Page 1

SATELLITE COMMUNI CATI ONS APPLI CATION S

.SA TE L LITE COMMUNICAT I ONS

AMPLIFIER

.1625 - 1665 MHz

.18/28 VOLTS

.INPUT/OUTPUT 50 OHMS

.P

= 10 W MIN.

OUT

.GAIN = 30 dB MIN.

STM1645-10

RF POWER MODULES

PRELIMINARY DATA

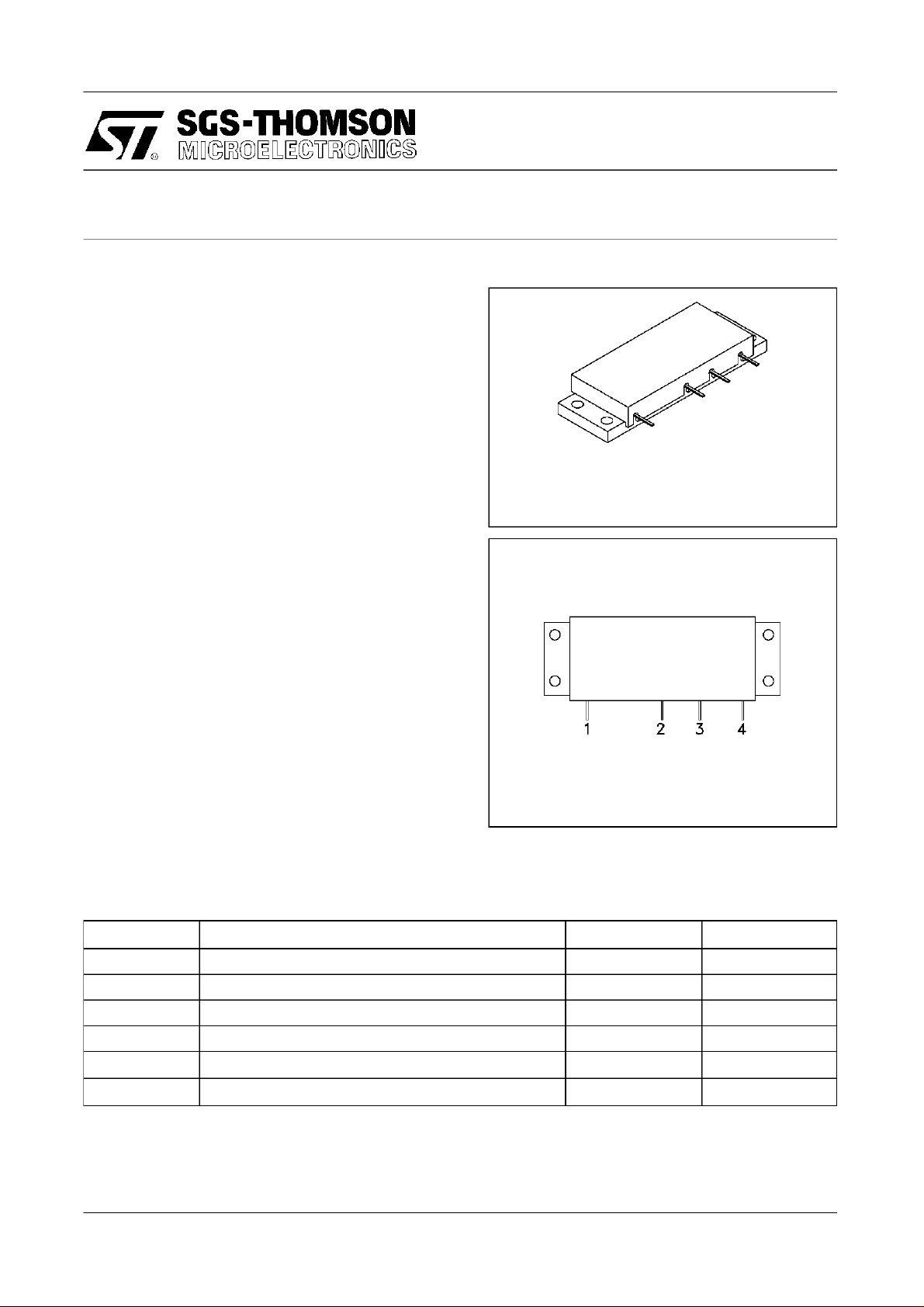

CASE STYLE H150

ORDERCOD E

STM1645-10

PI N C O NNECTION

BRANDING

STM1645-10

DESCRIP TION

The STM1645-10 module is des igned for high

power satellite communication applications in

the 1.6 GHz f requency r ange operating at 28

Volts.

ABSOLUTE MAXI MUM RATI NGS (T

Symbol Parameter Value Unit

P

T

V

V

P

OUT

STG

T

C1

C2

IN

C

DC Supp ly Voltage 20 Vdc

DC Supp ly Voltage 32 Vdc

RF Input Power 20 mW

RF Out put Po we r 16 W

Storage Temperature

Operating Case Temperature

case

=

25°C)

1. RF Input 2. VC1, 18V

3. V

, 28V 4. RF Output

C2

− 40 to +100

− 35 t o +70

°

C

°

C

April 4, 1996

1/5

Page 2

STM 1645-10

ELECTRICAL SPECIFICATIONS (T

Symbol Parameter Test Conditions

case

=25°C, V

=18V,VC2=28V)

C1*

Value

Min. Typ. Max.

BW Frequency Range 1625 — 1665 MHz

— — 10.0 dBm

30 — — dB

30 35 — %

—

−45 −40

No Degradation in Outp ut

Power

G

IN

P

η

Input Power

Power Gain

Efficiency

P

H Harmonics

Z

Input Impedance

IN

— Load Mismatch

*Note: VC1= 18V Regulat ed ± 1%

P

P

P

P

P

10 W

=

OUT

= 10 W

OUT

= 10 W

OUT

10 W reference

=

OUT

= 10 W ZG,ZL=50Ω — 1.5 :1 2.0: 1 VSWR

OUT

VSWR = 10:1 V = 28 Vdc

P

= 10 W

OUT

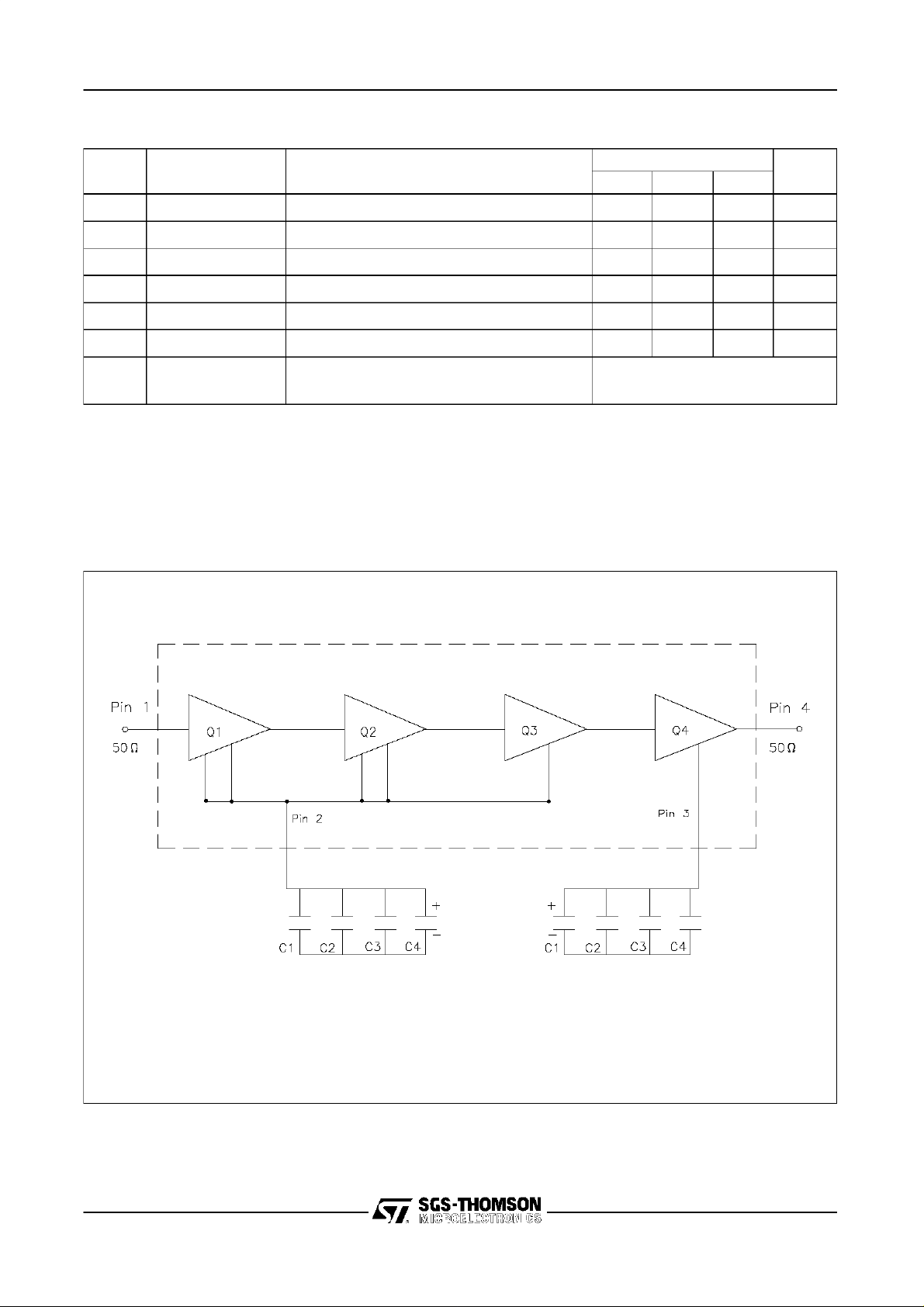

D.C. TEST FIXTURE BYPASSING

Unit

dBc

2/5

C1 : 100pf Chip Capacitor

C2 : 1000pf Chip Capacitor

C3 : .01µf Chip Capacitor

C4 : 10µf Chip Capacitor

Page 3

TYPICAL PERFORMANCE

STM 1645-10

POWER OUTPUT vs FREQUENCY

20

Pin = 10mW

Vc1 = 18V

Vc2 = 28V

18

16

14

Power Output (Watts)

12

10

1620 1625 1630 1635 1640 1645 1650 1655 1660 1665 1670

Frequency (MHz)

-35 deg C

+25 deg C

+70 deg C

VC2 vs FLANGE TEMPERATURE

30

Vc1 = 18V

Pin = 10mW

28

Pout = 10W

26

24

Vc2 (Volts)

22

20

0 10203040506070800-10-20-30-40

Temperature(Deg C)

1662 MHz

1626 MHz

3/5

Page 4

STM 1645-10

APPLI CATI O NS RECOMMENDATIONS

OPERATION LIMITS

The STM1645-10 power module should never be

operated under any condition which exceeds the

Absolute Maximum Ratings presented on this

data sheet. Nor should the module be operated

continuously at any of the specified maximum ratings. If the module is to be subjected to one or

more of the maximum rating conditions, care must

be taken to monitor other parameters which may

be affected.

DECOUPLING

Failure to properly decouple any of the voltage

supply pins mayl result in oscillations at certain

operating frequencies. Therefore, it is recommended that these pins be bypassed as indicated

in the Module DC and Test Fixture Configuration

drawing of this data sheet.

POWER CONTROL

The recommeded method of power control for the

STM1645-10 is to set P

and V

= 28 volts nominal at a flange tempera-

C2

= 10mW, VC1= 18V

IN

ture of 25°C to achieve an output power of 10

watts. Varing V

will allow stable power control

C2

over a wide range of flange temperature. The current consumption of V

is typically 850mA to

C2

900mA for 10 watts power ouput.

MODULE MOUNTING

To insure adequate thermal transfer from the

module to the heatsink, it is recommended that a

satisfactory thermal compound such as Dow

Corning 340, Wakefield 120-2 or equivalent be

applied between the module flange and the

heatsink.

The heatsink mounting surface under the module

should be flat to within ± 0.05mm (± 0.002 inch).

The module should be mounted to the heatsink

using 3 mm (or 4-40) or equivalent screws torqued to 5-6 kg-cm (4-6 in-lb).

The module leads should be attached to equipment PC board using 180°C solder applied to the

leads with a properly grounded soldering iron tip,

not to exceed 195°C, applied a minimum of 2mm

(0.080 inch) from the body of the module for a

duration not to exceed 15 seconds per lead. It is

imperative that no other portion of the module,

other than the leads, be subjected to temperatures in excess of 100°C (maximum storage tem-

perature), for any period of time, as the plastic

moulded cover, internal components and sealing

adhesives may be adversely affected by such

conditions.

Due to the construction techniques and materials

used within the module, reflow soldering of the

flange heatsink or leads, is not recommended.

4/5

Page 5

PACKAGE MECHANICAL DATA

Ref.: Dwg. No. 1018019 rev. D

STM 1645-10

Inform ation f urnished is believed to be accurate a nd reliable. However, SGS - THOMSON Mi cr oel ec t r oni c s assumes no responsibi l ity for

the consequences of use of su ch information nor for any i nf r ingement of patents or other r ights of third parti es which may result from

its use. No license is granted by implication or ot her w ise under any patent or pat ent rights o f S G S - T H O M S O N Microe le ctronics.

Specifications ment i oned in this publicati on ar e subject to change without notice. This publicat ion super s edes and r eplaces all

infor m at i on previously suppl i ed. S GS - THOMS ON M icroelectr onics products ar e not aut hor i zed for use as cr itical com ponents in li f e

support d evices or s ystems wit hout express written approval of SG S - THOMSON M icroelectr oni c s.

1996 S GS-THOM SON Microelectronics - All Right s Reserved

Austr alia - B razil - France - Germ any - H ong K ong - Italy - Japan - K orea - Malaysia -

Mal t a - Mor occo - The N et her lands - Singapore - Spai n - S w eden - Swit zer l and - T ai wan -

SGS-THOMSON Microelectronics GROUP OF COMPANIES

T hai land - U nited Ki ngdom - U.S.A.

5/5

Loading...

Loading...