Page 1

■ LINEARPOWER AMPLIFIER

■ 890-915MHz

■ 12.5 VOLTS

■ INPUT/OUTPUT50 OHMS

■ POUT = 16 W MIN.

■ GAIN = 42 dB MIN.

DESCRIPTION

The STM915-16 is a linear power module

designed for 12.5 V applications in GSM Cellular

Radio Systems. The STM915-16 uses gold

metallized transistors with diffused emitter ballast

resistors for high linearity Class AB operation.

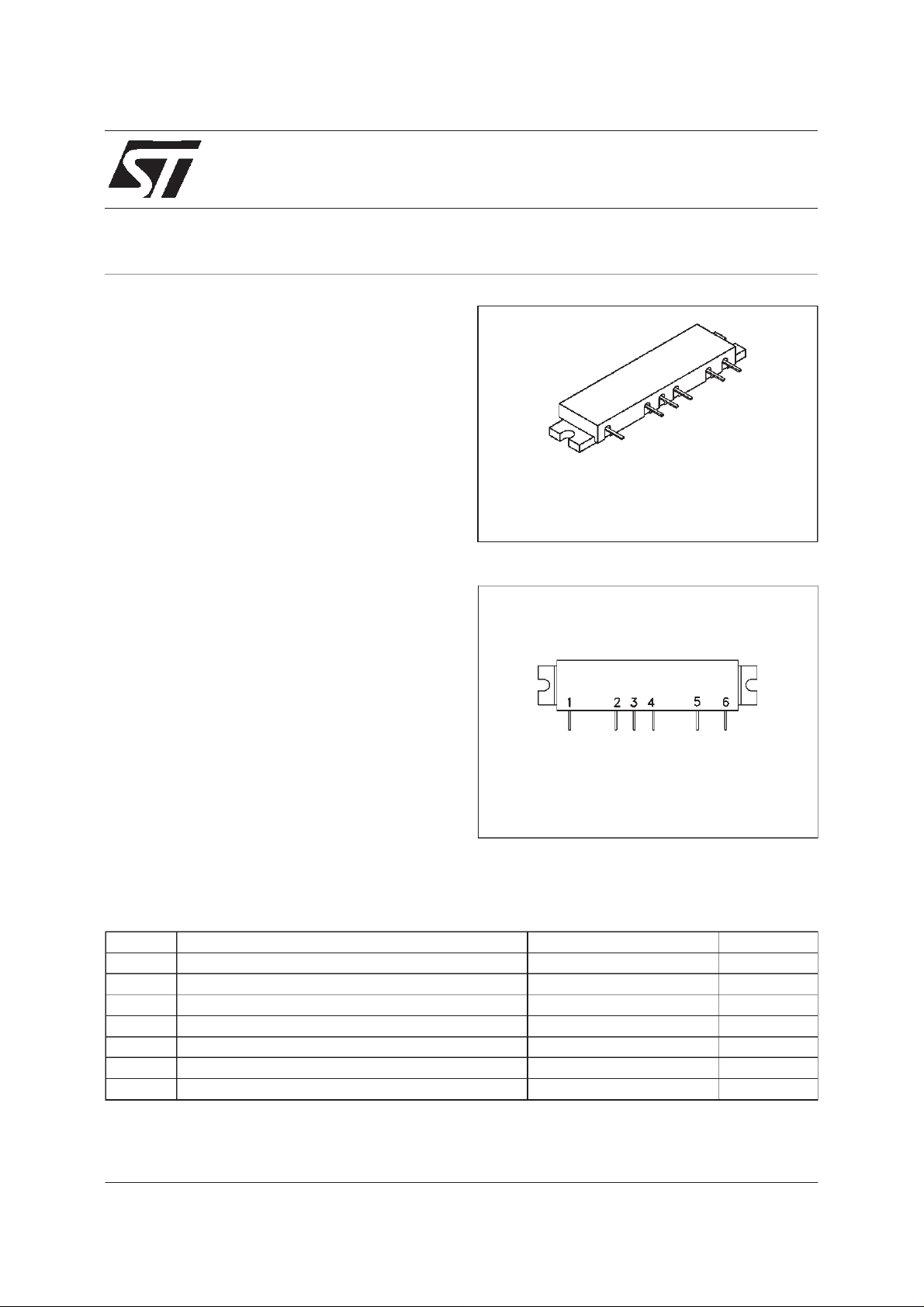

STM915-16

RF POWER MODULE

GSM MOBILE APPLICATIONS

CASE H100

ORDER CODE BRANDING

STM915-16 STM915-16

PIN CONNECTION

1 RF Input 4 8.0 Vdc

2 8.0Vdc 5 12.5 Vdc

3 12.5 Vdc 6 RF Output

ABSOLUTE MAXIMUM RATINGS (T

Symb o l Para meter Val u e Unit

V

S2,VS4

V

S1,VS3

V

CONTROL

P

P

OUT

T

T

Note1: Pulse Width= 577 µsec.

June 1999

DC Supply V olt ag e (RF appl ied / No RF ap plied ) 15.6/ 30.0 Vdc

DC Supply V olt ag e 8.5 Vdc

DC Contr o l Voltage 4.5 Vdc

RF I nput P ower (P

IN

1

RF O utpu t Power (VS2,VS4=12.5V) 20 W

Sto rage Tempe r ature - 30 to + 100

STG

Oper ating Case Tem peratu re - 30 to + 100

C

Repetition rate = 4.6 msec.

OUT

=25oC)

case

≤ 17 W)

3.0 mW

o

C

o

C

1/7

Page 2

STM915-16

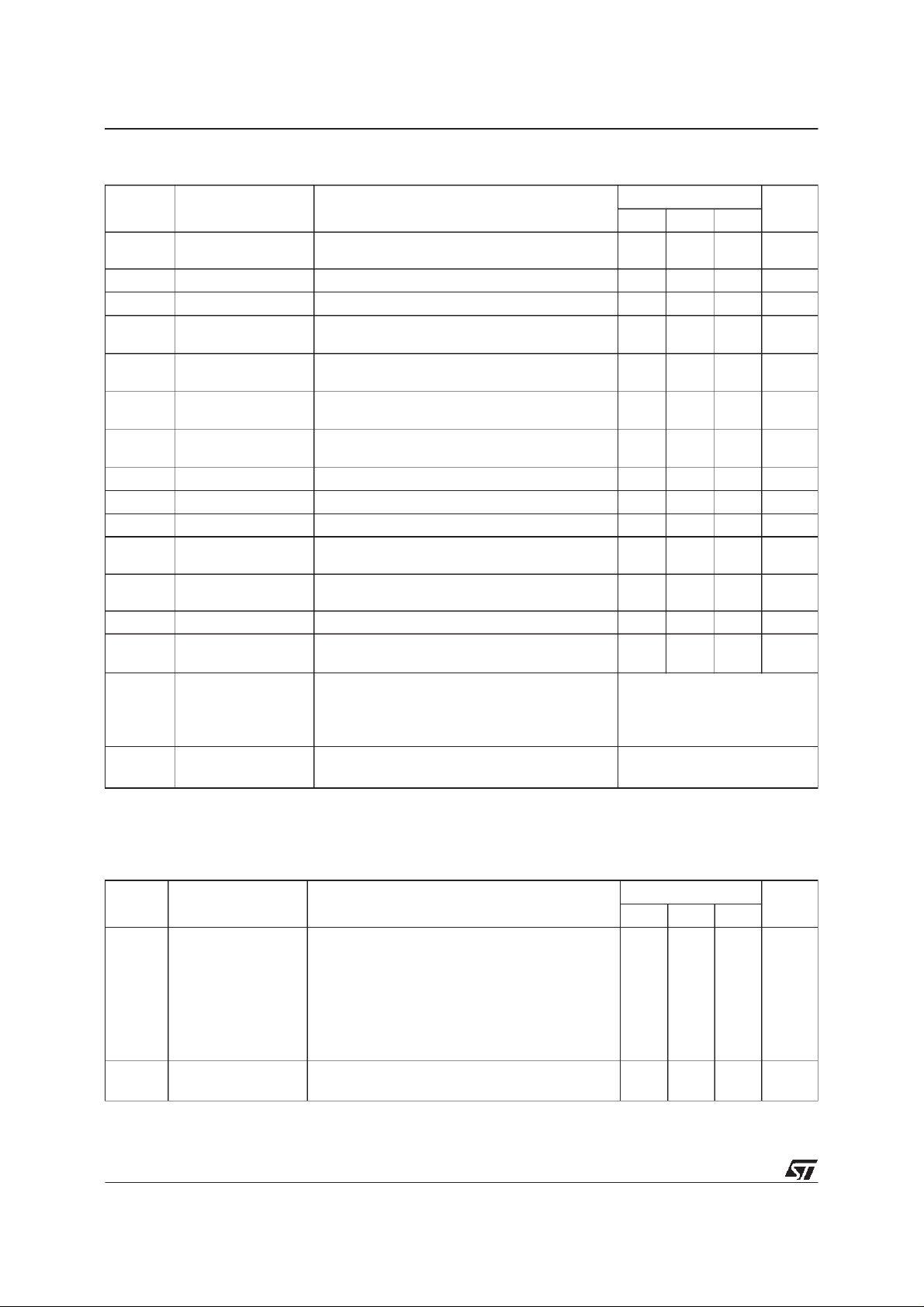

ELECTRICALSPECIFICATIONS(T

case

25°C, V

=

S1

, V

S3

=

8.0 Vdc; V

S2

, V

S4

=

12.5 Vdc)

Symbol Parame ter Test Condi tio ns Value Unit

Min. Typ. Max.

BW Frequ e nc y Range 890 915 MHz

P

I

I

I

Output Power

OUT

η

Efficiency

Leakag e Curr en t ,

Q1

V

S1,VS2

Bias Curre nt,

Q2

V

S3

Quiescent Current ,

Q3

V

S4

Contr ol Dynamic

Range

Isol at i on

H Harmonics

VSWR

V

CONT

I

CONT

Input VS WR

IN

Contr ol Volt a ge 0 4.0 Vdc

Contr ol Current 1.0 2.0 mA

1,2

1, 2

3

1, 2

1,2

V

P

V

V

V

V

V

P

P

=

4.0 Vdc PIN= 1mW

CONT

16 W

=

OUT

=

0Vdc PIN=

CONT

=

0Vdc PIN=

CONT

=

0Vdc PIN=

CONT

=

0to4.0V

CONT

=

0Vdc V

CONT

=

42 dBm reference

OUT

=

+13dBmto+42dBm

OUT

S2, S4

1mW

1mW

1mW

=

0 to 15. 6V

16 W

35 41 %

0.5 2.0 mA

140 150 mA

200 250 mA

56 dB

−14 d Bm

−45 dBc

2.0:1

T

r

Notes: 1) P

2) PulseWidth

Repetition rate

Rise Time

Noise Power 30 KHz B and width, 20 MH z ab ove f

Stab ilit y

Load Mi s match

1.0mW adjust V

IN =

1, 2, 4

1, 2

CONTROL

577 µsec. 4)Trmeasured at 1% to81% ofP

=

4.6 msec.

=

P

=

+13 to +42 dBm

OUT

P

=

+13dBmto+42dBmCW

OUT

P

= − 14 to +42 dBm

OUT

=

V

S2,VS4

Load VSWR

10.8to15.6V

=

6:1 Sourc e VS WR= 3:1

All phase angles T

1,2

VSWR= 10:1 Al l p hase angles

=

15.6Vdc P

V

forspecified P

OUT

OUT

.3)P

=

− 20 to + 6 0°C

C

= 16 W

(Reference) =42 dBm

OUT

1.0 µSec

0

−70 −65 dBm

AllSpurious outputs more

than 60dB below carrier

No Degradationin Output

Power

OUT

in watts

REF. 1014655E

GSM SPECIFIC TESTS

Symbol Parameter Test Conditi ons Value Unit

Min. Typ. Max.

AM/AM Conversion

Gain

PIN= fo(0 dBm)+[fo+200kHz(−40 dBm )]

V

CONT RO L

P

OUT

P

OUT(fo

P

OUT(fo

adjusted for

= 13, 30, 42 dBm

+200kHz)

− 20 0 k Hz )

− 40

− 45

dBc

dBc

2/7

AM/PM Conversion

= +13 t o + 42 dBm

P

OUT

varied +/− .5 dB

P

IN

4 °/dB

Page 3

MODULEDCAND TEST FIXTURE CONFIGURATION

STM915-16

REF. 1015959E

3/7

Page 4

STM915-16

TYPICALPERFORMANCE

OutputPowervs Frequency

ControlVoltagevs Case Temperature

ControlVoltage,Efficiency & Input VSWR vs

Frequency

OutputPower vs Case Temperature

OutputPowervs ControlVoltage

4/7

Page 5

APPLICATIONS RECOMMENDATIONS

STM915-16

OPERATIONLIMITS

The STM915-16 power module should never be

operated under any condition which exceeds

the Absolute Maximum Ratings presented on

this data sheet. Nor should the module be

operated continuously at any of the specified

maximum ratings. If the module is to be

operated under any condition such that it may

be subjected to one or more of the maximum

rating conditions,care must be taken to monitor

other parameters which may be affected. For

example, a combination of high V

and input

S3

overdrive could result in exceeding the

maximum output power rating; in this condition,

the output power must be maintainedbelow the

maximum rating by use of the gain control pin.

GAIN CONTROL

The module output power should be limited to

20 watts (43 dBm). The module is designed to

be operated with V

and VS4set to 12.5 Vdc and input power

V

S2

and VS3set to 8.0 Vdc,

S1

set to 1.0 mW (0 dBm).Module gain is adjusted

by varyingV

CONTROL

.

DECOUPLING

The bypassing internal to the module is

sufficient for the frequencyrange 90-1300 MHz.

Care should be taken to insure proper

decoupling for each application as the module

is capable of a wide range of operating

characteristics including ”linear” operation, in

which an important design criteria is the use of

appropriate bypassing. For bypassing low

frequencies while maintaining the electrical

specifications contained in this data sheet, use

of the decouplingnetwork shown in the ”Module

DC and Test Fixture Configuration” diagram

herein is recommended.

The heatsink mounting surface under the module

should be flat to within ± 0.05 mm (± 0.002 inch).

The module should be mounted to the heatsink

using 3 mm (or 4-40) or equivalent screws

torquedto 5-6 kg-cm (4-6 in-lb).

The module leads are attached to the equipment

PC board using 180°Csolder applied to the leads

with it properly grounded soldering iron trip, not to

exceed 195°C, applied a minimum of 2 mm

(0.080 inch) from the body of the module for a

duration not to exceed 15 seconds per lead. It is

imperative that no other portion of the module,

other than the leads, be subjected to

temperatures in excess of 100°C (maximum

storage temperature), for any period of time, as

the plastic moulded cover, internal components

and sealing adhesivesmay be adverselyaffected

by such conditions.

Due to the construction techniques and the

materials used within the module, reflow

soldering of the flange heatsink or leads, is not

recommended.

THERMALCONSIDERATIONS

It will be necessaryto providea suitable heatsink

in order to maintain the module flange

temperature at or below the maximum case

operating temperature. In a case where the

module output power will be limited to +42 dBm

(16 W) and designing for the worst case

efficiency of 35%, the power dissipated by the

module will be 29.7 watts. The heatsink must be

designed such that the thermal rise will be less

than the difference between the maximum

ambient temperature at which the module will

operate and the maximum operating case

temperature of the module while dissipating 29.7

watts.

MODULEMOUNTING

To insure adequate thermal transfer from the

module to the heatsink, it is recommendedthat

a satisfactory thermal compound such as Dow

Corning 340, Wakefield 120-2 or equivalent be

applied between the module flange and the

heatsink.

5/7

Page 6

STM915-16

H100 MECHANICAL DATA

DIM.

A 60.45 60.83 2.380 2.395

B 50.04 50.54 1.970 1.990

C 11.31 11.81 0.445 0.465

D 6.35 6.73 0.250 0.265

E 2.16 2.54 0.085 0.100

F 3.35 0.132

G 0.13 0.38 0.005 0.015

H 57.40 2.260

J 51.87 2.042

K 39.17 1.542

L 34.09 1.342

M 29.01 1.142

N 16.31 0.642

P 8.69 0.342

Q 0.38 0.64 0.015 0.025

R 3.05 3.30 0.120 0.130

S 13.59 14.09 0.535 0.555

V 4.49 5.51 0.177 0.217

W 6.78 7.06 0.267 0.278

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

6/7

1013762F

Page 7

STM915-16

Information furnished isbelieved tobe accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. Thispublication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a trademark of STMicroelectronics

1999 STMicroelectronics – PrintedinItaly– All Rights Reserved

STMicroelectronicsGROUP OF COMPANIES

Australia - Brazil -Canada - China - France -Germany - Italy- Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands-

Singapore - Spain - Sweden -Switzerland- Taiwan -Thailand - United Kingdom - U.S.A.

http://www.st.com

.

7/7

Loading...

Loading...