOT163A

Note

1. SOT146-1; 1996 November 26.

2. SOT163-1; 1996 November 26.

June 1993 2

PACKAGE

(1)

(2)

Page 3

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

June 1993 3

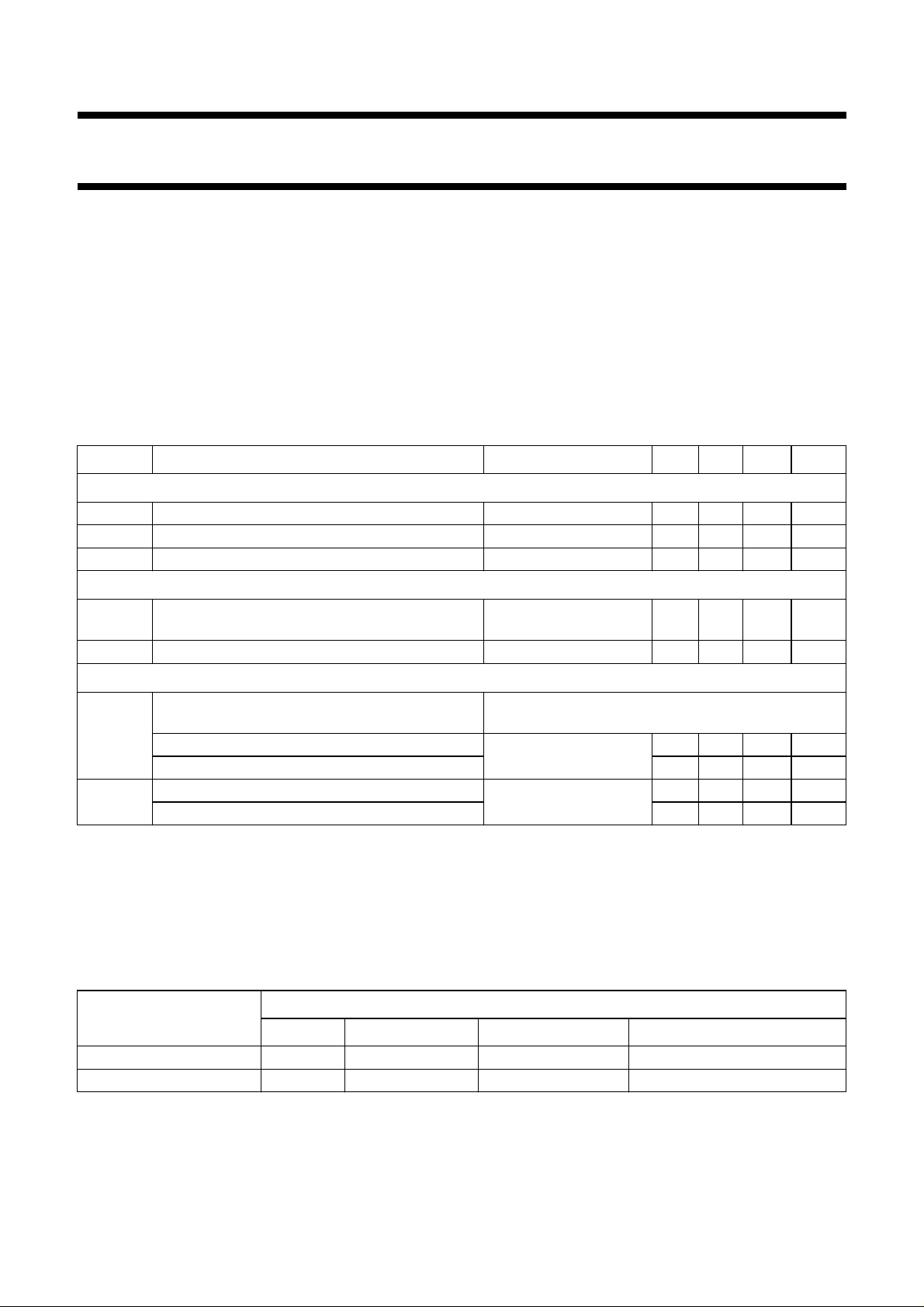

Fig.1 Block diagram.

Page 4

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

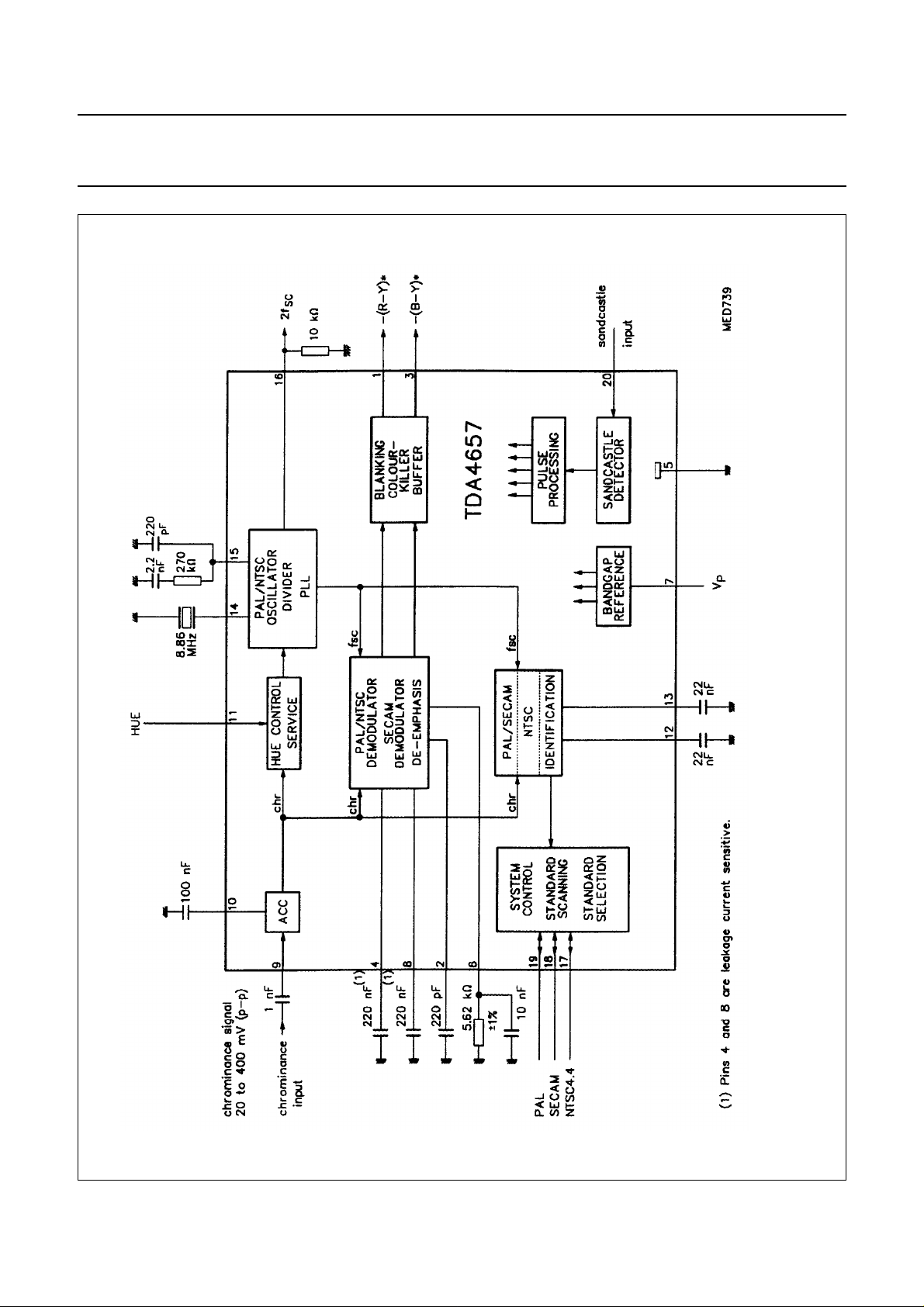

PINNING

SYMBOL PIN DESCRIPTION

−(R−Y)

DEEM 2 external capacitor for SECAM de-emphasis

−(B−Y)

CFOB 4 external capacitor SECAM demodulator control (B−Y) Channel

GND 5 ground

I

REF

V

P

CFOR 8 external capacitor SECAM demodulator control (R−Y) Channel

CHR

I

C

ACC

HUE 11 input for HUE control and service switch

N

IDT

P

IDT

OSC 14 PAL crystal

PLL 15 external loop filter

2FSC 16 2 × f

N

o

SEC

o

PAL

o

SC 20 sandcastle input

1 colour difference signal output −(R−Y)* for baseband delay line

O

3 colour difference signal output −(B−Y)* for baseband delay line

O

6 external resistor for SECAM oscillator

7 supply 8 V

9 chrominance signal input

10 external capacitor for ACC control

12 external capacitor for identification circuit (NTSC)

13 external capacitor for identification circuit (PAL and SECAM)

output

sc

17 standard setting input/output for NTSC 4.43

18 standard setting input/output for SECAM

19 standard setting input/output for PAL

Fig.2 Pin configuration.

June 1993 4

Page 5

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

FUNCTIONAL DESCRIPTION

The IC contains all functions required for the identification

and demodulation of signals with the standards PAL,

SECAM and NTSC 4.3 with 4.43 MHz colour-carrier

frequency. When an unknown signal is fed into the input,

the circuit has to detect the standard of the signal, and has

to switch on successively the appropriate input filter and

demodulator and finally, after having identified the signal,

it has to switch on the colour and, in event of NTSC

reception, the hue control. At the outputs the two colour

difference signals −(R−Y)* and −(B−Y)* are available.

ACC stage

The chrominance signal is fed into the asymmetrical input

(pin 9) of the ACC stage (Automatic Colour Control). The

input has to be AC coupled and has an input impedance of

20 kΩ in parallel with 10 pF.

To control the chrominance amplitude the modulation

independent burst amplitude is measured during the

burstkey pulse which is derived from the sandcastle pulse

present at pin 20. The generated error current is fed into

an external storage capacitor at pin 10. The integrated

error voltage controls the gain of the ACC stage so that its

output is independent of input signal variations.

The measurement is disabled during the vertical blanking

to avoid failures because of missing burst signals.

Reference signal generation

The reference signal generation is achieved by a PLL

system. The reference oscillator operates at twice the

colour-carrier frequency and is locked on the burst of the

chrominance signal (chr). A divider provides reference

signals (f

) with the correct phase relationship for the

sc

PAL/NTSC demodulator and the identification part. In the

SECAM mode the two f0 frequencies are derived from the

PAL crystal frequency by special dividers. In this mode the

oscillator is not locked to the input signal. In the NTSC

mode the hue control circuit is switched between ACC

stage and PLL. The phase shift of the signal can be

controlled by a DC voltage at pin 11. The hue control circuit

is switched off during scanning.

The reference frequency (2 × fsc) is available at pin 16 to

drive a PAL comb filter for example.

Demodulation

The demodulation of the colour signal requires two

demodulators. One is common for PAL and NTSC signals,

the other is for SECAM signals.

The PAL/NTSC demodulator consists of two synchronized

demodulators, one for the (B−Y) Channel and the other for

the (R−Y) Channel. The required reference signals (f

)

sc

are input from the reference oscillator. In NTSC mode the

PAL switch is disabled.

The SECAM demodulator consists of a PLL system.

During vertical blanking the PLL oscillator is tuned to the

f0 frequencies to provide a fixed black level at the

demodulator output. During demodulation the control

voltages are stored in the external capacitors at pins 4

and 8.

The oscillator requires an external resistor at pin 6. Behind

the PLL demodulator the signal is fed into the de-emphasis

network which consists of two internal resistors

(2.8 kΩ and 5.6 kΩ) and an external capacitor connected

at pin 2 (220 pF).

After demodulation the signal is filtered and then fed into

the next stage.

Blanking, colour killer, buffers

As a result of using only one demodulator in SECAM mode

the demodulated signal has to be split up in the (B−Y)

Channel and the (R−Y) Channel. The unwanted signals

occurring every second line, (R−Y) in the (B−Y) Channel

and (B−Y) in the (R−Y) Channel, have to be blanked. This

happens in the blanking stage by an artificial black level

being inserted alternately every second line.

To avoid disturbances during line and field flyback these

parts of the colour differential signals are blanked in all

modes.

When no signal has been identified, the colour is switched

off (signals are blanked) by the colour killer.

At the end of the colour channels are low-ohmic buffers

(emitter followers). The CD output signals −(B−Y)* and

−(R−Y)* are available at pins 1 and 3.

Identification and system control

The identification part contains three identification

demodulators.

The first demodulates in PAL mode. It is only active during

the burstkey pulse. The reference signal (fsc) has the

(R−Y) phase.

The second demodulator (PLL system) operates in

SECAM mode and is active also during the burstkey pulse,

but delayed by 2 µs.

The PLL demodulator discriminates the frequency

difference between the unmodulated f0 frequencies of the

incoming signal (chr) and the reference frequency input

from the crystal oscillator.

These two demodulators are followed by an H/2 switch

‘rectifying’ the demodulated signal. The result is an

identification signal (P

, pin 13) that is positive for a PAL

IDT

signal in PAL mode, for a SECAM signal in SECAM mode

June 1993 5

Page 6

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

and for a PAL signal in NTSC 4.4 mode. If P

in SECAM mode, the scanner switches back to the PAL

mode in order to prevent a PAL signal being erroneously

identified as a SECAM signal (PAL priority).

If then P

mode and remains there if P

is not positive, the scanner returns to SECAM

IDT

is positive again. In the

IDT

event of a field frequency of 60 Hz the signal can not be

identified as a SECAM signal, even if P

IDT

this event the scanner switches forward in the NTSC 4.4

mode. If the H/2 signal has the wrong polarity, the

identification signal is negative and the H/2 flip-flop is set

to the correct phase.

The third demodulator operates in NTSC mode and is

active during the burstkey pulse. The resulting

identification signal (N

, pin 12) is positive for PAL and

IDT

NTSC 4.4 signals in NTSC 4.4 mode. The reference signal

has the (B−Y) phase.

The two identification signals allow an unequivocal

identification of the received signal. In the event of a signal

being identified, the scanning is stopped and after a delay

time the colour is switched on.

is positive

IDT

is positive. In

pins 17, 18 and 19. During scanning the HIGH level is

2.5 V and when a signal has been identified the HIGH level

is switched to 6 V. The standard pins can also be used as

inputs in order to force the IC into a desired mode (Forced

Standard Setting).

Sandcastle detector and pulse processing

In the sandcastle detector the super sandcastle pulse (SC)

present at pin 20 is compared with three internal threshold

levels by means of three differential amplifiers. The

derived signals are the burstkey pulse, the horizontal

blanking pulse and the combined horizontal and vertical

blanking pulse. These signals are processed into various

control pulses required for the timing of the IC.

Bandgap reference

In order to ensure that the CD output signals and the

threshold levels of the sandcastle detector are

independent of supply voltage variations a bandgap

reference voltage has been integrated.

The standard outputs (active HIGH) are available at the

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

T

T

V

P

V

stg

amb

P

tot

20

storage temperature −25 +150 °C

operating ambient temperature 0 +70 °C

supply voltage − 8.8 V

power dissipation without load − 330 mW

voltage at pin 20 I

voltage at all other pins I

=10µA − 15 V

max

= 100 µA − VP+ vbeV

max

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

th j-a

thermal resistance on printed-circuit board from junction to

ambient in free air (without heat spreader)

SO 20 90 K/W

DIL 20 70 K/W

June 1993 6

Page 7

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

CHARACTERISTICS

Measured with application circuit (Fig.4) at T

200 mV (peak-to-peak value) and nominal phase for NTSC unless otherwise specified. All voltages measured

referenced to ground.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

P

supply voltage 7.2 8.0 8.8 V

I supply current V

P

tot

total power dissipation VP= 8.0 V without

CD signals outputs (pins 1 and 3)

PAL or NTSC

V

1

colour difference output signals independent of supply voltage; note 1

−(R−Y) output PAL and NTSC 4.43 MHz

(peak-to-peak value)

V

3

−(B−Y) output PAL and NTSC 4.43 MHz

(peak-to-peak value)

V

1/V3

ratio of CD signal amplitudes

V(R−Y)/V(B−Y)

m signal linearity −(R−Y) output V

signal linearity −(B−Y) output V

f

g

t

d

cut-off frequency (both outputs) −3dB − 1 − MHz

chrominance delay time 220 270 320 ns

S/N signal to noise ratio for nominal output

voltages

V

, V

1

residual carrier at CD outputs

3

1 × subcarrier frequency

(peak-to-peak value)

2 × subcarrier frequency

(peak-to-peak value)

H/2 content at R−Y output at nominal input

signal (peak-to-peak value)

A crosstalk between CD Channels −40 −− dB

R1, R

I

, I

1

3

output resistance (npn emitter follower) −−200 Ω

3

output current −−−3mA

= +25 °C, 8 V supply, 75% colour bar chrominance input signal of

amb

= 8.0 V without

P

25 31 37 mA

load

− 248 296 mW

load

442 525 624 mV

559 665 791 mV

note 2 0.75 0.79 0.83 −

= 0.8 V (p-p) 0.8 −− −

1

= 1.0 V (p-p) 0.8 −− −

3

note 3 40 −− dB

−−10 mV

−−30 mV

−−10 mV

June 1993 7

Page 8

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

SECAM

V

1

V

3

V

1/V3

m signal linearity at nominal output voltage 0.8 −− −

f

g

t

d

S/N signal to noise ratio for 100 mV (p-p) input

V

, V

1

∆V

3

∆V

1

Impedance and currents see PAL or NTSC specification

colour difference output signals independent of supply voltage; note 4

−(R−Y) output (peak-to-peak value) 0.95 1.05 1.15 V

−(B−Y) output (peak-to-peak value) 1.20 1.33 1.46 V

ratio of CD signal amplitudes

0.75 0.79 0.83 −

V(R−Y)/V(B−Y)

cut-off frequency −3dB − 730 − kHz

chrominance delay time 400 500 600 ns

note 3 40 −− dB

signal and nominal output voltages

residual carrier at CD outputs:

3

−−10 mV

1 × subcarrier frequency

(peak-to-peak value)

2 × subcarrier frequency

−−20 mV

(peak-to-peak value)

shift of demodulated f0 level relative to

note 8 − 0 ±13 mV

blanking level −(B−Y) output

−(R−Y) output − 0 ±10 mV

Capacitor for SECAM de-emphasis (pin 2)

C

2

R

A

R

B

∆(R

A/RB

value of external capacitor − 220 − pF

value of internal de-emphasis resistors T

=35°C 2.4 2.8 3.2 kΩ

amb

) relative tolerance of de-emphasis resistors −−±5%

Capacitors for SECAM demodulator control (pins 4 and 8; note 5)

∆V

1, 3

shift of demodulated f0 level due to

C

= 220 nF −−0.3 mV/nA

ext

external leakage current

Resistor for SECAM oscillator (pin 6)

V

6

R

6

C

6

DC voltage 2.4 2.81 3.2 V

value of external resistor (±1%) − 5.62 − kΩ

value of external capacitor (±20%) − 10 − nF

Chrominance input (pin 9)

V

9

R

9

C

9

input signal (peak-to-peak value) note 6 20 200 400 mV

input resistance 16 20 24 kΩ

input capacitance −−10 pF

Capacitor for ACC (pin 10; note 7)

∆V

1, 3

change of CD output signals during field

C

= 100 nF − 0.2 − %/nA

ext

blanking due to external leakage current

4.8 5.6 6.4 kΩ

June 1993 8

Page 9

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Hue control (NTSC) and service switch (pin 11)

φ phase shift of reference carrier

relative to phase at open-circuit pin 11

V

11

internal bias voltage

(proportional to supply voltage)

R

11

input resistance 25 30 35 kΩ

Capacitor for identification (pins 12 and 13)

, V

V

12

DC voltage for an identified signal 2.8 3.2 3.5 V

13

DC voltage for an unidentified signal 1.5 2.0 2.3 V

PLL oscillator measured with nominal crystal (pin 14; see Table 1)

R

14

C

14

∆f

L

initial oscillator amplifier input resistance −500 −− Ω

oscillator amplifier input capacitance −−10 pF

lock-in-range referenced to

4.43361875 MHz

φ phase difference for ±400 Hz deviation of

colour carrier frequency

=3V −30 −− degree

V

11

V

= open-circuit −50+5 degree

11

V

=5 V +30 −− degree

11

pin 11 open-circuit 3.8 4.0 4.2 V

note 9 ±400 −±1300 Hz

−−1 degree

2xf

output (pin 16; if the output is not used, the pin should be connected to supply)

sc

V

16

R

16

I

16

V

16

DC output level I16= 0 A 6.1 6.3 6.5 V

output resistance I16=0A −−350 Ω

output current −−−1.0 mA

output signal (peak-to-peak value) − 250 − mV

Standard setting inputs/outputs (pins 17 to 19; note 10)

used as output: npn emitter follower output with 0.1 mA source to ground

V

O

on-state, during scanning, colour OFF 2.3 2.5 2.7 V

on-state, colour ON 5.8 6.0 6.2 V

R

O

I

O

output resistance IO=0 −−300 Ω

output current −−−3mA

used as input: forced system switching

V

O

I

O

threshold for system ON 6.8 7.0 7.2 V

input current 100 150 180 µA

June 1993 9

Page 10

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Sandcastle pulse detector (pin 20; note 11)

C

20

V

20

System control processing (note 12)

t

d

t

s

input capacitance −−10 pF

thresholds for field and line pulse pulse ON 1.3 1.6 1.9 V

separation pulse OFF 1.1 1.4 1.7 V

line pulse separation pulse ON 3.3 3.6 3.9 V

pulse OFF 3.1 3.4 3.7 V

burst pulse separation pulse ON 5.3 5.6 5.9 V

pulse OFF 5.1 5.4 5.7 V

system hold delay in event of a signal

disappearing for a

2 − 3 field

periods

short time

colour killer; colour ON delay switching occurs

during field blanking

2 − 3 field

periods

colour OFF delay 0 − 1 field

periods

scanning time for each system − 4 − field

periods

QUALITY SPECIFICATION: URV-4-2-59/601

Notes to the characteristics

1. Burstkey width 4.3 µs.

Burst width 2.25 µs, ratio burst chrominance amplitude 1/2.2.

2. At nominal phase of hue control.

3. V (p-p) of signal divided by 6 times effective noise voltage.

4. H/2 blanking alternately every second line.

5. These pins are leakage current sensitive. Pin 4 for (B−Y) Channel, pin 8 for (R−Y) Channel.

6. Within 2 dB output voltage deviation.

7. This pin is leakage current sensitive.

8. IC only.

9. Depends also on network on pin 15.

10. Pin 19 for PAL, pin 18 for SECAM, pin 17 for NTSC 4.43 MHz.

Threshold levels are dependent of supply.

11. The field interval of the sandcastle has to be adapted to the ICs TDA2579B and TDA4690.

The thresholds are independent of supply voltage.

12. System scanning sequence: PAL, SECAM, NTSC 4.4.

June 1993 10

Page 11

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

Table 1 Specification of quartz crystals in HC-49/U13 holder; standard application.

SYMBOL PARAMETER VALUE UNIT

9922 520 00385

f

n

C

L

∆f

n

R

r

R

dld max

R

n

C

1

C

0

T

amb

∆f

n

nominal frequency 8.867570 MHz

load capacitance series resonance

adjustment tolerance of fn at +25 °C ±20 ppm

resonance resistance over temperature range ≤ 60 Ω

in the drive level range between 10

resonance resistance may not exceed (at +25 °C) the value of R

resonance resistance of unwanted response 2R

−12

W and 1.0 × 10−3W, the

dld max

tbn Ω

r (+25 °C)

Ω

motional capacitance (±20%) 14.0 fF

parallel capacitance (±20%) 3.6 pF

operating ambient temperature −10 to +60 °C

frequency tolerance over temperature ±20 ppm

June 1993 11

Page 12

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

June 1993 12

Fig.3 Internal circuits.

Page 13

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

June 1993 13

Fig.4 Application circuit.

Page 14

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

PACKAGE OUTLINES

DIP20: plastic dual in-line package; 20 leads (300 mil)

SOT146-1

seating plane

L

Z

20

pin 1 index

1

D

A

2

A

A

1

e

b

w M

b

1

11

E

10

M

E

c

(e )

1

M

H

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

max.

mm

OUTLINE

VERSION

SOT146-1

1 2

min.

max.

1.73

1.30

0.068

0.051

IEC JEDEC EIAJ

b

b

1

0.53

0.38

0.021

0.015

0.36

0.23

0.014

0.009

REFERENCES

cD E e M

(1) (1)

26.92

26.54

1.060

1.045

SC603

June 1993 14

6.40

6.22

0.25

0.24

M

e

L

1

3.60

8.25

3.05

7.80

0.14

0.32

0.12

0.31

EUROPEAN

PROJECTION

H

E

10.0

0.2542.54 7.62

8.3

0.39

0.010.10 0.30

0.33

ISSUE DATE

w

92-11-17

95-05-24

Z

max.

2.04.2 0.51 3.2

0.0780.17 0.020 0.13

(1)

Page 15

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

SO20: plastic small outline package; 20 leads; body width 7.5 mm

D

c

y

Z

20

pin 1 index

1

e

11

A

2

10

w M

b

p

SOT163-1

E

H

E

Q

A

1

L

p

L

detail X

(A )

A

X

v M

A

A

3

θ

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT163-1

A

max.

2.65

0.10

A

1

0.30

0.10

0.012

0.004

A2A

2.45

2.25

0.096

0.089

IEC JEDEC EIAJ

075E04 MS-013AC

0.25

0.01

b

3

p

0.49

0.32

0.36

0.23

0.019

0.013

0.014

0.009

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

(1)E(1) (1)

cD

13.0

7.6

7.4

0.30

0.29

1.27

0.050

12.6

0.51

0.49

REFERENCES

June 1993 15

eHELLpQ

10.65

10.00

0.419

0.394

1.4

0.055

1.1

0.4

0.043

0.016

1.1

1.0

0.043

0.039

PROJECTION

0.25

0.25 0.1

0.01

0.01

EUROPEAN

ywv θ

Z

0.9

0.4

0.035

0.004

0.016

ISSUE DATE

95-01-24

97-05-22

o

8

o

0

Page 16

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

(order code 9398 652 90011).

DIP

SOLDERING BY DIPPING OR BY WAVE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

stg max

). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

SO

REFLOW SOLDERING

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

W

AVE SOLDERING

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

R

EPAIRING SOLDERED JOINTS

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

June 1993 16

Page 17

Philips Semiconductors Preliminary specification

Generic multi-standard decoder TDA4657

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

June 1993 17

Loading...

Loading...