Page 1

®

TURBOSWITCH ULTRA-FAST HIGH VOLTAGE DIODE

MAIN PRODUCT CHARACTERISTIC S

STTA106/U

I

F(AV)

V

RRM

t

(typ) 20ns

rr

V

(max) 1.5V

F

1A

600V

FEATURES AND BENEFITS

SPECIFIC TO FREEWHEEL MODE

OPERATIONS : FREEWHEEL OR BOOSTER

DIODE

ULTRA-FAST AND SOFT RECOVERY

VERY LOW OVERALL POWER LOSSES IN

BOTH THE DIODE AND THE COMPANION

TRANSISTOR

HIGH FREQUENCY OPERATIONS

DESCRIPTION

The TURBOSWITCH is a very high performance

series of ultra-fast high voltage power diodes.

TURBOSWITCH family drastically cuts losses in

both the diode and the associated switching IGBT

and MOSFET in all freewheel mode operations

and is particulary suitable and efficient in motor

SMB

STTA106U

F126

STTA106

control freewheel applications and in booster diode

applications in power factor control circuitries.

Available either in SMB or F126 axial package,

these 600V devices are particularly intended for

use on 240V domestic mains.

ABSOLUTE RATINGS (limiting values)

Symbol Parameter Value Unit

V

RRM

I

F(RMS)

I

FRM

Repetitive peak reverse voltage 600 V

RMS forward current 6 A

Repetitive peak forward current tp = 5 µs

10 A

F = 5kHz s quare

I

FSM

T

j

T

stg

TM : TURBOSWITCH is a trademark of STMicroelectronics

November 1999 - Ed: 5C

Surge non repetitive forward current tp = 10 ms sinusoidal 25 A

Maximum operating junction temperature 125 ° C

Storage temperature range - 65 to + 150 ° C

1/8

Page 2

STTA106/U

THERMAL AND P OW ER DATA

Symbol Parameter Test conditions Value Unit

R

th(j-I)

P

1

P

max

STATIC ELECTRICAL CHARACTE RISTICS

Symbol Parameter Test conditions Min Typ Max Unit

V

F *

I

R **

V

to

Rd Dynamic resistance 350 m

Test pulse : * tp = 380 µs, δ < 2%

Junction to lead SMB 23 °C/W

Junction to lead L=5mm F126 45 ° C/W

Conduction power

dissipation

I

= 0.8A δ = 0.5

F(AV)

Tlead= 93°C

I

= 0.8A δ = 0.5

F(AV)

SMB 1.4 W

F126 1.4 W

Tlead= 60°C

Total power dissipation

Pmax = P1 + P3

Tlead= 90°C SMB 1.5 W

Tlead= 60°C F126 1.5 W

(P3 = 10% P1)

Forward voltage drop IF = 1A Tj = 25°C

Reve rse le akag e curre nt VR = 0.8 x

Threshold voltage Ip < 3.I

** tp = 5 ms, δ < 2%

V

RRM

F(AV)

Tj = 125°C

Tj = 25°C

Tj = 125°C 25010750

Tj = 125°C 1.15 V

1.1

1.75

1.5

V

A

µ

Ω

To evaluate the maximum conduction losses use the following equation :

P = V

x I

to

F(AV)

+ Rd x I

F2(RMS)

DYNAMIC ELECTRICAL CHARACTE RISTICS

TURN-OFF SWITCHING

Symbol Parameter Test conditions Min Typ Max Unit

t

rr

Reverse

recover y time

I

RM

Maximum

recover y curre nt

S factor Softness factor Tj = 125°C V

Tj = 25°C

I

= 0.5 A IR = 1A Irr = 0.25A

F

I

= 1 A dIF/dt =-50A/µs VR = 30V

F

20

50

Tj = 125°C VR = 400V IF = 1A

dI

/dt = -8 A/µs

F

dI

/dt = -50 A/µs1.6

F

= 400V IF =1A

R

dI

/dt = -50 A/µs1.1

F

0.6

TURN-ON SWITCHING

Symbol Parameter Test conditions Min Typ Max Unit

t

fr

Forward

recove ry time

V

Fp

Peak forward

Tj = 25°C

I

= 1 A, dIF/dt = 8 A/µs

F

measured at 1.1

×

VF max

500 ns

10 V

voltage

ns

A

/

2/8

Page 3

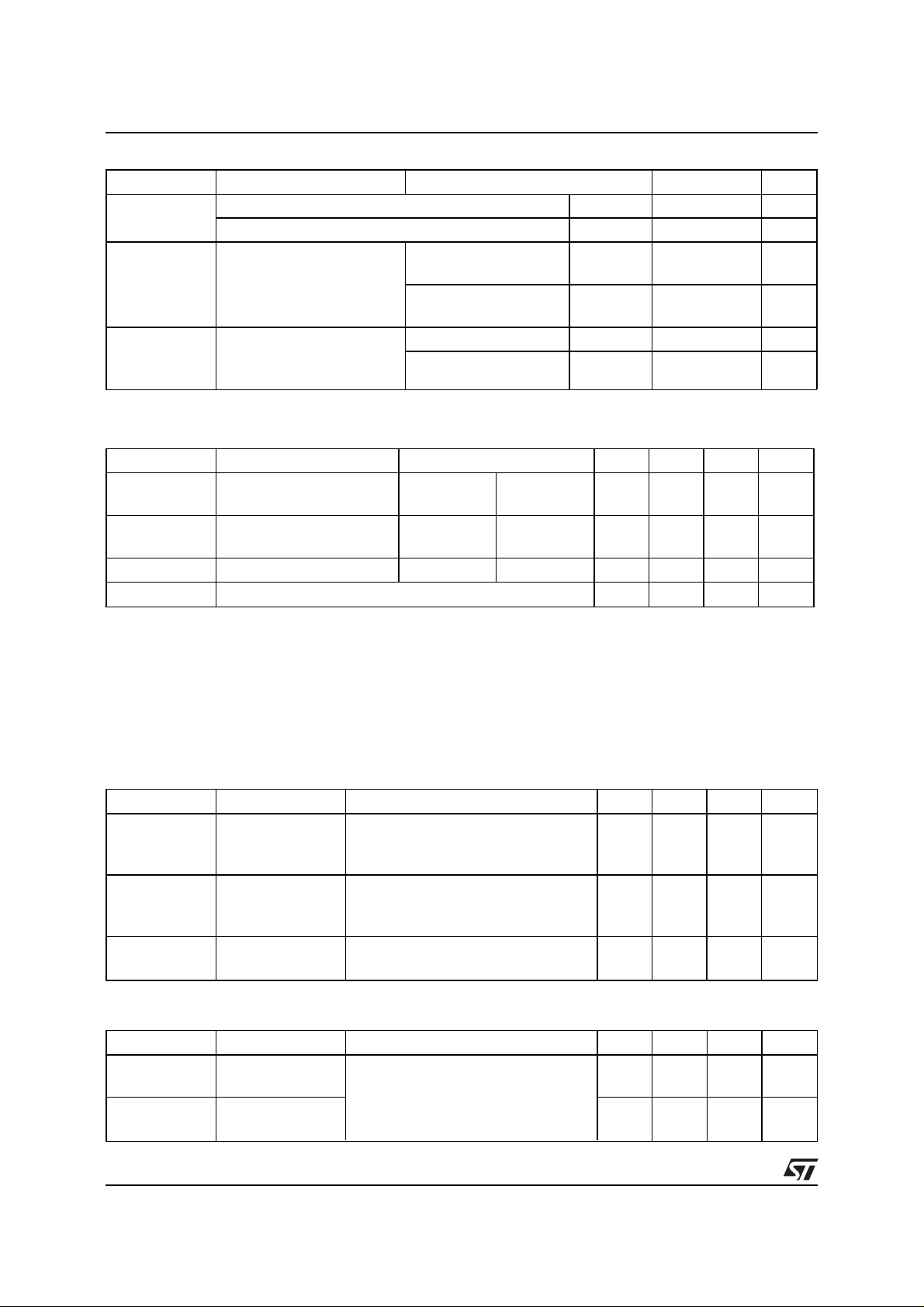

: Conduction losses versus average current.

Fig. 1

Forward voltage drop versus forward cur-

Fig. 2:

rent (maximum values).

STTA106/U

P1(W)

1.8

1.6

1.4

1.2

δ = 0.05

δ = 0.1

δ = 0.2

δ = 0.5

δ = 1

1.0

0.8

0.6

0.4

0.2

0.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1

Peak re verse r ecovery current v ersus dI

Fig. 3:

IF(av) (A)

(90% confidence).

IRM(A)

8

VR=400V

7

Tj=125°C

6

5

4

3

2

1

0

0 50 100 150 200

dIF/dt(A/µs)

IF=2*IF(av)

IF=IF(av)

IFM(A)

1E+1

1E+0

1E-1

1E-2

0.0 0.5 1.0 1.5 2.0 2.5 3.0

/dt

F

Reverse recovery time versus dI

Fig. 4:

Tj=125°C

VFM(V)

Tj=25°C

/dt (90%

F

confidence).

trr(ns)

225

200

175

150

125

100

75

50

25

0

0 20 40 60 80 100 120 140 160 180 200

IF=2*IF(av)

dIF/dt(A/µs)

IF=IF(av)

VR=400V

Tj=125°C

Softness factor (tb/ta) versus dI

Fig. 5:

/dt (typical

F

values).

S factor

1.6

1.4

1.2

1.0

0.8

0.6

0 102030405060708090100

dIF/dt(A/µs)

IF=2*IF(av)

VR=400V

Tj=125°C

Fig. 6:

Relative variation of dynamic parameters

vers us junction te m pe r ature ( r eference Tj = 125°C).

1.1

1.0

0.9

0.8

0.7

25 50 75 100 125

S factor

IRM

Tj(°C)

3/8

Page 4

STTA106/U

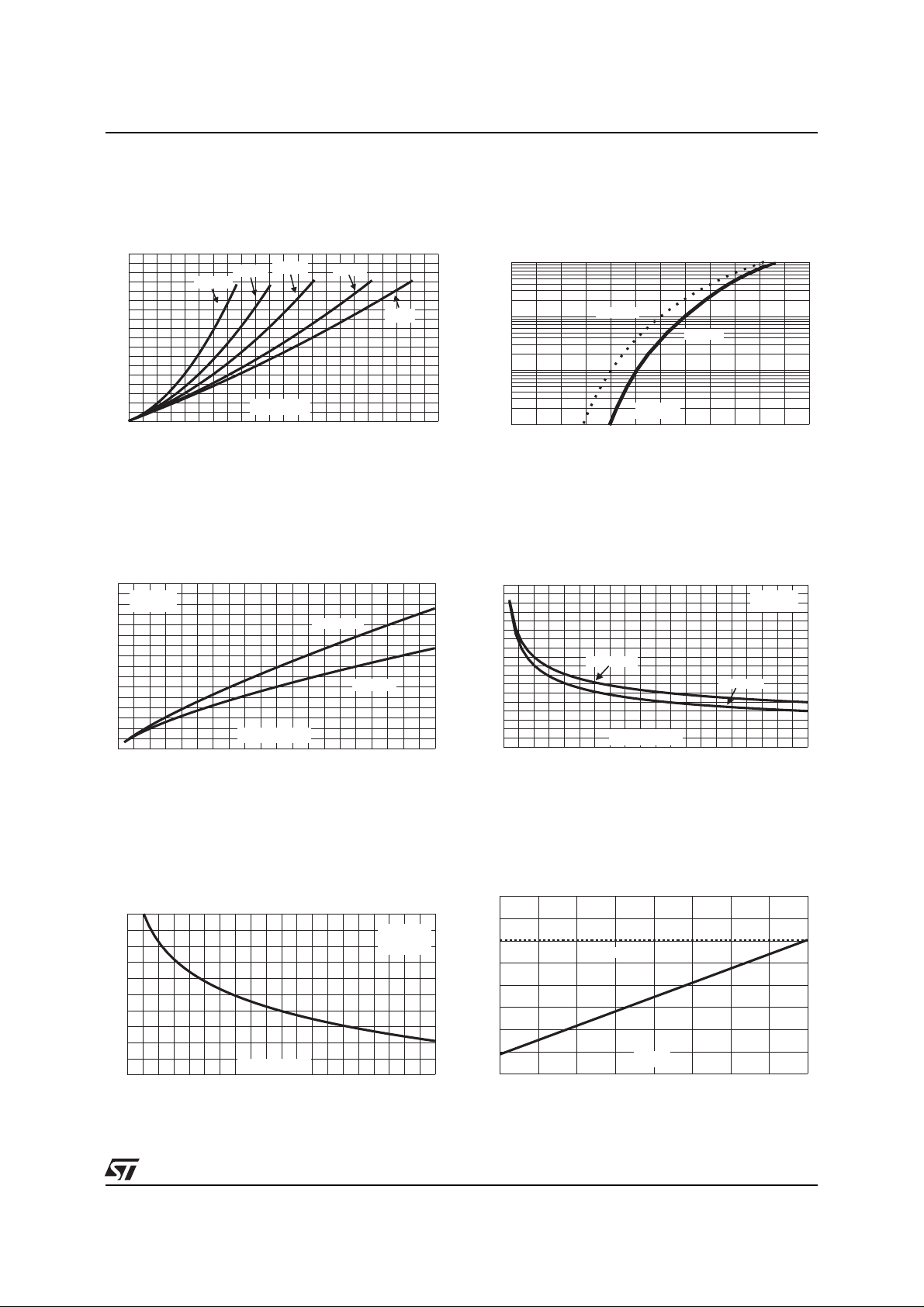

Fig. 7:

dI

40

35

30

25

20

15

10

Fig. 9:

Transient peak forward voltage versus

/dt (90% confidence).

F

VFP(V)

IF=2A

Tj=125°C

5

0

0 20 40 60 80 100 120 140 160 180 200

dIF/dt(A/µs)

Junction capacitance versus reverse volt-

age applied (typical values).

C(pF)

10

F=1MHz

Forwa rd rec ov e ry t i me v ers us dI

Fig. 8:

/dt (90%

F

confidence).

tfr(ns)

550

500

450

400

350

300

250

200

150

100

50

0

0 20 40 60 80 100 120 140 160 180 200

dIF/dt(A/µs)

IF=2A

VFR=1.1*VF max.

Tj=125°C

5

2

VR(V)

1

1 10 100 200

4/8

Page 5

APPLICATION DATA

The TURBOSWITCH

provide the lowest overall power losses in any

"Freewhell Mode" application (see fig. A)

considering both diode and companion transistor,

thus optimizing the overall performance in the end

application.

TM

is especially designed to

P = P1+ P2+ P3+ P4+ P5 Watts

TOTAL LOSSES

due to the diode

STTA106/U

The way of calculating the power losses is given

below :

Fig. A :

CONDUCTION

LOSSES

in the diode

"FREEWHEEL" MODE

SWITCHING

TRANSISTOR

V

R

tp

REVERSE

LOSSES

in the diode

SWITCHING

LOSSES

in the diode

SWITCHING

LOSSES

in the transistor

due to the diode

IL

DIODE:

TURBOSWITCH

T

F=1/T δ= tp/T

LOAD

5/8

Page 6

STTA106/U

APPLICATION DATA (Cont’d)

Fig. B :

Fig. C :

STATIC CHARACTERISTICS

I

I

F

Rd

V

R

to

V

F

V

I

R

TURN-OFF CHARACTERIS TICS

V

TRANSISTOR

I

IL

x I

to

F(AV)

losses :

x I

R

R x (1 -

losses :

losses :

+ Rd x I

)

δ

F2(RMS)

Conduction

P1 = V

V

Reverse

P2 = V

Turn-on

(in the transistor, due to the diode)

I

RM

I

2

RM

6 x

×

×

2

× (3+2 ×

dI

⁄

F

×

I

S

(

L

dI

dt

⁄

F

×

V

R

P5 =

t

+

×

V

R

S

dt

+ 2) ×

F

)

×

F

I

dI /dt

V

I

RM

I

V

trr = ta + tb

S=tb/ta

F

DIODE

tbta

dI /dt

R

trr = ta + tb S = tb / ta

dI /dt

R

RECTIFIER

OPERATION

dIF/dt = VR/L

tbta

I

RM

VR

V

t

Turn-off

t

losses (in t he diode) :

P3 =

×

V

R

I

6 x

RM

dI

2

F

× S ×

dt

⁄

F

P3 and P5 are suitable for power MOSFET and

R

IGBT

6/8

Page 7

APPLICATION DATA (Cont’d)

STTA106/U

Fig. D :

TURN-ON CHARACTERIST ICS

I

F

dI /dt

F

0

V

F

V

Fp

1.1V

F

0t

tfr

PACKAGE MECHANICAL DATA

SMB

E1

I

Fmax

Turn-on

P4

t

V

F

D

losses :

= 0.4 (VFP - VF) x I

Fmax

x t

x F

fr

DIMENSIONS

REF.

Millimeters Inches

Min. Max. Min. Max.

A1 1.90 2.45 0.075 0.096

E

C

L

FOOTPRINT DIMENSIONS

1.52 2.75

A1

A2

(in millimeters)

2.3

1.52

A2 0.05 0.20 0.002 0.008

b 1.95 2.20 0.077 0.087

c 0.15 0.41 0.006 0.016

E 5.10 5.60 0.201 0.220

E1 4.05 4.60 0.159 0.181

D 3.30 3.95 0.130 0.156

b

L 0.75 1.60 0.030 0.063

7/8

Page 8

STTA106/U

PACKAGE MECHANICAL DATA

F126

A

CC

REF.

Millimeters Inches

DIMENSIONS

Min. Typ. Max. Min. Typ. Max.

A 6.05 6.20 6.35 0.2380.244 0.250

D

B

D

B 2.95 3.00 3.05 0.1160.118 0.120

C 26 31 1.024 1.220

D 0.76 0.81 0.86 0.030 0.032 0.034

MARKING

Type Marking Package Weight Base Qty Delivery mode

STTA106U T01 SMB 0.11g 2500 tape & reel

STTA106 STTA106 F126 0.39g 1000 box

STTA106RL STTA106 F126 0.39g 6000 tape & reel

Band indicates cathode

Epoxy meets UL94,V0

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted by

implication or otherwis e under any patent or patent rights of STMicroelec tronics. Specificati ons mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products ar e not authorized for use as critical c om ponents in life support devi ces or systems without ex press written approval of STMicroelectronics.

The ST logo is a registered trademark of S TMicroelectron ics

© 1999 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

8/8

Loading...

Loading...