Page 1

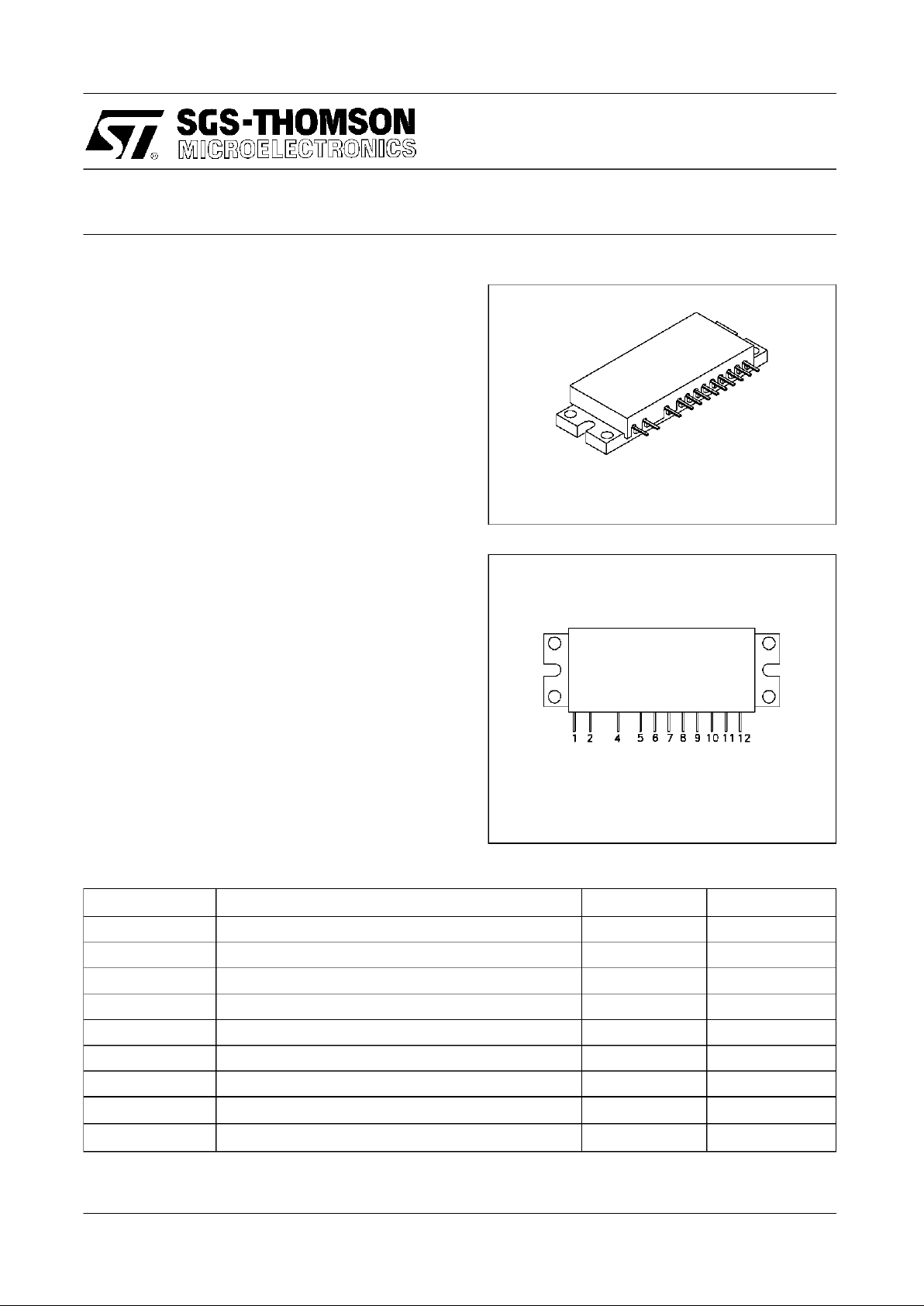

CASE STYLEH 14 1

RF POW ER MO DU LE

LINEAR BASE STATI ON APPLIC ATIONS

.LINEAR POWER AMPLIFI ER

.860 - 900 MHz

.26 VOLTS

.INPUT/OUTPUT 50 OHMS

.P

OUT

= +44.7 dBm PEP

.GAIN

=

35 dB MIN.

DESCRI P TI ON

The STM901-30 module is d esigned for d igital

cellular radio ba se station a pplications in t he

860-900 MHz fr equency range operating at

26V.

The STM901-30 is designed t o meet the low

distortion, high linearity requirements of modern digital cellular base station e quipment.

PI N CONNE CTION

ABSOLUTE MAXIMUM RATINGS (Tcase = 25°C)

STM 9 01- 30

1. RF Input 2. V

G1

3. deleted 4. V

G2

5. V

D

6. V

B1

7. Cap18. V

C1

9. V

B2

10. Cap211. V

C2

12. RF Output

ORDERCODE

STM901-30

BRANDING

STM901-30

Symbol Parameter Value Unit

V, VD,VC1,VC2DC Supply Voltage 28 Vdc

I

Q1 Bias Current @ V

= 26V, 1st Stage

0.40 Adc

I

Q2 Bias Current @ V = 26V, 2nd St age

0.40 Adc

I

Q3 Bias Current @ V = 26V, 3rd St age

0.54 Adc

I

Q4 Bias Current @ V = 26V, 4th Stage

1.62 Adc

P

IN

RF Input Power (P

OUT

< 4 4.7 dBm PEP) 14 dBm PEP

P

OUT

RF Ou t p ut Powe r (V = 26V)

48 dBm PEP

T

STG

Storage Temperature

− 30 to +100

°

C

T

OPER

Operating Temperature

− 30 to +100

°

C

October 31, 1997 1/8

Page 2

ELECTRICAL SP ECI FICATIONS (T

case

=25°C, VD,VC1,VC2= 26V) (I

DQ1

= 100 mA,

I

DQ2

= 180mA, I

CQ1

=50mA,I

CQ2

=150mA)

Symbol Parameter Test Cond itions

Value

Uni t

Min. Typ. Max.

BW Frequency Range 860 — 900 MHz

G

P

Power Gain

P

OUT

=

+44.7 dBm PEP

35 38 — dB

η

dt

*

Double-Tone

Efficiency

P

OUT

=

+44.7 dBm PEP

27 30 — %

Input VSWR

P

OUT

=

+44.7 dBm PEP

— 1.5:1 3:1

IMD* Intermodulation

Distortion

P

OUT

=

+44.7 dBm PEP

—

−33 −26

dBT**

— Load Mismatch

VSWR

=

5:1 V= 26Vdc

P

OUT

=

+44.7 dBm PEP

No Degradation in Output

Power

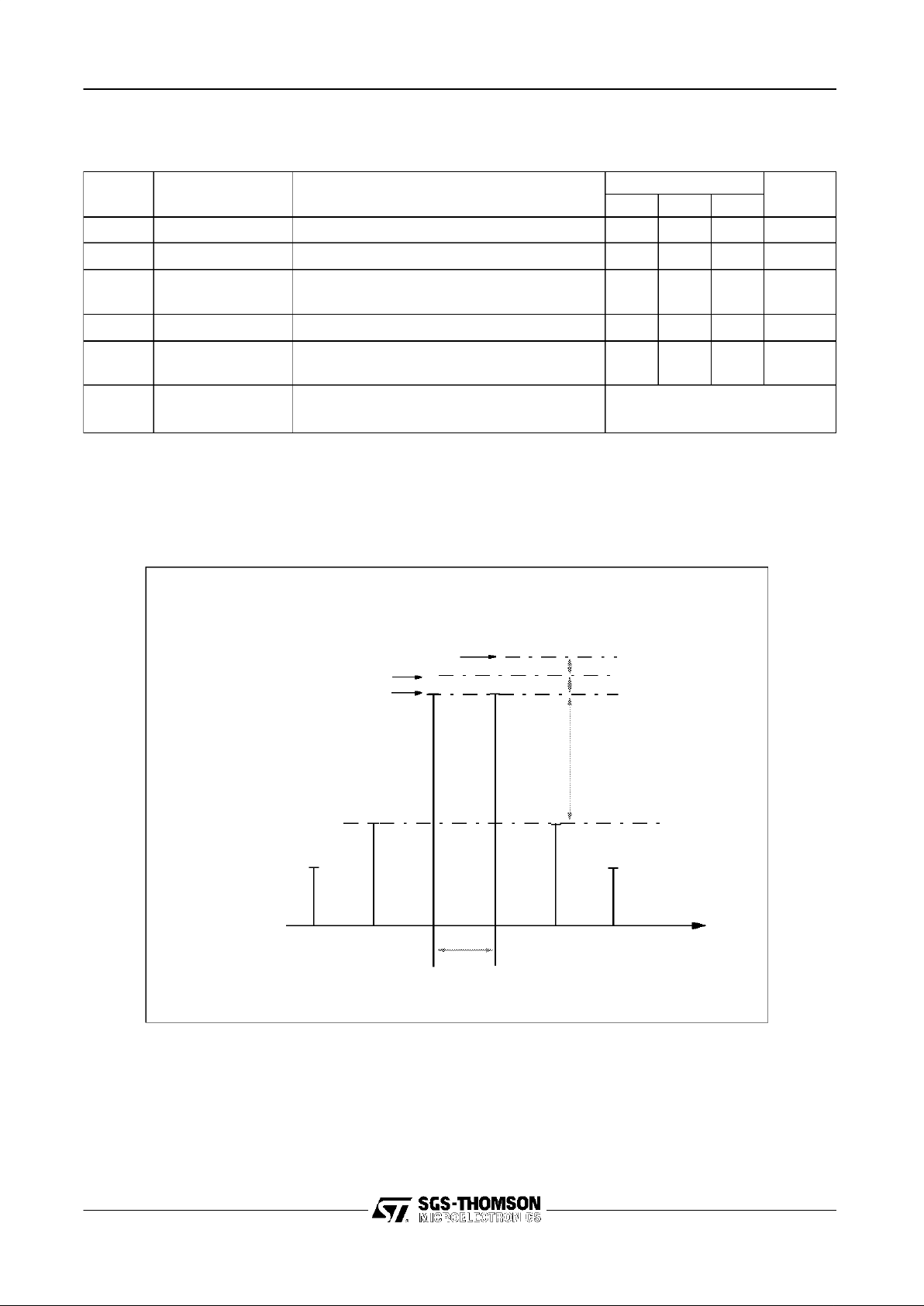

Note : * Tw o-Tone test ; 20 KHz sep ar ation ** dB T - i n dB, referenced t o tone lev el (See Fi gur e 1 belo w )

20 kHz

PEP (PeakEnvelope Power)Carrier Level

Total Avg. Powerof TwoTone

AVERAGE Powerof Each Tone

3 dB min

3 dB min

26 dB min

freq

Max IMD in dBT

Figure 1

STM901-30

2/8 October 31, 1997

Page 3

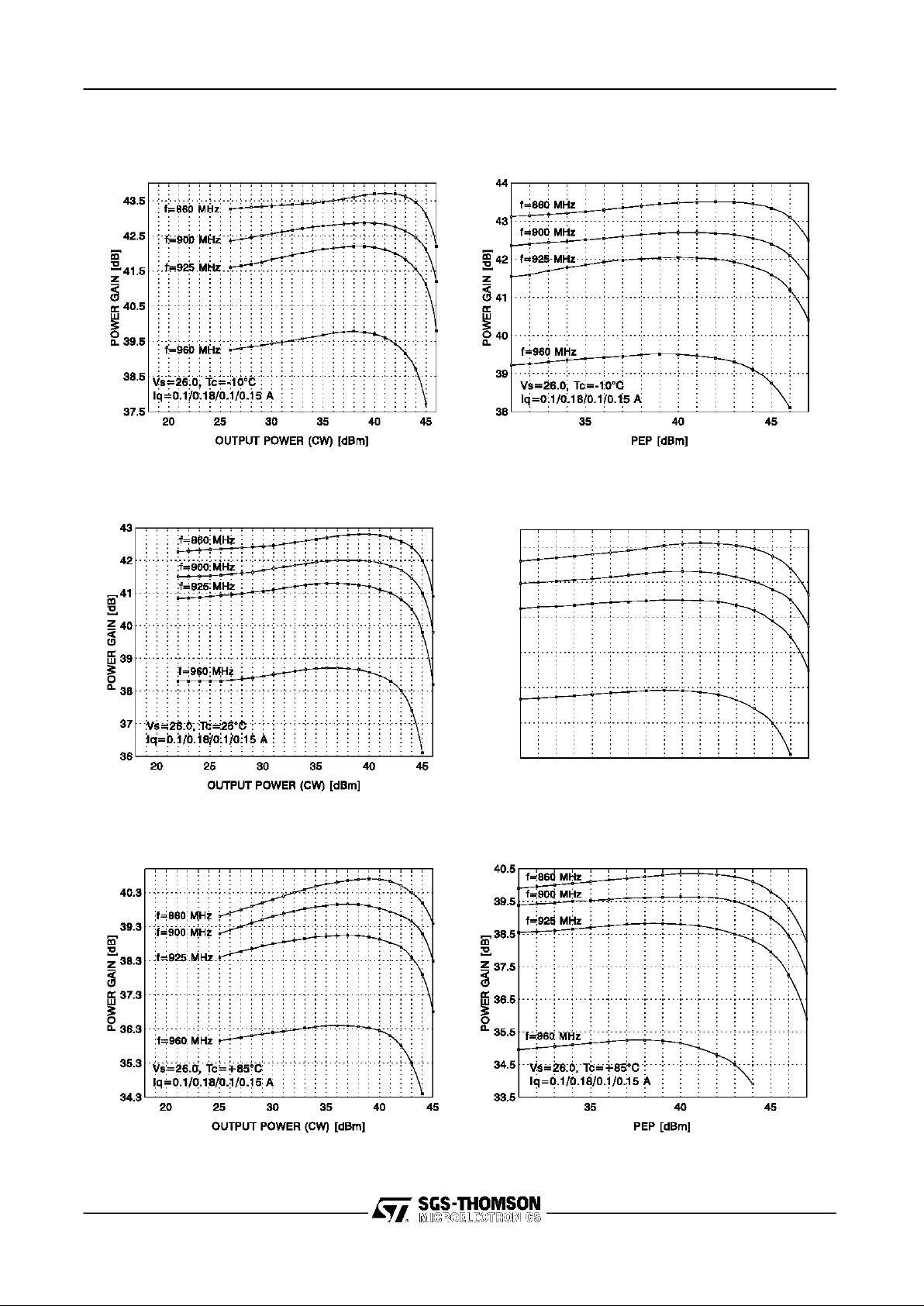

POWER GAIN vs OUTPUT POWER &

FREQUENCY

POWER GAIN vs OUTPUT POWER &

FREQUENCY

POWER GAIN vs OUTPUT POWER &

FREQUENCY

POWER GAIN vs PEP & FREQUENCY

POWER GAIN vs PEP & FREQUENCY

POWER GAIN vs PEP & FREQUENCY

PEP [dBm]

POWER GAIN [dB]

35 40 45

36.5

37.5

38.5

39.5

40.5

41.5

42.5

f=900 MHz

f=860 MHz

f=925 MHz

f=960 MHz

Vs=26.0, Tc=25°C

Iq=0.1/0.18/0.1/0.15 A

TYPICAL PERFORMANCE

STM901-30

October 31, 1997 3/8

Page 4

5th ORDER IMD vs PEP

5th ORDER IMD vs PEP

5th ORDER IMD vs PEP

3rd ORDER IMD vs PEP

3rd ORDER IMD vs PEP

3rd ORDER IMD vs PEP

PEP [dBm]

3rd IMD [dBT]

20 25 30 35 40 45

-20

-25

-30

-35

-40

f=900 MHz

f=860 MHz

f=925 MHz

f=960 MHz

Vs= 26.0, Tc=+85°C

Iq=0.1/0. 18/0. 05/0.15 A

TYPICAL PERFORMANCE

STM901-30

4/8 October 31, 1997

Page 5

GAIN & RETURN LOSS vs FREQUENCY

EFFICIENCY vs FREQUENCY

CW EFFICIENCY vs OUTPUT POWER

& FREQUENCY

TYPICAL PERFORMANCE

STM901-30

October 31, 1997 5/8

Page 6

C1, C3, C 5, C7, C11, C 13, C 17 : 100 pF

C2, C4, C 6, C8, C12, C 14, C 18 : . 001 µF

C19 : .1µF

C20, C22 : 100 µF

F1, F 2, F3 : FAIR-RITE #2664000101

L1, L2, L3 : 5 T ur ns of 24 AWG Wir e, Inner Dia met er

1.27mm

R1, R2, R3, R4 : 20 KOHM

Setting Bias: (Ex.: I

Q1

=

.1A, I

Q2

=

.18A, I

Q3

=

.050A, I

Q4

=

.150A)

1. Set all variable resistors clockwise. (No bias current flows through

transistors when all variable resistors are set clockwise.)

2. Record stationary current IO.

3. Adjust R1 for (IO+ 100)mA.

4. Adjust R2 for (IO+ 100 + 180)mA.

5. Adjust R3 for (IO+ 100 + 180 + 50)mA.

6. Adjust R4 for (IO+ 100 + 180 + 50 + 150)mA.

MODULE DC AND TES T FIXTURE CONFI G URATION

STM901-30

6/8 October 31, 1997

Page 7

APPLI CATI O NS RECOMMENDATI ONS

OPERATION LIMITS

The STM901-30 power module should never be operated under any condition which exceeds the Absolute Maximum Ratings presented on this data

sheet. Nor should the module be operated continuously at any of the specified maximum ratings. If

the module is to be operated under any condition

such that it may be subjected to one or more of the

maximum rating conditions, care must be taken to

monitor other parameters which may be affected.

DECOUPLING

Failure to properly decouple any of the voltage supply pins will result in oscillations at certain operating

frequencies. Therefore, it is recommended that

these pins be bypassed as indicated in the Module

DC and Test Fixture Configuration drawing of this

data sheet.

MODULE MOUNTING

To insure adequate thermal transfer from the module to the heatsink, it is recommended that a satisfactory thermal compound such as Dow Corning

340, Wakefield 120-2 or equivalent be applied between the module flange and the heatsink.

The heatsink mounting surface under the module

should be flat to within +/- 0.05 mm (+/- 0.002

inch). The module should be mounted to the

heatsink using 3 mm (or 4-40) or equivalent screws

torqued to 5-6 kg-cm (4-6 in-lb).

The module leads are attached to the equipment

PC board using 180°C solder applied to the leads

with a properly grounded soldering iron tip, not to

exceed 195°C, applied a minimum of 2 mm (0.080

inch) from the body of the module for a duration not

to exceed 15 seconds per lead. It is imperative that

no other portion of the module, other than the

leads, be subjected to temperatures in excess of

100°C (maximum storage temperature), for any period of time, as the plastic moulded cover, internal

components and sealing adhesives may be adversely affectedby such conditions.

Due to the construction techniques and the materials used within the module, reflow soldering of the

flange heatsink or the leads, is not recommended.

THERMAL CONSIDERATIONS

It will be necessary to provide a suitable heatsink in

order to maintain the module flange temperature at

or below the maximum case operating temperature.

In a case where the module output power will be

limited to +44.7 dBm (30W PEP) and designing for

the worst case double-tone efficiency of 25%, the

power dissipated by the module will be 48 watts.

The heatsink must be designed such that the thermal rise will be less than the difference between

the maximum ambient temperature at which the

module will operate and the maximum operating

case temperature of the module while dissipating

48 watts.

At T

case

= +85°C, V = 26v, IQ1= 0.1A, IQ2= 0.18A,

I

Q3

= 0.05A, IQ4= 0.2A, ZL= 50 ohms and P

OUT

=

+44.7dBm PEP, maximum junction temperatures for

the individual transistors should be below the following values:

Q1 = 115°C

Q2 = 130°C

Q3 = 125°C

Q4 = 145°C

STM901-30

October 31, 1997 7/8

Page 8

PACKAGE MECHANICAL DATA

UDCS No. 1010946 rev D

Inform ation furnished is believed to be accurat e a nd rel iable. However, SGS-T H O MS O N Microelectroni cs assumes no responsibility for

the consequences of use of such inf or mat ion nor for any infri ngement of patent s or ot her ri ght s of thir d par t i es which ma y result from

its use. N o license is granted by i mplicati on or otherw i se under any patent or patent ri ghts of SG S - T H O M S O N Mi c roe le ctronics.

Specificati ons ment ioned in t hi s publ ication ar e subject t o c hange with out not ice. This publi cat ion supers edes and replaces all

infor m at i on previously suppl ied. SGS- THOM S O N Microelectronics products are not authorized f or use as critical components in li fe

support device s or syst ems wit hout express writ t e n approval of S G S - THOMSO N Microelectr oni c s.

1997 SGS-THOMSON Microelectroni cs - All Rights Reserved

SGS-THOMSON Microelectronics GROUP O F COMPANIES

Austr alia - Brazil - Canada - China - France - Germany - Ita ly - Japan - Korea

Mal ays i a - Malt a - Morocco - The Net herlands - Singapor e - Spain - Sweden - Swit zerland

Taiwan - Thail and - U ni ted K i ngdom - U.S.A.

RF Pr oduc t s Divi s i on

141 Commerce Drive Montgomeryville, PA 18936

tel 215-361-6400 fax 215-36 2-12 93

STM901-30

8/8 October 31, 1997

Loading...

Loading...